Patents

Literature

38results about How to "Reduce decomposition reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

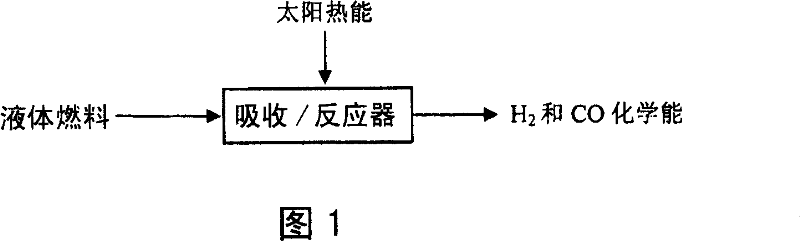

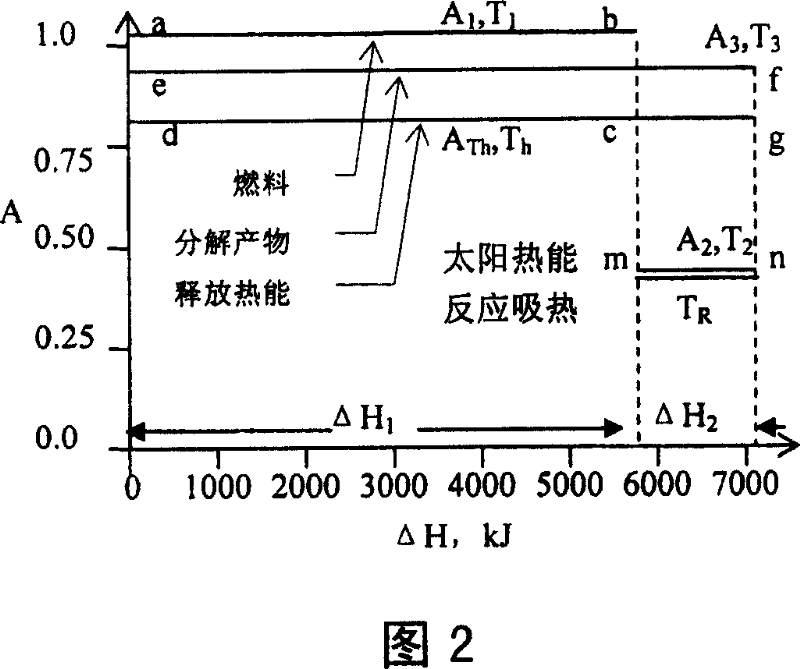

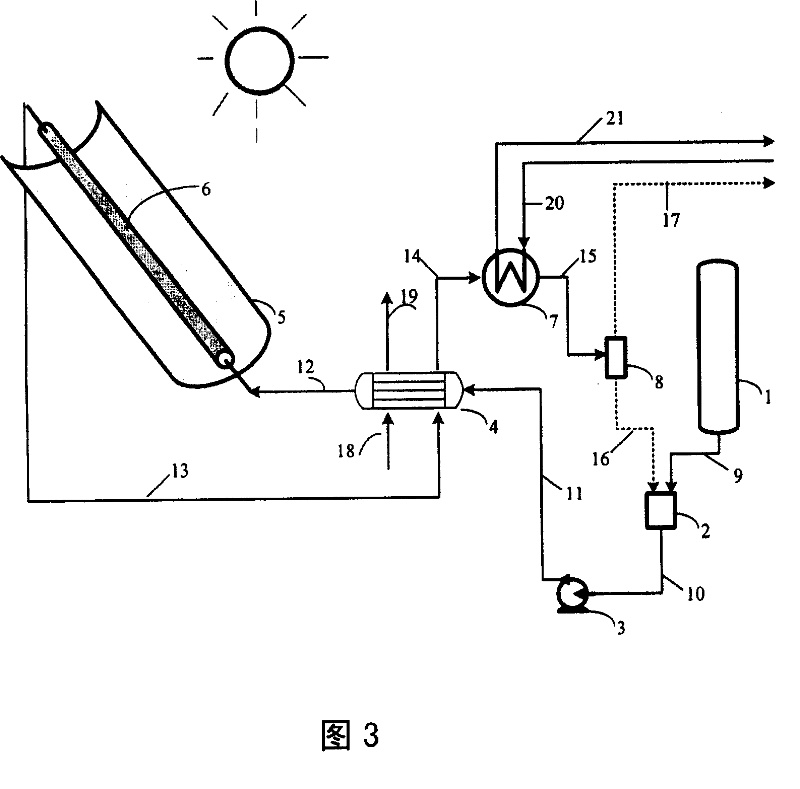

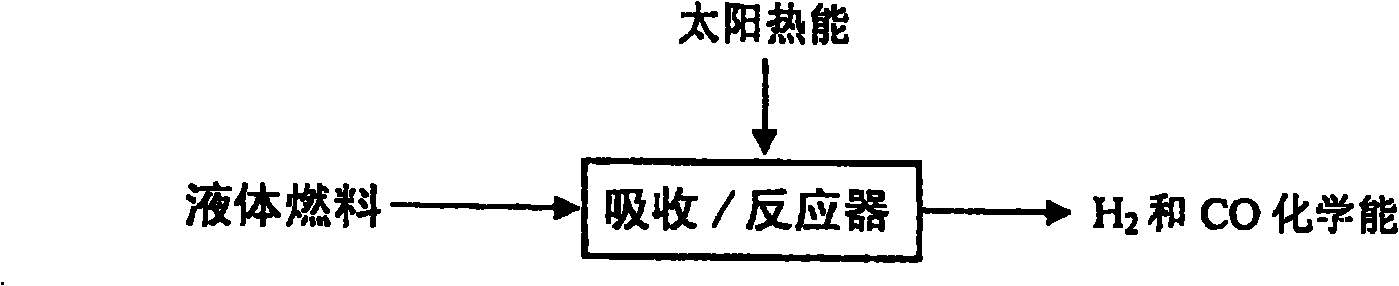

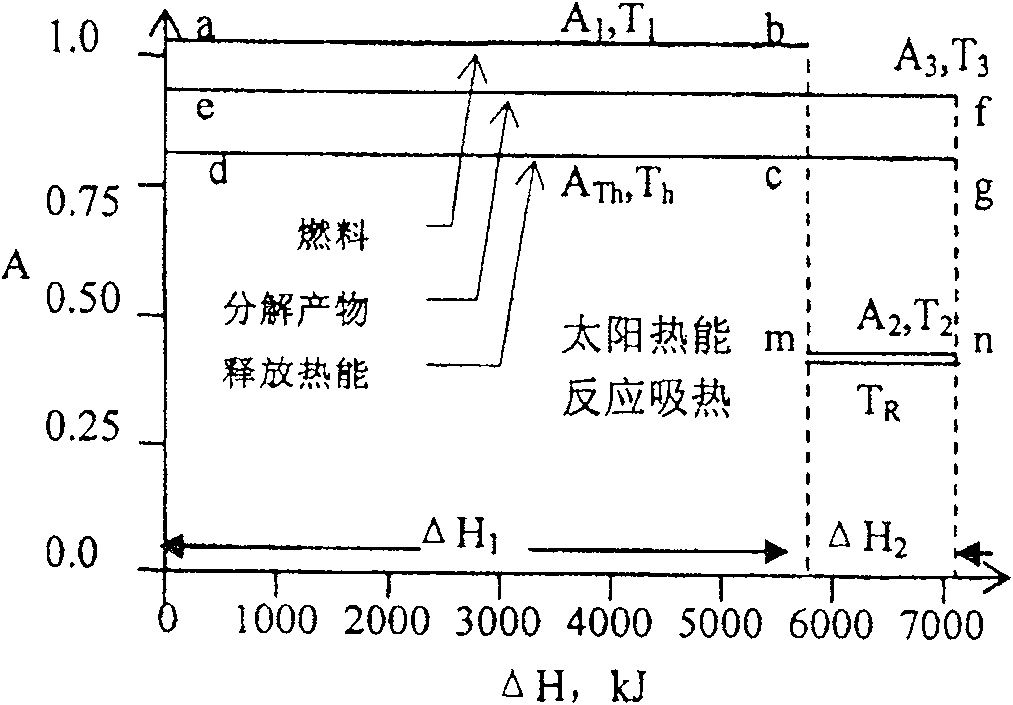

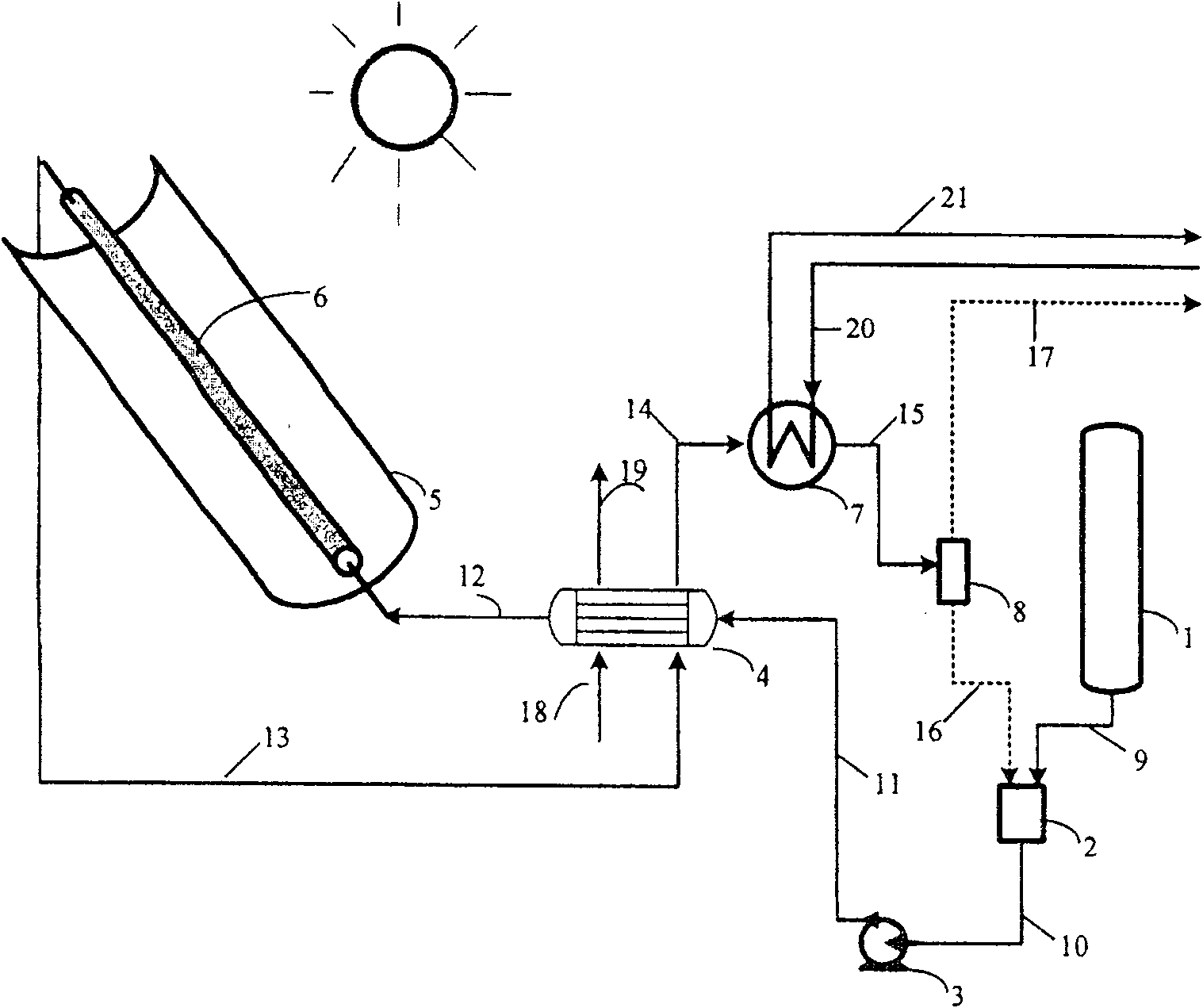

Method and apparatus for converting solar energy into fuel chemical energy

It relates to a method and device of changing solar energy to chemical energy. It accumulates the solar energy and changing it to heat energy ranging from 150deg.C-300deg.C, providing reaction heat for the liquid fuels, allowing the middle and low level solar energy changing and stored into high level chemical energy, with the liquid being carbinol or dimethyl ether synthetic fuel, with the catabolite being hydrogen and monoxide formed gas. It can be used for multi purposes, providing fine synthetic fuel and material for customers.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

