Carbon fiber emulsion sizing agent and preparation method and application thereof

A technology of carbon fiber and sizing agent, which is applied in the directions of carbon fiber, fiber processing, textile and paper making, etc., can solve the problems of complicated preparation of component B, and achieve the effects of easy implementation, increased stability and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

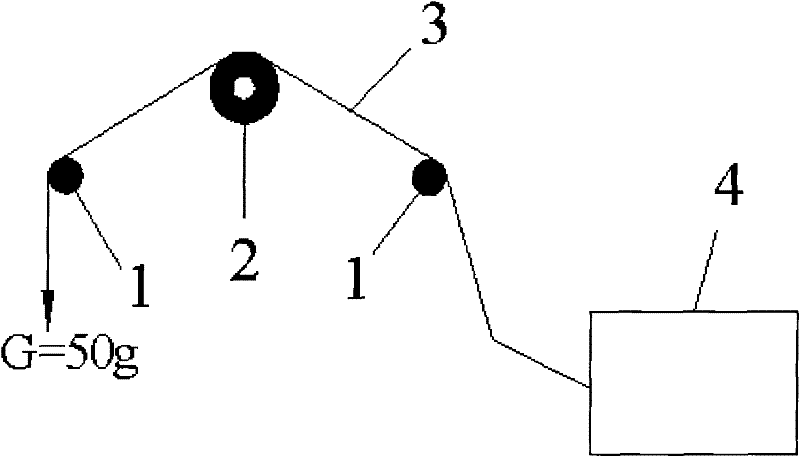

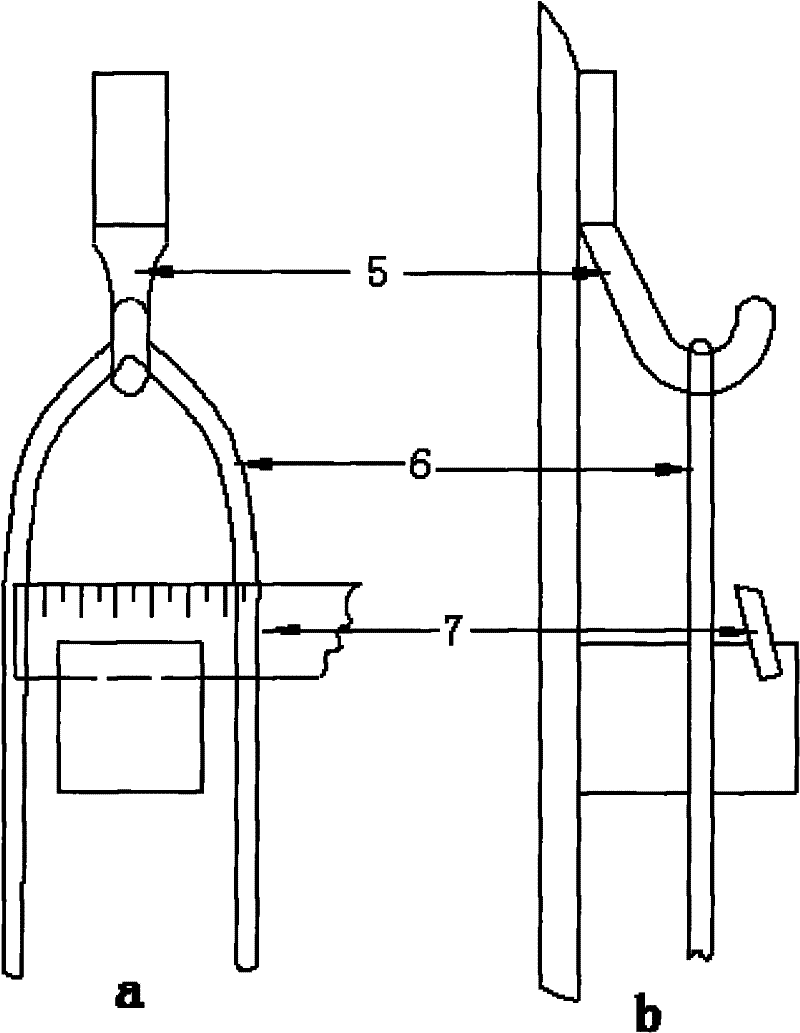

Method used

Image

Examples

Embodiment 1

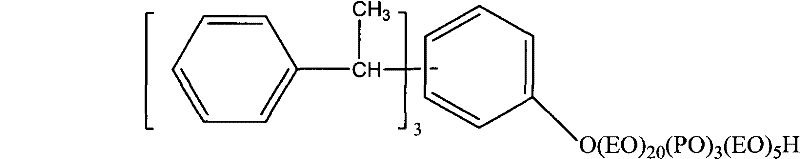

[0037] Preheat the emulsifier NP-10 phosphate ammonium salt and OP-10 at a ratio of 75:25, and the emulsifier and penetrant sec-octanol polyoxyethylene ether (JFC-2) at a ratio of 80:20 to 50℃ and mix well. Place it in the container to get the mixing aid. The epoxy resin E-44 and the epoxidized polybutadiene resin were mixed uniformly at a mass ratio of 80:20 to obtain the main sizing agent slurry, which was dissolved in acetone, and the mass ratio of acetone to the main slurry was 40: 60, then add the above mixing aids, the added amount of mixing aids is 15% of the main slurry. Heat the mixture to 50°C and mix uniformly, then stir at a high speed at a constant rate of 10000r / min. Add deionized water dropwise. The ratio of deionized water to the main slurry is 80:20. After adding water, continue to stir for 20 minutes , Get sizing agent emulsion. The emulsion was diluted to a solid content of 0.5%, and the concentration of the sizing agent was attached to the polyacrylonitril...

Embodiment 2

