Patents

Literature

56results about How to "Improve self-discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

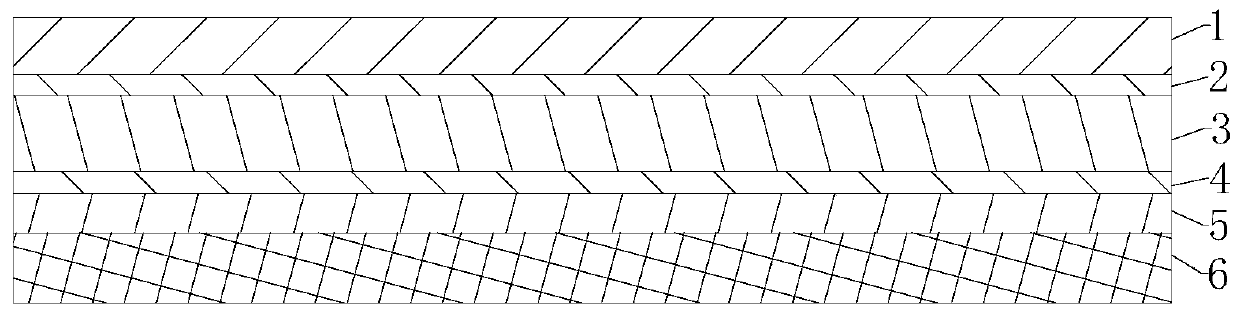

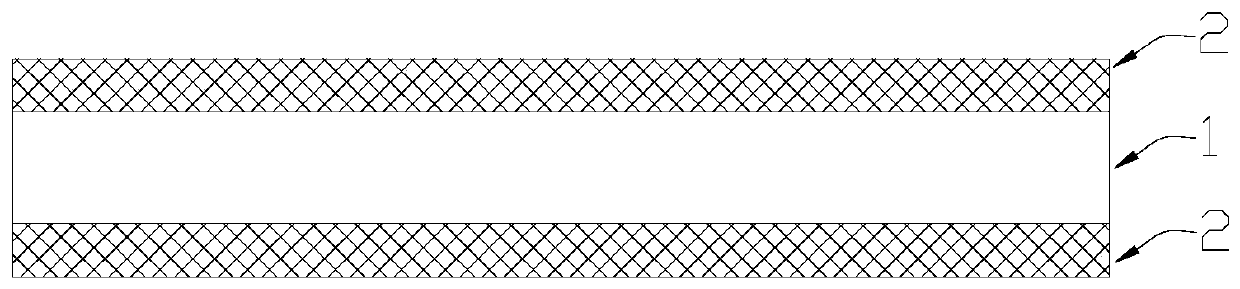

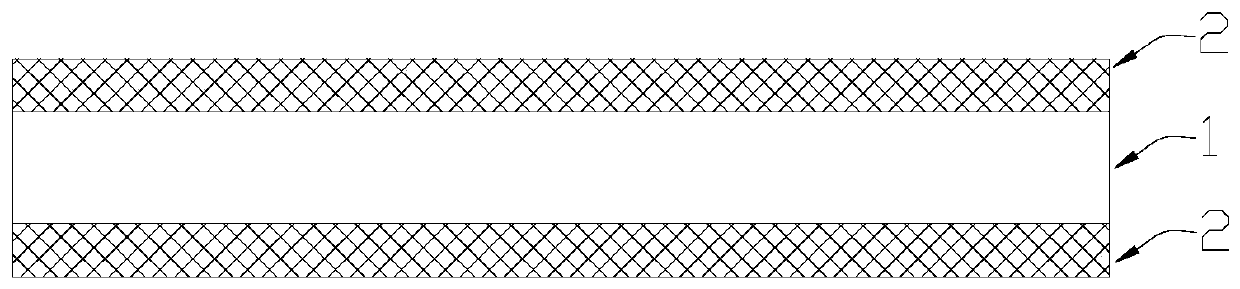

Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

InactiveCN107895765AHigh mechanical strengthImprove reliabilityCell component detailsSecondary cells servicing/maintenancePolymer adhesiveSlurry

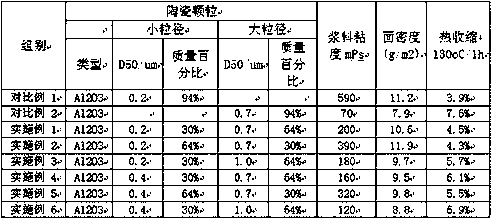

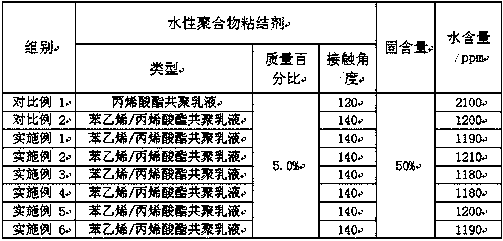

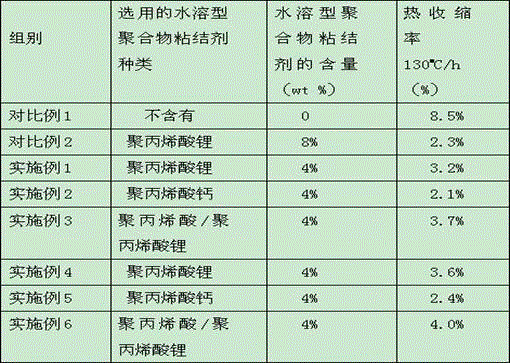

The invention discloses an inorganic / organic composite functional porous isolating membrane. The isolating membrane comprises porous base material and at least one inorganic functional coating adhering to the surface of the porous base material, and aqueous slurry prepared for the inorganic functional coatings is prepared from inorganic ceramic particles, water-soluble polymer thickener and aqueous polymer adhesive; the inorganic ceramic particles comprise the same substance in two types of particle sizes, wherein the average particle size (D50) of the smaller inorganic ceramic particles is 0.2-0.5 micrometer, and the average particle size (D50) of the larger inorganic ceramic particles is 0.6-1.0 micrometer; the aqueous polymer adhesive is a hydrophobic high-molecular polymer with the water drop contact angle of the dry adhesive of the aqueous polymer adhesive 110-140 degrees; the solid content of the aqueous slurry is 40-60%. According to the inorganic / organic composite functional porous isolating membrane, the high-temperature thermal stability of the isolating membrane can be effectively improved by means of the inorganic functional coatings, and the water content of the inorganic coatings is effectively reduced, so that the safe performance of a battery and the stability of long-term circulation are improved.

Owner:深圳市旭然电子有限公司

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

Polyethylene microporous membrane, preparation method and lithium ion battery

ActiveCN104362276AImprove breathabilityImprove mechanical propertiesCell component detailsPhysical chemistryLithium-ion battery

The invention provides a polyethylene microporous membrane, a preparation method and a lithium ion battery. The polyethylene microporous membrane comprises a front side and a reverse side, wherein the average aperture size of the front side is 100 to 200nm; the average aperture size of the reverse side is 50 to 100nm; the average aperture size ratio A:B of the front side and the reverse side is 1.1 to 4.0:1; the aperture size distribution is smaller than 30 percent. When the microporous membrane prepared through the preparation method is applied in the lithium ion battery, the front side is close to the positive pole of the battery and the reverse side is close to the negative pole of the battery, so that the polyethylene microporous membrane not only has a good high-rate discharge performance, but also has a good self-discharge performance.

