Sn-Bi-Cu-Ag-Ni-Sb low temperature lead-free solder alloy with high mechanical property

A sn-bi-cu-ag-ni-sb, lead-free solder alloy technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problem of reduction, achieve a high degree of alloying, Uniform refinement of solder crystal structure and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A kind of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with high mechanical properties at low temperature, in terms of mass percentage, the lead-free solder alloy comprises: Bi14%, Cu 0.5%, Ag0.6%, Ni 0.04%, Sb 0.004%, the balance of Sn and unavoidable impurities; in the preparation process of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties, Ag, Cu and Ni are respectively used as master alloy sn 3 Ag, Sn 10 Cu, Sn 4 Ni is added in form, Sb is added as pure substance, and insufficient Sn is added as pure Sn;

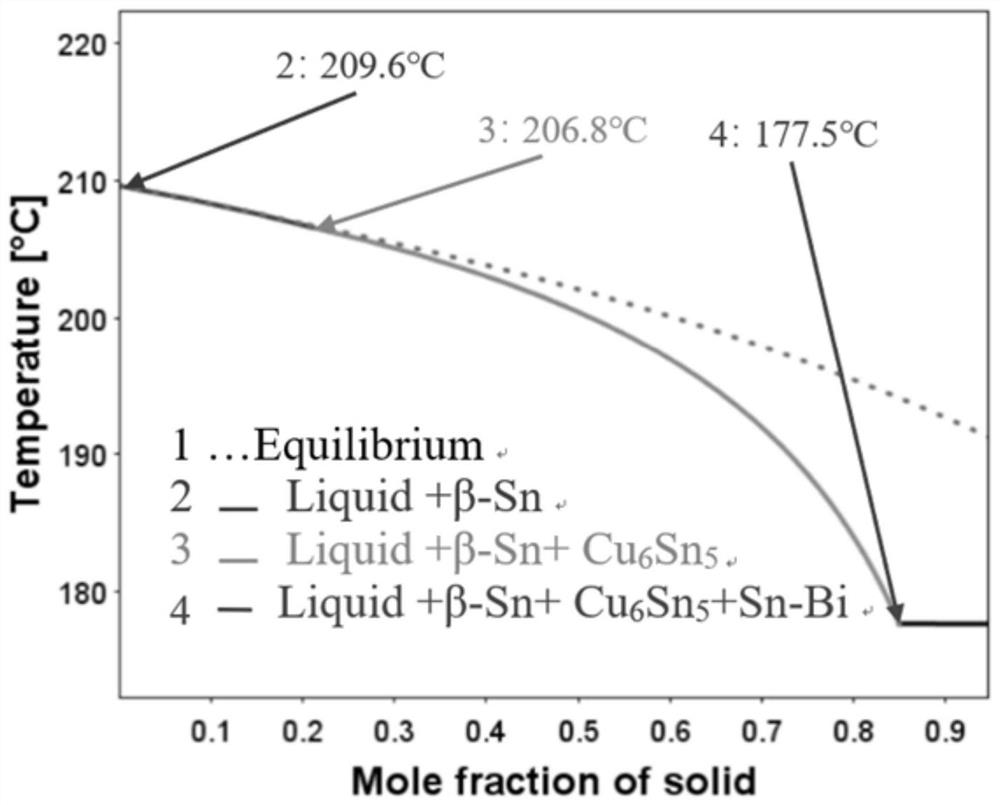

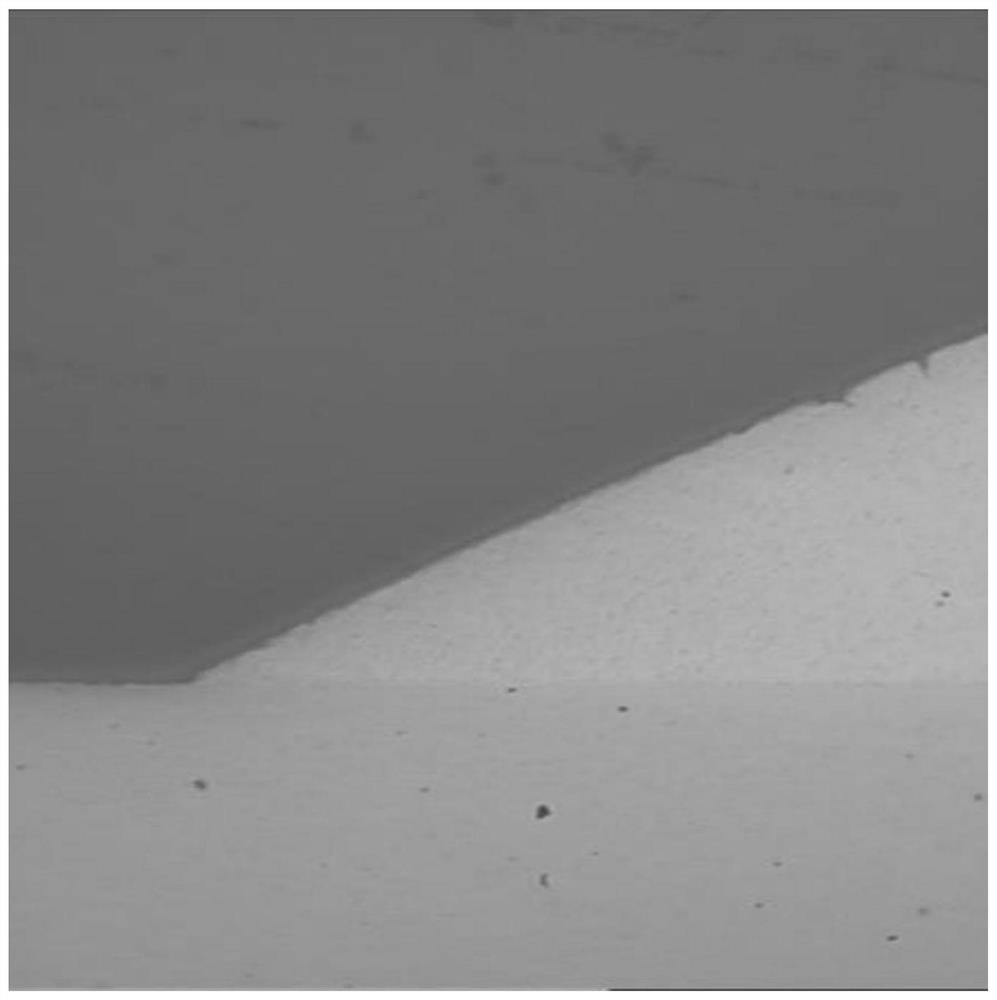

[0020] The metallographic structure diagram of the cross-section of the solder joint of the Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties in this embodiment is as follows figure 1 shown, from figure 2 It can be seen that the structure of the solder alloy matrix is uniform, the grains are refined, the wetting angle is small, and the wettability is good.

[0...

Embodiment 2

[0022] Embodiment 2: A kind of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with high mechanical properties at low temperature, in terms of mass percentage, the lead-free solder alloy includes: Bi14%, Cu 0.5%, Ag0.6%, Ni 0.03%, Sb 0.01%, the balance of Sn and unavoidable impurities; during the preparation process of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties, Ag, Cu and Ni are respectively used as intermediate alloys sn 3 Ag, Sn 10 Cu, Sn 4 Ni is added in form, Sb is added as pure substance, and insufficient Sn is added as pure Sn;

