Dehydrogenation catalyzing material as well as preparation method and application thereof

A catalytic material and dehydrogenation technology, applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of poor catalyst activity and stability, achieve reduced deactivation rate, high propane dehydrogenation activity, inhibit enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Prepare the propane dehydrogenation catalytic material according to the following steps:

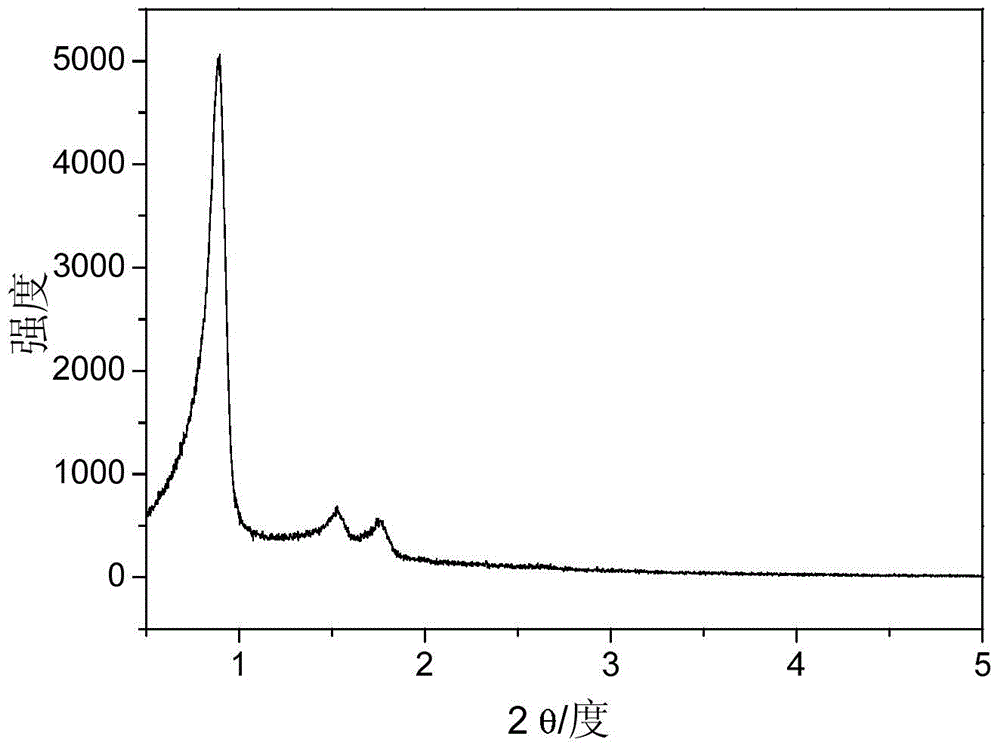

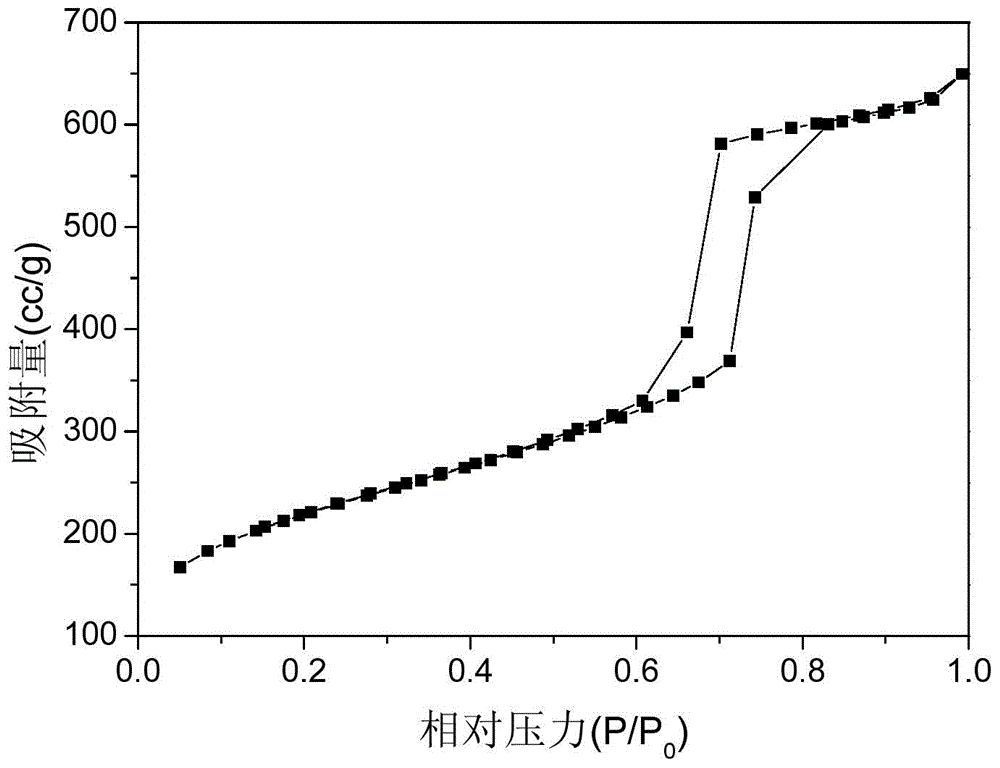

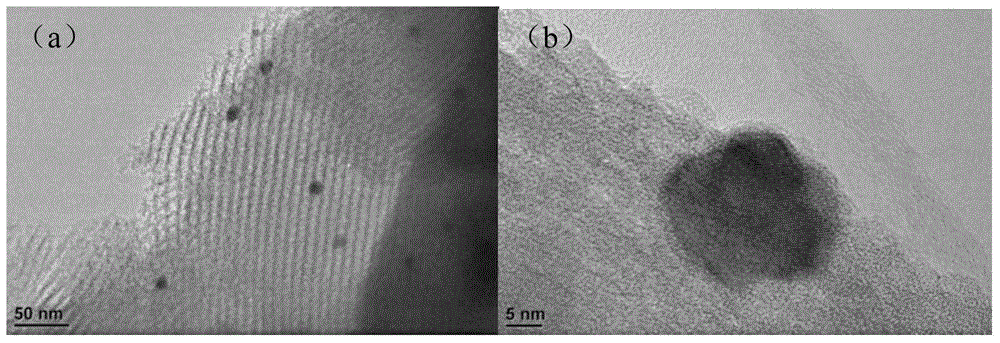

[0093] Weigh 8g of P123 into a 500ml beaker, then add 60ml of deionized water, 240ml of 2mol / L hydrochloric acid, and stir at 40°C for 4h. 17g of TEOS was slowly added dropwise and continued to stir vigorously at 40°C for 24h. The obtained white turbid liquid was transferred into a high-pressure reactor with a polytetrafluoroethylene inner sleeve, crystallized at 100°C for 48 hours, cooled, washed, and dried. The obtained white solid was calcined at 550° C. for 6 h with a heating rate of 2° C. / min, and the obtained solid was the SBA-15 carrier. Small-angle X-ray (SAXRD) and N 2 Adsorption-desorption isotherm characterization, the spectrum is as follows figure 1 shown by figure 1 It can be seen that the prepared SBA-15 carrier has a regular two-dimensional hexagonal mesoporous channel structure.

[0094] 0.013g chloroplatinic acid, 0.03g SnCl 4 ·5H 2 O, 0.042g of aluminum ni...

Embodiment 2

[0097] The synthesis steps of the SBA-15 carrier are shown in Example 1, and the calcination time is 8 hours.

