Lithium-supplementing negative electrode piece, preparation method thereof, and lithium ion battery

A negative electrode sheet and lithium supplement technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of high packaging cost, unhelpful safety performance, and reduced initial efficiency, so as to reduce the risk of transportation and improve self-discharge Performance, the effect of increasing the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

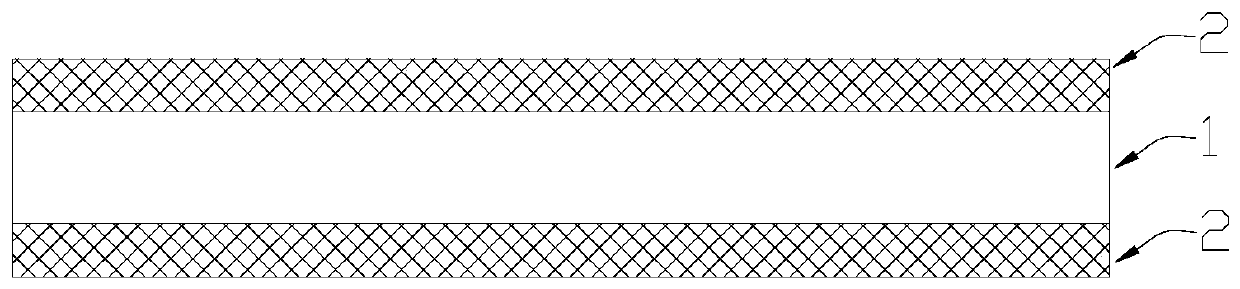

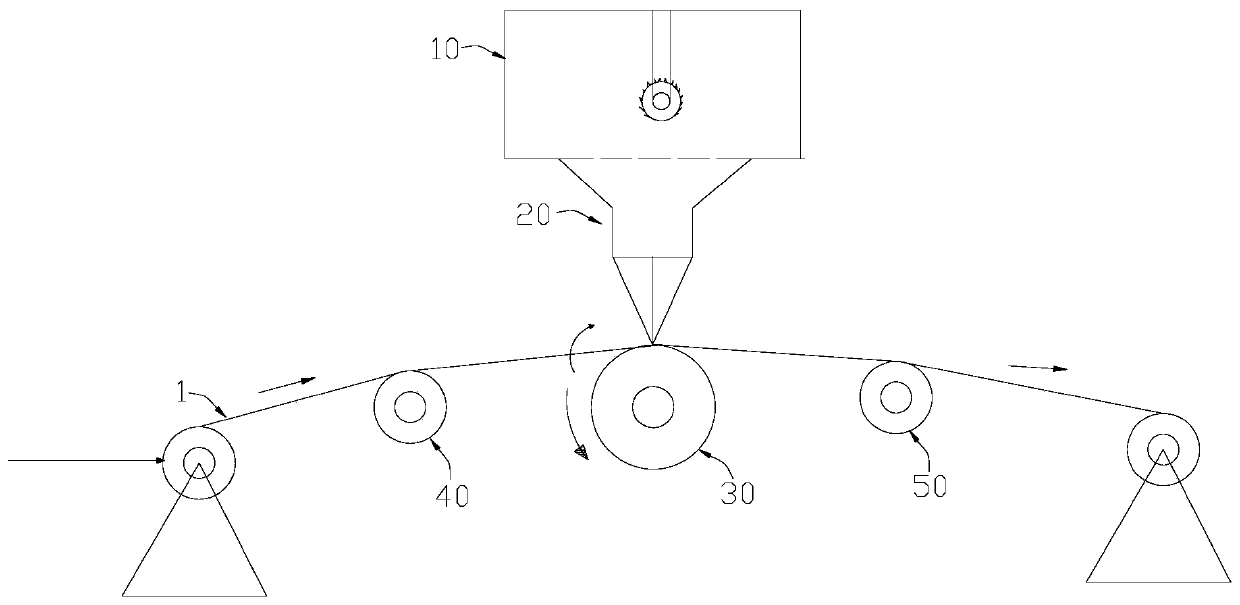

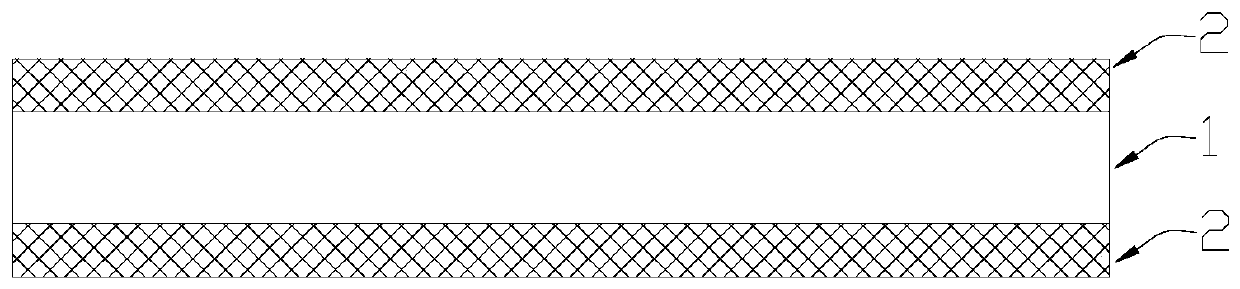

[0040] refer to figure 1 , the preparation method of one embodiment of the lithium-supplementing negative electrode sheet of the present invention may include the following steps:

[0041] S1. Mix lithium alloy powder, ceramic powder and binder according to mass percentage, add to solvent to make organic lithium slurry with solid content of 35%-80% and viscosity of 200-2000mPa.s.

[0042] Wherein the solvent and the solvent in the negative plate body 1 adopt the same non-aqueous organic solvent, such as NMP (N-methylpyrrolidone), acetone, DMF (dimethylformamide), DMAC (dimethylacetamide) and ethanol One or more of them require a purity of at least 99.99%.

[0043] S2. Coating the organic lithium slurry prepared above on the surface of the negative electrode body (dry electrode sheet or wet electrode sheet) 1 .

[0044] S3. Baking the negative electrode body 1 coated with the organic lithium slurry in an inert gas atmosphere, and solidifying the organic lithium slurry to form...

Embodiment 1

