Patents

Literature

104results about How to "Improved post-processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

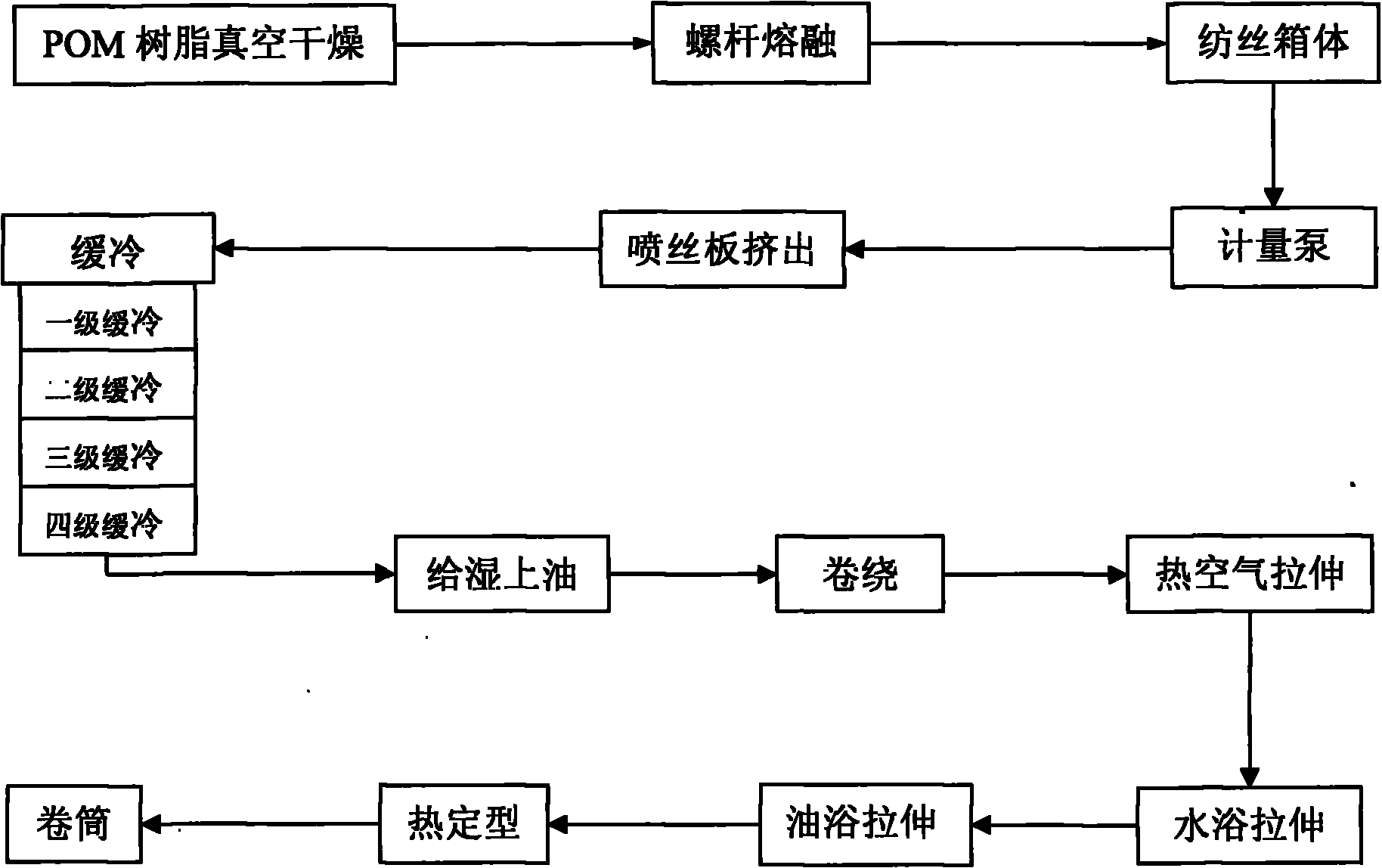

Novel preparation technology of polyoxymethylene fiber

InactiveCN101792938AStable structureReduce swellingArtificial filament heat treatmentStretch-spinning methodsFiberSolvent

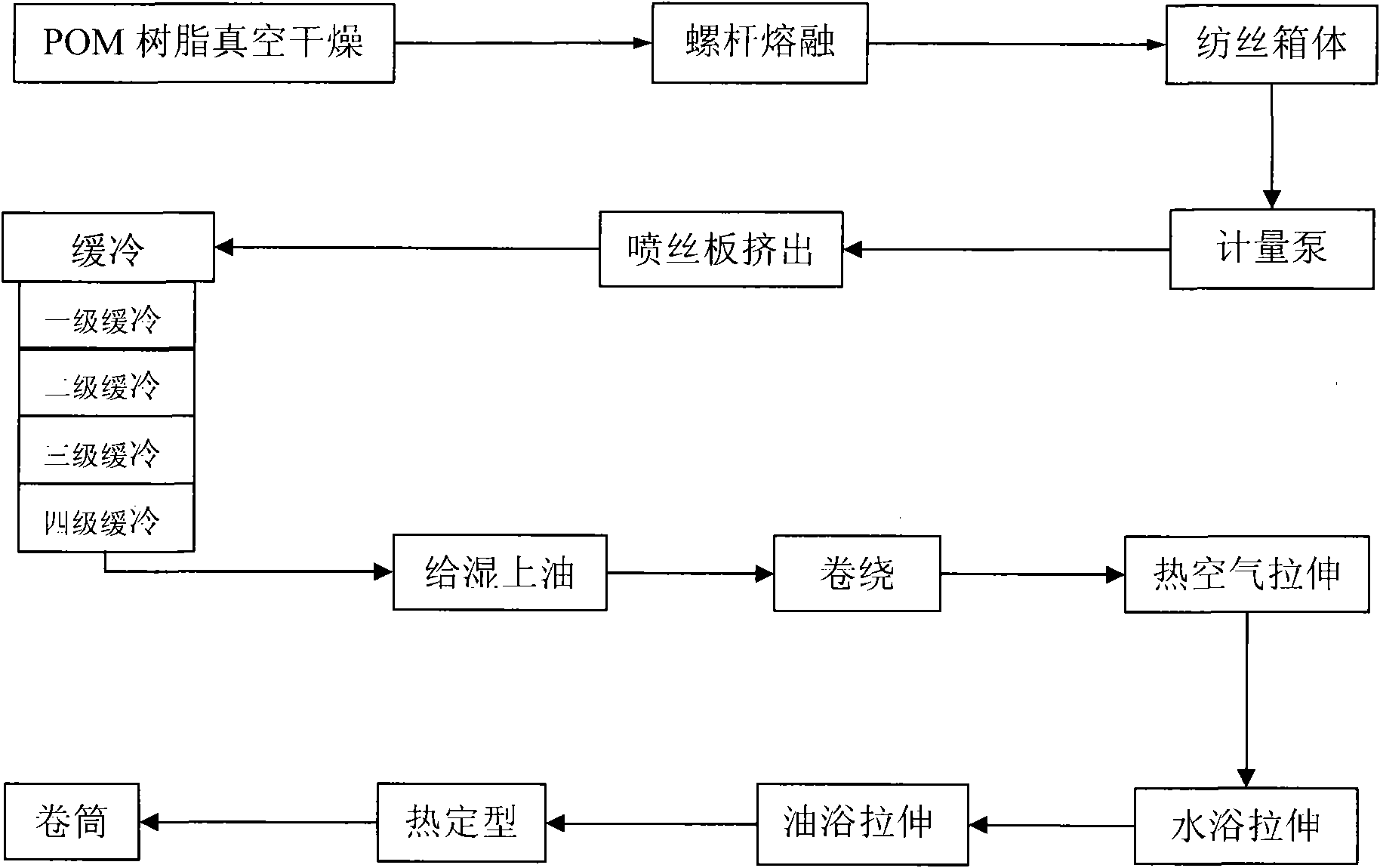

The invention relates to a novel preparation technology of polyoxymethylene fiber, in particular to the novel preparation technology of the polyoxymethylene fiber via multi-stage slow cooling and three-stage drawing with different media, which comprises the following steps: vacuum-drying polyoxymethylene granular materials, heating and melting via a screw extruder, melting and extruding by a spinneret, leading small melt flow to pass through the multi-stage slow cooling, carrying out high-speed traction, passing through a moistening and oiling cluster, winding, then obtaining as-spun fiber, carrying out hot air drawing and two times of drawing with different types of solvent, then carrying out hot molding and finally preparing the polyoxymethylene fiber. The novel prepration technology can solve the problems of matching between the multiple sections of atmosphere and temperature and the spinning process control and the control of the drawing with multiple media and make up for the deficiencies that the single atmosphere and temperature and the single medium drawing of the prior art lead the structure to be difficult to stable and uniform.

Owner:DONGHUA UNIV +1

Carbon fiber emulsion sizing agent and preparation method and application thereof

The invention discloses a carbon fiber emulsion sizing agent. The sizing agent comprises a main sizing agent, an auxiliary agent, an organic solvent and de-ionized water, wherein the auxiliary agent accounts for 5 to 15 percent of the mass of the main sizing agent; the mass ratio of the organic solvent to the main sizing agent is 20-50 to 50-80; and the mass ratio of the de-ionized water to the main sizing agent is 50-90 to 10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent has low cost and environment friendliness and can be applied to different types of resin matrixes by varying the ratio of the components in the sizing agent. The preparation method is simple to operate and easy to implement. The sizing agent can improve the processability of the carbon fiber and the mechanical property of carbon fiber-enhanced resin-based composite materials when used in carbon fiber.

