Moisture-curing epoxy zinc phosphate over-rust primer

A technology of epoxy zinc phosphate and rust primer, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., and can solve the problems of affecting the service life and anti-corrosion effect of coatings, aggravated corrosion of metal substrates, and cross-linking of coating films Density reduction and other problems, to achieve excellent comprehensive physical and mechanical properties, improve wet adhesion, and improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described below in conjunction with the examples.

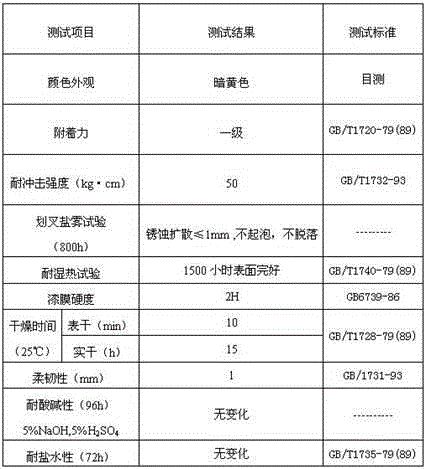

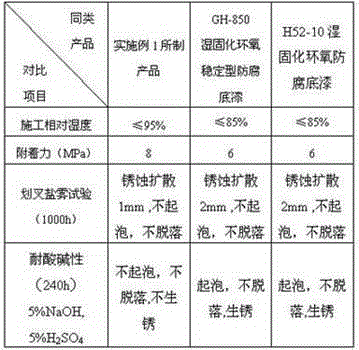

[0032] See Table 1 for the components and contents of the moisture-curing epoxy zinc phosphate rust primer in Examples 1 to 4.

[0033] Table 1

[0034]

[0035] The preparation technology of moisture curing epoxy zinc phosphate band rust primer in embodiment 1~embodiment 4 is as follows:

[0036] Weigh the components contained in component A as shown in Table 1, first put epoxy resin E44, cyclohexanone, and n-butanol into the mixer in sequence, stir at 800~1000 rpm for 10 minutes, and then add 209 zinc chrome yellow , 309 zinc chrome yellow, 109 zinc chrome yellow, iron oxide red, zinc phosphate, aluminum tripolyphosphate, and diphenylguanidine chromate were put into the mixer, stirred at 1000~1800 rpm for 30 min, put into the grinder and ground to 25 μm, Add xylene at last, and get A component after mixing.

[0037] Weigh each component contained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com