Patents

Literature

60results about How to "Suppressor enrichment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

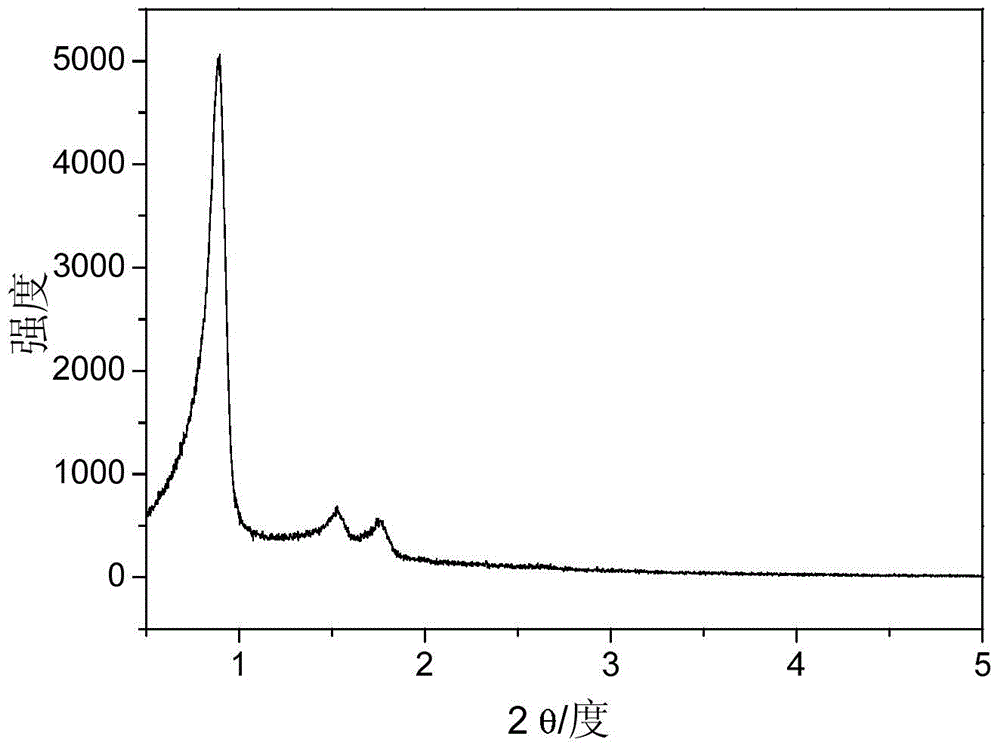

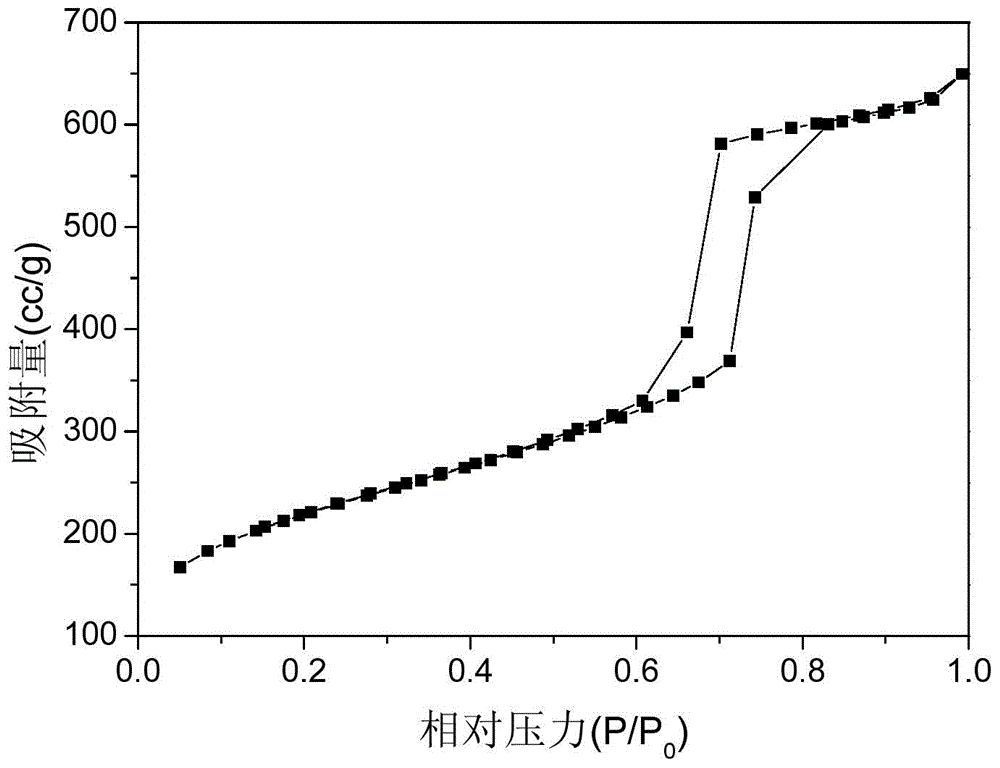

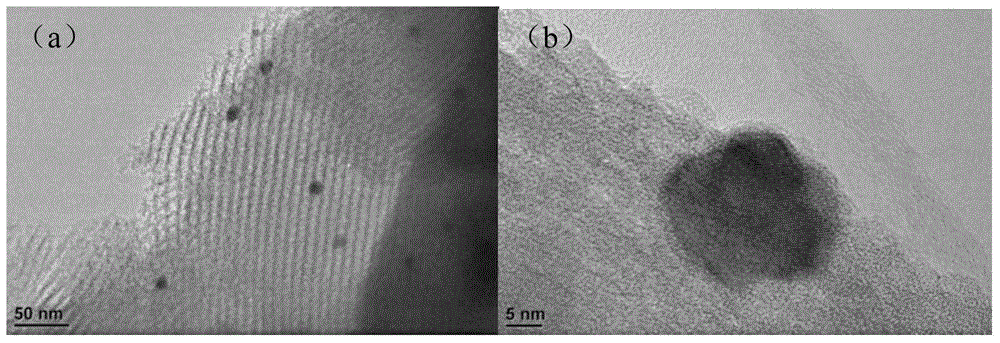

Dehydrogenation catalyzing material as well as preparation method and application thereof

ActiveCN103816933AImprove stabilitySuppressor enrichmentMolecular sieve catalystsHydrocarbonsPlatinumPtru catalyst

The invention provides a dehydrogenation catalyzing material as well as a preparation method and application thereof. The dehydrogenation catalyzing material comprises the following components by weight: 0.5-5% of platinum element, 1-10% of IVA metal, 0.1-1% of Al and the balance of mesoporous silicon material, wherein the mesoporous silicon material serves as a carrier, the platinum element serves as a catalyst, the IVA metal serves as a first auxiliary and the Al serves as a second auxiliary. Compared with a multiple dipping method, the preparation method has the advantages that the active components and auxiliary elements are dipped and carried on the mesoporous silicon carrier in one step, so that the preparation method is simple in operation and short in preparation cycle; molecules of the active components and auxiliaries of the catalytic material obtained through one-step dipping are in fuller contact, which is beneficial to inhibit the enrichment of carbon on the active components, so that the deactivation rate is reduced and the stability of the catalytic material is increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

