Patents

Literature

70results about How to "Reduce surface charge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

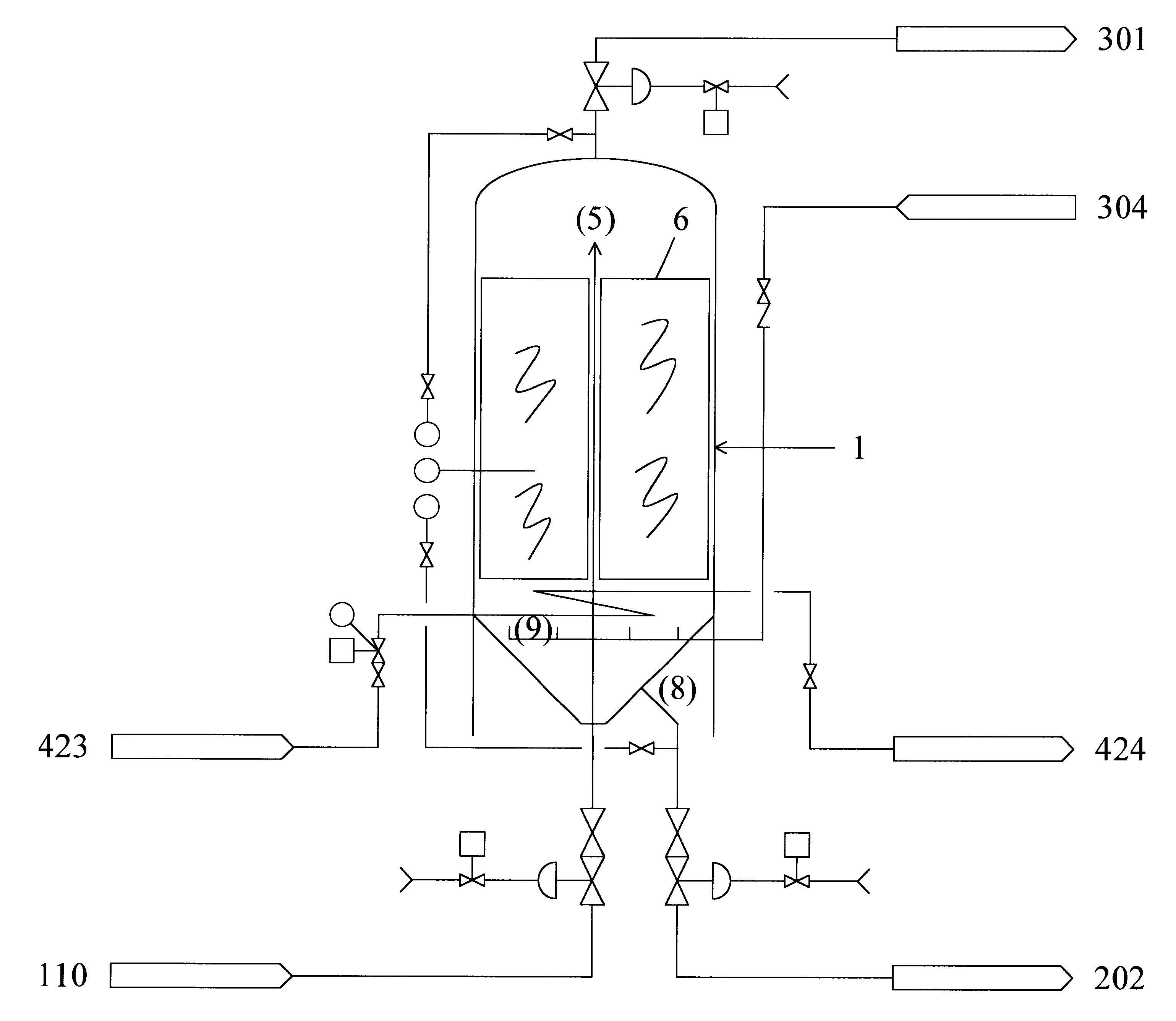

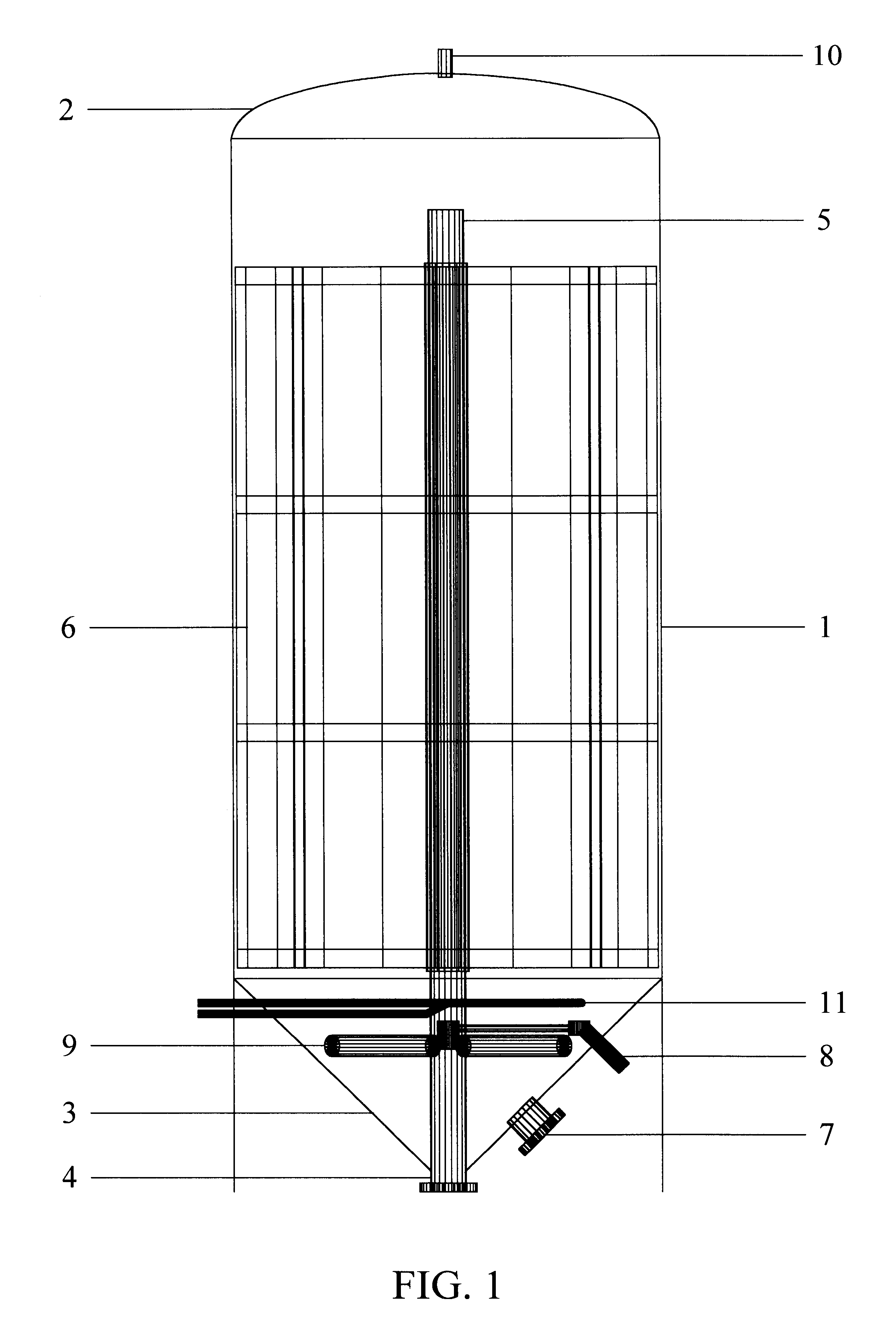

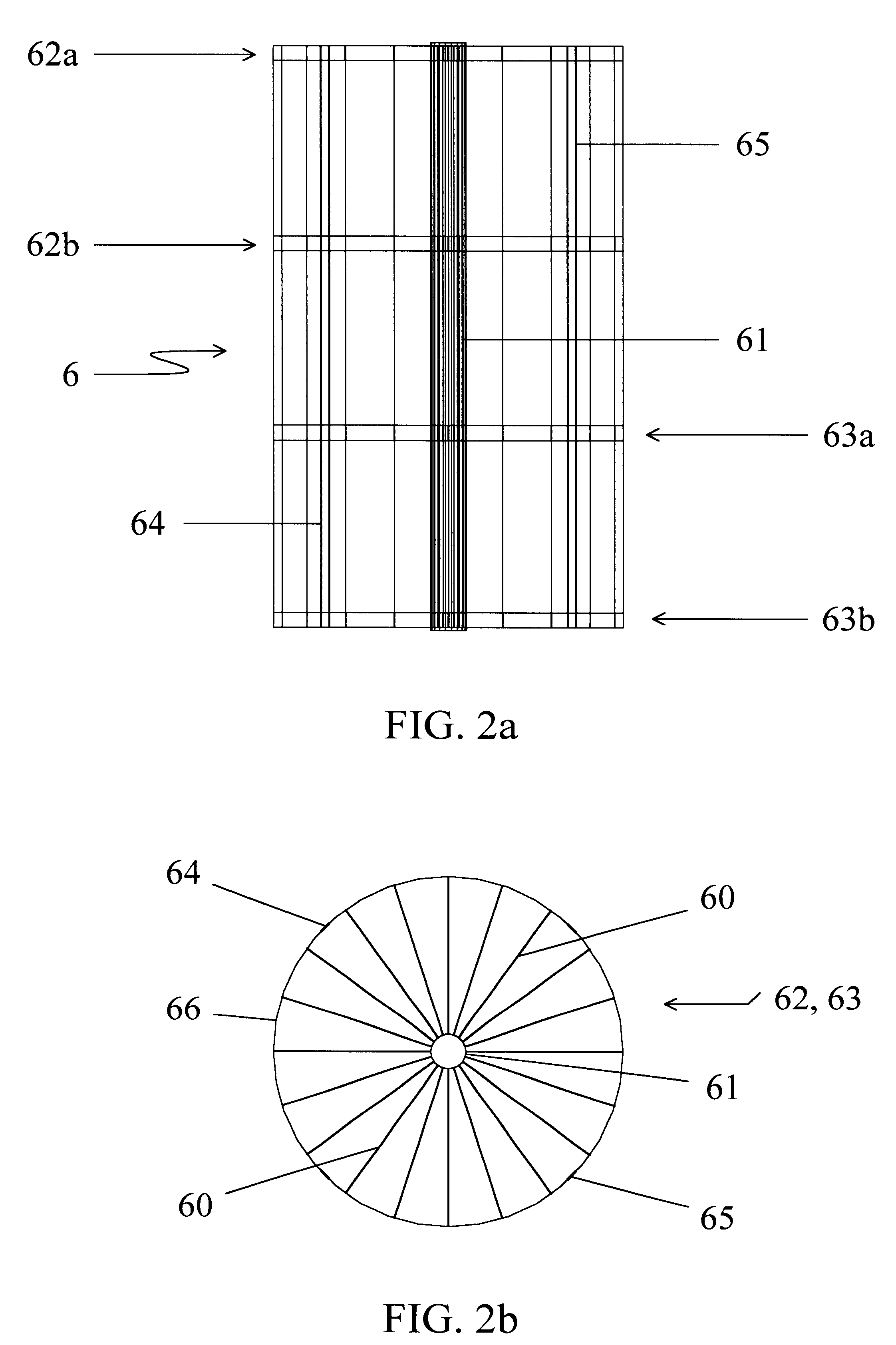

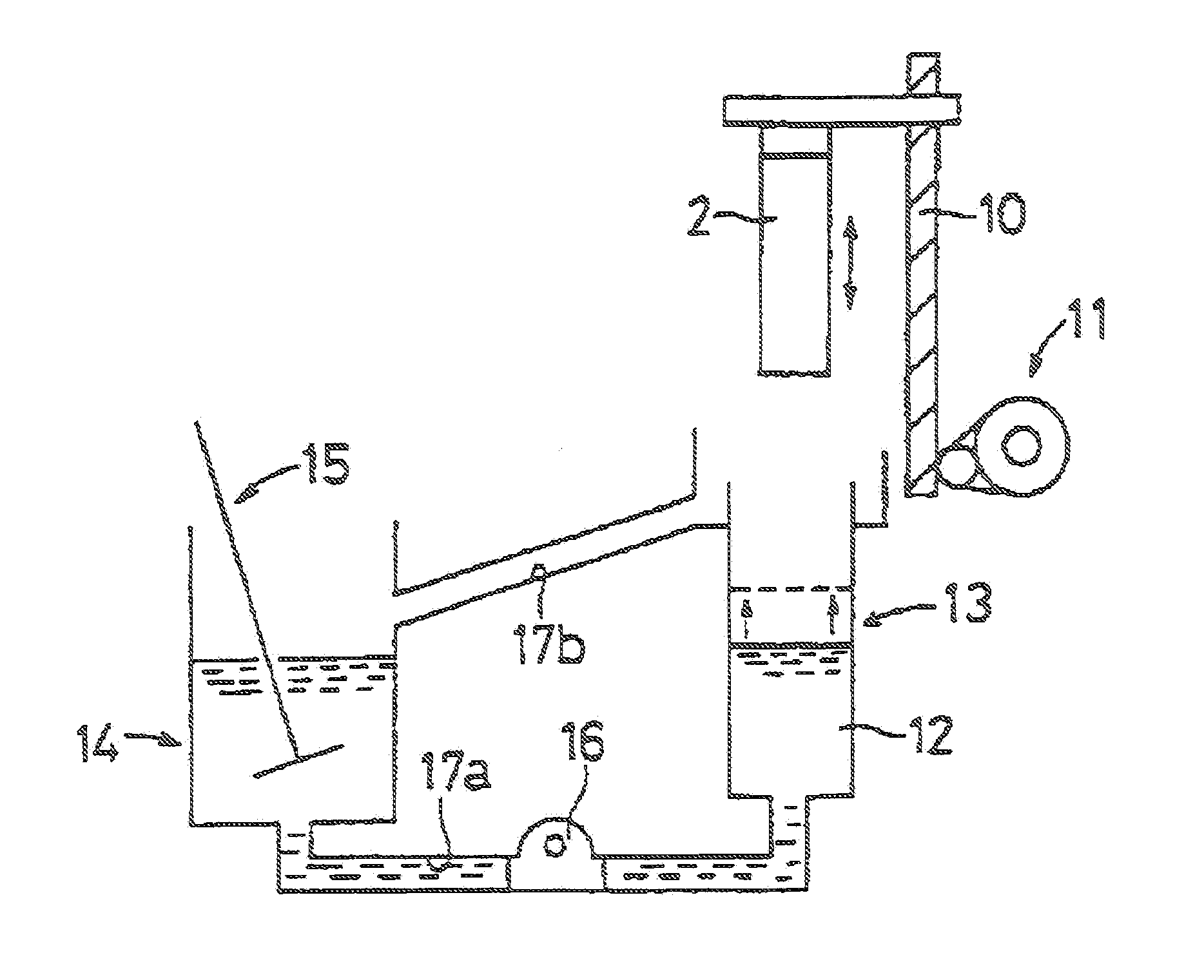

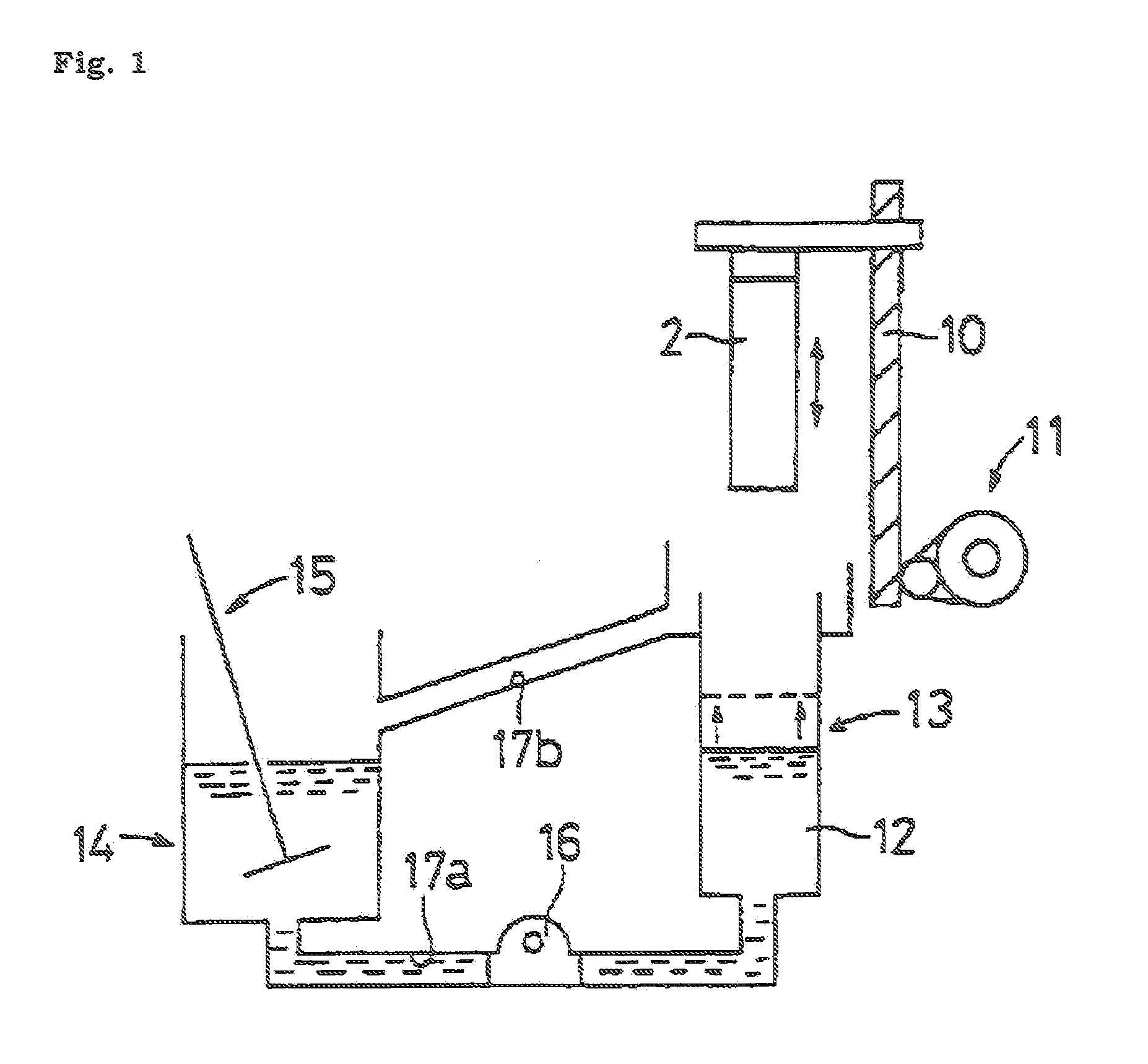

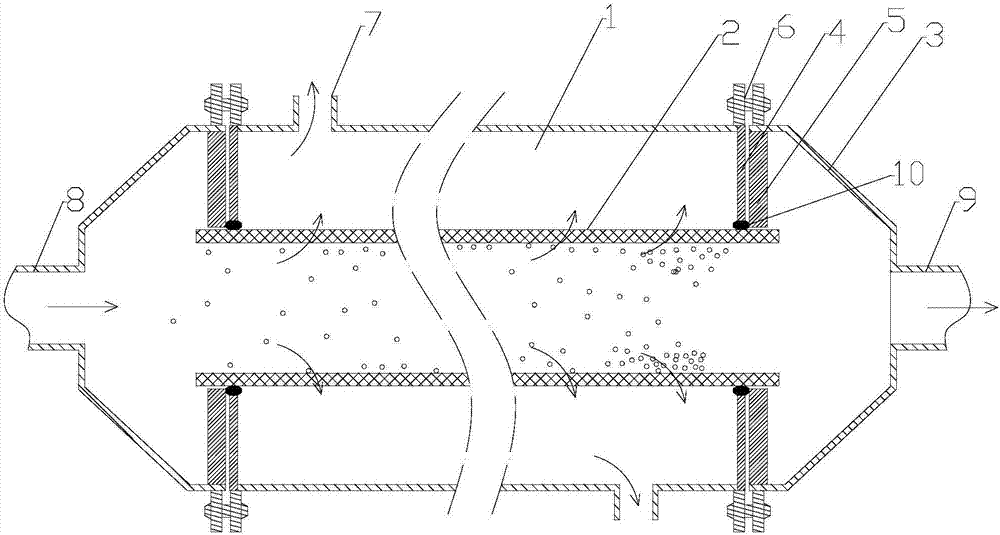

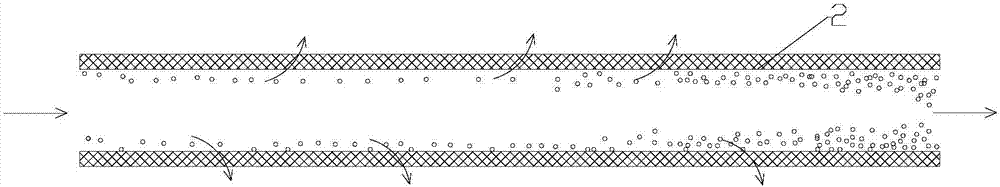

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

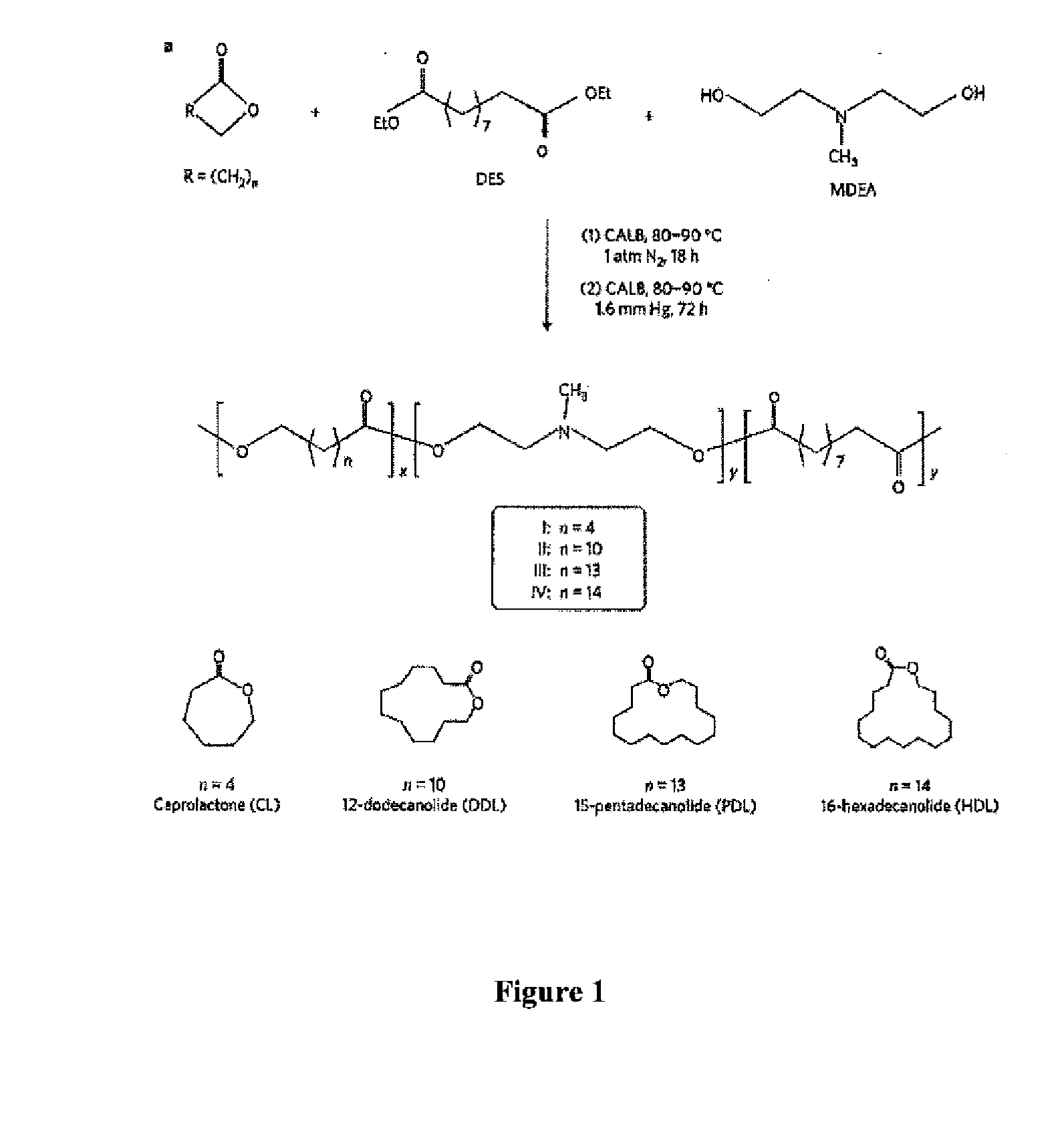

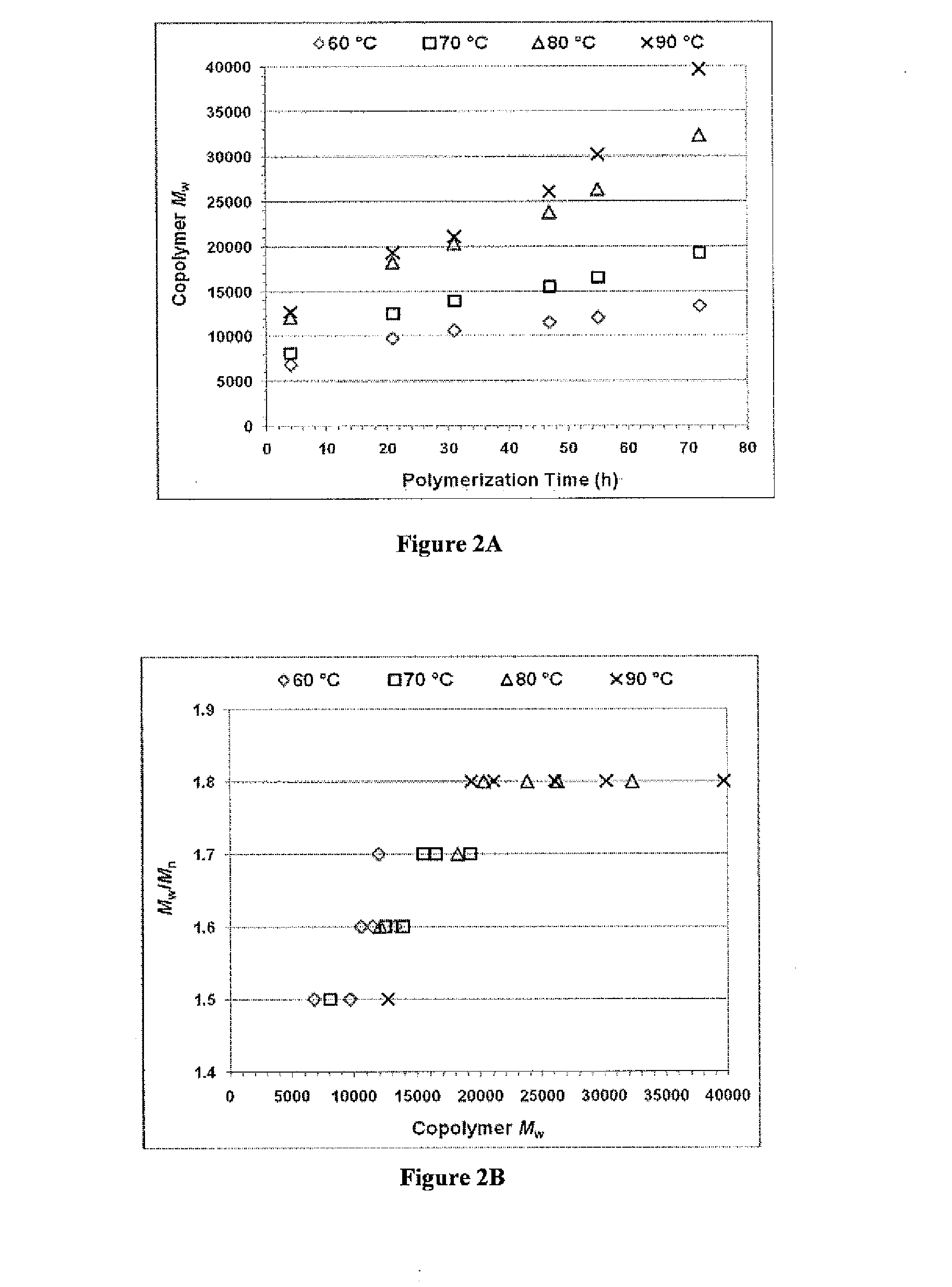

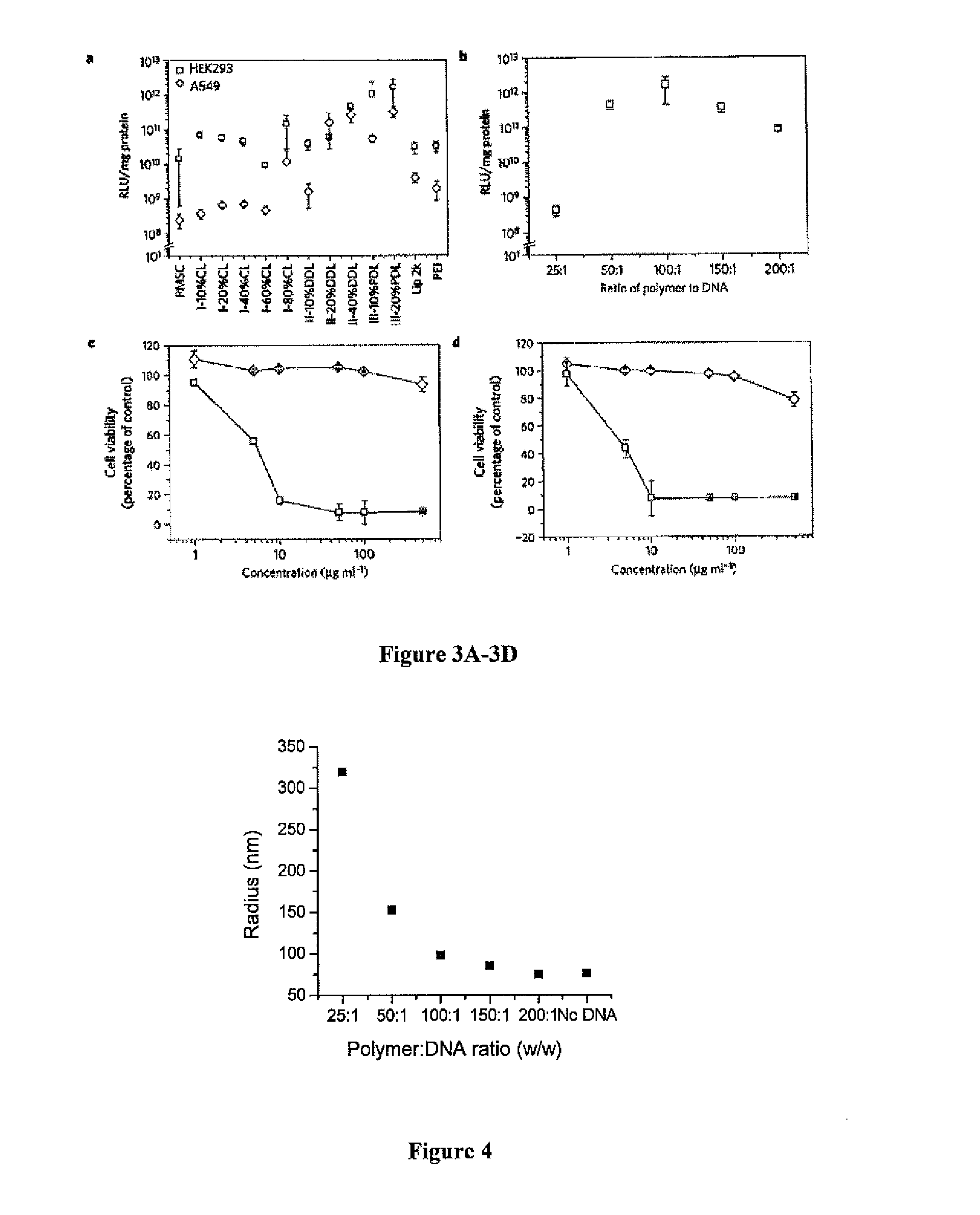

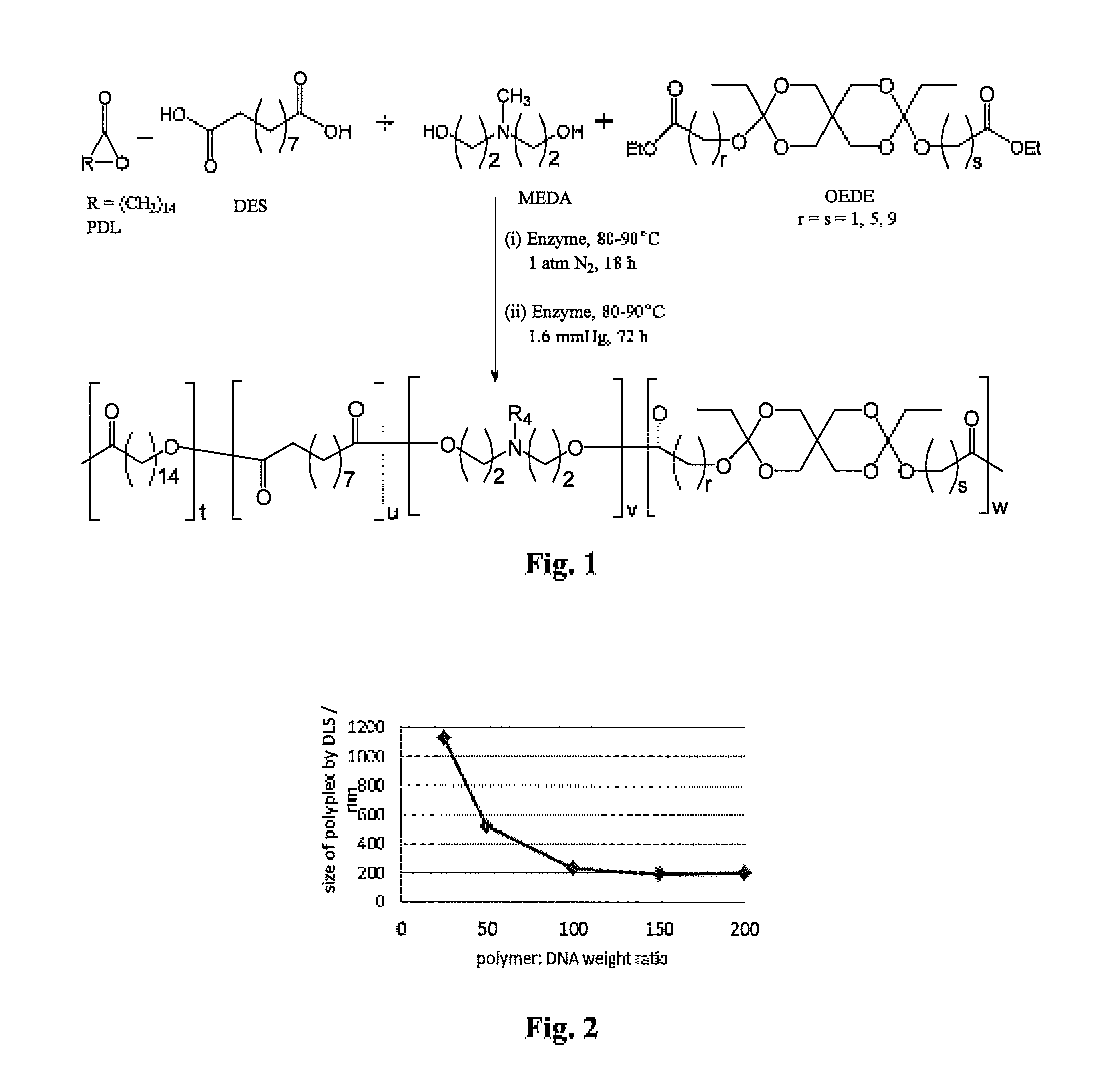

