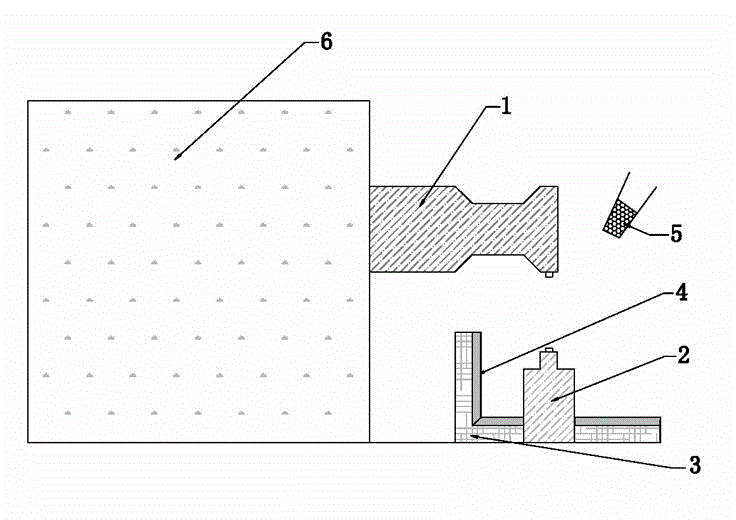

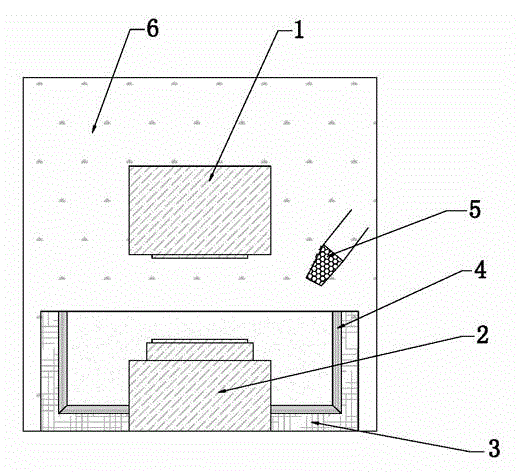

Lithium battery tab ultrasonic bonder with dust removal function and welding method

A lithium battery and welding machine technology, applied in the direction of smoke removal, welding equipment, non-electric welding equipment, etc., can solve problems such as welding slag pollution, achieve convenient and quick use, improve safety performance and self-discharge performance, and control welding slag pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The HTPF09140200-20Ah-3.3V laminated soft-pack power battery is welded using the KP2040 ultrasonic tab welding machine of KP The dust retaining groove is composed of three sides and a bottom surface, and the thickness of the dust retaining groove is 10mm. There are 250 layers of adhesive tape on the inner wall of the dust retaining groove. The adhesive side of the adhesive tape is facing the outside. The total thickness of the multi-layer adhesive tape is 5mm, and the thickness of the single-layer adhesive tape is 0.02mm. An air blowing device is installed above the side of the ultrasonic welding head. When the soft-pack lithium battery is welded, the air blowing device blows the welding slag generated by the welding to the sticky paper in the ultrasonic welding dust retaining groove, and the welding slag is stuck by the sticky dust tape. Hold, after the welding is completed, tear off the dust sticky tape on the inner wall of the dust retaining groove. The self-discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com