Preparation method for anode of lithium-sulfur battery

A lithium-sulfur battery and cathode technology, which is applied in the field of electrochemical batteries, can solve the problems of large specific surface area of carbon nanotubes, reduce the conductivity of the cathode, unfavorable conductive structure, etc., achieve large discharge specific capacity, improve adsorption, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

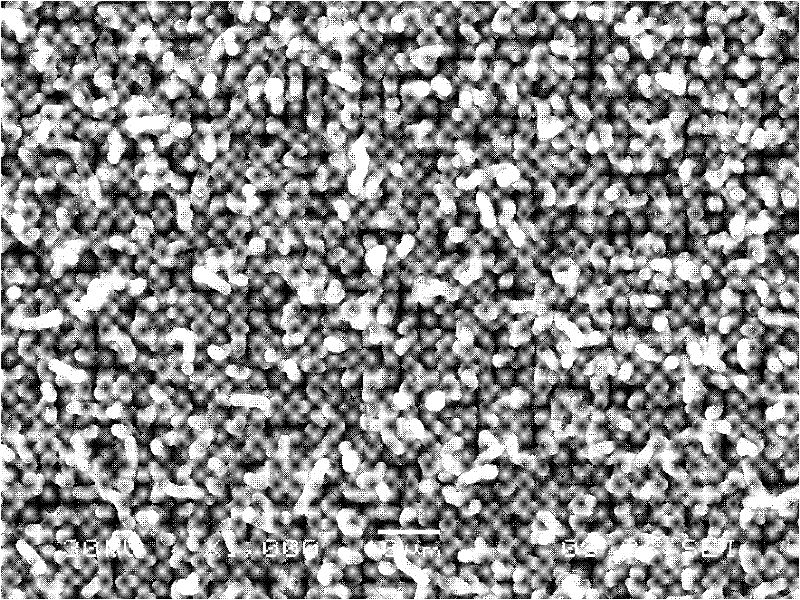

Image

Examples

Embodiment 1

[0021] Cut the nickel foil into discs with a diameter of 12 mm. Wipe the surface of the discs with acetone-absorbed cotton balls for 3 minutes, then put the discs into distilled water for ultrasonic cleaning for 3 minutes, and take them out to dry.

[0022] Put the dried nickel disc into the cavity of the microwave chemical vapor deposition device, and the reaction gas is H 2 and CH 4 , generated plasma by microwave excitation to decompose H 2 and CH 4 , the microwave power is 400W, H 2 and CH 4 The volume flows are 40sccm (ml / min under standard conditions) and 30sccm respectively, the reaction pressure is 2KPa, and the carbon fiber membrane is prepared on the surface of the nickel disc as a catalyst, and the preparation time is 40 minutes.

[0023] Sprinkle sulfur powder evenly on the surface of the prepared carbon fiber membrane. The mass of sulfur powder on each film-attached disc is 0.8g, and then put the disc into a tube furnace, keep it warm at 180°C for 4 hours in a...

Embodiment 2

[0025] Cut the iron foil into discs with a diameter of 13mm, first wipe the surface of the disc with acetone-absorbed cotton ball for 4 minutes, then put the disc into distilled water for ultrasonic cleaning for 3 minutes, take it out and dry it.

[0026] Put the dried iron disc into the cavity of the microwave chemical vapor deposition device, and the reaction gas is H 2 and CH 3 CH 2 OH vapor (by H 2 Carrying), plasma is generated by microwave excitation to decompose H 2 and CH 3 CH 2 OH vapor, microwave power 400W, H 2 and (H 2 +CH 3 CH 2 The volume flows of OH) are 30sccm and 80sccm respectively, the reaction pressure is 2.5KPa, and the iron disc is used as a catalyst to prepare a carbon fiber membrane on its surface, and the preparation time is 35 minutes.

[0027] Sprinkle sulfur powder evenly on the surface of the prepared carbon fiber membrane. The mass of sulfur powder on each film-attached disc is 1g, and then put the disc into a tube furnace, keep it warm a...

Embodiment 3

[0029] Cut the nickel foil into discs with a diameter of 11mm. Wipe the surface of the discs with acetone-absorbed cotton balls for 3 minutes, then put the discs into distilled water for ultrasonic cleaning for 3 minutes, and take them out to dry.

[0030] Put the dried nickel disc into the cavity of the hot wire chemical vapor deposition device, and the reaction gas is H 2 and CH 4 , decompose H through heat generated by the hot wire 2 and CH 4 , the heating wire power is 500W, H 2 and CH 4 The volume flows are 60sccm and 50sccm, respectively, the reaction pressure is 2KPa, and nickel discs are used as catalysts to prepare carbon fiber membranes on the surface, and the preparation time is 40 minutes.

[0031] Sprinkle sulfur powder evenly on the surface of the prepared carbon fiber membrane. The mass of sulfur powder on each film-attached disc is 1g, and then put the disc into a tube furnace, keep it warm at 190°C for 4h in an atmosphere filled with argon, and cool to Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com