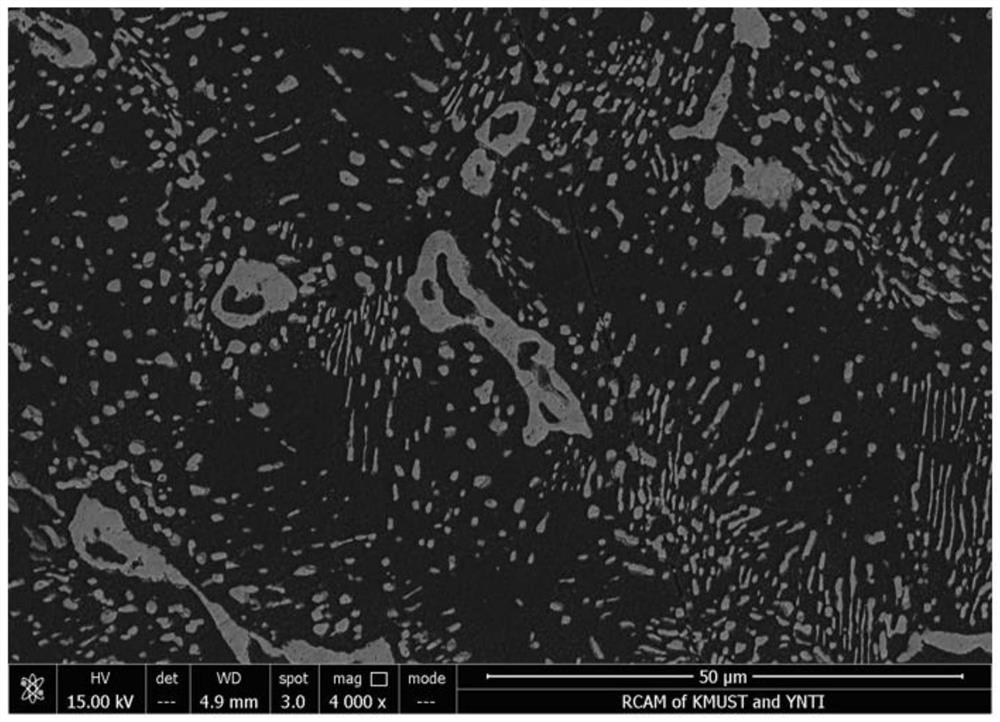

[0023] The solder alloy electronic scanning diagram of the present embodiment Sn-Bi-Cu-Ag-Ni-Sb low-temperature high-mechanical performance lead-free solder alloy is shown in image 3 shown, from image 3 It can be seen that Ag 3 Sn is uniformly distributed and distributed in orientation, and branched crystals strengthen the stability of solder;

[0024] The metallographic structure diagram of th...

Embodiment 3

[0026] Embodiment 3: A kind of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties, in terms of mass percentage, the lead-free solder alloy includes: Bi14%, Cu 0.6%, Ag0.6%, Ni 0.05%, Sb 0.04%, the balance of Sn and unavoidable impurities; in the preparation process of Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties, Ag, Cu and Ni are respectively used as intermediate alloys sn 3 Ag, Sn 10 Cu, Sn 4 Ni is added in form, Sb is added as pure substance, and insufficient Sn is added as pure Sn;

[0027] The performance test data of the Sn-Bi-Cu-Ag-Ni-Sb lead-free solder alloy with low temperature and high mechanical properties in this example is shown in Table 1. The melting point of the lead-free solder is 197.23°C, the melting range is 17.34°C, and the tensile strength is 98.34Mpa , yield strength 87.23Mpa, elongation 22.14%, wetting time 0.37s, maximum wetting force 0.93mN, density 8.29g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com