High-safety primary lithium-manganese battery and preparation method thereof

A lithium-manganese battery, high-safety technology, applied in primary batteries, electrodes of primary batteries, battery electrodes, etc., can solve the problem of lack of electrolyte safety performance, independent research and development and design, battery fire, deflagration and explosion, reduce battery safety and stability It can reduce the risk of puncturing the diaphragm, weaken the contact, and improve the safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

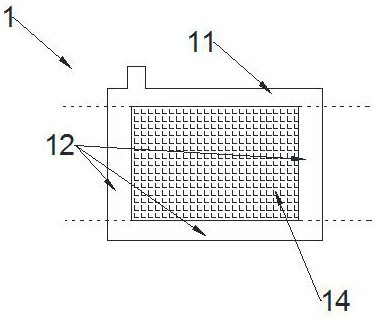

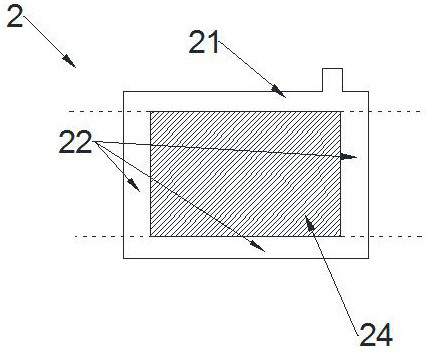

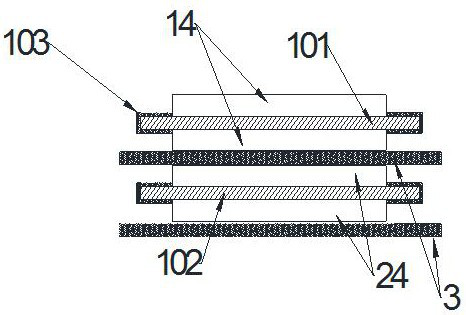

[0044] Such as Figure 1 to Figure 4 As shown, a high-safety primary lithium-manganese battery, a primary lithium-manganese battery includes a positive electrode sheet 1, a negative electrode sheet 2, a ceramic diaphragm 3, an electrolyte and a battery case 4, a positive electrode sheet 1, a ceramic diaphragm 3, a negative electrode sheet 2, The ceramic diaphragm 3 is stacked repeatedly in sequence to form a dry cell. The primary lithium-manganese battery is made by putting the dry cell into the battery case 4 and injecting electrolyte, aging, sealing, and aging. The negative electrode sheet is electrochemically pre-doped with lithium. The "full-charged secondary lithium battery negative electrode sheet" or "zero-charged lithium / carbon half-cell positive electrode sheet" is transformed into a pre-lithiated negative electrode sheet 2, and both sides of the positive electrode sheet 1 are provided with a positive electrode sheet pre-set. Tabs 11 are left, and the positive and neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com