a nursery shed

A seedling raising shed and support column technology, applied in the field of seedling raising sheds, can solve the problems of great influence on seedling growth in the shed, uneven growth, high labor intensity, etc., to improve the survival rate of seedlings, reduce rotten seedlings or burnt seedlings, and reduce cooling workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

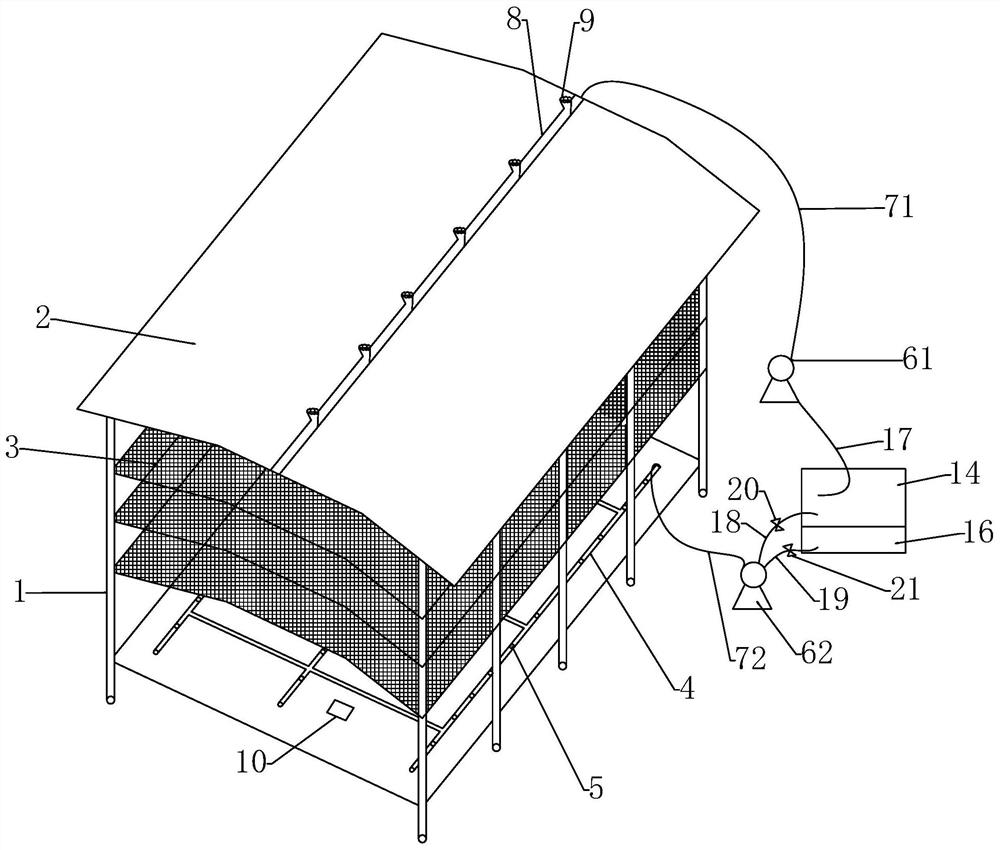

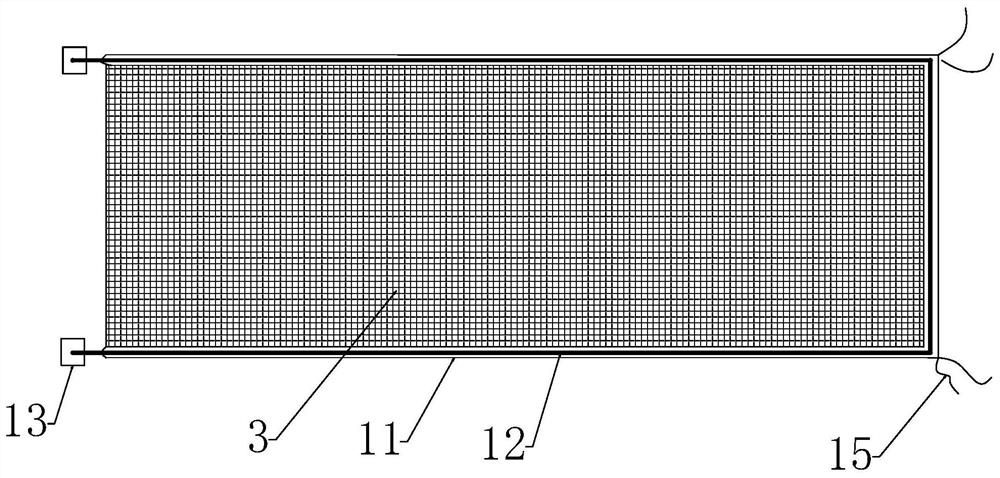

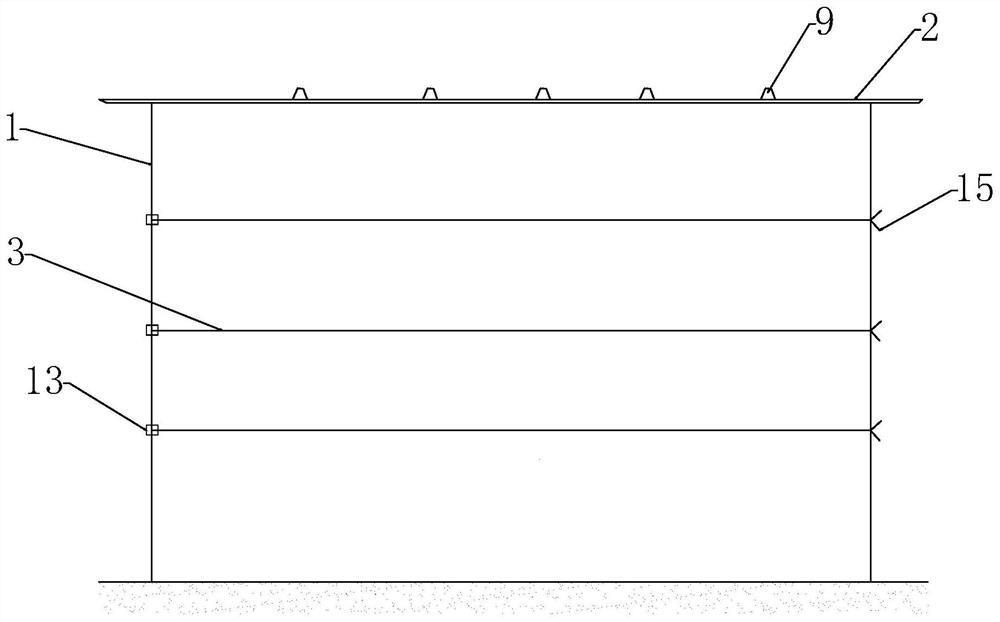

[0040] A kind of nursery shed, such as figure 1 As shown, the seedling shed includes a support column 1 embedded in the soil, a shed roof 2, a shading layer 3 and an automatic water supply system.

[0041] Described supporting column 1 is distributed around the nursery ground, and supporting column 1 is arranged side by side with two rows, and each row is five; The height of the part above the ground of described supporting column 1 is 4.2m, and this height is higher than the height of common seedling shed. To be high 0.7-1m, such a height can ensure smooth ventilation in the shed, and can ensure that the cost of the seedling-raising shed is not high; the transverse span of the seedling-raising shed, that is, the distance between two parallel support columns 1, is 18m, so The span is 3 times that of ordinary seedling sheds, and it is also to maintain smooth ventilation and improve the survival rate of seedlings; the upper end of the support column 1 is fixedly connected with t...

Embodiment 2

[0052] Basically the same as embodiment 1, the difference is that the configuration method of medicinal fertilizer water is as follows:

