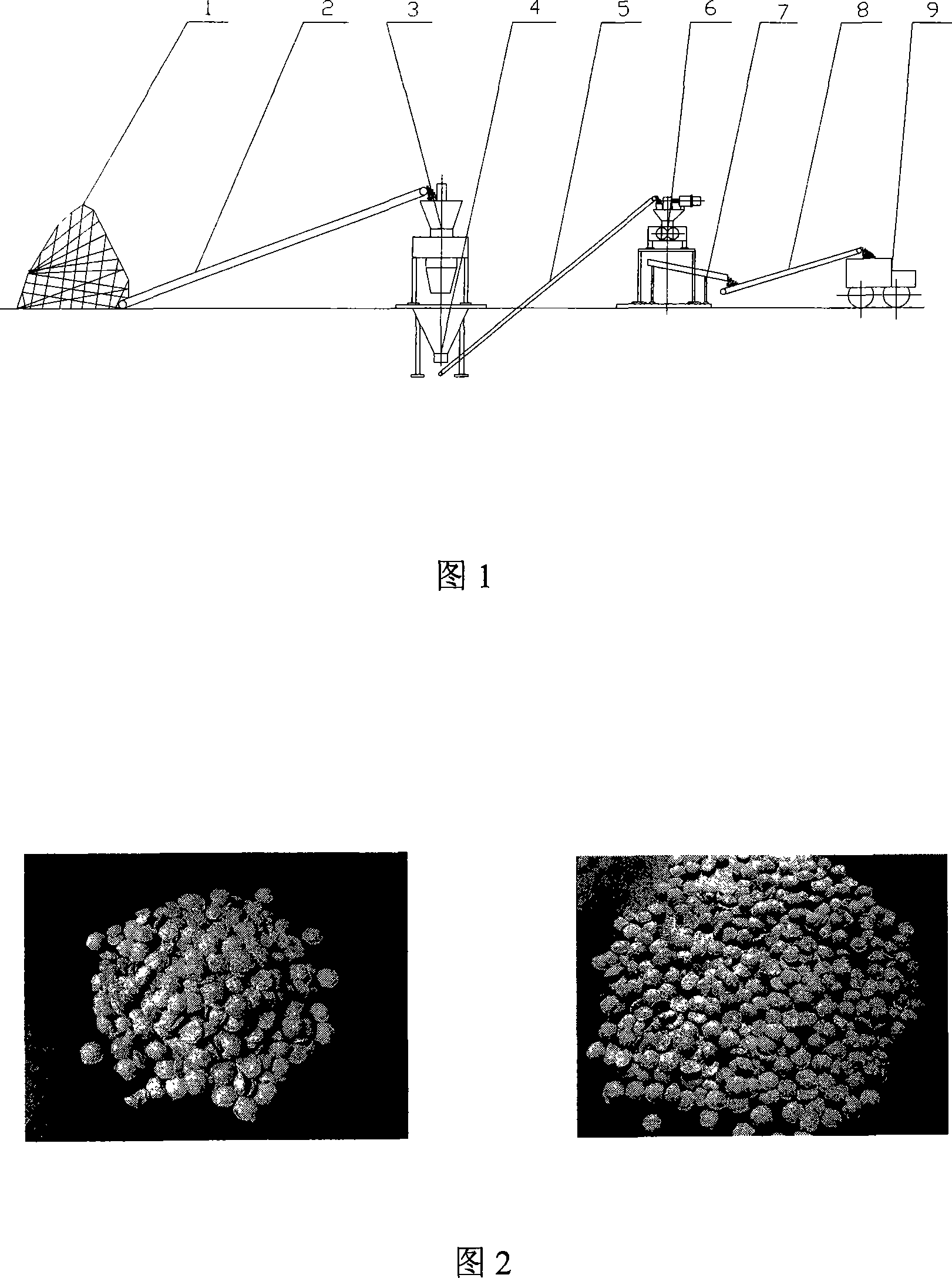

Desulfurization gypsum dry method granulation technique in power plant

A desulfurized gypsum and process technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of long production cycle and high production cost, and achieve the effect of short production cycle, easy operation, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