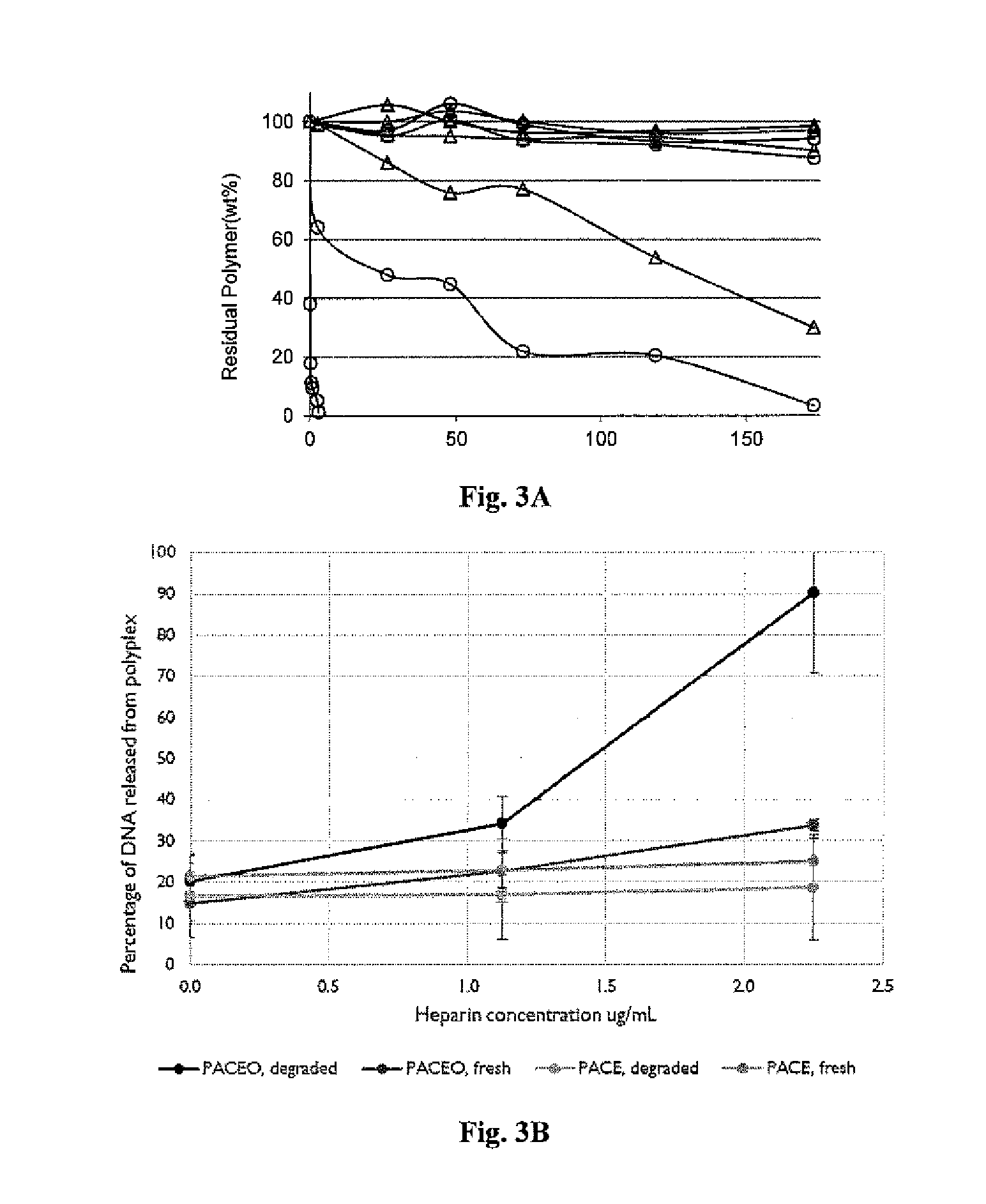

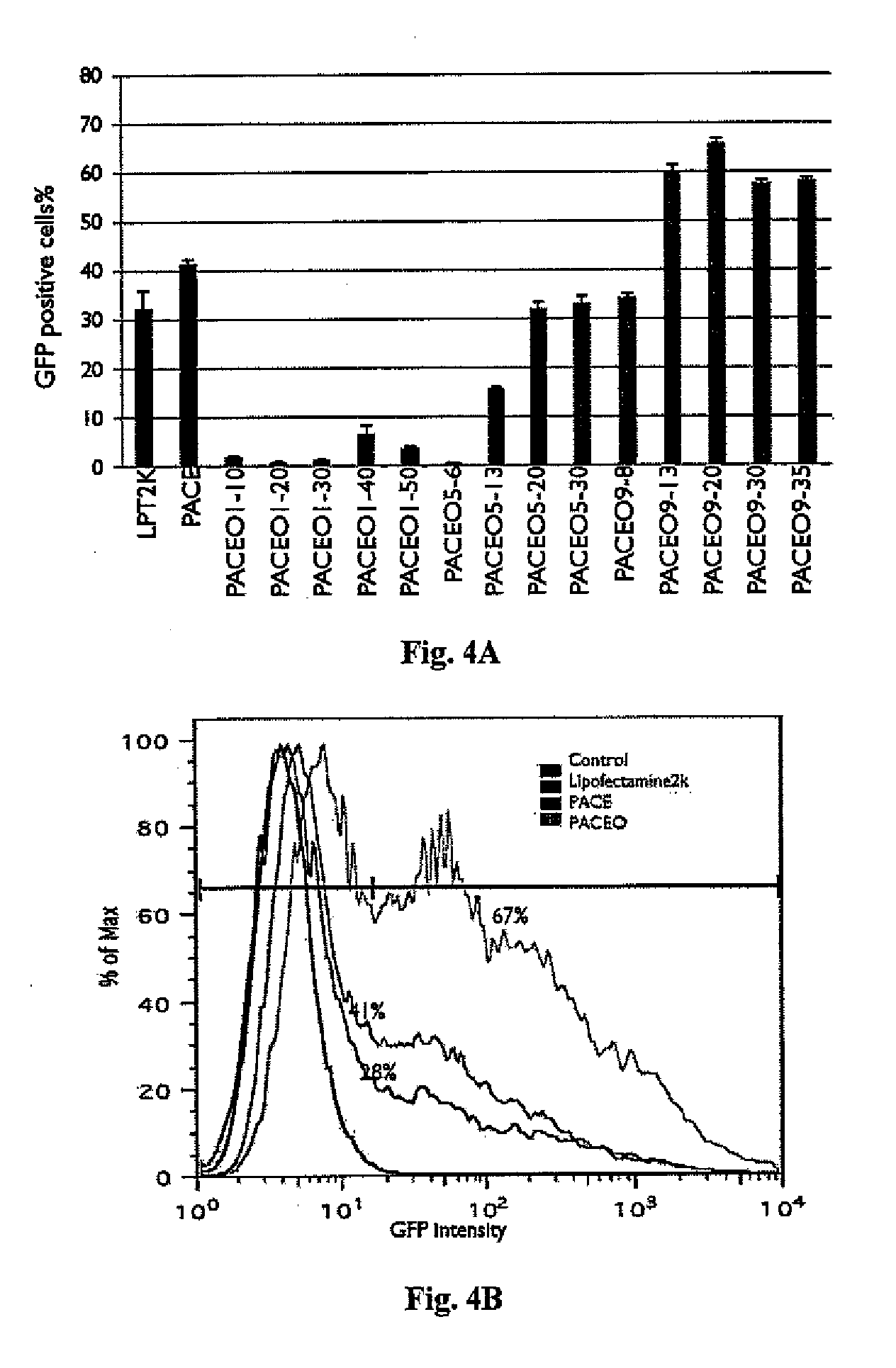

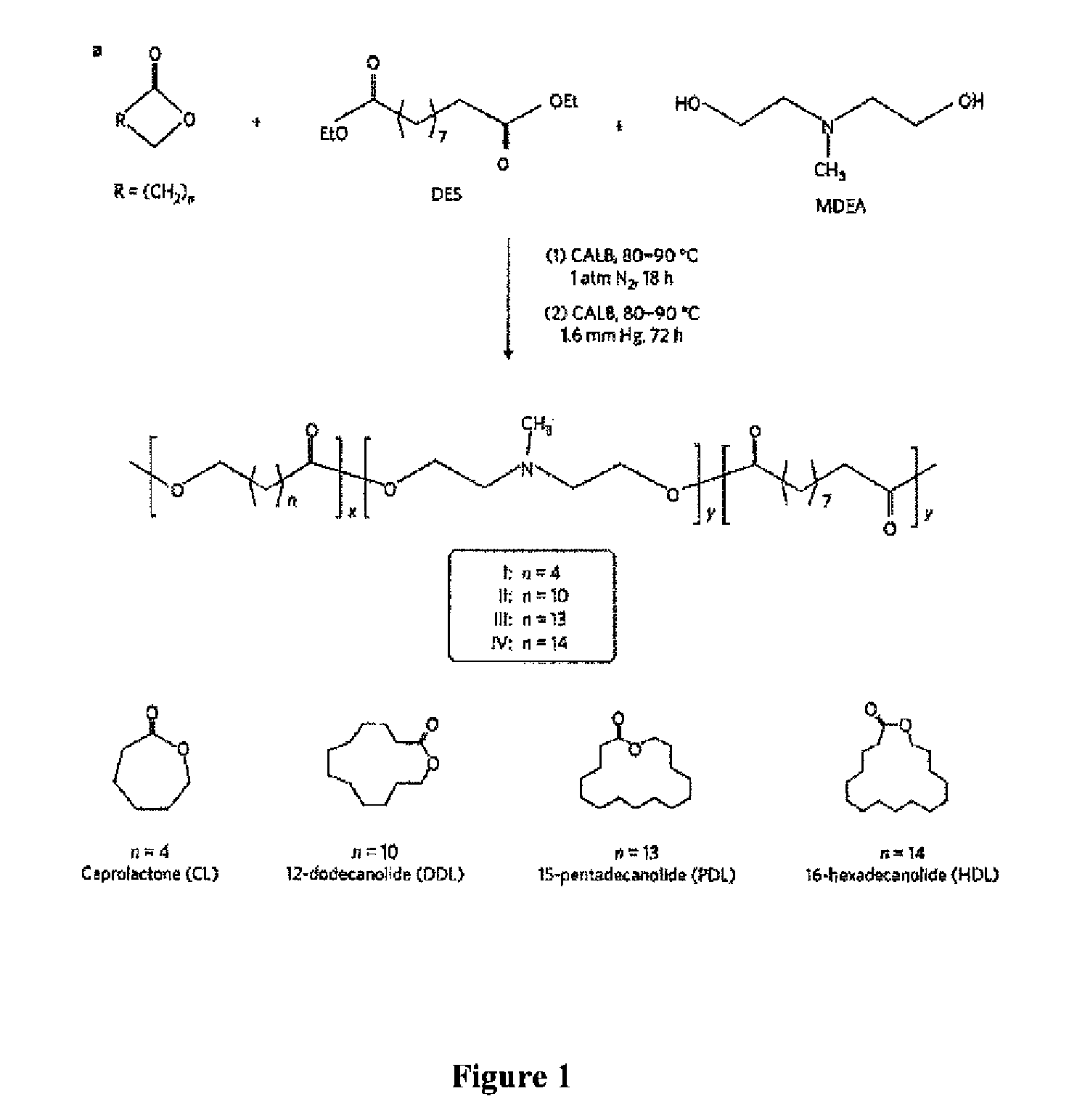

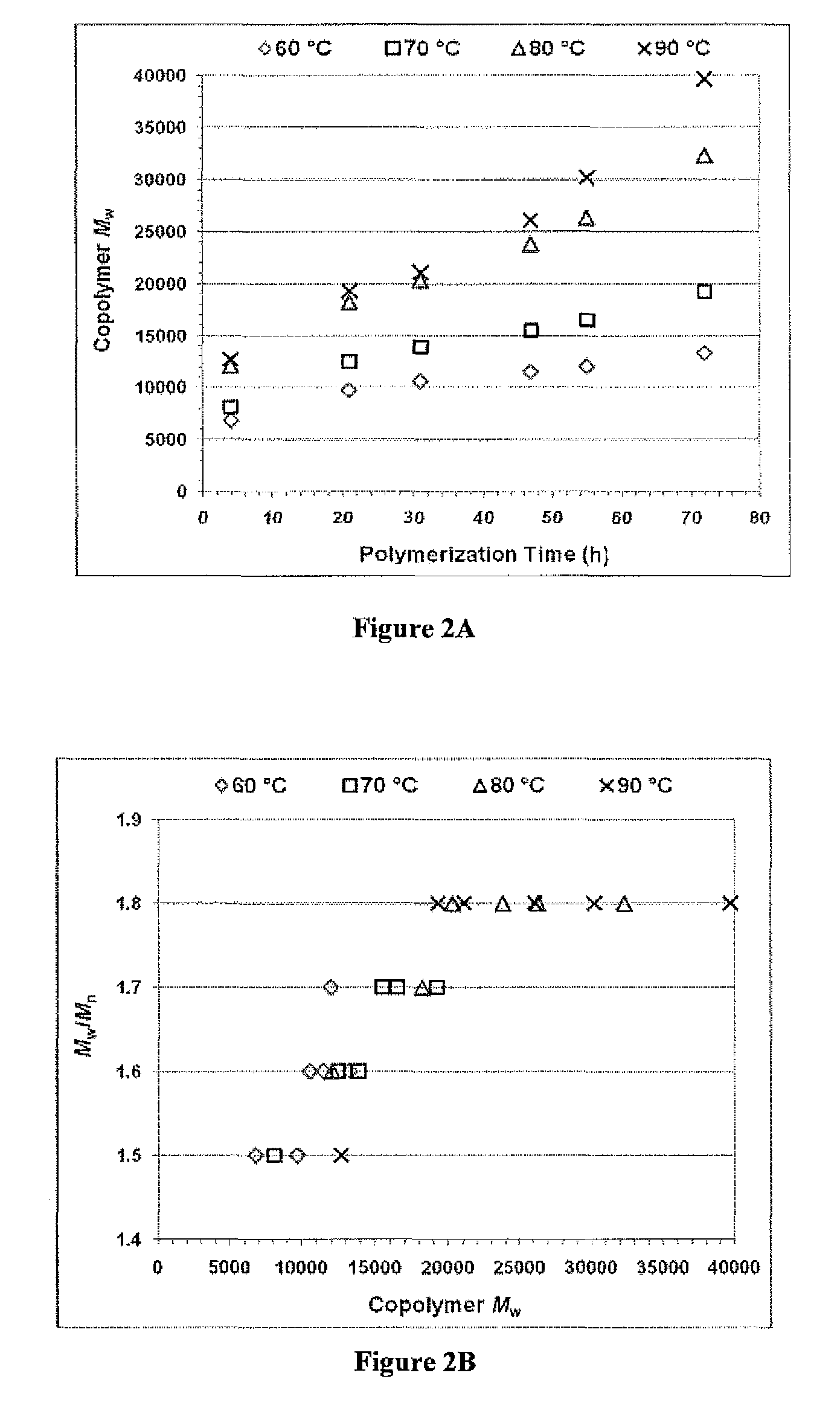

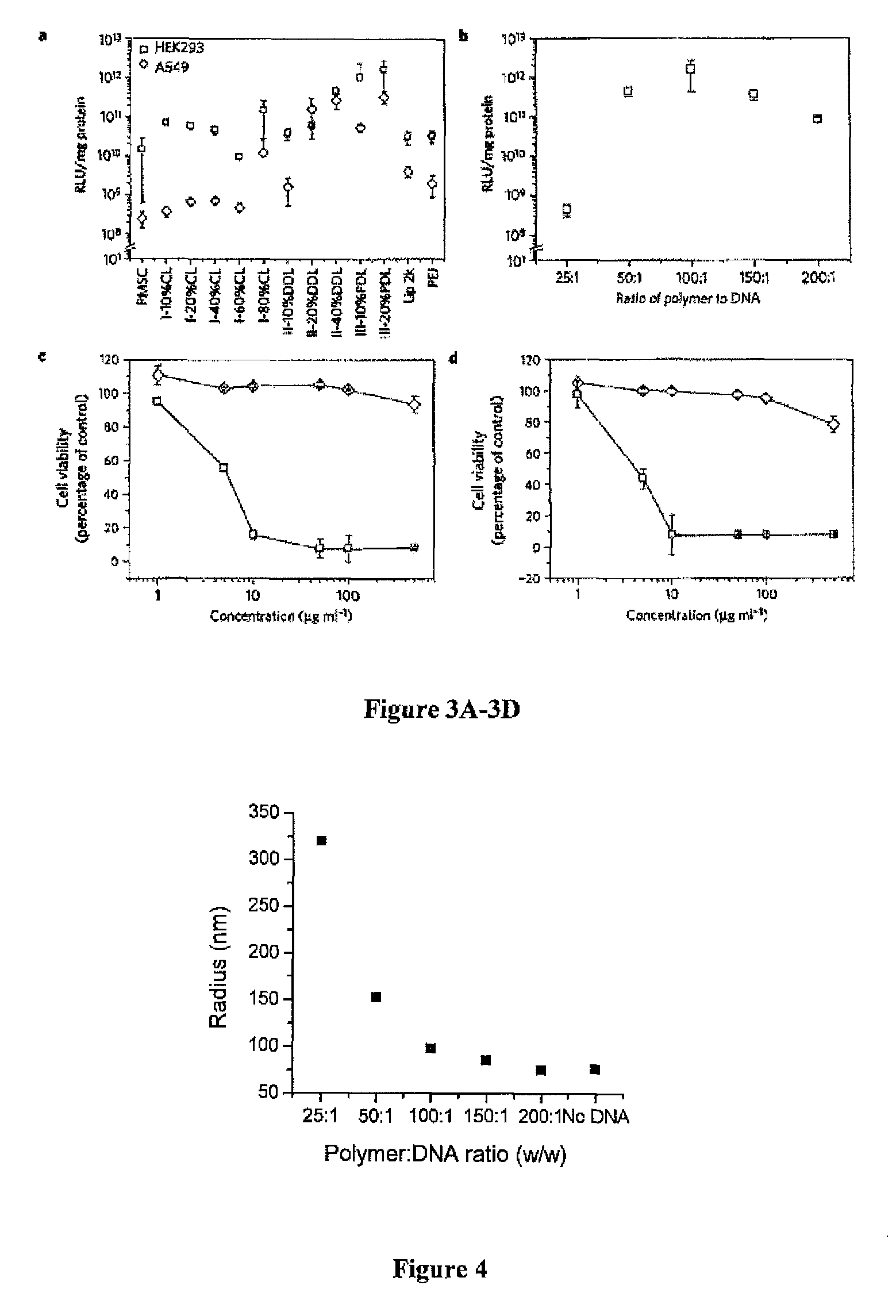

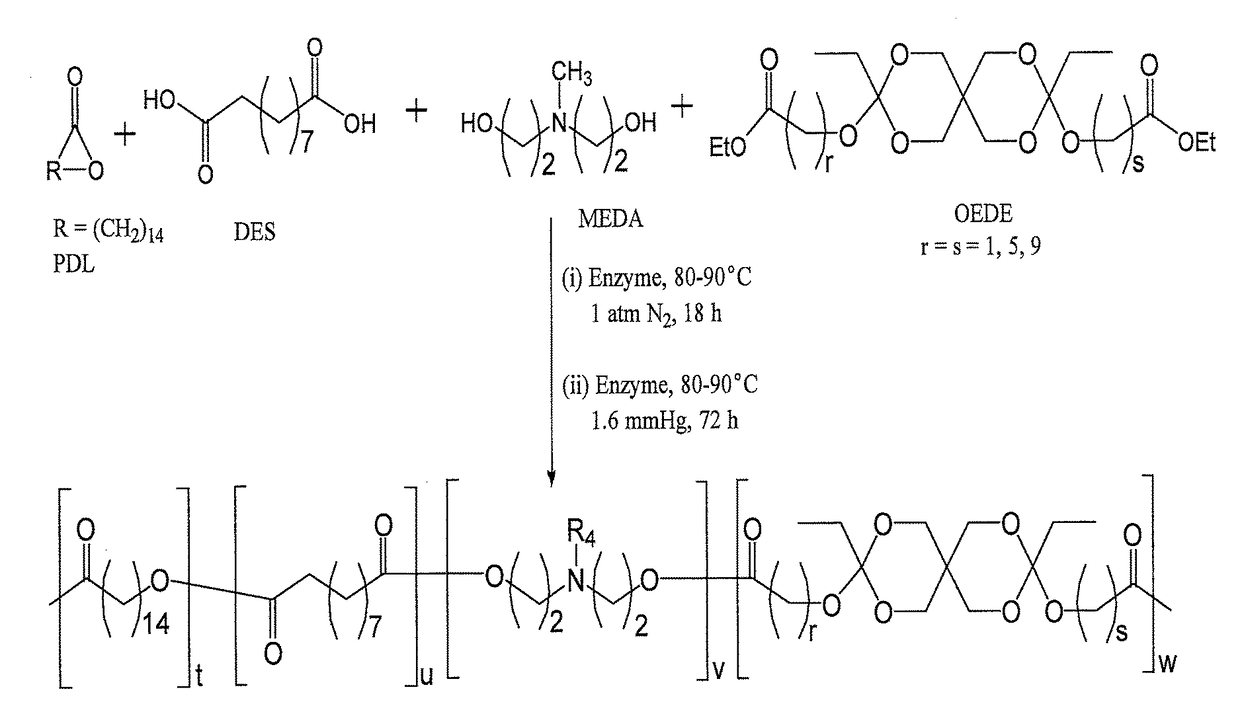

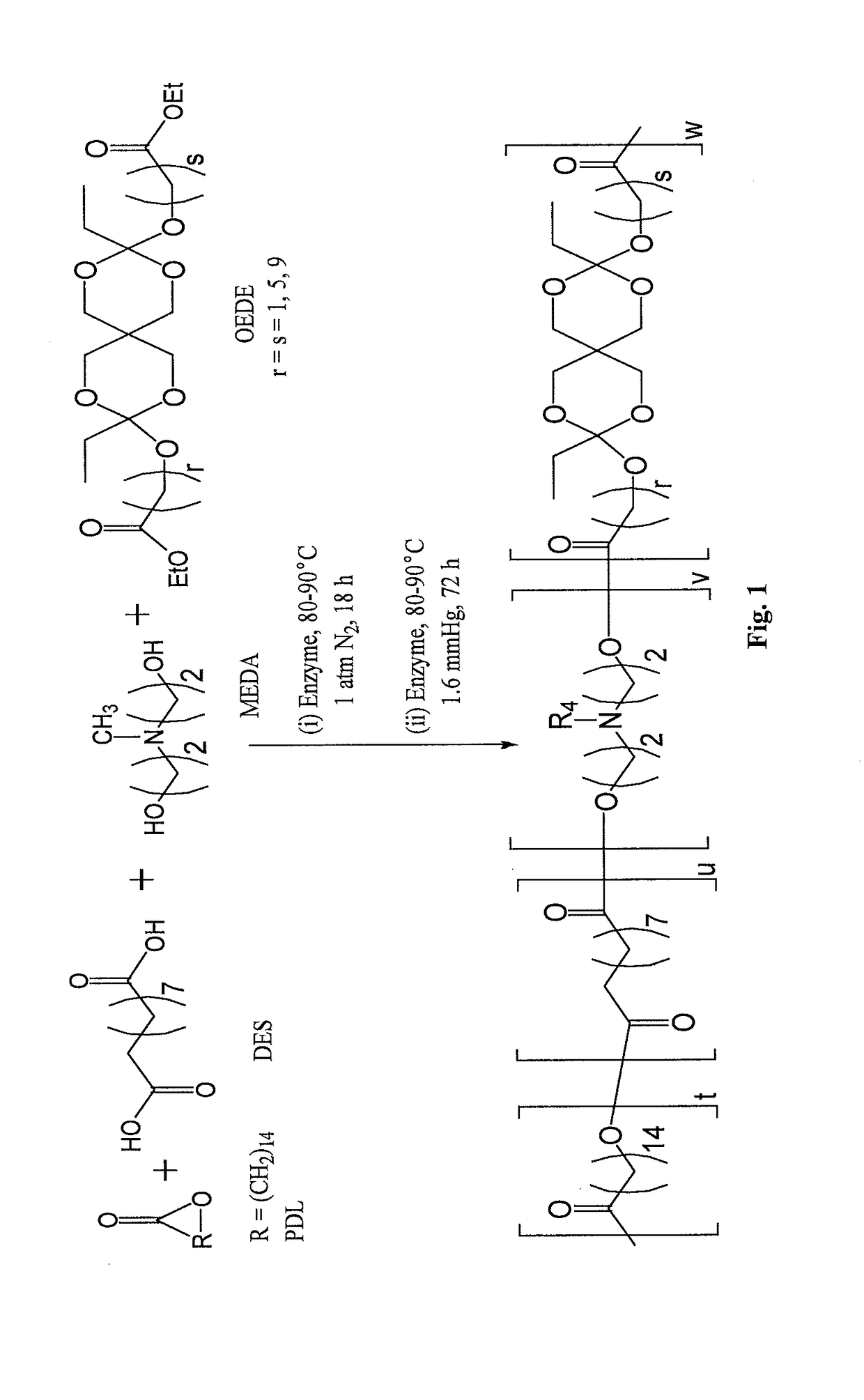

Enzymatic synthesis of poly(amine-co-esters) and methods of use thereof for gene delivery

ActiveUS20140342003A1Improve efficiencyMaterial efficiencyPowder deliveryBiocideDiseaseEnzymatic synthesis

Poly(amine-co-ester) polymers, methods of forming active agent-load nanoparticles therefrom, and methods of using the nanoparticles for drug delivery are disclosed. The nanoparticles can be coated with an agent that reduces surface charge, an agent that increases cell-specific targeting, or a combination thereof. Typically, the loaded nanoparticles are less toxic, more efficient at drug delivery, or a combination thereof compared to a control other transfection reagents. In some embodiments, the nanoparticles are suitable for in vivo delivery, and can be administered systemically to a subject to treat a disease or condition.

Owner:YALE UNIV

Formulations for targeted release of agents to low ph tissue environments or cellular compartments and methods of use thereof

ActiveUS20150073041A1Easy to optimizeEfficient deliveryOrganic active ingredientsOther foreign material introduction processesCell specificActive agent

Polyamine-co-ester-co-ortho ester) polymers, methods of forming active agent-load nanoparticles therefrom, and methods of using the nanoparticles for drug delivery are disclosed. The nanoparticles can be coated with an agent that reduces surface charge, an agent that increases cell-specific targeting, or a combination thereof. Typically, the loaded nanoparticles are less toxic, more efficient at drug delivery, or a combination thereof compared to a control or other transfection reagents.