Owner:乐凯胶片股份有限公司 +1

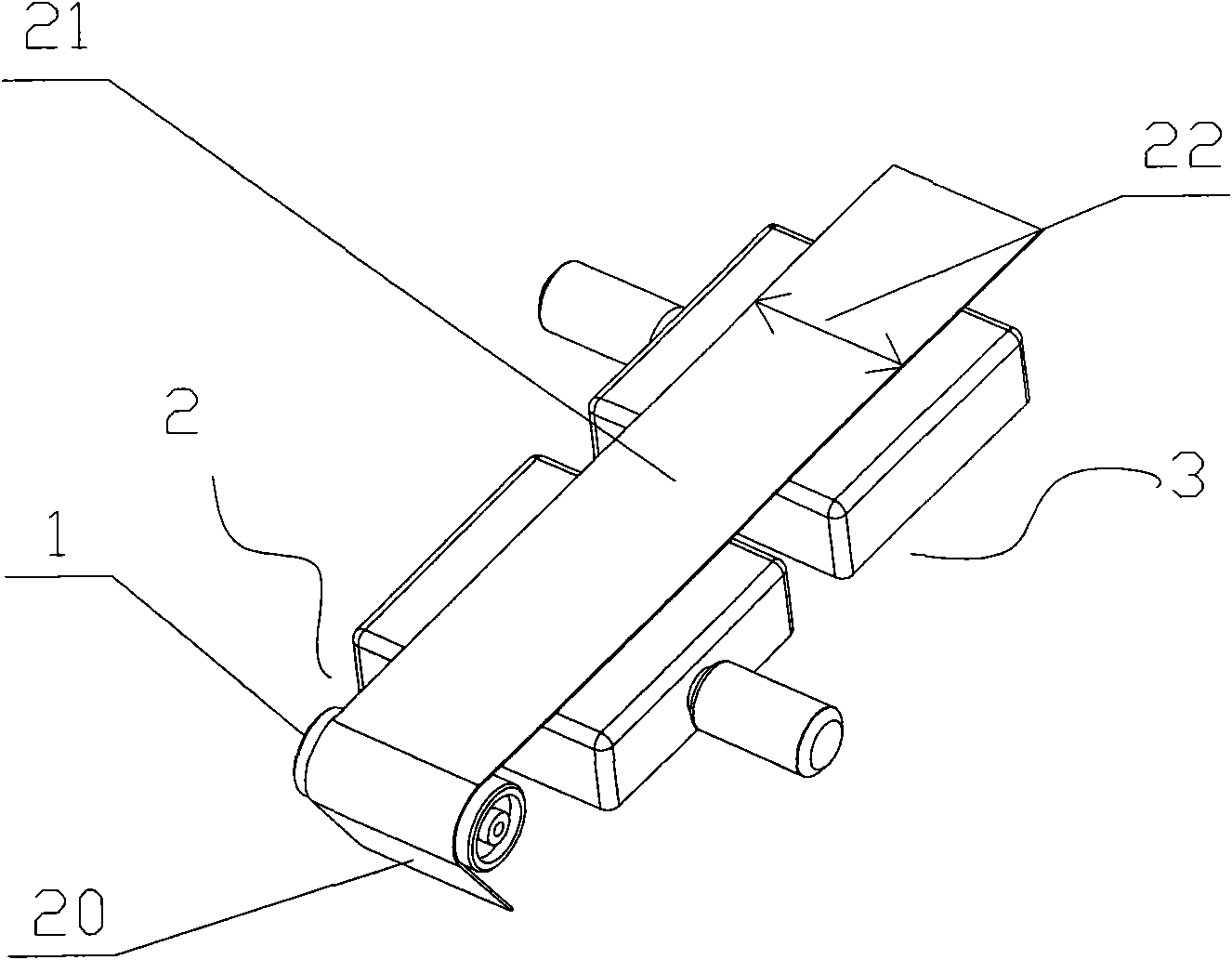

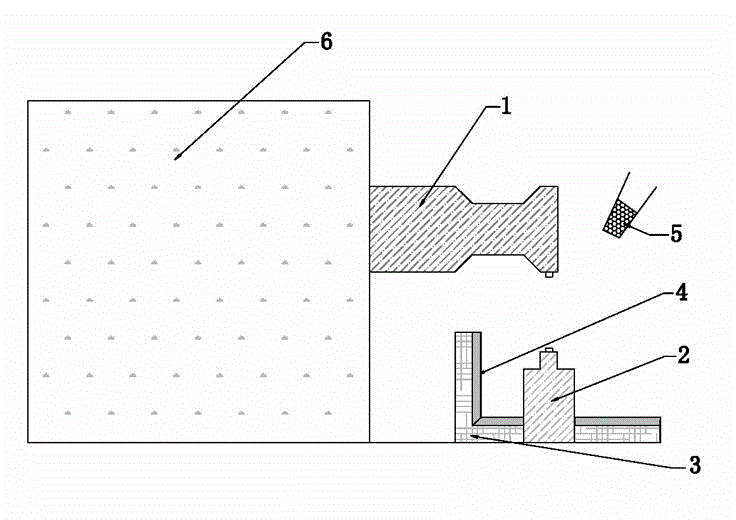

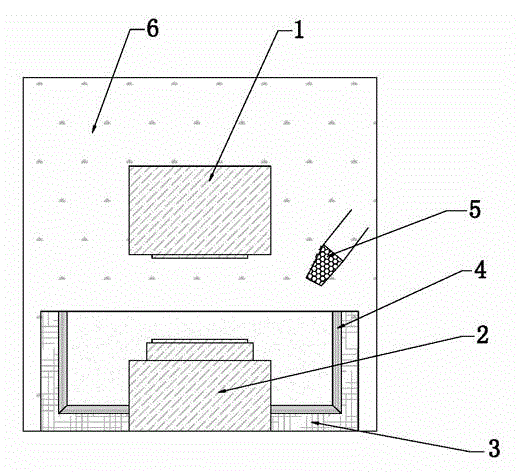

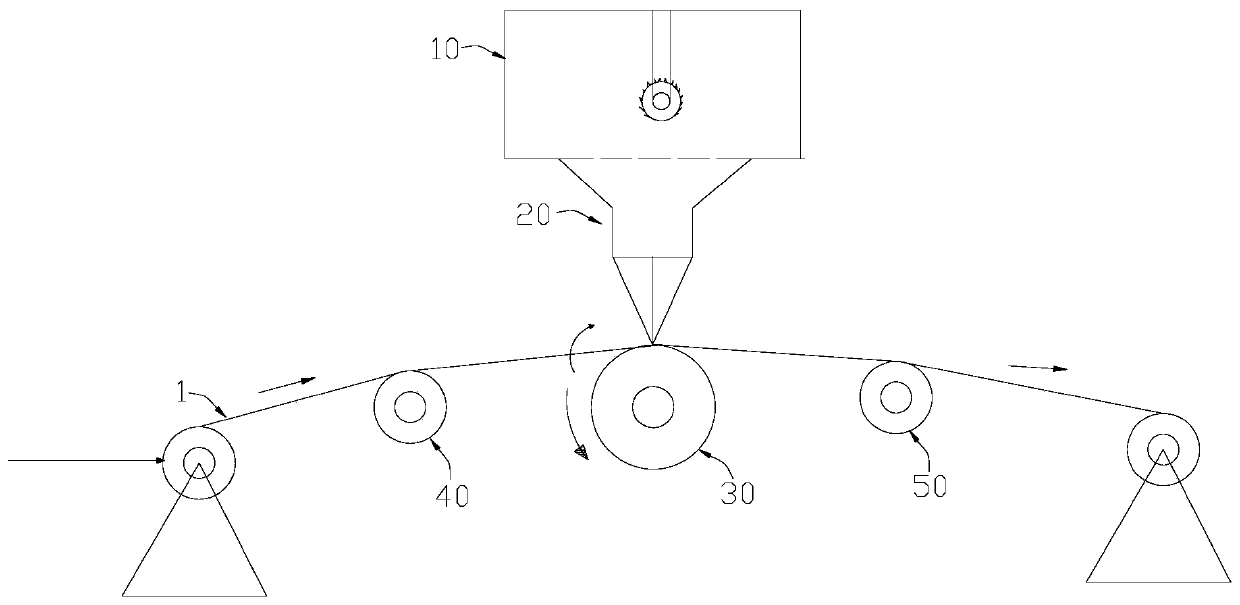

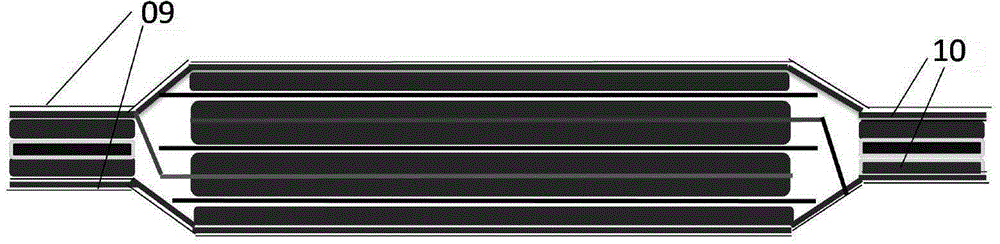

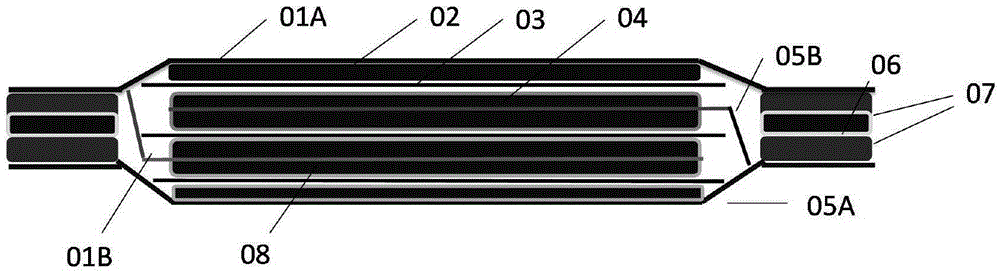

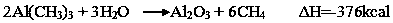

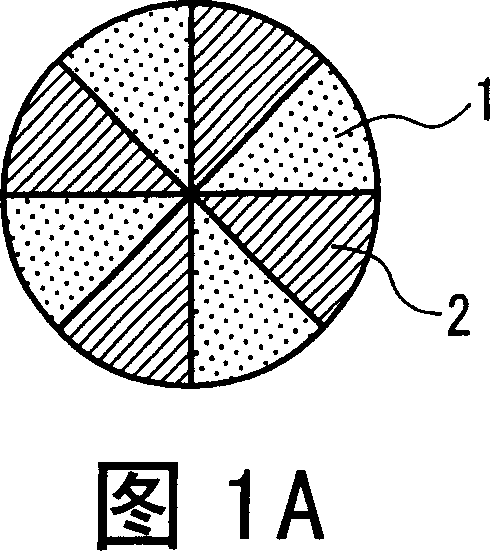

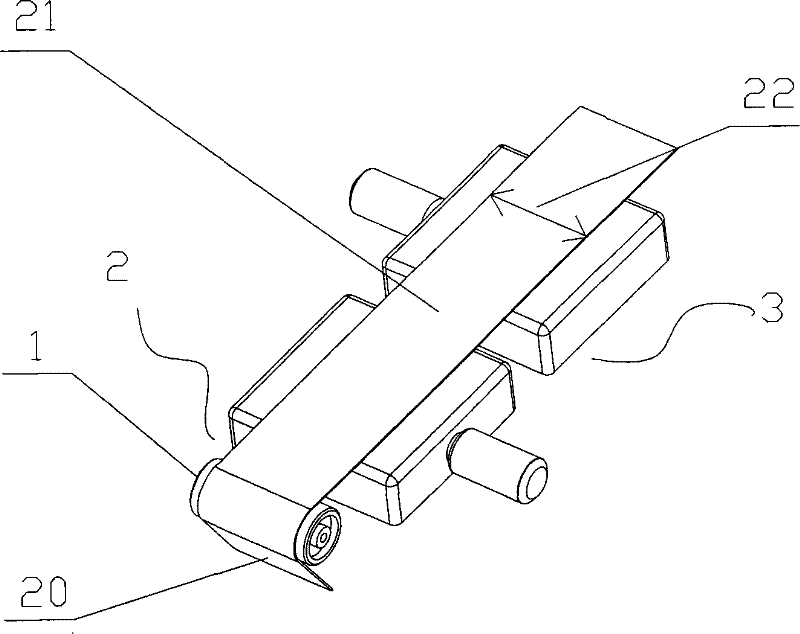

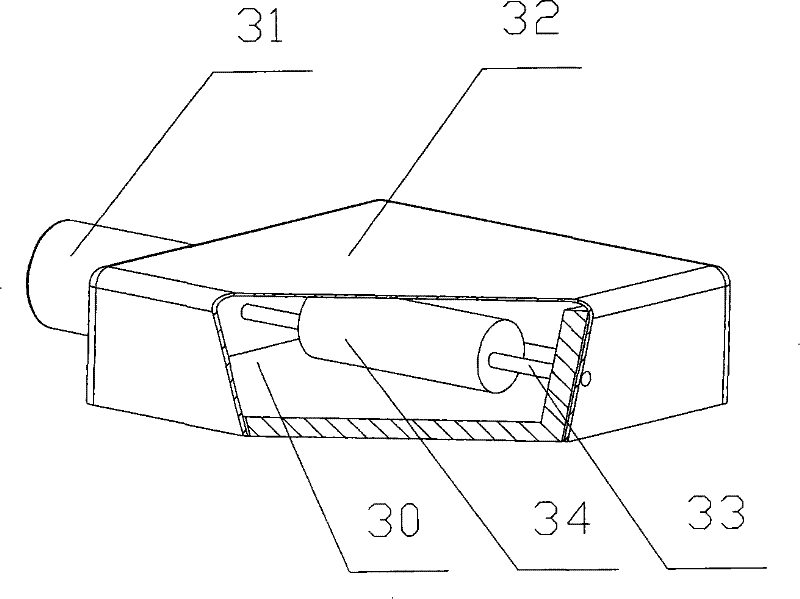

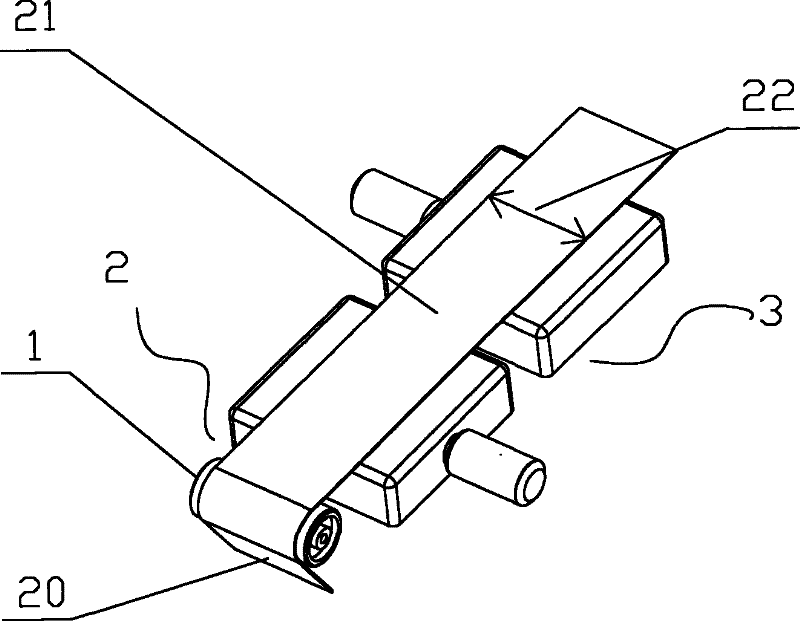

Method and device for preparing battery pole piece

ActiveCN101615667AImprove self-discharge performanceImprove performanceElectrode manufacturing processesPretreated surfacesElectrical batteryEngineering

The invention provides a method for preparing a battery pole piece. The method comprises the following steps: coating pole slurry on a current collecting body; and vibrating the obtained current collecting body coated with the pole slurry on the surface. The invention provides a device for preparing the battery pole piece. The device comprises a coating device and a vibrating device, wherein the pole slurry is coated on the surface of the current collecting body by the coating device, and the vibrating device is used for vibrating the current collecting body coated with the pole slurry on the surface. After being placed in a room with the temperature of 20+ / -2 DEG C and the humidity of 20 percent-50 percent for 28 days in an open circuit, a battery with the volume of 4.2 V, which is prepared by the battery pole piece prepared by the device and the method, reduces the voltage by 5 mV at most, and the micro-short circuit rate tested by 20,000 batteries is 0.01 percent; and the battery prepared by a device and a method in the prior art has the voltage reduction up to 50 mV and the micro-short circuit rate of 0.05 percent under the completely same condition.

Owner:SHANGHAI BYD

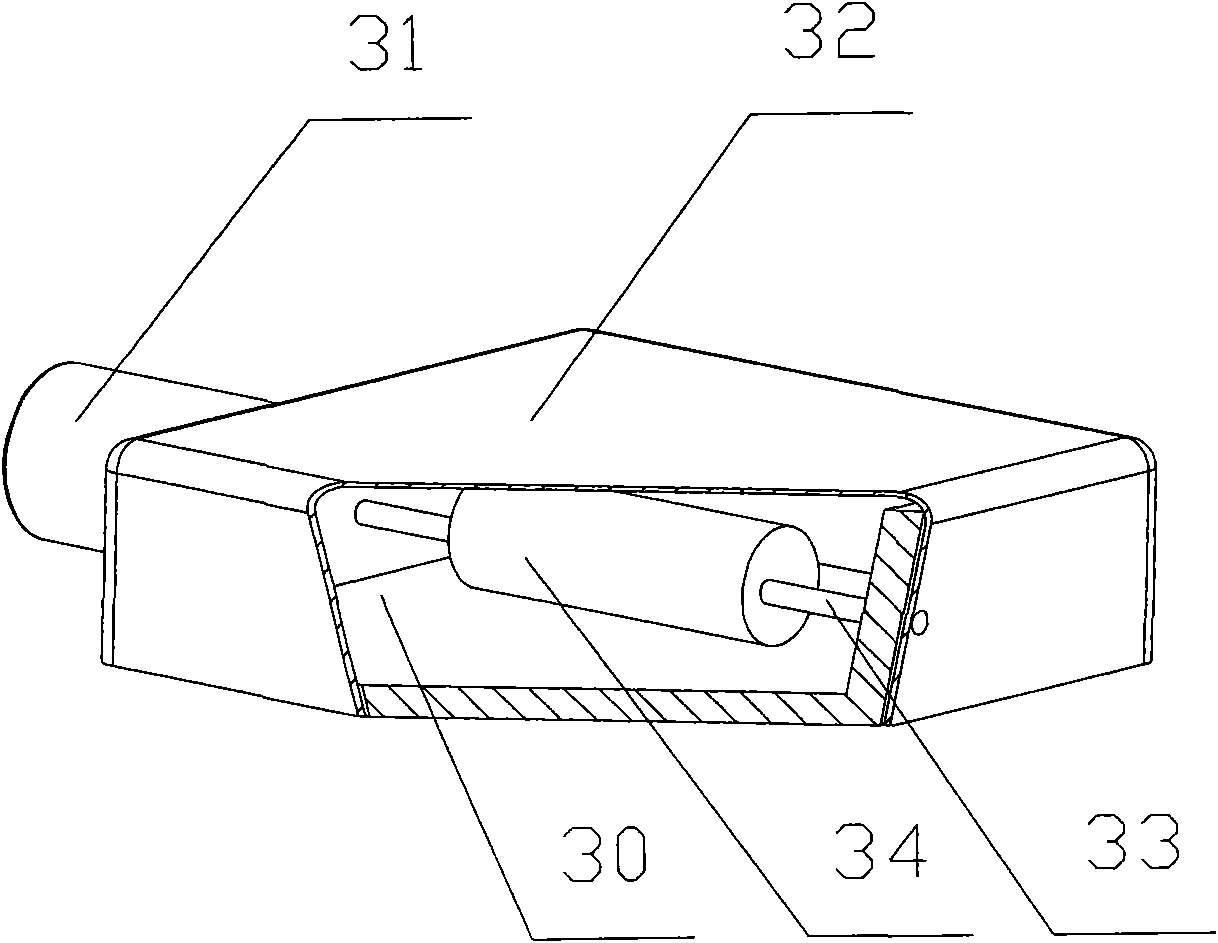

Lithium battery tab ultrasonic bonder with dust removal function and welding method

InactiveCN104475962APrevent splashNot easy to cleanDirt cleaningNon-electric welding apparatusSlagEngineering

The invention belongs to the technical field of welding, and relates to a lithium battery tab ultrasonic bonder with the dust removal function and a lithium battery tab dust-free welding method of the lithium battery tab ultrasonic bonder. The lithium battery tab ultrasonic bonder with the dust removal function comprises a bonder body, an upper bonder head of the bonder, a lower bonder head of the bonder and an air blowing device, and is characterized in that a dust blocking trough is installed around the lower bonder head, the dust blocking trough is composed of a left side face, a right side face, a rear side face and a bottom face, a plurality of layers of dust sticking adhesive tape are attached to the inner wall of the dust blocking trough, the sticky face of the adhesive tape faces outwards, and the air blowing device is installed above and on the side of the lower bonder head of the bonder. The lithium battery tab ultrasonic bonder with the dust removal function and the lithium battery tab dust-free welding method of the lithium battery tab ultrasonic bonder have the advantages that because the dust blocking trough is installed around the lower bonder head of the tab ultrasonic bonder, the phenomenon that welding slag generated due to tab welding flies far so that welding slag cannot be easily cleaned away can be effectively prevented.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

