Thermoplastic emulsion sizing agent for carbon fiber and preparation method thereof and application thereof

A carbon fiber and thermoplastic technology, applied in the field of thermoplastic emulsion sizing agent for carbon fiber, to achieve performance improvement, good application effect, and increased interlayer shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

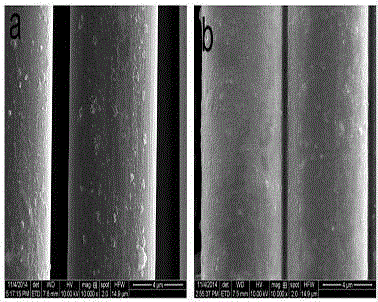

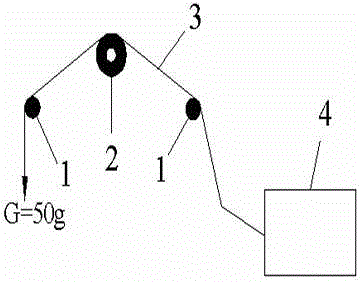

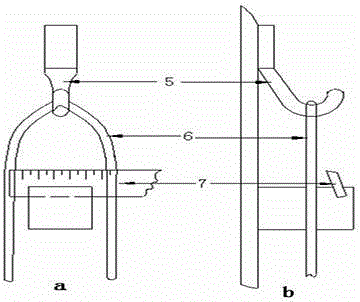

Image

Examples

Embodiment 1

[0045]Synthesis of terpolymer NSM: Add a certain mass of xylene solution of styrene (St) monomer, phenylmaleimide (NPMI) monomer and maleic anhydride (MAH) monomer into a condensing reflux device into a three-neck flask, and put in the initiator di-tert-butyl peroxyphthalate, heated to 125°C, reacted for 4 hours under the protection of nitrogen, and cooled rapidly with ice water to terminate the reaction. The NSM terpolymer was obtained, and the mass ratio of the three components was N:S:M=47:51:2.

[0046] Preparation of sizing agent: Physically blend PA-709 ABS and NSM at a mass ratio of 50:50, then add the acetone solution of Nongru 1601 to the above mixture and stir evenly. The quality of the emulsifier is 10% of the mass of the main slurry, and the quality of the main slurry is 0.5% of the mass of acetone. Finally, high-speed shear stirring at a constant rate of 8000r / min, slowly drop deionized water, the mass of the main slurry is 0.5% of the mass of deionized water, an...

Embodiment 2

[0050] Synthesis of terpolymer NSM: Add a certain mass of xylene solution of styrene (St) monomer, phenylmaleimide (NPMI) monomer and maleic anhydride (MAH) monomer into a condensing reflux device into a three-neck flask, and put in the initiator di-tert-butyl peroxyphthalate, heated to 125°C, reacted for 4 hours under the protection of nitrogen, and cooled rapidly with ice water to terminate the reaction. The NSM terpolymer was obtained, and the mass ratio of the three components was N:S:M=47:51:2.

[0051] Preparation of sizing agent: physically blend PA-709 ABS and NSM at a ratio of 70:30, then add the acetone solution of EL-20 to the above mixture and stir evenly. The quality of the emulsifier is 40% of the mass of the main slurry, and the quality of the main slurry is 1.5% of the mass of acetone. Finally, under high-speed shear stirring at a constant rate of 12000r / min, slowly drop deionized water, the mass of the main slurry is 1% of the mass of deionized water, and con...

Embodiment 3

[0055] Preparation of sizing agent: use pure PS-777B ABS as the main slurry, then add OP-10 cyclopentanone solution into the above mixture and stir evenly. The quality of the emulsifier is 30% of the quality of the main slurry, and the quality of the main slurry is 1.2% of the quality of cyclopentanone. Finally, high-speed shear stirring at a constant rate of 9000r / min, slowly drop deionized water, the mass of the main slurry is 0.7% of the mass of deionized water, and continue stirring for 25 min after adding water to obtain a sizing agent emulsion.

[0056] Sizing treatment: the above-mentioned emulsion sizing agent was attached to the carbon fiber by dipping method, the dipping time was 30s, and the carbon fiber was dried at 120°C for 20 min after sizing.

[0057] Measure the standing stability, average particle size of this sizing agent emulsion under room temperature and normal pressure, the sizing rate of carbon fiber, stiffness, hair amount, wear times, the interlaminar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com