[0053] a. Weigh 20 parts of Tripterygium wilfordii, 15 parts of spearmint, 10 parts of castor bean, 8 parts of atractylodes, 8 parts of croton, 7 parts of Polygonum, and 5 parts of Erythrina, add 90 parts of clear water and soak for 40 minutes Afterwards, carry out boiling, after boiling for 50 minutes, cool and filter, get the filtrate and be the water for preventing diseases and insect pests, and set aside;

[0054] b. Take 50 parts of silkworm excrement and 70 parts of water in parts by weight, mix and boil for 30 minutes, filter after cooling, take the filtrate as silkworm excrement water, and set aside;

[0055] c, take by weight 20 parts of urea, 20 parts of calcium magnesium phosphate fertilizer, 0.8 part of manganese sulfate, 0.8 part of ferric citrate, 2 parts of zinc EDTA, 70 parts of water for preventing diseases and insect pests ...

Embodiment 3

[0057] Basically the same as embodiment 1, the difference is that the configuration method of medicinal fertilizer water is as follows:

[0058] a. Weigh 25 parts of Tripterygium wilfordii, 20 parts of spearmint, 15 parts of castor bean, 10 parts of atractylodes, 10 parts of croton, 9 parts of Polygonum, and 8 parts of Erythrina, add 100 parts of clear water and soak for 30 minutes Afterwards, carry out boiling, after boiling for 60 minutes, cool and filter, get the filtrate and be the water for preventing diseases and insect pests, and set aside;

[0059] b. Take 60 parts of silkworm excrement and 90 parts of water in parts by weight, mix and boil for 40 minutes, filter after cooling, take the filtrate as silkworm excrement water, and set aside;

[0060] c, take by weight 30 parts of urea, 25 parts of calcium magnesium phosphate fertilizer, 1.5 parts of manganese sulfate, 1.2 parts of ferric citrate, 4 parts of zinc EDTA, 80 parts of water for preventing diseases and insect p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| shading coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com