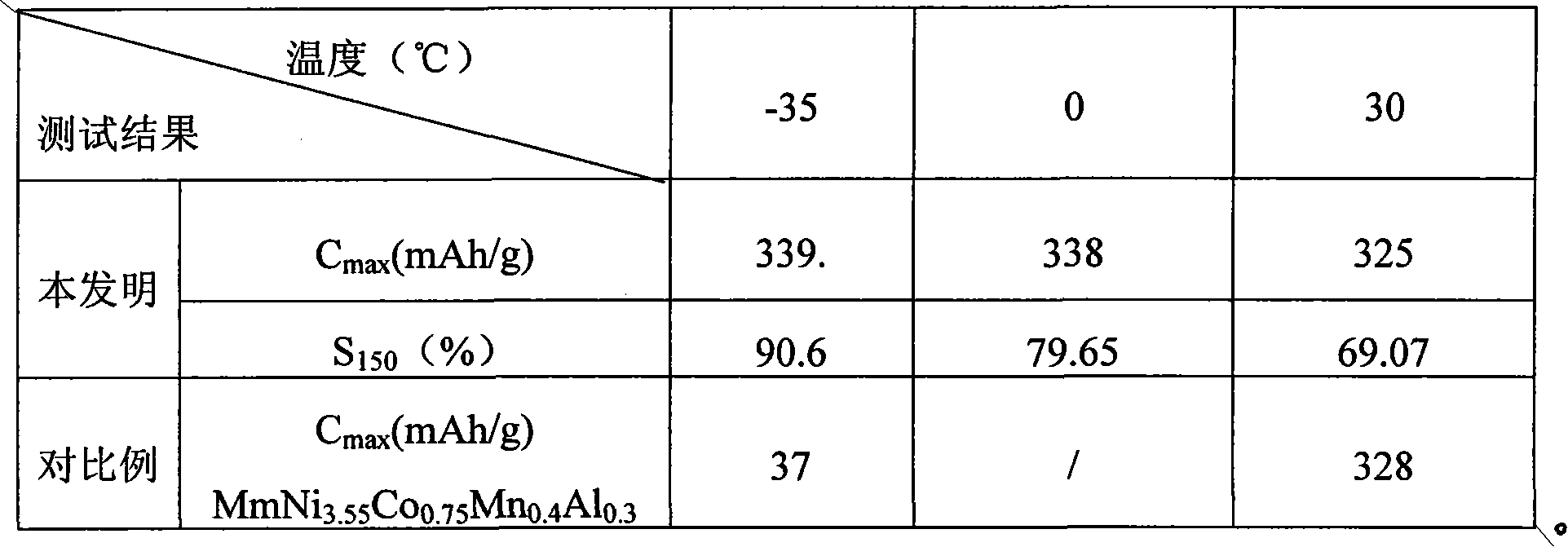

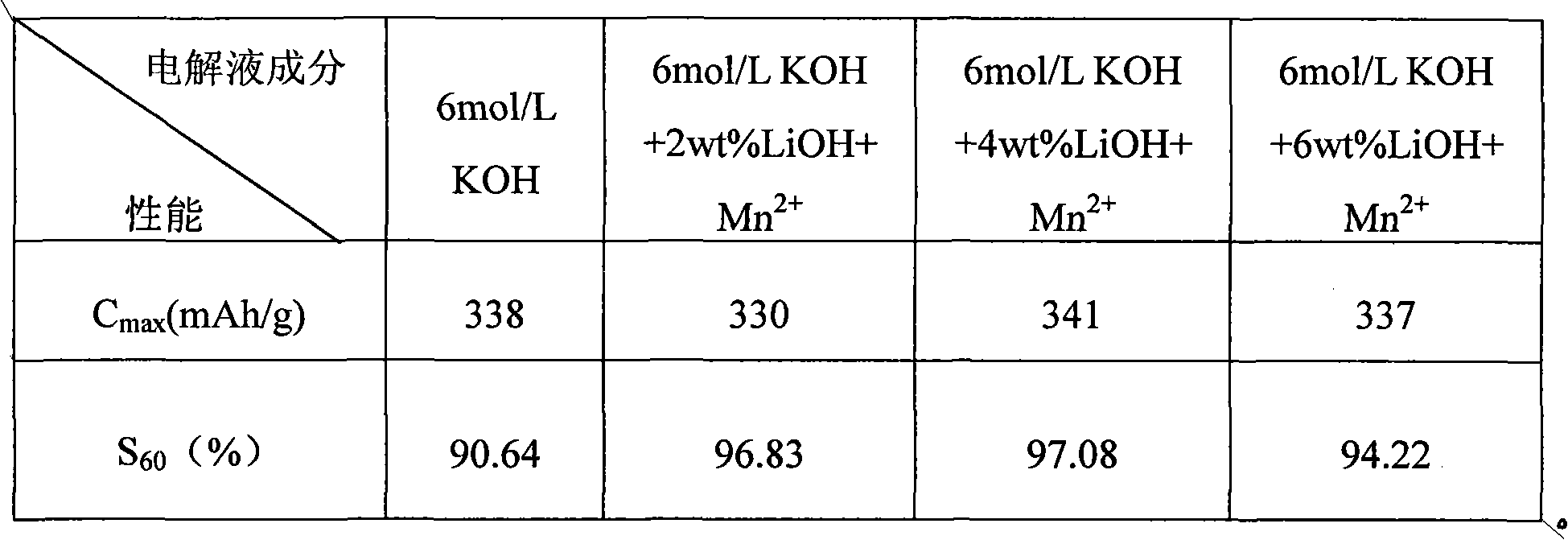

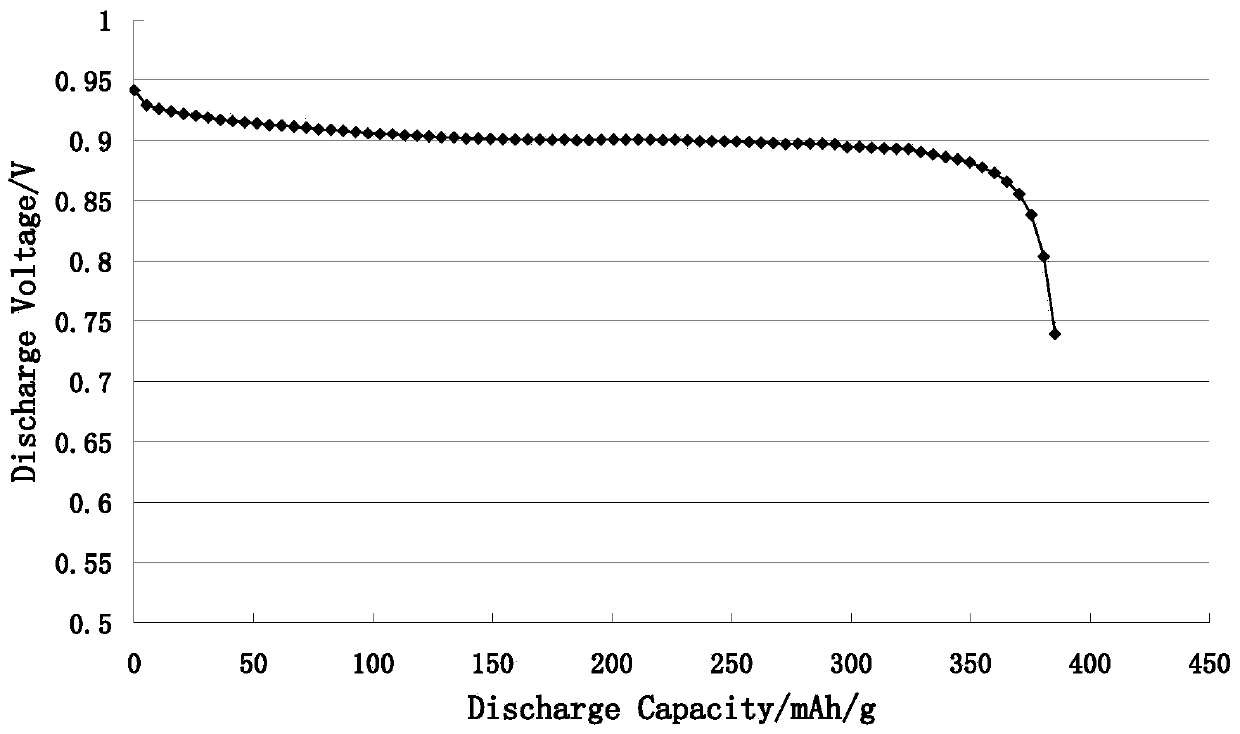

Nickel-hydrogen battery negative electrode hydrogen storage material capable of being used at low temperature and matched electrolytic solution thereof

InactiveCN101871060AImprove self-discharge performanceImproved high rate discharge performanceAlkaline accumulator electrodesNickel accumulatorsAdditive ingredientRare earth

The invention discloses a negative electrode hydrogen storage material for a nickel-hydrogen battery capable of being used at a low temperature, which comprises the atomic ratio ingredient composition shown as the following formula: RExMg<1-x>NiyxMz, wherein in the formula, x is greater than or equal to 0.7 and is smaller than or equal to 1, y is greater than or equal to 3.5 and is smaller than or equal to 3.9, z is greater than or equal to 1 and is smaller than or equal to 1.4, RE is one kind of materials or a mixture prepared from several kinds of materials at any mixture ratio in rare earth metals La, Ce, Pr or Nd, Ce-enriched mixed rare earth metal Mm, and La-enriched mixed rare earth metal Ml, and M is one kind of materials or a mixture of several kinds of materials at any mixture ratio in transition metal elements Co, Al, Mn, Fe, Cr and Ti. The discharging capacity during the application of the nickel-hydrogen battery negative electrode hydrogen storage alloy material of the invention under the low temperature (i.e. the temperature is ranged from 35 DEG C below zero to 0 DEG C) is much higher than the electrochemical discharging capacity of the existing products sold on markets, and the low-temperature performance is greatly improved. In addition, nickel-hydrogen battery products prepared from the negative electrode hydrogen storage material and the electrolytic solution of the invention have the characteristics of high low-temperature electrochemical capacity, obviously improved self discharging performance and high-speed discharging performance, wide application temperature range and the like, and can completely meet the requirement of normal use in low-temperature and normal-temperature environment.

Owner:GUILIN UNIV OF ELECTRONIC TECH

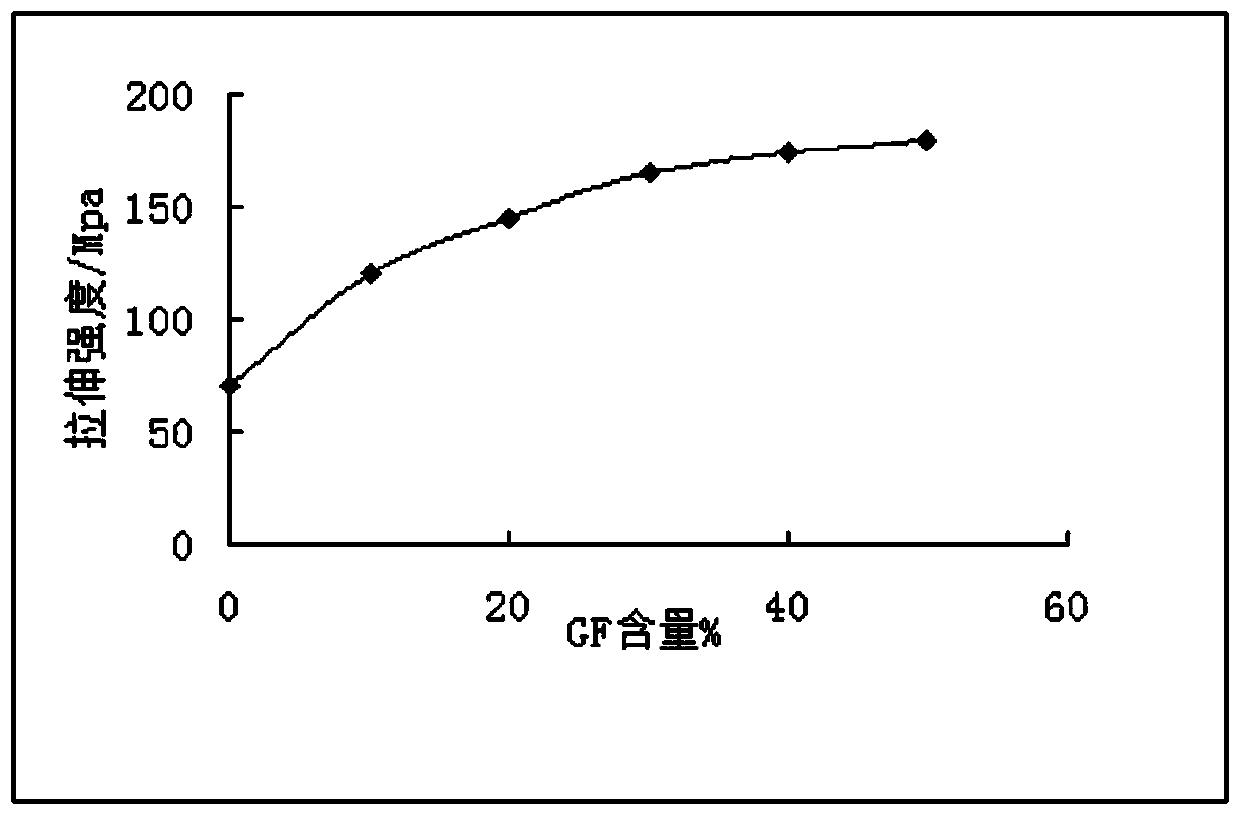

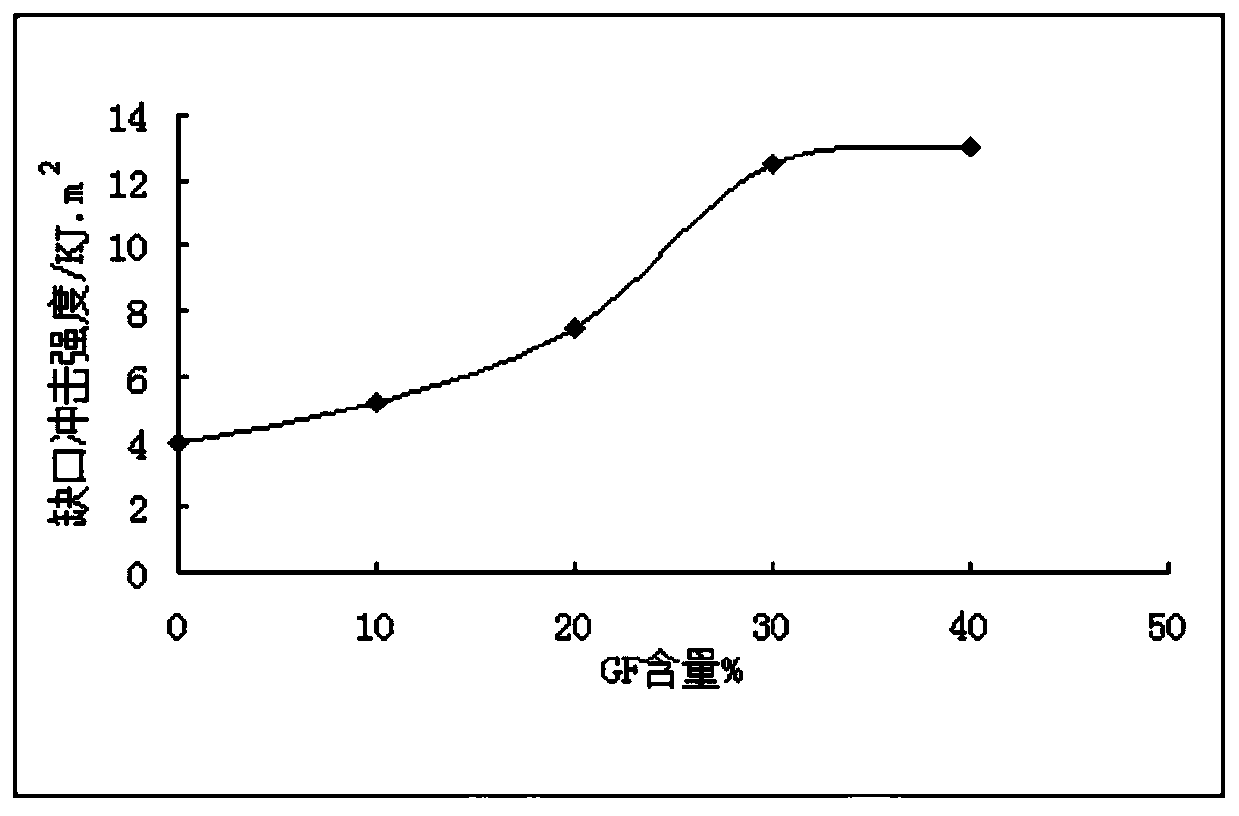

High-barrier corrosion-resistant lithium battery packaging film and preparation method thereof

ActiveCN110893705AImprove corrosion resistanceImprove electrochemical performanceFlexible coversWrappersPolypropylenePowder talc

The invention discloses a high-barrier corrosion-resistant lithium battery packaging film, which comprises a nylon layer, an aluminum foil layer and a heat-seal layer, and further comprises an outer graphene layer, an inner graphene layer and a silicone rubber layer, wherein the nylon layer, the outer graphene layer, the aluminum foil layer, the inner graphene layer, the silicone rubber layer andthe heat-seal layer are sequentially distributed from outside to inside, the nylon layer is prepared from MXD6, glass fibers, LLDPE-g-MAH, nanometer silicon dioxide, a silane coupling agent and hydroquinone, and the heat-seal layer comprises polypropylene, glass fibers, nanometer calcium carbonate, talcum powder and barium sulfate. The high-barrier corrosion-resistant lithium battery packaging film has good corrosion resistance.

Owner:NINGBO RUICHENG PACKING MATERIAL

Lithium-supplementing negative electrode piece, preparation method thereof, and lithium ion battery

ActiveCN109713215AImprove safety performanceImprove self-discharge performanceElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesLithium electrodeSelf-discharge

The invention discloses a lithium-supplementing negative electrode piece, a preparation method thereof, and a lithium ion battery. The lithium-supplementing negative electrode piece comprises a negative electrode piece body and a lithium-supplementing composite layer coated on the surface of the negative electrode piece body. The lithium-supplementing composite layer comprises the following raw materials in percentage by mass: 20%-65% of alloy lithium powder; 30%-70% of ceramic powder; and 5%-50% of a binder. According to the lithium-supplementing negative electrode piece disclosed by the invention, by arranging the lithium-supplementing composite layer, the safety performance of the lithium ion battery is enhanced, and the self-discharge performance of the battery is increased from -0.06mv / h to -0.04mv / h. The lithium alloy powder in the lithium-supplementing composite layer can effectively reduce the activity of lithium and reduce the transportation risk; and the ceramic powder can improve the electrolyte absorption performance of the electrolyte and prolong the cycle life of the battery cell.