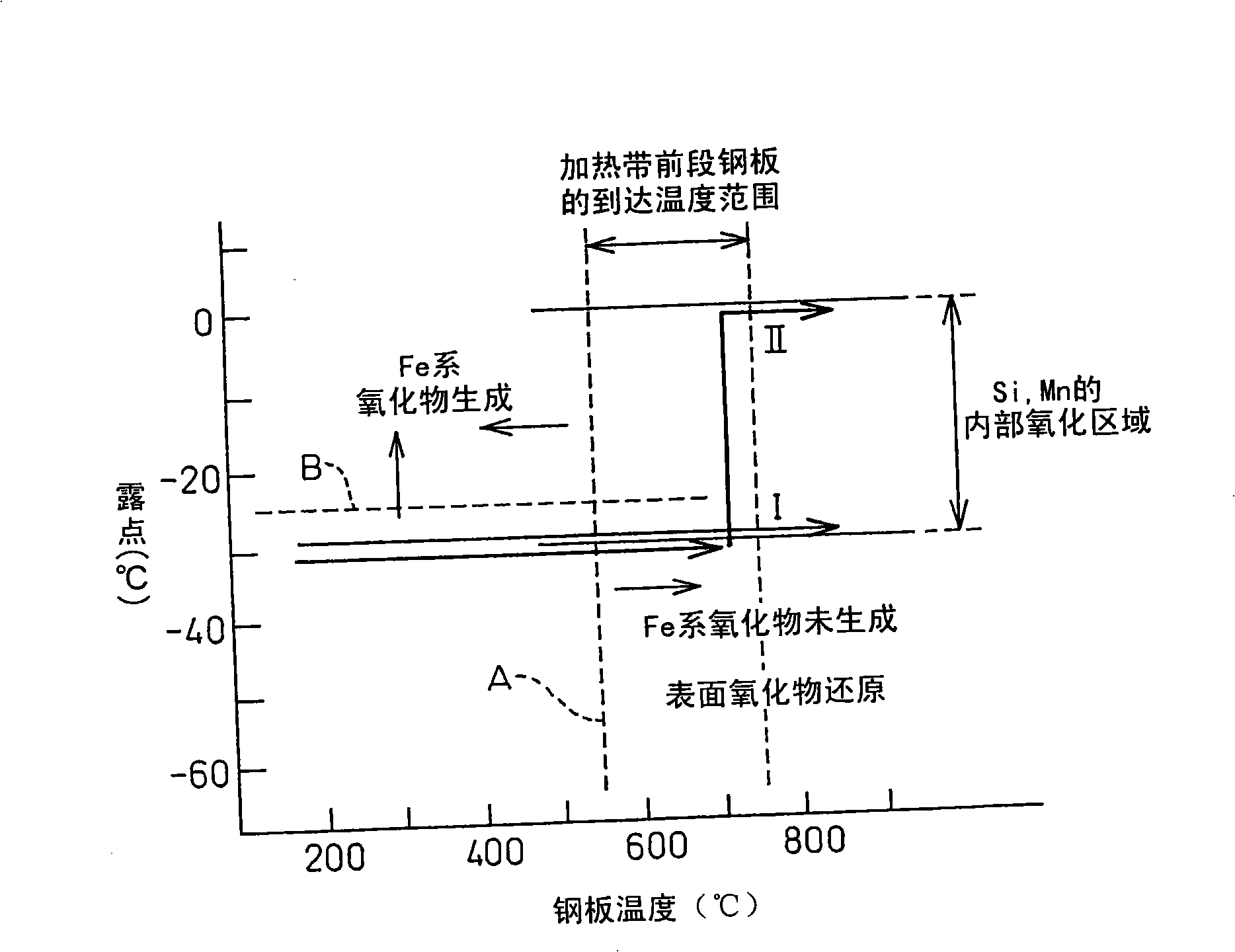

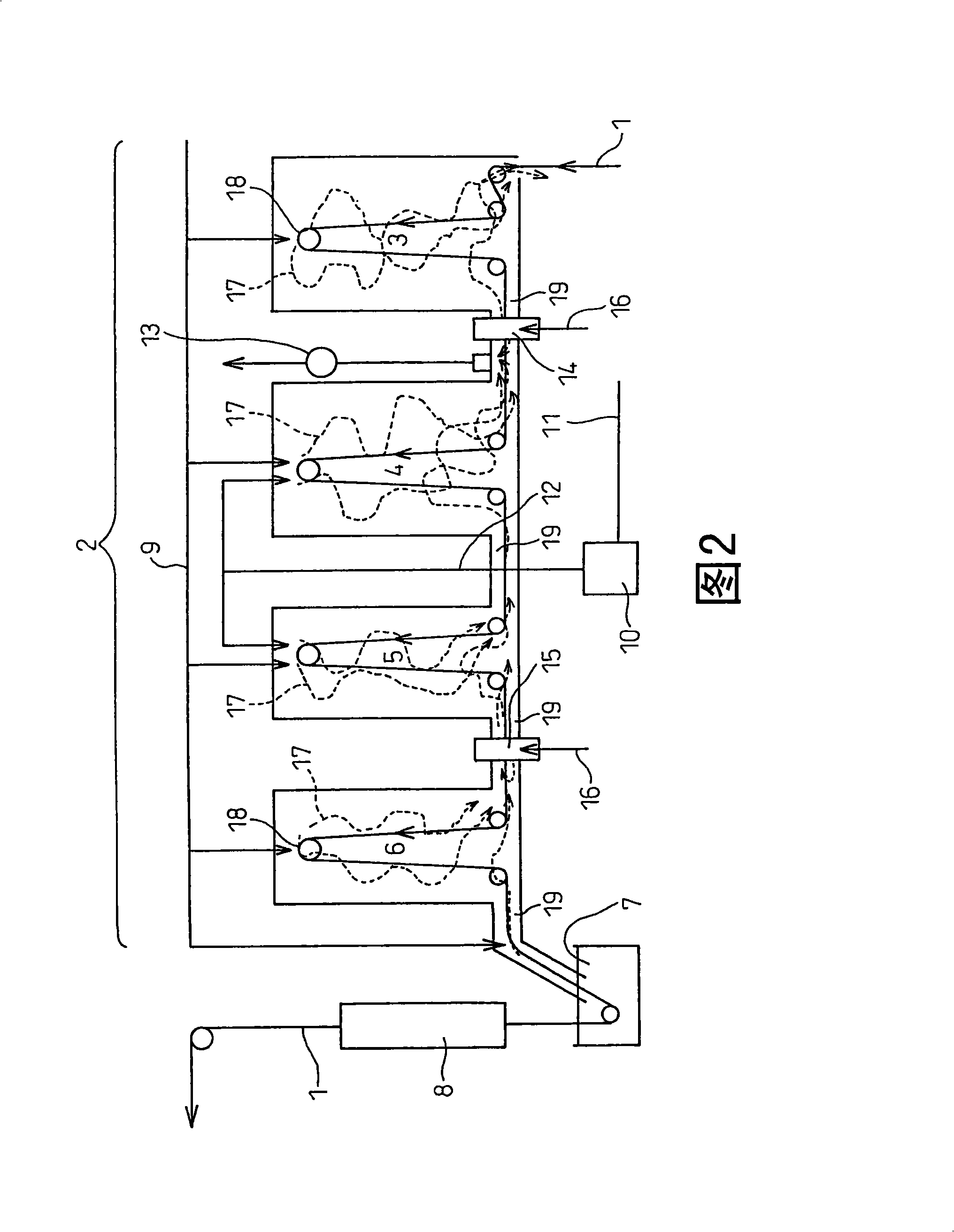

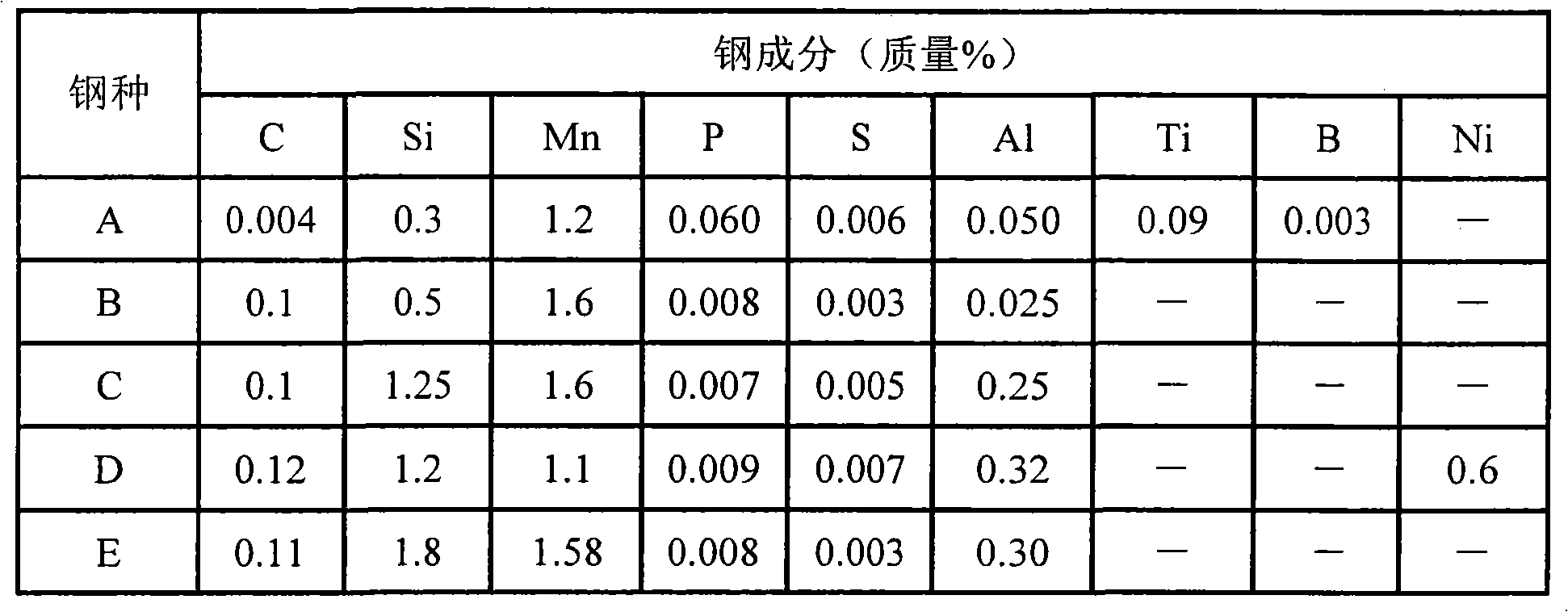

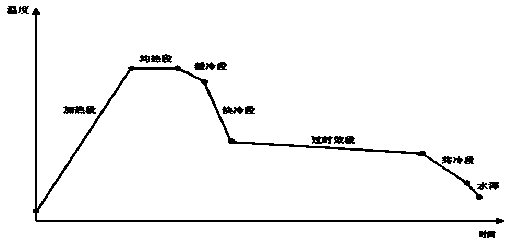

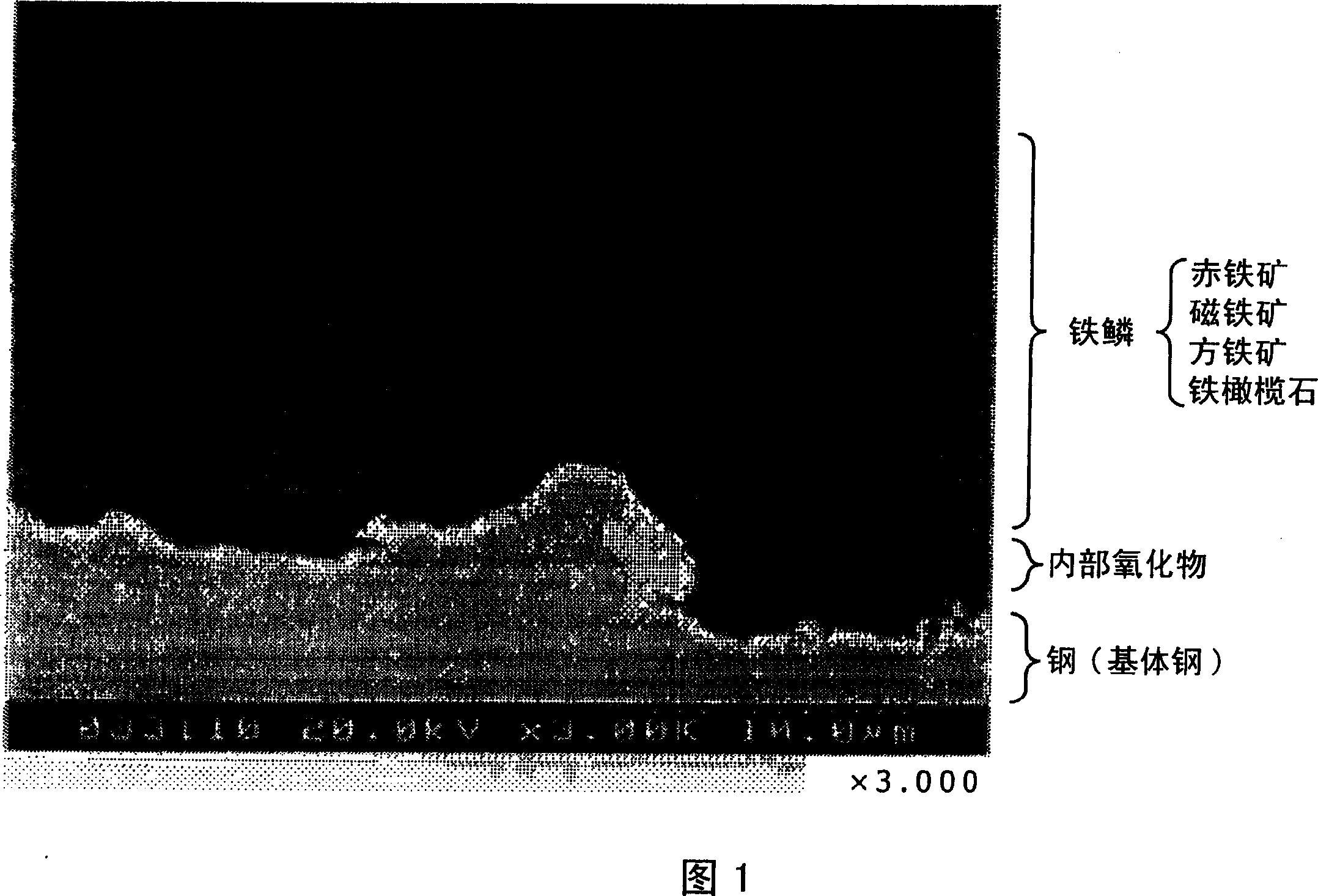

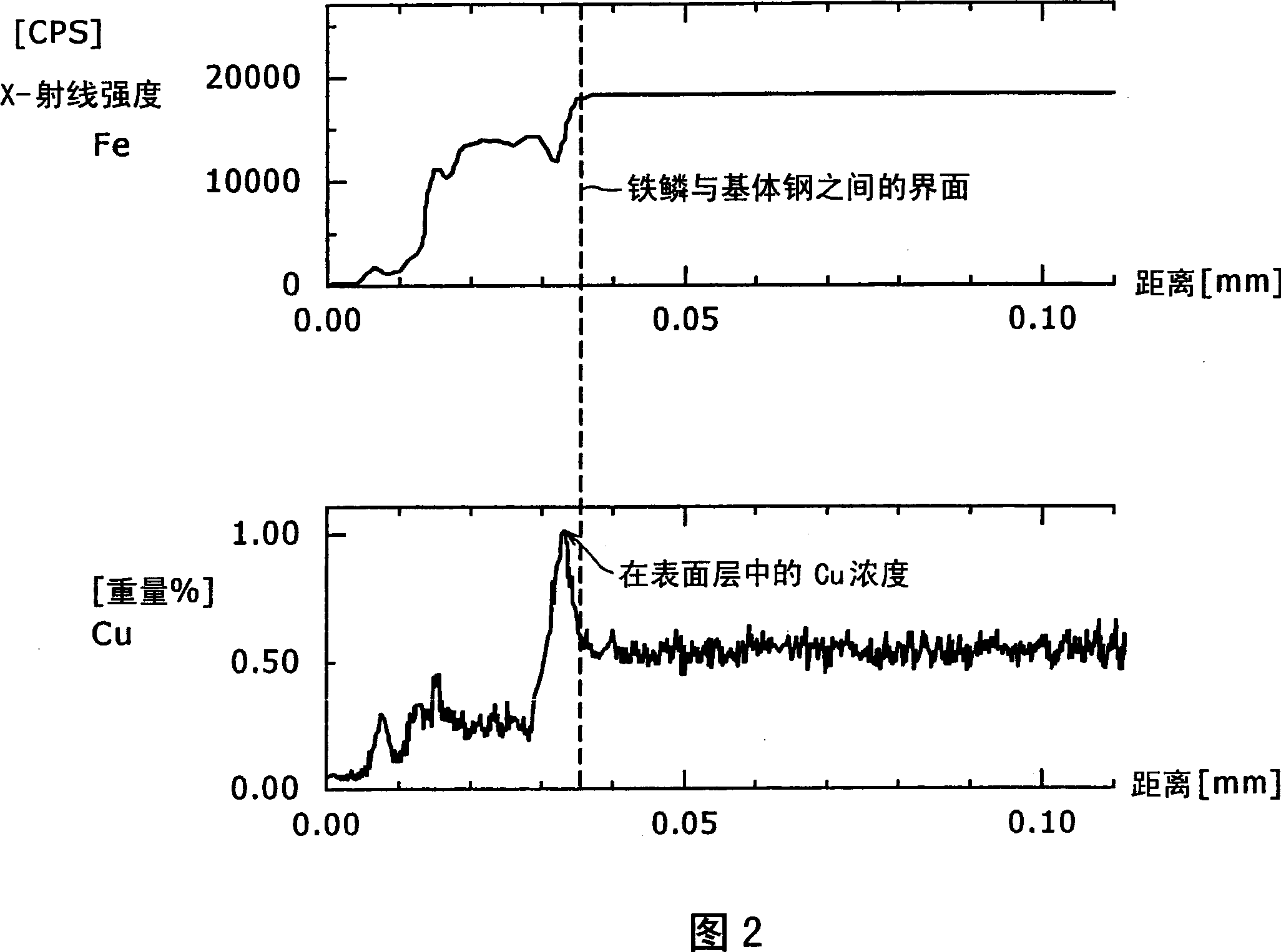

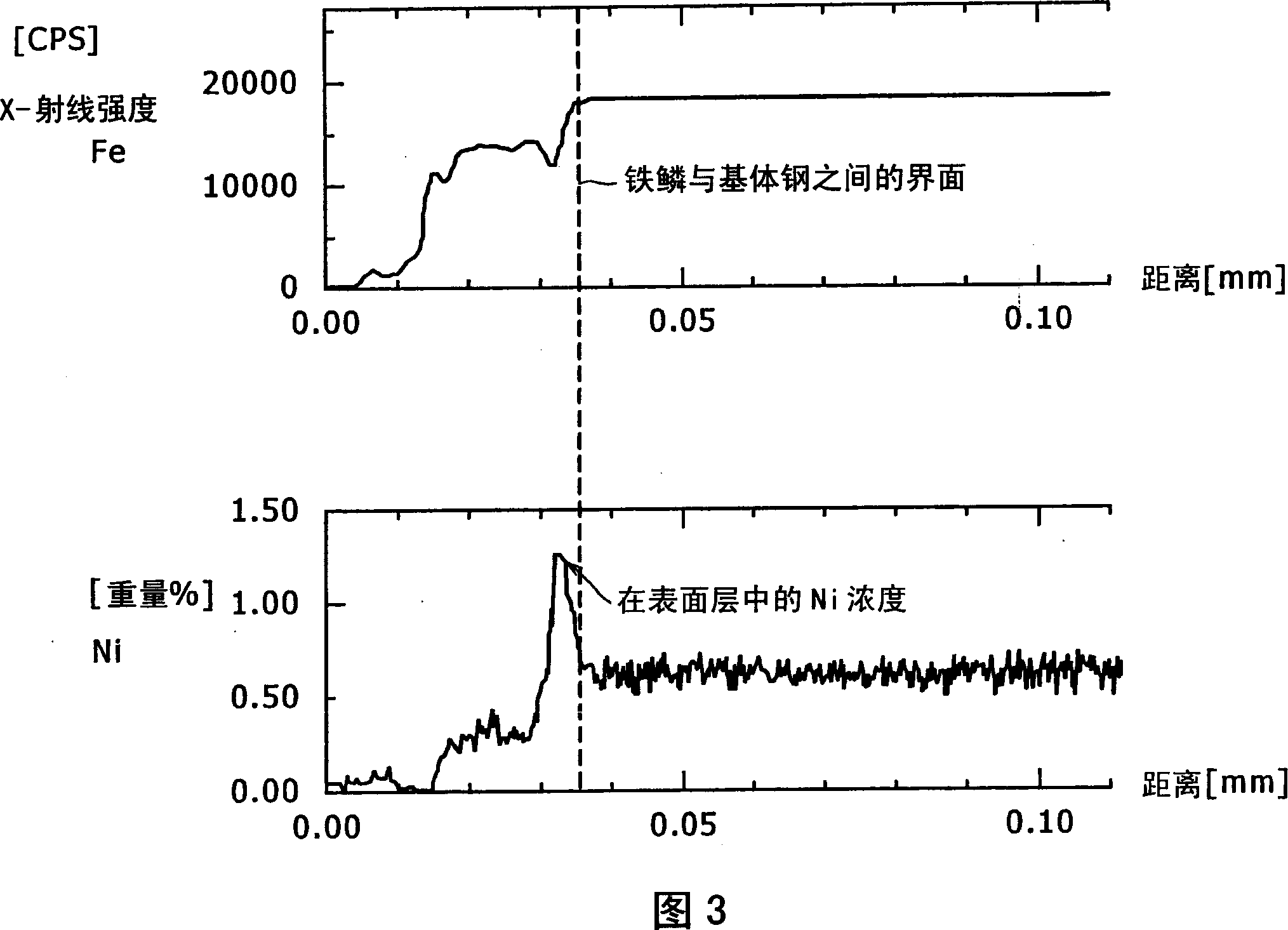

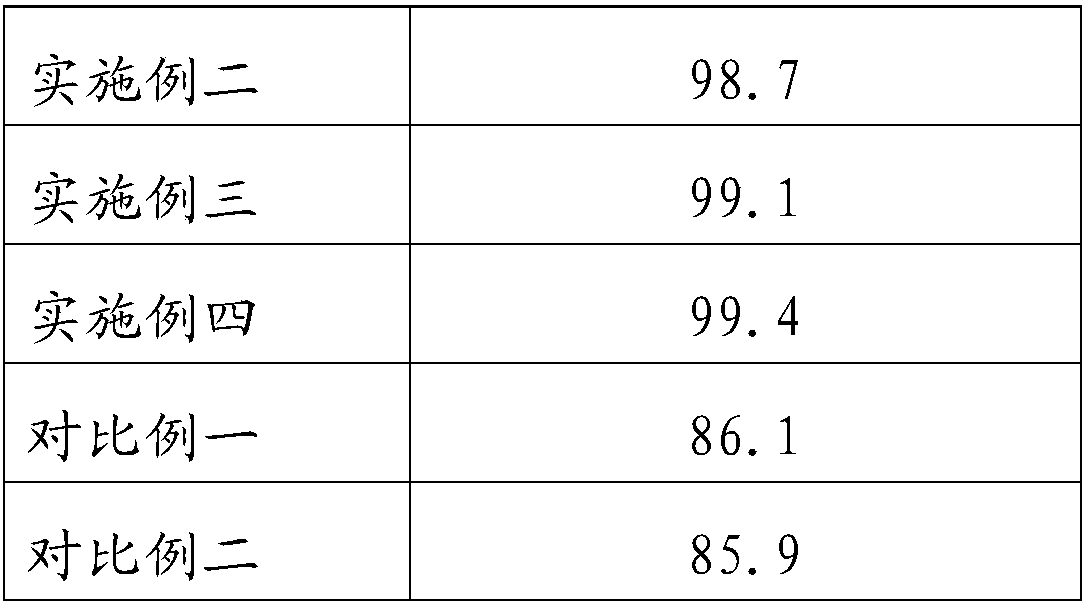

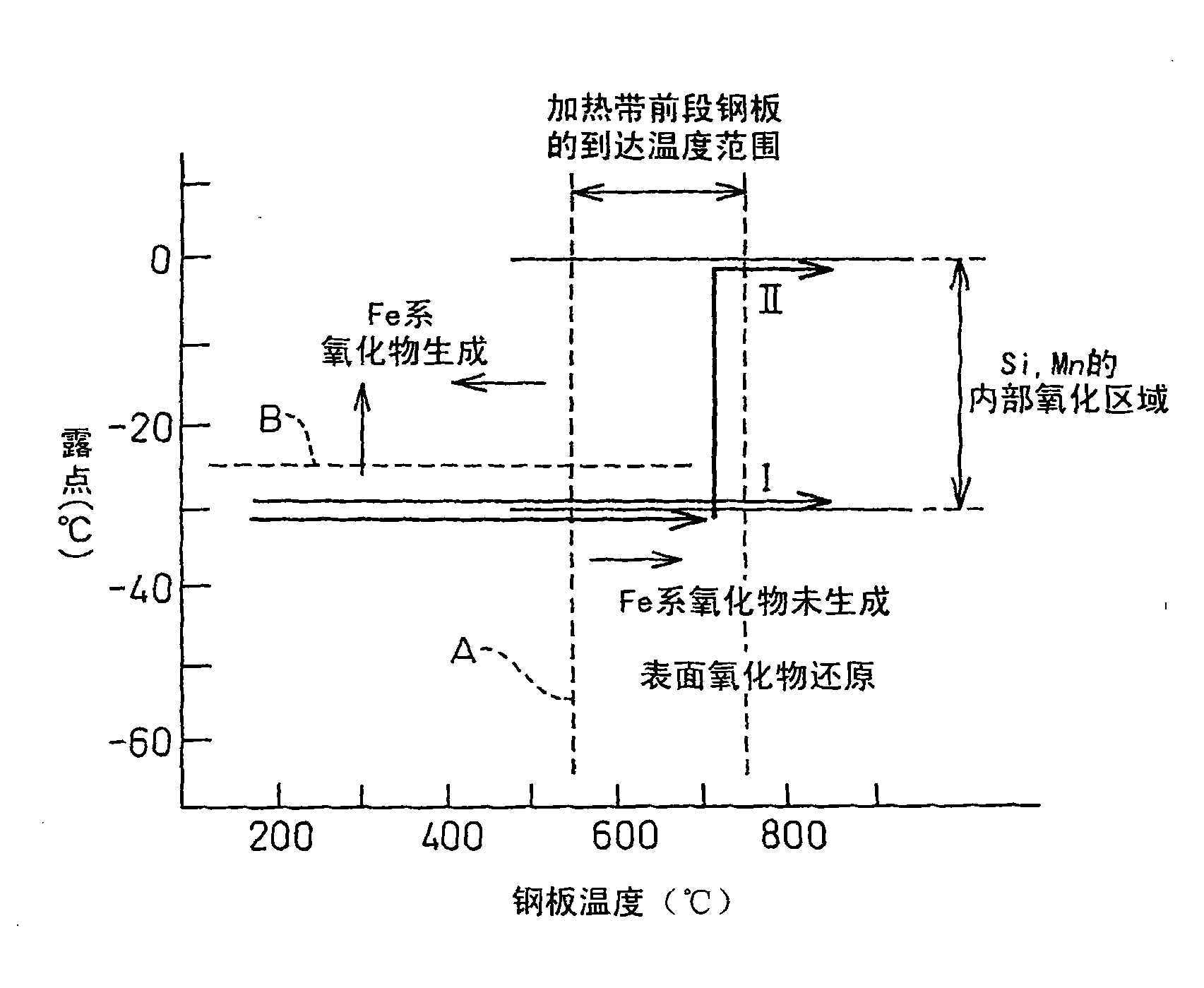

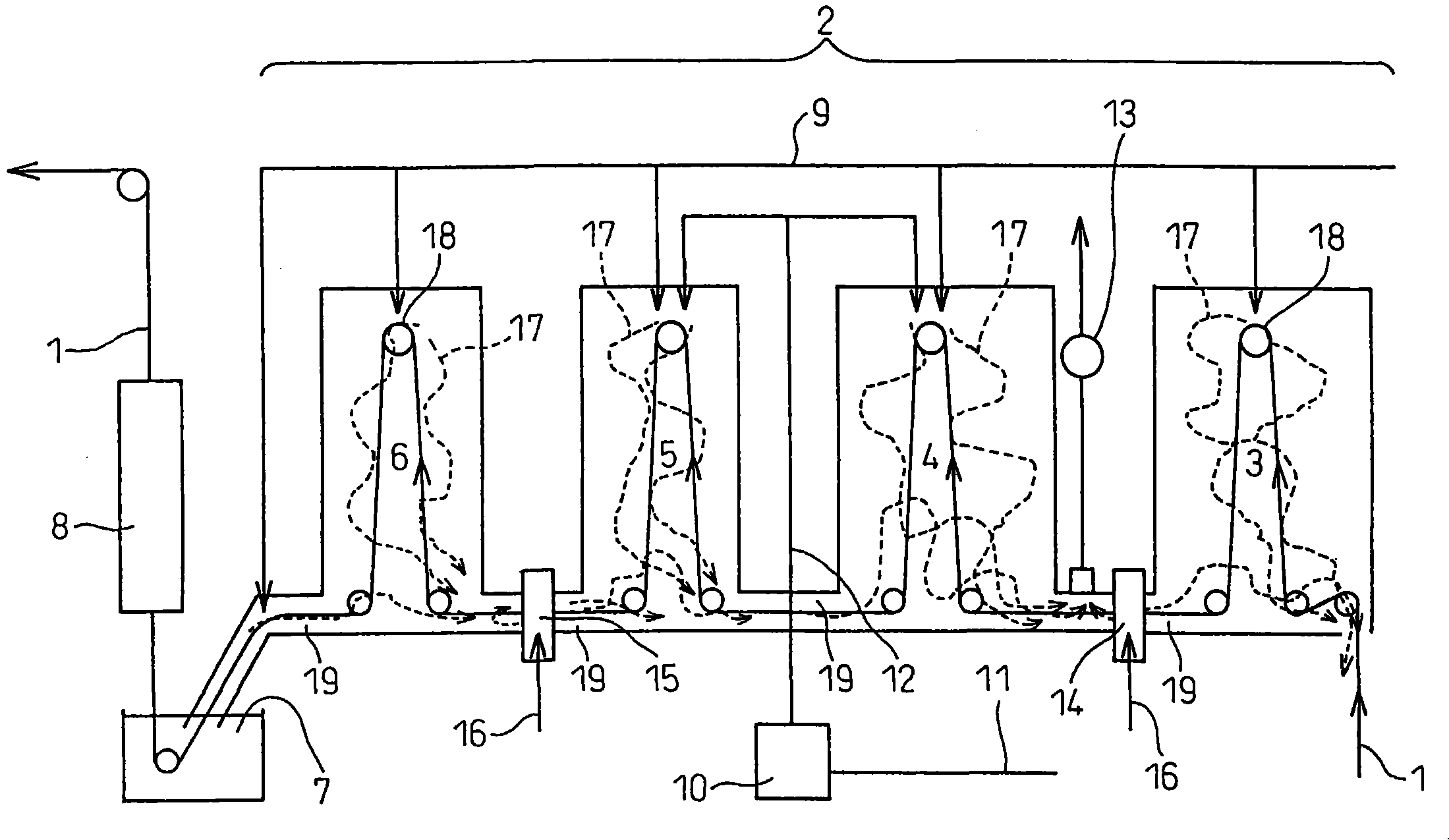

Method of continous annealing/hot-dipping of steel sheet containing silicon and apparatus for continuous annealing/hot-dipping

ActiveCN101287854ASuppressor enrichmentAvoid generatingHot-dipping/immersion processesFurnace typesSheet steelHydrogen

A method of continuous annealing / hot-dipping using a hot-dipping apparatus having an annealing furnace in which a silicon-containing steel sheet is hot-dipped. In this method, the silicon contained in the steel is caused to undergo internal oxidation without undergoing surface oxidation to thereby avoid a decrease in deposit adhesion to the steel and a delay in galvannealing. Also provided is the apparatus for use in this method. The method of continuous annealing / hot-dipping employs an annealing furnace having a former heating zone, latter heating zone, heat retention zone, and cooling zone in this order and a hot-dipping bath. It comprises conducting annealing under the following conditions. In regions where the steel sheet has a temperature of at least 300 DEG C, the steel sheet is heated or kept hot by means of indirect heating. The atmosphere inside the furnace in each zone is an atmosphere consisting of 1-10 vol.% hydrogen and, as the remainder, nitrogen and unavoidable impurities. In the former heating zone, the steel is heated to a maximum temperature of 550-750 DEG C and the atmosphere is regulated so as to have a dew point lower than -25 DEG C. In the subsequent latter heating zone and heat retention zone, the dew point is regulated to from -30 DEG C to 0 DEG C. In the cooling zone, the dew point is regulated to below -25 DEG C.

