Cold-resistant acrylate rubber as well as preparation and application thereof

A technology of acrylate and methyl acrylate, which is applied in the field of synthetic acrylate rubber, which can solve the problems of easy roll sticking, poor strength, oil resistance, poor overall performance, and poor post-processing performance, and achieve high strength and post-processing performance. Good effect with good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

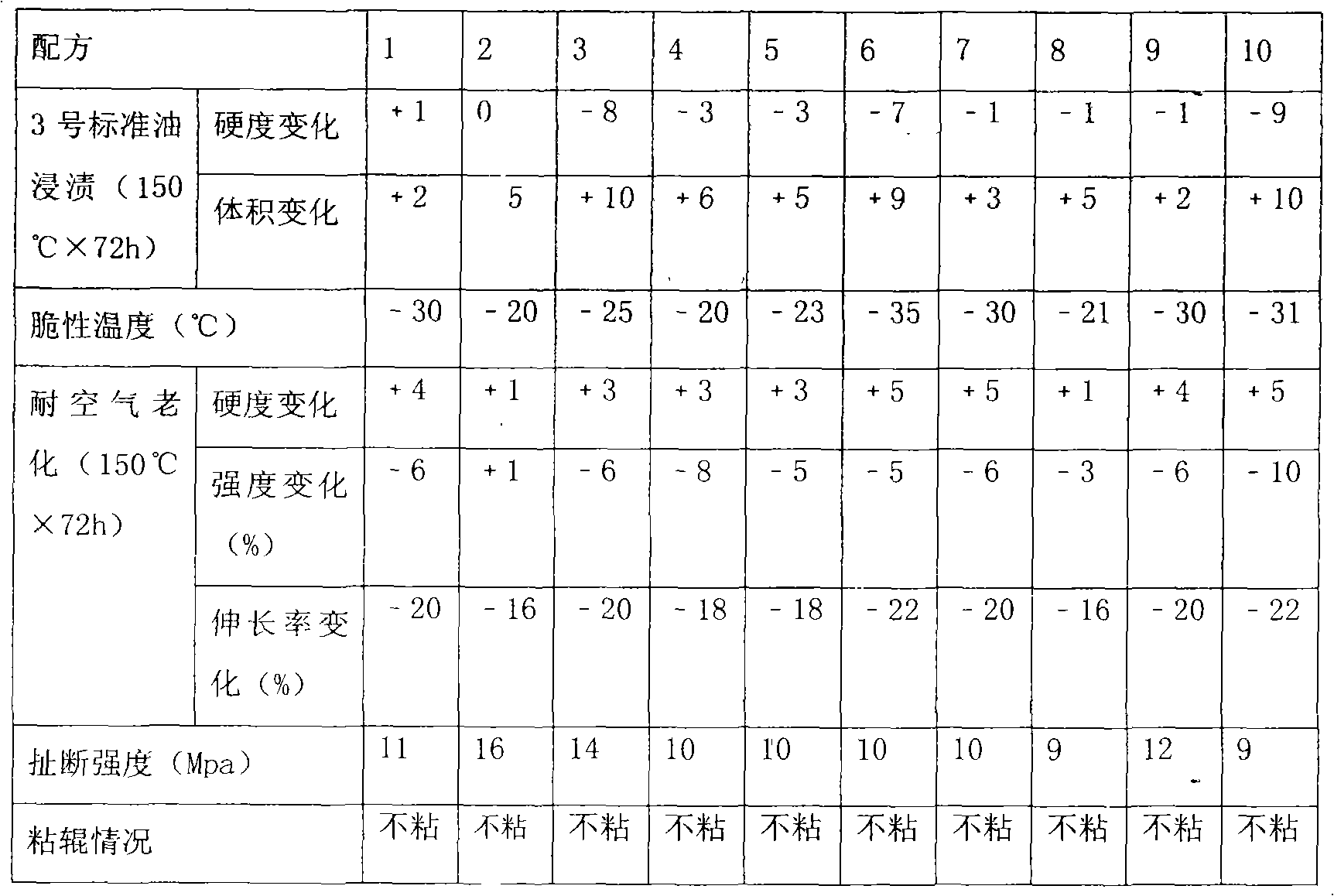

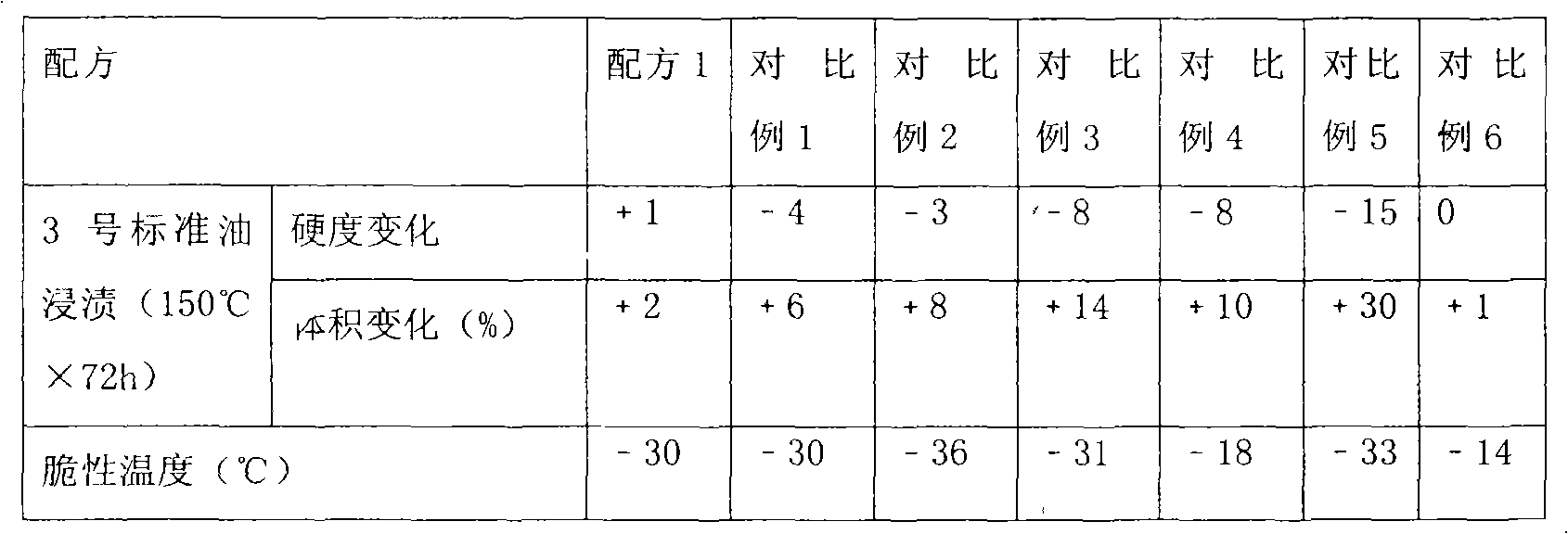

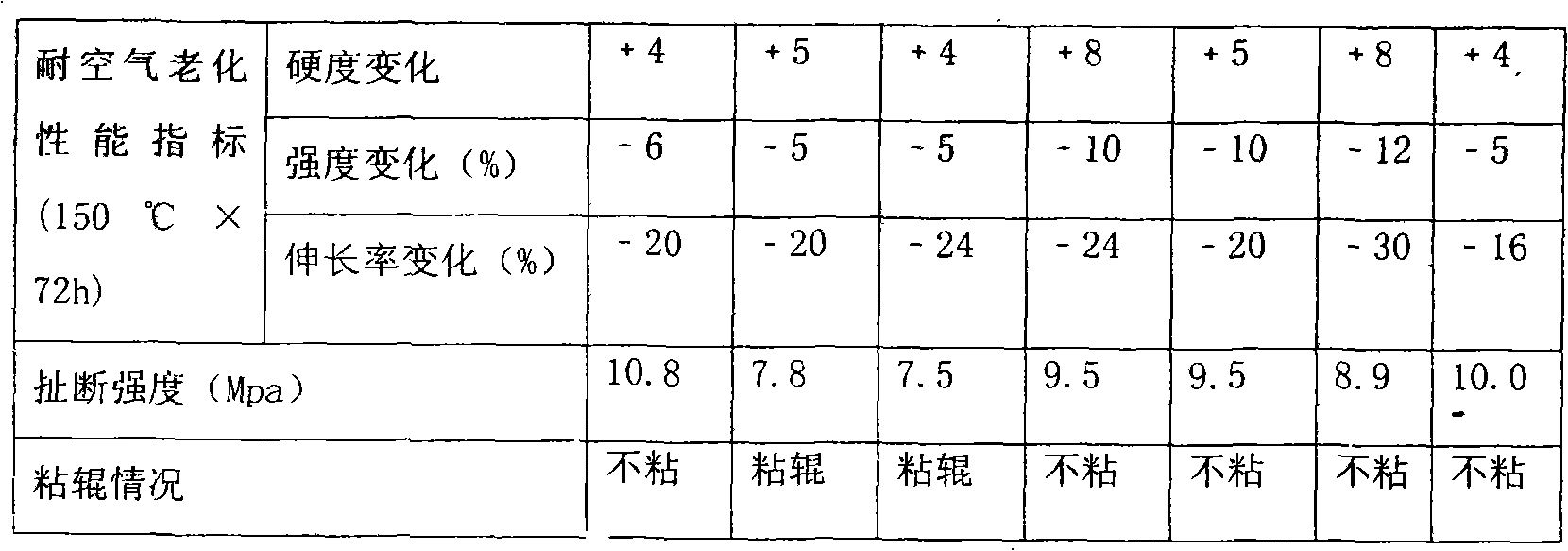

[0033] Rubber was prepared according to the formula and process parameters in Table 1.

[0034] preparation steps

[0035] 1) Basic monomer ingredients: mix methyl acrylate, ethyl acrylate, butyl acrylate, ethyl methoxyacrylate, and vulcanization point monomers in a premixing tank in proportion to make a hydrocarbon phase solution for later use;

[0036] 2) Put the emulsifier into the reaction kettle, fully stir for standby;

[0037] 3) Emulsion polymerization: Put the hydrocarbon phase solution prepared in step 1) into the reaction kettle in proportion, stir well, add an initiator in proportion between 5-50°C to initiate the reaction, control its reaction speed and peak value, until the hydrocarbon phase reaction is complete;

[0038] 4) Salt polymerization: Send the fully reacted glue in step 3) to the coagulation pool with compressed air to mix with the coagulant, break the emulsion at a temperature of 20-70°C, and coagulate into a white solid elastomer, which is ready af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com