Owner:UNIV OF JINAN

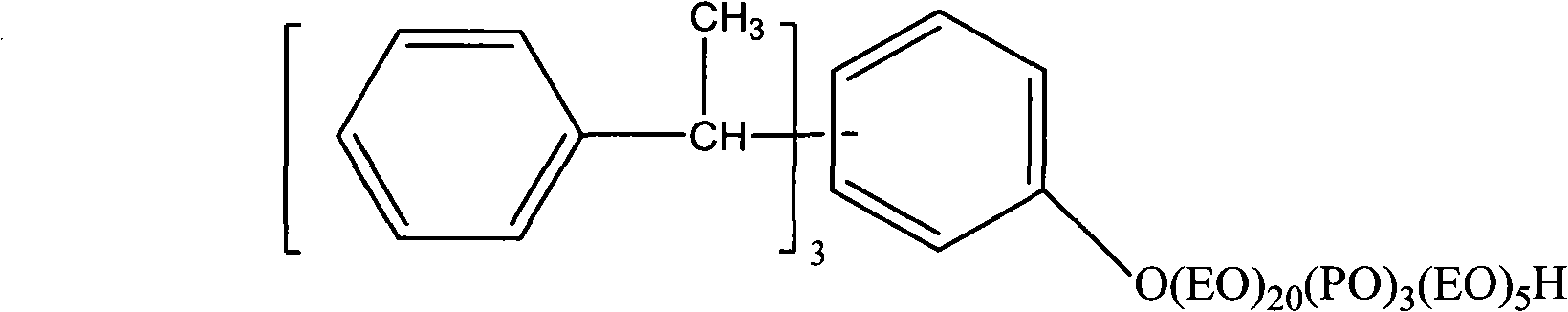

Carbon fiber water-soluble epoxy resin sizing agent

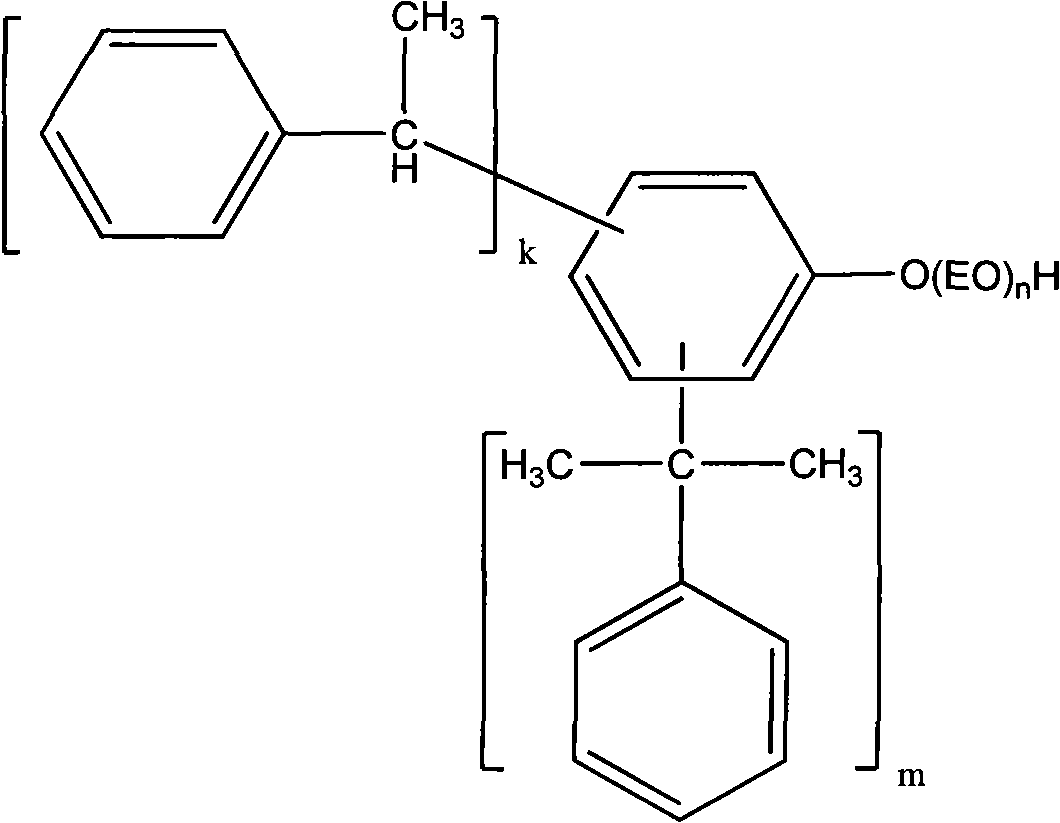

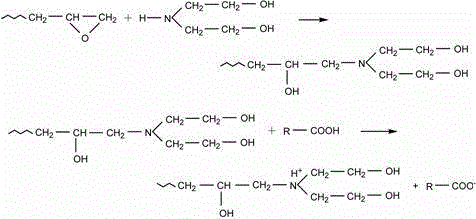

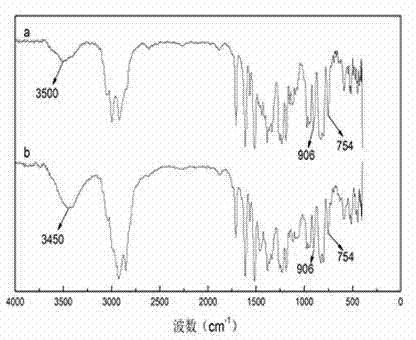

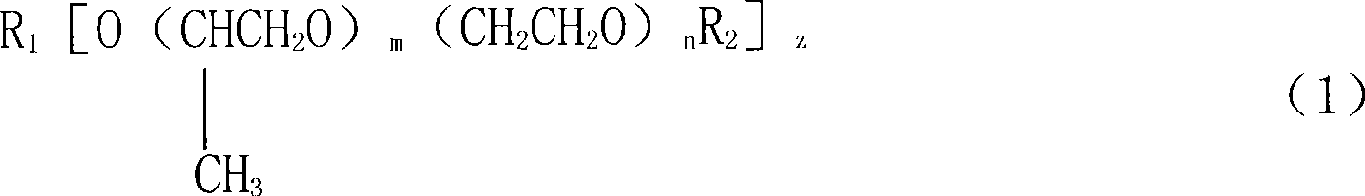

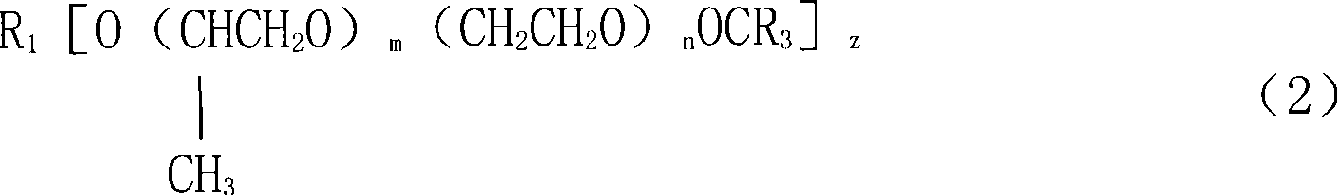

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The sizing agent comprises main slurry and deionized water as main components, wherein the mass ratio of the main slurry to the deionized water is (50-80):(20-50); and the main slurry consists of modified phenol-formaldehyde epoxy resin and allyl polyoxylethylene ether (AEPH), and the mass ratio of the modified phenol-formaldehyde epoxy resin to AEPH is (60-90):(10-40). The preparation method of the sizing agent comprises the following steps: firstly reacting phenol-formaldehyde epoxy resin with diethanolamine to obtain water-soluble phenol-formaldehyde epoxy resin; and then mixing the water-soluble resin with AEPH in proportion, and performing dilution to reach a certain concentration by using the deionized water to obtain the sizing agent. The sizing agent disclosed by the invention is good in stability and low in cost, cannot cause environmental pollution, and is simple in preparation method; good post-processing performance of carbon fibers can be provided by adding flexible molecular AEPH; experiments show that after the carbon fibers are coated with a proper amount of the sizing agent, the post-processing performance can be significantly improved; and the performance of a carbon fiber epoxy resin composite material can be improved.

Owner:UNIV OF JINAN

Temperature-resistant type emulsion sizing agent for carbon fiber, as well as preparation method and application of sizing agent

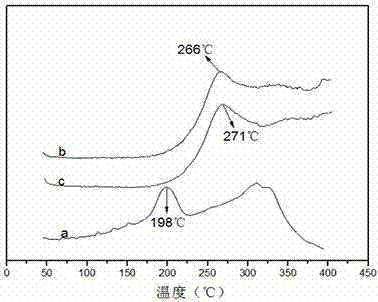

InactiveCN104294602AHigh glass transition temperatureImprove temperature resistanceCarbon fibresEmulsionMass ratio

The invention discloses a temperature-resistant type emulsion sizing agent for a carbon fiber. The temperature-resistant type emulsion sizing agent comprises the following materials: main size, an emulsifying agent, an additive and deionized water, wherein the main size is glycidyl amine type epoxy resin modified by dodecanamine, and in modification, the mass ratio of dodecanamine to the epoxy resin is (10-40) to (60-90); the mass of the emulsifying agent is 5-15% of the mass of the main size; the additive comprises a diluting agent and a penetrating agent, the mass of the diluting agent is 0-100% of the mass of the main size, and the mass of the penetrating agent is 1-5% of the mass of the main size; the mass ratio of the deionized water to the main size is (50-90) to (10-50). The invention also discloses a preparation method and application of the sizing agent. The sizing agent disclosed by the invention is high in stability and does not cause pollution to the environment, and the preparation method is simple; in the presence of a flexible molecule, namely dodecanamine, the carbon fiber has relatively high operability; proved by experiments, after the carbon fiber is treated by the sizing agent, the post processability is obviously improved; and the interface temperature resistance and the interlaminar shear strength (ILSS) of the carbon-fiber-enhanced epoxy resin composite material are also obviously improved.

Owner:UNIV OF JINAN

Spinning finish and preparation method thereof

ActiveCN103147168AIncrease molecular polarityLow smoke productionSynthetic polymer filament chemical after-treatmentFiberVegetable oil

The invention relates to a spinning finish and a preparation method thereof. The spinning finish is prepared from (a) 50-80 wt% of refined vegetable oil, (b) 20-40 wt% of polyglycerol fatty acid ester, (c) 5-20 wt% of antistatic agent and (d) 0.1-1 wt% of coking retarder. The preparation method comprises the following steps: accurately measuring the (a) refined vegetable oil, (b) polyglycerol fatty acid ester, (c) Gemini antistatic agent and (d) coking retarder according to the weight percents, sequentially adding the components while stirring, heating to 70-80 DEG C until the components are completely dissolved, continuing keeping the temperature and stirring for 15 minutes, cooling to 50 DEG C below within 1 hour, filtering, and packaging to obtain the required spinning finish. The spinning finish provided by the invention has excellent heat resistance, and is environment-friendly since the vegetable oil is used as the main component. In the spinning technique, the spinning finish has the advantages of low smoke, easily cleaned coking substances, and low waste fiber rate; the spinning finish improves the working environment of the spinning workshop, and enhances the work efficiency; the raw materials are accessible and cheap and have favorable biodegradability; and the spinning finish is free of PEG (polyethylene glycol) and APEO (alkylphenol ethoxylate), and thus, is environment-friendly.