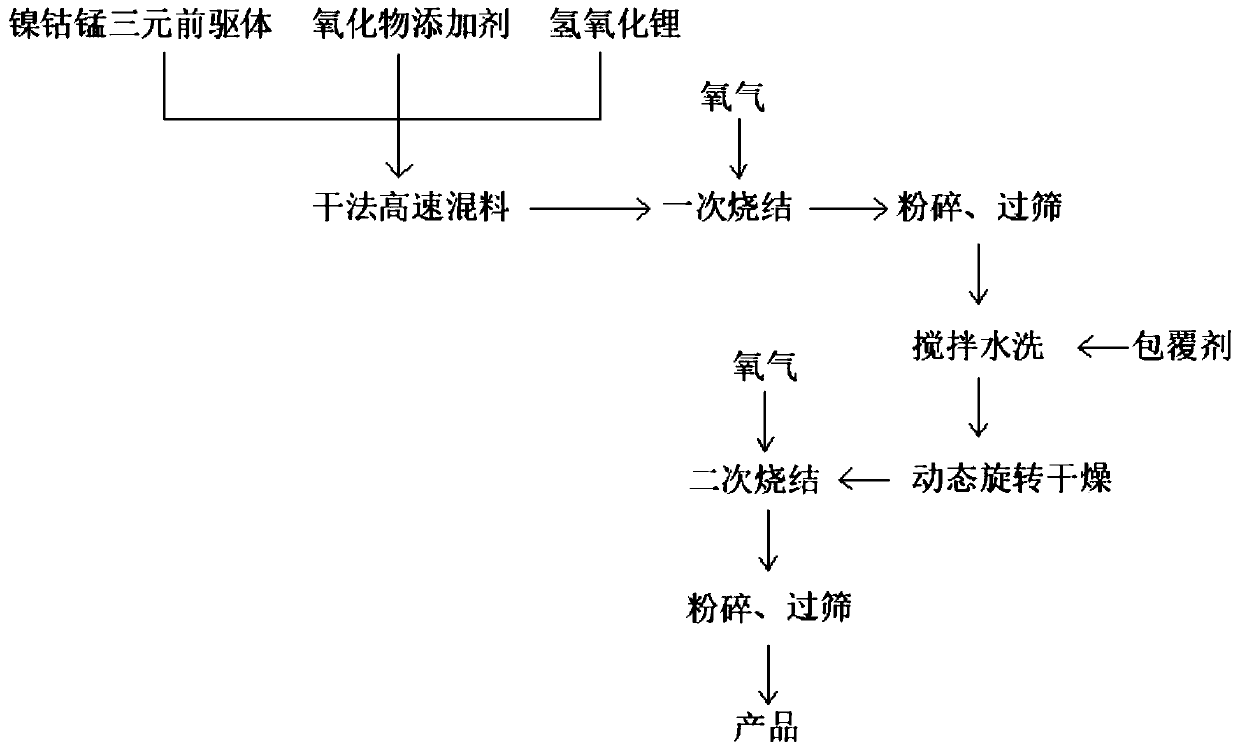

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

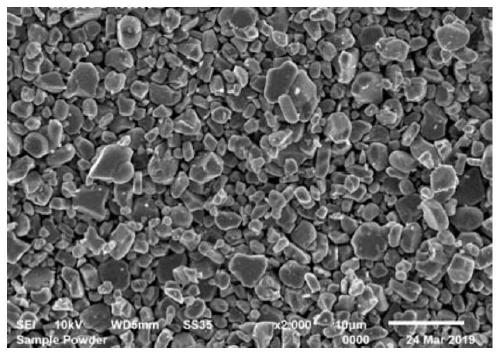

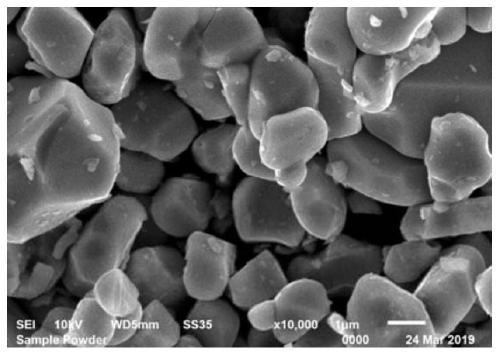

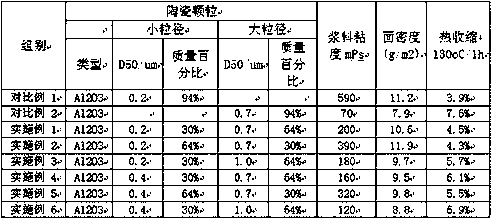

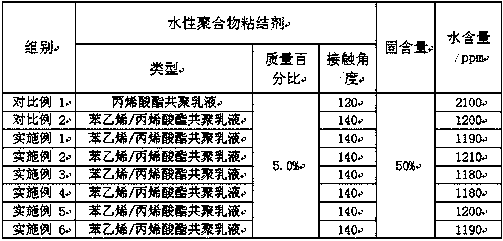

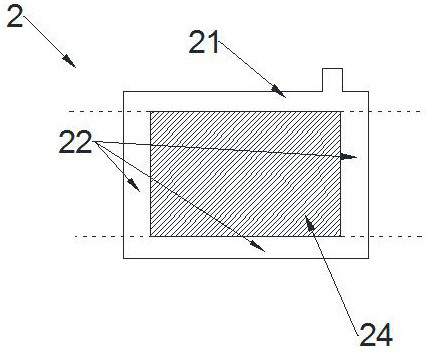

Inorganic/organic composite porous isolating membrane, preparation method and lithium-ion battery thereof

InactiveCN107895765AHigh mechanical strengthImprove reliabilityCell component detailsSecondary cells servicing/maintenancePolymer adhesiveSlurry

The invention discloses an inorganic / organic composite functional porous isolating membrane. The isolating membrane comprises porous base material and at least one inorganic functional coating adhering to the surface of the porous base material, and aqueous slurry prepared for the inorganic functional coatings is prepared from inorganic ceramic particles, water-soluble polymer thickener and aqueous polymer adhesive; the inorganic ceramic particles comprise the same substance in two types of particle sizes, wherein the average particle size (D50) of the smaller inorganic ceramic particles is 0.2-0.5 micrometer, and the average particle size (D50) of the larger inorganic ceramic particles is 0.6-1.0 micrometer; the aqueous polymer adhesive is a hydrophobic high-molecular polymer with the water drop contact angle of the dry adhesive of the aqueous polymer adhesive 110-140 degrees; the solid content of the aqueous slurry is 40-60%. According to the inorganic / organic composite functional porous isolating membrane, the high-temperature thermal stability of the isolating membrane can be effectively improved by means of the inorganic functional coatings, and the water content of the inorganic coatings is effectively reduced, so that the safe performance of a battery and the stability of long-term circulation are improved.

Owner:深圳市旭然电子有限公司

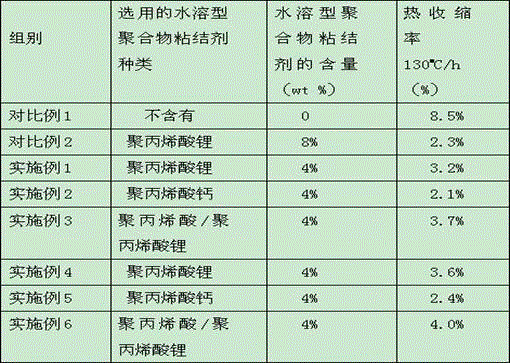

Inorganic/organic compound functional porous isolating membrane and preparation method as well as lithium ion battery adopting inorganic/organic compound functional porous isolating membrane

ActiveCN105789523AGood dispersionImproved high temperature thermal stabilitySecondary cellsCell component detailsPorous substrateOrganic compound

The invention provides an inorganic / organic compound functional porous isolating membrane. The inorganic / organic compound functional porous isolating membrane comprises a porous substrate and an inorganic functional coating which is adhered to at least one surface of the porous substrate, wherein the inorganic functional coating is prepared from inorganic ceramic particles, a water-soluble macromolecular thickening agent, a water emulsion type polymer binding agent and a water soluble type polymer binding agent; the water emulsion type polymer binding agent is a macromolecular polymer with the surface tensile force of 40dyne / cm to 50dyne / cm, and a water drip contact angle of water emulsion type polymer binding agent dry glue is 100 degrees to 130 degrees; the water emulsion type polymer binding agent is a polar macromolecular polymer with the glass transition temperature of 100 DEG C to 150 DEG C. Therefore, the inorganic / organic compound functional porous isolating membrane has the advantages that the heat stability of the isolating membrane can be effectively improved, and the moisture content of the inorganic coating can also be reduced, so that the safety performance of a battery and the stability of long-period cycle are improved.