Owner:NIPPON STEEL CORP

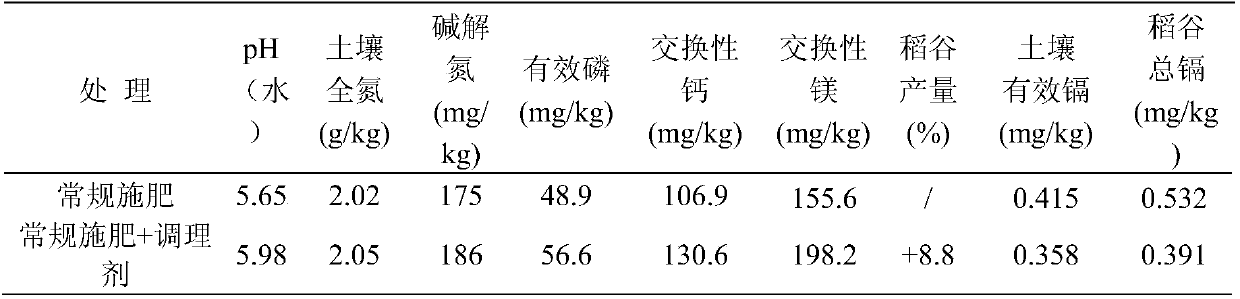

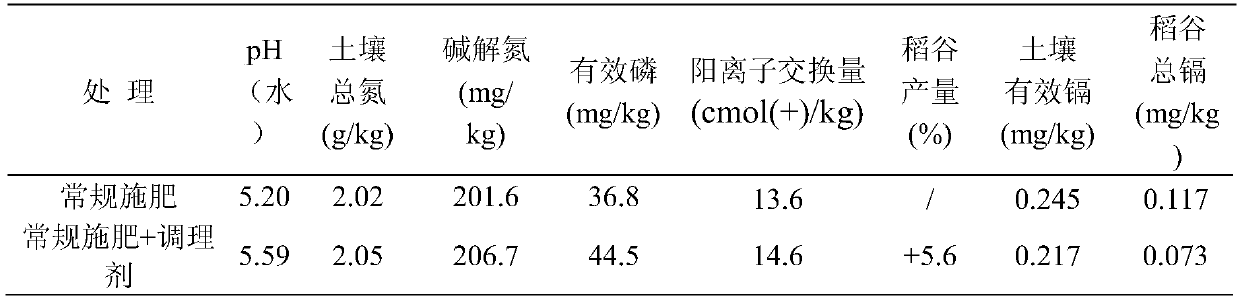

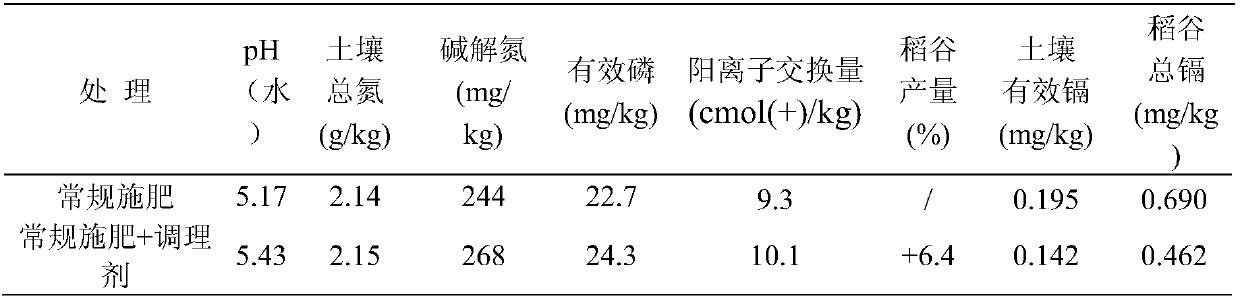

Acidic soil conditioner and application thereof

InactiveCN107629798ARaise the pHImprove and restore traitsOther chemical processesOrganic fertilisersContaminationCalcium magnesium

The invention discloses an acidic soil conditioner and an application thereof. The acidic soil conditioner comprises, by mass, 33-36% of rice husk ash, 14-16% of quicklime, 24-26% of calcium magnesiumphosphate, 22-24% of sepiolite and 1.5-2% of dicyandiamide. The conditioner includes the rice husk ash, quicklime, calcium magnesium phosphate, sepiolite and dicyandiamide, and the rice husk ash, quicklime and calcium magnesium phosphate fertilizer are alkaline substances and can increase the pH value of the soil. The rice husk ash and calcium magnesium phosphate commonly act to supplement nutrients lost due to soil acidification. The sepiolite and dicyandiamide commonly act to improve the nitrogen fertilizer utilization rate. The rice husk ash and sepiolite commonly act to improve and repairacidic heavy metal contaminated soil. The rice husk ash, calcium magnesium phosphate and sepiolite commonly act to inhibit the enrichment of cadmium and other heavy metals in crops. The acidic soil conditioner can comprehensively improve the properties of the soil, improve the fertility level of the soil, reduce the cadmium contamination risk of the crops and increase the yield of the crops.

Owner:HUNAN SOIL & FERTILIZER INST

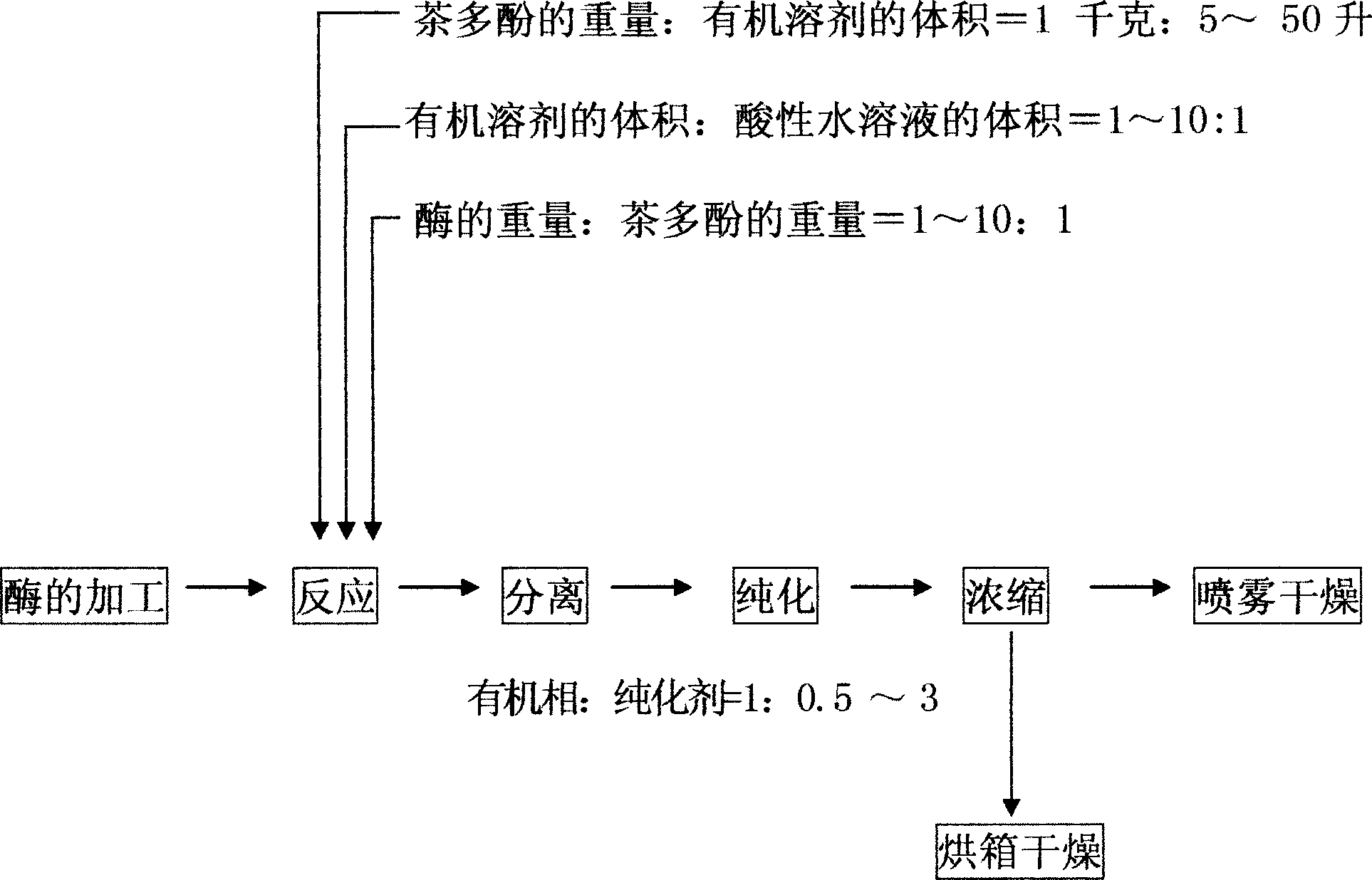

Method for preparing tea pigment

A process for preparing the tea pigment includes such steps as mashing fresh tea leaves, adding enzyme, adding them to the solution of theopolyphenol in organic solvent, adding acidic aqueous solution, enzymatic oxidizing-polymerizing reaction, separating to obtain tea red, tea yellow and tea brown, purifying, concentrating and drying.