[0098] 0.026g chloroplatinic acid, 0.059g SnCl 4 ·5H 2 O, 0.025g aluminum chloride was dissolved in a certain amount of deionized water, then added SBA-15 carrier, ultrasonicated for 60min, dried in an oven at 40°C for 24h, and then roasted at 500°C for 6h, before propane dehydrogenation reaction, the Catalytic material at 550°C H 2 Medium treatment 2h. Among them, platinum, tin, and aluminum loadings are 1wt%, 2wt%, and 0.5wt%, respectively. The specific surface area of the catalytic material is 738.2m 2 / g.

[0099] The evaluation of propane dehydrogenation performance of the catalytic material is the same as in Example 1. Under the reaction condition of 590°C, the initial propane conversion rate of the catalytic material is 51.2%, the initial yield of propylene is 50.5%, and the high propane conversion rate is still 39.1% after 6 hours of reaction , the se...

Embodiment 3

[0101] The synthesis steps of the SBA-15 carrier are shown in Example 1, and the crystallization temperature is 120°C.

[0102] 0.13g chloroplatinic acid, 0.29g SnCl 4 ·5H 2 O, 0.14g of aluminum nitrate was dissolved in a certain amount of deionized water, and then SBA-15 carrier was added, ultrasonicated for 30min, dried in an oven at 40°C for 12h, and then roasted at 550°C for 4h. Before the propane dehydrogenation reaction, the catalytic material H at 400°C 2 Medium treatment 10h. Wherein, platinum, tin, and aluminum are loaded in amounts of 5wt%, 10wt%, and 1wt%, respectively. The specific surface area of the catalytic material is 713.9m 2 / g.

[0103] The evaluation of propane dehydrogenation performance of the catalytic material is the same as that in Example 1. The catalytic material has an initial propane conversion rate of 41.5% and a propylene yield of 40.9% at a reaction temperature of 590°C. After 6 hours of reaction, the conversion rate is still high at 35....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com