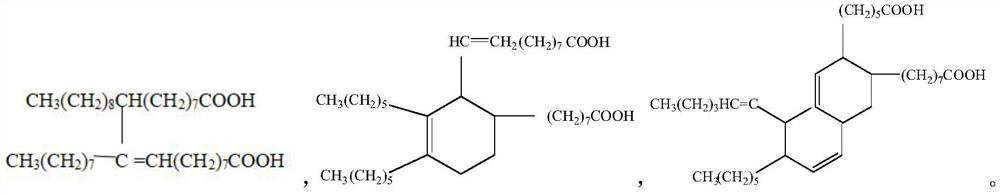

Two-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of lower production efficiency, complicated process, time-consuming, etc., and achieve high bonding shear strength , low mixing viscosity, good fluidity and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

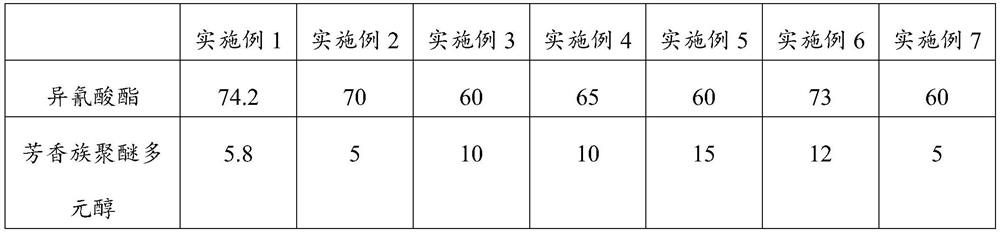

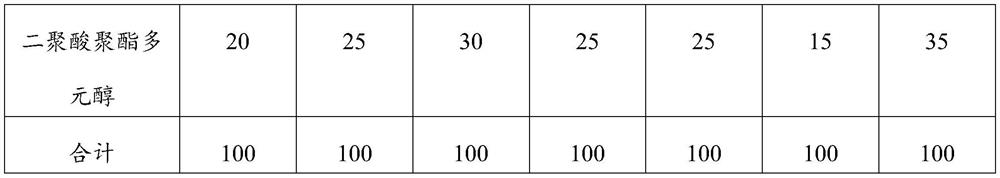

Embodiment 1

[0039] This embodiment provides a preparation method of a two-component polyurethane adhesive, comprising the following steps:

[0040] Preparation of component A: In parts by weight, add 72 parts of primary refined castor oil (hydroxyl value 164mgKOH / g), 10 parts T-400 and 6 parts of hydroxyl-terminated polybutadiene Polybd R45V, 11 parts of dipropylene glycol were heated to 120 ° C, and stirred and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, and then 0.59 parts of defoamer BYK6880, 0.01 1 part of wetting agent BYK307, 0.3 part of 3A molecular sieve, 0.1 part of fumed silica HDK H15, stirred for 1 hour in a vacuum state and discharged to prepare component A.

[0041] Preparation of component B: respectively add 67.5 parts of isocyanate CDMDI100L and 6.7 parts of isocyanate Suprasec 1004 into the reactor, continuously feed nitrogen, add dropwise 5.8 parts of bisphenol A polyether polyol BSA-30F, after the addition is completed, the temperature at 80±2 React a...

Embodiment 2

[0044] This embodiment provides a preparation method of a two-component polyurethane adhesive, comprising the following steps:

[0045] Preparation of component A: In parts by weight, add 61.5 parts of primary refined castor oil (hydroxyl value 164mgKOH / g), 10 parts of A30 castor oil modified polyol and 15 parts of hydrogenated hydroxyl-terminated polybutadiene polyol into the reactor Cray HLBH-P2000, 10 parts of 1,4-butanediol was heated to 120°C, stirred and dehydrated under vacuum for 2 hours, then cooled to 60°C, and then 0.5 parts of defoamer BYK067A, 0.2 parts of wetting agent TEGO- 4100, 1.5 parts of 4A molecular sieves, 0.3 parts of fumed silica AEROSIL R972, stirred for 1 hour in a vacuum state and discharged to obtain component A.

[0046] Preparation of component B: respectively add 63 parts of isocyanate MDI and 7 parts of isocyanate MDI-50 into the reactor, continuously feed nitrogen, add 5 parts of bisphenol A polyether polyol BSA-30F dropwise, after the additi...

Embodiment 3

[0049] This embodiment provides a preparation method of a two-component polyurethane adhesive, comprising the following steps:

[0050] Preparation of component A: in parts by weight, add 75 parts of primary refined castor oil (hydroxyl value 164mgKOH / g), 5 parts T-400 (hydroxyl value 450mgKOH / g) and 9.5 parts of hydroxyl-terminated polybutadiene polyol Cray LBH-P 2000, heat 7 parts of dipropylene glycol to 120°C, stir and dehydrate under vacuum for 2 hours, then cool down to 60°C, add 1 part of defoamer MOK6621, 0.2 parts of wetting agent TEGO-Wet265, 1.8 parts 3A molecular sieve, 0.5 parts fumed silica TS-720, stirred under vacuum for 1 hour and discharged to obtain component A.

[0051] Preparation of component B: respectively add 54 parts of isocyanate CDMDI100L and 6 parts of isocyanate MDI-50 into the reactor, continuously feed nitrogen, add 10 parts of bisphenol A polyether polyol BSA-30F dropwise, after the addition is completed, the temperature will be 80± React...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com