Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

A glass fiber and sizing technology, which is applied in the field of glass fiber sizing and sizing, can solve the problems of low fatigue strength and achieve the effects of reducing interfacial energy, strong coating, and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

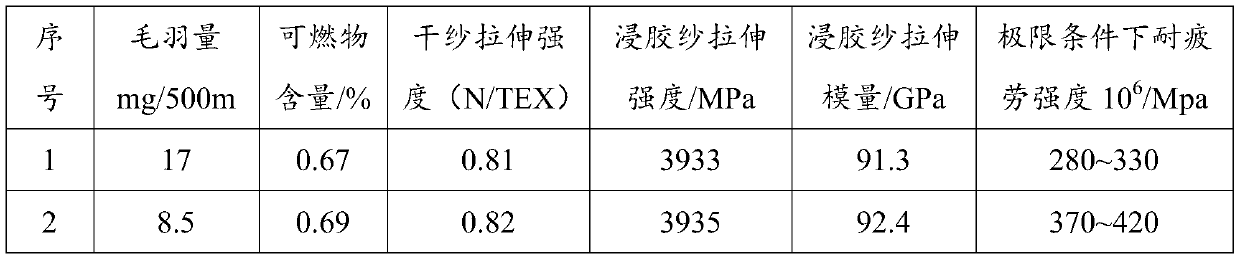

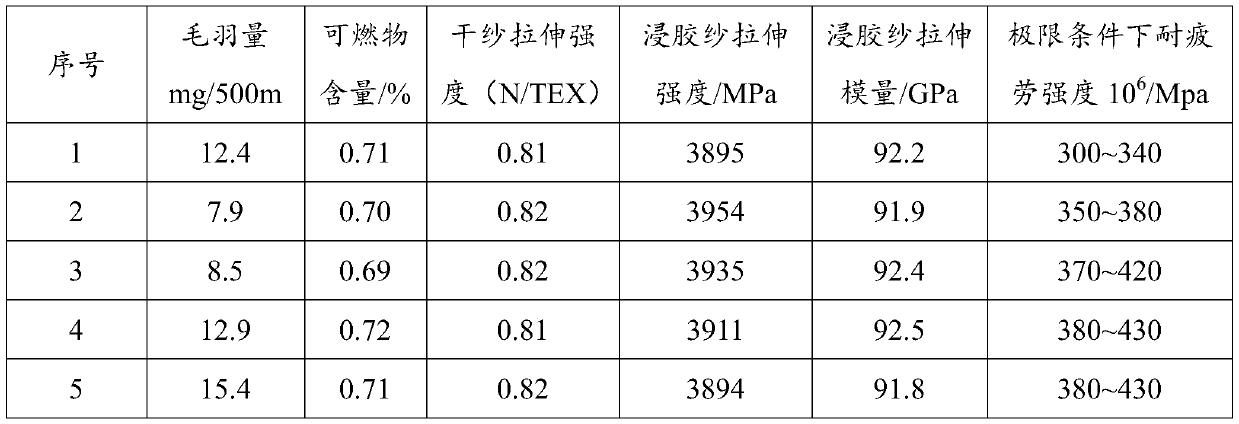

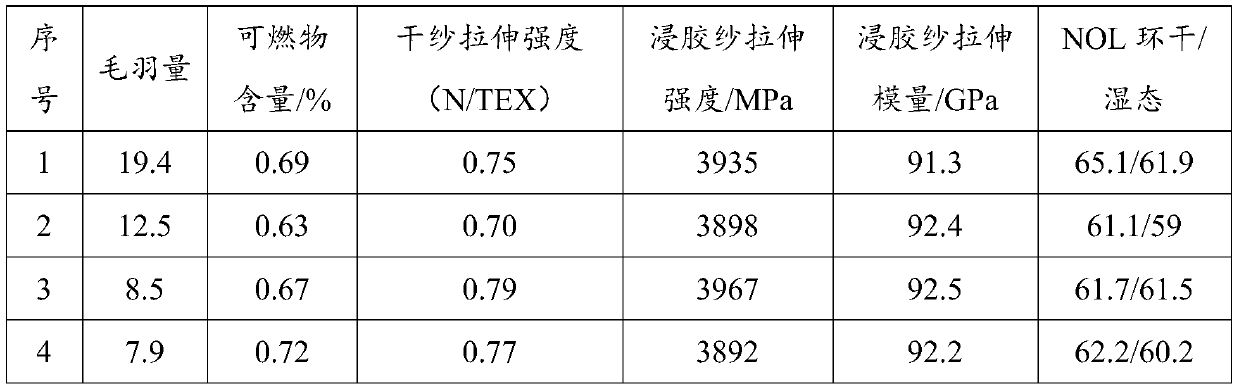

Embodiment 1

[0045] The present embodiment provides a glass fiber sizing, and its formula is as follows:

[0046] Epoxy resin emulsion 35kg; polyurethane emulsion NBR-460 5kg; A-1120 6.2kg; A-1741.5kg; NBR-1140 4.5kg; NBR-1090 5.5kg; A-008 0.5kg; Acetic acid 1kg; deionized water to make up to 1000kg.

[0047] The method for preparing the glass fiber sizing agent by adopting the above formula is as follows:

[0048] (1) Add the acetic acid into the first mixing container, stir and add deionized water until the pH of the aqueous solution is 6, then add A-1120 and A-174 while stirring, and continue stirring until the surface of the liquid is clarified to obtain the silane di Joint agent solution;

[0049] (2) Add epoxy resin emulsion in the second mixing container, add the deionized water of 5 times of quality of epoxy resin emulsion again, stir, obtain the epoxy resin emulsion of dilution;

[0050] (3) After the polyurethane emulsion NBR-460 is fully diluted with deionized water of 5 time...

Embodiment 2

[0055] The present embodiment provides a glass fiber sizing, and its formula is as follows:

[0056] Epoxy resin emulsion 40kg; polyurethane emulsion NBR-460 0.5kg; A-1120 6.2kg; A-1741.5kg; NBR-1140 4.5kg; NBR-1090 5.5kg; A-008 0.5kg; ; Acetic acid 3.1kg; deionized water to make up to 1000kg.

