Durable carbon black conductive fiber and preparation method thereof

A conductive composite fiber, carbon black type technology, applied in conductive/antistatic filament manufacturing, fiber processing, filament/thread forming, etc., can solve the problems of high processing difficulty, reduced fiber functionality, and increased processing difficulty, etc. Achieve the effect of improving electrical conductivity, improving durability, and not easy to peel off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

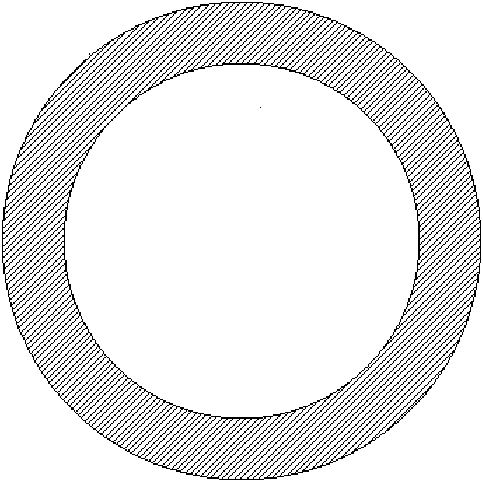

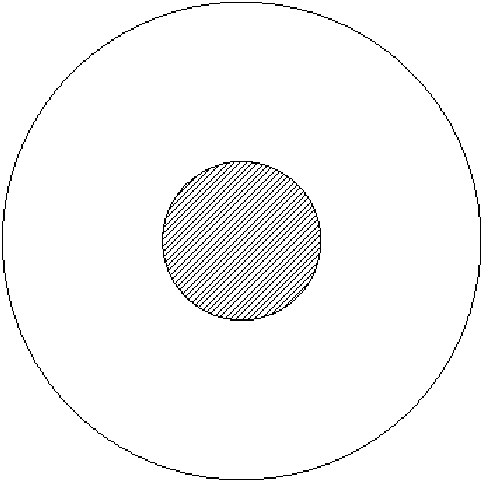

[0042] A high-structure conductive carbon black powder accounting for 28% of the total weight of the functional layer with a particle size of 30-50nm and a specific resistance ≤ 10Ω·cm, and polybutylene terephthalate (PBT) accounting for 71.6% of the total weight of the functional layer and Dispersant, coupling agent, antioxidant, etc. are coated, dispersed, and mixed, and the A component is obtained by twin-screw granulation; the fiber-grade polyethylene terephthalate chips are used as the B component; two The components are added to the A and B feed bins of the compound spinning machine respectively, and then enter the dryer for drying. Component A can also be dried by vacuum drum and directly put into the component A dry slice silo.

[0043] After the A and B components are melted and extruded by the A and B screws respectively, the melts are extruded into the spinneret components by the A and B metering pumps at a ratio of 22%:78%, and the melts are compounded in the compo...

Embodiment 2

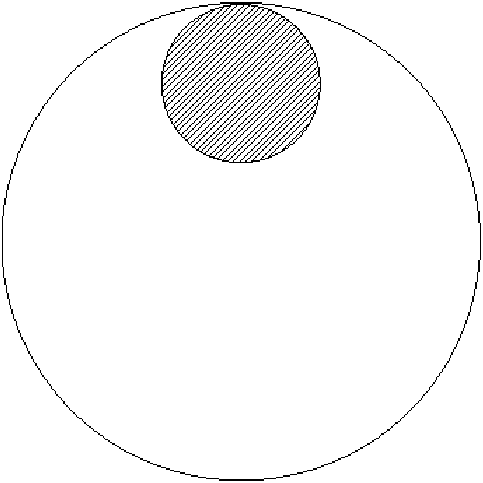

[0046] The preparation method of A component is the same as embodiment, only changes the proportioning of A component carbon black, and it accounts for 22% of functional layer gross weight, accounts for the polybutylene terephthalate (PBT) of functional layer gross weight 77.2%. ), all the other make A component with embodiment 1, and adopt the spinning process identical with embodiment, make such as Figure 7 Conductive composite fibers of cross-section shown.

[0047] The linear density of the conductive fiber is 23.4dtex / 3f, the breaking strength is 2.9cN / dtex, the breaking elongation is 61%, and the fiber resistance is 7.9×10 7 Ω / cm.

Embodiment 3

[0049] A high-structure conductive carbon black powder with a particle size of 30-50nm and a specific resistance ≤ 10Ω·cm, which accounts for 30% of the total weight of the functional layer, and polycaprolactam (PA6), which accounts for 69% of the total weight of the functional layer, and the corresponding dispersant, couple Coating agent, antioxidant, etc. are coated, dispersed, and mixed, and the A component is obtained by twin-screw granulation; the fiber-grade polycaprolactam chips are used as the B component. The two components are respectively added to the bins A and B of the compound spinning machine, and then enter the dryer for drying. Component A can also be dried by vacuum drum and directly put into the component A dry slice silo.

[0050] After the A and B components are melted and extruded by the A and B screws respectively, the melts are extruded into the spinneret components by the A and B metering pumps at a ratio of 18%:82%, and the melts are compounded in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com