Preparation process of mesophase pitch based protofilament continuous filament

A mesophase pitch and preparation process technology, which is applied in filament forming treatment, filament/wire forming, spinneret assembly, etc., can solve the difficulties of post-processing, low production efficiency of mesophase pitch, and low performance of raw silk and other problems, to achieve the effect of reducing hole defects, reducing friction, and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

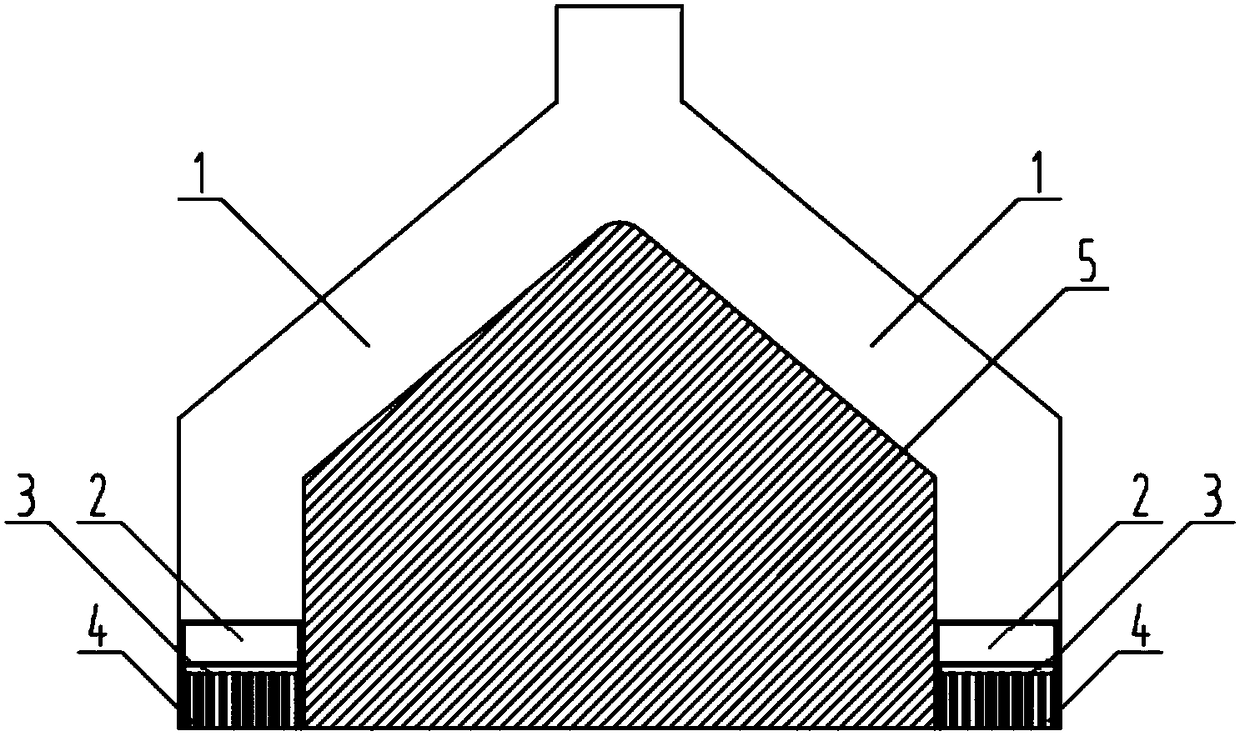

Image

Examples

Embodiment 1

[0042] Step 1: Grind and pulverize the mesophase pitch, and send it to the screw extruder through the feeder.

[0043] Step 2: The mesophase pitch is mixed and melted through multiple heating zones of the screw extruder, and the screw heating temperature of the extruder is 130-310°C. The temperature in the initial zone is 20°C lower than the temperature at which the mesophase pitch begins to oxidize, and the temperature in the final temperature zone is 310°C, which is higher than the softening point of the mesophase pitch and 20°C lower than the spinning temperature. After the final zone, a suction port is set, and the vacuum degassing after the final temperature zone of the screw extruder is opened, and the pressure of the degassing degassing is -0.1MPa.

[0044] Step 3: The screw extruder sends the melted and defoamed melt to the metering pump, and the pressure before the pump is kept between 1.5 and 2 MPa. The melt is accurately metered and delivered to the spinning assemb...

Embodiment 2

[0050] Step 1: Grind and pulverize the mesophase pitch, and send it to the screw extruder through the feeder.

[0051] Step 2: The mesophase pitch is mixed and melted through multiple heating zones of the screw extruder, and the heating temperature is 130-310°C. The temperature in the initial zone is 20°C lower than the temperature at which the mesophase pitch begins to oxidize, and the temperature in the final temperature zone is 310°C, which is higher than the softening point of the mesophase pitch and 20°C lower than the spinning temperature. After the final zone, a suction port is set, and the vacuum degassing after the final temperature zone of the screw extruder is opened, and the pressure of the degassing degassing is -0.1MPa.

[0052] Step 3: The screw extruder sends the melted and defoamed melt to the metering pump, and the pressure before the pump is kept between 1 and 1.3 MPa. The melt is accurately metered and delivered to the spinning assembly by a metering pump ...

Embodiment 3

[0067] Step 1: Send the pulverized mesophase pitch to the screw extruder through the feeder;

[0068] Step 2: The screw of the extruder heats the mesophase pitch, and sets an air extraction port after the final zone, and degasses under pressure during the operation of the screw; wherein, the heating temperature of the screw of the extruder is 140-300°C, and the temperature of the initial zone is less than The temperature at which the mesophase pitch begins to oxidize is 10°C, and the temperature in the final temperature zone is 300°C, which is higher than the softening point of the mesophase pitch and lower than the spinning temperature of 30°C. The pressure for defoaming is -0.05MPa.

[0069] Step 3: The screw extruder sends the melted and defoamed melt to the metering pump, and the pressure before the pump is kept between 1.5 and 2 MPa. The melt is accurately metered and delivered to the spinning assembly by a metering pump and pressurized. The molten and defoamed melt is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com