Owner:安徽灵达高新材料有限公司

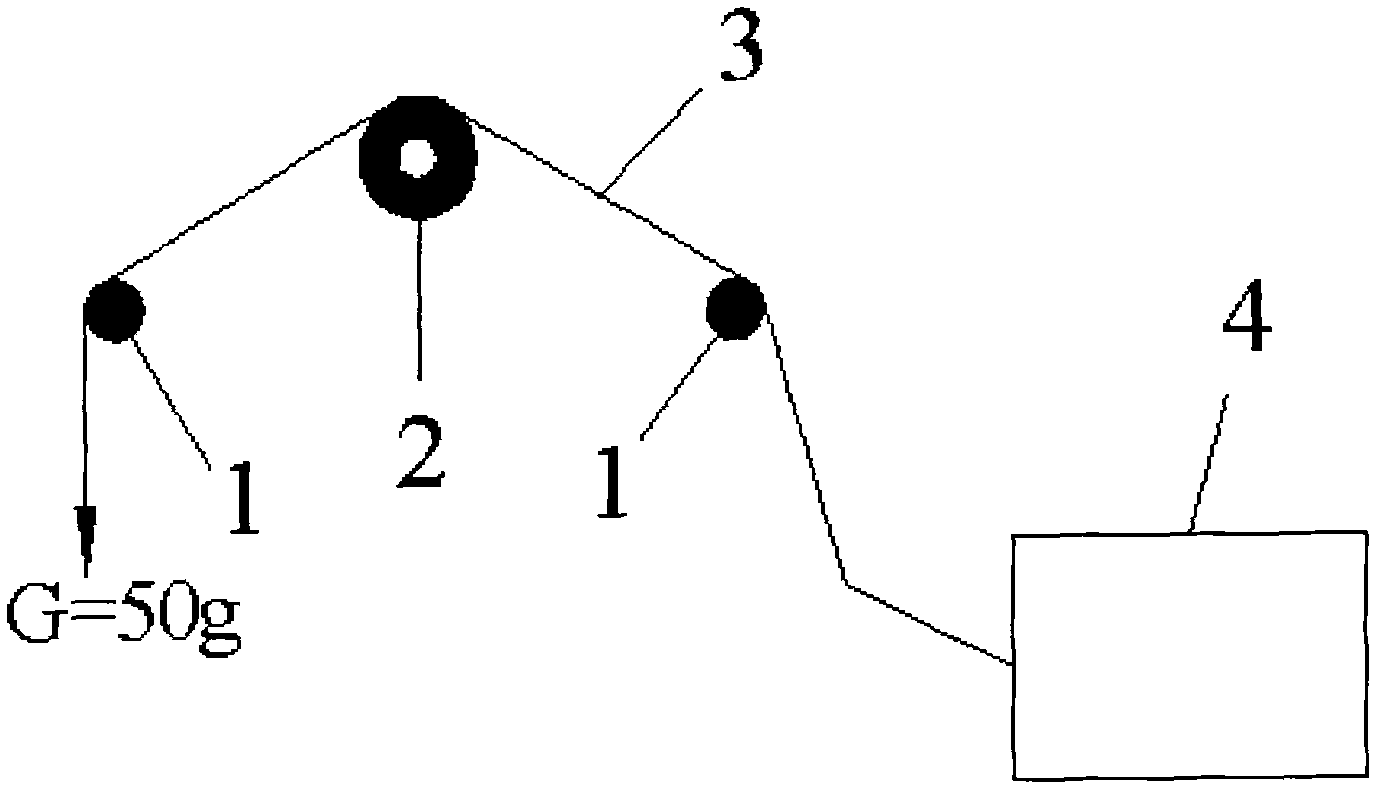

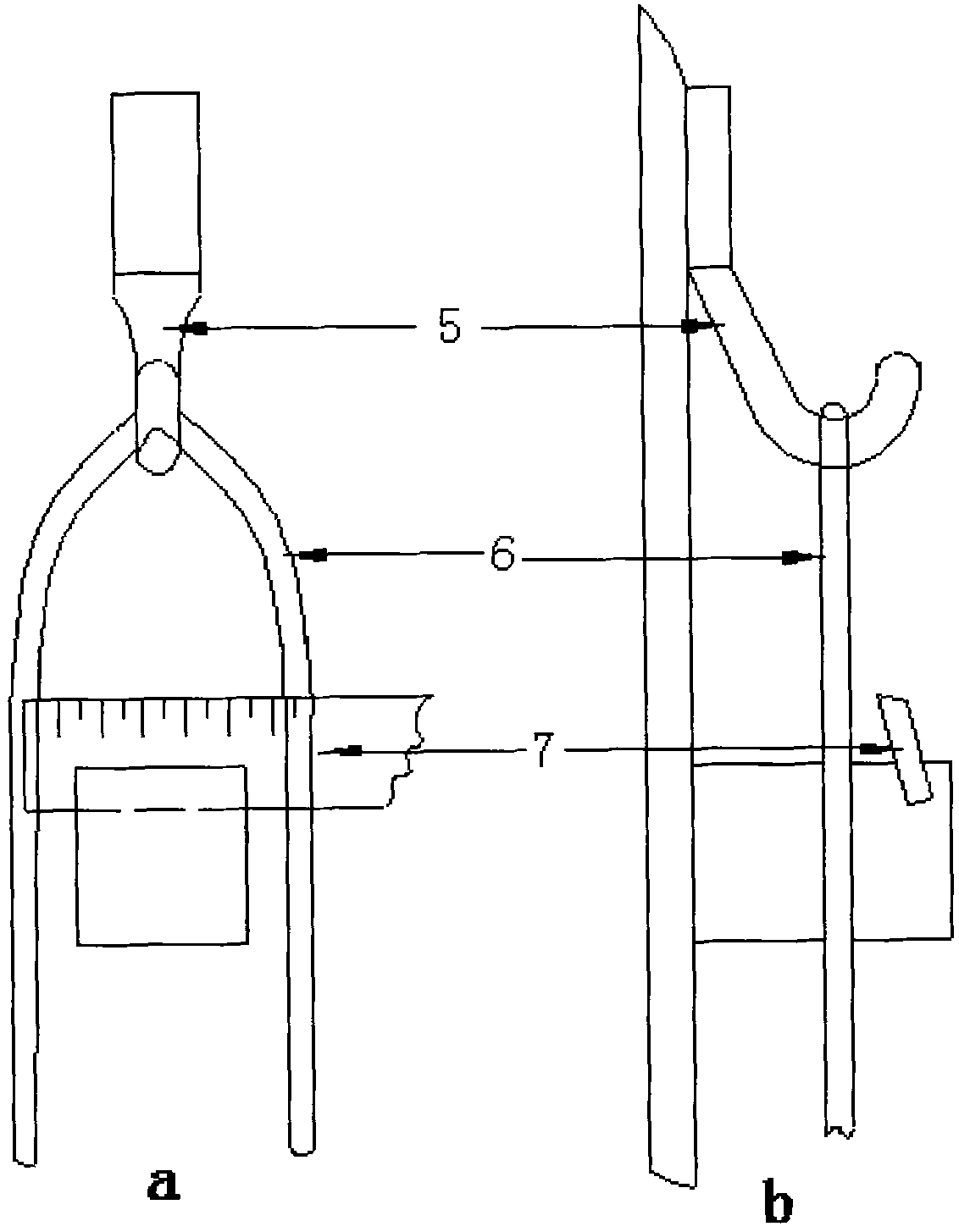

Production method of fine-denier hollow nylon 6FDY filament

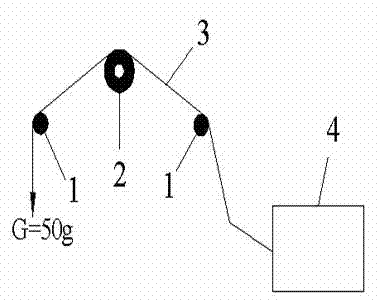

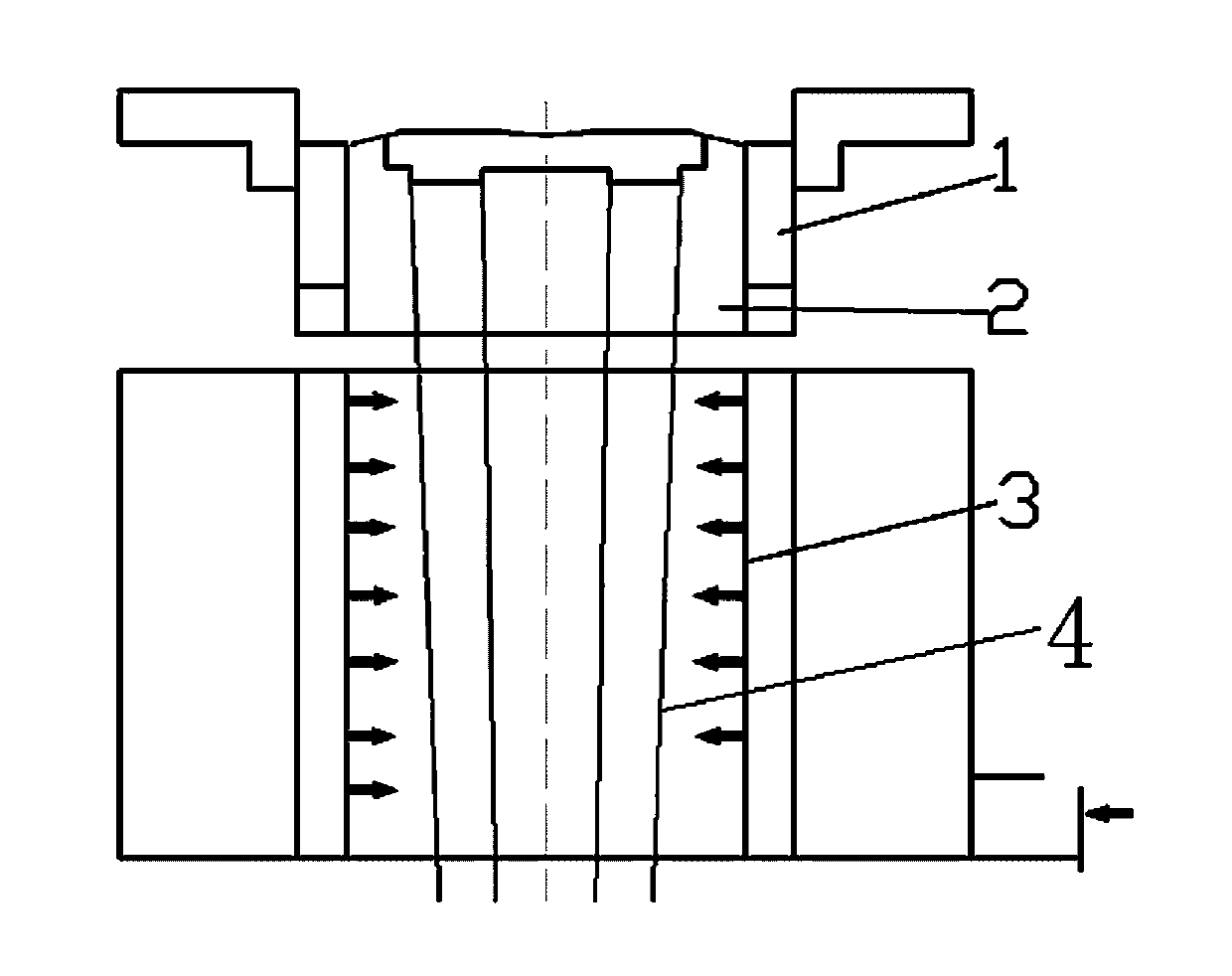

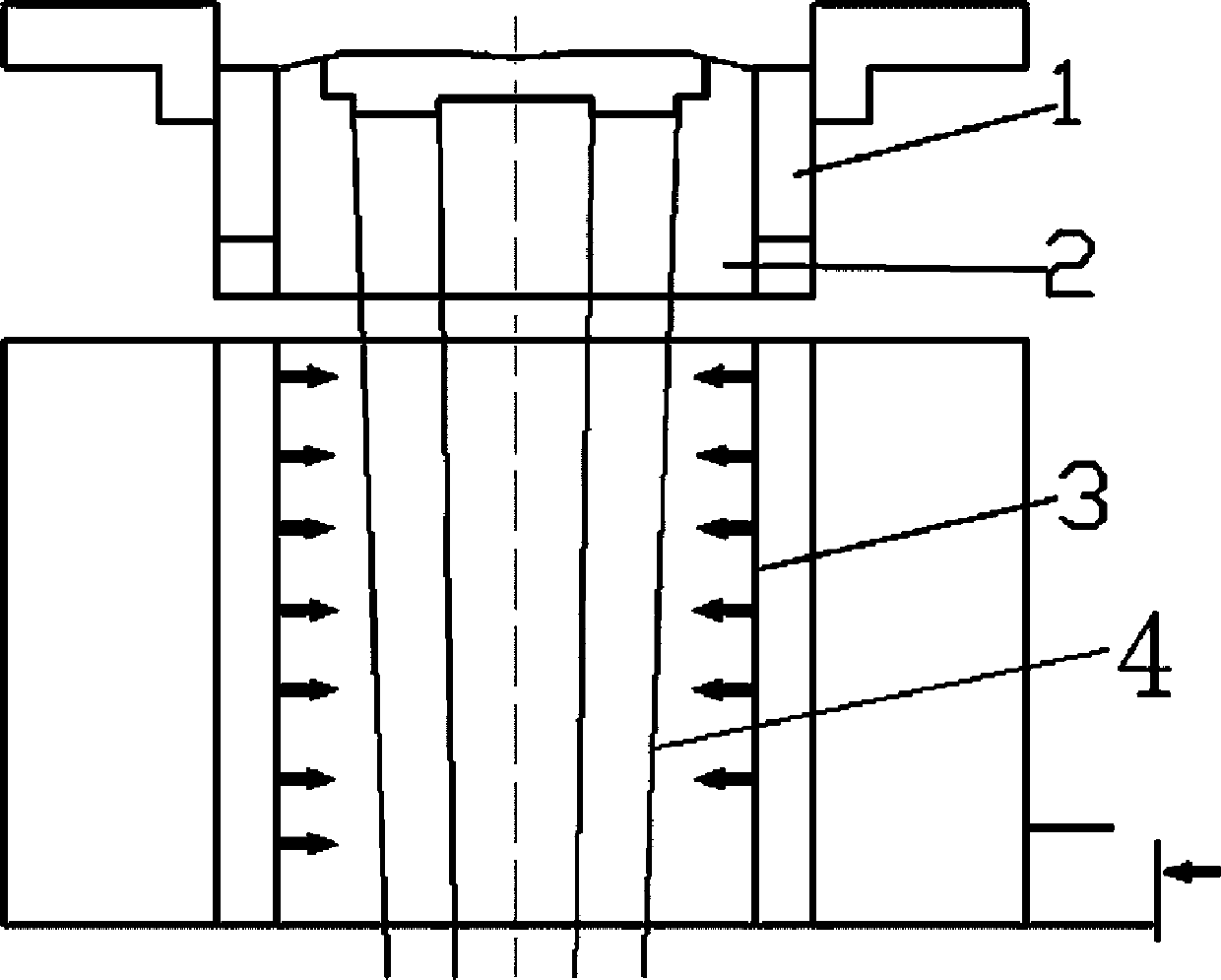

InactiveCN101768789ARealize fine denier spinningEnhanced melt tensile strengthHollow filament manufactureMonocomponent polyamides artificial filamentNylon materialFree zone

