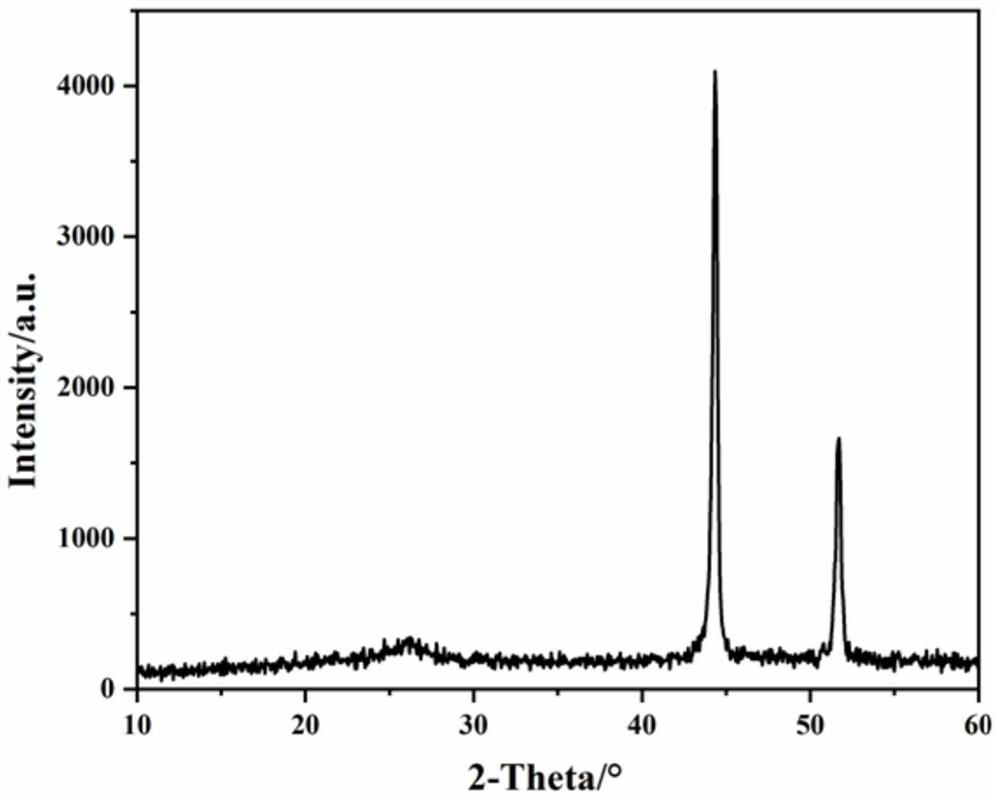

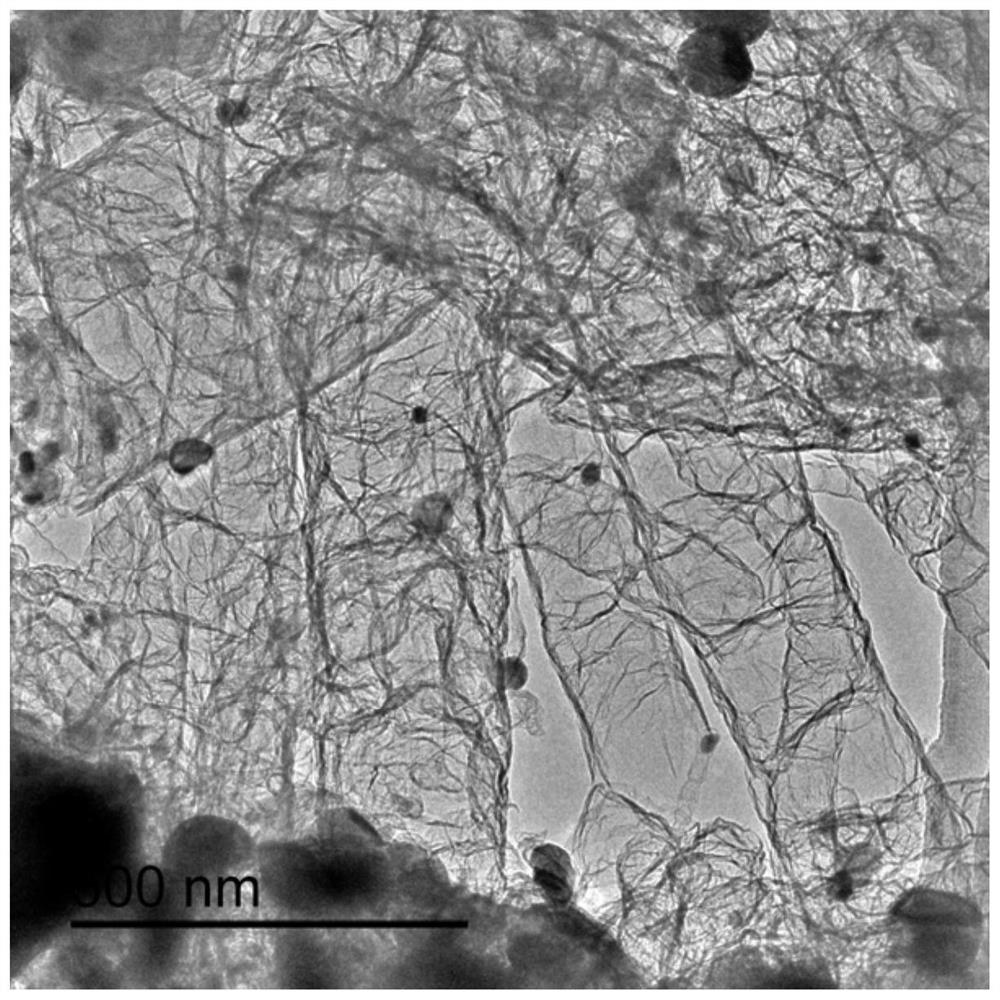

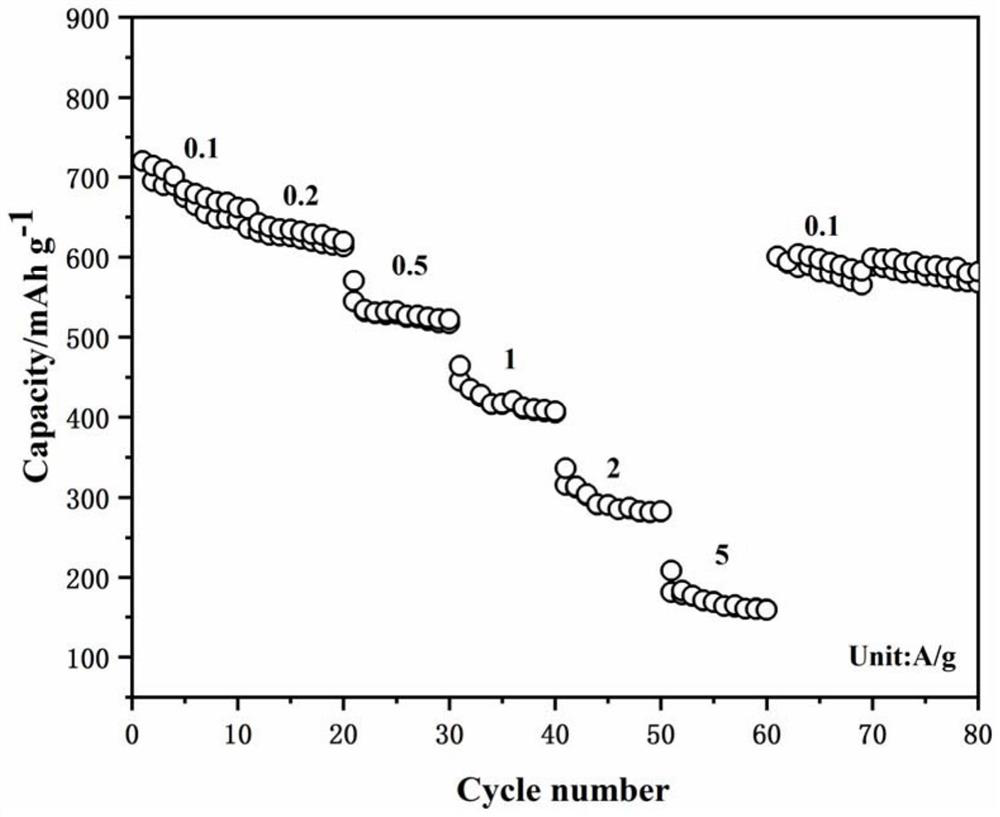

FeCoCuZn co-doped Ni-based alloy-carbon nanotube composite material modified diaphragm as well as preparation method and application thereof

A carbon nanotube and composite material technology is applied in the field of battery separators to achieve the effects of suppressing capacity loss, improving positive conductivity, and alleviating battery swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Weigh ferrous ammonium sulfate, cobalt carbonate, copper nitrate, zinc sulfate heptahydrate, sulfuric acid according to the molar ratio of iron, cobalt, copper, zinc, nickel and carbon atoms 0.1:0.1:0.1:0.1:5:20 Nickel and urea were mixed, and then added to the high-speed centrifugal dispersion tank, and the material was dispersed in the high-speed centrifugal dispersion tank at a speed of 1500r / min for 30 minutes, and the mixture A was obtained by taking it out;

[0035] Step 2: Put the mixture A in a high-temperature tube furnace, and rapidly raise the temperature from room temperature to 140 °C at a rate of 15 °C / min in a flowing argon atmosphere of 100 sccm, keep it warm for 1 hour, and cool it naturally to room temperature after the heat preservation is over. After taking out, obtain product B;