Owner:SHIJI BIOLOGICAL MEDICINES WUXI CITY

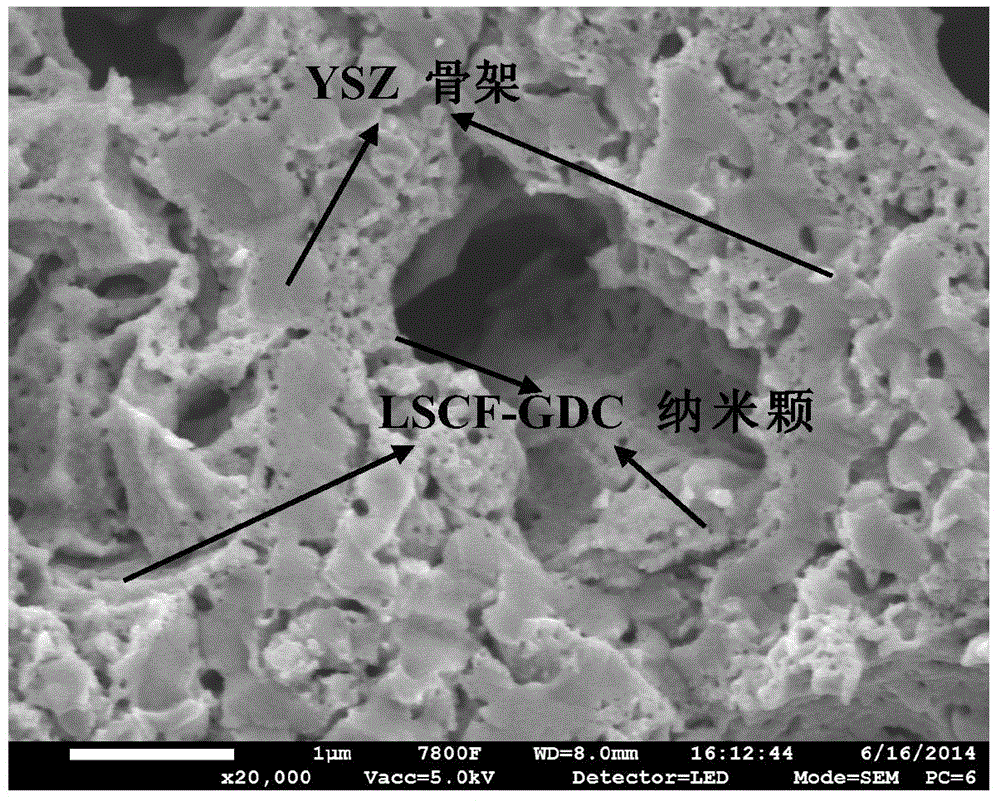

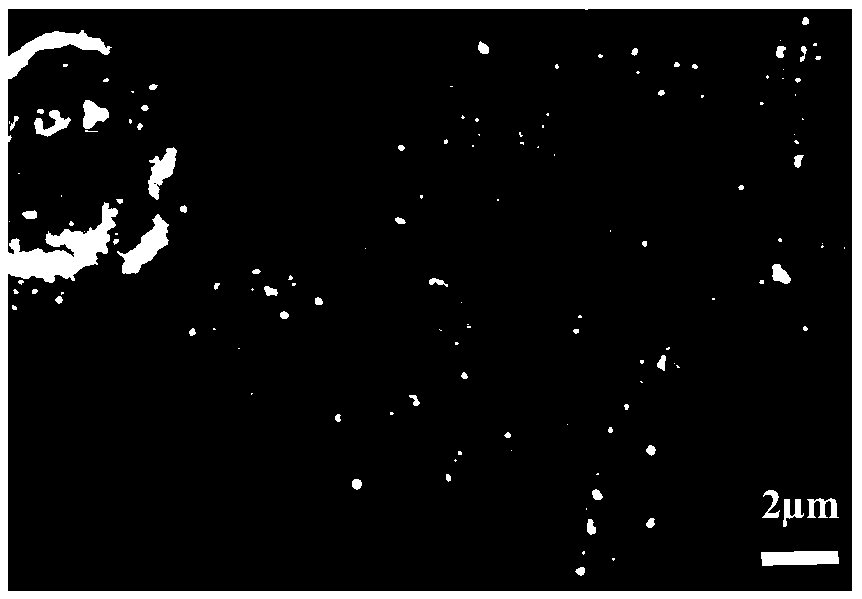

Positive electrode material provided with pomegranate fruit structure for solid-oxide fuel cell and preparation of positive electrode material

The invention relates to high-performance and intermediate- and low-temperature composite positive electrode material with a pomegranate fruit structure for a solid-oxide fuel cell. The composite positive electrode is particularly an LSCF-GDC & YSZ nanometer composite positive electrode in which an LSCF-GDC pomegranate seed layer is attached onto an YSZ framework diaphragm, wherein the size of pomegranate seed LSCF-GDC particle is 10-20 nanometers, and the YSZ diaphragm is formed by connecting particles of around 200 nanometers. The positive electrode with such structure has a relatively long three-phase boundary, and the YSZ diaphragm is grown with an electrolyte membrane after high-temperature sintering to form a smooth ionic conductive passage; and moreover, with the addition of GDC in the LSCF-GDC nanometer composite particle, Sr is prevented from being enriched in an LSCF surface, thus, the generation of a high-resistance phase SrZrO<3> is prevented, and the performance and the stability of the electrode are remarkably improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cathode material of solid oxide fuel cell and preparation and application thereof

ActiveCN105226294AReduce surface chargeReduce surface stressCell electrodesSputteringScreen printing

The invention discloses a cathode material of a solid oxide fuel cell and a preparation method thereof. The cathode material is characterized in that the cathode material is a composite negative electrode formed by a perovskite oxide and an oxide MO2 modified on the surface of the perovskite oxide, wherein M is Ti, Zr, Nb, Ce, Ru or Sn, the mass content of the oxide MO2 in the composite negative electrode accounts for 1-20%, the particle size of the oxide MO2 is 0.5 to 100 nanometers, and the oxide MO2 in the composite negative electrode coats the surface of the perovskite oxide. The perovskite oxide can be first prepared on the surface of an electrolyte or a partition layer of the battery by methods of coating, silk-screen printing, flow casting and the like, and then the oxide MO2 is modified on the surface of the perovskite oxide in the negative electrode by methods of solution impregnation, sol impregnation, magnetron sputtering and the like. The cathode material disclosed by the invention is endowed with excellent electrochemical performance and favorable stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of catalyst used for preparing vinyl chloride by acetylene hydrochlorination

InactiveCN103418411AInhibit migrationSuppressor enrichmentPreparation by halogen halide additionCatalyst activation/preparationActivated carbonActive carbon

The invention provides a preparation method of a catalyst used for preparing vinyl chloride by acetylene gas-phase hydrochlorination. Active carbon is used as a carrier. The preparation method comprises following steps: active carbon is used as a carrier, a reactive metal is fixed on active carbon by immersing; and after that, the active carbon carrier is placed in a drying tower, and is provided with electricity so that heat is generated and the drying process of the catalyst preparation is completed. The activity of the catalyst prepared by the preparation method is higher than that of the catalyst prepared by traditional drying method.

Owner:冯良荣

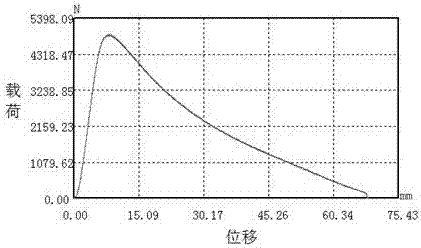

Tin-bismuth composite alloy and preparation method thereof

The invention discloses a tin-bismuth composite alloy and a preparation method thereof. The method comprises the following steps: synthesizing conductive polymer nano fiber, and preparing a metal coating layer on the surface of the conductive polymer nano fiber; adding the conductive polymer nano fiber with the metal coating layer into an organic solvent, and dispersing; performing secondary doping treatment; preparing nano tin powder and nano bismuth powder respectively; adding the obtained nano tin powder and nano bismuth powder into the organic solvent, and performing acid pickling treatment; performing purification treatment to obtain pure nano composite powder; mixing the obtained conductive polymer nano fiber after the secondary doping treatment, the obtained nano composite powder and a soldering flux, and stirring to obtain uniform tin-bismuth composite powder; performing sintering treatment on the tin-bismuth composite powder to obtain the tin-bismuth composite alloy. Through the method, a low-temperature tin-bismuth composite alloy material with a low melting point and high toughness is obtained.

Owner:HOERSON ELECTRONICS TECH +1

Control method of coating performance surface quality of double-phase steel cold-rolled high-strength automobile board

ActiveCN109136739AIncrease roughnessImprove surface qualityFurnace typesHeat treatment furnacesDouble phaseHigh pressure water

The invention discloses a control method of coating performance surface quality of a double-phase steel cold-rolled high-strength automobile board, which comprises smelting, continuous casting, hot rolling, descaling, acid rolling, continuous annealing and leveling. The descaling process uses a three-stage descaling process, wherein the descaling position comprises descaling after a heating furnace, descaling before rough rolling and descaling before finish rolling, the descaling pressure at each descaling point is greater than or equal to 24MPa, the rough rolling is reciprocating rolling, therolling is carried out for 5 times, and high-pressure water descaling is carried out for every time. By adjusting and optimizing a whole process production process, including controlling the chemicalcomposition of a continuous casting blank, improving the heating and cooling system of the continuous casting, hot rolling, and cold rolling, controlling the hot rolling and descaling processes and cold rolling and acid rolling processes, controlling the roughness of a leveled steel strip, and the like, the surface quality of the double-phase steel cold-rolled automobile board is improved, the element enrichment on the surface of the steel board is inhibited, the quality of a phosphating film is improved, the coating performance of the double-phase steel cold-rolled high-strength automobile board and the anti-corrosion performance of the double-phase steel cold-rolled high-strength automobile board after being coated are improved.

Owner:TANGSHAN IRON & STEEL GROUP +1

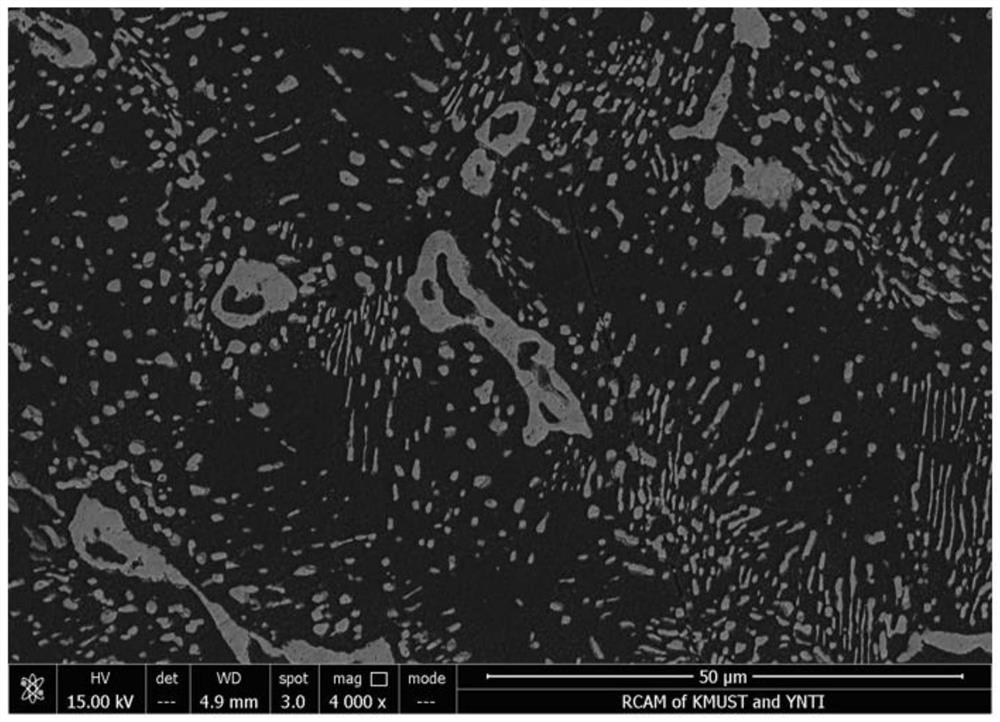

1500MPa ultrahigh-strength low-density steel and preparation method thereof

ActiveCN112813356ARaise the solid solution limitIncreased austenite contentFurnace typesHeat treatment furnacesManganeseMetallic materials

The invention discloses 1500MPa ultrahigh-strength low-density steel and a preparation method thereof, and belongs to the field of advanced metal materials. Aiming at the problems of low plasticity and poor comprehensive mechanical property of existing medium-low manganese low-density steel, the invention provides the 1500MPa ultrahigh-strength low-density steel which comprises the following components in percentage by mass: 1-1.6% of C, 8-16% of Mn, 6-11% of Al, 1.5-9% of Cr and the balance of Fe and inevitable impurity elements in iron. By adding the chromium element, the solid solution limit of carbon atoms is improved, the solidification rate of molten steel is high in the solidification process, enrichment of kappa carbides at the grain boundary of a low-density steel matrix and precipitation of intracrystalline coarse kappa carbides are inhibited, and therefore the plasticity of the steel is greatly improved. In addition, the element Cr is beneficial to the corrosion resistance and the oxidation resistance of the steel matrix. The tensile strength of the steel reaches 1500 MPa, the percentage elongation after fracture ranges from 10% to 50%, and the mechanical property is stable. According to the preparation method, the strength is further improved, the process is simple, consumed time is short, and the preparation and production efficiency of the high-performance low-density steel plate is greatly improved.