Owner:深圳市旭然电子有限公司

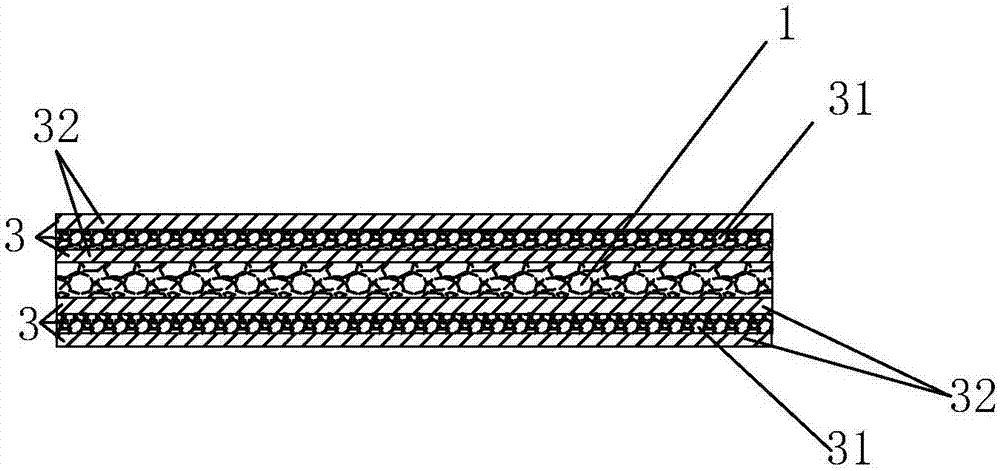

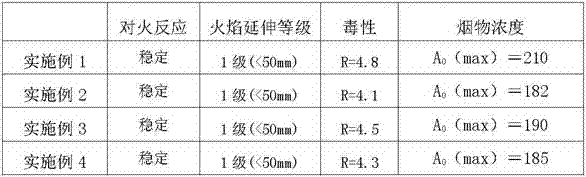

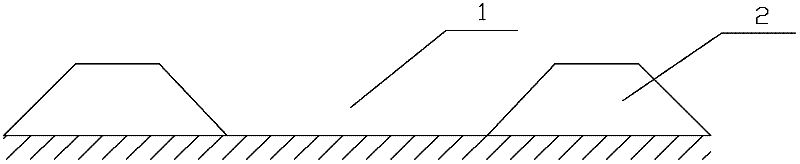

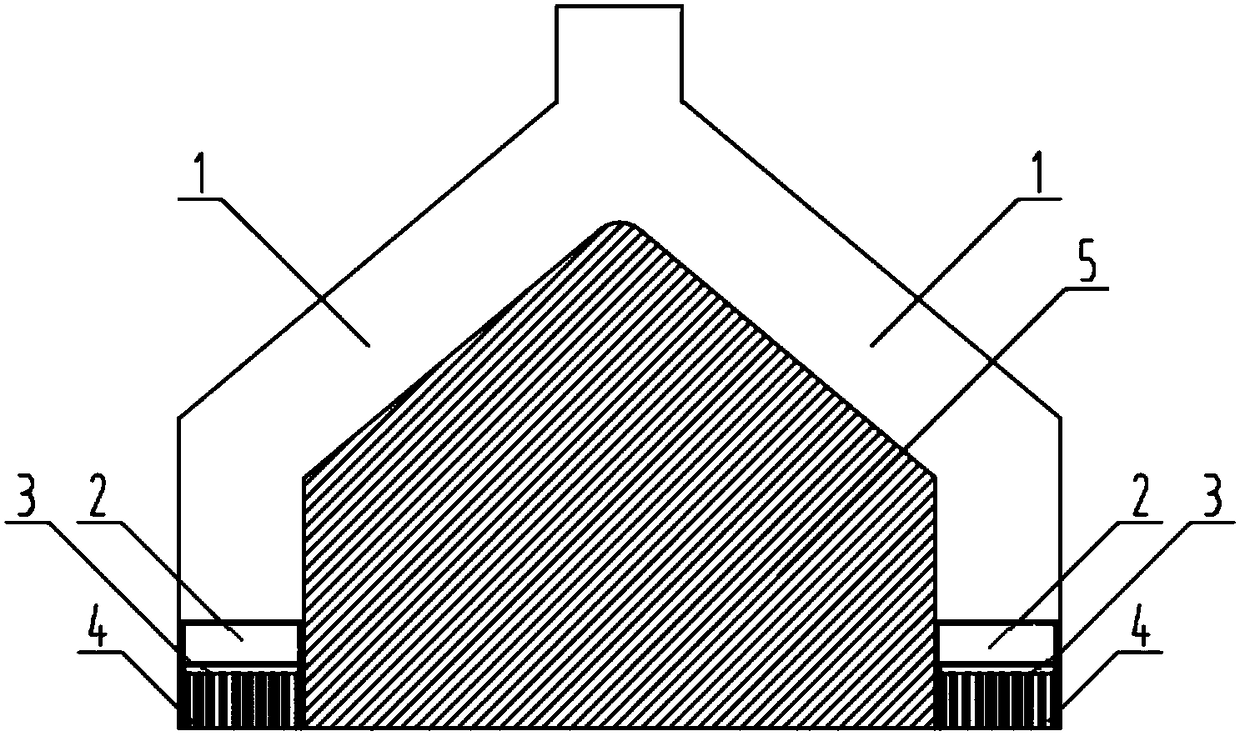

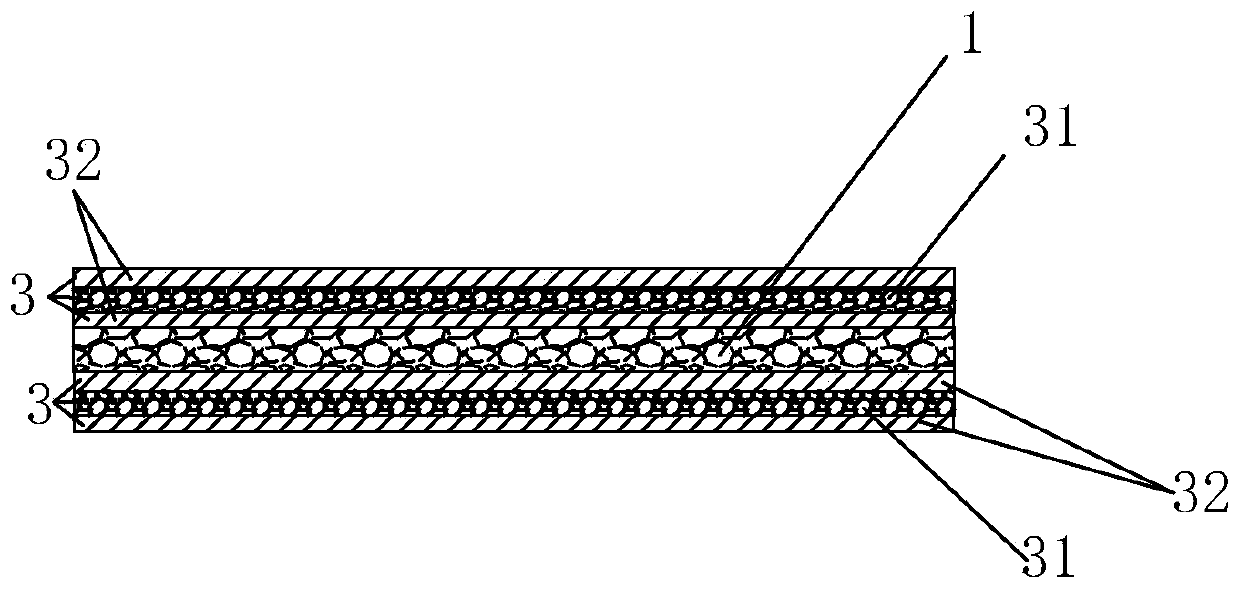

Light-weight fiber-reinforced phenolic sandwich plate and preparation method thereof

ActiveCN107351852AGood smoke densityGood smoke toxicity performanceLamination ancillary operationsSynthetic resin layered productsSurface layerUltimate tensile strength

The invention discloses a light-weight fiber-reinforced phenolic sandwich plate and a preparation method thereof. The light-weight fiber-reinforced phenolic sandwich plate is composed of two surface layers and a core material layer between the two surface layers or is composed of two sandwich surface layers and a core material layer between the two sandwich surface layers, and the core material layer is a fiber-reinforced phenolic light-weight foam layer. The plate disclosed by the invention solves the problem of brittleness of phenolic foam, and the plate is composed of phenolic materials with better flame resistance from inside to outside, so that the flame resistance of the plate is excellent, the plate can resist to high temperature of 150-180 DEG C, the plate strength retention ratio at high temperature is high, and thus fireproof requirements of locomotives can be met. The core material and surface layers of the plate are light materials, so that the light-weight requirement of vehicles can be met. The core material and surface layers of the plate are reinforced by fiber, the fiber in the core material can effectively increase the strength and rigidity of the phenolic foam, and the fiber in the surface layers can effectively increase the strength and rigidity of the phenolic plate, so that the obtained sandwich plate has better strength and rigidity.

Owner:常州诺法新材料科技有限公司

Air-drying method for improving quality of alfalfa

InactiveCN102228132AIncrease flow spaceHigh trafficDrying solid materials with heatAnimal feeding stuffLoss ratePositive interaction

The invention discloses an air-drying method for improving the quality of alfalfa. The method comprises the following steps of: 1) ridging; 2) selecting materials and treating; and 3) air-drying. The method has the advantages that: 1, the ridging increases the air flow space on the bottom of a grass layer; 2, the fracture of stalks accelerates the evaporation rate of the moisture in the stalks, so that the drying time is shortened; 3, the combination of field ridging and fracturing and air-drying of the stalks has a positive interaction effect on the loss of the moisture of fresh alfalfa forage; 4, the loss rate of the moisture of the fresh alfalfa forage is remarkably and negatively correlative with the residual amount of crude proteins in green hay; 5, the aims of accelerating the drying of the alfalfa, uniformly drying and improving the quality of the green hay are fulfilled; and 6, operation steps are simple and easy, the drying cost is low, and the efficiency is high.