Owner:YALE UNIV

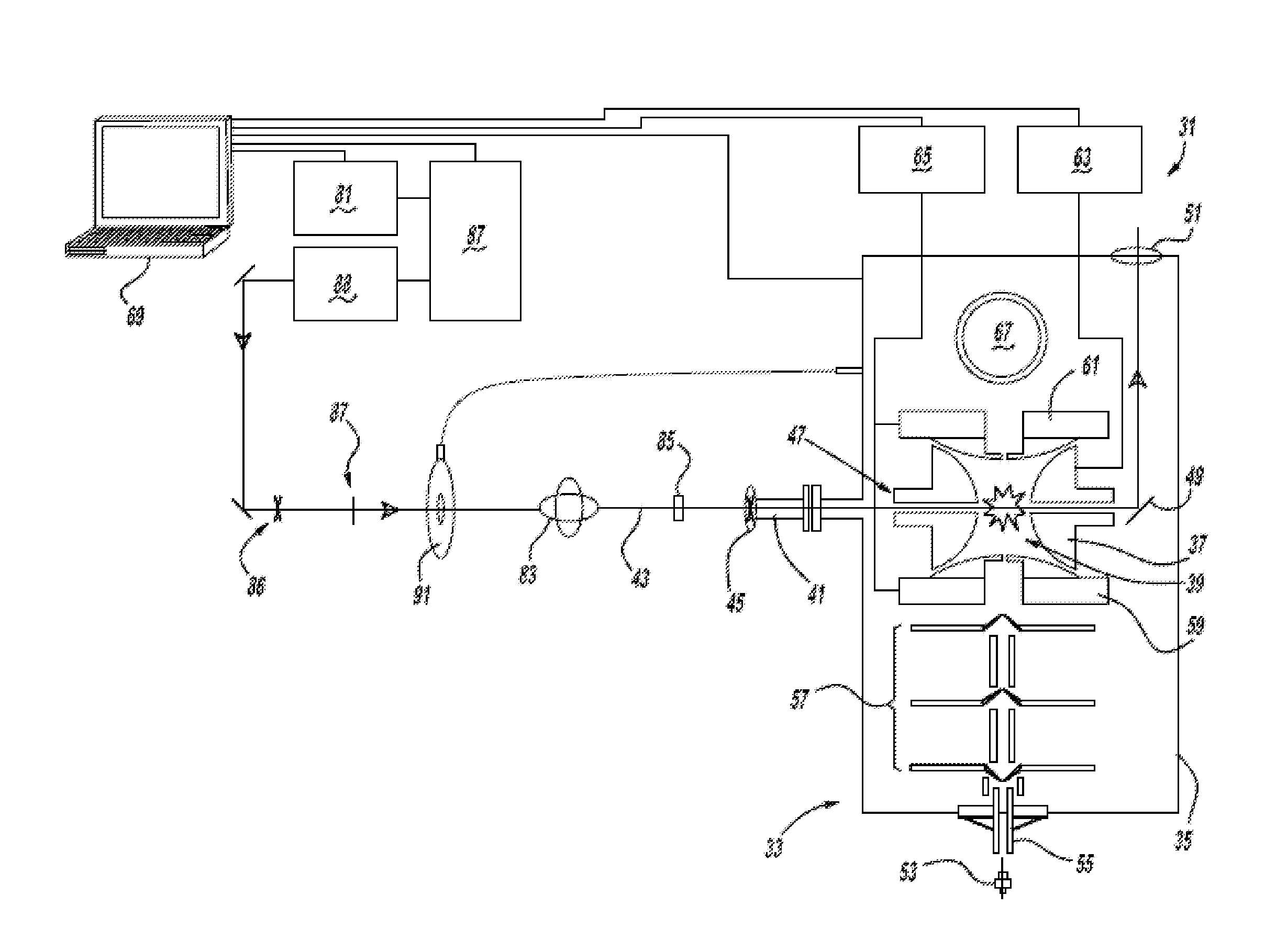

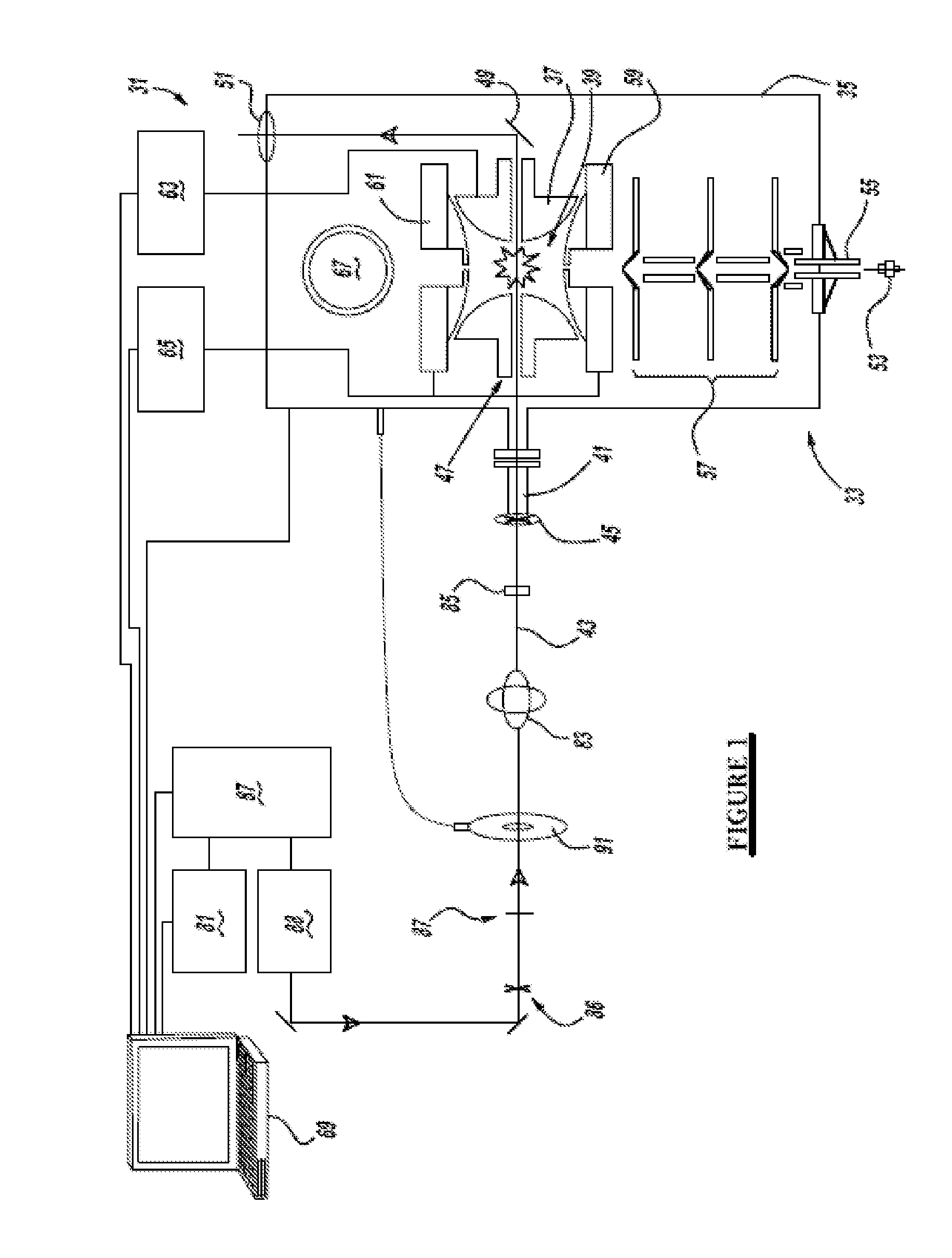

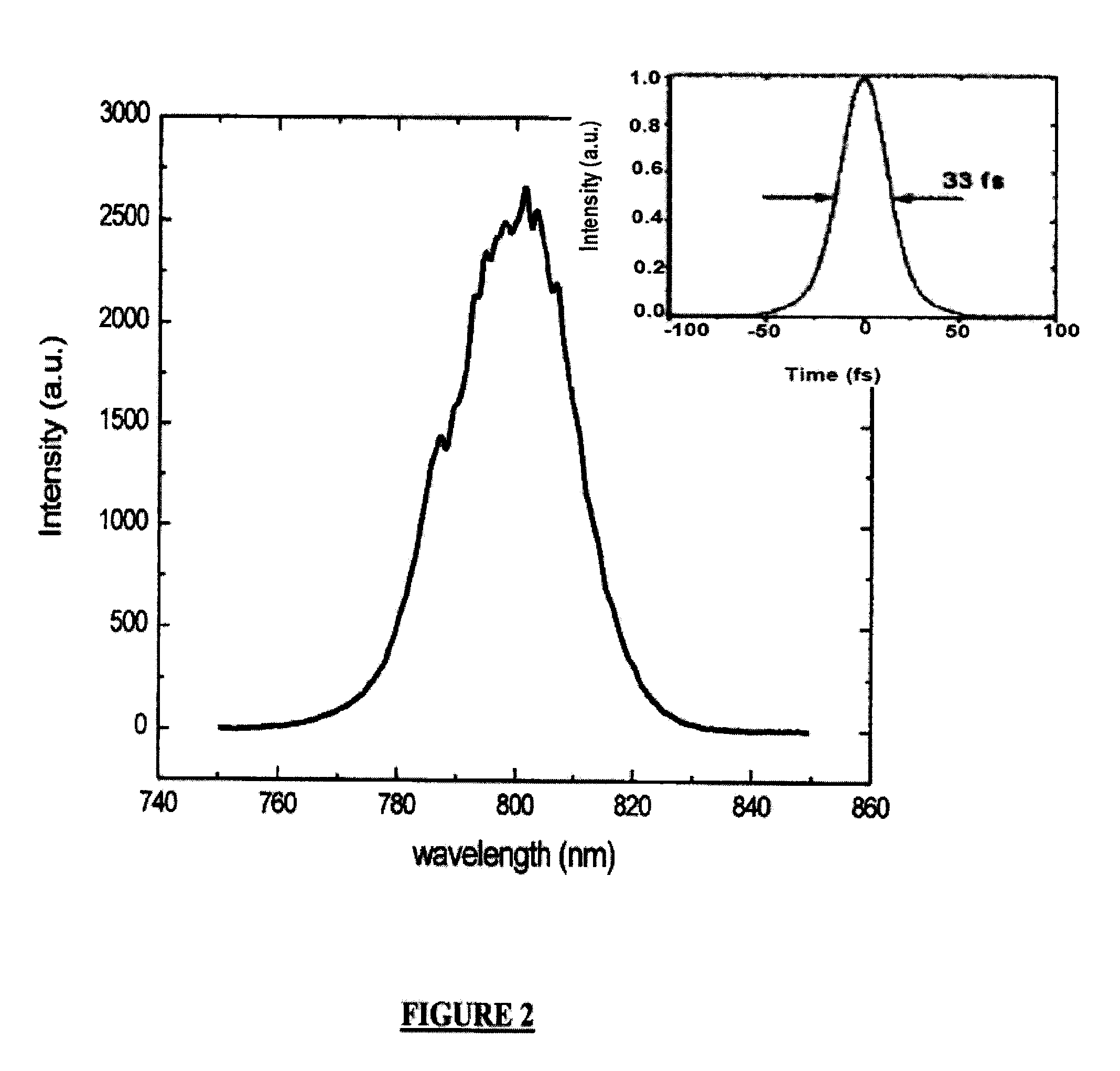

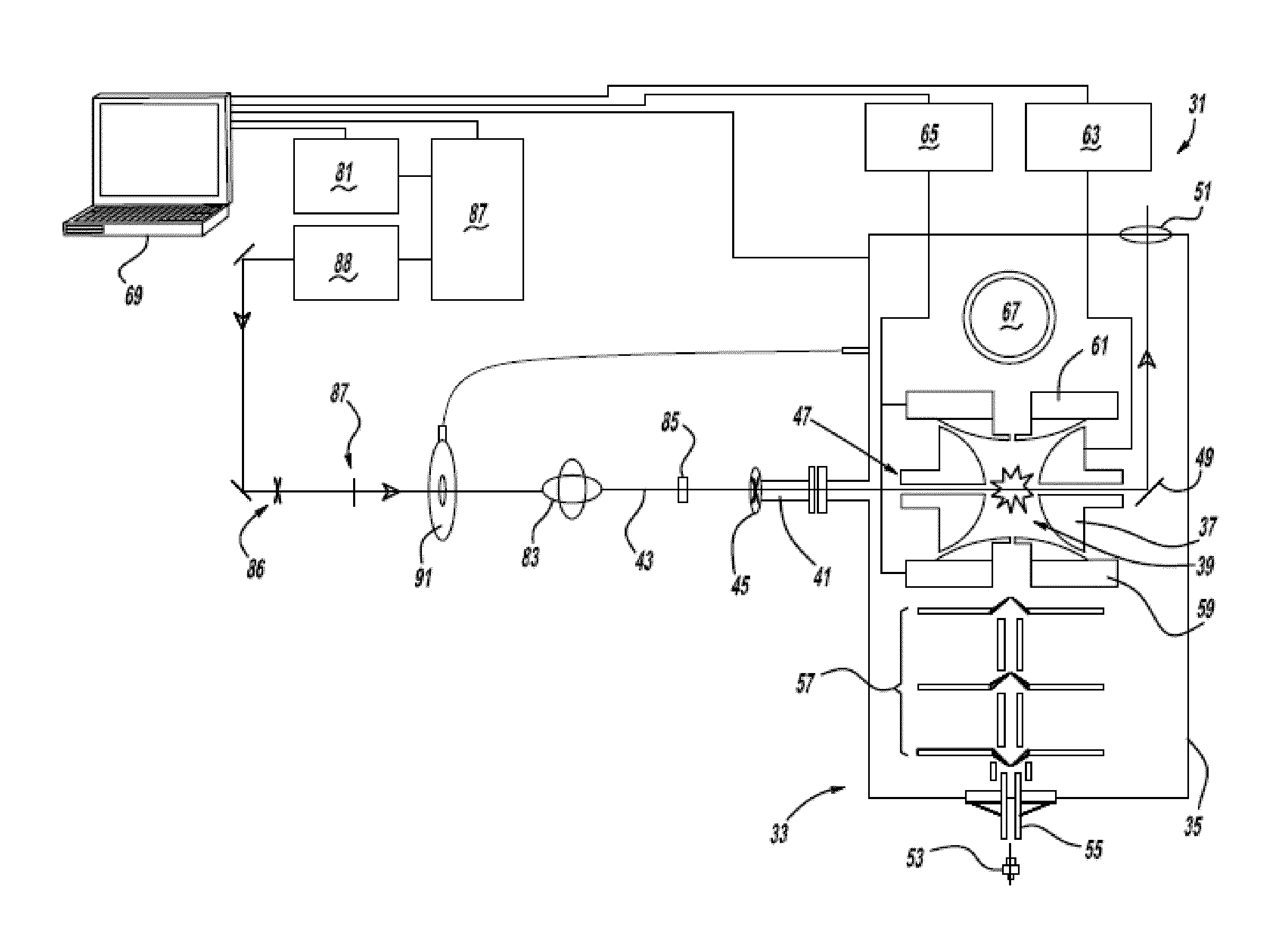

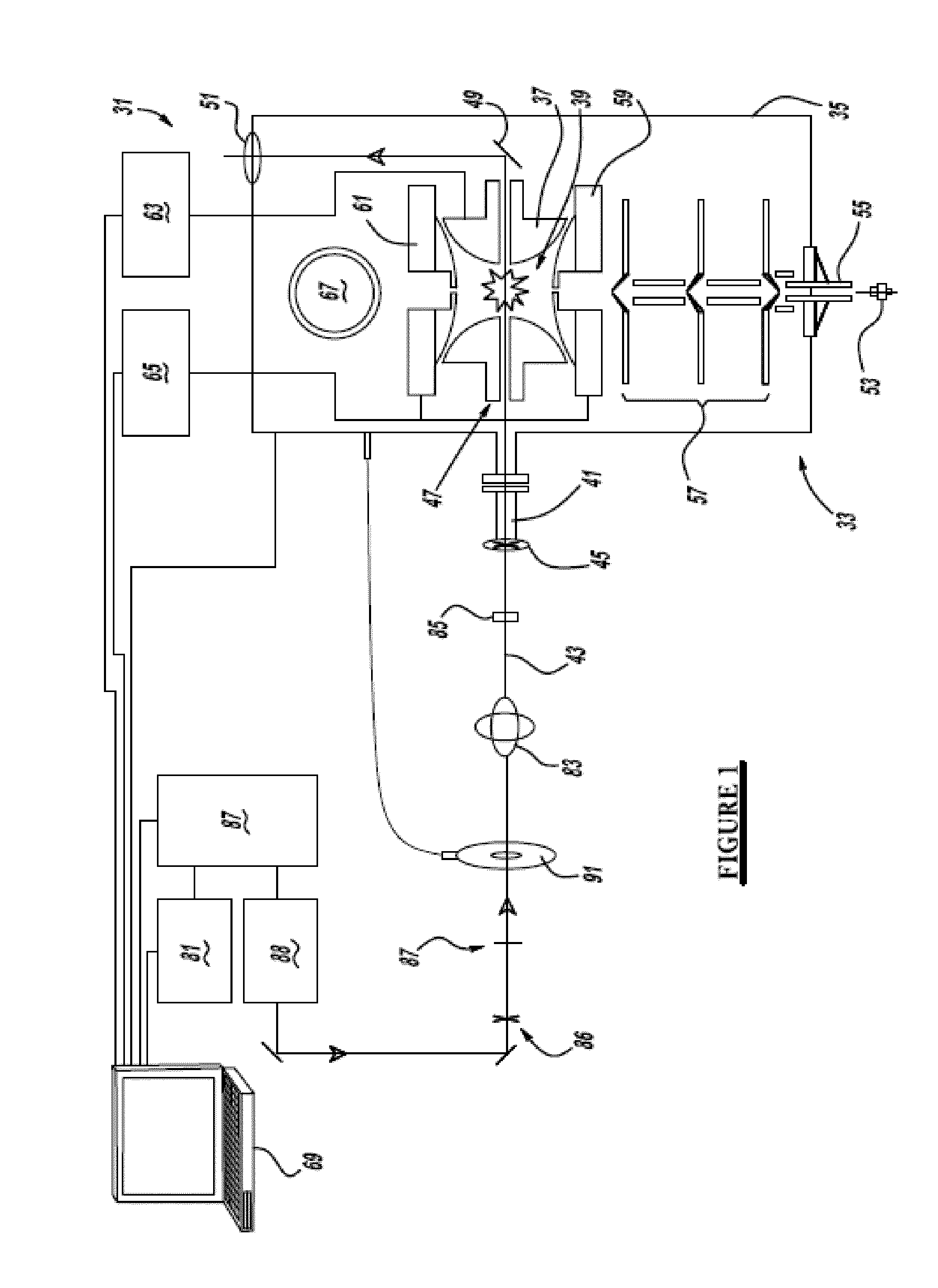

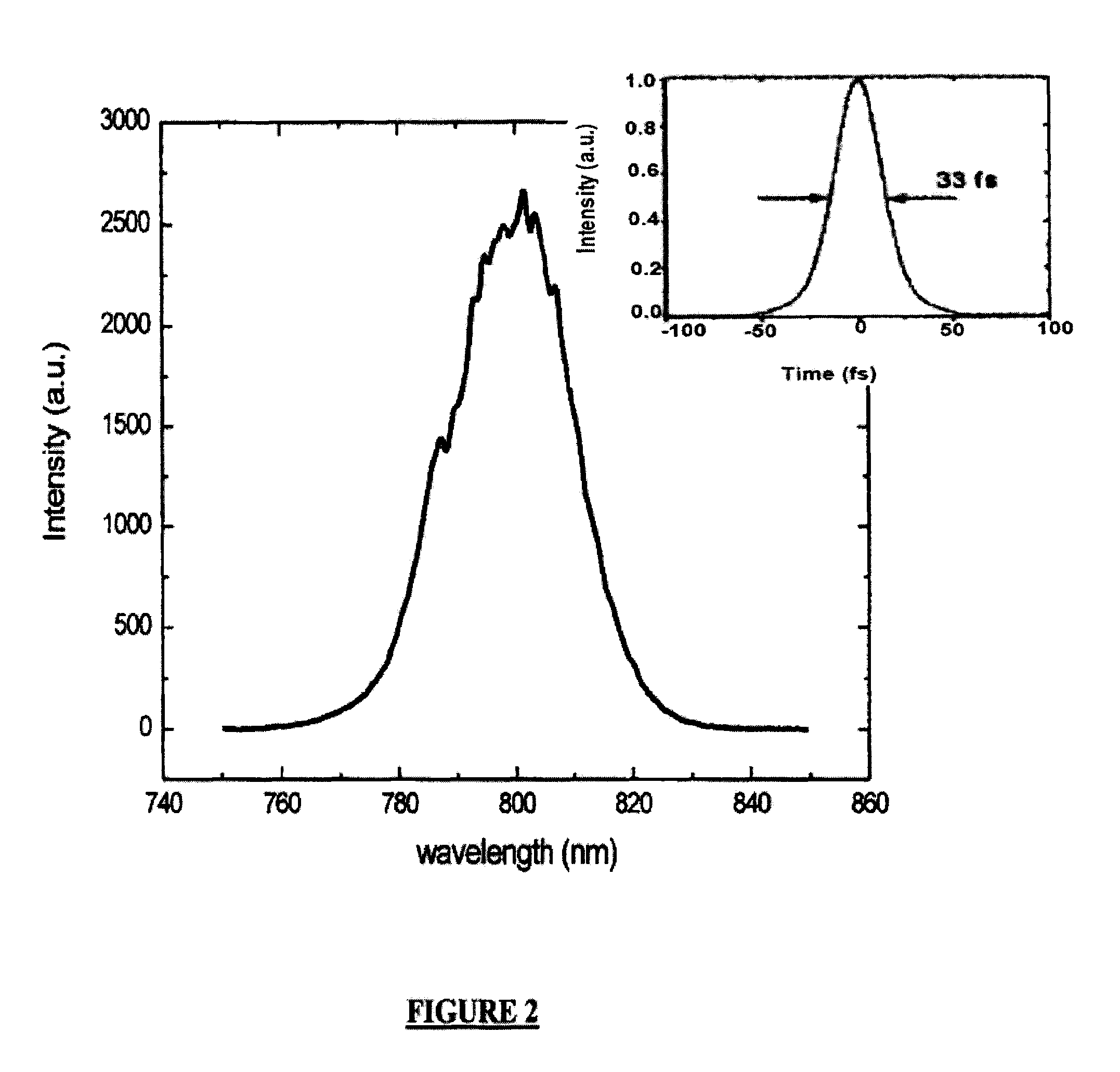

Ultrafast laser system for biological mass spectrometry

ActiveUS20100123075A1Reduce surface chargeImproves structural analysisIsotope separationMass spectrometersIon trap mass spectrometryFemto second laser

One aspect of the system provides the use of a laser with a mass spectrometer. Another aspect of the present application employs a laser emitting a pulse of less than one picosecond duration into an ion-trap mass spectrometer. In yet another aspect of the present application, a femtosecond laser beam pulse is emitted upon an ionized specimen to remove at least one electron therefrom.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