Owner:SHENZHEN BETTERPOWER BATTERY

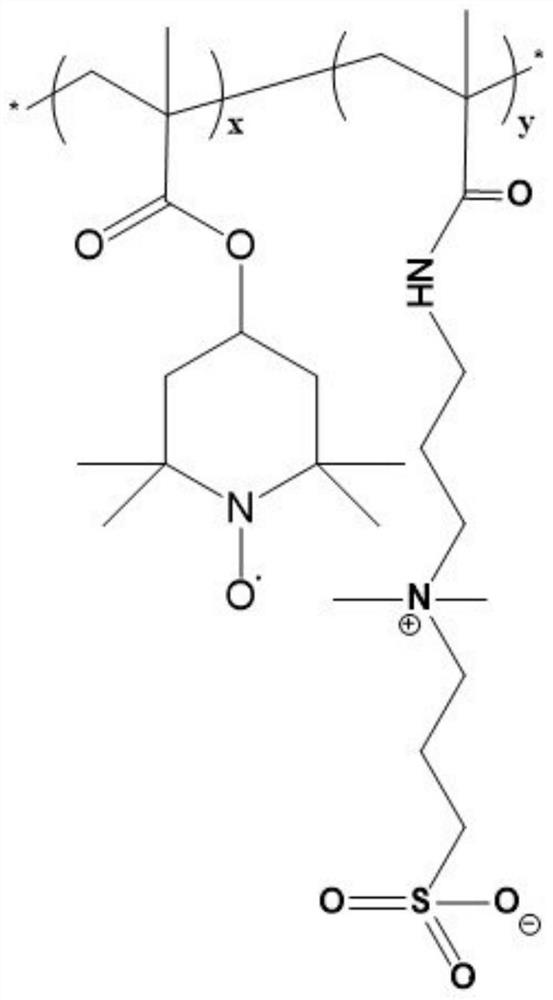

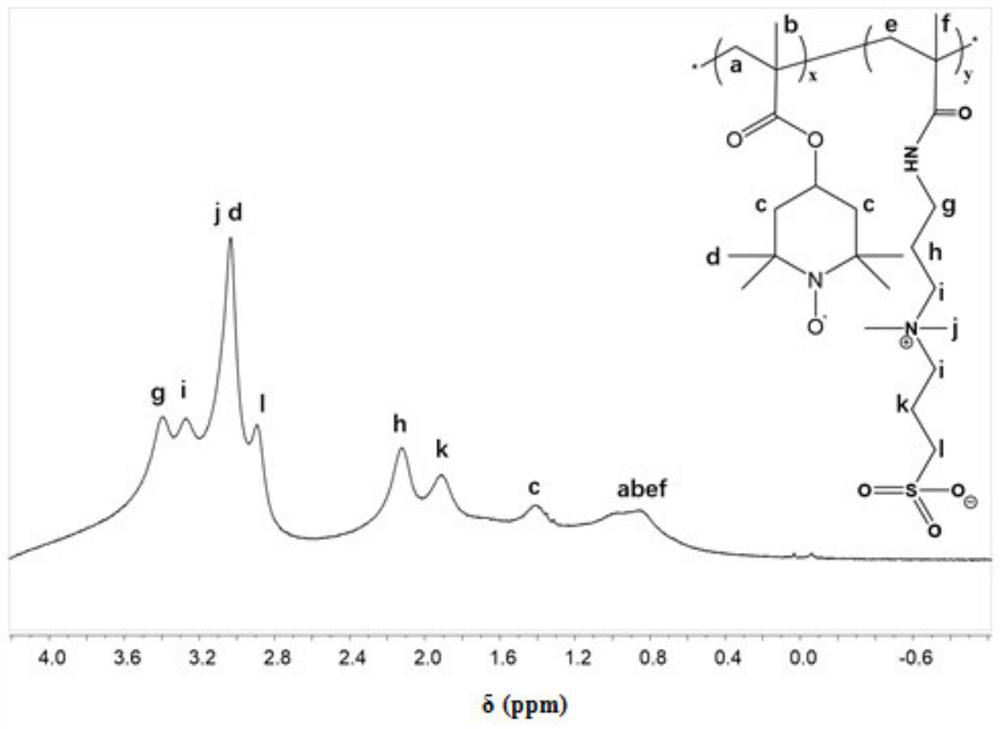

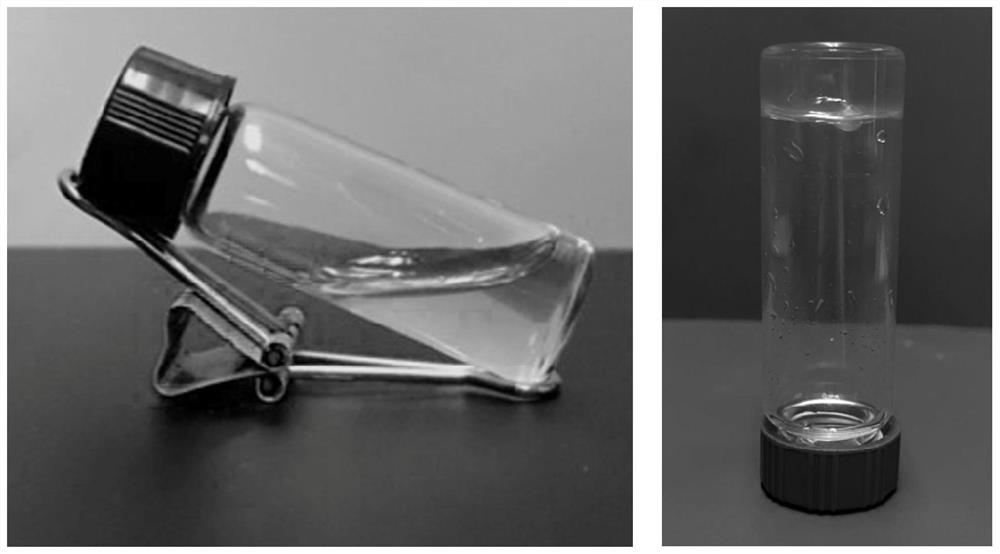

Preparation method of redox type gel electrolyte for all-solid-state supercapacitor

ActiveCN111952081AHigh energy storage densityGood cycle stability and self-discharge performanceHybrid capacitor electrolytesNitric oxideInorganic salts

The invention provides a preparation method of a redox type gel electrolyte for an all-solid-state supercapacitor, and the method comprises the following steps: synthesizing a polymer P(PDP-co-TEMPO)(([3-(methacrylamido)propyl]dimethyl(3-thiopropyl) ammonium hydroxide inner salt)-2-methyl-2-methacrylic acid-2, 2, 6, 6-tetramethyl-4-piperidyl nitric oxide copolymer) by using a free radical polymerization method; preparing P(PDP-co-TEMPO) powder by adopting a freeze-drying method, and then dissolving the obtained powder into a lithium chloride aqueous solution to form the final redox type gel electrolyte. The preparation method provided by the invention is simple in process, low in cost and high in yield, can be used for mass production, and can achieve ultrahigh electrochemical performanceand good self-discharge performance and cycle performance when being applied to an all-solid-state supercapacitor. By controlling the amount of inorganic salt lithium chloride, the ionic conductivityand the water content of the polyamphoteric gel electrolyte can be controlled.

Owner:江西普瑞森新能源科技有限公司

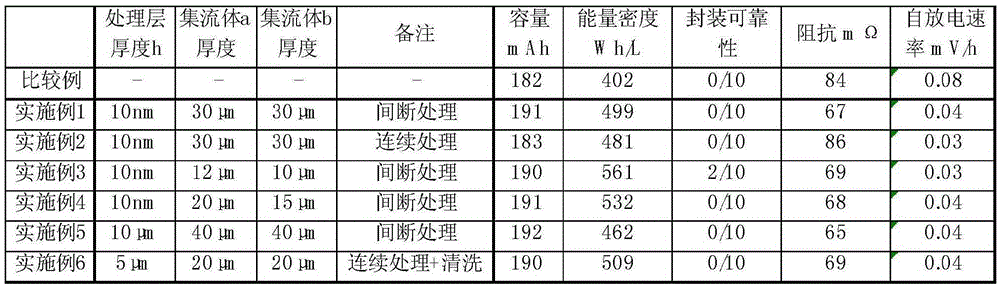

Electrochemical battery and preparation method thereof

InactiveCN105390628AIncrease energy densityReduce typesElectrode manufacturing processesSmall-sized cells cases/jacketsSide effectPositive current

The invention belongs to the technical field of flexible devices, and particularly relates to an electrochemical battery. The electrochemical battery comprises positive electrodes, an isolating membrane, negative electrodes, an electrolyte and an outer package structure, wherein the sum n of the number of the positive electrodes and the number of the negative electrodes is an even number; the outer package structure at least comprises a positive current collector a or / and a negative current collector b; and the outer package structure is a positive tab and a negative tab of a battery core respectively. The electrode current collectors at the outmost layer demonstrate the functions of the package material of the battery and the battery tabs; the variety and the comsumption of materials are reduced; the material cost is reduced; meanwhile the energy density of the battery is improved; and in the preparation process, only the current collectors on the seal edge are subjected to packaging assistant treatment, so that the problems of the package reliability can be solved; the treatment cost can be reduced (the consumption of an expensive treating fluid is reduced); and finally the side effect of an electrode impedance increase caused by the packaging assistant treatment can also be reduced.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

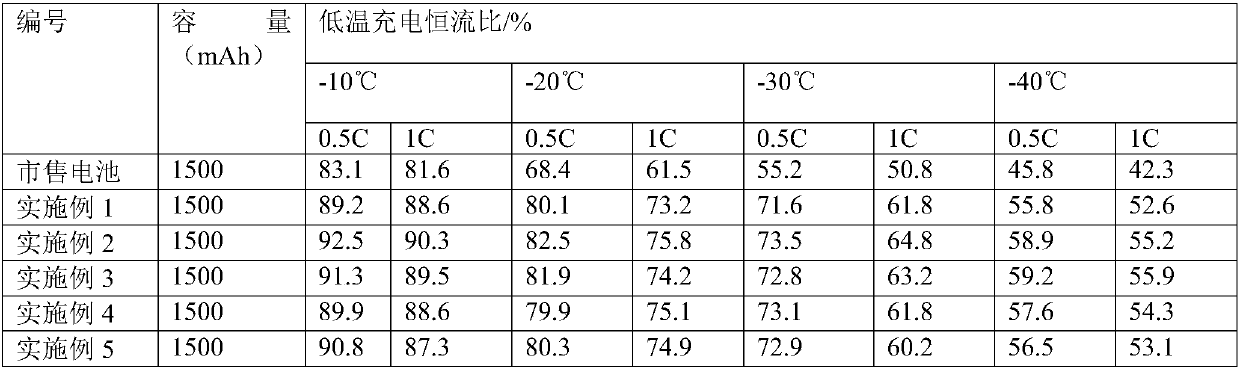

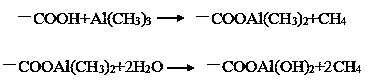

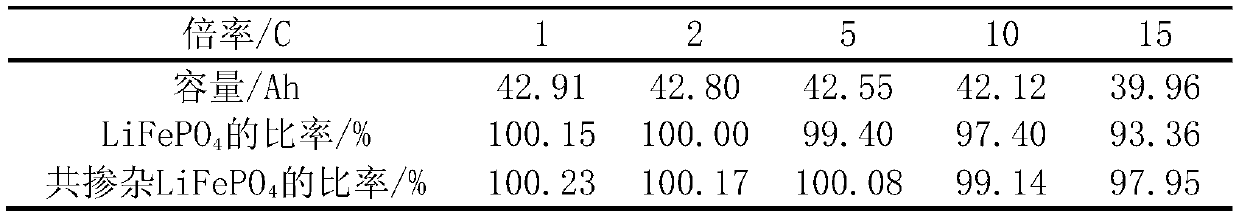

Method for preparing water-based super-nano lithium iron phosphate battery

ActiveCN109921098AHigh magnificationIncrease loopFinal product manufactureCell electrodesWater basedLithium iron phosphate

The invention relates to the field of preparation of lithium batteries, and in particular to a method for preparing a water-based super-nano lithium iron phosphate battery. The lithium iron phosphatebattery provided by the invention is prepared from the following steps: firstly preparing positive and negative electrode slurry, respectively coating the obtained positive and negative electrode slurry on the surface of an aluminum foil to obtain positive and negative pole pieces, and laminating the positive and negative pole pieces, then placing the same in a battery shell, injecting electrolyte, and finally completing formation and volume separation steps to obtain the lithium iron phosphate battery. By adoption of the method provided by the invention, the problem of poor performance at lowtemperature of the lithium iron phosphate battery in the prior art is overcome, and the lithium iron phosphate battery has the advantages of good low temperature resistance, high energy density, better safety performance and smaller resistance.

Owner:WANXIANG 123 CO LTD

Conductive polymer hydrogel as well as preparation method and application thereof

ActiveCN108110234AHigh dopingImprove electrical performanceCell electrodesSecondary cellsConductive polymerReaction temperature

The invention provides conductive polymer hydrogel as well as a preparation method and application thereof and relates to hydrogel as well as a preparation method and the application thereof. The preparation method comprises the following steps: dissolving an acrylic monomer and an aniline monomer in water or a water mixed solvent, standing and fully stirring; then weighing an initiating agent andpreparing an aqueous solution; slowly dropwise adding the prepared aqueous solution in a co-solution of the acrylic monomer and the aniline monomer, controlling the reaction temperature and performing co-polymerization reaction for 0.5-5 hours in an inert gas protection environment to obtain the polyacrylic acid-doped polyaniline-stabilized polyaniline conductive polymer gel synthesized by a one-step method; then adding a precipitating agent for precipitation, filtering, washing and drying to obtain a sample. The conductive polymer hydrogel provided by the invention is used as a cathode material to prepare a lithium battery and has good charge and discharge performances, cyclic stability and capacity retention ratio as the lithium ion battery cathode material.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