Owner:SHANGHAI UNIV

Spring steel wire rod excellent in pickling performance

InactiveCN1982494AImprove surface propertiesImprove pickling effectSpringsFurnace typesWire rodSurface layer

Owner:KOBE STEEL LTD

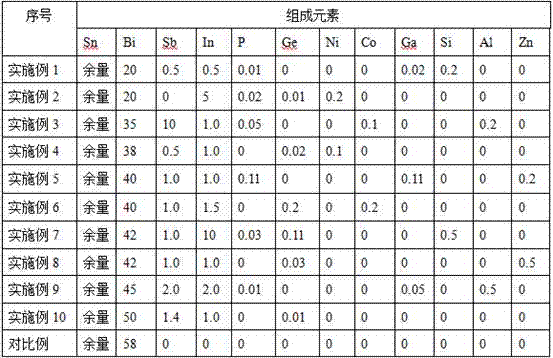

Low-temperature lead-free solder alloy

InactiveCN107984110AImprove mechanical propertiesAvoid it happening againWelding/cutting media/materialsSoldering mediaMechanical propertyMulti element

Owner:KUNMING UNIV OF SCI & TECH +1

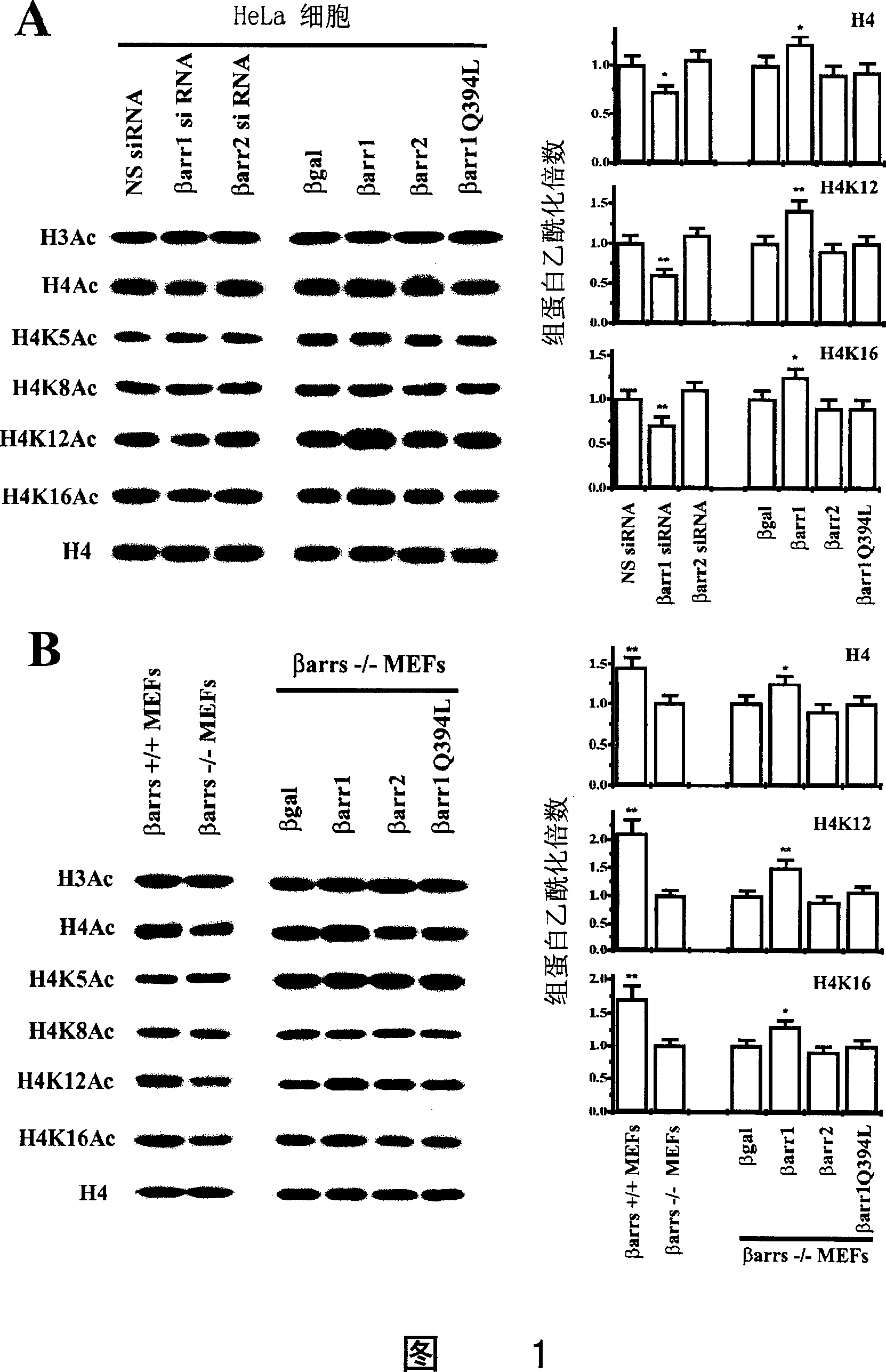

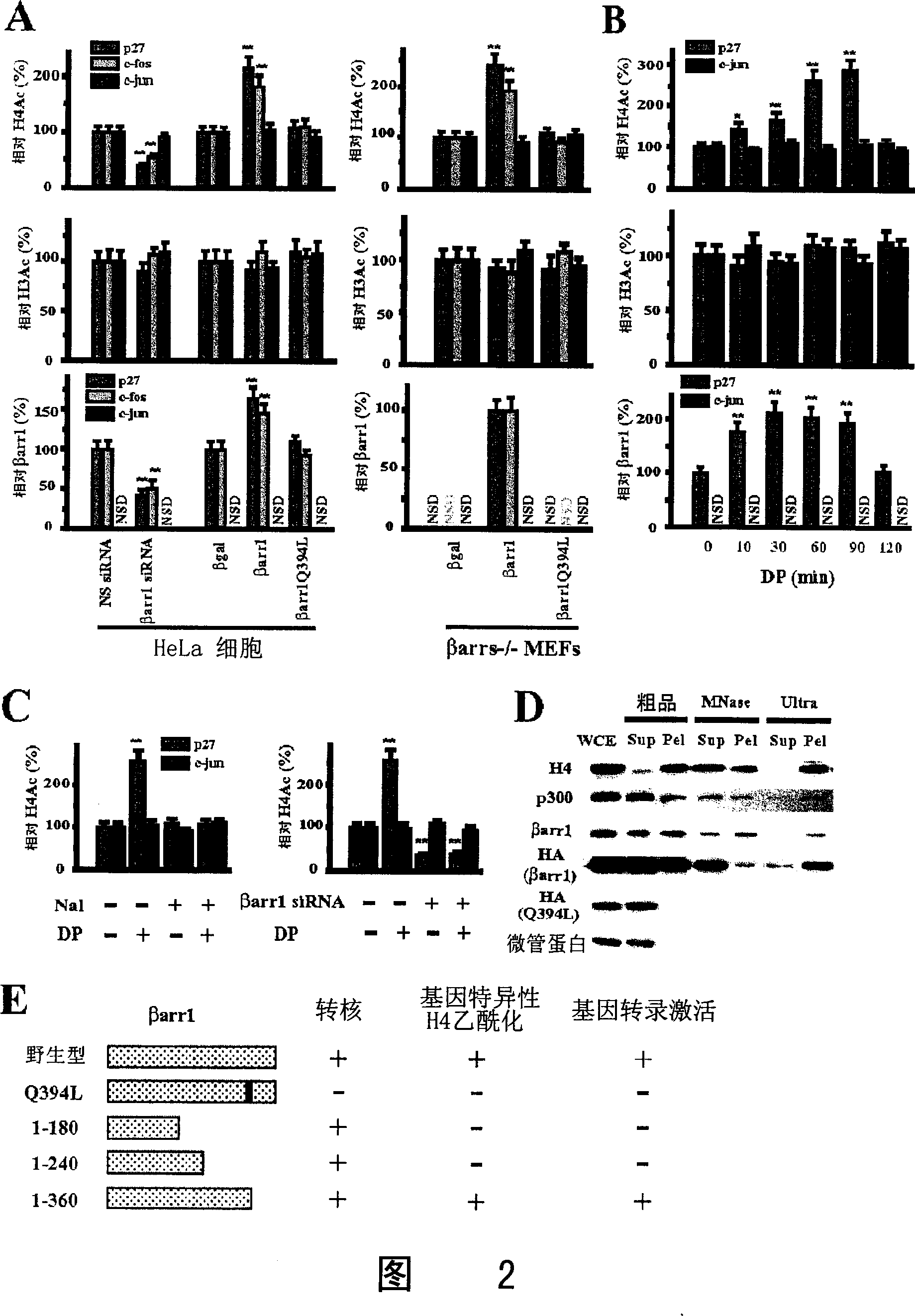

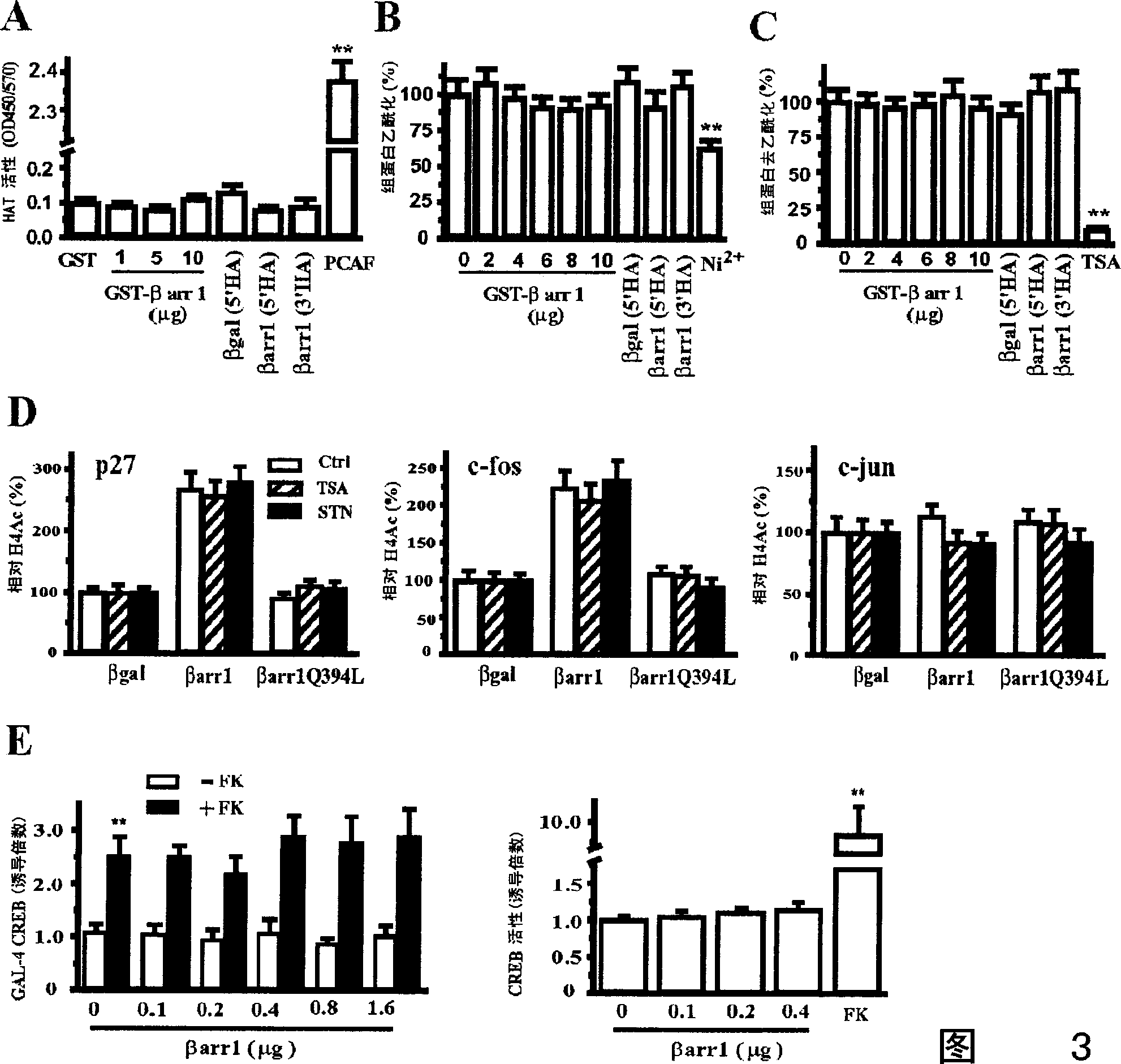

Application of beta-protein inhibitor in preparation of medicament for treating genetic correlated disease

InactiveCN1970074AImprove the level ofDoes not affect activityNervous disorderPeptide/protein ingredientsDiseaseMedicine

The invention discloses a beta-inhibiting protein, nucleonic sequence and application of composition with nucleonic sequence to treat relative disease with histone acetylated reduction level, which also relates to the application of delta opitum receptor stimulating agent or k opitum receptor exciting agent to treat relative disease with histone acetylated reduction level. The invention provides a drug sieving method from candidate material to treat relative disease with histone acetylated reduction level.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI +1

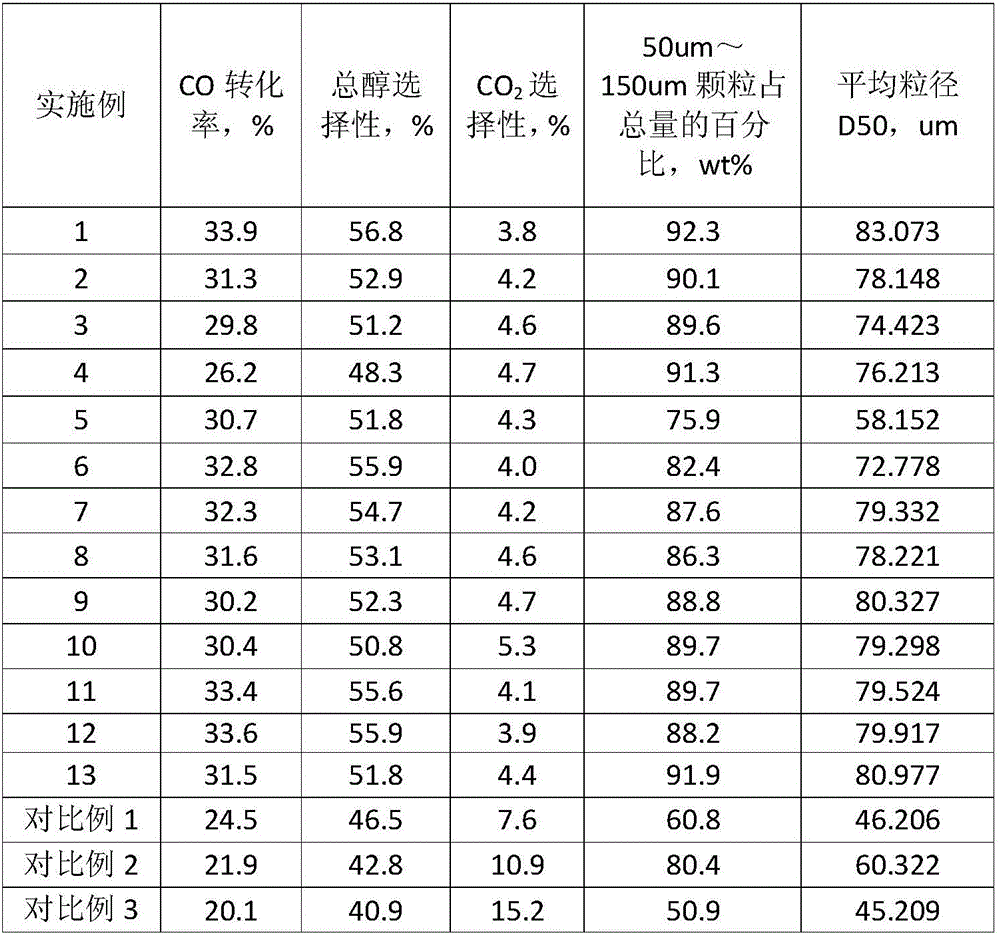

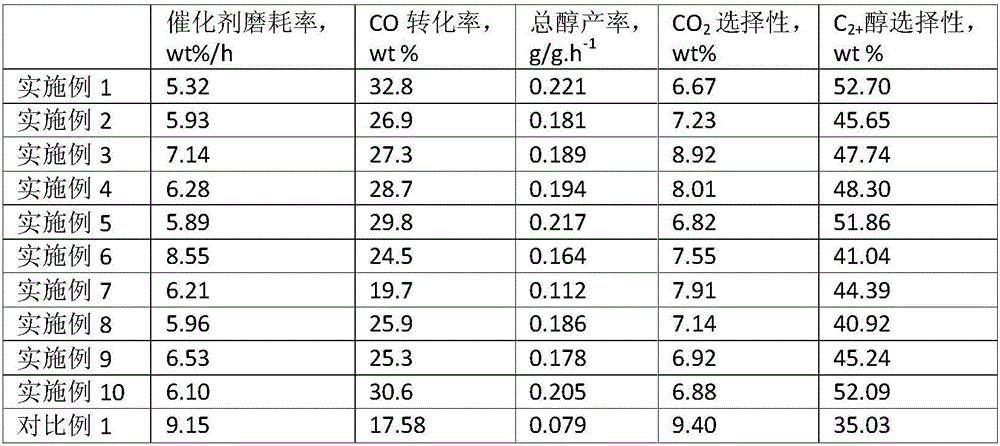

Catalyst, and preparation method and application thereof

ActiveCN106492814AEvenly dispersedSuppressor enrichmentOrganic compound preparationHydroxy compound preparationActive componentReaction temperature