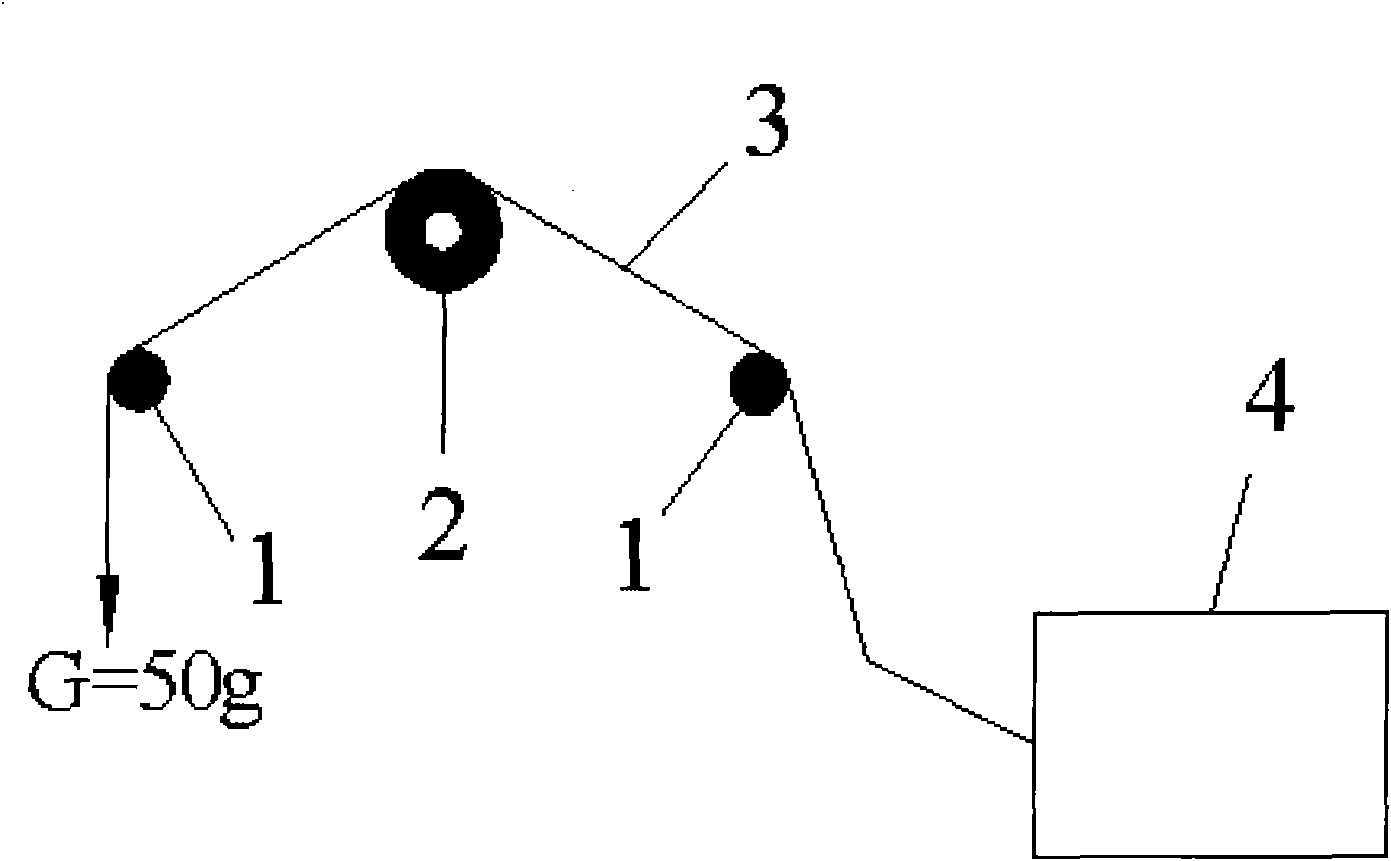

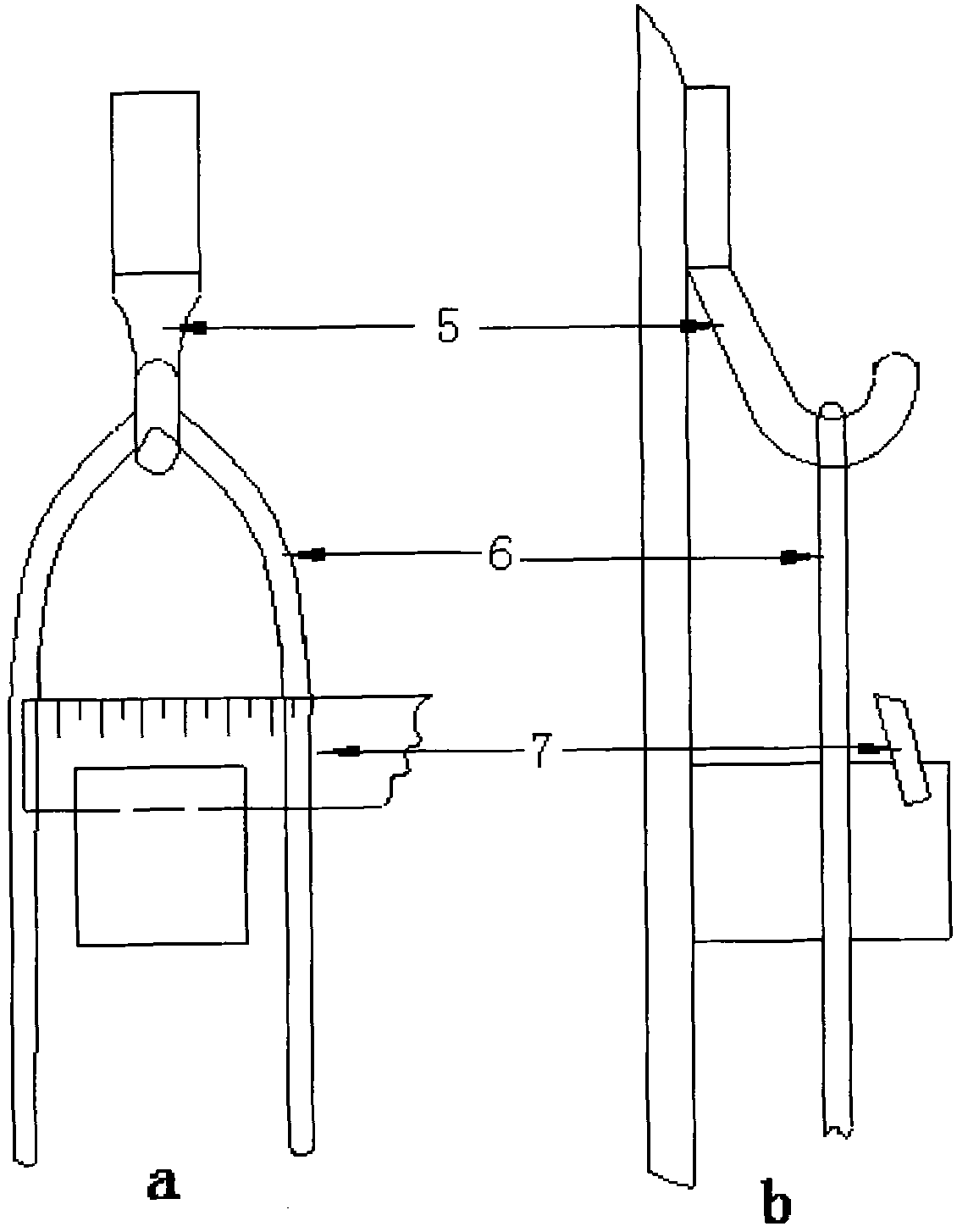

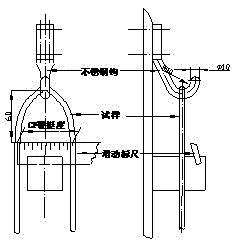

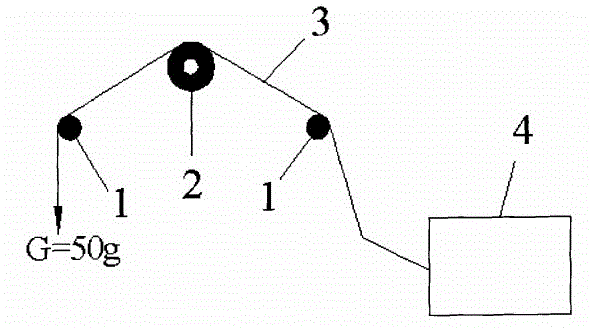

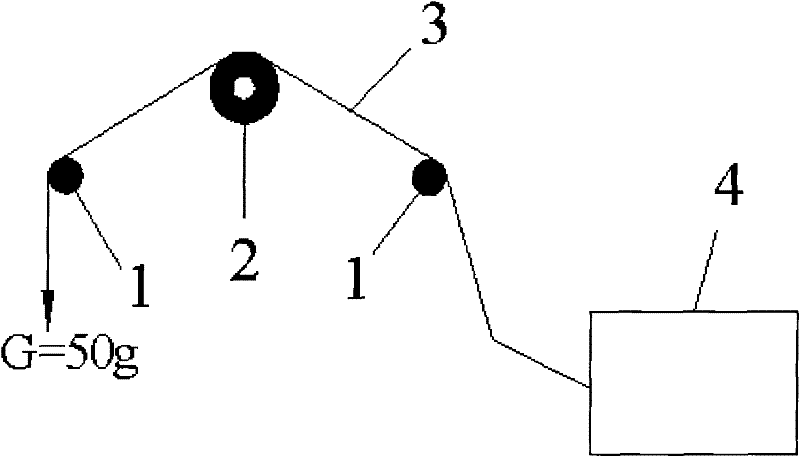

The invention relates to a production method of a fine-denier hollow nylon 6FDY filament. The technical problem to be solved is as follows: the denier of the produced nylon fiber is lower than 1.0dtex. The weight ratio of the nylon chips with specific viscosity requirements and fine-denier nylon master batch adopted by the invention is 1:20 50. in the process route, 1) a spinning pack keeps steady pressure: 12 - 18MPa; 2) metal sand filter of 40 - 100 meshes is adopted; 3) the bore diameter of the hollow spinneret plate is 0.15 - 0.30mm, the aspect ratio is 2 - 4; 4) a slow-cooling device (1) is arranged at the back of the spinning pack, the slow-cooling device is a ring-shaped heating cap with temperature of 160 - 180 degrees C., and a wind-free zone (2) with height of 20-40 cm is formed between the slow-cooling device (1) and a ring-shaped air-blowing device (3); 5) the location of the cluster point is uplifted; 6) the winding speed of spinning is 3000-5000m / min.

Owner:HANGZHOU NORMAL UNIVERSITY

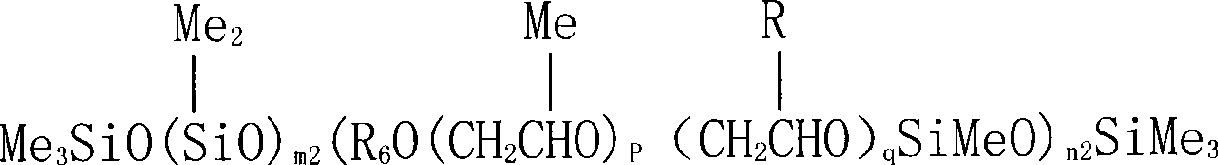

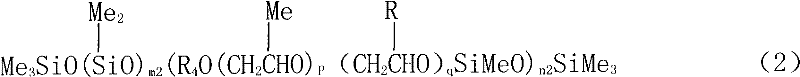

Short-fiber oil agent for aromatic polyamide fiber

The invention discloses a short-fiber oil agent for aromatic polyamide fiber, which is prepared from 3 to 40 weight percent of polyol fatty acid ester, 5 to 70 weight percent of polyoxyethylene polyol fatty acid ester, 5 to 40 weight percent of fatty alcohol ethylene oxide-propylene oxide random copolyether or polyether ester, 1 to 40 weight percent of fatty alcohol polyethenoxy ether organic phosphate salt, 1 to 30 weight percent of fatty alcohol polyethenoxy ether sulfuric acid ester salt and 0.1 to 10 weight percent of polyether modified silicon oil. The oil agent can solve the defects of the poor main performance, i.e. poor electrostatic resistance, poor heat resistance, poor saturation, and the like of the prior oil agent, aims to provide an aramid short-fiber oil agent which has excellent electrostatic resistance, smoothness, softness and dyeing uniformity, enables the aramid short fiber to have excellent post processing performance, and the like.

Owner:CHINA PETROCHEMICAL CORP +1

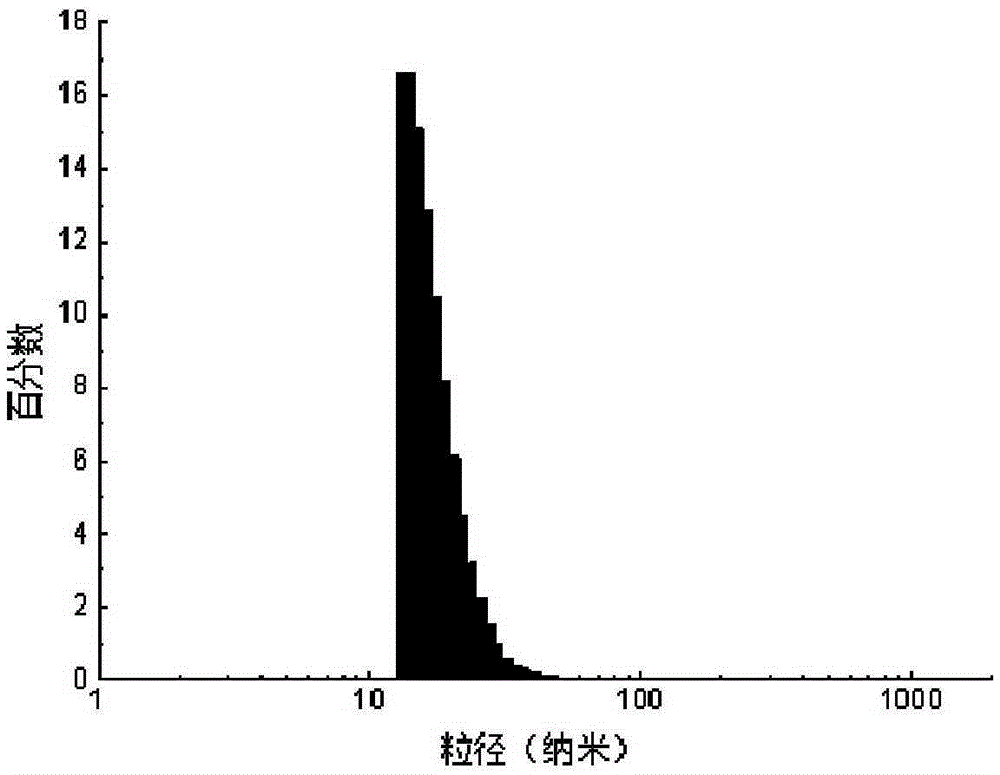

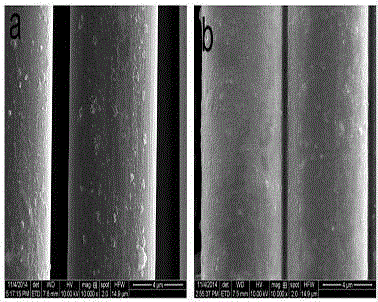

Water-borne sizing agent for carbon fiber and preparation method and sizing method thereof

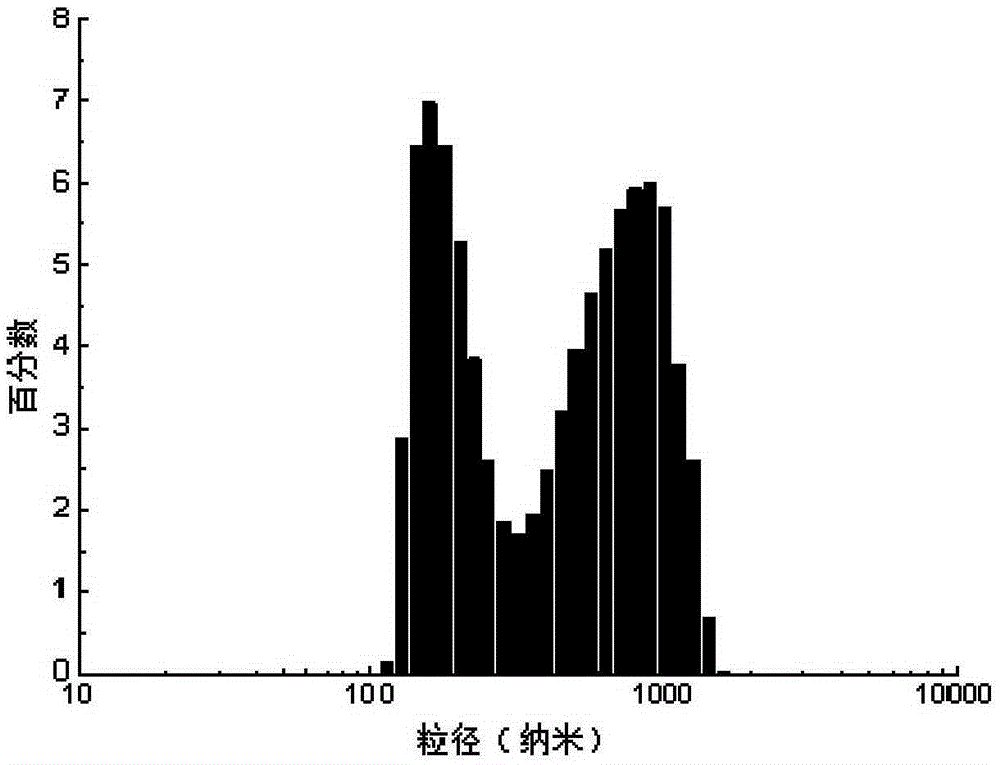

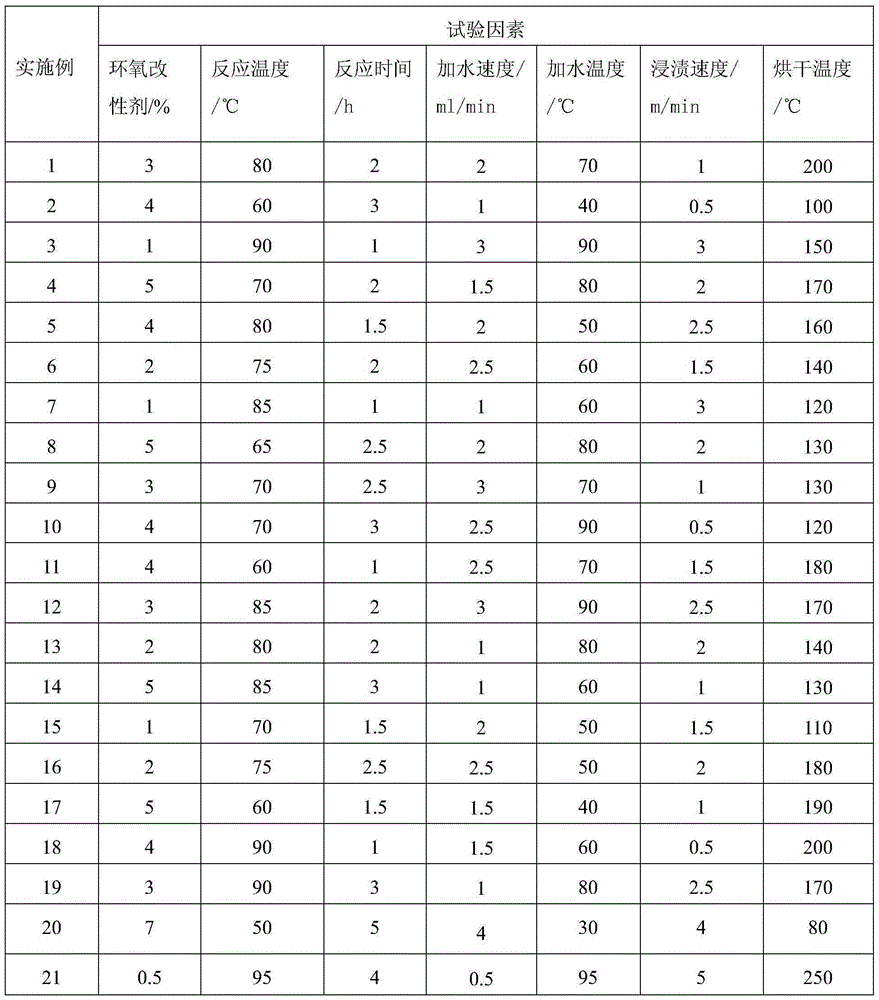

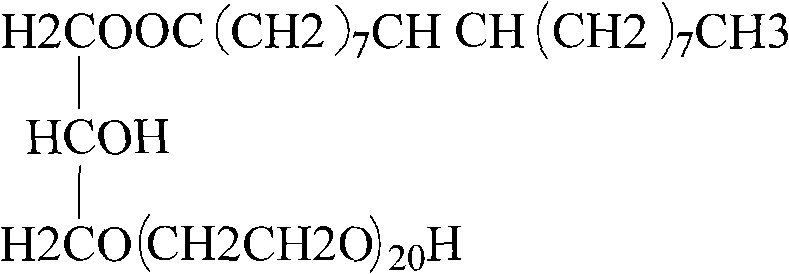

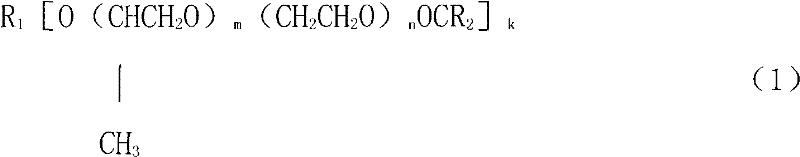

InactiveCN105332285ASmall particle sizeNarrow particle size distributionCarbon fibresEpoxyAdhesion force

The invention discloses a water-borne sizing agent for carbon fiber. The water-borne sizing agent is prepared from 5-10% of epoxy resin modifier, 10-25% of epoxy resin, 65-80% of deionized water and 1-5% of auxiliary. The invention further provides a preparation method of the water-borne sizing agent for the carbon fiber. According to the preparation method, a certain amount of epoxy resin and modifier are taken and subjected to reaction for 1-3 hours to prepare anionic modified epoxy resin, and then a certain amount of deionized water is dripped and other auxiliaries are added to prepare the anionic water-borne epoxy sizing agent for the carbon fiber. The invention further provides a sizing method of the water-borne sizing agent for the carbon fiber. According to the epoxy carbon fiber sizing agent, the emulsion particle diameter is small, particle diameter distribution is narrow, and stability is high; through strict control over reaction conditions, when the carbon fiber subjected to sizing is used for preparing a PA6 (nylon 6) composite material, the adhesion force at the interface between the carbon fiber and resin is enhanced, wear resistance is improved, and tensile strength, bending strength and other properties are greatly improved.