[0036] Step 3: Grind the product B with a mortar for 20 minutes, then put the ground solid powder into a freeze-drying box, and let it stand at a low temperature o...

Embodiment 2

[0041] Step 1: Weigh ferrous sulfate, cobalt nitrate, copper nitrate, zinc sulfate monohydrate, nickel sulfate according to the amount ratio of iron, cobalt, copper, zinc, nickel and carbon atoms 1:1:1:1:20:50 Mix it with urea, then add it to the high-speed centrifugal dispersion tank, disperse the material in the high-speed centrifugal dispersion tank at a speed of 2500r / min for 5 minutes, and take it out to obtain mixture A;

[0042] Step 2: Put the mixture A in a high-temperature tube furnace, and in a flowing argon atmosphere of 100 sccm, rapidly raise the temperature from room temperature to 200°C at a rate of 30°C / min, keep it warm for 0.5h, and cool it naturally to Take out after room temperature, obtain product B;

[0043] Step 3: Grind the product B with a mortar for 25 minutes, then put the ground solid powder into a freeze-drying box, and let it stand at a low temperature of -30°C for 3 hours;

[0044] Step 4: Take the above product out and put it into a high-tempe...

Embodiment 3

[0048] Step 1: Take ferrous chloride, cobalt sulfate, copper nitrate, zinc acetate, nickel sulfate and Mix urea, then add it to the high-speed centrifugal dispersion tank, disperse the material in the high-speed centrifugal dispersion tank at a speed of 2000r / min for 20min, and take it out to obtain mixture A;

[0049] Step 2: Put the mixture A in a high-temperature tube furnace, and rapidly raise the temperature from room temperature to 180°C at a rate of 20°C / min in a flowing argon atmosphere of 100 sccm, keep it warm for 0.8h, and cool it naturally to Take out after room temperature, obtain product B;

[0050] Step 3: Grind the product B with a mortar for 30 minutes, then put the ground solid powder into a freeze-drying box, and let it stand at a low temperature of -20°C for 5 hours;

[0051] Step 4: Take the above product out and put it into a high-temperature tube furnace. In a flowing argon atmosphere of 100 sccm, rapidly raise the temperature to 750 °C at a rate of 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com