[0058] The emulsifier NP-10 ammonium sulfate and NP-10 are in a ratio of 70:30, and the emulsifier and penetrant OP-7 are preheated to 60°C in a ratio of 85:15, mixed uniformly, and then placed in a container to obtain a mixing aid. The epoxy resin E-51 and the epoxidized polybutadiene resin were mixed uniformly at a mass ratio of 20:80 to obtain the main sizing agent slurry, which was dissolved in acetone, and the mass ratio of acetone to the main slurry was 50: 50, then add the above mixing aids, the added amount of mixing aids is 12% of the main slurry. Heat the mixture to 60℃ and mix evenly, then stir at a high speed at a constant rate of 11000r / min, add deionized water dropwise, the ratio of deionized water to the main slurry is 70:30, and continue stirring for 20 minutes after adding water , Get sizing agent emulsion. The emulsion was diluted to a solid content of 1.0%, and the concentration of the sizing agent was attached to the polyacrylonitrile carbon fiber by the di...

Embodiment 3

[0060] Preheat the emulsifier NP-10 ammonium sulfate to agricultural milk 1601 in a ratio of 65:35, and the emulsifier and penetrant sec-octanol polyoxyethylene ether (JFC-2) in a ratio of 90:10 to 60℃, mix well and place it in In the container, a mixing aid is obtained. The epoxy resin E-55 and the epoxidized polybutadiene resin were mixed uniformly at a mass ratio of 25:75 to obtain the main sizing agent slurry, which was dissolved in acetone, and the mass ratio of acetone to the main slurry was 50: 50, then add the above mixing aids, the added amount of mixing aids is 10% of the main slurry. Heat the mixture to 60℃ and mix uniformly, then stir at a constant speed of 9000r / min at a high speed, add deionized water dropwise, the ratio of deionized water to the main slurry is 60:40, continue to stir for 30min after adding water , Get sizing agent emulsion. The emulsion was diluted to a solid content of 2.0%, and the concentration of the sizing agent was attached to the polyacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com