Owner:GANSU AGRI UNIV

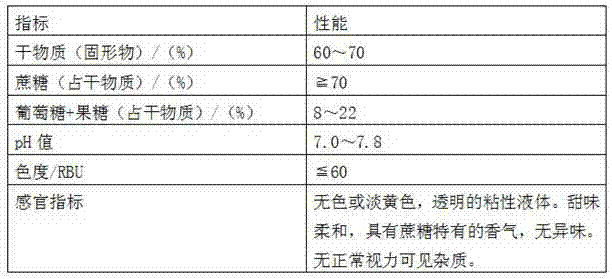

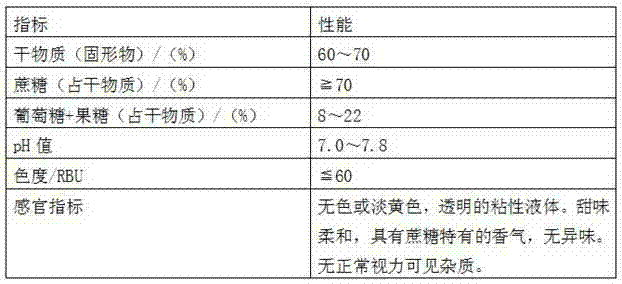

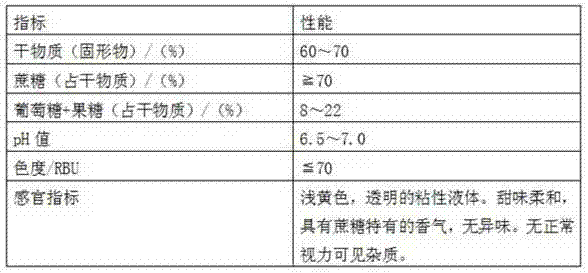

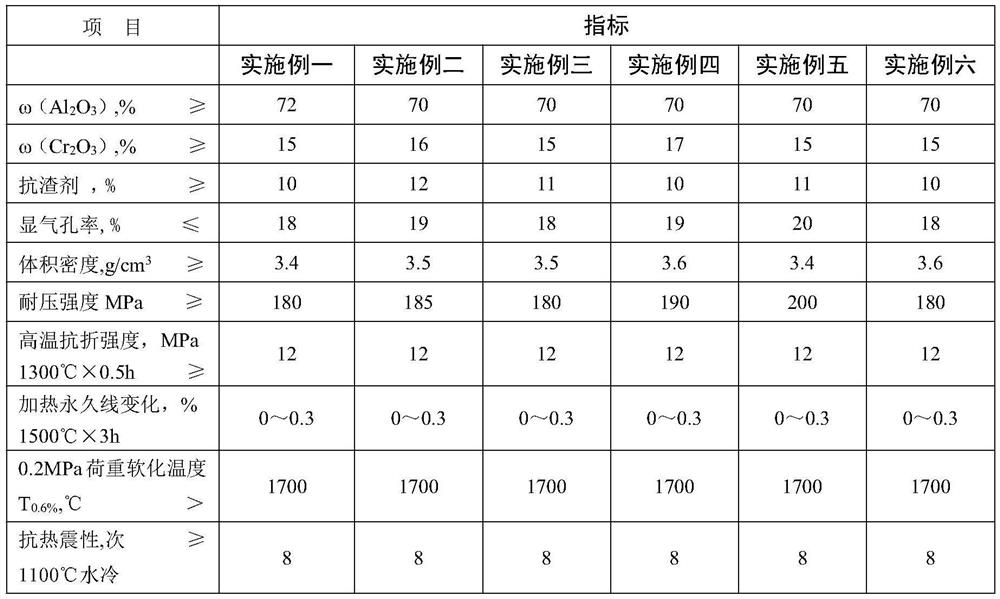

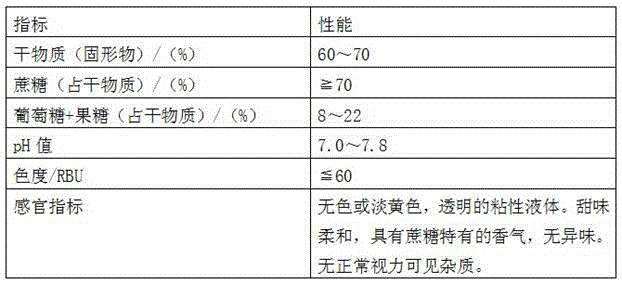

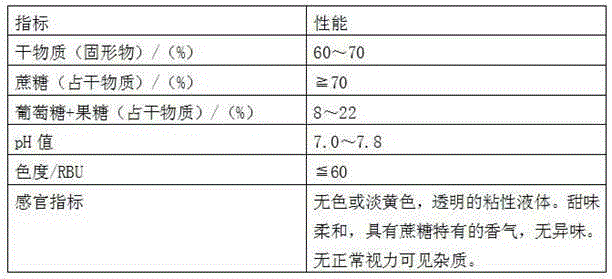

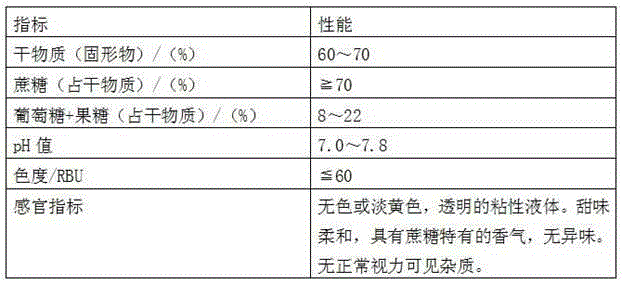

Syrup

InactiveCN103695568AReduce decomposition reactionsHigh purityPurification using adsorption agentsPurification by physical meansActivated carbonDecomposition

The invention discloses syrup. The syrup is prepared by comprising the steps: performing activated carbon adsorption to mother liquor obtained after crystallization of single-crystal sugar in a crystal sugar preparation process; or, firstly sulfitating the mother liquor obtained after crystallization of single crystal sugar, then carrying out activated carbon adsorption, and then adsorbing with discolored resin, to obtain syrup. According to the syrup, the purity of cane sugar in the syrup is greatly improved, the application field of products is wide, the decomposition reaction of cane sugar can be reduced, and the hyperchromic reaction of glucose and fructose can be decreased; the syrup treatment cost is greatly lowered, in addition, after the purity of the treated cane sugar is improved, the selling price is greatly increased, and the economic benefits of enterprises can be increased; the production efficiency is enhanced; the comprehensive utilization rate of cane sugar can be improved, and the lack situation of cane sugar in China can be improved; and waste syrup does not exist, and the environment pollution can be decreased.

Owner:邢台平安糖业有限公司

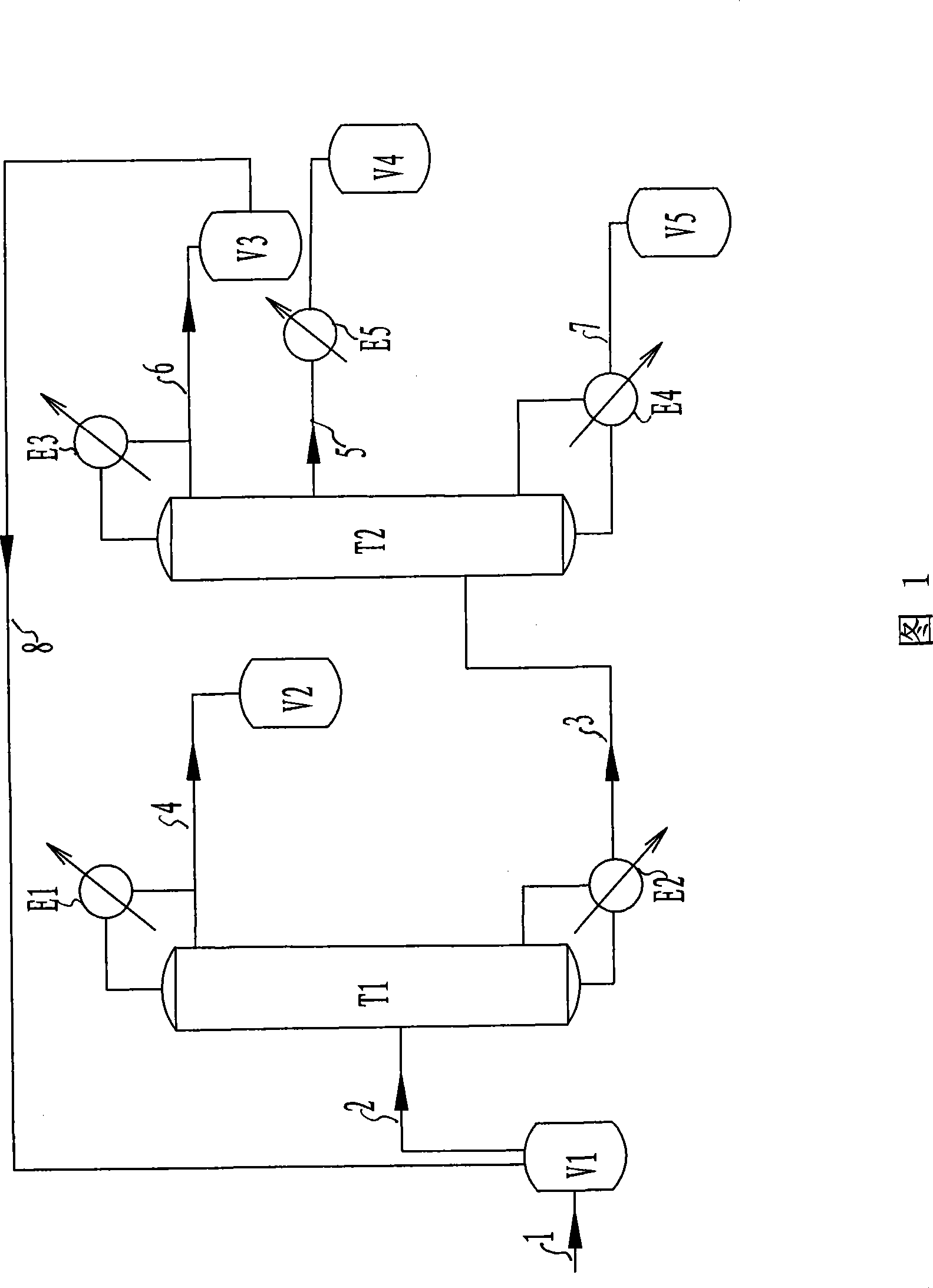

Refining method of isopropenyl acetate

InactiveCN101391954AReduce the temperature of the tower kettleReduce decomposition reactionsOrganic compound preparationCarboxylic acid esters preparationProcess engineeringIsopropenyl acetate

The invention discloses a refining method of isopropenylacetate, which comprises the steps that: an isopropenylacetate crude product is rectified by a first rectifying tower to remove most low-boiling residues to obtain tower bottoms, then the tower bottoms are rectified by a second rectifying tower, and the isopropenylacetate elaboration product is extracted from the liquid phase lateral line discharging materials of the rectifying section of the second rectifying tower. The invention overcomes the defects of the current isopropenylacetate refining method that production capacity is low, the production period is long, the product quality repetitiveness is poor and large-scale series production can not be dissatisfied, or final products can not reach high purity, or investment is large, energy consumption is high and large amount of wastewater is generated, and provides the refining method of the isopropenylacetate. The method can be suitable for large-scale series industrial production, does not need additional components such as entrainer and the like, and has the advantages of simple step, low energy consumption, small loss and high product purity.

