Cleaning agent for treating polymer-containing oil sludge and treatment method thereof

A treatment method and a technology of sludge accumulation, which is applied in the direction of detergent composition, detergent compounding agent, biological sludge treatment, etc., can solve the problems of high treatment cost, great difference, and troubles of sludge accumulation, and achieve low treatment temperature , low cost, reducing oil-solid interfacial energy and the effect of crude oil viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

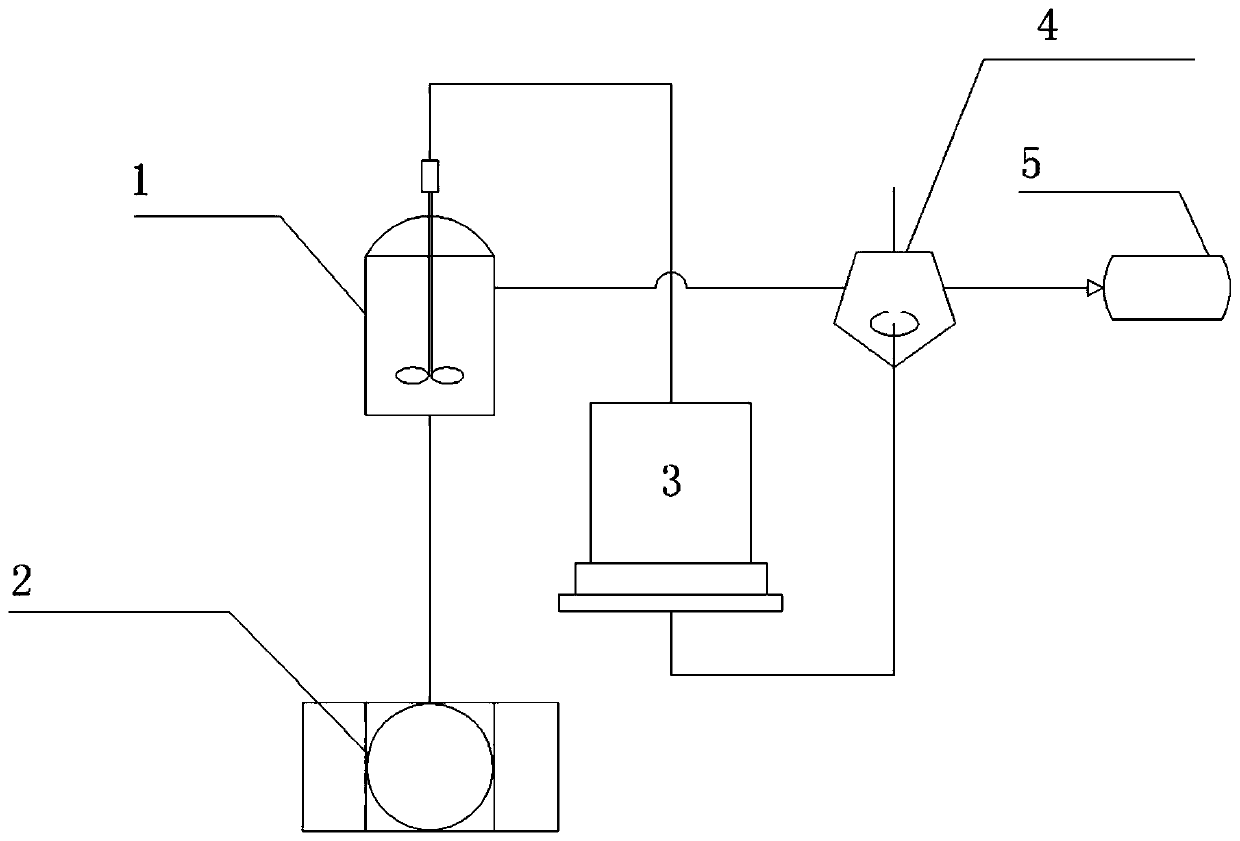

Image

Examples

Embodiment 1

[0039] A cleaning agent for treating poly-oil sludge, which is prepared by mixing 0.5% fatty peptide biological enzyme, 2% sodium phosphate, 0.2% humic acid, 2% caustic soda, 0.01% AEO-9 and water according to the mass ratio.

Embodiment 2

[0041]A cleaning agent for processing oily sludge containing 0.1% rhamnose carbohydrase, 1.5% potassium permanganate, 0.1% iron sulfate, 0.1% nano silicon dioxide, 2% soda ash, and 0.01% AEO-9 by mass ratio % mixed with water.

Embodiment 3

[0043] A cleaning agent for treating poly-oil sludge, which consists of 0.1% fatty peptide biological enzyme, 1% sodium peroxide, 1% low-density nano-activated carbon, 1% caustic soda, 0.1% sodium dodecylbenzenesulfonate and water by mass ratio Prepared by mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com