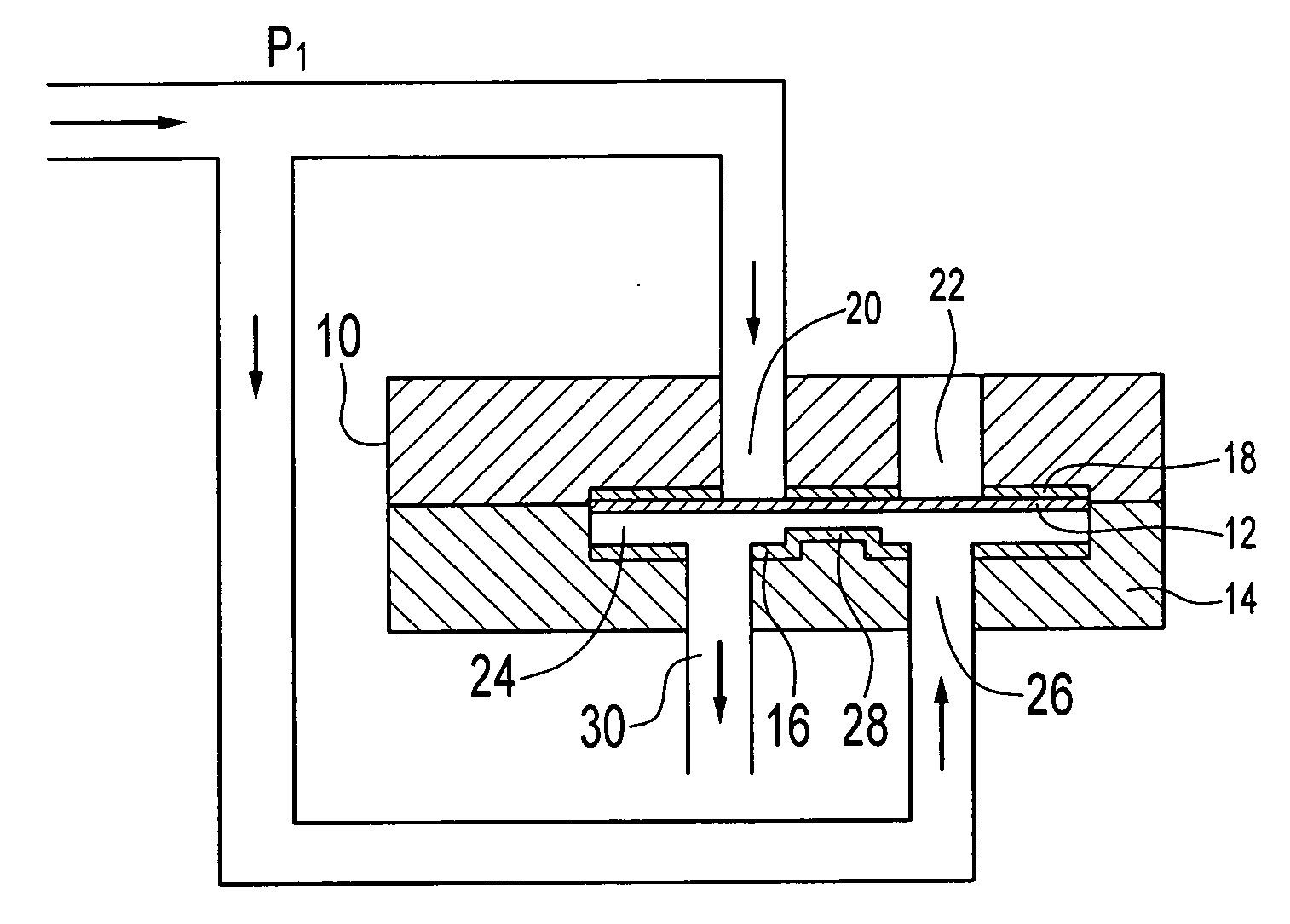

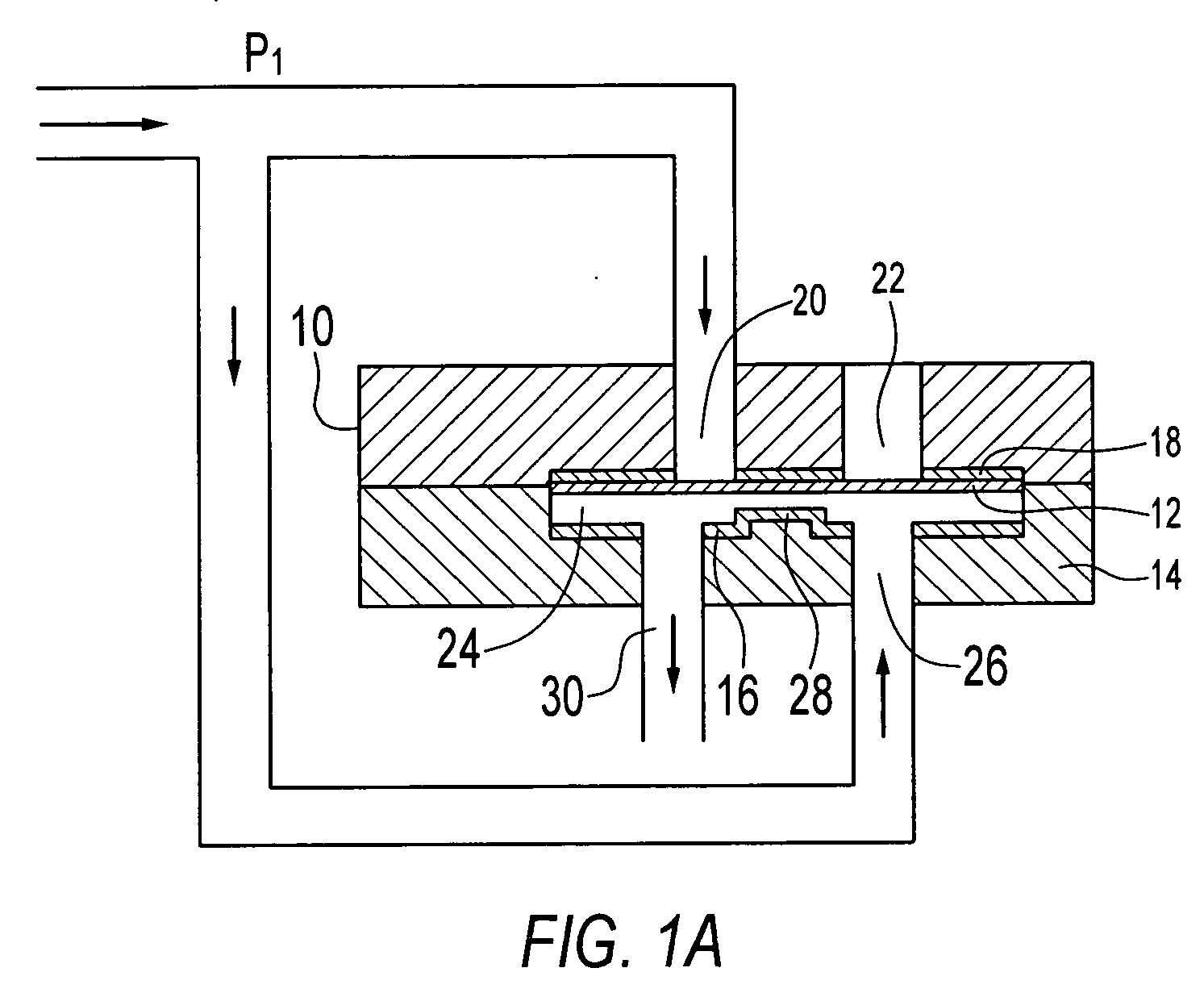

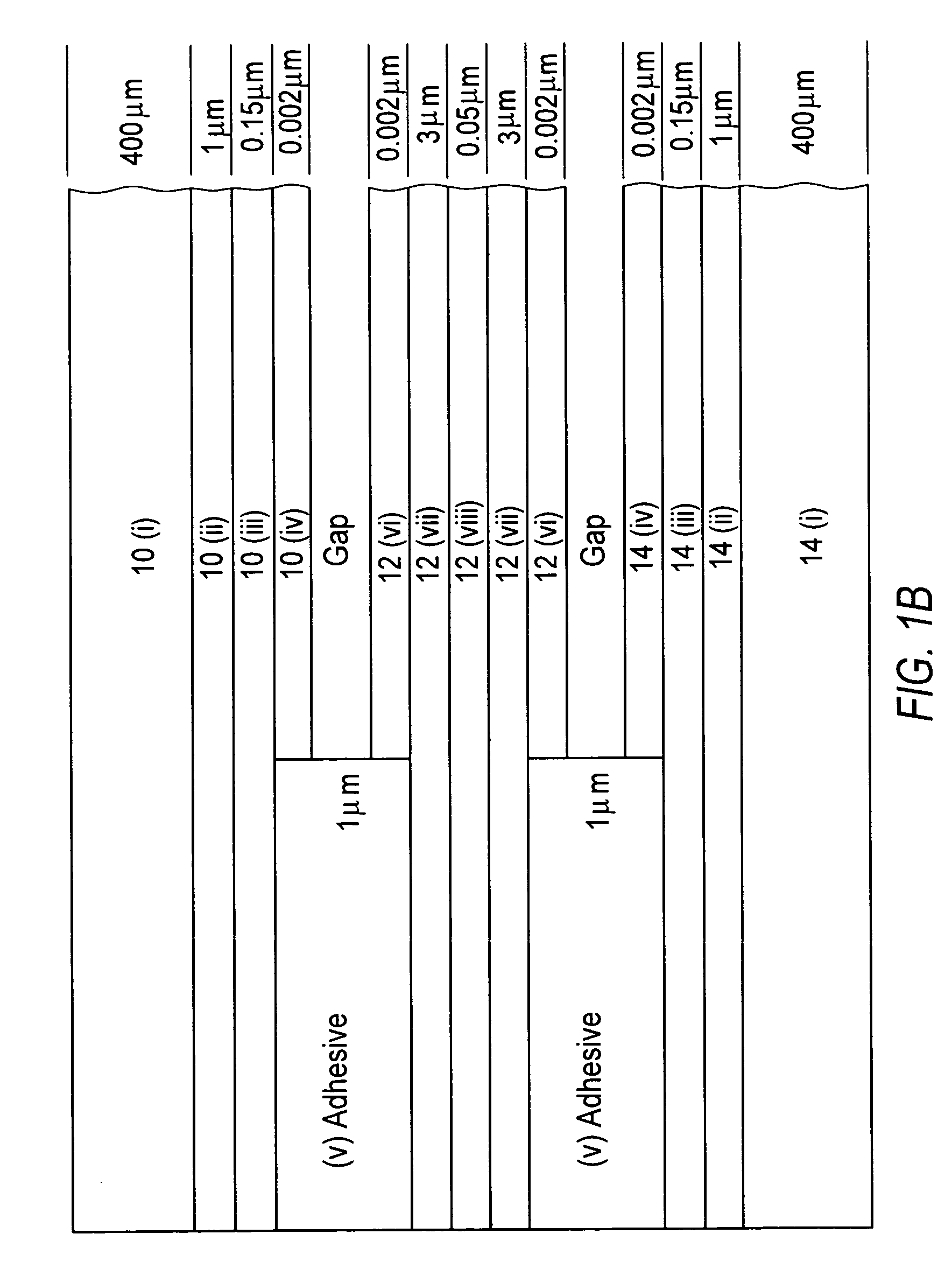