Owner:SHANGHAI WUJING CHEM +1

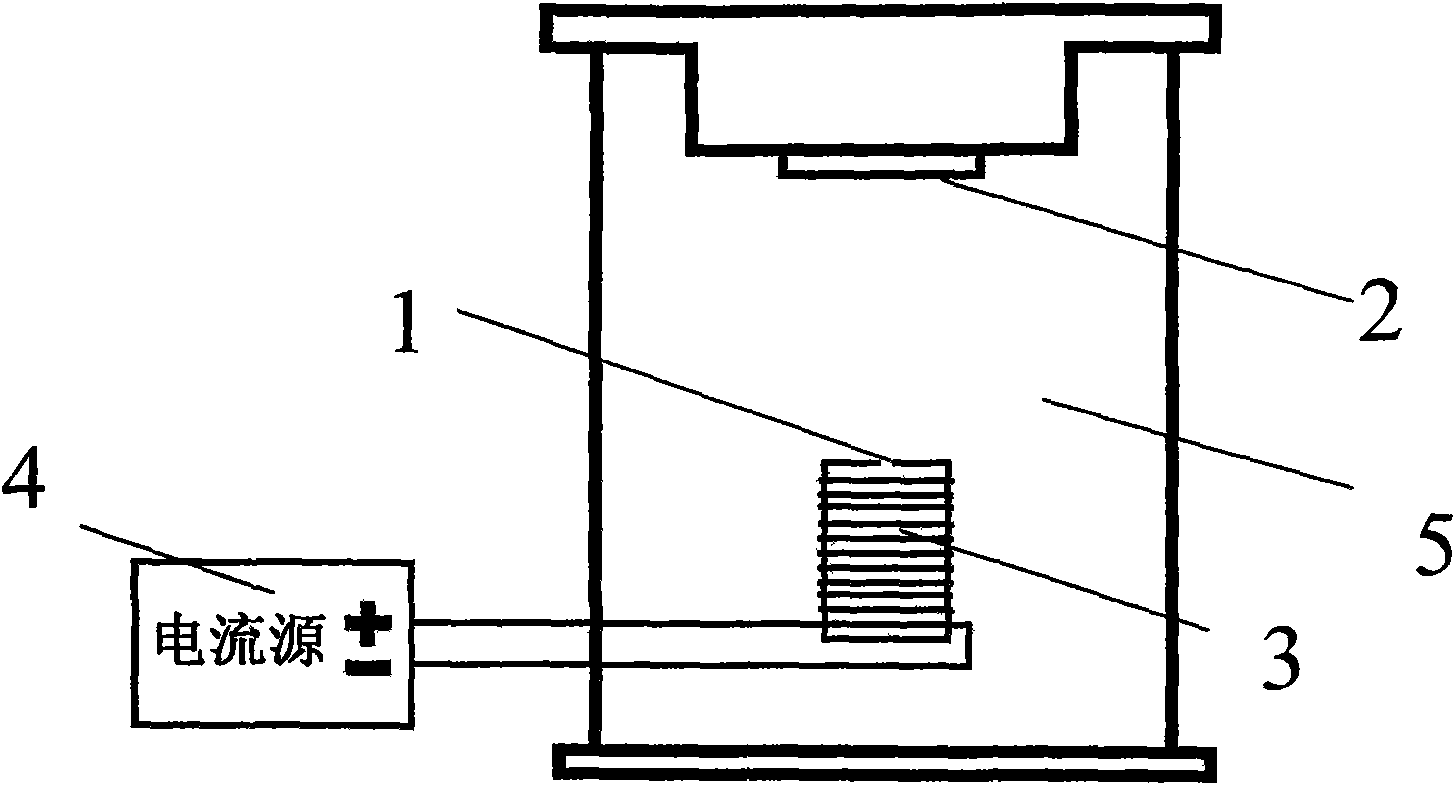

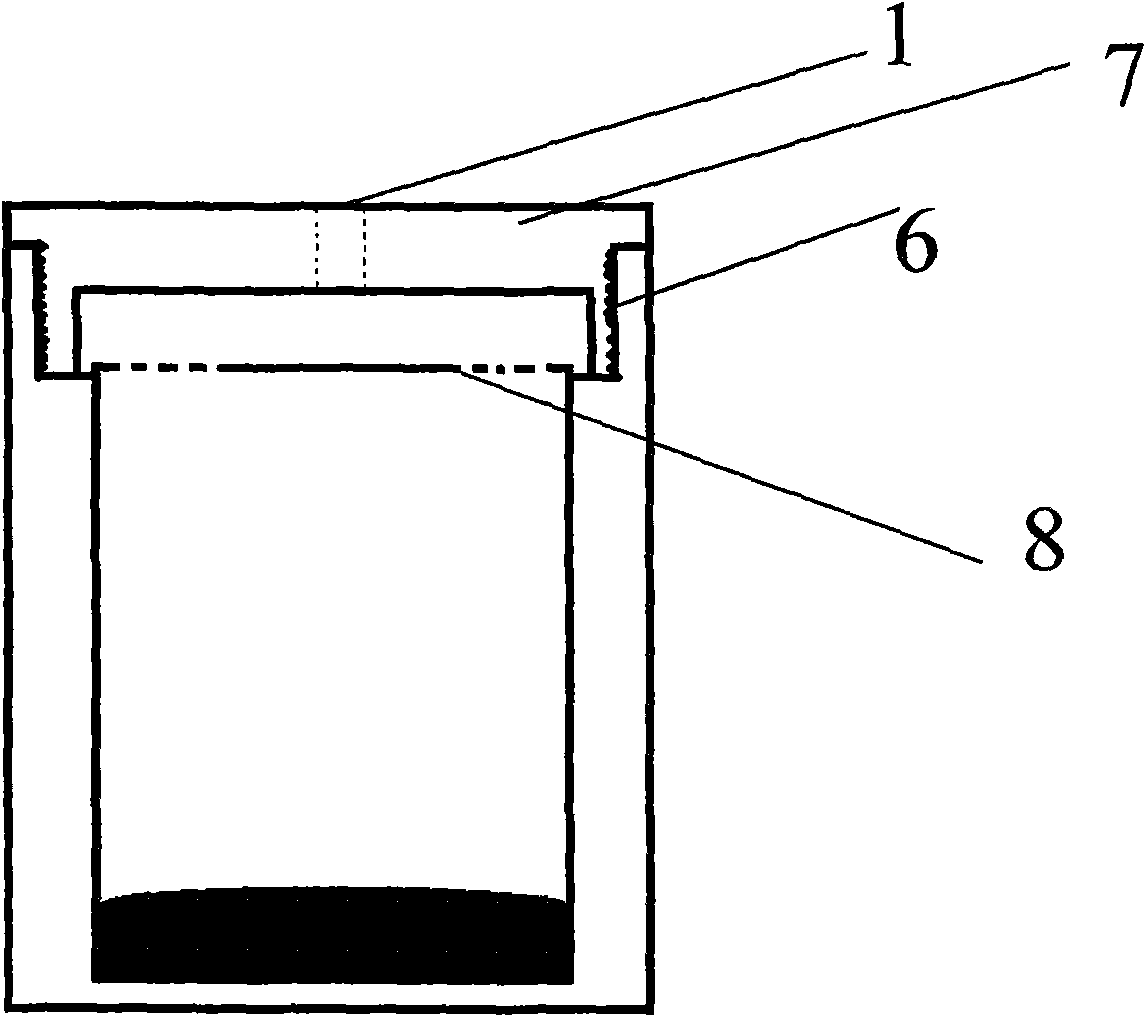

Method for thermally evaporating and preparing organic material nanometer cluster

InactiveCN101619439AIncrease aggregation densityReduce decomposition reactionsVacuum evaporation coatingSputtering coatingAmpereEvaporation

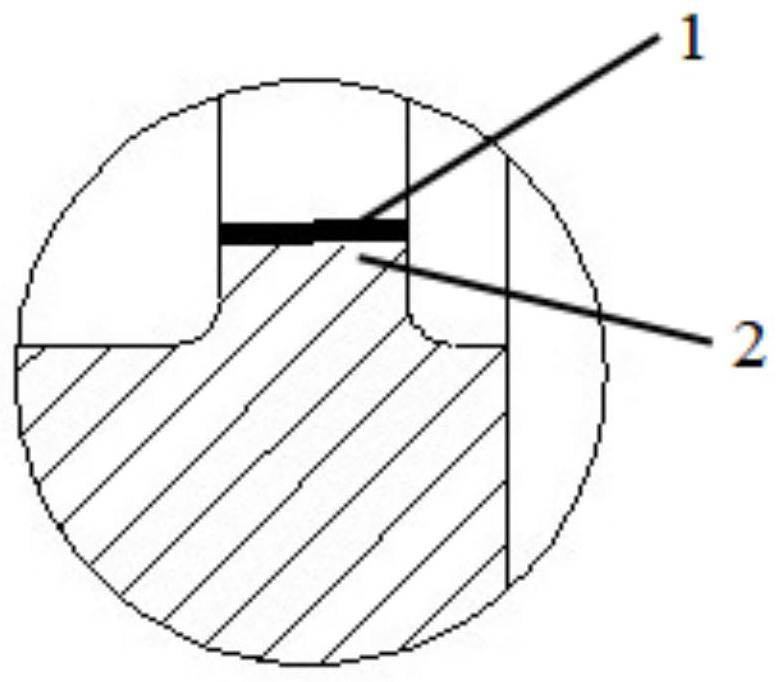

The invention relates to a method for evaporating and preparing an organic light emitting device by utilizing a cluster, which comprises the following steps: arranging a boron nitride crucible (3) in a vacuum chamber (5) as a nanometer cluster film preparation device, firstly, compressing air to be in a superhigh vacuum state of 5*10<5> Pa by using the film preparation device during the preparation process of an organic material nanometer cluster film and leading a resistance wire on the boron nitride crucible to switch on a current source (4) to heat the boron nitride crucible; then, leading the current of the current source to be 22-25 amperes during the evaporation process; gradually increasing the pressure intensity in the crucible during the heating and ceaselessly accumulating material steam inside the boron nitride crucible; and finally, quickly spraying high-temperature gaseous materials through a small hole (1) and absorbing the high-temperature gaseous materials to a base plate (2). The temperature of the base plate (2) is at a room temperature during the whole process. The film has strong adhesion, stable performance and high aggregation density. The device prepared by adopting the method has long service life, the photoelectric property of the device is improved remarkably and the luminous efficiency and the brightness of the device are also improved.

Owner:SOUTHEAST UNIV

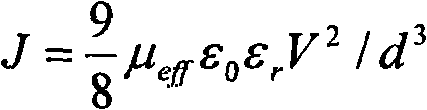

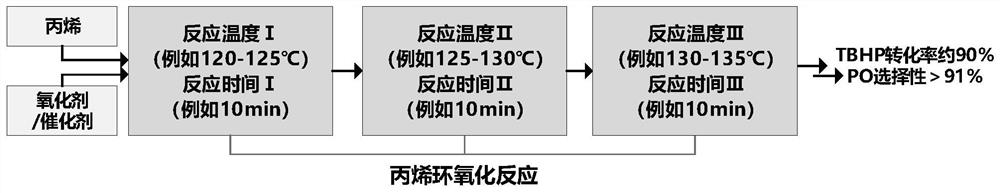

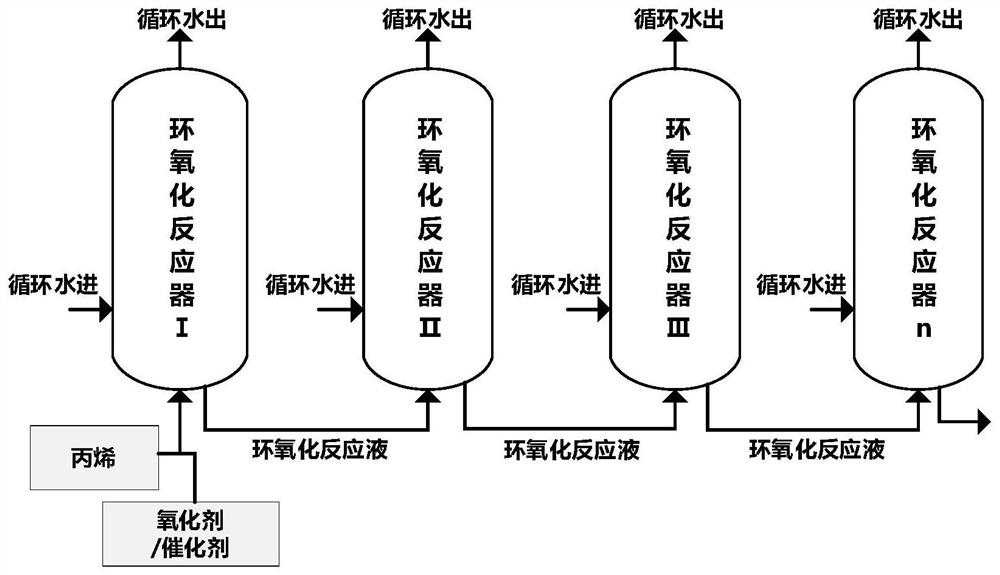

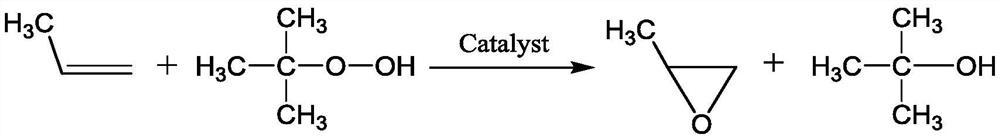

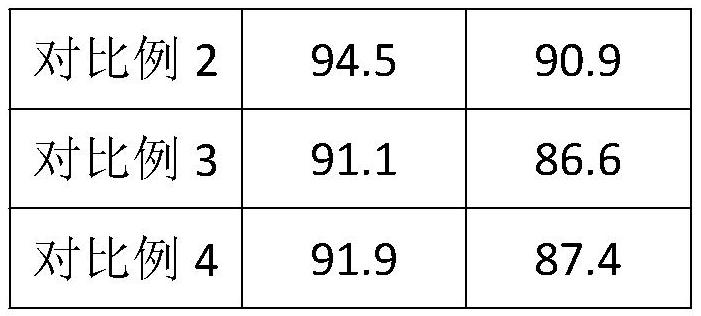

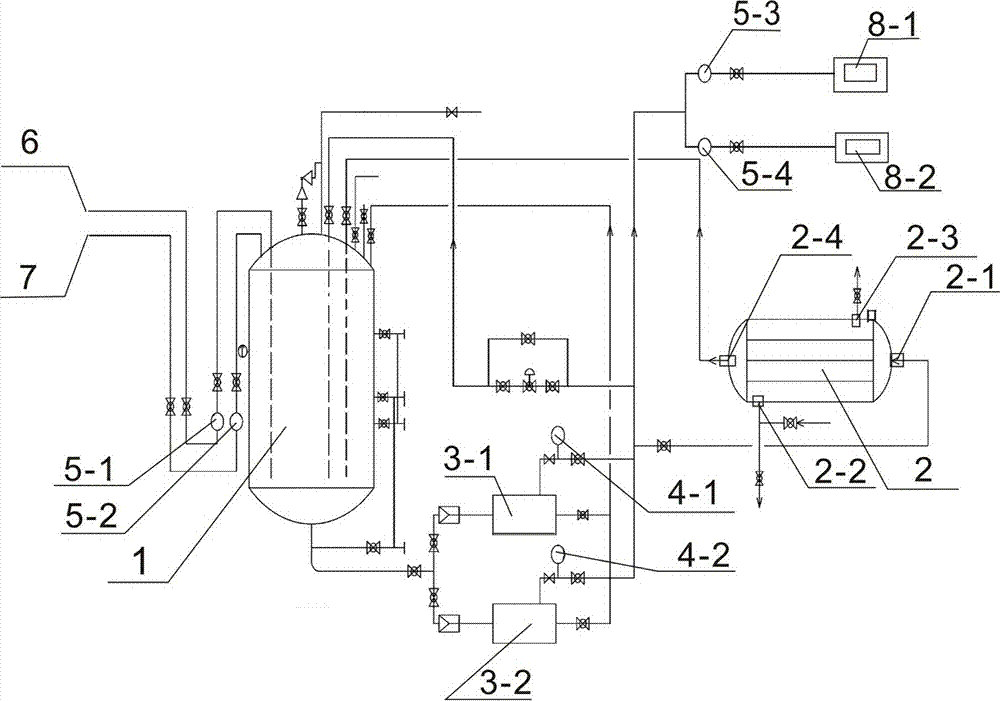

Preparation method of epoxy compound

ActiveCN112250643AReduce decomposition reactionsIncrease reaction rateOrganic chemistryChemistrySide reaction

