Functional ceramic fiber air filter element and preparation method thereof

A ceramic fiber and air filter technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of solid waste pollution, reduced adsorption efficiency, high replacement frequency, etc., achieve antibacterial negative ion concentration, increase negative ion concentration , High filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a. Add high silicon molecular sieve ZSM-5 and negative ion powder with a particle size of 10 μm into the silica sol with a concentration of 20% in a ratio of 15:1 by weight, and control the mass percentage of high silicon molecular sieve ZSM-5 and negative ion powder in the glue to be 20%, then add 0.55% sodium citrate (dispersant) and 0.2% polyether lipid defoamer by weight of the inorganic glue, stir and disperse evenly to obtain a viscous slurry,

[0029] b. Immerse 0.5mm high-purity ceramic fiber paper into the viscous slurry prepared in step a, and then obtain ceramic fiber paper with molecular sieve adsorbent and functional additives attached to it after dipping, pulling and scraping the film, heating, drying and curing process, ceramic Fiber paper density is 168kg / m 3 ,

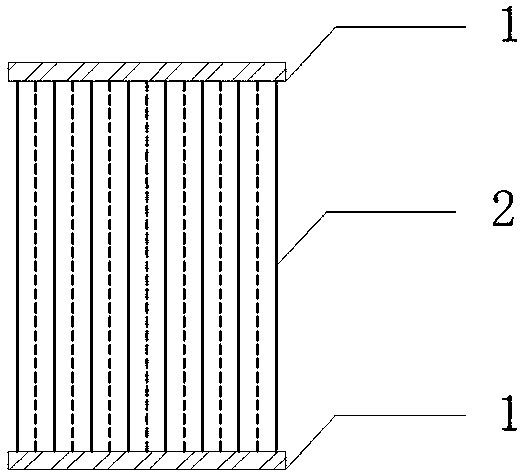

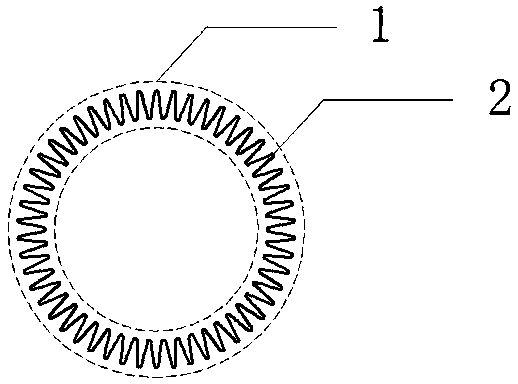

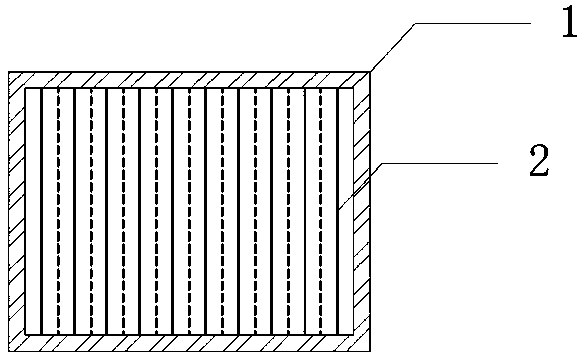

[0030] c. Use an origami machine to fold the ceramic fiber paper into a pile of paper with a height of 20mm, use a glue line machine to glue and cut the pile of paper, and form the pile of cera...

Embodiment 2

[0033]a. Add high-silicon molecular sieve ZSM-5 and negative ion powder with a particle size of 5 μm to 25% silica sol at a ratio of 25:1, and control the mass percentage of high-silicon molecular sieve ZSM-5 and negative ion powder in the glue to 30 %, add 0.9% methylcellulose (dispersant) and 0.3% polyether lipid defoamer by weight of the inorganic glue in turn, stir and disperse evenly to prepare a viscous slurry,

[0034] b. Immerse 1 mm of high-purity ceramic fiber paper into the viscous slurry prepared in step a, and then obtain ceramic fiber paper and fiber paper with molecular sieve adsorbent and functional additives attached after dipping, pulling and scraping the film, heating, drying and curing process The density is 207kg / m 3 ,

[0035] c. Use an origami machine to fold the ceramic fiber paper into a pile of paper with a height of 15mm, use a glue line machine to glue and cut the pile of paper, and form the pile of ceramic fiber paper after cutting into a drum sha...

Embodiment 3

[0038] a. Add high-silicon Y-type molecular sieve with a particle size of 10 μm and silver ion antibacterial agent to 30% aluminum sol at a ratio of 50:1 to control the quality of high-silicon Y-type molecular sieve and silver ion antibacterial agent powder in the glue The percentage is 30%, add 0.7% polyvinyl alcohol (dispersant) and 0.1% organic silicon defoamer in sequence by the weight of the inorganic glue, stir and disperse evenly to make a viscous slurry,

[0039] b. Immerse 0.5mm high-purity ceramic fiber paper into the viscous slurry prepared in step a, and then obtain ceramic fiber paper with molecular sieve adsorbent and functional additives attached to it after dipping, pulling and scraping the film, heating, drying and curing processes, and the fiber Paper density is 225kg / m 3 ,

[0040] c. Use an origami machine to fold the ceramic fiber paper into a pile of paper with a height of 20mm, use a glue line machine to glue and cut the pile of paper, and form the pile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com