Nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material and preparation method thereof

A flame retardant polymer and composite material technology, applied in the field of flame retardant, can solve the problems of poor compatibility of flame retardant dispersion matrix, harm to human health and environment, complex preparation process, etc., to increase heterogeneous nucleation points, The effect of less smoke production and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

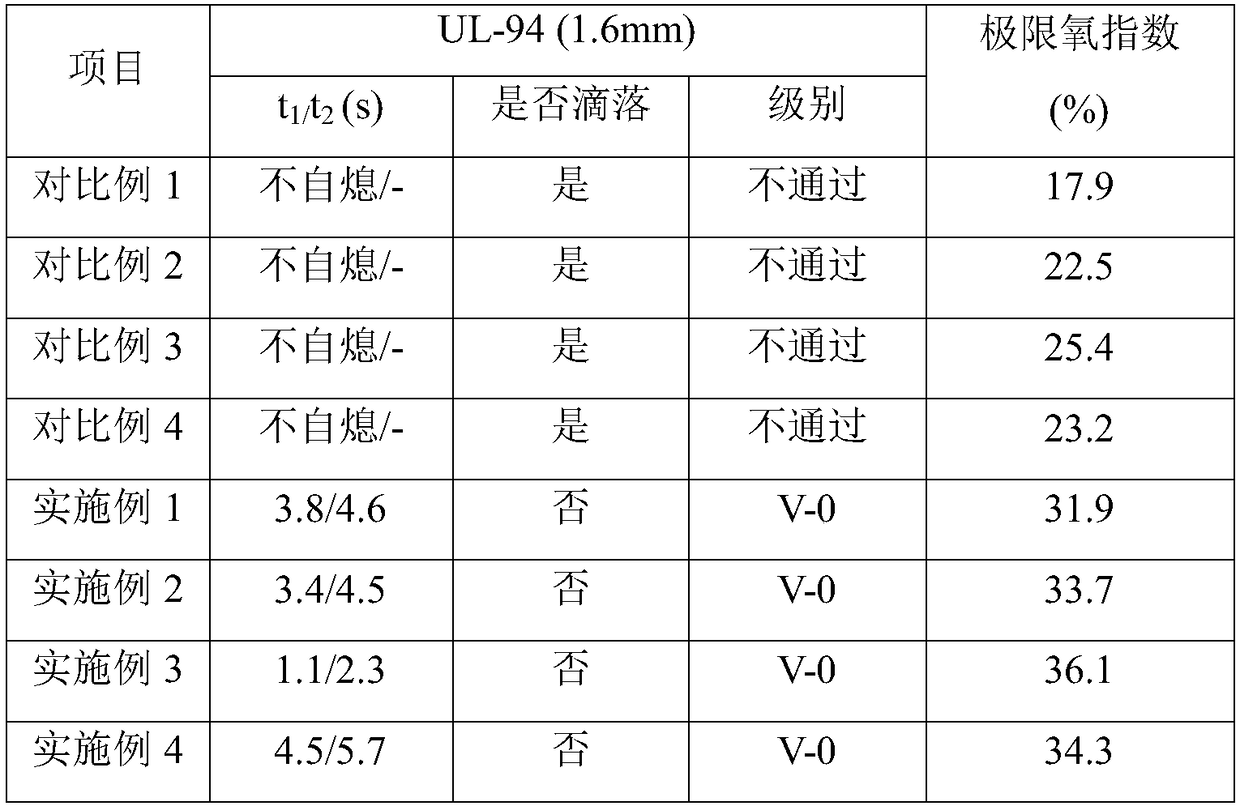

Examples

Embodiment 1

[0032] Mix polypropylene and nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant uniformly at a weight ratio of 75:25, then dry the above mixture in a blast drying oven at 60°C for 12 hours, and then dry it in an internal mixer at 190°C Refining for 15 minutes at a speed of 60 r / min, and finally putting the obtained pulverized block-shaped blended object in a mold of a certain specification, molding it on a flat vulcanizing machine, and then testing the flame retardancy.

Embodiment 2

[0034] Mix nylon 6 and nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant uniformly in a weight ratio of 80:20, then dry the above mixture in a blast drying oven at 60°C for 12h, and then put it in a twin-screw extruder at 270 °C, melt blending, extrusion, granulation, and finally the obtained blend particles were injection-molded in an injection molding machine for flame retardant performance testing.

Embodiment 3

[0036] Mix polycarbonate and nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant uniformly at a weight ratio of 85:15, then dry the above mixture in a blast drying oven at 60°C for 12 hours, and then dry it in an internal mixer at 240°C Blend for 10 minutes, the speed is 60r / min. Finally, the obtained pulverized block blended object is molded on a flat vulcanizing machine in a mold of a certain specification, and then the flame retardancy test is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com