Owner:GUANGDONG UNIV OF TECH

Method of producing lighting terylene short fiber

InactiveCN101289769AImprove uniformityReduce the number of times of spinning and trimmingSpinnerette packsFilament/thread formingPolyesterNonwoven fabric

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

Polyester staple fiber double-component assembled oil solution and preparation method

InactiveCN101307564AHigh strengthImprove smoothnessFibre typesSynthetic polymer filament chemical after-treatmentFiberPolyester

The invention discloses a polyester staple fiber two-component composite oil agent and a method for preparing the same. The oil agent is formed by combining a smoothing oil agent No. 4 and an antistatic oil agent No. 2. The components by weight percentage of the smoothing oil agent No. 4 are: 10-20 percent of smoothing agent, 20-25 percent of emulsifier, 1-3 percent of penetrating agent and the balance being water. The components by weight percentage of the antistatic oil agent No. 2 are 24-27 percent of natural fatty alcohol, 6.0-6.5 percent of phosphorus pentoxide, 8-10 percent of potassium hydroxide and the balance being water. The preparation method comprises the following steps of preparing the smoothing oil agent No. 4 in a reaction kettle and preparing the antistatic oil agent No. 2 in an esterification reactor and a neutralization reactor. The oil agent has the advantages of low production cost, good stability, high oil film strength, good gliding property and excellently antistatic property and bundle collection property.

Owner:张金惠

Filament oil agent for poly-p-phenylene telephthalamide

The invention discloses a filament oil agent for poly-p-phenylene telephthalamide, aiming to solve the problems, such as poor heat resistance, smoothness, adaptability and the like of the oil agent in the prior art. The filament oil agent for the poly-p-phenylene telephthalamide, provided by the invention, comprises the following components: (a) 3-60wt% polyol fatty acid ester, (b) 2-40wt% polyoxyethylene polyol fatty acid ester, (c) 5-40wt% fatty alcohol ethylene oxide-propylene oxide polyether fatty acid ester, (d) 1-20wt% polyoxyethylene alkyl phosphonate, (e) 5-30wt% long-chain fatty alcohol and fatty acid ester, (f) 1-20wt% adhesion property improver and (g) 0.1-5wt% polyether modified silicone oil. The oil agent has the advantages of good smoothness, heat resistance, antistatic property, dyeing uniformity and post processing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

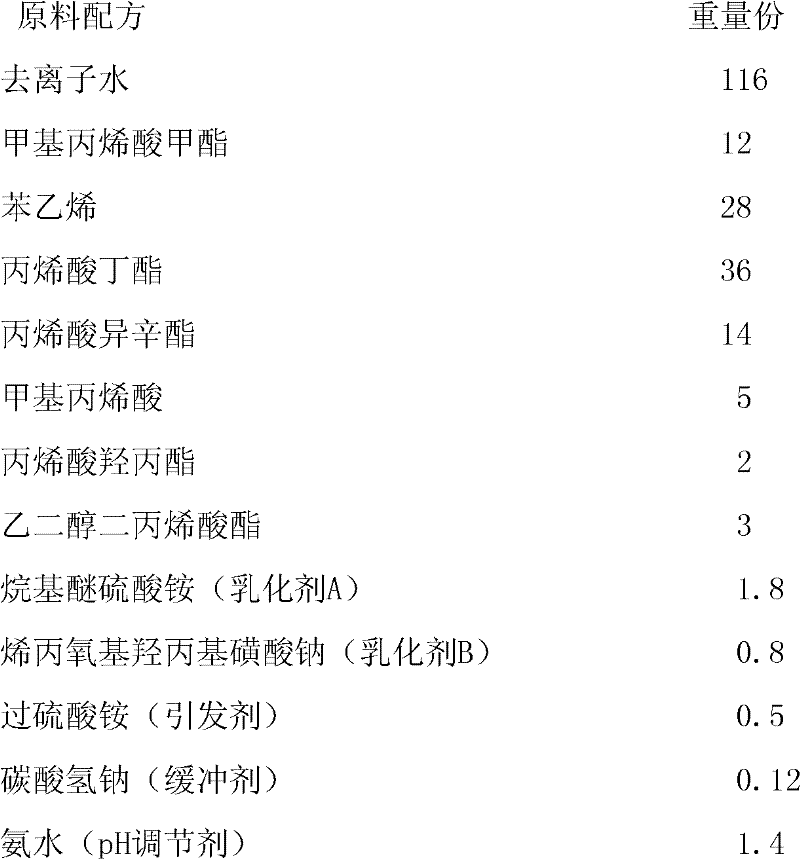

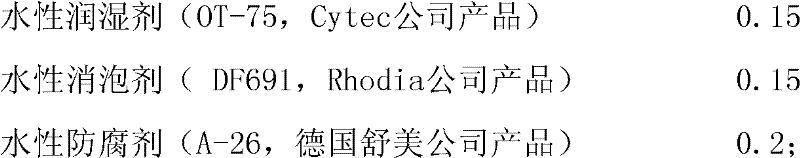

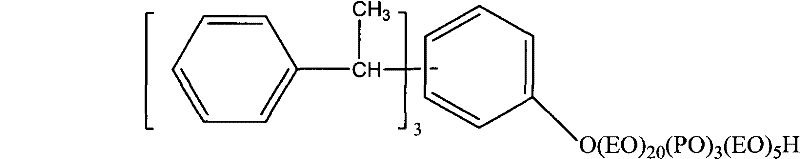

Aqueous laminating adhesive for gold and silver cards and preparation method thereof

InactiveCN102229789AImprove initial tack performanceHigh bonding strengthEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

Belonging to the field of aqueous binder preparation, the invention discloses an aqueous laminating adhesive for gold and silver cards and a preparation method thereof. With a solid content of 45-55%, the laminating adhesive is an aqueous laminating adhesive employing monomers, an emulsifier, an initiator, a buffering agent, a pH conditioning agent, aqueous auxiliary agents and deionized water asthe raw materials, which undergo the steps of pre-emulsification, seed reaction, polymerization and complex formulation. Wherein, the monomers include hard monomers, soft monomers and functional monomers containing -COOH and -OH groups; the hard monomers consist of methyl methacrylate and styrene; the soft monomers consist of butyl acrylate monomer and enthyl hexyl acrylate; the functional monomers containing -COOH and -OH groups are composed of any of methacrylic acid and acrylic acid, any of hydroxyethyl acrylate and hydroxypropyl acrylate, and ethylene glycol diacrylate; the emulsifier is composed of alkyl ether ammonium sulfate and KD AHPS with a ratio of 1:0.4-0.8 by weight.

Owner:BEIJING COMENS YANSHAN TECH

Preparation method for resin/ cement composite light weight board

The invention discloses a preparation method for a resin / cement composite light weight board. The resin / cement composite light weight board is processed and prepared by adopting compound resin, a water-based curing agent, alkali-proof glass staple fibers, a foaming agent, coal ash, calcium hydroxide powder, low-alkaline sulphate aluminium cement, a chemical additive and water in accordance with certain weight proportion. The chemical additive is prepared by adopting the following raw materials in accordance with certain weight proportion: carboxy methyl starch, polyacrylic acid, Alpha-cellulose, lignose, boric acid, calcium sulfonate and calcium chloride. Compared with traditional boards, the resin / cement composite forming board prepared by the preparation method has the advantages that the intensity and toughness are high, the hanging force is strong, the durability is good and the like; moreover, the resin / cement composite light weight board has the characteristics that the heat insulation, sound-proof and damp-proof performances, fire resistance, high durability, light weight, shock resistance are achieved, the manufacture process is simple, the construction is convenient and the like, and the resin / cement composite light weight board is an ideal environment-friendly wall body material.

Owner:万卓(武汉)新材料有限公司

Carbon fiber emulsion sizing agent and preparation method and application thereof