The invention provides a catalyst, and a preparation method and an application thereof. The catalyst comprises an active component and silicon dioxide; the composition of the active component is represented by the general formula (I): CuaFebLacSidOx, wherein a, b, c, d and x successively represent the atomic molar number of elements Cu, Fe, La, Si and O, a is 1, b is 0.1-3, c is 0.01-2, d is 0.01-2, x is determined by the oxygen number in oxides of the elements Cu, Fe, La and Si, and silicon dioxide accounts for 1-30% of the total weight of the catalyst. The prepared catalyst has the advantages of low reaction temperature and pressure, low carbon dioxide selectivity, long service life and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Catalyst as well as preparation method and application thereof

InactiveCN106423195AHigh yieldSuppressor enrichmentOrganic compound preparationHeterogenous catalyst chemical elementsCarbon dioxideHigh selectivity

The invention provides a catalyst as well as a preparation method and application thereof. The catalyst contains an active component and silicon dioxide, wherein the composition of the active component is shown by a general formula (I): CuaFebMncOd; a, b, c and d represent the atomic mole numbers of elements Cu, Fe, Mn and O respectively; a is 1, b is 0.2-3, c is 0.02-2, and d is determined by the number of oxygen in the oxides of elements Cu, Fe and Mn; and the silicon dioxide accounts for 1-30% of total weight of the catalyst. The catalyst provided by the invention has the advantages of low reaction temperature and pressure, low selectivity on carbon dioxide, high selectivity on total alcohol, high wear resistance, long service life and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Preparation method of copper loaded activated carbon adsorbent

InactiveCN103506070AAvoid uneven heatingImprove distributionOther chemical processesDispersed particle separationActivated carbonPower flow

The invention provides a preparation method of an adsorbent for gas adsorbing separation. The adsorbent is used for the gas separation through pressure swing adsorption or temperature swing adsorption. The preparation method which treats activated carbon as a carrier comprises the following steps: dipping a copper salt and / or other assistants onto the active carbon carrier, placing the above obtained dipped activated carbon in a drying tower, and galvanizing the dipped activated carbon for heating the activated carbon in order to complete the drying process of the preparation of the adsorbent. The copper salt in the obtained adsorbent has a large load capacity and uniform dispersion on the surface of the activated carbon, so the adsorbent has a higher adsorption capability than traditional drying methods.

Owner:冯良荣

Hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and manufacturing method thereof

ActiveCN110760773AIncrease contactIncreasing the thicknessHot-dipping/immersion processesSuperimposed coating processChemical compositionUltimate tensile strength

The invention discloses a hot galvanized high-strength steel plate with high surface quality and excellent corrosion resistance and a manufacturing method thereof. The hot galvanized high-strength steel plate sequentially comprises a substrate, a pre-metallization layer and Fe-Al barrier layer and a galvanized layer from bottom to top, wherein the chemical composition of the substrate comprises the following chemical components of, in percentage by weight, 0.15 wt% to 0.25wt% of C, 1.00 wt% to 2.00 wt% of Si, 1.50 wt% to 3.00 wt% of Mn, less than or equal to 0. 015 wt% of P, less than or equalto 0.012 wt% of S, 0.03 wt% to 0.06 wt% of Al and the balance Fe and inevitable impurities, and the pre-metallization layer is a metal Ni layer. The hot galvanized high-strength steel plate is good in surface quality, uniform and complete in plating layer, and better in corrosion resistance compared with a conventional hot galvanized product; and the yield strength of the hot galvanized steel plate is 600-900 MPa, the tensile strength is 980 MPa or above, the elongation is 15-22%, the surface quality and corrosion resistance are superior to those of conventional hot galvanized high-strength steel, and the hot galvanized teel plate is suitable for automobile structural parts and outer plates with higher requirements on surface quality, corrosion resistance and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

Shock-resistant corrosion-resistant aluminum alloy softball bat material and preparing method thereof

The invention discloses a shock-resistant corrosion-resistant aluminum alloy softball bat material and a preparing method thereof, and relates to the technical field of aluminum alloys. The shock-resistant corrosion-resistant aluminum alloy softball bat material comprises, by weight percentage, 0.3%-0.5% of Si, 0.8%-1.1% of Mg, 0.1%-0.3% of Mn, 0.3%-0.5% of Cu, 0.4%-0.7% of Fe, 3.5%-3.9% of Zn, 0.1%-0.3% of Li, 0.1%-0.3% of Cr, 0.3%-0.5% of Ti, 0.1%-0.3% of Ce, 0.05%-0.1% of Sc and the balance Al. All elements and contents in the alloy are reasonably optimized, the good mechanical property anddecay resistance are achieved, melt is subject to vibration scattering under a certain frequency in the preparing process, grains can be effectively refined, refining and homogenization of material organization and a second phase are facilitated, a casting ingot is subject to homogenization treatment through three-stage continuous temperature rise, the homogenization degree is more high, the mechanical property of the alloy can be further improved, the material organization is improved, the alloy material obtained after heat treatment has the good strength, hardness and corrosion resistance,the material is used for a softball bat, acute impact of balls to a bat body can be borne for a long period, cracking deformation is not prone to occurrence, and the service life is long.

Owner:TIANCHANG ZHENGMU ALUMINUM TECH

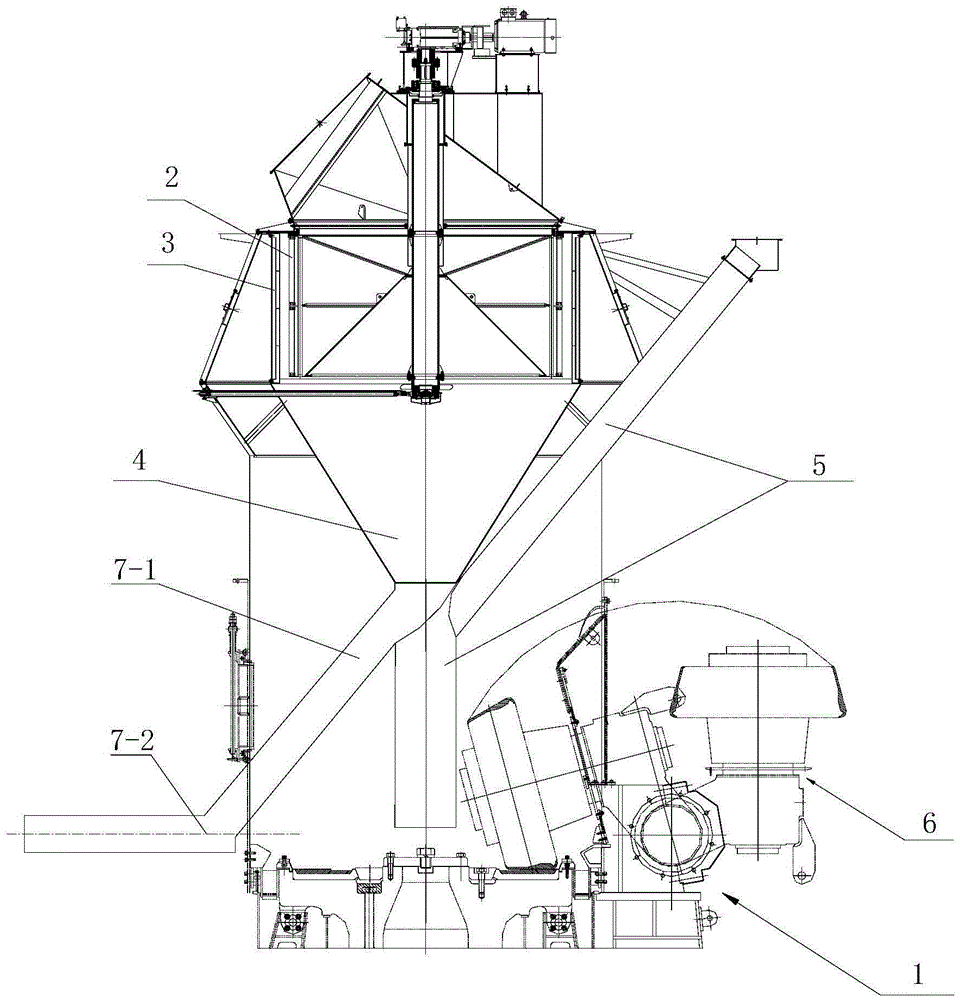

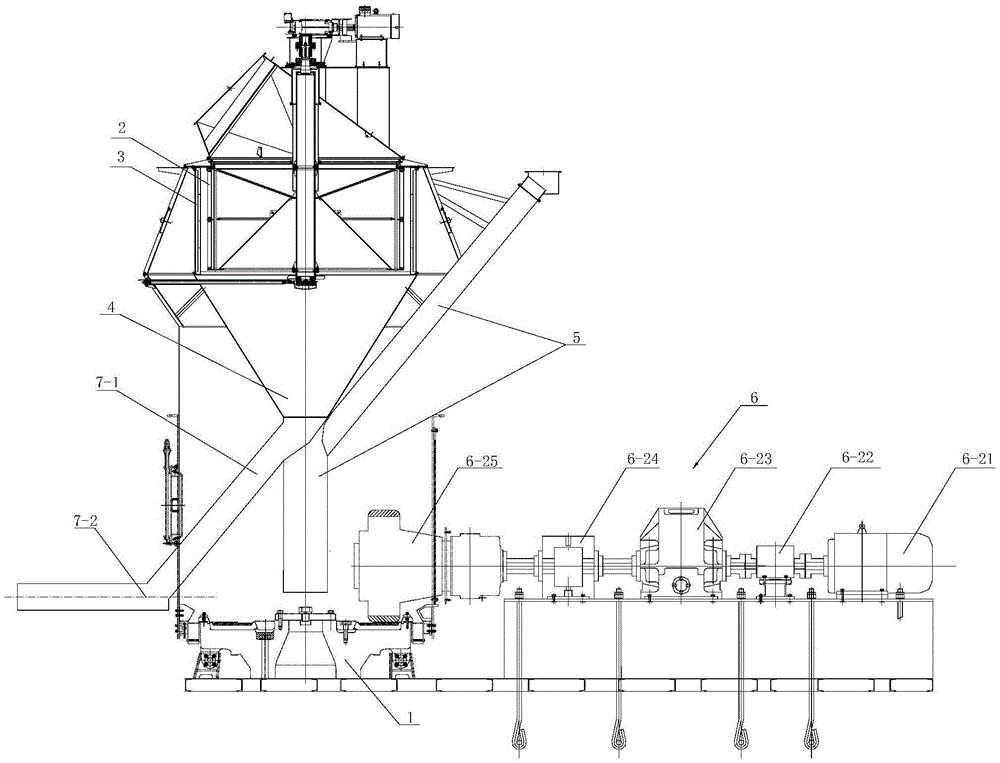

Novel vertical roll mill with grinded powder outward-guide mechanism

InactiveCN105642408AImprove grinding efficiencyLow energy consumption in ore processing productionGrain treatmentsWear resistantEngineering

The invention relates to a novel vertical roll mill with a grinded powder outward-guide mechanism. The novel vertical roll mill comprises a vertical roll mill grinding disc, a powder selector rotor, static wind guide blades, a discharge cone, a charge chute and a roll mill drive device. The novel vertical roll mill is characterized by further comprising the grinded powder outward-guide mechanism, wherein the outward-guide mechanism is connected with the discharge cone of the vertical roll mill, and comprises a guide chute and a horizontal conveying mechanism; the guide chute is connected to the bottom of the discharge cone, the guide chute is communicated with the inner cavity of the discharge cone, and the lower end of the guide chute is inclined outwards to form an inclined slope; and the horizontal conveying mechanism is adjacent to the lower end part of the guide chute. Due to the above-mentioned structure, adjustment for the specific surface area of materials in a reasonable range is ensured; medium grains or finished products are guided out of the mill, thus material circulation is reduced, pressure loss in the mill is reduced, grinding efficiency is improved, energy consumption is saved, the wear of the grinding disc and grinding roll sleeves is reduced, and the lives of wear-resistant parts are prolonged; and the returned powder is easily finely grinded, and due to the reduction of the part of materials, the stability of a material layer is improved, and the vibration and noise of the mill are reduced.

Owner:SINOMA TECH & EQUIP GRP

Control method for protective atmosphere of bell-type annealing furnace

InactiveCN113430339ASuppressor enrichmentEliminate chromatic aberration defectsHeat treatment process controlBell type furnacesShielding gasStrip steel

The invention relates to a control method for a protective atmosphere of a bell-type annealing furnace, and belongs to the technical field of bell-type annealing processes in the metallurgical industry. According to the technical scheme, the method is operated according to the following steps: (1) inner cover cold sealing is tested; (2) safe purging: purging air in an inner cover by adopting N2 before annealing heating is started; (3) after safe purging is finished, a heating cover is buckled up, heating is carried out according to a set annealing process, in the heating process, purging is carried out with H2, N2 in the furnace is completely removed, and the purpose of all-hydrogen annealing is achieved; (4) before heating is finished, inner cover heat sealing testing is carried out, and it is ensured that an inner cover heat sealing testing test is qualified; and (5) when the temperature of a coil base is cooled to the tapping temperature, purging replacement is conducted on H2 in the furnace through protective gas N2. The method has the beneficial effects that Mn and Si elements in the steel can be inhibited from being enriched on the surface in a weak oxygen atmosphere and forming granular aggregates to cover the surface of the strip steel, so that the aim of eliminating the color difference defect of the edge part of a steel coil is fulfilled.

Owner:TANGSHAN IRON & STEEL GROUP +1

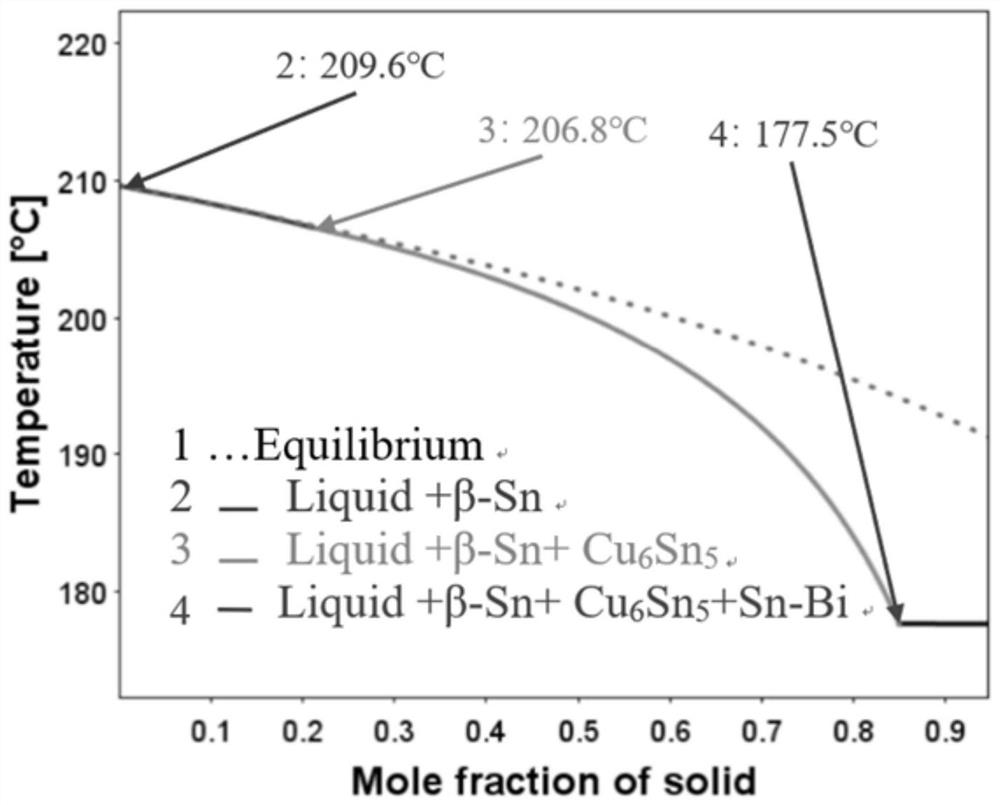

Sn-Bi-Cu-Ag-Ni-Sb low temperature lead-free solder alloy with high mechanical property

InactiveCN112643241AHigh degree of alloyingSuppressor enrichmentWelding/cutting media/materialsSoldering mediaMechanical propertyMechanical properties of carbon nanotubes

The invention discloses a Sn-Bi-Cu-Ag-Ni-Sb low temperature lead-free solder alloy with a high mechanical property and belongs to the technical field of electronic welding. The lead-free solder alloy comprises 14-18% of Bi, 0.4-0.6% of Cu, 0.5-0.8% of Ag, 0.03-0.07% of Ni, 0.001-0.2% of Sb and the balance of Sn and inevitable impurities. In a preparation process of the Sn-Bi-Cu-Ag-Ni-Sb low temperature lead-free solder alloy with the high mechanical property, Cu, Ag, Ni and Sb are added in form of intermediate alloys. The alloy has good lubricating performance at a low temperature and the mechanical property is superior to that of Sn-Ag-Cu lead-free solder. As the percent by pass of Ag is reduced, the production cost of the lead-free solder alloy is lowered greatly and the smelting point ranges from 176 to 205 DEG C.