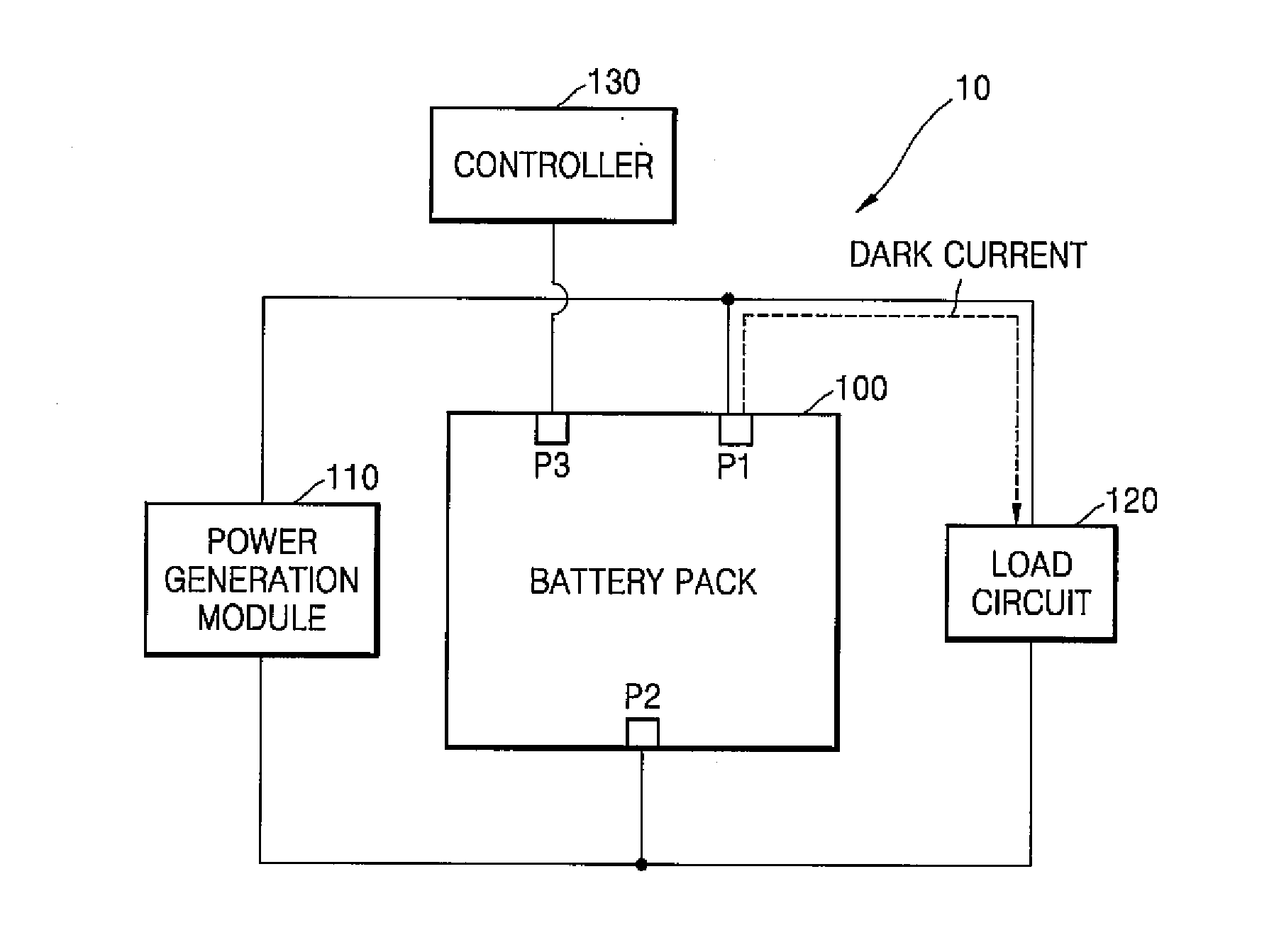

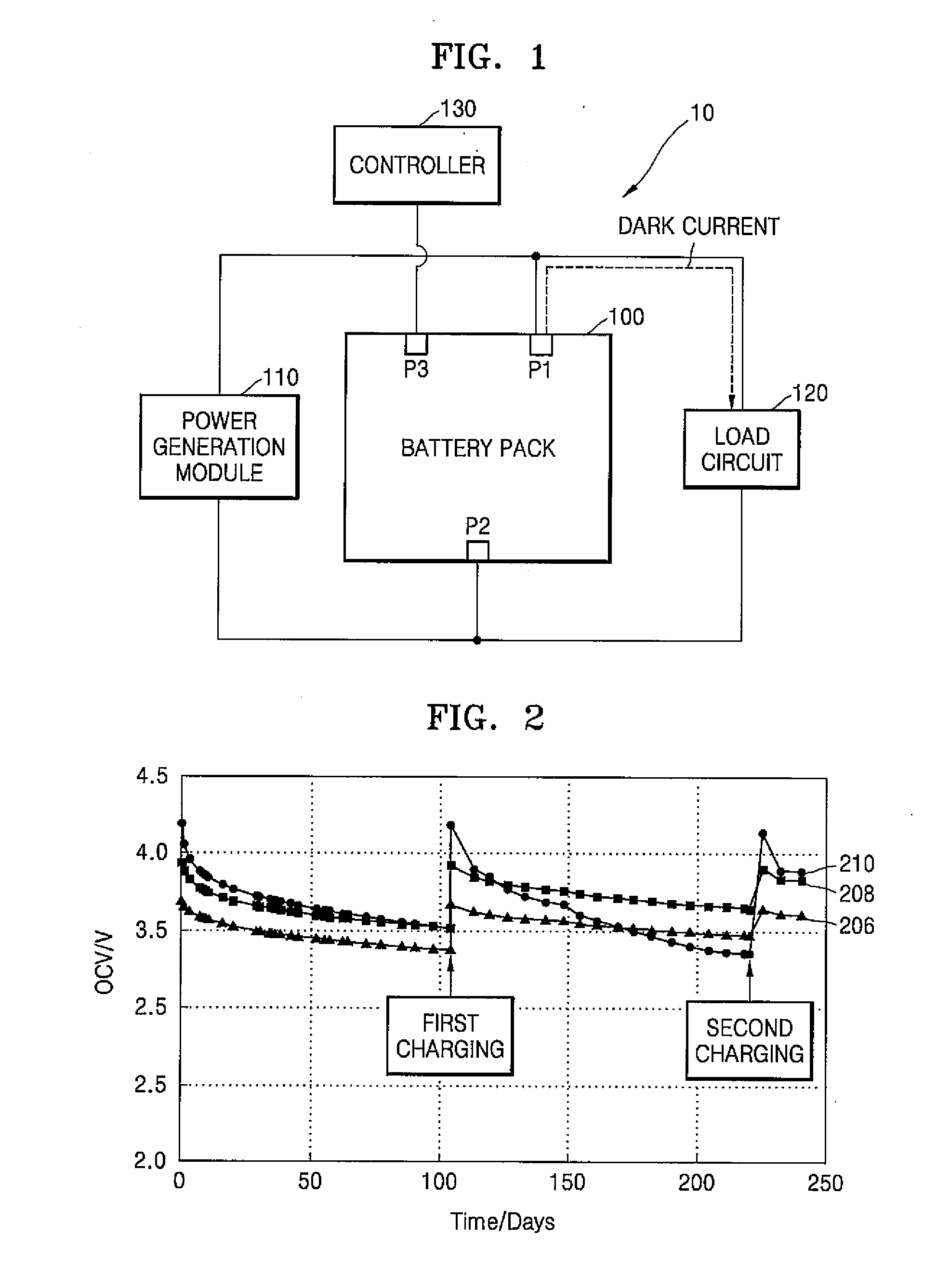

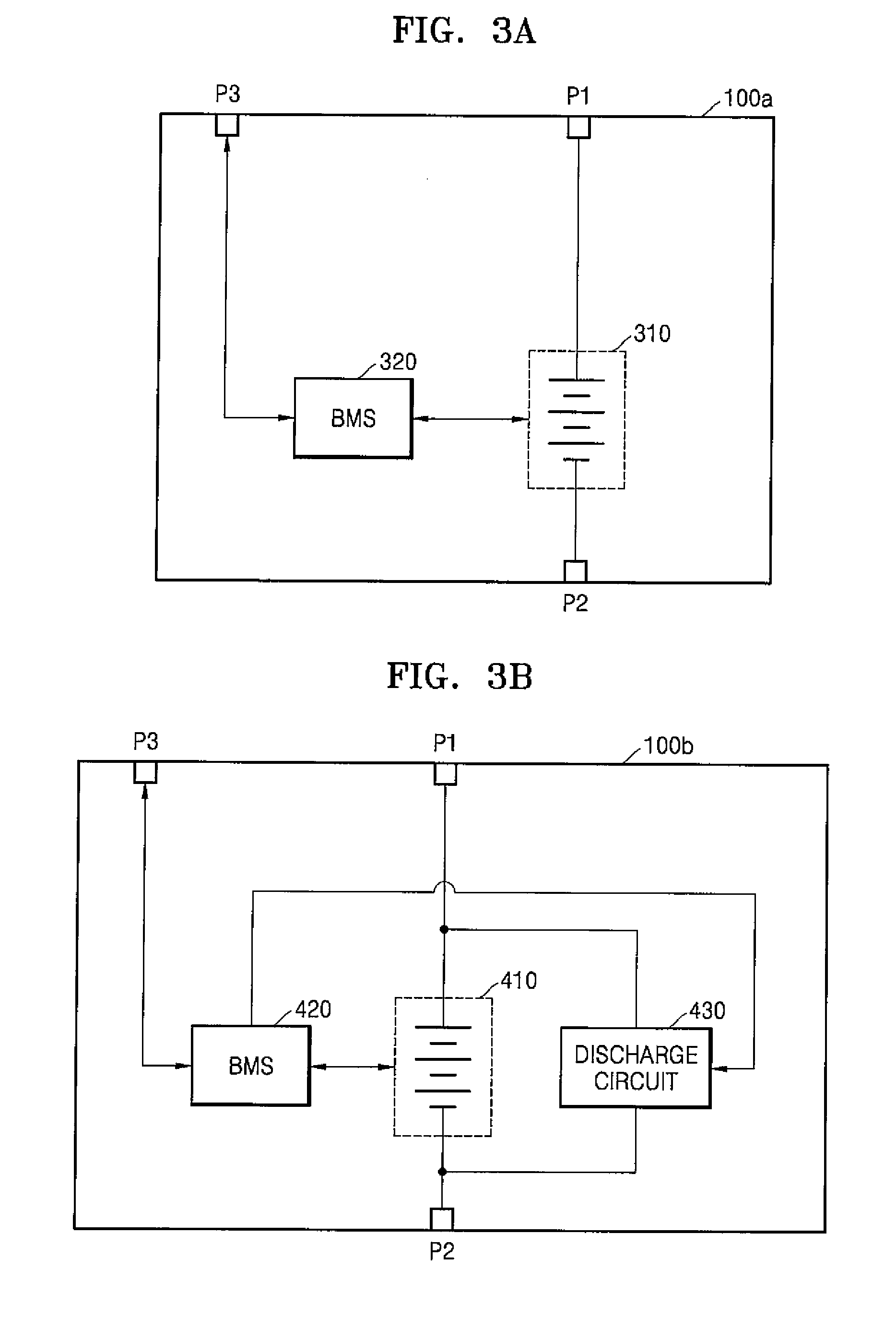

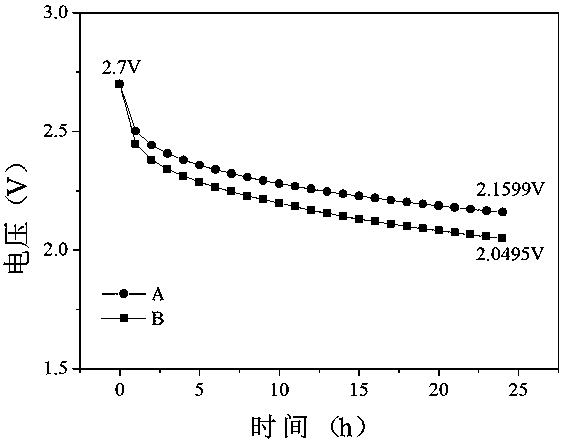

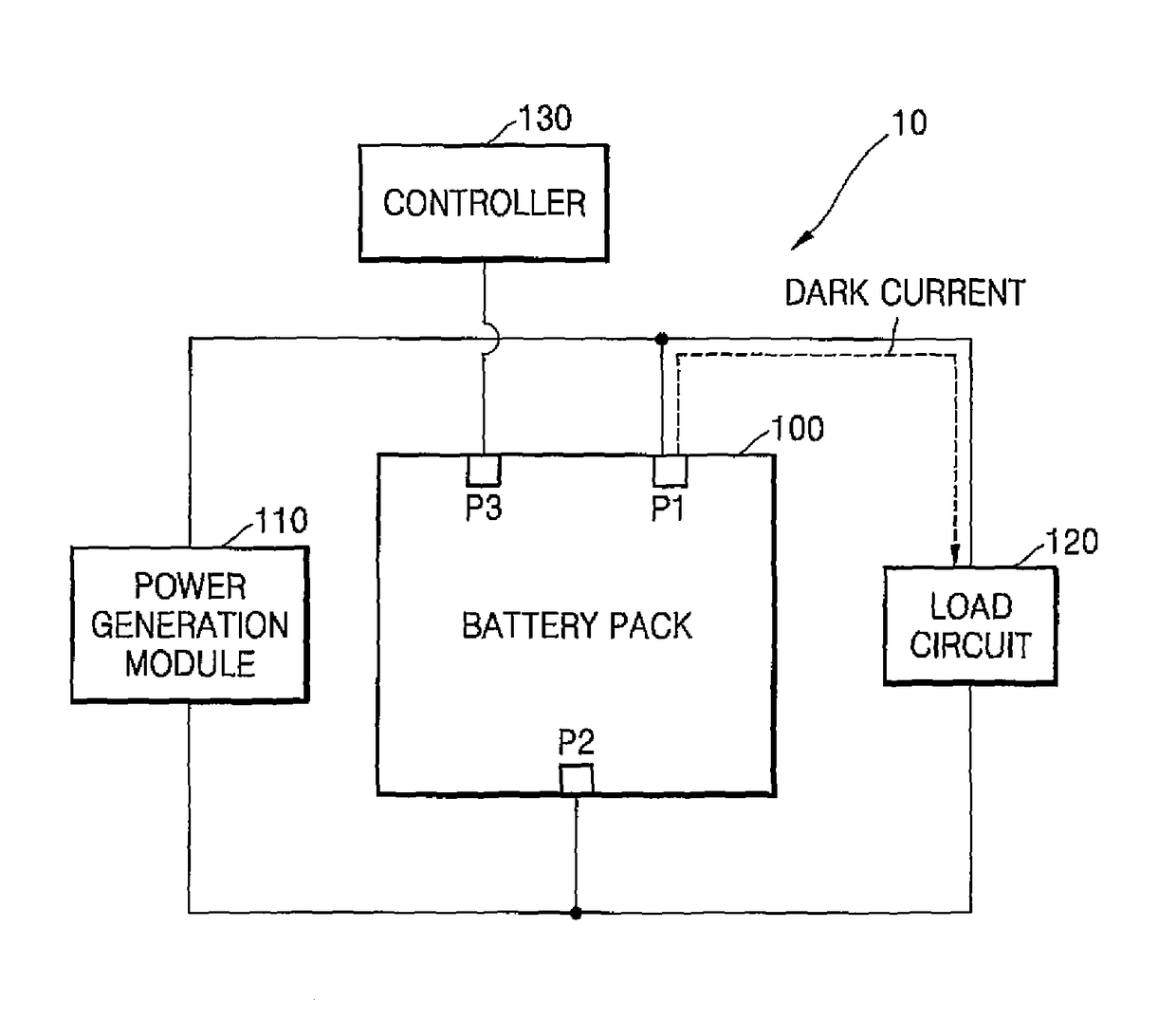

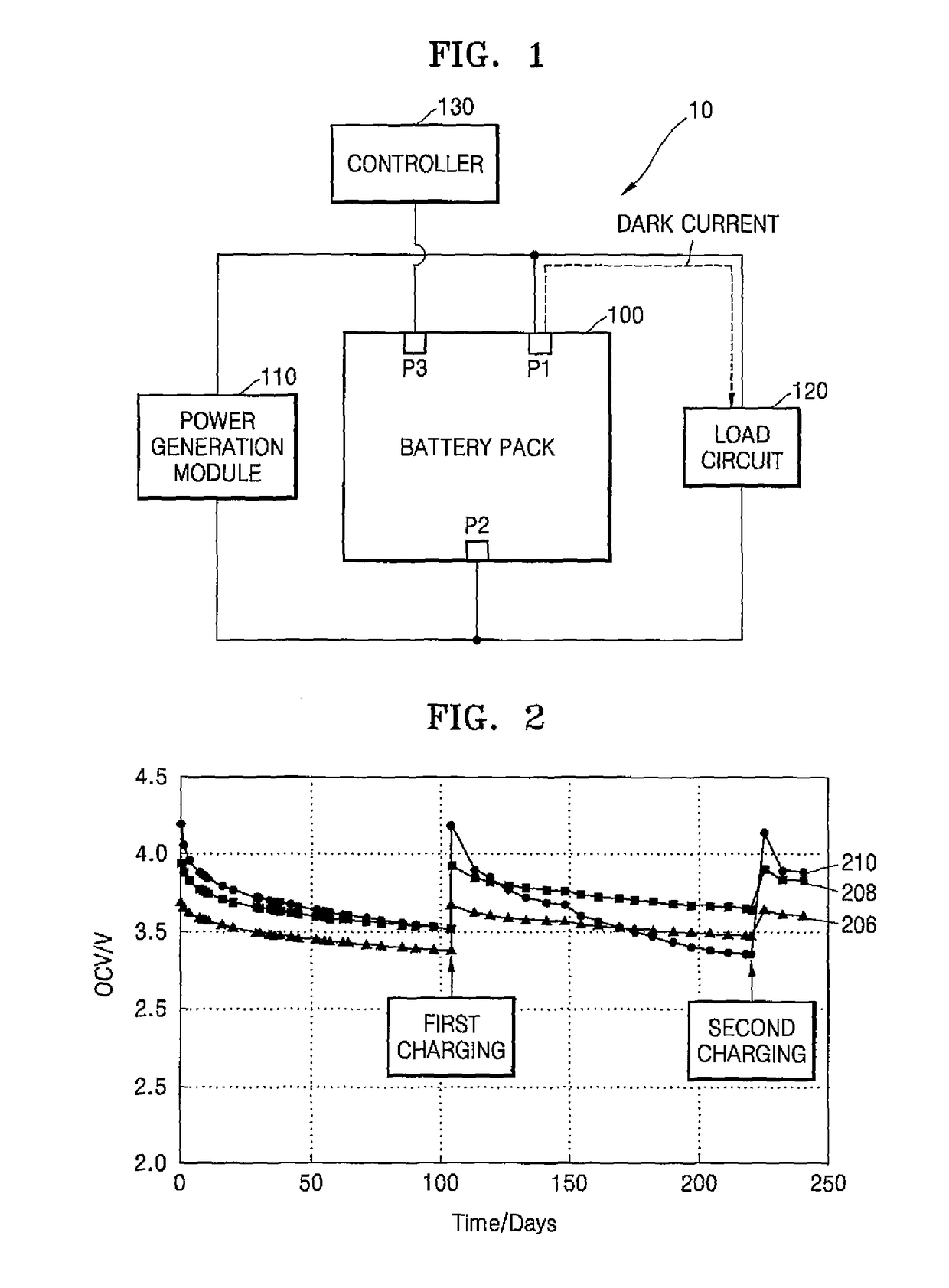

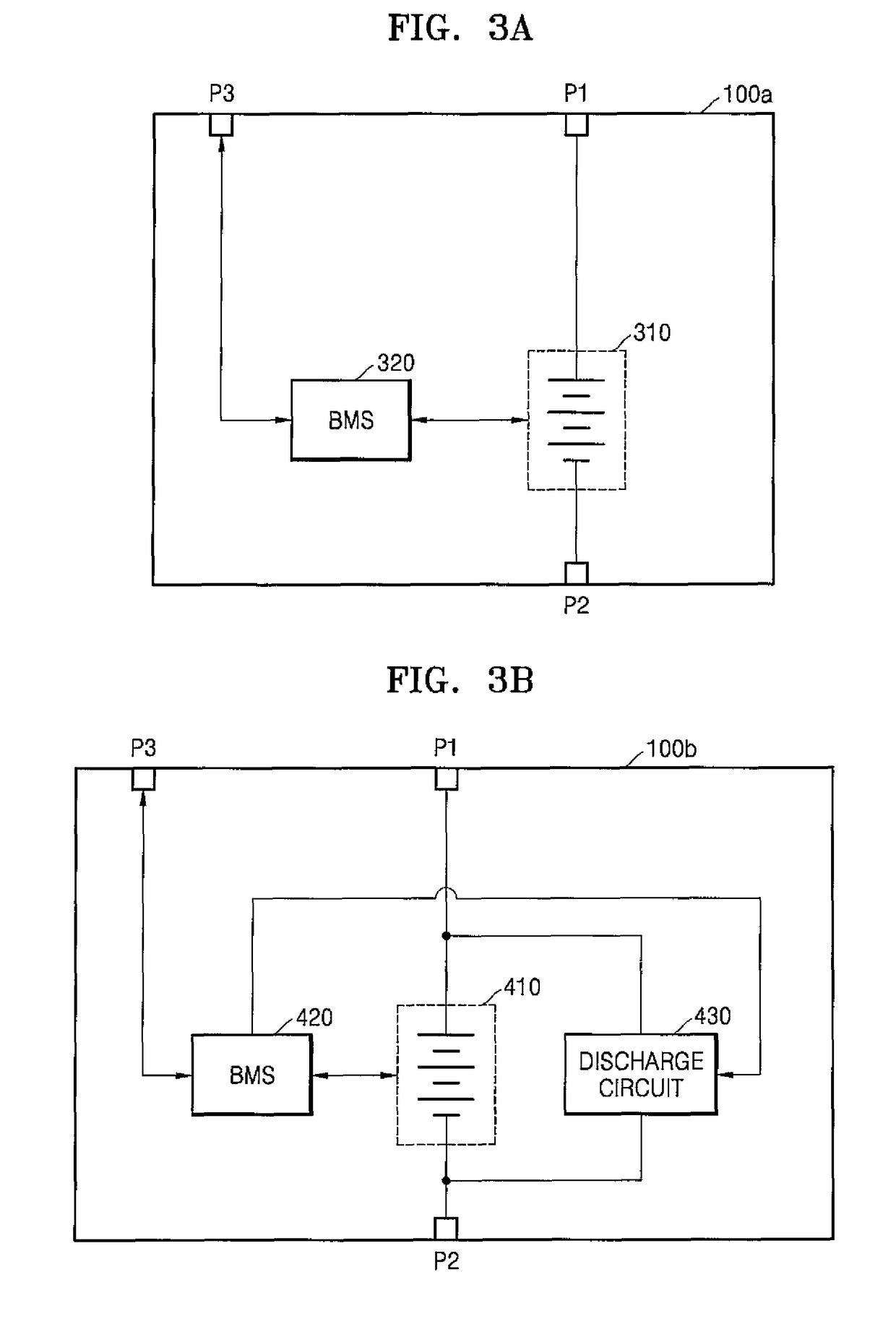

Battery pack, apparatus having the same and method of controlling battery

ActiveUS20150061572A1Improve self-discharge performanceElectric devicesElectric powerLoad circuitState of charge

A battery pack includes a battery coupled between a first terminal and a second terminal and a battery manager configured to sense a state of charge of the battery; a load circuit coupled between the first terminal and the second terminal and configured to receive discharge power from the battery; a power generator coupled between the first terminal and the second terminal and configured to supply charge power to the battery; and a controller configured to control the battery pack and the power generator and to force discharging of the battery to make the state of charge of the battery equal to a reference value when a signal to initiate self-discharging is received from a user.

Owner:SAMSUNG SDI CO LTD

Method for improving self discharge of super capacitor

ActiveCN108231432ALarge area continuousControl the thickness required for growthHybrid capacitor electrodesChemical vapor deposition coatingActivated carbonSupercapacitor

The invention belongs to the technical field of electrochemistry, and in particular relates to a method for improving self discharge of a super capacitor. The method comprises the following steps: 1)putting an activated carbon electrode as a substrate in a vacuum reaction chamber; 2) introducing first precursor gas into the vacuum reaction chamber, wherein the first precursor gas is reacted witha surface functional group of the activated carbon electrode; 3) flushing the electrode with inert gas; and 4) introducing the first precursor gas as a metal source and the second precursor gas as anoxygen source into the vacuum reaction chamber and carrying out atomic layer deposition circulation in an inert gas atmosphere till forming a metal oxide film with a targeted thickness. The metal oxide is deposited to the surface of the activated carbon electrode to form a coating layer by means of the atomic layer deposition technology, so that the surface structure of the carbon electrode is improved, and the stability of the super capacitor in the using process is enhanced; and the purpose of simply and precisely controlling the thickness needed by growth of a film can be achieved by controlling the periodicity of the reaction.

Owner:柔电(武汉)科技有限公司

Separator material and method of producing the same, and alkali secondary battery separator

InactiveCN100346505CEasy to processHigh short-circuit resistanceAlkaline accumulatorsFinal product manufacturePolyolefinPolymer science