Owner:UNIV OF JINAN

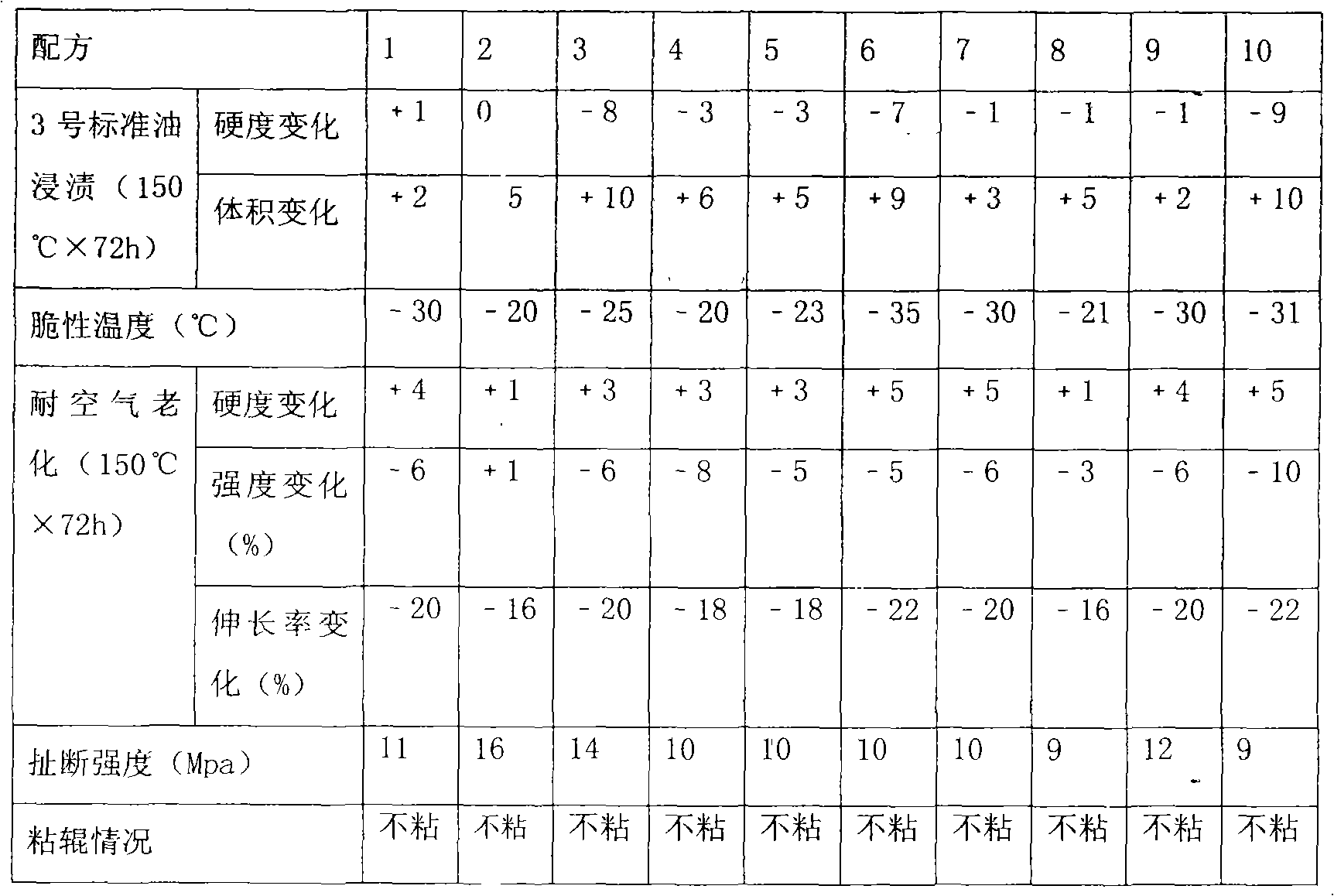

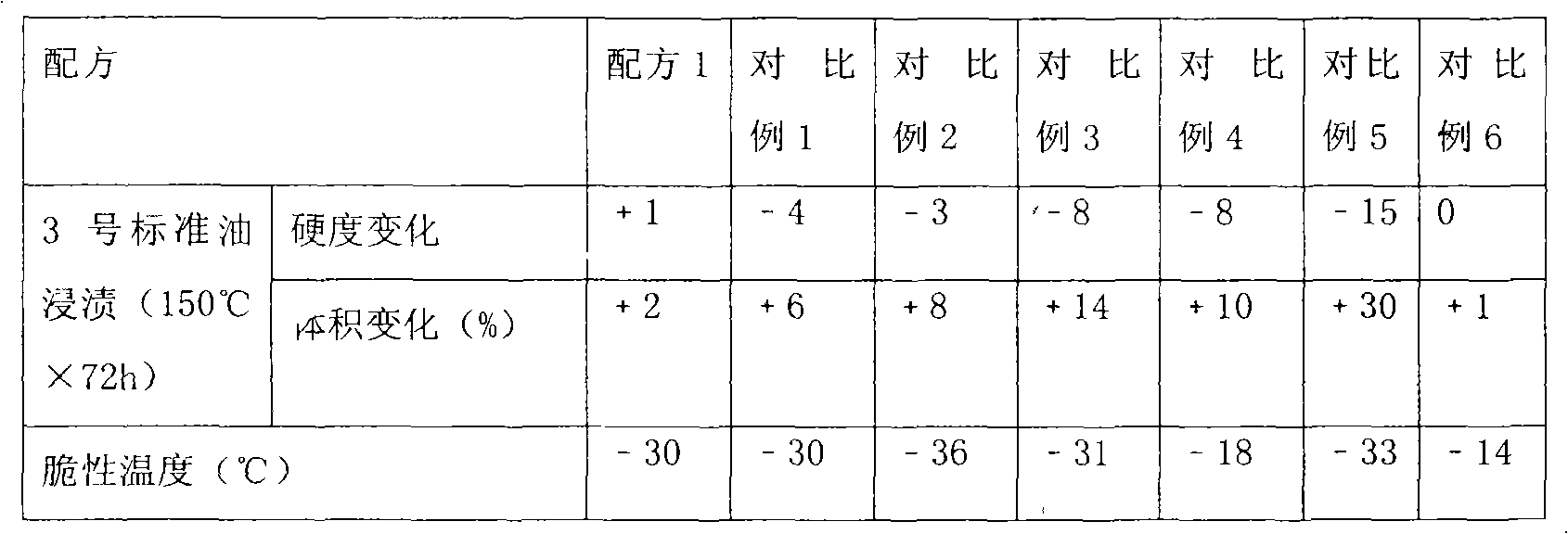

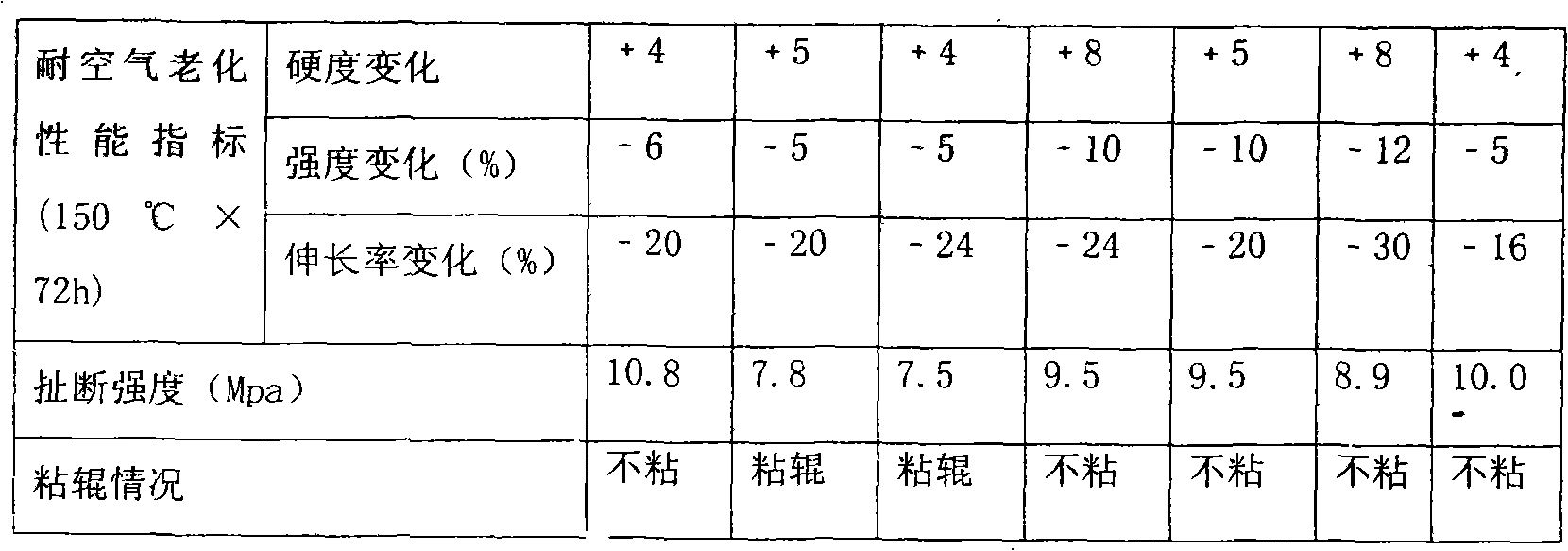

Cold-resistant acrylate rubber as well as preparation and application thereof

InactiveCN101993511AGood comprehensive physical and mechanical propertiesHigh strengthButyl acrylateComposite material

The invention discloses a cold-resistant acrylate rubber as well as preparation and application thereof. As the total weight of acrylate monomer and vulcanization point monomer is 100%, the cold-resistant acrylate rubber comprises the following raw materials in percentage by weight: 0-30% of methyl acrylate, 20-50% of ethyl acrylate, 30-60% of butyl acrylate, 8-30% of methoxyl ethyl acrylate, 1-5% of vulcanization point monomer, 0.0001-1% of initiator, 1-10% of emulsifying agent and 2-40% of flocculant. The cold-resistant acrylate rubber is prepared by using an emulsion polymerization method, and can be used for automobiles, motorcycles, transformers, rubber tubes and the like.

Owner:袁文阳

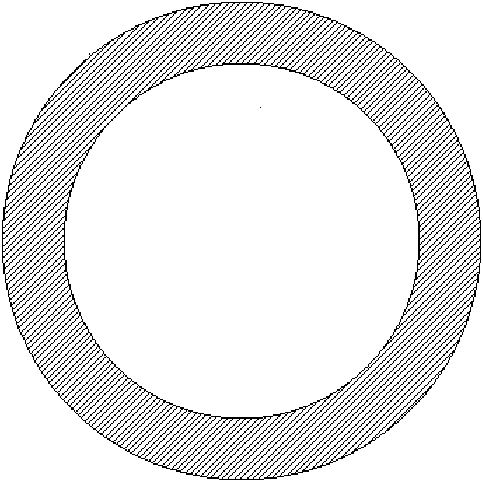

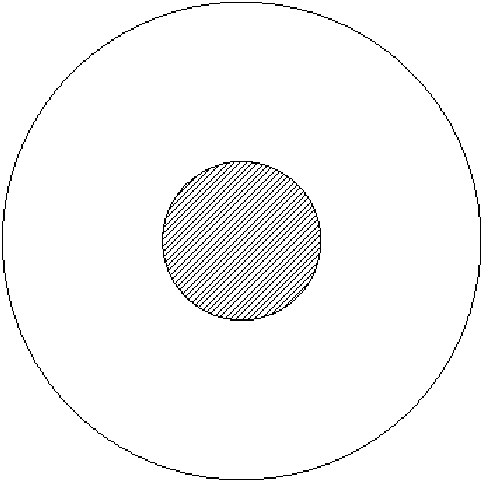

Durable carbon black conductive fiber and preparation method thereof

ActiveCN102031588AImprove conductivityNot easy to peel offElectroconductive/antistatic filament manufactureFilament/thread formingFiberSpecial design

The invention provides durable carbon black conductive complex fiber and a manufacturing method thereof. The complex fiber comprises a functional layer and a protective layer, wherein in a circle O2 of the cross section of the complex fiber, the functional layer comprises a part surrounded by three equilong circular arcs L1, L2 and L3 and the periphery of the circle O2; the three equilong circular arcs respectively pass through three equidistant points on a concentric circle O1 of which the radius is smaller than that of the circle O2; and the three equilong circular arcs are non-intersected mutually. The preparation method of the conductive fiber comprises the following steps: evenly mixing conductive carbon black and an additive; then adding fiber-forming high polymer to prepare conductive master batch; and after drying the master batch, preparing the conductive complex fiber from the master batch and the fiber-forming high polymer by a spinning and drafting one step method. Due to the cross-section structure with the special design of the conductive complex fiber, the carbon black in the fiber can not peel off easily, so that the durability is improved. Simultaneously, the mechanical properties of the fiber are improved, and the surface friction coefficient of the fiber is reduced, thereby improving the post processing performance and being more favorable for use for customers.

Owner:CTA HIGH TECH FIBER

Method for preparing fine denier strong viscose fibers

ActiveCN108677273AReduce manufacturing costImprove the pressing effectArtificial filament washing/dryingArtificial filaments from viscoseSulfonateAfter treatment

Owner:赛得利(福建)纤维有限公司

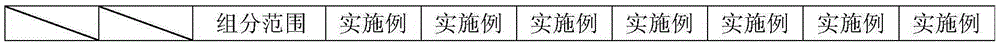

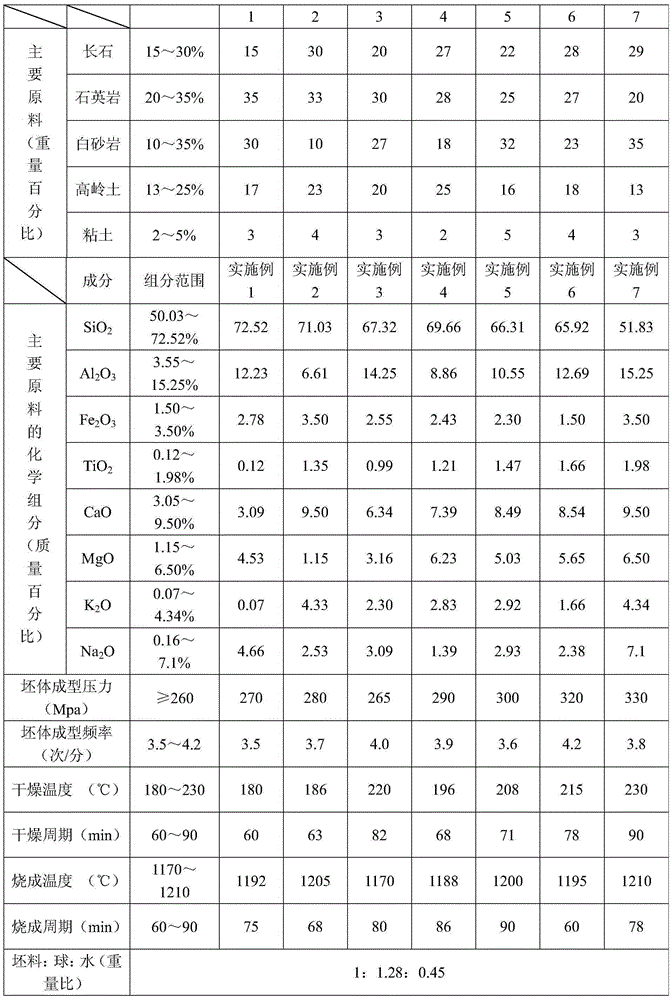

Tile with high whole body whiteness

ActiveCN105330256AConsistent whitenessImprove the decorative effectClaywaresAdditive ingredientWhole body

The invention discloses a tile with high whole body whiteness. The tile is prepared from the following main raw materials in percentage by weight: 15 to 30% of feldspar, 20 to 35% of quartzite, 10 to 35% of white sandstone, 13 to 25% of kaolin and 2 to 5% of clay. The main raw materials comprise the following chemical components in percentage by mass: 52.03 to 72.52% of SiO2, 3.55 to 15.25% of Al2O3, 1.50 to 3.50% of Fe2O3, 0.12 to 1.98% of TiO2, 3.05 to 9.50% of CaO, 1.15 to 6.50% of MgO, 0.07 to 4.34% of K2O and 0.16 to 7.1% of Na2O. A preparation method of the tile comprises the following steps: purchasing the raw materials, selecting the raw materials, making a formula, ball milling ingredients, preparing slurry, ageing the slurry, sieving and removing iron, spray drying, preparing powder, ageing the powder, distributing the powder, arranging a material, pressing and forming, drying, firing, edging, classifying, packing and putting products in a storehouse. The tile with the high whole body whiteness adopts the northern local raw materials, is smooth in texture, high in whole body whiteness, low in radioactivity and long in service life, and is energy-saving and environmentally-friendly.

