Carbon fiber water-soluble epoxy resin sizing agent

A technology of epoxy resin and novolac epoxy resin, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of poor compatibility between emulsifier and resin, complicated preparation process, and effective component analysis, etc., to achieve Excellent static stability, simple preparation method, and the effect of reducing the amount of fuzz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

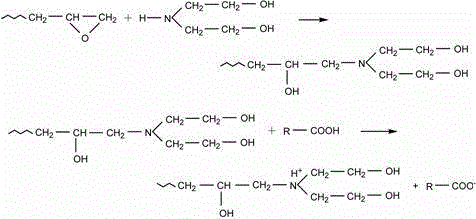

[0030] Synthesis of modified novolac epoxy resin: (1) Add the ethanol solution of novolak epoxy resin F-48 into a three-necked flask equipped with a condensation reflux device, stir at a constant speed of 50°C; The ethanol solution of diethanolamine was added dropwise, and the reaction was stirred at constant temperature for 2 hours to obtain the adduct EPN-DEA of novolac epoxy resin and diethanolamine. (2) Take glacial acetic acid in the amount of diethanolamine and other substances, dilute it to 60wt% with deionized water, and add it dropwise at 50°C to neutralize EPN-DEA to form a salt; The solvent is distilled off to obtain the modified novolac epoxy resin. In the above-mentioned reaction process, the mass ratio of epoxy novolac resin and ethanol is 30:70; The mass ratio of diethanolamine and ethanol is 50:50; The mol ratio of epoxy novolac resin and diethanolamine is 1:2.

[0031] Preparation of sizing agent: Mix the modified novolac epoxy resin and AEPH at a ratio of 70...

Embodiment 2

[0052] Synthesis of modified novolac epoxy resin: (1) Add the ethanol solution of novolac epoxy resin F-44 into a three-necked flask equipped with a condensation reflux device, stir at a constant speed of 40°C; The ethanol solution of diethanolamine was added dropwise in the mixture, and the reaction was stirred at constant temperature for 1 hour to obtain the adduct EPN-DEA of novolac epoxy resin and diethanolamine. (2) Take glacial acetic acid in the amount of diethanolamine and other substances, dilute it to 60wt% with deionized water, and add it dropwise at 40°C to neutralize EPN-DEA to form a salt; The solvent is distilled off to obtain the modified novolac epoxy resin. In the above-mentioned reaction process, the mass ratio of novolac epoxy resin and ethanol is 40:60; the mass ratio of diethanolamine and ethanol is 40:60; the molar ratio of novolak epoxy resin and diethanolamine is 3:2.

[0053] Preparation of sizing agent: Mix the modified novolac epoxy resin and AEPH ...

Embodiment 3

[0057] Synthesis of modified novolac epoxy resin: (1) Add the ethanol solution of novolak epoxy resin F-51 into a three-necked flask equipped with a condensation reflux device, and stir at a constant speed of 60°C; The ethanol solution of diethanolamine was added dropwise, and stirred at constant temperature for 3 hours to obtain the adduct EPN-DEA of novolac epoxy resin and diethanolamine. (2) Take glacial acetic acid in the amount of diethanolamine and other substances, dilute it to 60wt% with deionized water, and add it dropwise at 60°C to neutralize EPN-DEA to form a salt; The solvent is distilled off to obtain the modified novolac epoxy resin. In the above-mentioned reaction process, the mass ratio of epoxy novolac resin and ethanol is 50:50; The mass ratio of diethanolamine and ethanol is 60:40; The mol ratio of epoxy novolac resin and diethanolamine is 1:1.

[0058] Preparation of sizing agent: Mix the modified novolac epoxy resin and AEPH at a ratio of 90:10 at 50°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com