[0057] The method for preparing the glass fiber sizing agent by adopting the above formula is as follows:

[0058] (1) Add the acetic acid to the first mixing container, stir and add deionized water until the pH of the aqueous solution is 5, then add A-1120 and A-174 while stirring, and continue stirring until the surface of the liquid is clear to obtain silane coupling agent solution;

[0059] (2) Add epoxy resin emulsion in the second mixing container, add the deionized water of 5 times of quality of epoxy resin emulsion again, stir, obtain the epoxy resin emulsion of dilution;

[0060] (3) After the polyurethane emulsion NBR-460 is fully diluted with deionized water of 5 times it...

Embodiment 3

[0065] The present embodiment provides a glass fiber sizing, and its formula is as follows:

[0066] Epoxy resin emulsion 36.5kg; polyurethane emulsion NBR-460 1.5kg; A-1120 6.2kg; A-1741.5kg; NBR-1140 5kg; NBR-1090 3kg; A-008 0.5kg; Acetic acid 5kg; deionized water to make up to 1000kg.

[0067] The method for preparing the glass fiber sizing agent by adopting the above formula is as follows:

[0068] (1) Add the acetic acid to the first mixing container, stir and add deionized water until the pH of the aqueous solution is 3, then add A-1120 and A-174 while stirring, and continue stirring until the surface of the liquid is clear to obtain silane coupling agent solution;

[0069] (2) Add epoxy resin emulsion in the second mixing container, add the deionized water of 5 times of quality of epoxy resin emulsion again, stir, obtain the epoxy resin emulsion of dilution;

[0070] (3) After the polyurethane emulsion NBR-460 is fully diluted with deionized water of 5 times its mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com