Owner:内蒙古建亨能源科技有限公司

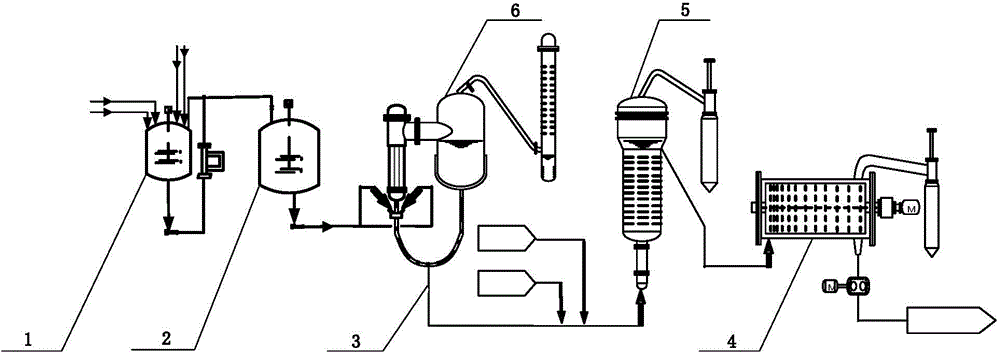

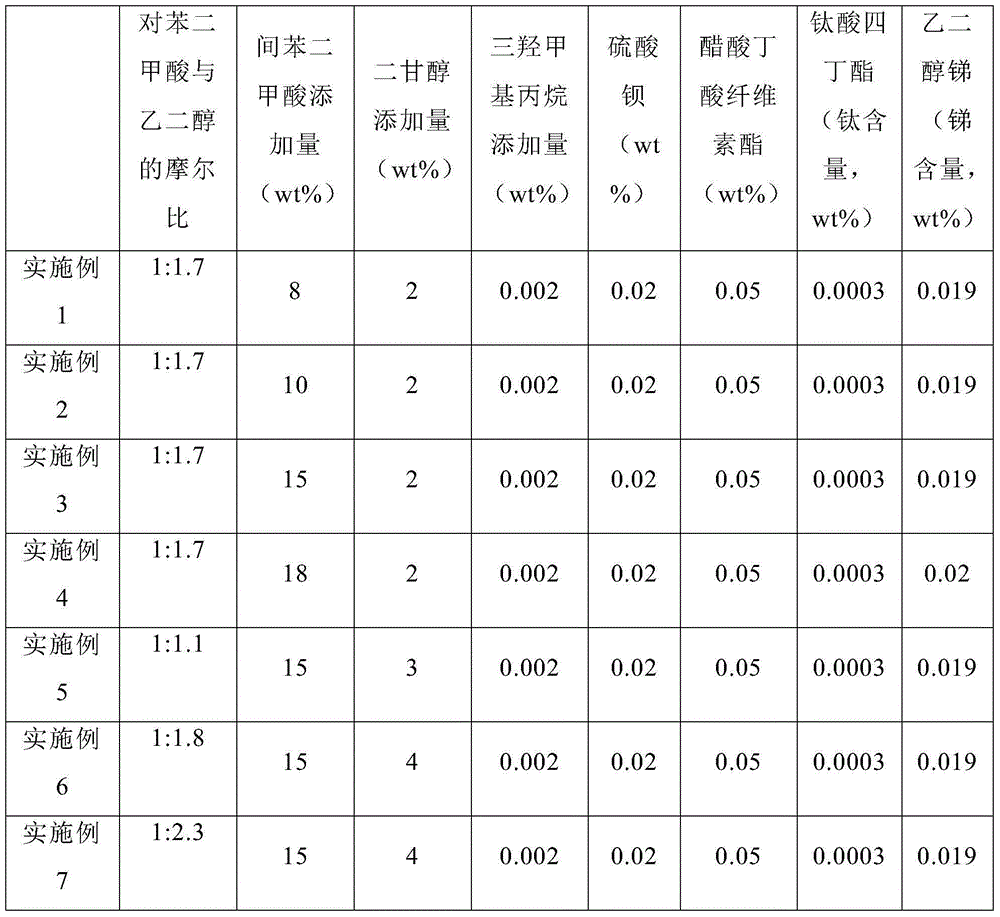

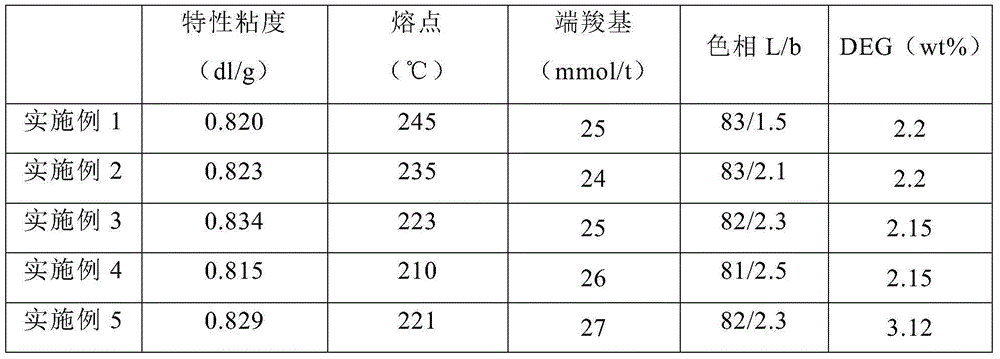

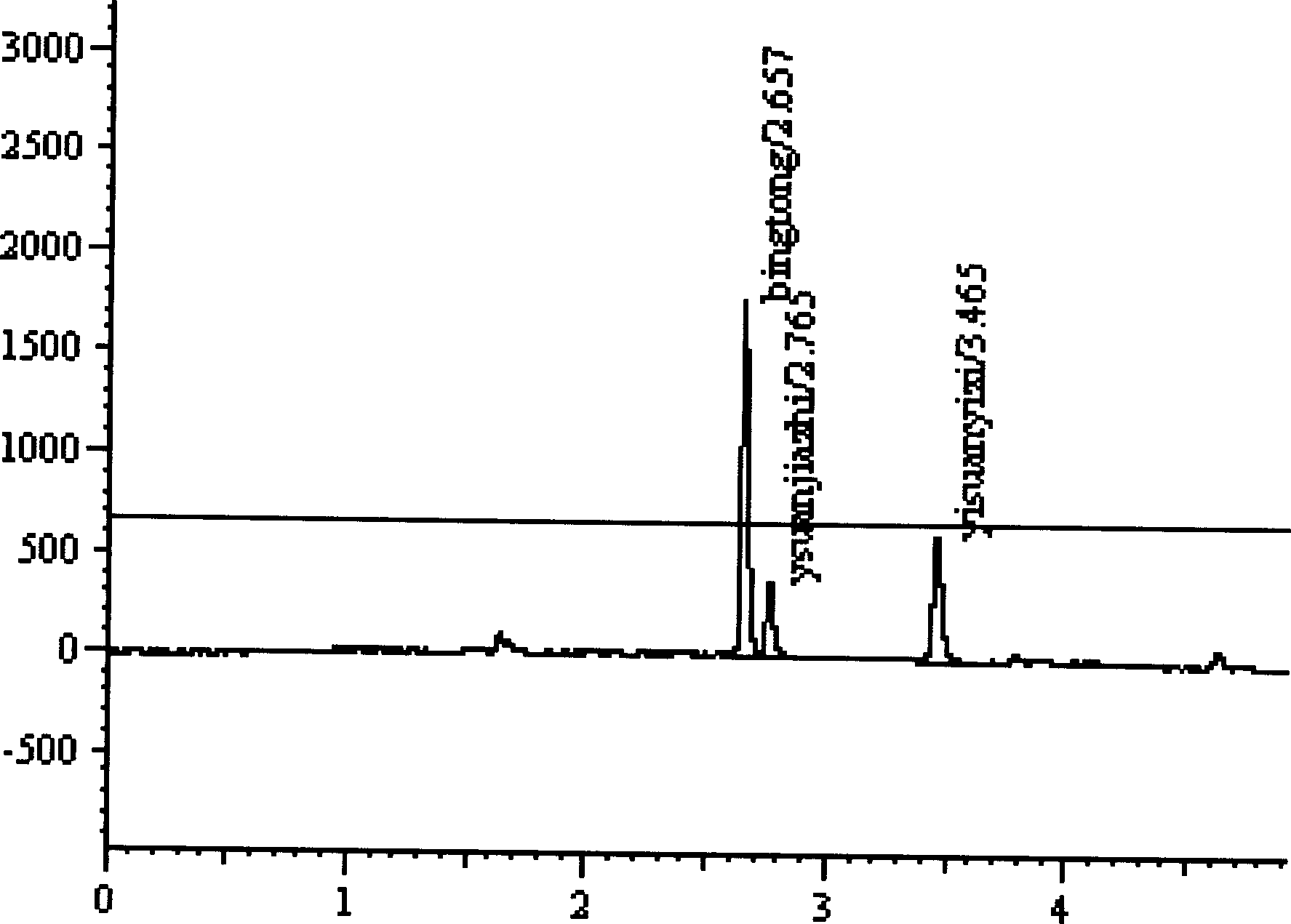

Polyester used for plates and preparing method thereof

The invention discloses polyester used for plates and a preparing method thereof. Raw materials of the polyester comprise, based on the theoretical weight of the polyester, terephthalic acid, ethylene glycol, 5-20 wt% of a dicarboxylic acid except the terephthalic acid, 1-5 wt% of diol, 0.002-0.006 wt% of a polyol compound, 0.01-0.1 wt% of a hydrophilic modification agent and 0.01-0.03 wt% of a heterogeneous inorganic substance. The polyester is used for extrusion molding of the plates. After molding, the plates have good post processing performance such as subsequent plastic vacuum forming, is advantaged by moisture resistance, static electricity resistance, high transparency, high impact strength, high heat deflection temperature, and the like, and can partially replace ABS for wide applications in cases, hand plate manufacturing, electronic and electric products, and other fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing medicinal mixture containing amoxicillin sodium and potassium clavulanate

ActiveCN1850074AGuaranteed sterilityUniform particlesAntibacterial agentsPowder deliveryOrganic solventActive component

The present invention relates to a method for preparing medicine mixture containing amoxicillin sodium and potassium clavulunate. Said method includes the following processes: (a), dissolving two medicine active components in solvent according to a certain ratio so as to form a solution; (b), mixing said solution with supercritical fluid; and (c), separating out medicine micropowder from supercritical fluid. Said medicine granules have good fluidity.

Owner:ZHUHAI UNITED LAB

Thermoplastic emulsion sizing agent for carbon fiber and preparation method thereof and application thereof

The invention discloses a thermoplastic emulsion sizing agent for carbon fiber. The thermoplastic emulsion sizing agent comprises main pulp, an emulsifying agent, an organic solvent and deionized water. The main pulp is Acrylonitrile-Butadiene-Styrene (ABS) formed by modifying N-Phenylmaleimide-Styrene-Maleic anhydride (NSM). And the mass ratio of the ABS and the NSM is 50-100:0-50. The mass of the emulsifying agent accounts for 10-40% the mass of the main pulp, the mass of the main pulp accounts for 0.5-1.5% the mass of the organic solvent, and the mass of the main pulp accounts for 0.5-1% the mass of the deionized water. The invention further discloses the preparation method of the sizing agent and the application of the sizing agent. The sizing agent is good in stability, low in environmental pollution and simple in preparation method. The NSM can assist a carbon fiber rubber layer generated after sizing is conducted in keeping better completeness in the composite material hot press molding process. It is tested by experiment that the post-processability of the carbon fiber is obviously improved after the carbon fiber is processed through the sizing agent, and the inter-laminar shear strength (ILSS) of the carbon fiber reinforced ABS composite material is obviously improved as well.

Owner:UNIV OF JINAN

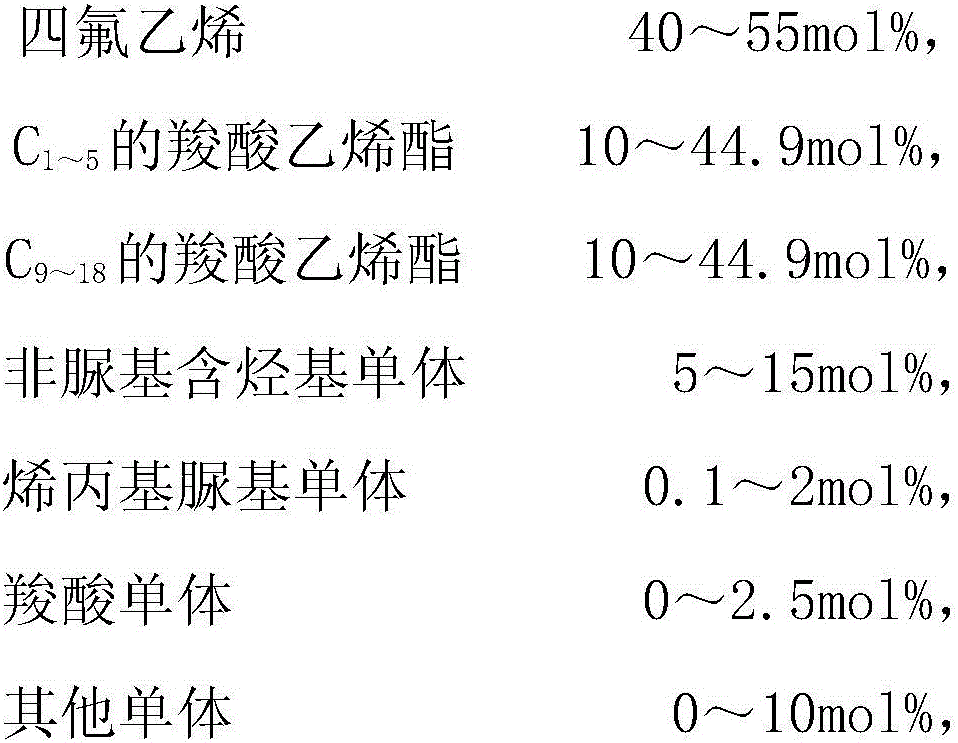

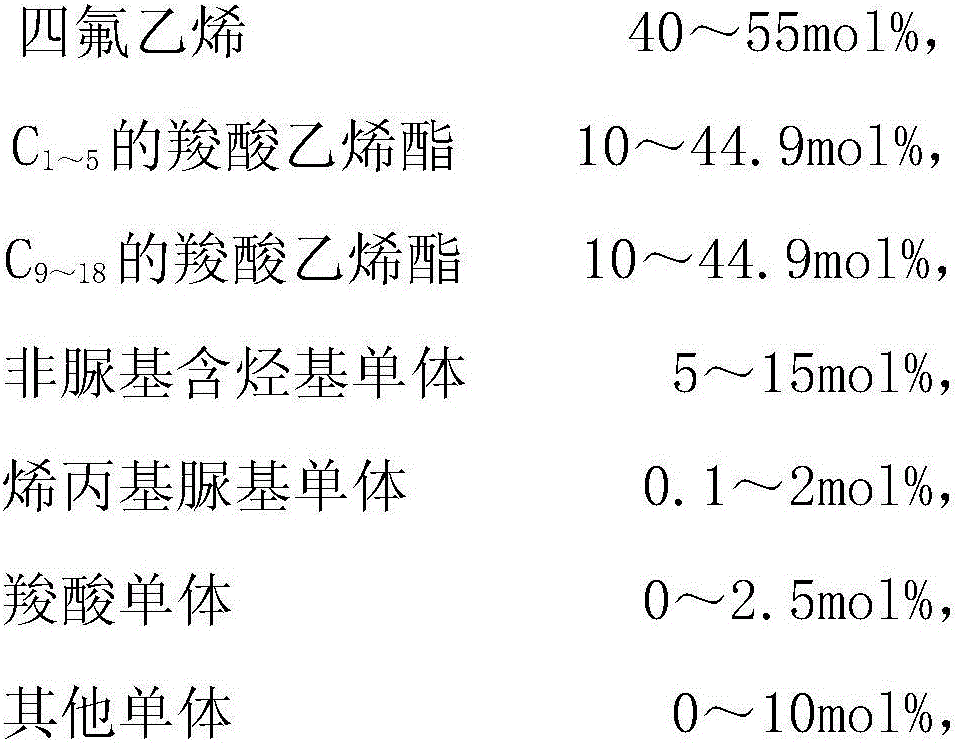

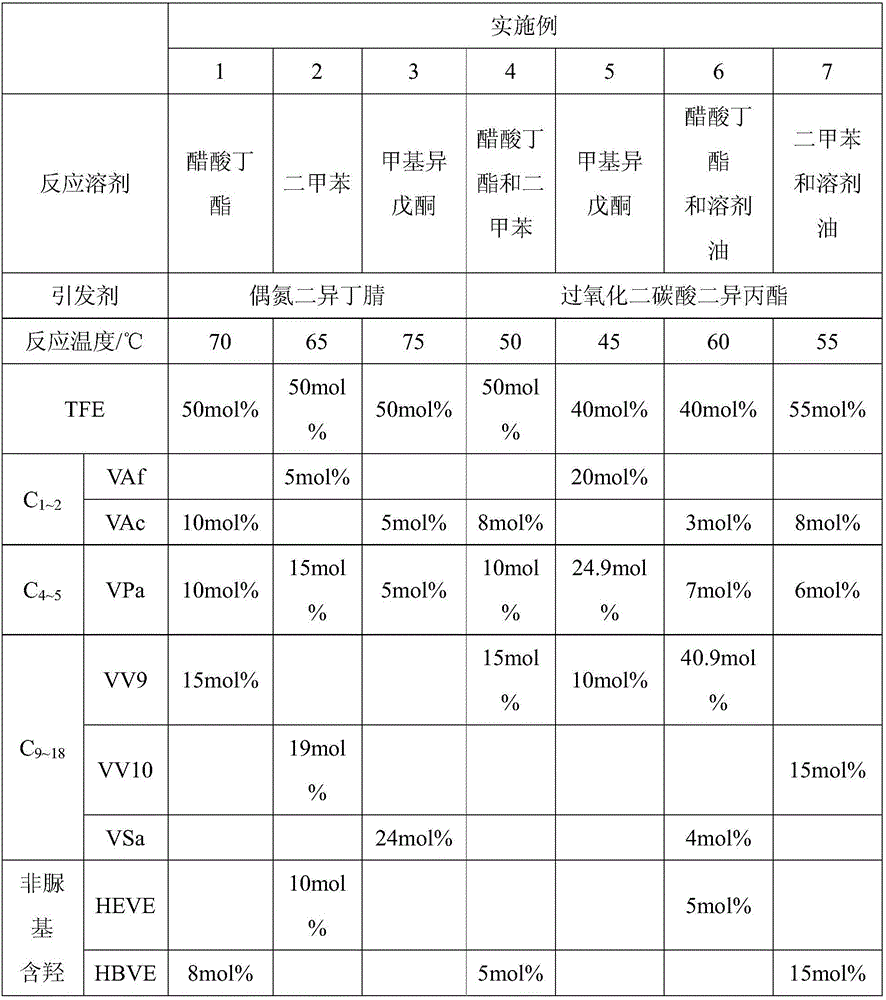

Tetrafluoroethylene copolymer resin for coating and preparation method thereof

ActiveCN106674407AGood dispersion and wettabilityImproved post-processing performanceCoatingsFiberTetrafluoroethylene