The separator material of the present invention is a sulfonated non-woven fabric comprising polyolefin ultrafine short fibers with a denier of less than 0.5 dtex and one or more other polyolefin short fibers. The other polyolefin staple fibers include polyolefin thermally bonded staple fibers. At least a portion of the polyolefin thermally bonded staple fibers are flattened to bond the component fibers together. The nonwoven fabric has a specific surface area in the range of 0.6 m2 / g to 1.5 m2 / g and satisfies the following range. (1) The ratio (S / C)E of the number of sulfur atoms (S) to the number of carbon atoms (C) in the non-woven fabric measured by electron spectroscopy (ESCA) for chemical analysis is in the range of 5×10-3-60×10- 3 range. (2) The ratio (S / C)B of the number of sulfur atoms (S) to the number of carbon atoms (C) in the nonwoven fabric measured by the flask combustion technique is in the range of 2.5×10-3-7×10-3. (3) The ratio (S / C)E / (S / C)B (depth of sulfonation) of (S / C)E to (S / C)B is in the range of 1.5-12. Thus, there are provided a separator material having high self-discharge performance when charge and discharge are repeatedly performed, high processability when assembling a storage battery, and high resistance to short-circuit capability; a method of producing the separator; and a An alkaline secondary battery separator.

Owner:DAIWA BOSEKI KK

Preparation method of lead-acid storage battery anode for electric bike

InactiveCN102403487ASimple recipeReasonable compositionLead-acid accumulator electrodesElectric bicycleAnode

The invention discloses a preparation method of a lead-acid storage battery anode for an electric bike. The lead-acid storage battery anode comprises the following components in percent by weight: 1.2-1.6 percent of Sn, 0.2-0.6 percent of Al, 0.01-0.02 percent of Bi, 0.02-0.08 percent of Ag, 0.02-0.05 percent of In, 0.05-0.10 percent of Cu and the balance of Pb. The preparation method comprises the steps of: 1, placing the Sn, the Ag, the In and the Cu into a crucible, heating to reach the temperature of 1130-1150 DEG C for melting, uniformly stirring, pouring into an ingot mould, cooling to obtain an ingot casting for later use; 2, smelting the Al and the Bi in a lead pan, melting at a temperature of 640-660 DEG C and preserving the temperature, placing the ingot casting into the lead pan, uniformly stirring after the ingot casting is molten, standing for 15-20min; and 3, regulating the pouring temperature to be 570-580 DEG C, and pouring into a board gate mould to form a board gate.

Owner:徐艳

Nickel hydrogen charging battery

ActiveCN101267047AIncreased monthly capacity retentionGood capacity retentionAlkaline accumulator electrodesNickel accumulatorsLutetiumMass ratio

The present invention provides a nickel-metal hydride charge battery, which resolves the problem of reducing the high self charge in the storaging course of the nickel-metal hydride battery. The invention adopts following technical scheme: a nickel-metal hydride charge battery includes a cathode, a diaphragm, an electrolyte and an anode, the electrolyte contains KOH solution, the cathode contains at least one oxide or hydroxide of titanium, yttrium, erbium, thulium, ytterbium, lutetium, calcium or barium element, the mass ratio of the content to the whole cathode active material is 0.1-10%. Compared with the prior art, the battery cathode contains oxide or hydroxide of titanium, yttrium, erbium, thulium, ytterbium, lutetium, calcium or barium element, the month capacity retention rate of the battery is increased more than 90%, the year capacity retention rate is increased more than 80%, having excellent self-discharge performance and having high capacity retention rate.