[0059] In an argon atmosphere, alloy lithium powder (the content of lithium is 30%, the content of silicon is 50%, and the content of aluminum is 20%), ceramic powder and The binder is mixed uniformly to form a mixed powder. Get 5 grams of mixed powder and 10 grams of NMP into the stirring device to stir and disperse, the stirring temperature is 25 ° C to 35 ° C, to obtain an organic lithium slurry with a concentration of 0.02M, and spray the organic lithium slurry on the surface of the negative plate body ( The active material in the negative electrode sheet body is graphite), so that the lithium ions in the organic lithium slurry are reduced to metallic lithium and embedded in the negative electrode sheet body, so that the lithium intercalation amount in the graphite is 4% of the total graphite capacity, and then the negative electrode is dried sheet to prepare a lithium-supplementing negative electrode sheet.

Embodiment 2

[0061] In an argon atmosphere, alloy lithium powder (the content of lithium is 30%, the content of silicon is 50%, and the content of aluminum is 20%), ceramic powder and The binder is mixed uniformly to form a mixed powder. Take 5 grams of mixed powder and 10 grams of NMP and add them to the stirring device for stirring and dispersing. The stirring temperature is 25° C. to 35° C. to obtain an organic lithium slurry with a concentration of 0.04 M. The organic lithium slurry is sprayed on the surface of the negative plate body ( The active material in the negative electrode sheet body is silicon carbon), so that the lithium ions in the organic lithium slurry are reduced to metal lithium and embedded in the negative electrode sheet body, so that the lithium intercalation amount in the stone silicon carbon is 8% of the total graphite capacity, The negative electrode sheet is then dried to obtain a lithium-supplementing negative electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com