The invention provides a preparation method of an epoxy compound, and develops a step-by-step heating preparation process. When the concentration of an oxidizing agent is high, a low-temperature reaction is selected, so that the decomposition reaction of the oxidizing agent is reduced on the premise of ensuring the reaction rate; and when the concentration of the oxidizing agent is reduced, the reaction rate is increased by increasing the reaction temperature, and the side reaction of epoxy compound decomposition is reduced. The process does not need to add the oxidizing agent in batches, so that the complexity of process operation is simplified. Compared with the preparation method reported in the existing literature, the step-by-step heating method ensures the high conversion rate of theoxidizing agent, enhances the selectivity of the epoxidation reaction, simplifies the production operation and enhances the process safety.

Owner:北京水木滨华科技有限公司

High-temperature storage method of lithium manganate battery

InactiveCN111710857AHigh chemical inertnessReduce decomposition reactionsFinal product manufacturePositive electrodesPhysical chemistryBattery cell

The invention provides a high-temperature storage method of a lithium manganate battery. A positive electrode active material of the lithium manganate battery comprises lithium manganate accounting for more than 50% of the total mass of the active material. The high-temperature storage method comprises: heating the assembled lithium manganate battery to 40 to 50 DEG C; injecting a first electrolyte at normal temperature; adjusting the temperature of the battery to be below 10 DEG C; and carrying out constant-current charging to a first predetermined voltage, adjusting the temperature of the battery to 40-50 DEG C, carrying out constant-voltage charging at the first predetermined voltage, injecting a second electrolyte at normal temperature, carrying out constant-current charging and discharging circulation between a charging cut-off voltage and a discharging cut-off voltage for a plurality of times, and storing the battery in an environment with the temperature of 30 DEG C or above. The battery stored by the storage method disclosed by the invention can be stored for more than 100 days in an environment with the temperature of more than 30 DEG C, and the attenuation of the cycle capacity is controlled within 5%.

Owner:钱起

Natural graphite modification method for lithium ion battery negative electrode material

ActiveCN104916843AReduce peelingReduced responseMaterial nanotechnologyCell electrodesElectrical batteryCarbon nanotube

A natural graphite modification method for a lithium ion battery negative electrode material comprises the following steps: taking Ti(OC4H9)4 and CH3COOLi.2H2O according to mass proportions, carrying out low speed stirring for 10min, adding carbon-nanotube, carrying out ultrasonic dispersion for 10-60min to obtain an LTO nanosphere / carbon nanotube, adding natural graphite, carrying out low speed stirring for 10min, adding ethanol to form sol-gel at 50DEG C, continuously heating on the basis of 50DEG C until ethanol is completely evaporated in order to obtain brown solid powder, drying the brown solid powder at 150DEG C for 8h to obtain LTO precursor solid powder, heating the LTO precursor solid powder under the protection of nitrogen according to a heating rate of 10DEG C / min until the temperature rises 750DEG C, and sintering for 8h to obtain the LTO nanosphere / carbon nanotube coated natural graphite negative electrode material. The method improves the electric conductivity and the structure stability of a natural graphite coating layer.

Owner:LUOYANG YUEXING NEW ENERGY TECH

Method for preparing high-temperature resistant fluorescent glass for LED

InactiveCN110627356AIsotropicNo fixed melting pointGlass shaping apparatusFluorescenceHeat resistance

The invention relates to a method for preparing high-temperature resistant fluorescent glass for an LED and belongs to the technical field of LEDs. The high-temperature resistant fluorescent glass forthe LED is prepared through taking quartz glass as a substrate and adding modified alumina whiskers. According to the method, the quartz glass has the characteristics of isotropy, metastability, no definite melting point and continuity and reversibility of property change; and the quartz glass has an extremely low coefficient of thermal expansion, high temperature resistance, excellent chemical stability and excellent electrical insulating performance, alumina whiskers are a highly heat-conductive material, modified alumina whiskers can be effectively dispersed inside the fluorescent glass and can effectively fill up voids and improve thermal conductivity, and thus, the heat resistance of the fluorescent glass is improved.

Owner:吴俊楠

Method and device for synthesizing sodium hydrosulfite

ActiveCN103482585AReduce decomposition reactionsIncrease the alcohol-to-water ratioThiosulfates/dithionites/polythionitesSodium metabisulfiteAlcohol

The invention provides a process control method of the later period of a sodium hydrosulfite synthetic reaction, aiming at increasing the alcohol and water ratio at the later period of the synthetic reaction and reducing the occurrence probability of a decomposition reaction of sodium hydrosulfite. The method concretely comprises the steps of slowly dissolving solid sodium formate and sodium metabisulfite into a 60-70% methyl alcohol water solution according to the molar ratio of 2: 1; controlling the temperature of a reaction kettle to be 80-85 DEG C, controlling the pressure to be 0.15-0.25Mpa and controlling the pH to be 4.4-5.0; slowly adding liquid sulfur dioxide into the reaction kettle; after the raw material feeding is stopped, slowly adding the mixed solution of sulfur dioxide and methyl alcohol into the raw material; and additionally arranging a set of sulfur dioxide and methyl alcohol matching preparation device on the basis of original production equipment. According to the method and the device provided by the invention, the alcohol and water ratio of a reaction system can be increased, the side reaction is restricted, the purity of the product can be improved to more than 90%, and the safety risk in the production process is reduced.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

Method and apparatus for converting solar energy into fuel chemical energy

It relates to a method and device of changing solar energy to chemical energy. It accumulates the solar energy and changing it to heat energy ranging from 150deg.C-300deg.C, providing reaction heat for the liquid fuels, allowing the middle and low level solar energy changing and stored into high level chemical energy, with the liquid being carbinol or dimethyl ether synthetic fuel, with the catabolite being hydrogen and monoxide formed gas. It can be used for multi purposes, providing fine synthetic fuel and material for customers.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Preparation process of mesophase pitch based protofilament continuous filament

InactiveCN108385179AReduce wire breakageReduce void defectsSpinning solution filteringSpinning solution de-aeratingFiber bundleGas bubble

The invention discloses a preparation process of a mesophase pitch based a protofilament continuous filament. The preparation process comprises the following steps of sending mesophase pitch into a screw extruder through a feeder; heating, by a screw of the extruder, the mesophase pitch, and carrying out reduced pressure deaeration when the screw runs; conveying, by the screw extruder, a melted and deaerated melt into a spinning component through a metering pump, spreading the melt into a spinneret through a spure spreader of the spinning component, and extruding through spinneret orifices ofthe spinneret to carry out spinning; oiling an extrusion-molded fiber bundle, drawing by a drawing roll, and then collecting the filament. A reduced pressure deaeration opening in the preparation process is located behind a final zone; on one hand, the melt in a melting zone can be prevented from being evacuated and broken down to cause that a suction gas is dissolved in the melt. The mesophase pitch is completely molten after passing through a screw melting zone, and is uniformly mixed under the shearing action of a twin screw to be capable of forming a layer of thin and uniform melt in a tank; at the moment, gas bubbles in the interior of the melt can be completely separated through the reduced pressure deaeration. The preparation process is good in production efficiency, and moreover, the prepared mesophase pitch based protofilament is good in performance.

Owner:西安天运新材料科技有限公司

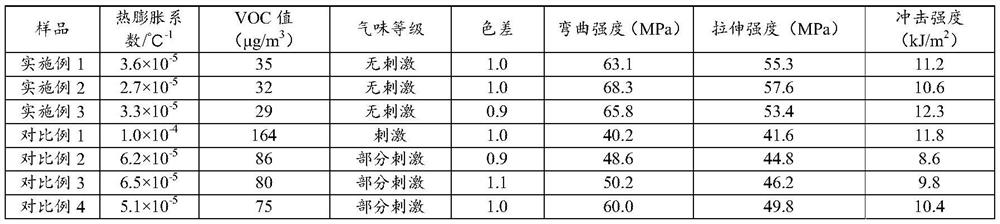

Shrinkage-warping-resistant ASA 3D printing material and preparation method thereof

PendingCN113024981ASmall coefficient of thermal expansionInhibit internal stressAdditive manufacturing apparatus3d printPolymer science

The invention discloses a shrinkage-warping-resistant ASA 3D printing material. ASA resin is used as a raw material, and HIPS, organic montmorillonite, a compatilizer, a heat stabilizer, an antioxidant and a lubricant are added; and the prepared 3D printing material has excellent shrinkage warping resistance, mechanical properties and weather resistance, and is especially suitable for 3D printing in the engineering field. In addition, the invention further discloses a preparation method of the 3D printing material, and the prepared ASA 3D printing material is low in shrinkage warping rate.