Owner:LEXEL BATTERYSHENZHEN

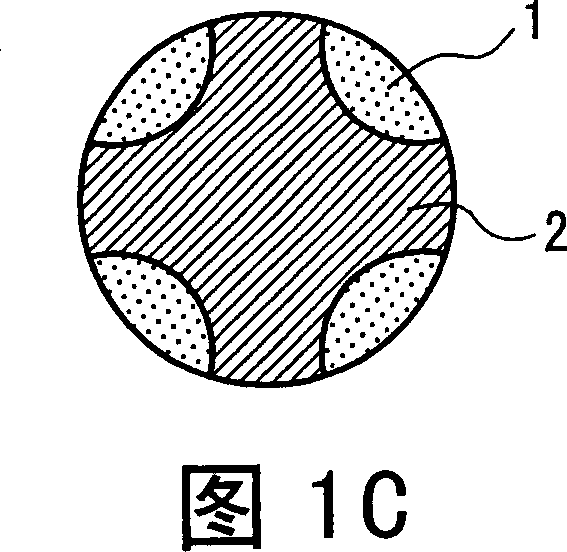

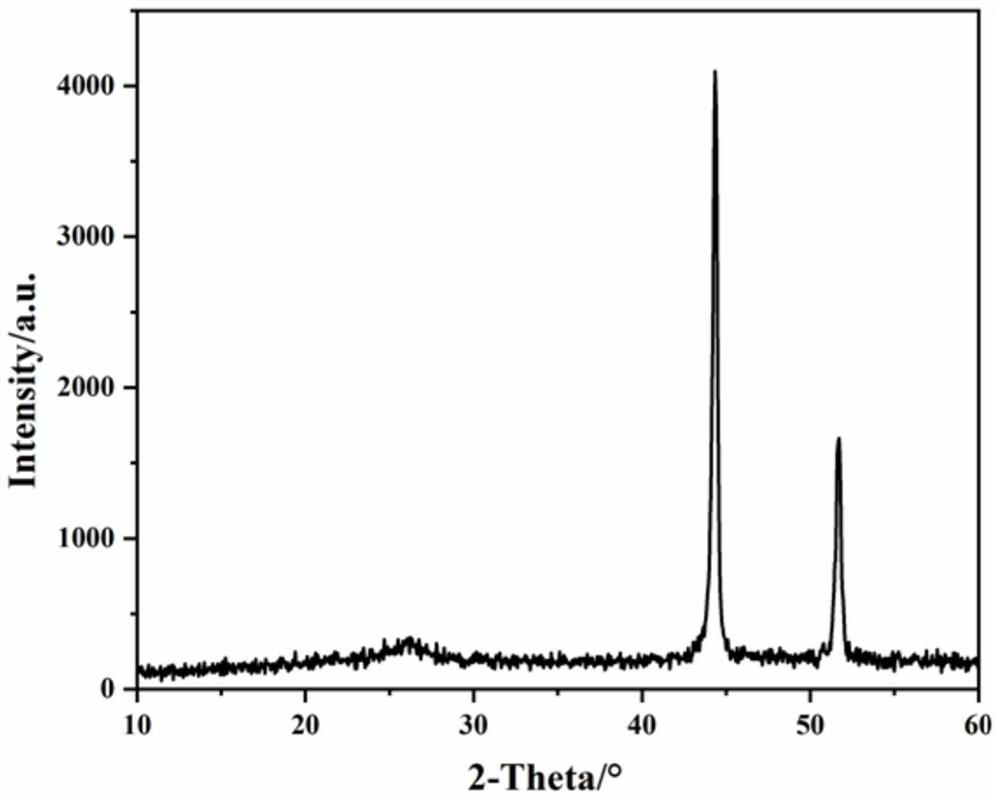

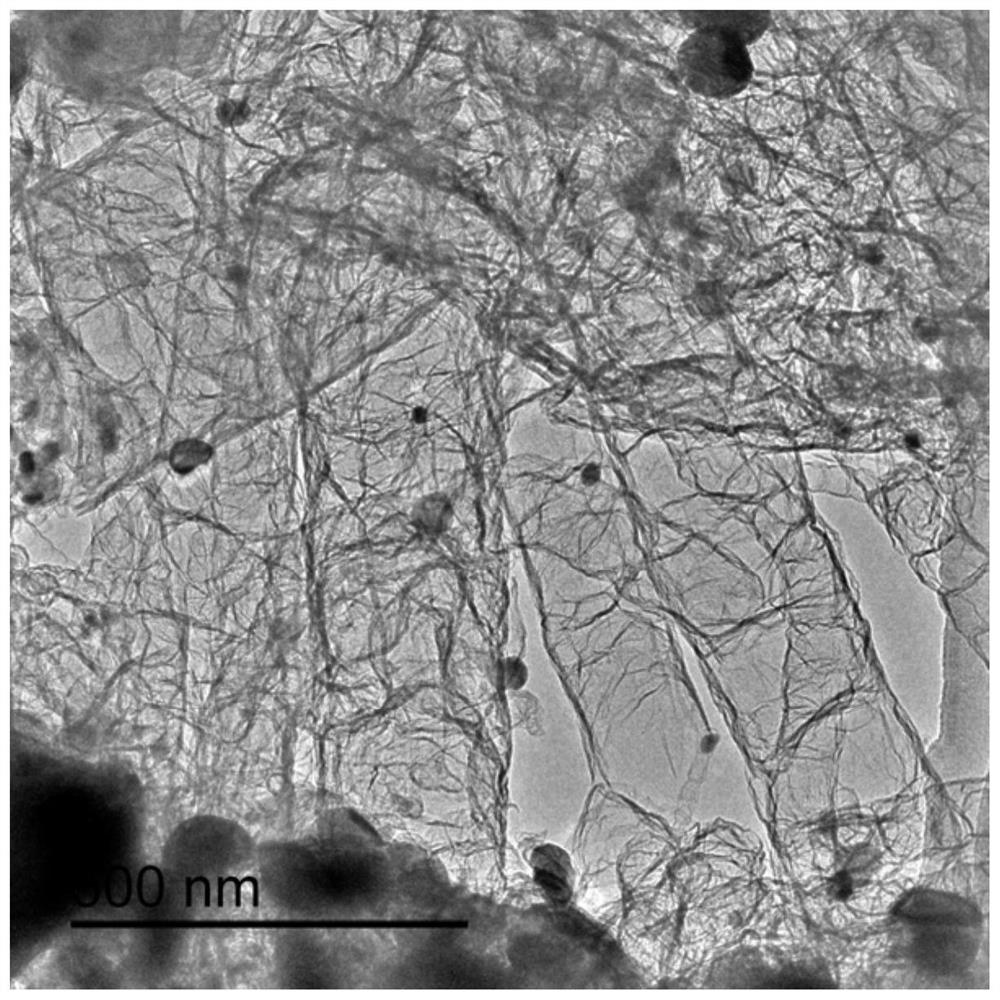

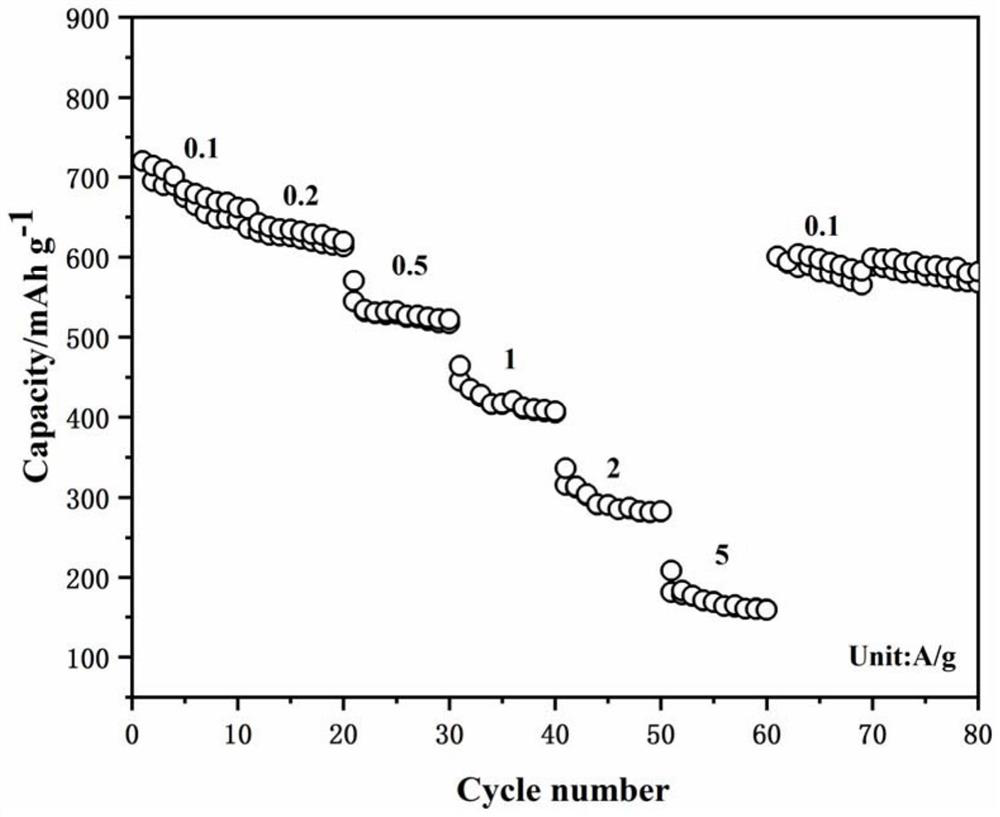

FeCoCuZn co-doped Ni-based alloy-carbon nanotube composite material modified diaphragm as well as preparation method and application thereof

PendingCN113991243AImprove positive electrode conductivityAlleviate battery swellingSecondary cellsCell component detailsHigh entropy alloysSelf-discharge

The invention discloses a preparation method of a FeCoCuZn co-doped Ni-based alloy-carbon nanotube composite material modified diaphragm. The method comprises the following steps: weighing a self-synthesized high-entropy alloy / carbon nano composite material and a binder according to a ratio, uniformly grinding, dropwise adding a solvent to prepare slurry, and coating a diaphragm base membrane with the slurry by using a coating machine; and performing microwave heating treatment under inert gas protection for 5-30 minutes, enabling the heating temperature of the diaphragm coated with the slurry to be 50-80 DEG C, and cooling the diaphragm to normal temperature at a cooling speed of about 20 DEG C / min after heating to obtain a modified diaphragm with the FeCoCuZn co-doped Ni-based alloy-carbon nano tube composite material coating. The thickness of the FeCoCuZn co-doped Ni-based alloy-carbon nanotube composite material coating of the diaphragm is 2-15 [mu]m. When the modified diaphragm is applied to a battery, the conductivity of a positive electrode can be improved, battery expansion can be relieved, the side reaction of the positive electrode and an electrolyte can be inhibited, the mechanical lightness and puncture strength of the diaphragm can be improved, and the safety and self-discharge performance of the battery can be effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method and device for preparing battery pole piece

ActiveCN101615667BImprove self-discharge performanceImprove performanceElectrode manufacturing processesPretreated surfacesElectrical batteryPole piece

The invention provides a method for preparing a battery pole piece. The method comprises the following steps: coating pole slurry on a current collecting body; and vibrating the obtained current collecting body coated with the pole slurry on the surface. The invention provides a device for preparing the battery pole piece. The device comprises a coating device and a vibrating device, wherein the pole slurry is coated on the surface of the current collecting body by the coating device, and the vibrating device is used for vibrating the current collecting body coated with the pole slurry on thesurface. After being placed in a room with the temperature of 20+ / -2 DEG C and the humidity of 20 percent-50 percent for 28 days in an open circuit, a battery with the volume of 4.2 V, which is prepared by the battery pole piece prepared by the device and the method, reduces the voltage by 5 mV at most, and the micro-short circuit rate tested by 20,000 batteries is 0.01 percent; and the battery prepared by a device and a method in the prior art has the voltage reduction up to 50 mV and the micro-short circuit rate of 0.05 percent under the completely same condition.

Owner:SHANGHAI BYD

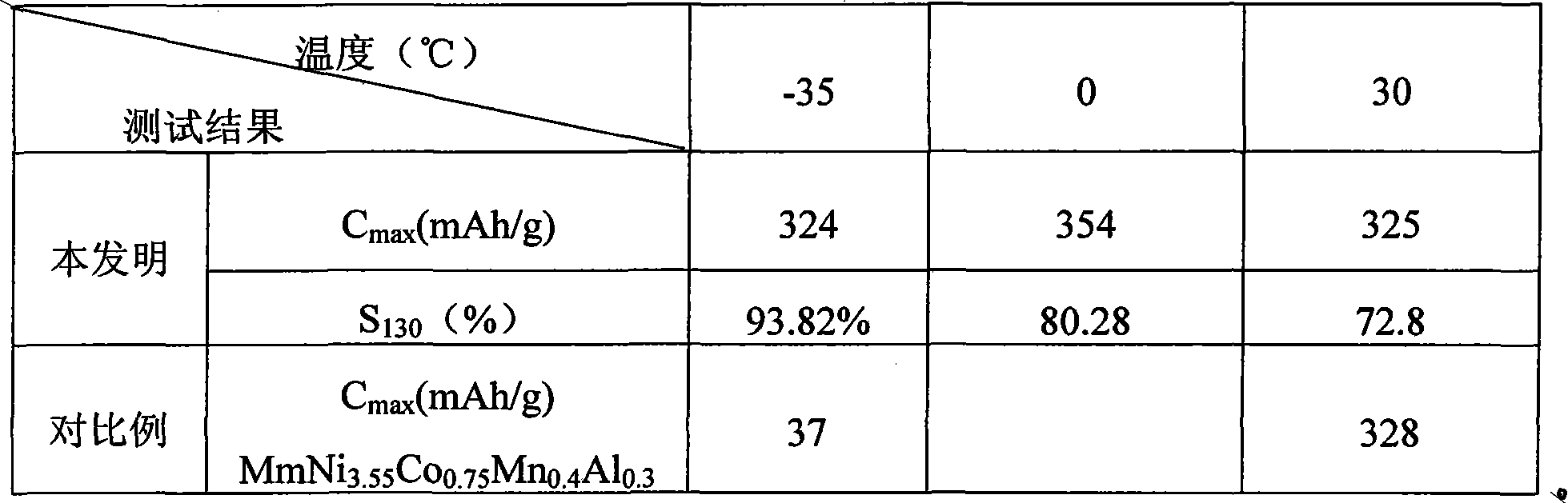

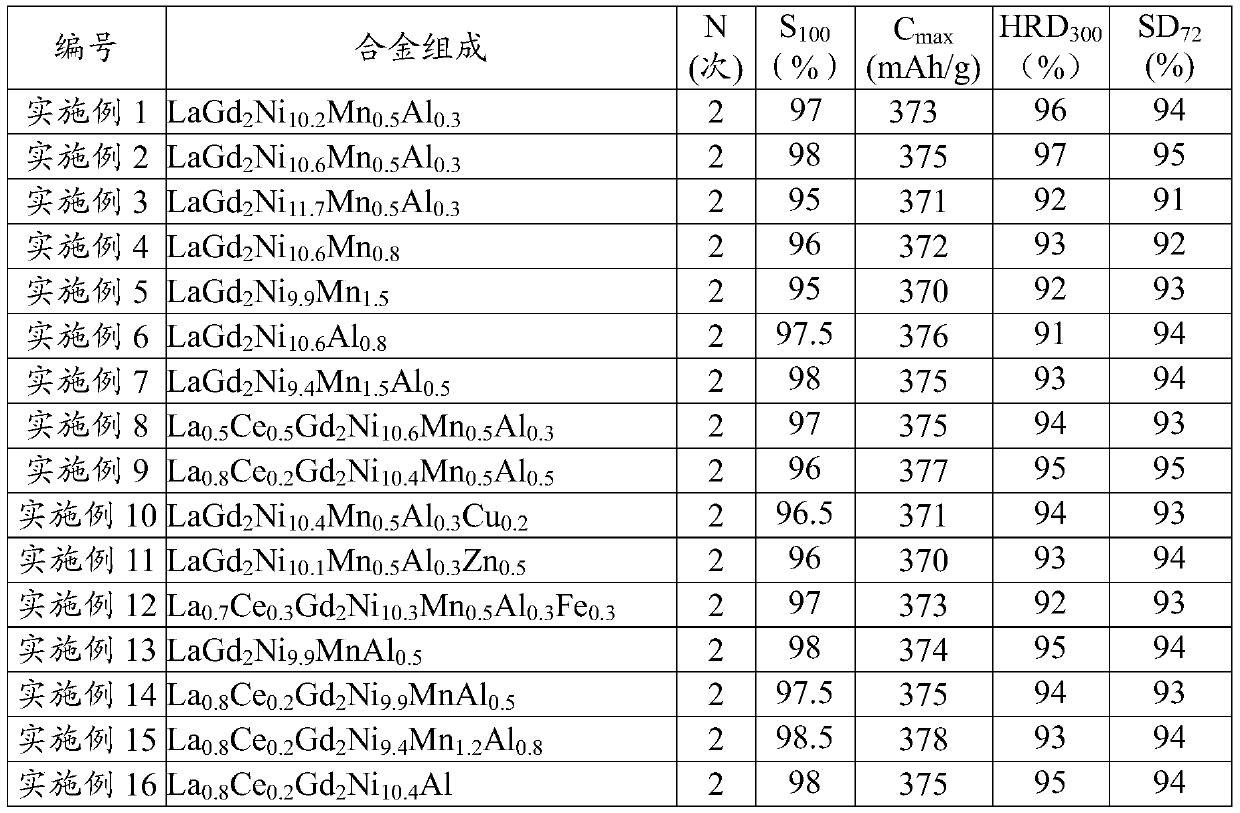

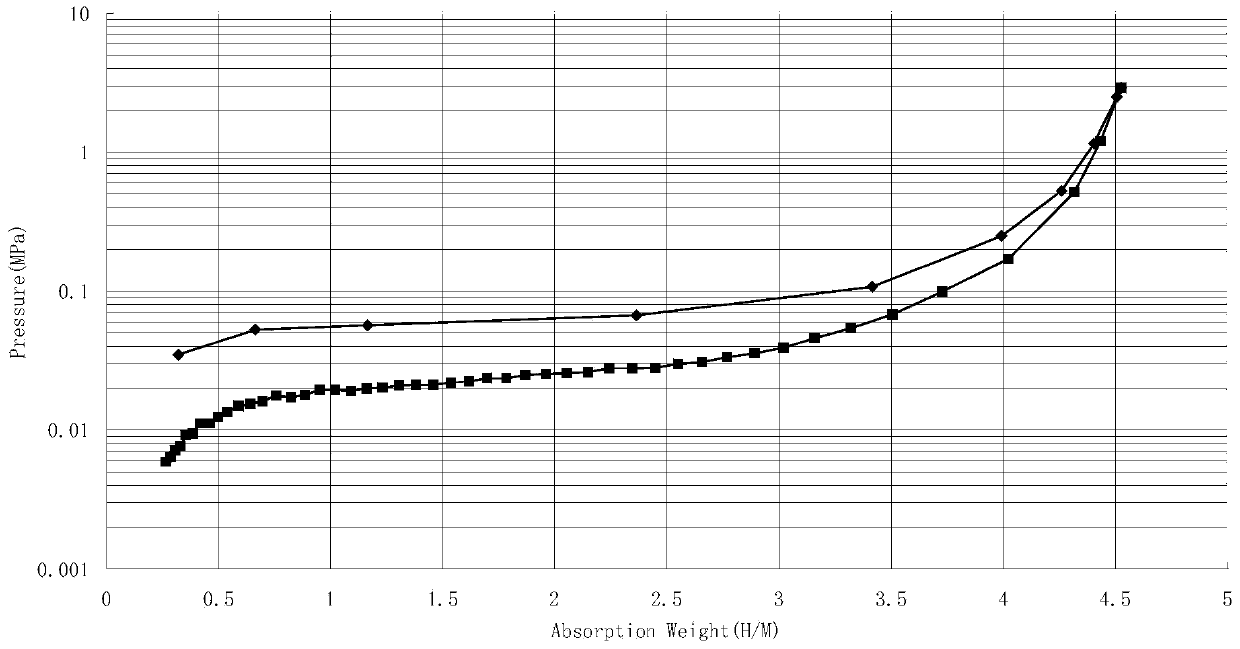

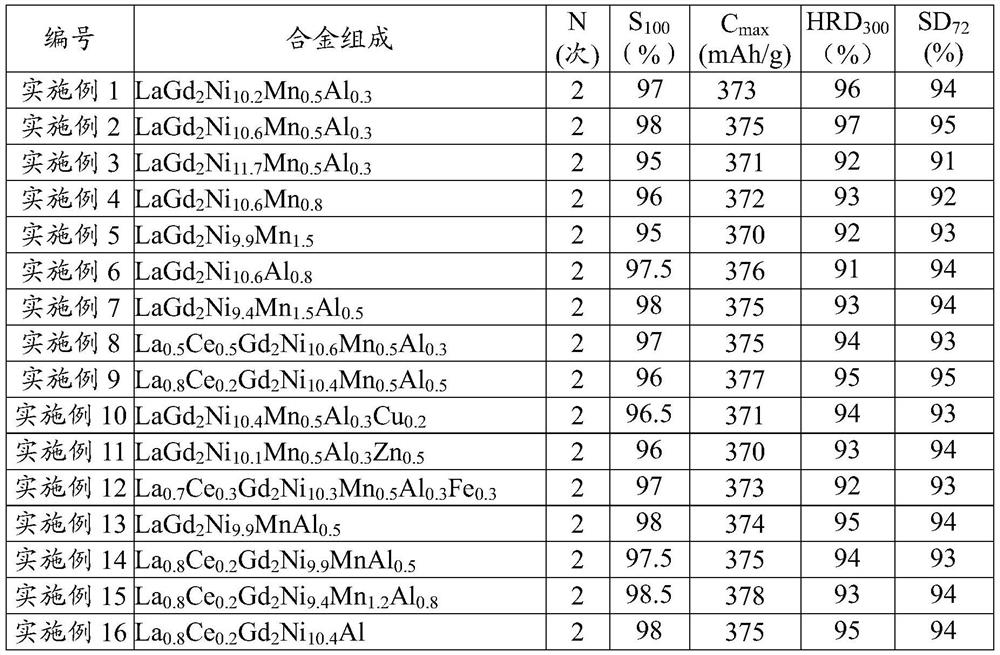

A5B19 type gadolinium-containing hydrogen storage alloy, negative electrode and preparation method

ActiveCN111411262AIncrease the maximum discharge capacityExtended service lifeHydrogenNegative electrodesMischmetalGadolinium

The invention discloses an A<5>B<19> type hydrogen storage alloy, a negative electrode and a preparation method. The composition formula of the hydrogen storage alloy is REGd<v>Ni<w-a-b-c>MnAlM<c>, RE is selected from one or more of rare earth metal elements except Gd, M is selected from one or more of Zn, V, W, Cu, Fe, Sn, Cr, Mo and Si elements, u, v, w, a, b and c represent mole fractions of all the elements correspondingly, u is larger than 0, v is larger than 0.1, u plus v is 3, w is less than 13 and larger than or equal to 11, a plus b is less than or equal to 4 and larger than0, c is less than or equal to 2 and larger than or equal to 0. According to the alloy and the method, the maximum discharge capacity of the hydrogen storage alloy is improved, and the service life ofthe hydrogen storage alloy is prolonged.