Owner:KUNMING UNIV OF SCI & TECH

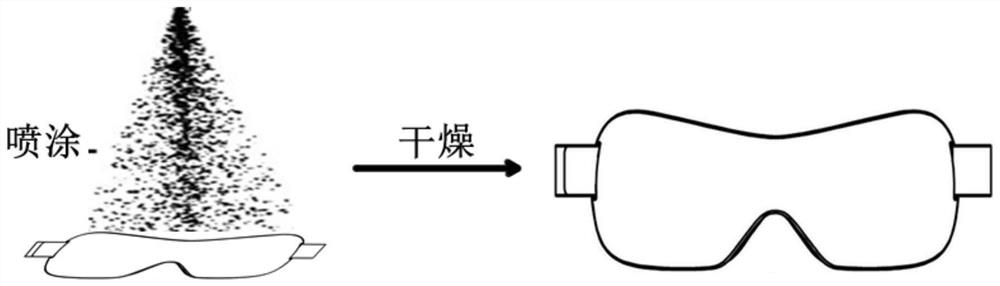

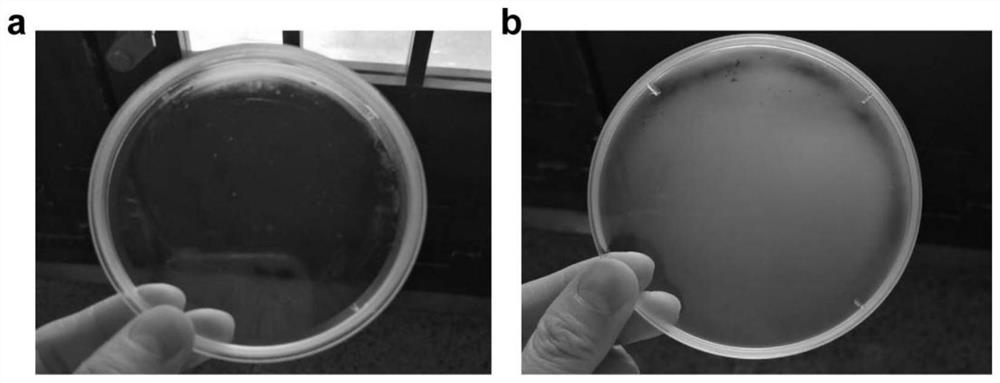

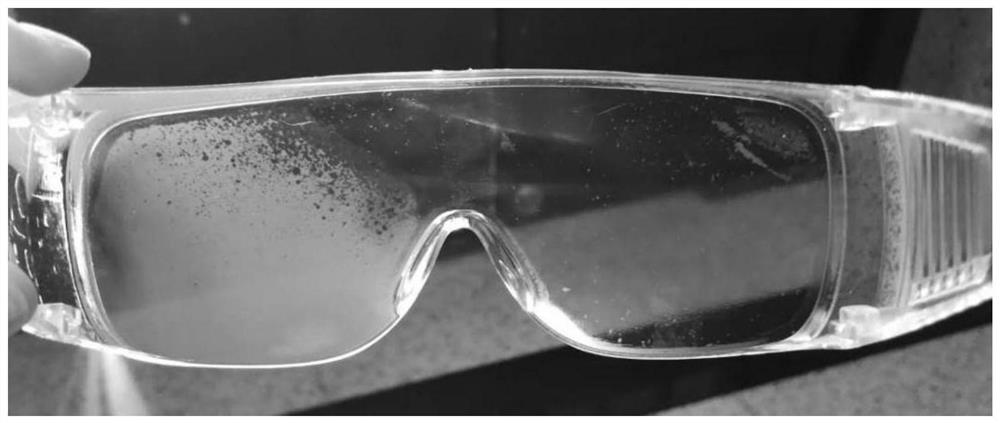

Preparation method and application of bionic high-adhesion long-acting antibacterial antifogging agent

PendingCN113583494APrevent foggingPrevent bacterial growthAntifouling/underwater paintsGogglesPolymer solutionSafety goggles

The invention belongs to the field of biomedical polymer materials, and discloses a preparation method and application of a bionic high-adhesion long-acting antibacterial antifogging agent. The antifogging agent is prepared by the steps that firstly, a hydrophilic bionic high-adhesion polymer is prepared, then the hydrophilic bionic high-adhesion polymer coats a surface to be treated through a solution of the hydrophilic bionic high-adhesion polymer, so as to inhibit surface fogging and bacterium breeding. A hydrophilic bionic high-adhesion polymer solution is prepared by controlling key raw materials, a flow process and the like of the antifogging agent, and the hydrophilic bionic high-adhesion polymer solution can be used as a long-acting antibacterial antifogging agent for antifogging and antibacterial treatment on the surfaces of medical goggles lenses and the like, has good biological safety, and can effectively inhibit fogging and bacterium breeding on the surfaces of the goggles.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A kind of solid oxide fuel cell cathode material and its preparation and application

ActiveCN105226294BReduce surface chargeReduce surface stressCell electrodesSputteringScreen printing

The invention discloses a solid oxide fuel cell cathode material and a preparation method thereof, which is characterized in that the cathode material is a perovskite oxide and an oxide MO2 (M=Ti, Zr) modified on the surface of the perovskite oxide , Nb, Ce, Ru, Sn) composite cathode. Wherein, the mass content of the oxide MO2 in the composite cathode is 1%-20%, the particle size of the oxide MO2 is 0.5-100 nanometers, and the oxide MO2 in the composite cathode is coated on the surface of the perovskite oxide. The perovskite oxide can be preferentially prepared on the surface of the electrolyte or separator of the battery by coating method, screen printing, casting method, etc., and then the oxide MO2 Modification of perovskite oxide surfaces in cathodes. The cathode material of the invention shows excellent electrochemical performance and good stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

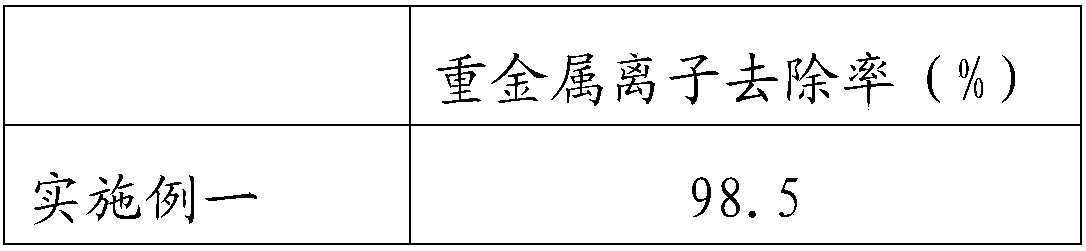

Environment-friendly heavy metal wastewater treating agent and preparation method thereof

InactiveCN107792928AQuick responsePromote conversionWater/sewage treatmentDipotassium hydrogen phosphateCyclodextrin

The invention relates to an environment-friendly heavy metal wastewater treatment agent and a preparation method thereof, comprising: water, β-cyclodextrin, plant polyphenols, sodium polyacrylate, calcium hypochlorite, organic silicon, dipotassium hydrogen phosphate, magnesium hydroxide, Iron oxide, sodium sulfate, chitosan, epichlorohydrin. The environmental-friendly heavy metal wastewater treatment agent of the present invention has fast reaction speed, high stability in the reagent treatment process, good solid-liquid separation effect, and can promote the transformation of heavy metals from a high bioavailable state to a low bioavailable state, thereby reducing the effective concentration of heavy metals in water bodies. It can also effectively inhibit the accumulation and transfer of heavy metals in crops, and reduce the toxicity of heavy metals.

Owner:GUILIN AONISITE ENERGY SAVING & ENVIRONMENT PROTECTION TECH

A high temperature fuel cell cathode and its application

The invention discloses a high-temperature fuel cell cathode and a preparation method thereof. The high-temperature fuel cell cathode is characterized in that a cathode material comprises a body layerand a modified layer, the body layer is perovskite oxide, the modified layer is a composite oxide comprising the perovskite oxide and a fluorite oxide, the mass ratio of the perovskite oxide to the fluorite oxide is 20%-80%, the particle size of the composite oxide of the modified layer is 0.5 to 300 nanometers, and the modified layer coats the surface of the body layer. The body layer can be preferentially prepared on the surface of an electrolyte or a separator of a battery by a coating method, a screen printing method, a tape casting method, and the like, and then the modified layer can beprepared onto the surface of the body layer by solution impregnation, sol-immersion, magnetron sputtering, or other method. The cathode material exhibits excellent electrochemical performances and good stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Special rice selenium-rich fertilizer capable of inhibiting heavy metal cadmium in crops as well as preparation method and application thereof

ActiveCN111470895ASuppressor enrichmentEfficient accumulationBio-organic fraction processingDi-calcium phosphate fertilisersFertilizerRice product

The invention discloses a special rice selenium-rich fertilizer capable of inhibiting heavy metal cadmium in crops as well as a preparation method and application thereof. The fertilizer is prepared from the following raw materials in parts by weight: 30-50 parts of orange peels, 10-20 parts of a cake fertilizer, 1-5 parts of calcium hydrogen phosphate, 1-5 parts of potassium chloride and 1-3 parts of sodium selenite, wherein the cake fertilizer is one or more of a soybean cake, a peanut cake, a rapeseed cake, a sesame cake and a tea seed cake. Agricultural and sideline products such as orangepeels and the cake fertilizer are fully utilized, and the problem of environmental pollution is solved. The special rice selenium-rich fertilizer can effectively accumulate selenium and inhibit enrichment of cadmium of a rice product.

Owner:沃博特生物科技有限公司

Method of continuous annealing/hot-dipping of steel sheet containing silicon and apparatus for continuous annealing/hot-dipping

ActiveCN101287854BSuppressor enrichmentAvoid generatingHot-dipping/immersion processesFurnace typesSurface oxidationInternal oxidation

Owner:NIPPON STEEL CORP

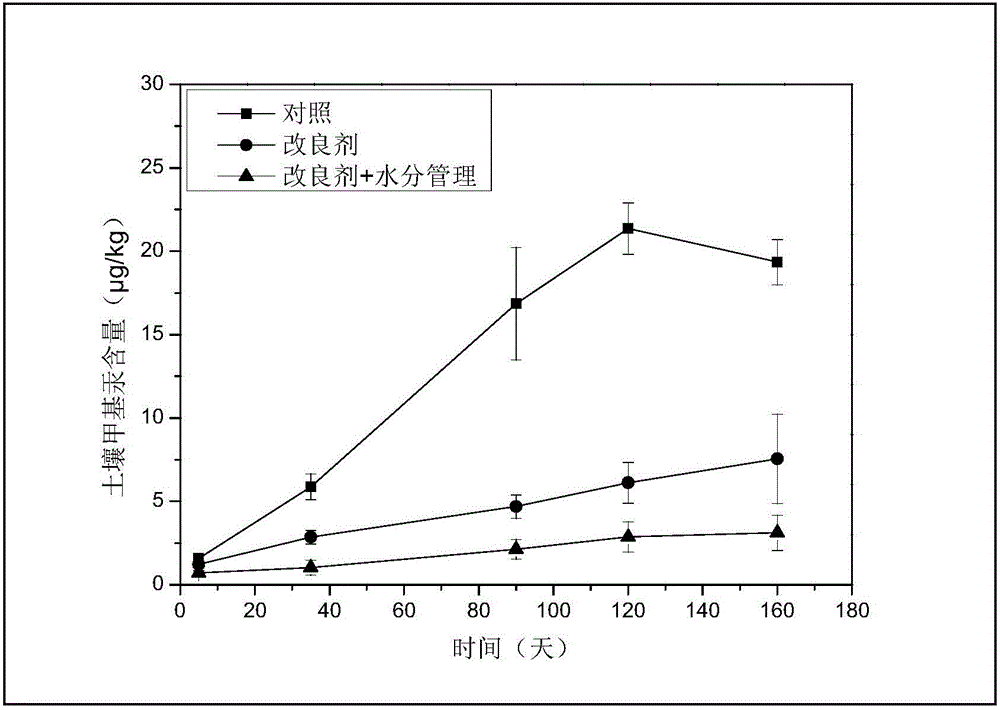

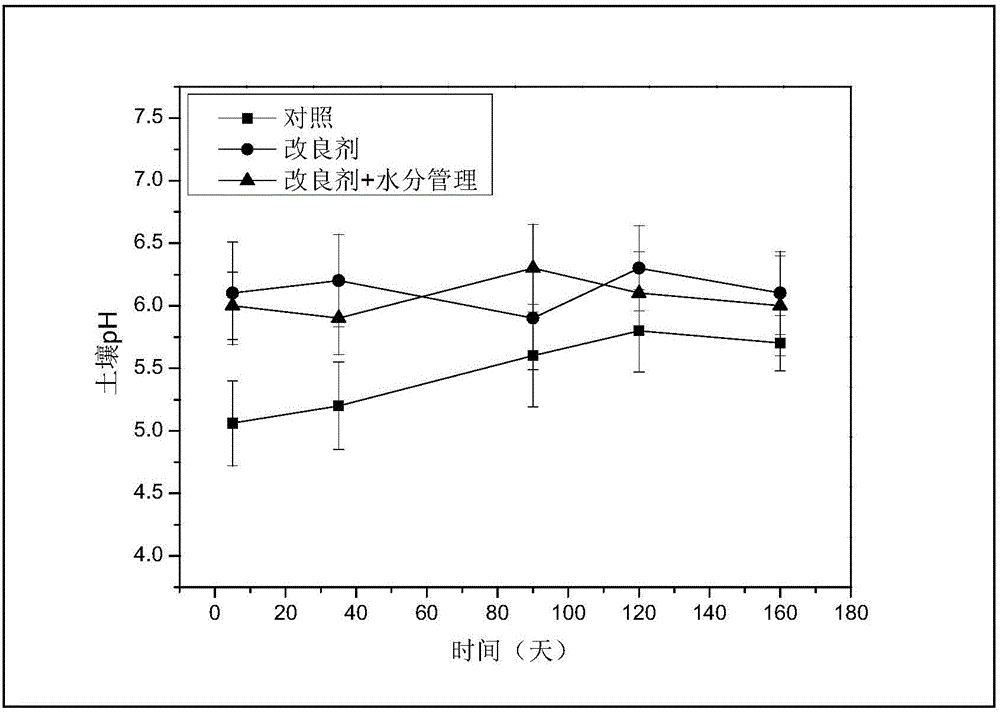

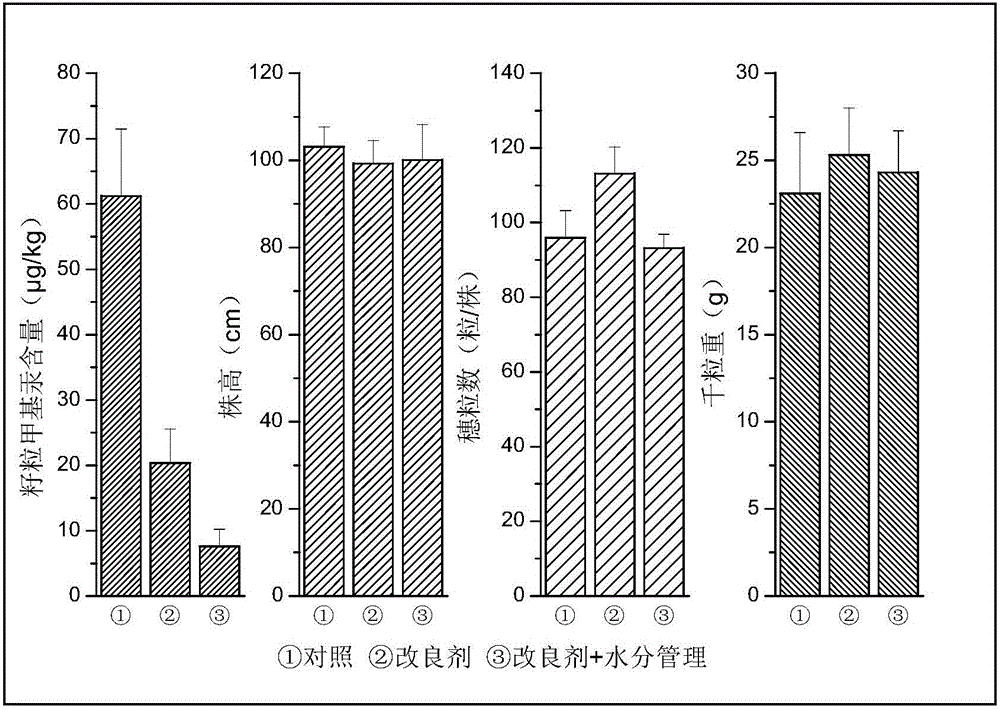

Modifier for reducing methyl mercury pollution in acidic rice field and method thereof