Owner:LIMING VOCATIONAL UNIV

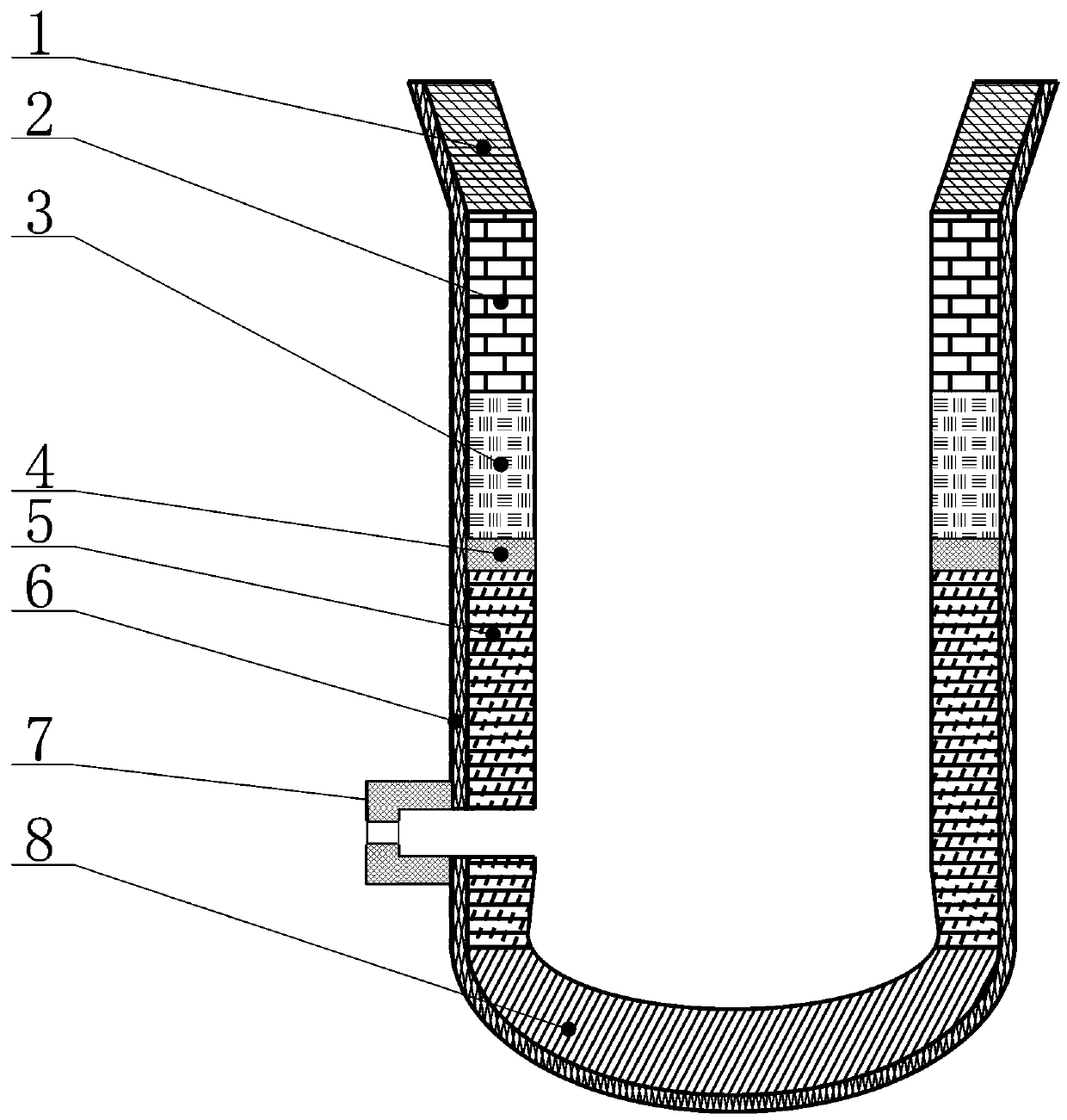

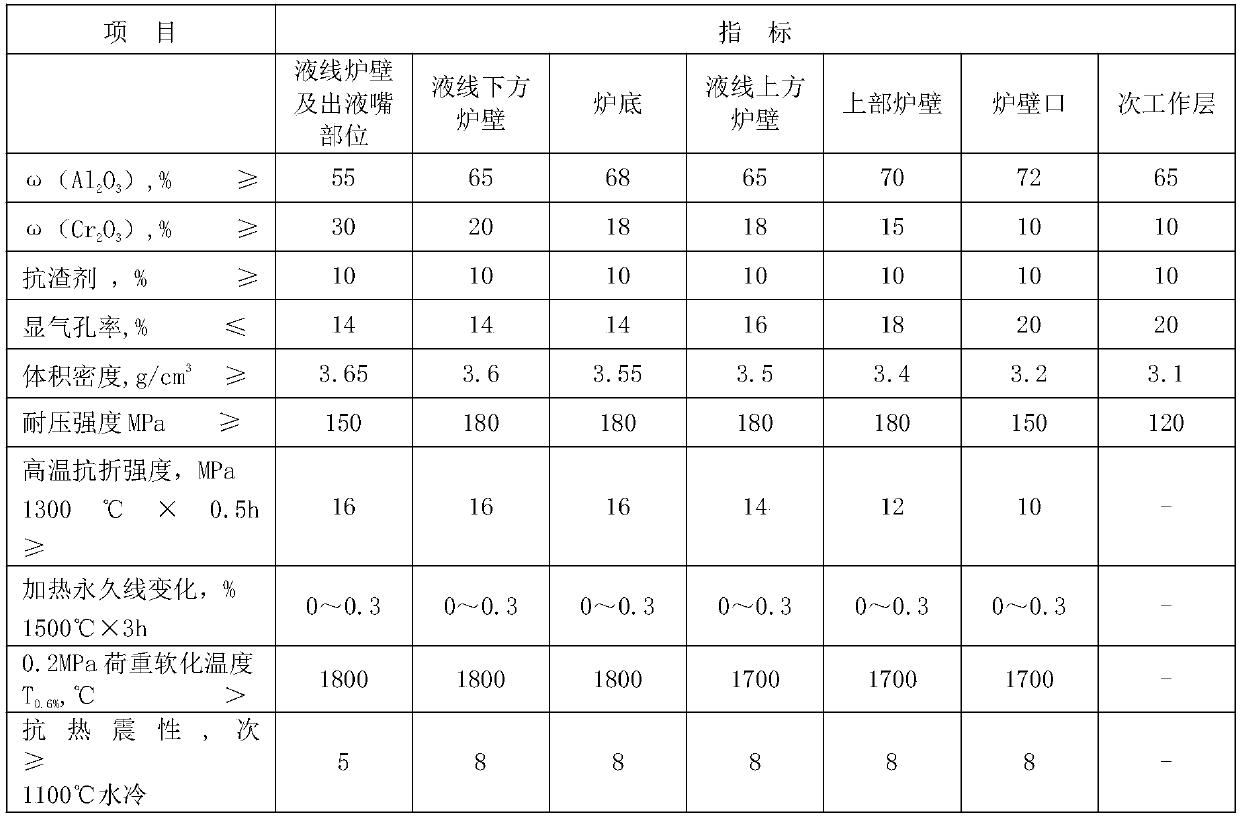

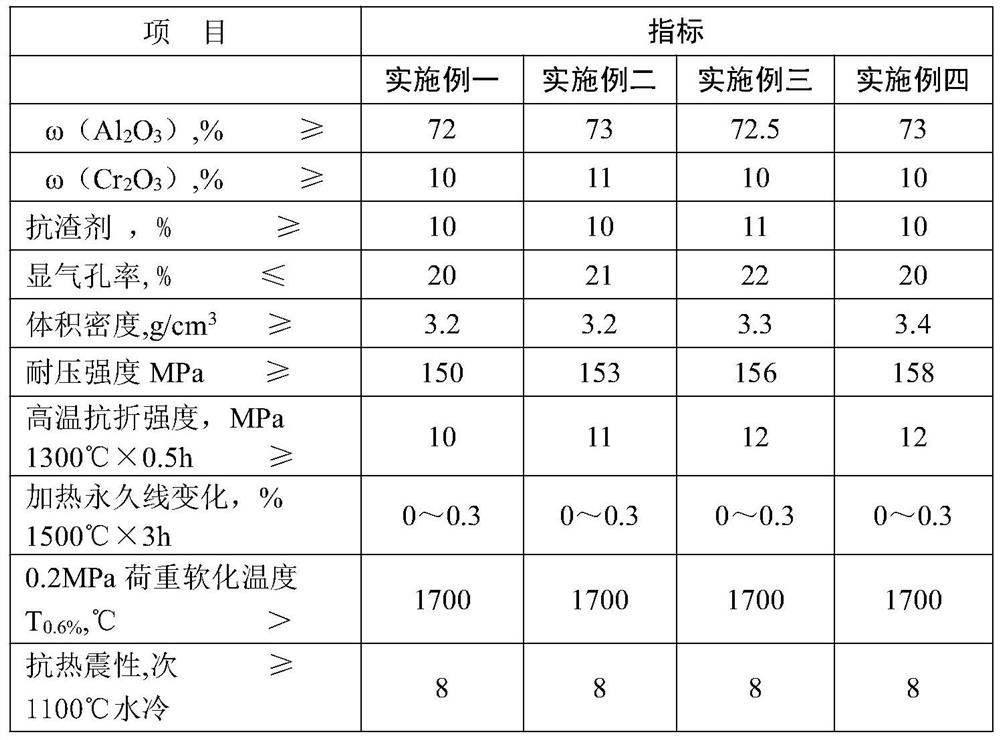

High-strength fusion smelter for colored strengthening smelting

ActiveCN109650856AReduce decomposition reactionsReduce heat responseCharge treatment typeFurnace liningsLiquid lineThermal shock

The invention relates to a high-strength fusion smelter for colored strengthening smelting. The smelter comprises a smelter wall port, an upper smelter wall, a smelter wall above a liquid line, a liquid line smelter wall, a smelter wall below the liquid line, a secondary working layer, a liquid outlet nozzle and a smelter bottom. All the parts of the smelter are made of fire-resistance materials,by analyzing working conditions of different parts of the high-strength fusion smelter for colored strengthening smelting, different kinds of fire-resistance material brasque are used as the corresponding parts, one or more properties of the erosion resistance, thermal shock resistance, washing resistance and permeability resistance of the brasque at the part are improved, the service life of thebrasque is greatly improved, frequent repairing and brasque replacement are avoided, and a large number of human resources and financial resources are saved.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

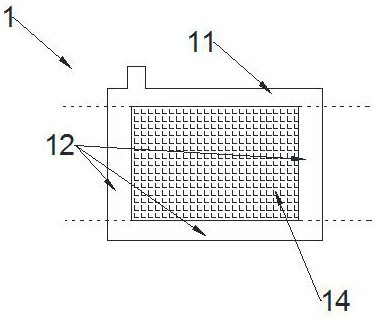

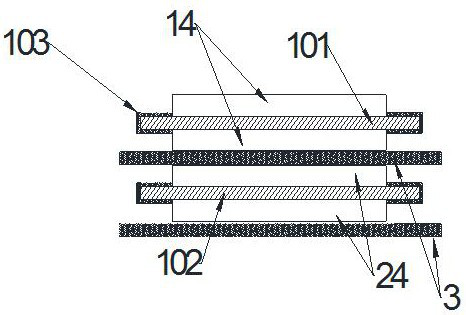

High-safety primary lithium-manganese battery and preparation method thereof

InactiveCN112447993AStable structureImprove electronic conductivityOrganic electrolyte cellsPrimary cell electrodesElectrical batteryEngineering

The invention discloses a high-safety primary lithium-manganese battery and a preparation method thereof. The primary lithium-manganese battery comprises a positive plate, a negative plate, a ceramicdiaphragm, electrolyte and a battery shell, and the positive plate, the ceramic diaphragm, the negative plate and the ceramic diaphragm are sequentially and repeatedly stacked to form a dry battery cell; the primary lithium-manganese battery is prepared by putting a dry battery cell into a battery shell, injecting electrolyte, aging, sealing and aging, and is characterized in that a negative plateis subjected to electrochemical lithium pre-doping, so that a 'fully charged secondary lithium battery negative plate' or a 'zero charged lithium / carbon half battery positive plate' is converted intoa pre-lithiated negative plate; positive plate reserved tabs are arranged on front face and back face of positive plate, and negative plate reserved tabs are arranged on front face and back face of negative plate. According to the primary lithium-manganese battery disclosed by the invention, after the primary lithium-manganese battery is subjected to impact, extrusion and needling tests, the phenomena of firing, deflagration and explosion are avoided, and the safety performance of the primary lithium-manganese battery is higher than that of the traditional primary lithium-manganese battery.

