99%-above alumina granulating powder and preparation method thereof

A technology of granulating powder and alumina, which is applied in the field of alumina ceramics, can solve the problems of low green density and poor post-processing performance, and achieve the effects of low cost, good application prospects, and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The ball mill adopts an octagonal ball mill. Put 150Kg of high-alumina alumina balls above 99% in the barrel (specifications Φ6, Φ8, Φ12 (mm) according to the mass ratio 3:3:4), and put in 100KgCT-3000SG, 50Kg deionized water, 200g oxidation Yttrium, 400g magnesia, 600gD-134 are ball milled for 46h, 2kgP-222 is added for 1.5h, 600gS-920 is ballmilled for 0.5h, and then the slurry is discharged. After the slurry is discharged, it is filtered with a 80-mesh screen, and the slurry enters the mixing tank for stirring over the magnet.

[0021] Start the centrifugal spray granulator, set the inlet temperature to 220°C, the outlet temperature to 95°C, the rotation speed to 15000rpm, and the negative pressure to 120pa.

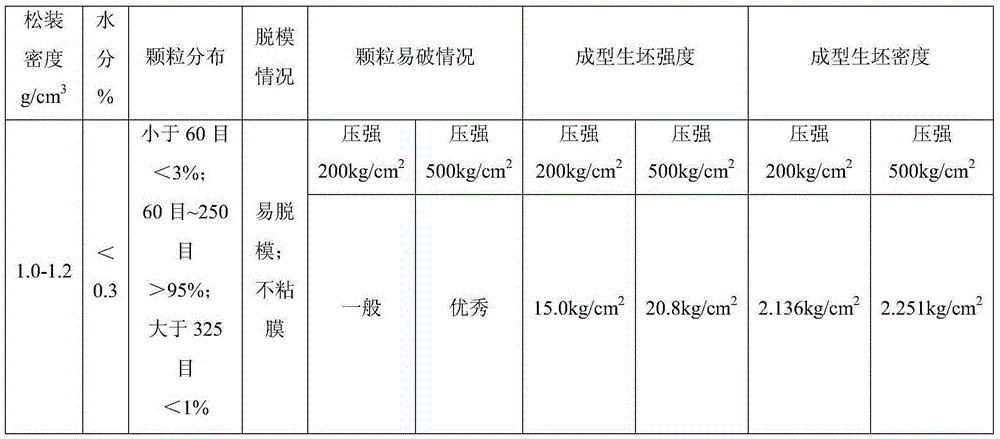

[0022] The granulated powder is sieved with 60 mesh and 325 mesh to remove coarse and fine particles. The powder must be iron-removed to remove impurities, and the powder is homogenized for 24 hours to make a billet by dry pressing metal mold forming method.

...

Embodiment 2

[0026] The ball mill adopts an octagonal ball mill. Put 100Kg of high-alumina alumina balls above 99% in the barrel (specifications Φ6, Φ8, Φ12 (mm) according to the mass ratio 3:3:4), and put in 50KgCT-3000SG, 80Kg deionized water, 400g oxidation Yttrium, 800g magnesia, 200gD-134 are ball milled for 40h, 3kgP-222 is added for 1h, 500gS-920 is ballmilled for 0.6h, and then the slurry is discharged. After the slurry is discharged, it is filtered with an 80-mesh screen, and the slurry enters the mixing tank for stirring. magnet.

[0027] Start the centrifugal spray granulator, set the inlet temperature to 220°C, the outlet temperature to 95°C, the rotation speed to 15000rpm, and the negative pressure to 120pa.

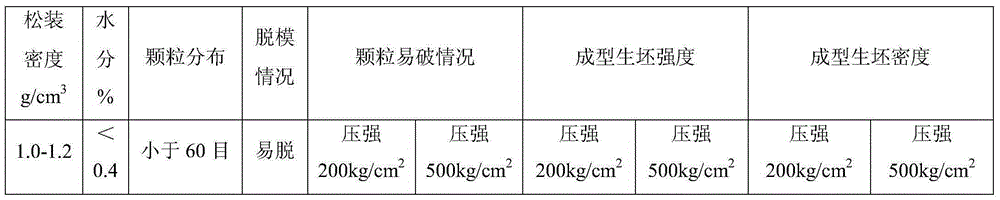

[0028] The granulated powder is sieved with 60 mesh and 325 mesh to remove coarse and fine particles. The powder must be iron-removed to remove impurities, and the powder is homogenized for 28 hours to make a billet by dry pressing metal mold forming method.

[0029] Th...

Embodiment 3

[0033] The ball mill adopts an octagonal ball mill. Put 150Kg of high-alumina alumina balls (specifications Φ6, Φ8, Φ12 (mm) according to the mass ratio of 3:3:4) in the barrel, and put 150KgCT-3000SG, 150Kg deionized water, 100g oxidation Yttrium, 200g magnesia, 600gD-134 are ball milled for 50h, 1kgP-222 is added for 3h, 600gS-920 is ballmilled for 1h, and then the slurry is discharged. After the slurry is discharged, it is filtered with an 80-mesh screen. The slurry enters the mixing tank and is stirred through the magnet. .

[0034] Start the centrifugal spray granulator, set the inlet temperature to 220°C, the outlet temperature to 95°C, the rotation speed to 15000rpm, and the negative pressure to 120pa.

[0035] The granulated powder is sieved with 60 mesh and 325 mesh to remove coarse and fine particles. The powder must be iron-removed to remove impurities, and the powder is homogenized for 36 hours to make a billet by dry pressing metal mold forming method.

[0036] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com