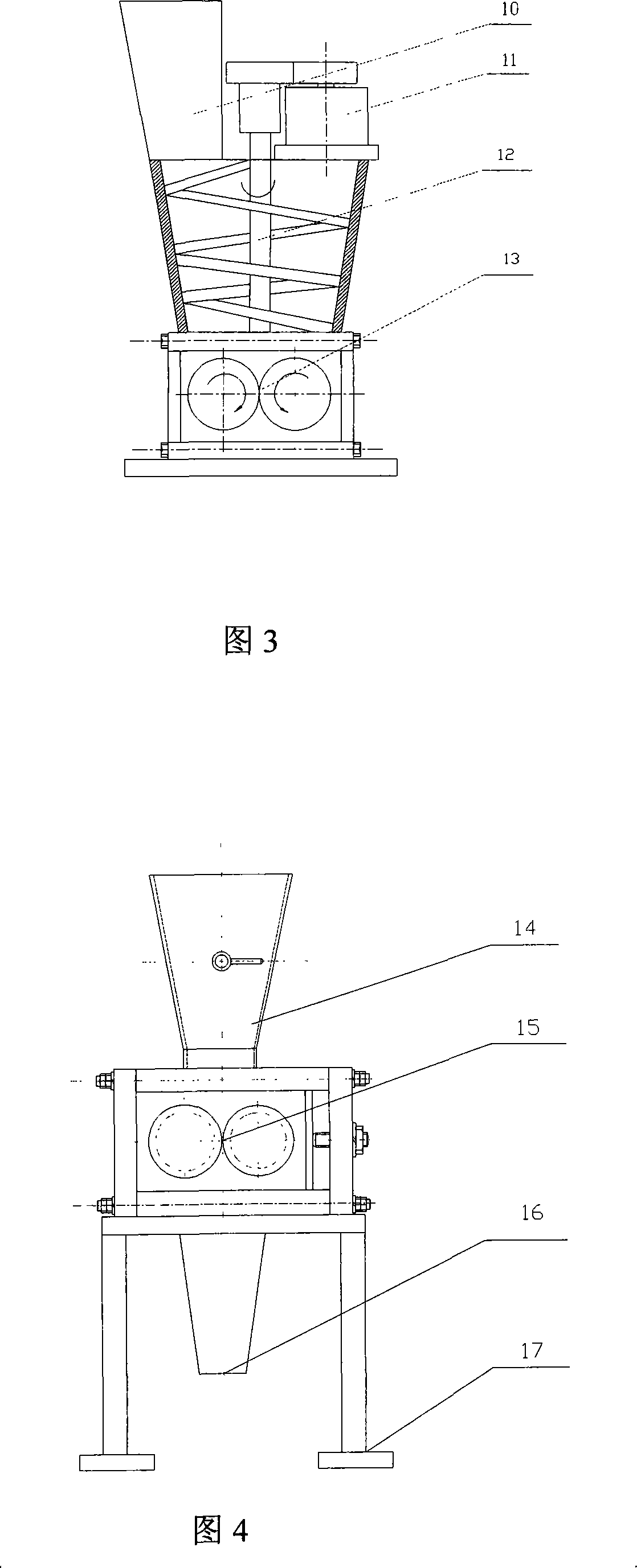

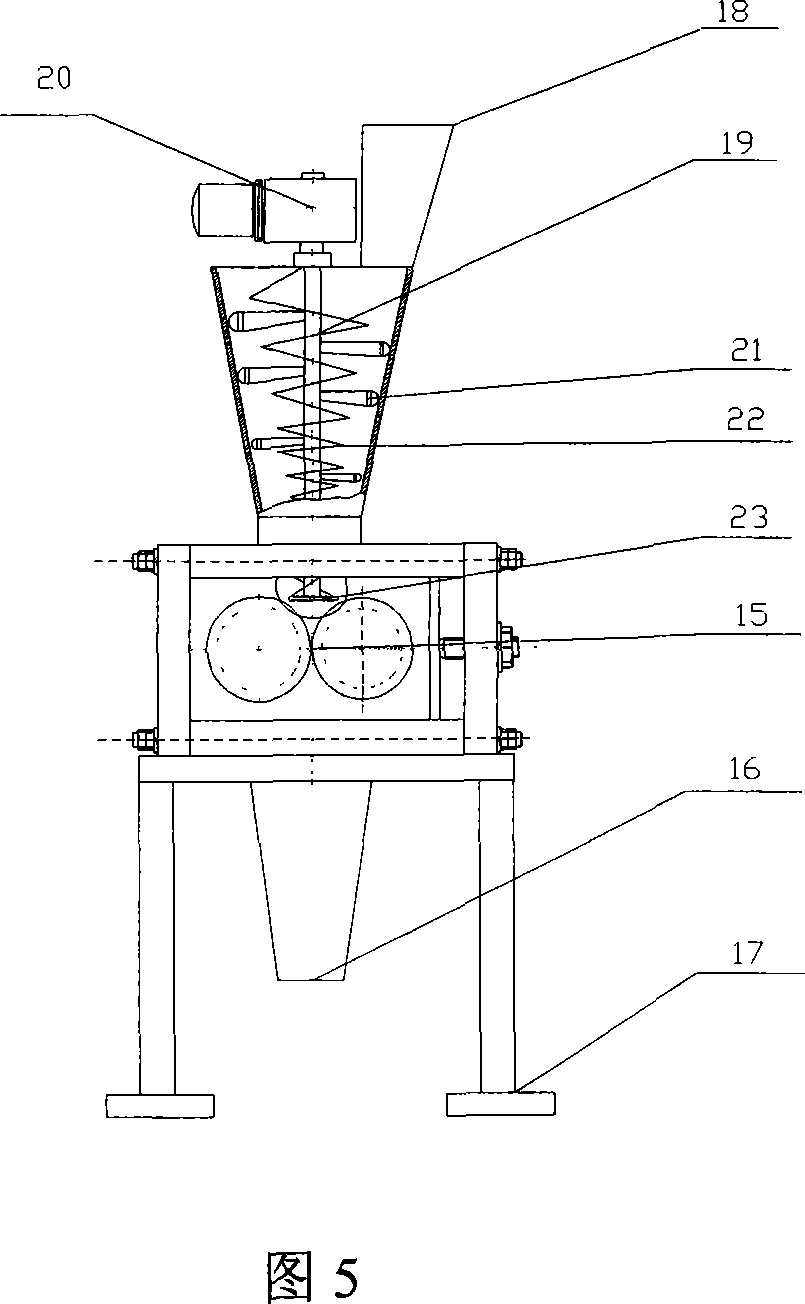

[0026] Example 1: dry granulation of desulfurized gypsum with a water content of 0% under strong pressure.

[0027]The desulfurized gypsum raw material is evenly sent to the screw mechanism of the degassing and densifying machine with a pitch of 50 mm by a belt conveyor. After the gypsum has a bulk density, it is directly sent to the smooth-surfaced pressure roller of the degassing densifier for second-stage degassing and densification. The speed of the pressure roller is 22 rpm, the diameter is 320 mm, and the width is 110 mm. The output is 2.5 tons / hour. Desulfurized gypsum after densification (its material properties are that the angle of repose is 22°, and the density is 1.1 g / cm 3 , the particle size distribution is: ≤200 mesh accounts for 4%~6%, 0.5~1.0 mm accounts for 9%~11%, 1.1~3.0 mm accounts for 64%~66%, 3.1~10.0 mm accounts for 14%~16%, ≥10.1 mm accounted for 4% to 6%) are evenly sent to the dry forced pressure granulator of B structure by the belt conveyor for g...

Embodiment 2

[0028] Example 2: dry granulation of desulfurized gypsum with a water content of 4% under strong pressure.

[0029] The desulfurized gypsum raw material is evenly sent to the screw mechanism of the degassing and densifying machine with a pitch of 80 mm by a belt conveyor, its rotating speed is 48 rpm, and the conveying output is 2.65 tons / hour. After removing air and initially increasing desulfurization After the gypsum has a bulk density, it is directly sent to the smooth-surfaced