InactiveCN106520137AImprove soil pH and mercury adsorption capacityReduced effectivenessAgriculture tools and machinesOther chemical processesHumic acidBiomass

The invention discloses a modifier for reducing methyl mercury pollution in an acidic rice field and a method thereof, which mainly relates to the field of agriculture pollution prevention and treatment. The method comprises basal application of the modifier and moisture management. The preparation method of the modifier is characterized in that weathered coal is prepared to coal-based humic acid, according to the weight percentage, 0.1-0.2% of sodium selenite is added and aged, calcium carbonate with the weight ratio of 1:1.2-1:1.5 is added, and the materials are uniformly mixed. The modifier has the beneficial effect that the modifier is used for the acidic rice field with pH value of 4-6 and the mercury pollution degree of lower than 6 mg / kg, compared with the contrast group, the methyl mercury content of soil and rice is reduce to 60% and more, the pH value of the soil is obviously increased, the modifier has good reappearance, and has the advantages of low cost, high efficiency and easy operation, the paddy rice output and plant biomass are not reduced, and the modifier has high economic effect.

Owner:农业部农业生态与资源保护总站

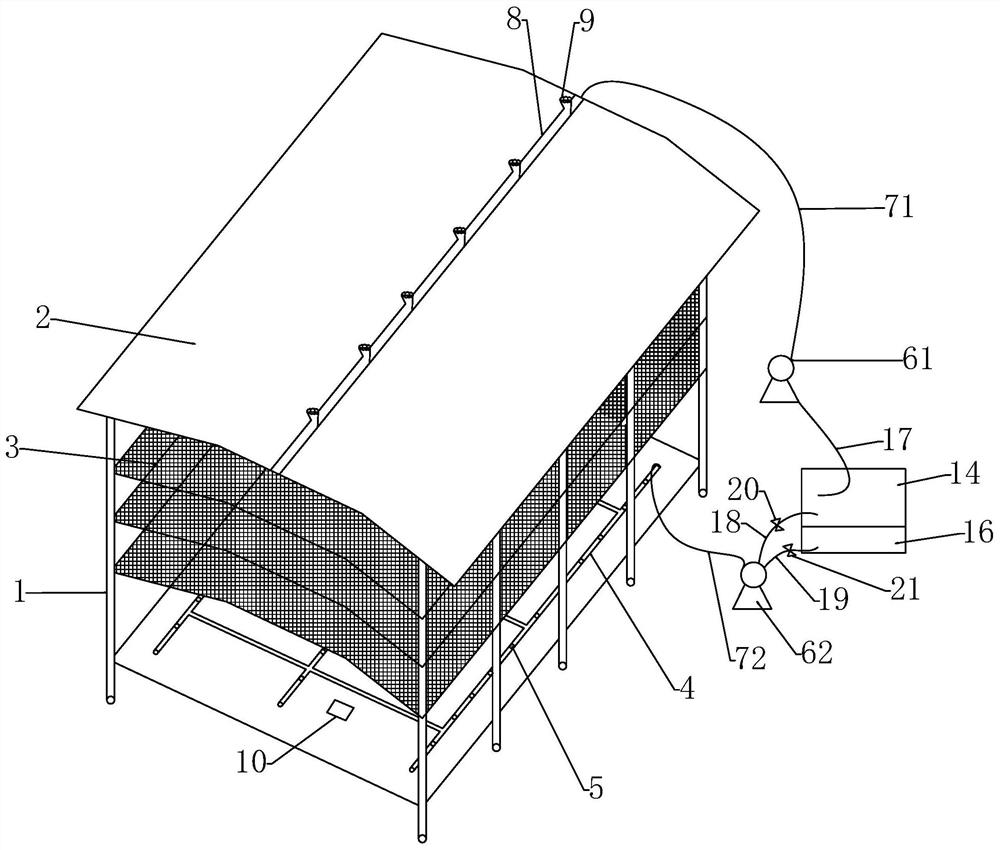

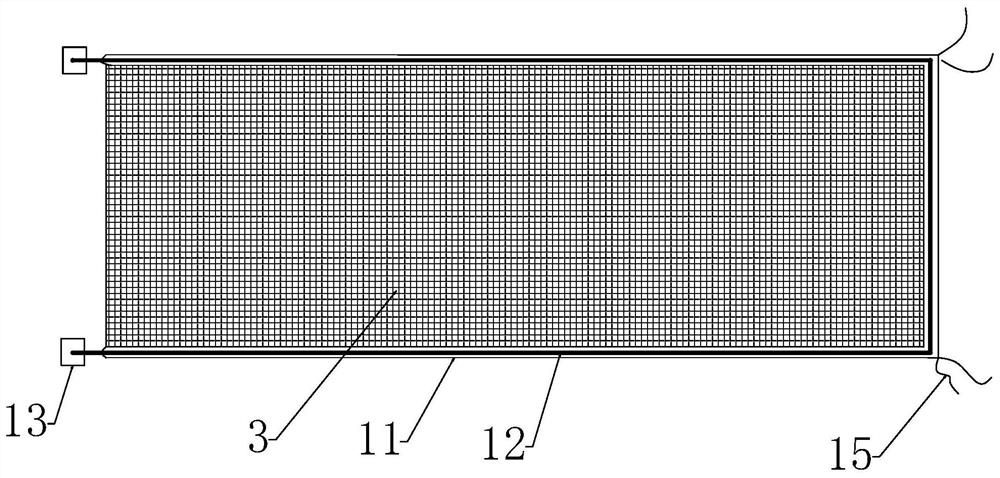

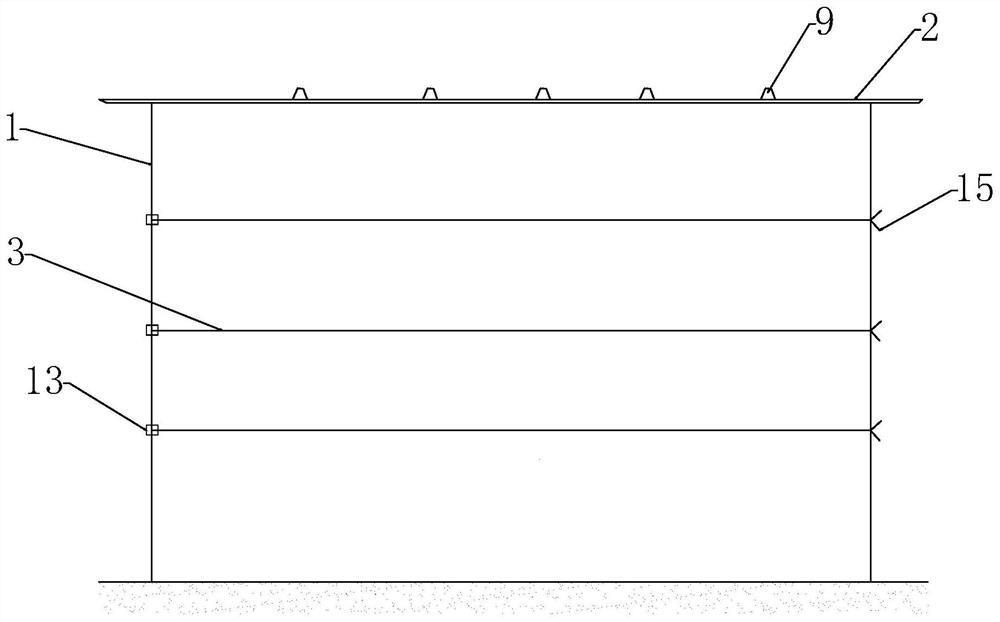

a nursery shed

ActiveCN107637336BAvoid heat dissipationImprove seedling survival rateClimate change adaptationPressurised distribution of liquid fertiliserGreenhouseAgricultural engineering

The invention discloses a seedling raising greenhouse and belongs to the field of planting device. The seedling raising greenhouse comprises supporting columns inserted and buried in soil, a roof, a sun-shading layer and an automatic water supply system. The supporting columns are distributed on the periphery of seedling raising land. The upper ends of the supporting columns are connected with theroof, spraying pipes are installed on the roof, spraying heads are arranged on the spraying pipes, and the spraying pipes are connected with a first water pump through a first pipeline. The sun-shading layer is a sun-shading net, is arranged under the roof and is parallel to the seedling raising land. The automatic water supply system comprises a second water pump, a second pipeline and water spraying pipes, wherein one end of the second pipeline is connected with the water spraying pipes, the other end of the second pipeline is connected with the second water pump, the water spraying pipes are laid in the seedling raising land, atomizing spray heads are arranged on the water spraying pipes, the first water pump is connected with an impounding reservoir, the second water pump is connectedwith the impounding reservoir and a pesticide and fertilizer pond. The seedling raising greenhouse can quickly and effectively control the temperature, humidity and lighting intensity in the greenhouse and can also provide sufficient nutrients for seedlings in the seedling raising greenhouse and effectively prevent and control diseases and pests.

Owner:百色科瑞农业科技有限公司

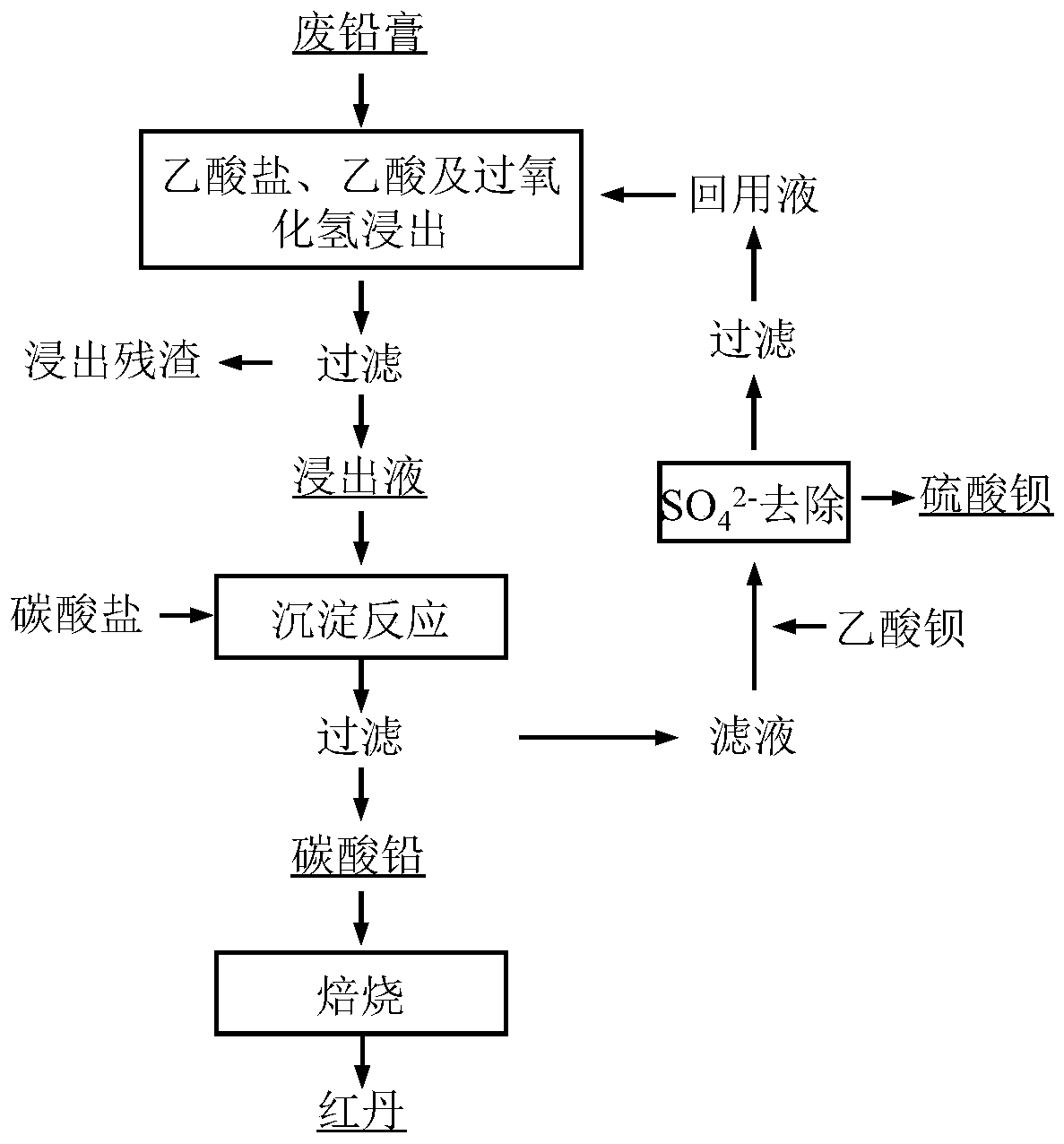

Method for achieving filter liquor circulation, recovering waste lead plaster through wet process and preparing high-purity red lead

ActiveCN109868366AClose the loopAchieve directional separationProcess efficiency improvementOrganic acidLead carbonate

The invention discloses a method for achieving filter liquor circulation, recovering waste lead plaster through a wet process and preparing high-purity red lead and relates to the technical field of waste lead-acid cell lead plaster wet process recovery and red lead preparation. The method comprises the following steps that 1, organic acid salt, organic acid and reducer mixed liquor are utilized for leaching out the waste lead plaster, and after solid and liquid are separated, lixivium is obtained; 2, a carbonate solution is added to the lixivium, the reaction pH is regulated, and solid and liquid separating is carried out to obtain lead carbonate sediment and filter liquor; and 3, lead carbonate is roasted in the aerobic atmosphere, and the high-purity red lead with low impurity content is prepared. The prepared red lead product is high in purity and low in impurity content, the content of main impurities Ba and Fe is smaller than 10 mg / kg, the content of Cu, Zn and Al impurity elements is smaller than 1 mg / kg, the filter liquor can achieve closed circulation of organic acid radical ligand in a leaching system, and the use efficiency of a leaching agent is improved remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com