Double-combination-sleeve connection structure and construction method for lattice beam connection

A combined sleeve and sleeve connection technology, which is applied in building construction, construction, etc., can solve the problems of unqualified connection quality of reserved steel bars, easy misalignment of the center line of reserved steel bars, and inability to connect reserved steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

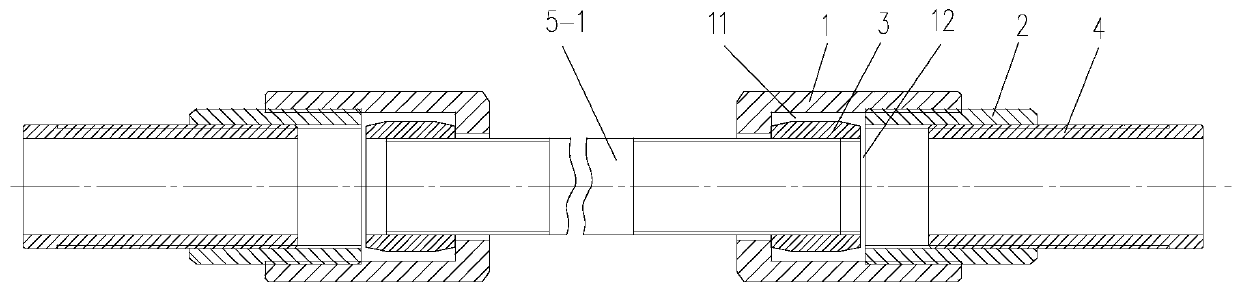

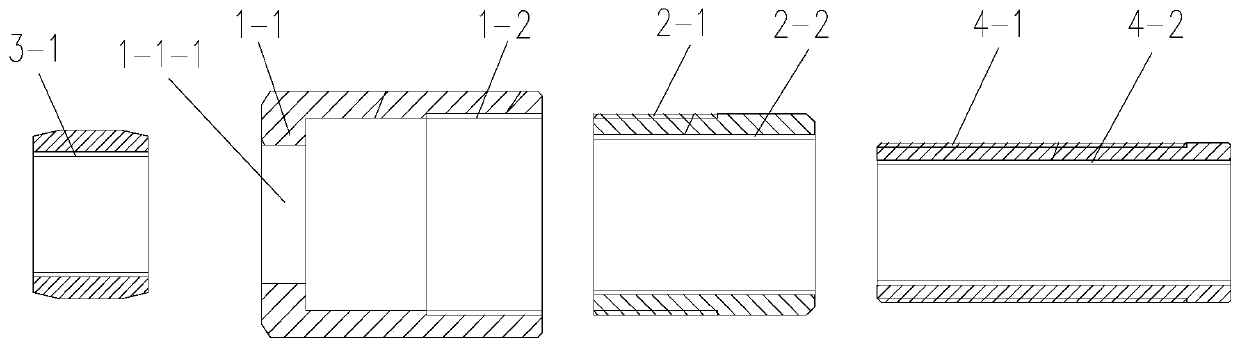

[0070] Such as figure 1 and image 3 The shown double combination sleeve connection structure includes a first combination sleeve and a second combination sleeve oppositely arranged, the first combination sleeve and the second combination sleeve are connected by a connecting rod, The structure of the first combined sleeve and the second combined sleeve is the same, and both the first combined sleeve and the second combined sleeve include a main sleeve 1, which are threadedly connected with the main sleeve 1 The auxiliary sleeve 2, the radial adjustment sleeve 3 set in the main sleeve 1 and the axial adjustment sleeve 4 threaded with the auxiliary sleeve 2, the inner surface of the main sleeve 1 One end is provided with a limiting plate 1-1, and the center of the limiting plate 1-1 is provided with a hole 1-1-1 for the exposed end of the embedded steel bar to pass through, and the other end of the inner surface of the main sleeve 1 is provided with a second An internal thread...

Embodiment 2

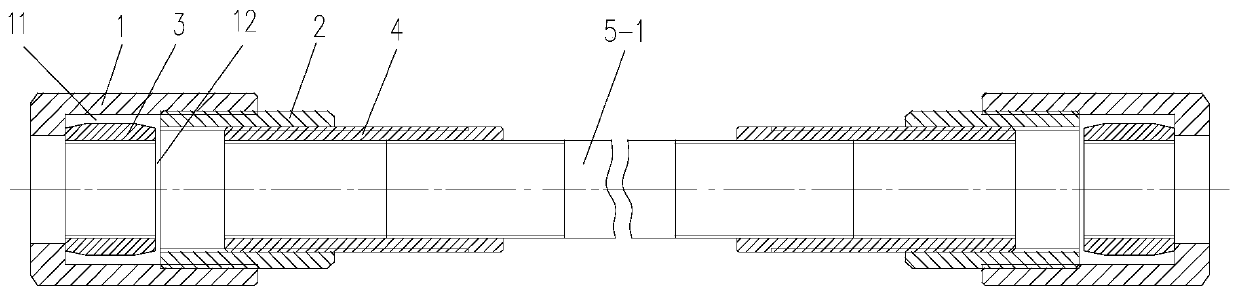

[0082] Such as figure 2 and image 3 As shown, in this embodiment, the difference from Embodiment 1 is that one end of the connecting rod is screwed to the axial adjustment sleeve 4 of the first combined sleeve, and the other end of the connecting rod is connected to the The axial adjustment sleeve 4 of the second combined sleeve is threaded.

[0083] In this embodiment, other structures and connections are the same as those in Embodiment 1.

[0084] Such as Figure 5 and Image 6 A construction method for lattice beam connection using a double-combined sleeve connection structure shown includes the following steps:

[0085] Step 1. Selection of double-combined sleeve connection structure:

[0086] The four lattice beams arranged in a square shape include a first lattice beam 6-1, a second lattice beam 6-2, a third lattice beam 6-3 and a fourth lattice beam 6-4. A connection node is formed among the first lattice beam 6-1, the second lattice beam 6-2, the third lattice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com