Owner:LONG POWER SYST NANTONG CO LTD

Lightweight fiber-reinforced phenolic sandwich board and preparation method thereof

ActiveCN107351852BGood smoke densityGood smoke toxicity performanceLamination ancillary operationsSynthetic resin layered productsSurface layerUltimate tensile strength

The invention discloses a light-weight fiber-reinforced phenolic sandwich plate and a preparation method thereof. The light-weight fiber-reinforced phenolic sandwich plate is composed of two surface layers and a core material layer between the two surface layers or is composed of two sandwich surface layers and a core material layer between the two sandwich surface layers, and the core material layer is a fiber-reinforced phenolic light-weight foam layer. The plate disclosed by the invention solves the problem of brittleness of phenolic foam, and the plate is composed of phenolic materials with better flame resistance from inside to outside, so that the flame resistance of the plate is excellent, the plate can resist to high temperature of 150-180 DEG C, the plate strength retention ratio at high temperature is high, and thus fireproof requirements of locomotives can be met. The core material and surface layers of the plate are light materials, so that the light-weight requirement of vehicles can be met. The core material and surface layers of the plate are reinforced by fiber, the fiber in the core material can effectively increase the strength and rigidity of the phenolic foam, and the fiber in the surface layers can effectively increase the strength and rigidity of the phenolic plate, so that the obtained sandwich plate has better strength and rigidity.

Owner:常州诺法新材料科技有限公司

Preparation method of magnesium nitrate and magnesium nitrate based multi-element molten salt

InactiveCN110054206ALow dehydration temperatureShorten the timeMagnesium nitratesHeat-exchange elementsDecompositionMolten salt

The invention discloses a preparation method of magnesium nitrate and magnesium nitrate based multi-element molten salt. The method includes the steps: placing an open container containing magnesium nitrate hexahydrate or multi-element molten salt mixture with the magnesium nitrate hexahydrate into a heating device for vacuum heating dehydration; placing dehydrated products into an anhydrous oxygen-free glove box and crushing the dehydrated products to obtain the magnesium nitrate or magnesium nitrate based multi-element molten salt. According to the preparation method, the content of alkali magnesium nitrate in the magnesium nitrate and magnesium nitrate based multi-element molten salt can be effectively decreased, high-purity magnesium nitrate or magnesium nitrate based multi-element molten salt can be acquired at lower temperature within a shorter time, and the acquired magnesium nitrate or magnesium nitrate based multi-element molten salt has higher decomposition temperature.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

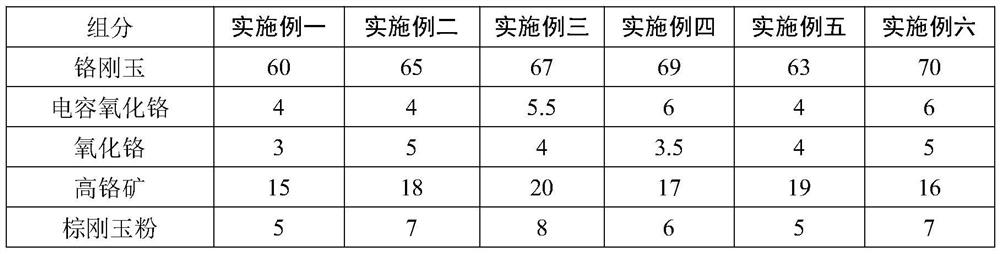

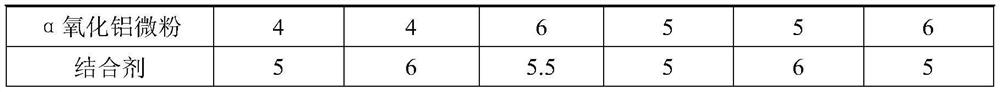

A kind of refractory material for upper furnace wall of non-ferrous smelting melting furnace and preparation method thereof

A refractory material for the upper furnace wall of a non-ferrous smelting melting furnace, which is suitable for the upper furnace wall of a non-ferrous smelting melting furnace. powder, α-alumina micropowder and binder. This technical solution uses chromium corundum, fused chromium oxide, chromium oxide, high chromium ore, brown corundum powder, and α-alumina micropowder as raw materials, which reduces the content of MgO, so that the dissolution and subsequent decomposition of MgO in the refractory material The reaction is greatly reduced, the related thermal reaction is reduced, and the refractory structure is prevented from being damaged by frequent reactions.

Owner:中钢洛耐科技服份有限公司

Oxynitride glass and production method thereof

InactiveCN109231818ALower melting temperatureReduce high temperature viscosityGlass furnace apparatusChemical compositionDecomposition

The invention provides oxynitride glass and a production method thereof, wherein the oxynitride glass is prepared from chemical composition by mass percent: 40-50% of SiO2, 10-25% of Al2O3, 10-20% ofY2O3, 10-15% of CaO, 1-8% of AlN, less than or equal to 20% of ZnO, and less than or equal to 1% of unavoidable impurities. By adopting the technical scheme of the invention, a corundum crucible is used in melting process, and cost is lower than the cost of a molybdenum crucible, a boron nitride crucible, a graphite crucible, a tungsten crucible, etc., and the use is more convenient and faster than partial metal crucibles; the oxynitride glass can be prepared at a lower temperature (1,450-1,550 DEG C), which reduces occurrence of decomposition reactions, and provides safer preparation process.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

a syrup

InactiveCN103695568BReduce decomposition reactionsHigh purityPurification using adsorption agentsPurification by physical meansBiotechnologyFructose

The invention discloses syrup. The syrup is prepared by comprising the steps: performing activated carbon adsorption to mother liquor obtained after crystallization of single-crystal sugar in a crystal sugar preparation process; or, firstly sulfitating the mother liquor obtained after crystallization of single crystal sugar, then carrying out activated carbon adsorption, and then adsorbing with discolored resin, to obtain syrup. According to the syrup, the purity of cane sugar in the syrup is greatly improved, the application field of products is wide, the decomposition reaction of cane sugar can be reduced, and the hyperchromic reaction of glucose and fructose can be decreased; the syrup treatment cost is greatly lowered, in addition, after the purity of the treated cane sugar is improved, the selling price is greatly increased, and the economic benefits of enterprises can be increased; the production efficiency is enhanced; the comprehensive utilization rate of cane sugar can be improved, and the lack situation of cane sugar in China can be improved; and waste syrup does not exist, and the environment pollution can be decreased.

Owner:邢台平安糖业有限公司

A Tetraploid Breeding Method of Non-heading Chinese Cabbage

InactiveCN108476979BChemically stableIncrease mutation ratePlant genotype modificationBiotechnologyColchicine

The invention discloses a tetraploid breeding method for non-heading Chinese cabbages. The method comprises the step of treating a growing point with a combined mutagenic agent when a cotyledon petiole included angle of diploid non-heading Chinese cabbages is of 40-60 degrees and a first true leaf does not grow, wherein the combined mutagenic agent is mainly composed of 0.1-0.2% colchicine and 40-60 [mu]mol / L amiprophos-methyl (APM), and treatment is performed for 2 to 4 times by using the combined mutagenic agent. According to the method disclosed by the invention, the tetraploid mutagenesisrate is as high as 12.6% by using a mixture of the low-concentration colchicine and APM, the mutagenesis rate is improved, and pollution to the environment and toxic effects on plants are reduced.

Owner:南京理想农业科技有限公司

A kind of refractory material for furnace wall port of non-ferrous smelting melting furnace and preparation method thereof

The invention discloses a refractory material for the furnace wall opening of a nonferrous smelting melting furnace, which is suitable for the position of the furnace wall opening of a nonferrous smelting melting furnace. The refractory material is composed of fused chromium corundum, chromium oxide and gel binder. The invention uses fused chromium corundum and chromium oxide as raw materials, reduces the content of MgO, greatly reduces the dissolution of MgO in the refractory material and subsequent decomposition reactions, reduces related thermal reactions, and avoids frequent damage to the refractory material structure. ground reaction damage. Fused chromium corundum makes the refractory material have excellent high temperature performance, good thermal shock stability and good corrosion resistance. The addition of chromium oxide makes the refractory material resistant to penetration.

Owner:中钢洛耐科技服份有限公司

A kind of natural graphite modification method for negative electrode material of lithium ion battery

ActiveCN104916843BReduce peelingReduced responseMaterial nanotechnologyCell electrodesElectrical batteryCarbon nanotube

A natural graphite modification method for a lithium ion battery negative electrode material comprises the following steps: taking Ti(OC4H9)4 and CH3COOLi.2H2O according to mass proportions, carrying out low speed stirring for 10min, adding carbon-nanotube, carrying out ultrasonic dispersion for 10-60min to obtain an LTO nanosphere / carbon nanotube, adding natural graphite, carrying out low speed stirring for 10min, adding ethanol to form sol-gel at 50DEG C, continuously heating on the basis of 50DEG C until ethanol is completely evaporated in order to obtain brown solid powder, drying the brown solid powder at 150DEG C for 8h to obtain LTO precursor solid powder, heating the LTO precursor solid powder under the protection of nitrogen according to a heating rate of 10DEG C / min until the temperature rises 750DEG C, and sintering for 8h to obtain the LTO nanosphere / carbon nanotube coated natural graphite negative electrode material. The method improves the electric conductivity and the structure stability of a natural graphite coating layer.

Owner:LUOYANG YUEXING NEW ENERGY TECH

A kind of high-voltage lithium-ion battery non-aqueous electrolyte

ActiveCN108987802BImprove high temperature storage performanceReduce decomposition reactionsSecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageElectrolytic agent

Owner:余姚市海泰贸易有限公司

Sugammadex sodium for injection and preparation method thereof

ActiveCN114773499AHigh yieldHigh purityMaterial nanotechnologyOrganic active ingredientsSugammadex SodiumPhysical chemistry

The invention discloses sugammadex sodium for injection and a preparation method thereof, and the preparation method comprises the following steps: S1, dissolving a sugammadex sodium crude product in deionized water, and adding a proper amount of alkali liquor to adjust the pH value of the solution to 6.7-6.9; s2, adding a magnetic nanotube into the alkalized solution, and stirring and adsorbing in a vacuum environment; s3, separating the magnetic nanotubes by using a magnetic field, and dispersing the magnetic nanotubes into deionized water for oscillation desorption; wherein the magnetic nanotube comprises a multi-layer structure, and the multi-layer structure sequentially comprises a compact silicon dioxide nanotube layer, a Fe3O4 layer and a mesoporous silicon dioxide layer from inside to outside; and S4, merging and crystallizing the sugammadex sodium solution obtained by oscillation desorption to obtain refined sugammadex sodium. In a weak acid environment, sugammadex sodium molecules are reversibly adsorbed by adopting a special structure of the magnetic nanotube, and the inner layer of the silicon dioxide nanotube and the outer layer of the mesoporous silicon dioxide layer can be subjected to a physical adsorption reaction with the sugammadex sodium molecules through hydrogen bonds, surface atomic coordination and the like.

Owner:SICHUAN PHARMA

Preparation method of surfacing coating on sealing surface of valve

PendingCN112853344AReduce decomposition reactionsHigh coating hardnessMetallic material coating processesMetal bindingPowder

The invention relates to a preparation method of a surfacing coating on a sealing surface of a valve. The preparation method of the surfacing coating on the sealing surface of the valve comprises the following steps of: (1) obtaining cladding powder: firstly blending a metal binding phase and a ceramic reinforced phase according to a proportion, then adding 0.4 to 0.6 percent of CeO2 as a grain inhibitor, and fully mixing through a mechanical method to obtain the cladding powder; (2) heating the sealing surface of the valve; (3) preserving heat, wherein a ceramic fiber heat preservation material is needed for whole-course heat preservation for a large-diameter valve part; and (4) forming a composite hardened coating: adopting a laser cladding mode to clad the mixed cladding powder on the preheated sealing surface of a valve body through a coaxial powder feeding mode so as to form the composite hardened coating. After the three kinds of powder are fully mixed and dried, the mixed powder is cladded on the sealing surface of the valve through a laser cladding technology to form the composite coating, so that the decarburization decomposition behavior of a ceramic phase is reduced, the grain size of the coating is refined, and the purpose of improving the hardness and the abrasion resistance of the coating is achieved.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com