Novel vertical roll mill with grinded powder outward-guide mechanism

A vertical roller mill and milling technology, which is applied in grain processing and other directions, can solve the problems of low grinding efficiency of ball mills, large number of equipment configurations, complex process systems, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

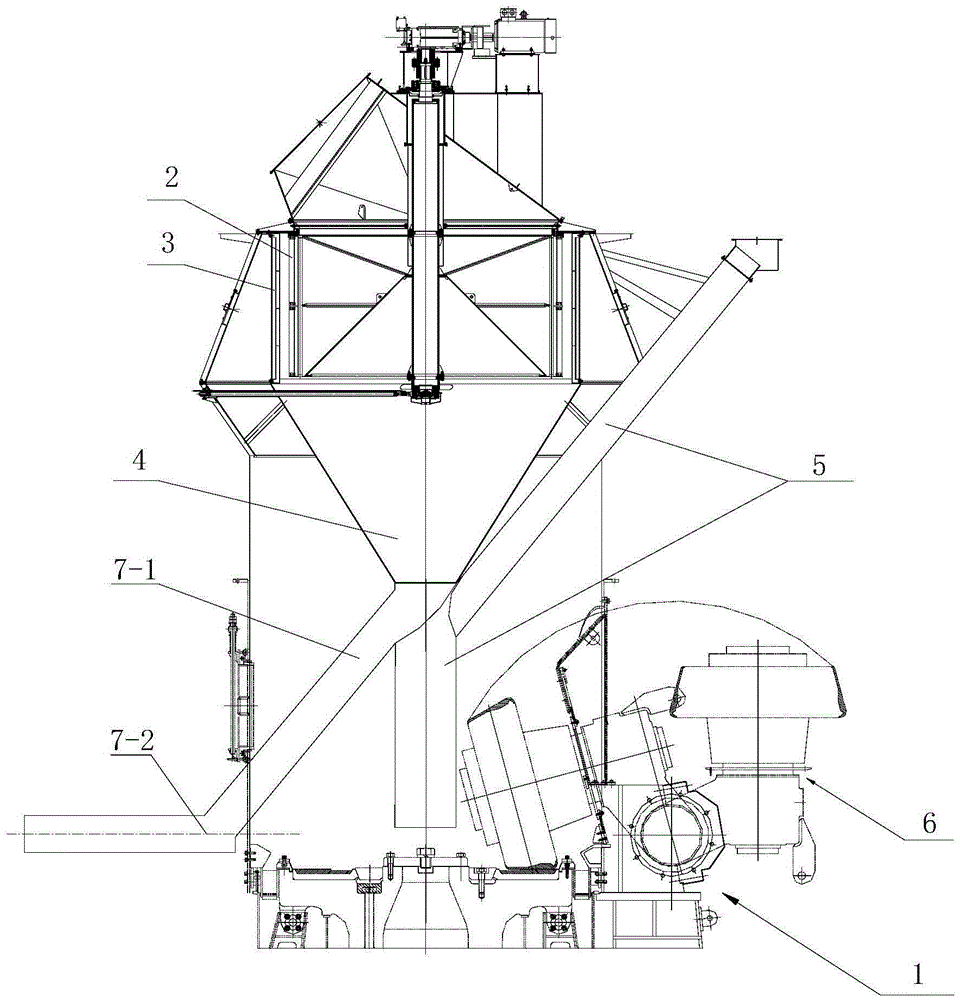

[0025] Example 1, see figure 1 , a new type of vertical roller mill powder separator with a grinding powder export mechanism, including a powder separator rotor 2 installed on the vertical roller mill grinding disc 1 and a static wind guide vane 3, which is installed at the lower end of the static wind guide vane The feeding cone 4 is connected to the feeding chute 5 at the lower end of the feeding chute, the lower end of the feeding chute extends vertically to the center of the grinding disc 1 of the vertical roller mill, and the roller mill driving device 6 also includes a powder grinding machine Lead-out mechanism 7, described outward lead-out mechanism is connected with the blanking cone 4 of vertical roller mill, comprises material guide chute 7-1 and horizontal conveying mechanism 7-2; Connects material guide chute 7-1 at the bottom of blanking cone 4, The material guide chute 7-1 communicates with the inner cavity of the blanking cone, and the lower end of the material ...

Embodiment 2

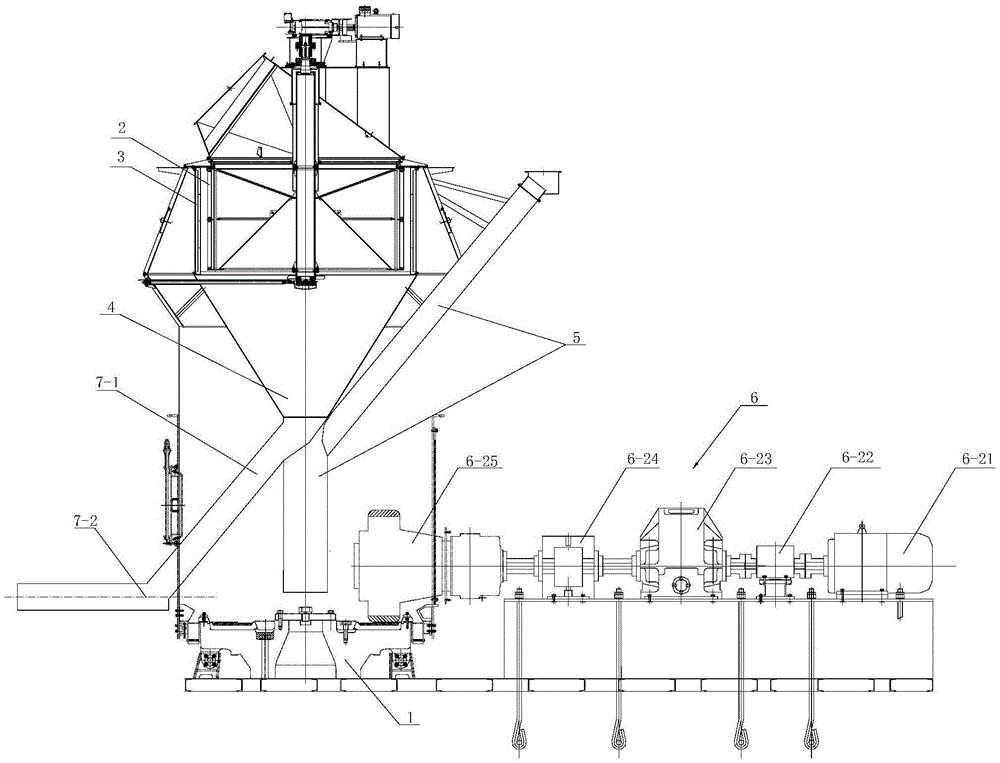

[0030] Example 2, see figure 2 , a vertical roller mill for ore grinding with a grinding powder export mechanism; it includes a powder separator rotor 2 installed on the vertical roller mill grinding disc 1 and a static wind guide vane 3, which is installed at the lower end of the static wind guide vane The feeding cone 4 is connected to the feeding chute 5 at the lower end of the feeding chute, the lower end of the feeding chute extends vertically to the center position of the grinding disc 1 of the vertical roller mill, and the roller mill driving device 6, the grinding disc 1 is driven , the ground material enters the rotor 2 of the classifying powder separator and the static air guide vane 3, the finished material enters the feeding cone 4, and the fine material passing through the powder separator is used as a by-product for further processing; the new feed is fed from the feed chute 5 Falling to the grinding table, the sorted finished products pass through the guide chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com