Catalyst, and preparation method and application thereof

A catalyst and binder technology, applied in the field of syngas to low-carbon alcohol, can solve the problem of high selectivity, achieve the effects of reduced selectivity, inhibition of aggregation and sintering, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

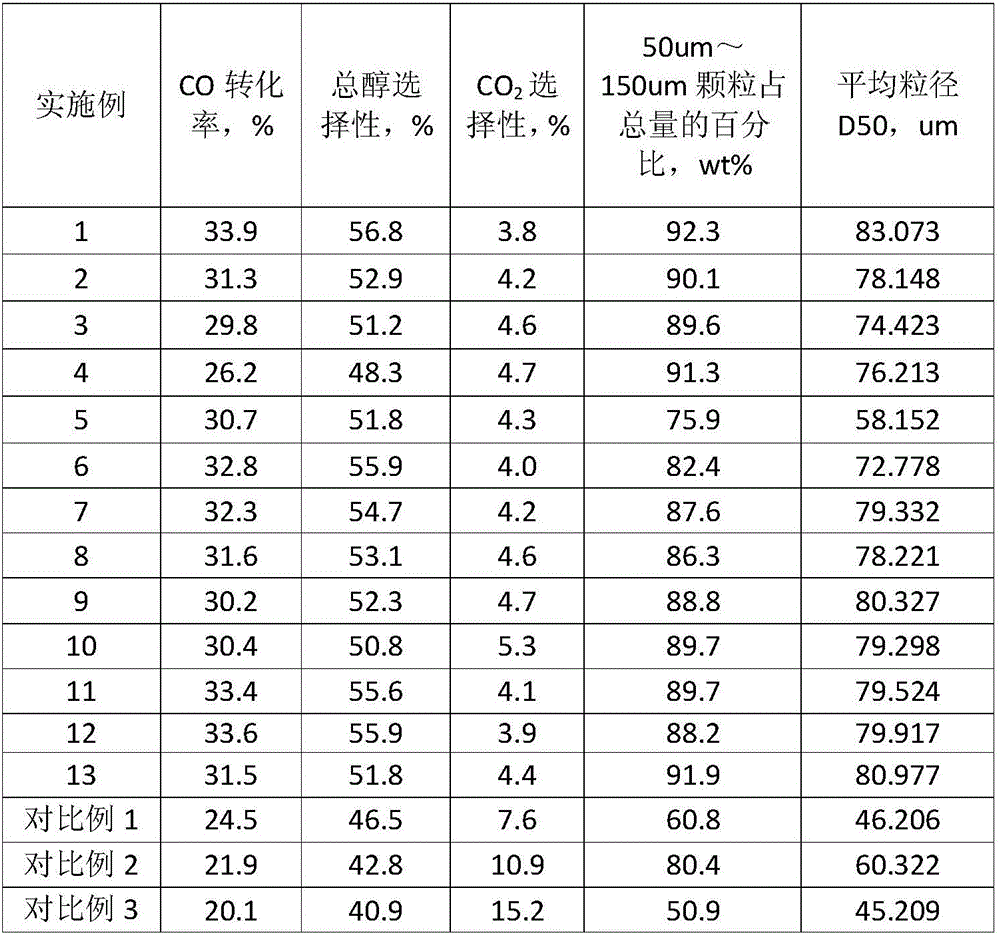

Examples

preparation example Construction

[0027] In order to obtain the catalyst with the above properties, the present invention also provides a preparation method of the catalyst, the preparation method comprising: precipitating a mixture of copper-containing soluble salt, iron-containing soluble salt and lanthanum-containing soluble salt, dispersant and precipitant After reacting and filtering, a filter cake is obtained; and the filter cake is mixed with water to form a slurry, and after the above slurry is mixed with a binder, the catalyst is obtained by drying and roasting; wherein the dispersant and the binder are independently selected from silicon Sols and / or siliceous soluble salts.

[0028] Adding a dispersant during the precipitation reaction in the above preparation method is beneficial to uniformly disperse the main active component, and further helps to inhibit the aggregation and sintering of the same component. An appropriate ratio of iron to copper enables the two to effectively synergize, and when th...

Embodiment 1

[0045] Weigh 362.4g Cu (NO 3 ) 2 ·3H 2 O, 424.2gFe(NO 3 ) 3 9H 2 O, 129.9gLa(NO 3 ) 3 ·6H 2 O, the concentration is 25% silica sol 36.01g, add 5L deionized water and mix and stir evenly to obtain a mixture.

[0046] Precipitate the above mixture with a precipitant (potassium carbonate solution) at 60°C and a pH of 7.2. After the reaction, age at 50°C for 4 hours, fully filter the precipitate to obtain a filter cake, and wash the filter cake until The conductivity of the washing liquid is below 100um / cm.

[0047] The catalyst filter cake was added to deionized water for beating, and the slurry was kept at normal temperature; 216.07 g of silica sol with a concentration of 25 wt % was heated to 60 ° C, and added to the slurry in a stirring state by positive addition (the weight percentage in the catalyst was 8.43%).

[0048] The type of spray drying tower atomizer is a centrifugal atomizer, and the fluid contact method between the raw material slurry and the dry hot air ...

Embodiment 2

[0051] The molar weight of La in catalyst element ratio is adjusted, promptly weighs 362.4g Cu (NO 3 ) 2 ·3H 2 O, 424.2gFe(NO 3 ) 3 9H 2 O, 12.99gLa(NO 3 ) 3 ·6H 2 O, concentration is 25wt% silica sol 36.01g, all the other conditions are identical with embodiment 1, the performance evaluation result that obtains is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com