pressure roller of the degassing densifier for second-stage degassing and densification. The speed of the pressure roller is 28 rpm, the diameter is 280 mm, and the width is 118 mm. The output is 2.65 tons / hour. Desulfurized gypsum after densification (its material performance is that angle of repose is 24 °, density is 1.25 g / cm 3 , the particle size distribution is: ≤200 mesh accounts for 4%~6%, 0.5~1.0 mm accounts for 9%~11%, 1.1~3.0 mm accounts for 64%~66%, 3.1~10.0 mm accounts for 14%~16%, ≥10...

Embodiment 3

[0030] Example 3: dry granulation of desulfurized gypsum with a water content of 8% under strong pressure.

[0031] The desulfurized gypsum raw material is evenly sent to the screw mechanism of the degassing and densifying machine with a pitch of 145 mm by a belt conveyor. After the gypsum has a bulk density, it is directly sent to the smooth-surfaced pressure roller of the degassing densifier for second-stage degassing and densification. The speed of the pressure roller is 30 rpm, the diameter is 264 mm, and the width is 125 mm. The output is 2.75 tons / hour. Desulfurized gypsum after densification (its material performance is that the angle of repose is 26°, and the density is 1.37 grams / cm 3 , the particle size distribution is: ≤200 mesh accounts for 4%~6%, 0.5~1.0 mm accounts for 9%~11%, 1.1~3.0 mm accounts for 64%~66%, 3.1~10.0 mm accounts for 14%~16%, ≥10.1 mm accounted for 4% to 6%), it is evenly sent to the dry pressure granulator of structure A by the belt conveyor f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com