The invention discloses tetrafluoroethylene copolymer resin for coating and a preparation method thereof. The tetrafluoroethylene copolymer resin is prepared from the following components in mol fractions: 40-55mol% of tetrafluoroethylene, 10-44.9mol% of C1-5 vinyl carboxylate, 10-44.9mol% of C9-18 vinyl carboxylate, 5-15mol% of non-carbamido hydroxyl containing monomer, 0.1-2mol% of allyl carbamido monomer, 0-2.5%mol% of carboxylic monomer and 0-10mol% of other monomers, wherein the C1-5 vinyl carboxylate is composed of C1-2 vinyl carboxylate and C4-5 branched vinyl carboxylate of which the mol ratio is 1:(0.1-10). The tetrafluoroethylene copolymer resin for coating disclosed by the invention has a good dispersion wetting property with a pigment, has good consistency with a curing agent and can be dissolved in a pure petroleum based solvent, coating prepared from the tetrafluoroethylene copolymer resin has good weather resistance and solvent resistance and is not easy to produce yellow stain, and the tetrafluoroethylene copolymer resin is not easy to crack or flake when used for surface coating of a fiber substrate.

Owner:QUZHOU FLUORIDE & SILICON RES INST

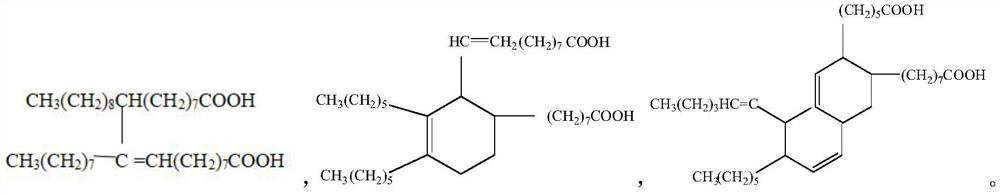

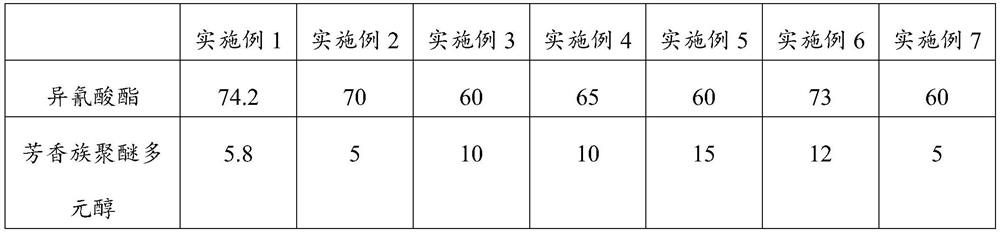

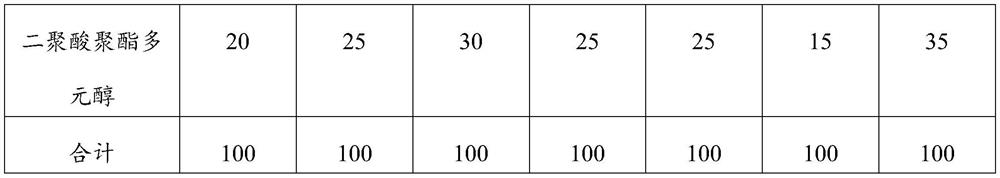

Two-component polyurethane adhesive and preparation method thereof

ActiveCN112724913AGood acid and alkali resistanceImprove hydrolysis resistanceNon-macromolecular adhesive additivesGeneral water supply conservationAdhesive cementPolymer science

The invention provides a two-component polyurethane adhesive and a preparation method thereof. The two-component polyurethane adhesive is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 65 parts to 85 parts of vegetable oil polyol, 5 parts to 20 parts of polymer polyol, 5 parts to 12 parts of small molecular polyol, 0.3 part to 1.3 parts of a defoaming agent, 0.01 part to 0.5 part of a wetting agent, 0.3 part to 3 parts of a water removal agent and 0.1 part to 1.5 parts of a rheological agent; and the component B comprises a polyurethane prepolymer, and the structure of the polyurethane prepolymer has a rigid benzene ring and a side group protection structure. Compared with the prior art, the acid and alkali resistance and hydrolysis resistance are good, and a foundation is provided for use under the strong corrosion condition; the mixed viscosity is small, so that the adhesive has good flowability and wettability, and subsequent use is facilitated; the strength and the toughness are considered, so that the adhesive has good post-processing performance; and the adhesive has high bonding shear strength with ABS and PVC, and has favorable bonding performance.

Owner:湖北南北车新材料有限公司 +1

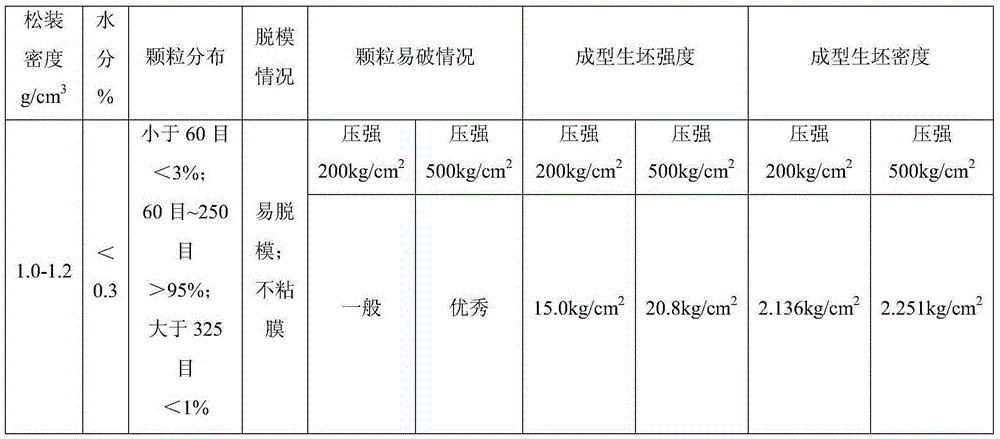

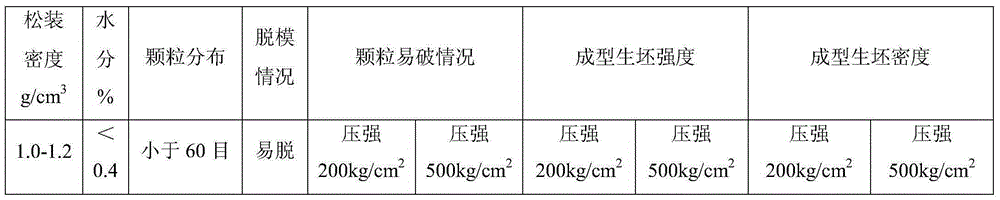

99%-above alumina granulating powder and preparation method thereof

The invention relates to 99%-above alumina granulating powder and a preparation method thereof. The 99%-above alumina granulating powder comprises the following components in parts by weight: 100-200 parts of high-aluminum alumina balls, 50-150 parts of a calcined material CT-3000SG, 1-5 parts of a binder, 0.1-1 part of a dispersant, 0.1-1 part of a demolding agent, 0.1-1 part of yttria, 0.1-1 part of magnesia and 50-150 parts of deionized water. The preparation method comprises the following steps: carrying out ball milling, sieving after pulp is obtained, stirring, and processing with magnets; carrying out centrifugal spraying granulation; removing coarse and fine particles from granulated powder by virtue of a sieve, then removing iron and impurities, and finally homogenizing. The granulating powder is low in water content and high in apparent density; after blank molding, a green body is high in density, good in stability and tenacity and excellent in post-machining performance and does not easily collapse from corners; the preparation method is simple in process and low in cost and has good application prospect.

Owner:SHANGHAI COMPANION PRECISION CERAMICS

Aluminum alloy refiner and aluminum alloy produced with the refiner

InactiveCN101294247AImproved post-processing performanceSimplify the joining processCrystalliteAluminium alloy

The invention discloses an aluminum alloy refiner and an aluminum alloy which is prepared by using the refiner. The aluminum alloy refiner is Zr-Cr-Nb, wherein, Zr, Cr, and Nb elements account for 0.2 to 0.5 percent of total mass percent of the alloy which is obtained from the preparation. By using the refiner, the aluminum alloy is prepared and obtained, the grains of which are small. When the refiner is used for preparing the aluminum alloy, the lattice type and the parameter of Al3Zr can be adjusted to form stable a L12 structure, the interfacial energy and the mispairing degree are reduced, the grain refining effect is increased, the fine uniform equiaxial cast structure is facilitated to be formed, and the subsequent processability of the aluminum alloy is increased. The adding technology of the refiner is simple, the price of the Zr, the Cr and the Nb is relatively cheap, and the aluminum alloy refiner and the aluminum alloy are applied to the industrialized production.

Owner:CENT SOUTH UNIV

Heat-resistant acrylic ester rubber

InactiveCN101445575AGood comprehensive physical propertiesGood post-processing performanceEthyl esterEthyl fumarate

The invention relates to a heat-resistant acrylic ester rubber which is made by copolymerization of methyl acrylate, ethyl acrylate, vinyl monochloroacetate and regulating agent. Calculating by mass percentage, the detailed mixture ratio is: methyl acrylate, 5-40%; ethyl acrylate, 50-94%; vinyl monochloroacetate, 1-10%; and regulating agent, 0.0001-1%; batch process emulsion polymerization technique is used in the process of synthesis; the initiation temperature in the process of polymerization is 10-50 DEG C and the condensation temperature is 40-70 DEG C. The invention has very excellent physical and mechanical properties and post-processing property, thus meeting requirements of the motorcycles and oil-resistant and heat-resistant rubber tubes on material, the formed product of the invention has the advantages of excellent heat-resistance and oil resistance and high tensile-strength, the application of the product ranges from leakproof material of motorcycles, oil-resistant and heat-resistant tubes to protecting jackets and the like.

Owner:JIUJIANG SHILONG RUBBER

Waterborne scroll-steel coating and preparation method thereof

ActiveCN109504244AStamping resistantImproved post-processing performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

The invention provides a waterborne scroll-steel coating and a preparation method thereof. The waterborne scroll-steel coating is prepared from primer and finish paint, wherein the primer is preparedfrom the following components: water, a dispersant, a wetting agent, epoxy modified acrylic resin, hexamethoxymethyl melamine resin, an acid catalyst, a pigment, a leveling agent, a pH (Potential of Hydrogen) regulator and a co-solvent; the finish paint is prepared from the following components: the water, the dispersant, the wetting agent, polyester modified acrylic resin, the hexamethoxymethyl melamine resin, the acid catalyst, the pigment, the leveling agent, the pH regulator and the co-solvent. The coating provided by the invention has the advantages of high T bending performance, punchingresistance, good post-processing performance, high rigidity, acid and alkali resistance, salt mist resistance, good weather resistance, low VOC (Volatile Organic Compounds), high economic benefits, no toxicity and environment protection.

Owner:ZHUHAI CBB CHEM

Method for preparing copolymers lactic acid/rubber

A process for preparing lactic acid-rubber copolymer includes such steps as dewatering lactic acid, polycondensating, modifying its terminal radical to obtain hydroxy terminated polylactic acid, copolymerizing reaction on the isocyanate terminated rubber, and extending chain. Its advantage is easy control to the mechanical performance and biodegradation of product.

Owner:DONGHUA UNIV

Low temperature curing transparent inner iron printing coating

ActiveCN106634480AGood yellowing resistanceImprove scratch resistancePolyester coatingsEnvironmental resistancePolyester

The invention discloses a low temperature curing transparent inner iron printing coating. The low temperature curing transparent inner iron printing coating contains raw material by weight part: 40-65 parts of saturated polyester, 5-10 parts of amino resin, 0.2-1 part of modified adhesion promoter, 0.5-1 part of wax powder, 0.1-0.3 part of catalyst and 18-25 parts of environment-friendly organic solvent, wherein the saturated polyester has Tu-4 cup viscosity of 60-80s, acid value of 2-4mgKOH / g, solid content of 55-60wt%, glass transition temperature of 40-50 DEG C, and average molecular weight between 4000Da and 6000Da. Compared with the prior art, by selecting the branched saturated polyester high in acid value and glass transition temperature, crosslinking the selected saturated polyester with partly methyl-etherified melamine formaldehyde resin and n-butyl-etherified melamine formaldehyde resin, which are good in hardness and high in reaction speed, and simultaneously using benzoguanamine resin and isocyanate for auxiliary crosslinking, the low temperature curing transparent inner iron printing coating has good adhesive force to base material, good yellowing resistance, good scratch resistance, strong resistance to corrosion, and good processing performance, and only needs to cure for 8-11min at low temperature of 125-135 DEG C, is environment friendly and safe, does contain materials such as bisphenol A and organic tin, and is a product which meets domestic and international innocuous and harmless test standards.

Owner:广东新威新材料技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com