Owner:BAOTOU RES INST OF RARE EARTHS

Praseodymium-free, neodymium-free and cobalt-free high capacity superlattice hydrogen storage alloy containing magnesium

The invention relates to praseodymium-free, neodymium-free and cobalt-free high capacity superlattice hydrogen storage alloy containing magnesium. The alloy is characterized in that a composite chemical formula of the alloy is one of Mm(1-x-y)LaxMgyNiaAlb, Mn(1-x-y-z)LaxMgyMzNiaAlb, Mm(1-x-y)LaxMgyNiaAlbNc or Mm(1-x-y-z)LaxMgyMzNiaAlbNc, wherein Mm is rare earth or misch metal at least containing one or more than one of La, Ce, Y, Sm and Gd; M is one or more than one of Ti, Zr and Hf; N is one or more than one of Mn, Sn, Cr, V, W and Mo; x, y, z, a, b and c represent molar ratios. Compared with the prior art, the alloy has the advantages of large discharge capacity, low cost and good low self discharge property.

Owner:鞍山鑫普新材料有限公司 +1

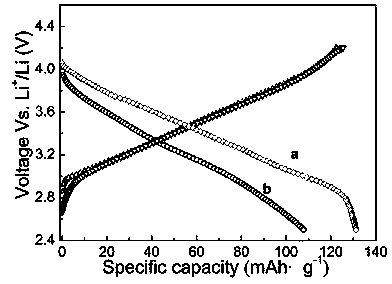

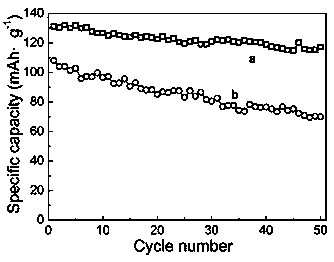

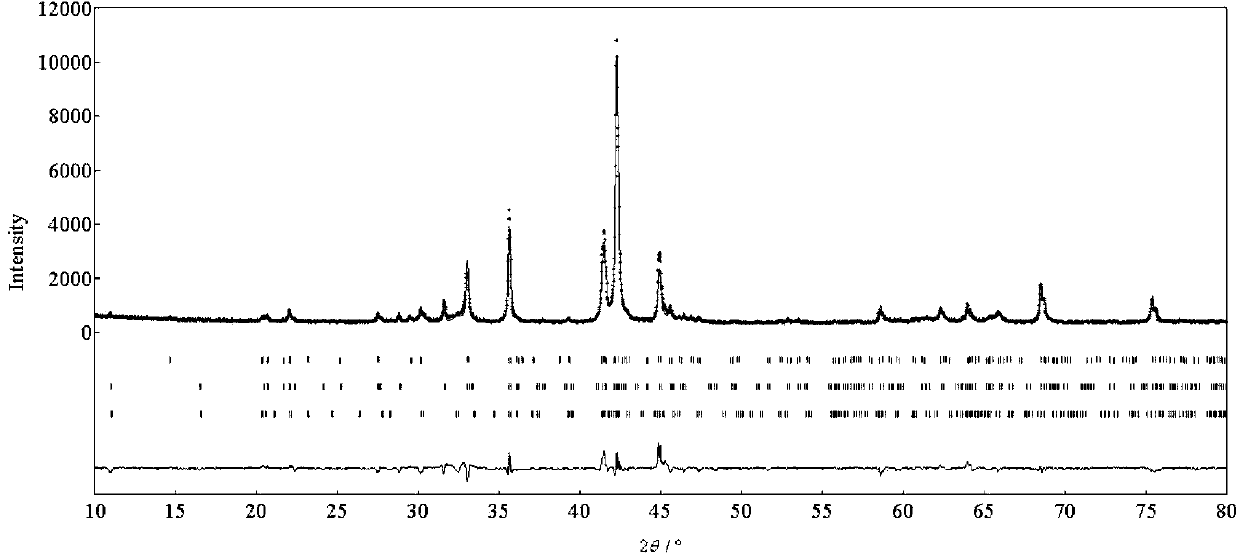

Lithium, aluminum and fluorine co-doped lithium iron phosphate positive electrode material and preparation method thereof

ActiveCN110021752AIncreased diffusion rateEasy to charge and dischargeMaterial nanotechnologySecondary cellsLithium iron phosphatePhysical chemistry

The invention relates to a lithium, aluminum and fluorine co-doped lithium iron phosphate positive electrode material and a preparation method thereof; the preparation method comprises the following steps of enabling Al(NO3)3.9H2O, LiNO3 and NH4F to be dissolved in deionized water separately and performing uniform mixing; next, adding LiFePO4 powder to be reacted, wherein the molar ratio of Al(NO3)3.9H2O to LiNO3 to NH4F to LiFePO4 is 1 to (0.8-1.2) to (4-4.5) to (30-36), the reaction temperature is 150-160 DEG C, and the reaction time is 5-8h; carrying out washing and drying, wherein the drying temperature is 80-90 DEG C, and the drying time is 12-14h; and next, carrying out calcining, wherein the calcining temperature is 500-550 DEG C and the calcining time is 6-8h, to obtain the lithium, aluminum and fluorine co-doped lithium iron phosphate positive electrode material. The conductivity of the prepared lithium iron phosphate positive electrode material is improved and the material isapplied to a battery, so that the electrochemical performance and the cycling performance of the battery are improved.

Owner:湖北锂诺新能源科技有限公司

A kind of polyethylene microporous film, preparation method and lithium ion battery

ActiveCN104362276BImprove breathabilityImprove mechanical propertiesCell component detailsPhysical chemistryLithium-ion battery

The invention provides a polyethylene microporous membrane, a preparation method and a lithium ion battery. The microporous membrane is composed of a front and a back: the average pore size of the front is 100-200 nm; the average pore size of the back is 50-100 nm, and The ratio of average pore size on both sides is A:B=1.1~4.0:1, and the pore size distribution is less than 30%. When the microporous membrane prepared by the invention is used in a lithium ion battery, the front side is close to the positive pole of the battery, and the back side is close to the negative pole of the battery, and not only has good high-rate discharge performance, but also has good self-discharge performance.

Owner:乐凯胶片股份有限公司 +1

Coating slurry, preparation method thereof, and composite porous diaphragm and lithium ion battery prepared by applying coating slurry

PendingCN114361714ACompressibleImprove interface fitSecondary cellsCell component detailsPhysical chemistryPolyvinylidene difluoride

The invention relates to the field of lithium batteries, in particular to coating slurry, a preparation method thereof, a composite porous diaphragm prepared by applying the coating slurry and a lithium ion battery. A composite porous diaphragm comprises a porous base material, at least one surface of the porous base material is coated with an inorganic / organic composite functional coating, the inorganic / organic composite functional coating is subjected to corona and plasma / ultraviolet radiation treatment, and the inorganic / organic composite functional coating is mainly prepared from coating slurry and 60-80 parts of deionized water; 10 to 20 parts of aluminum oxide; 5 to 12 parts of polyvinylidene fluoride; 6 to 12 parts of a thickening agent; 2-6 parts of a binder; and 2-4 parts of a carbonic ester compound. The composite porous diaphragm can be used for a lithium battery, and has the advantages of improving the stability and safety of long-term circulation of the battery and the like.

Owner:惠州市旭然新能源有限公司

Lead-acid storage battery positive electrode for electric bicycle

ActiveCN102403510AReduce wasteSimple recipeLead-acid accumulator electrodesMechanical engineeringChemistry

The invention discloses a lead-acid storage battery positive electrode for an electric bicycle. The positive electrode consists of the following components in percentage by weight: 1.2 to 1.6 percent of Sn, 0.2 to 0.6 percent of Al, 0.01 to 0.02 percent of Bi, 0.02 to 0.08 percent of Ag, 0.02 to 0.05 percent of In, 0.05 to 0.10 percent of Cu, and the balance of Pb.

Owner:海安华达石油仪器有限公司

Alkaline secondary battery positive electrode material and alkaline secondary battery

InactiveCN100511782CImprove self-discharge performancePromote oxidationAlkaline accumulatorsAlkaline accumulator electrodesNickel oxide hydroxideMetal powder

A positive electrode material of basic secondary battery is formed by nickel hydroxide powder, Co additive, binder and metal powder being prepared by one or a numbers of metals as V, Ti, Mo, Mn, Nb, Hf, Zr, Y and Ta. The basic secondary battery applying said positive electrode material is also disclosed.

Owner:BYD CO LTD

Battery pack, apparatus having the same and method of controlling battery

ActiveUS9923397B2Improve self-discharge performanceElectric devicesElectric powerLoad circuitElectrical battery

A battery pack includes a battery coupled between a first terminal and a second terminal and a battery manager configured to sense a state of charge of the battery; a load circuit coupled between the first terminal and the second terminal and configured to receive discharge power from the battery; a power generator coupled between the first terminal and the second terminal and configured to supply charge power to the battery; and a controller configured to control the battery pack and the power generator and to force discharging of the battery to make the state of charge of the battery equal to a reference value when a signal to initiate self-discharging is received from a user.

Owner:SAMSUNG SDI CO LTD

a5b19 type gadolinium-containing hydrogen storage alloy, negative electrode and preparation method

ActiveCN111411262BIncrease the maximum discharge capacityExtended service lifeHydrogenNegative electrodesMischmetalSi element

Owner:BAOTOU RES INST OF RARE EARTHS

Nickel hydrogen charging battery

ActiveCN101267047BIncreased monthly capacity retentionGood capacity retentionAlkaline accumulator electrodesNickel accumulatorsElectrolytic agentLutetium

The present invention provides a nickel-metal hydride charge battery, which resolves the problem of reducing the high self charge in the storaging course of the nickel-metal hydride battery. The invention adopts following technical scheme: a nickel-metal hydride charge battery includes a cathode, a diaphragm, an electrolyte and an anode, the electrolyte contains KOH solution, the cathode containsat least one oxide or hydroxide of titanium, yttrium, erbium, thulium, ytterbium, lutetium, calcium or barium element, the mass ratio of the content to the whole cathode active material is 0.1-10%. Compared with the prior art, the battery cathode contains oxide or hydroxide of titanium, yttrium, erbium, thulium, ytterbium, lutetium, calcium or barium element, the month capacity retention rate of the battery is increased more than 90%, the year capacity retention rate is increased more than 80%, having excellent self-discharge performance and having high capacity retention rate.

Owner:LEXEL BATTERYSHENZHEN

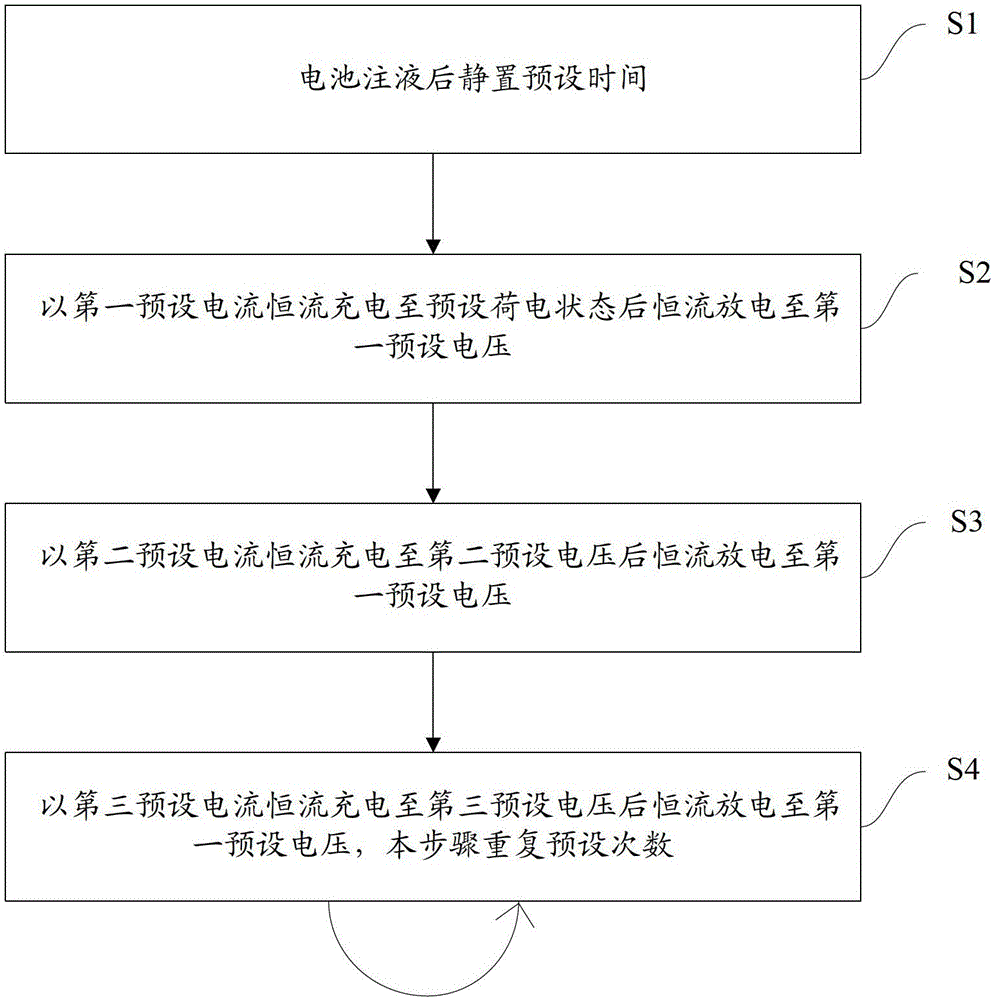

Formation method of lithium iron phosphate power battery

ActiveCN103579679BIncrease usable capacityImprove cycle performanceFinal product manufactureElectrolyte/reactants regenerationEngineeringChemical conversion

The invention discloses a method for forming a lithium iron phosphate power battery, comprising the following steps: S1, injecting electrolyte solution into the power battery and standing it for a preset time; S2, charging the battery cell of the power battery with a first preset current constant current to the preset state of charge, and then constant current discharge to the first preset voltage; S3, charge the cell of the power battery to the second preset current constant current to the second preset voltage, and then constant current discharge to the first preset voltage. Set the voltage, the second preset current is greater than the first preset current and the second preset voltage is greater than the first preset voltage; S4, charge the cell of the power battery with a third preset current to a third preset voltage at a constant current , and then constant current discharge to the first preset voltage, the third preset current is greater than the first preset current and the third preset voltage is greater than the first preset voltage; and S5, repeat step S4 for a preset number of times. According to the chemical formation method provided by the invention, the SEI film is stable, the thermal stability is better, and the safety performance is good.

Owner:BEIQI FOTON MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com