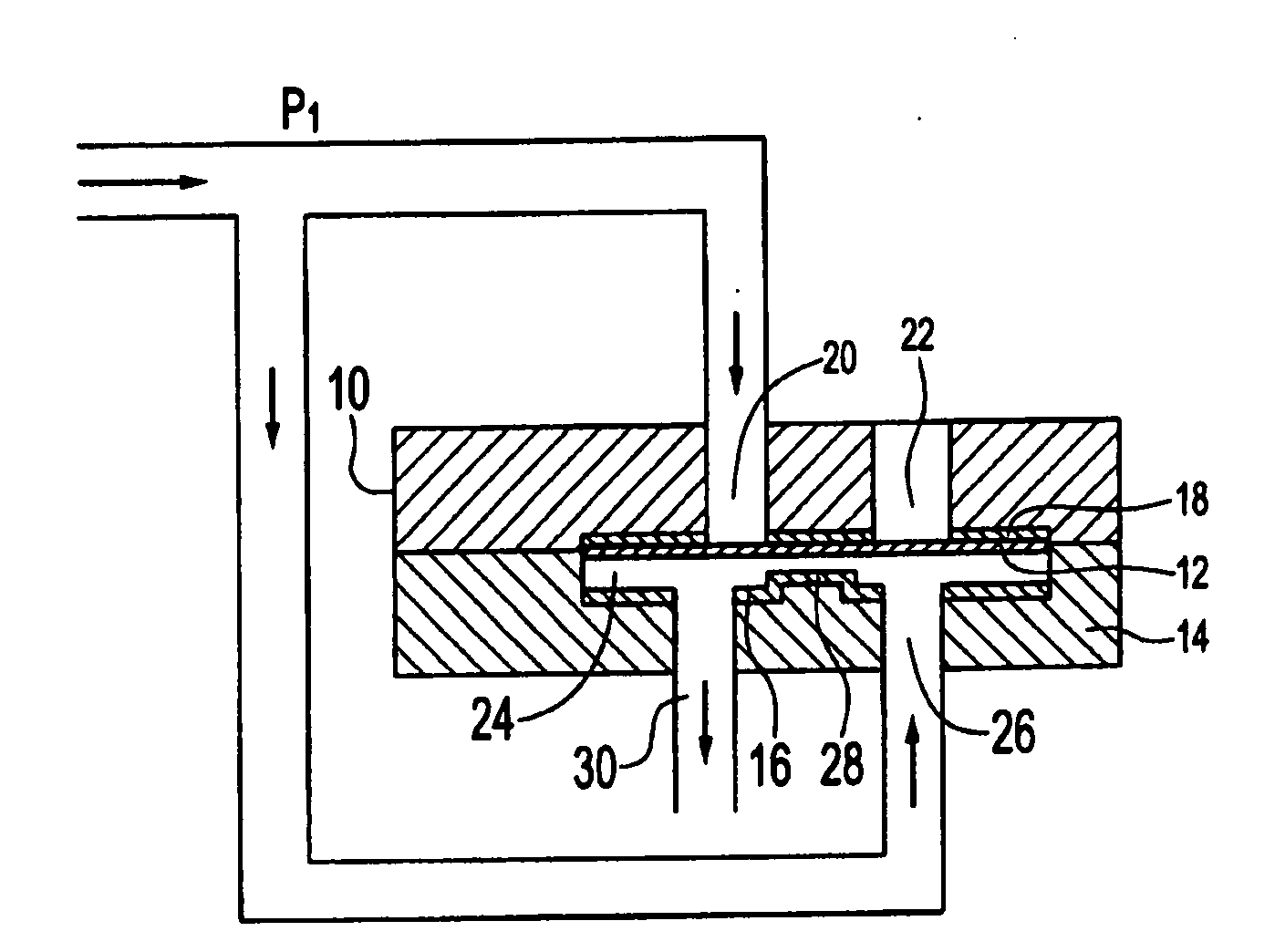

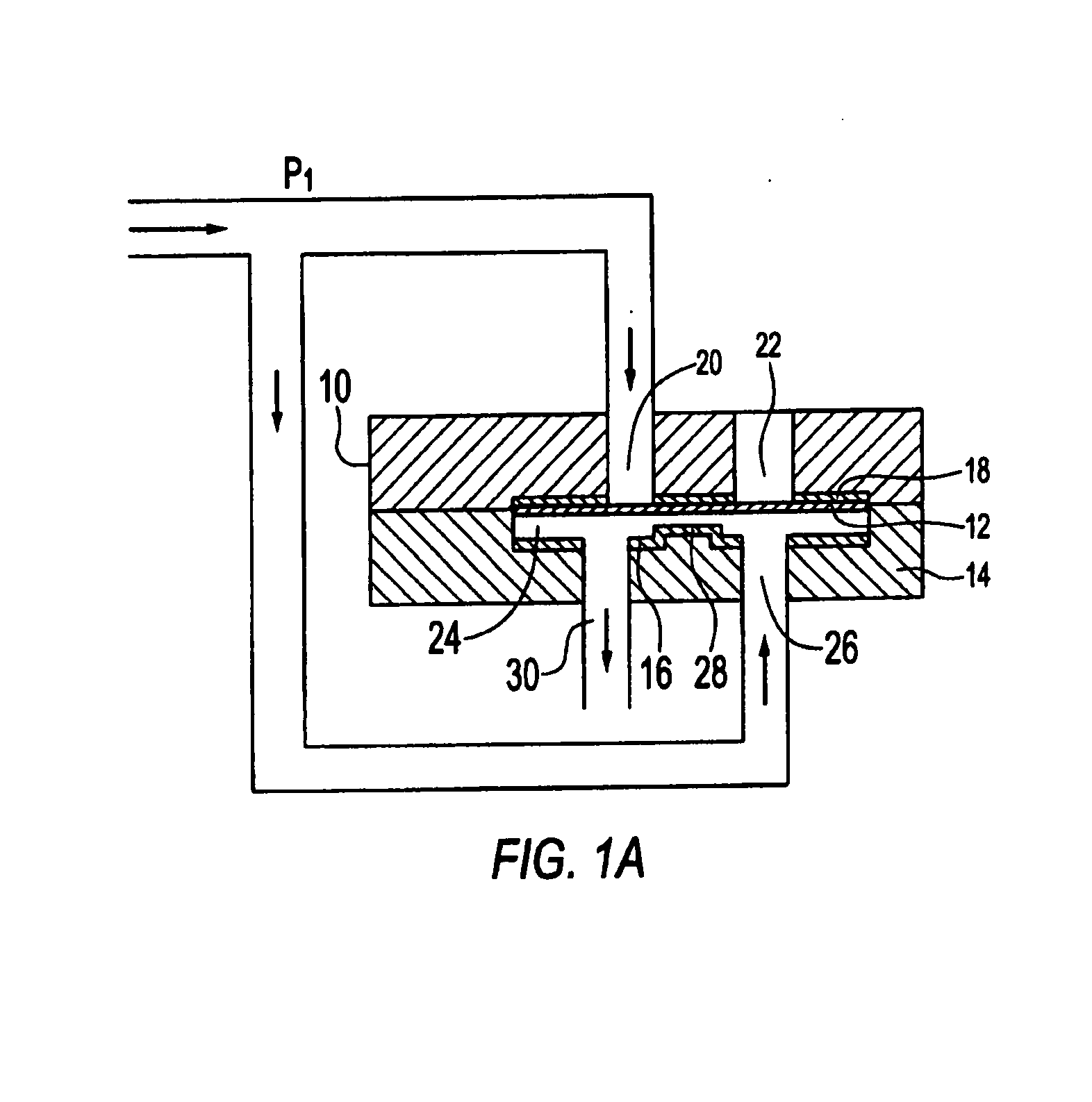

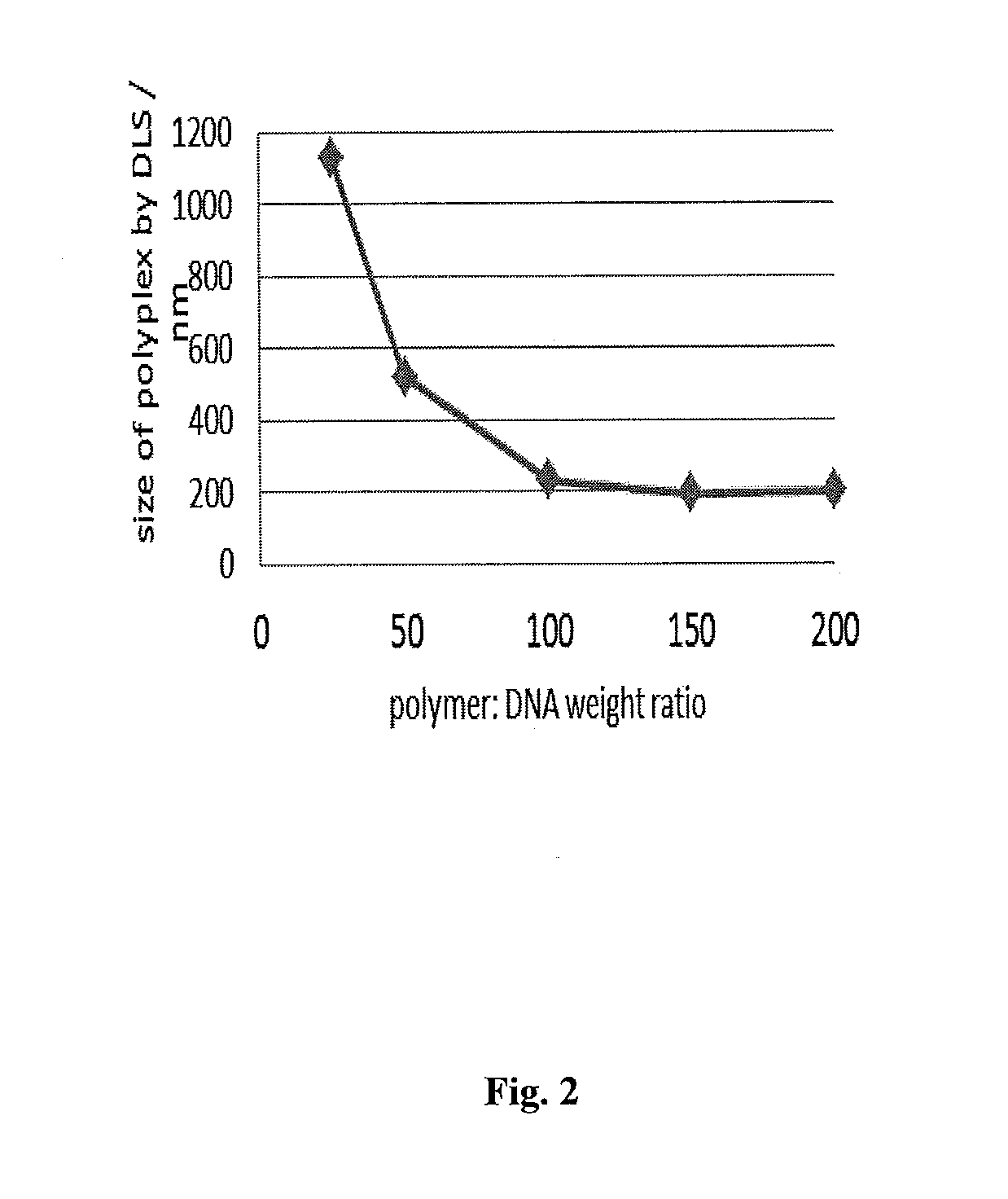

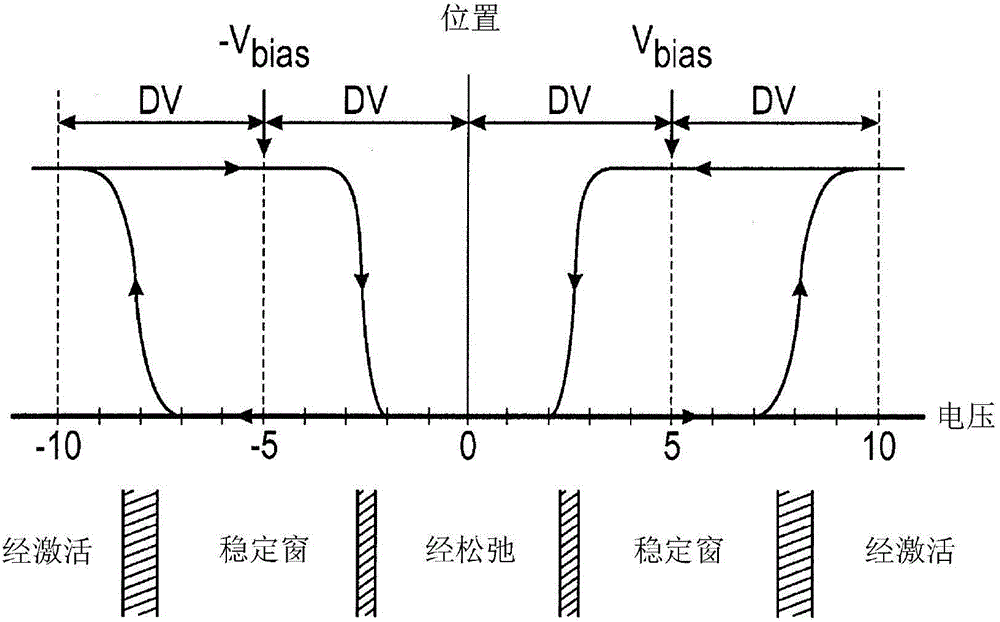

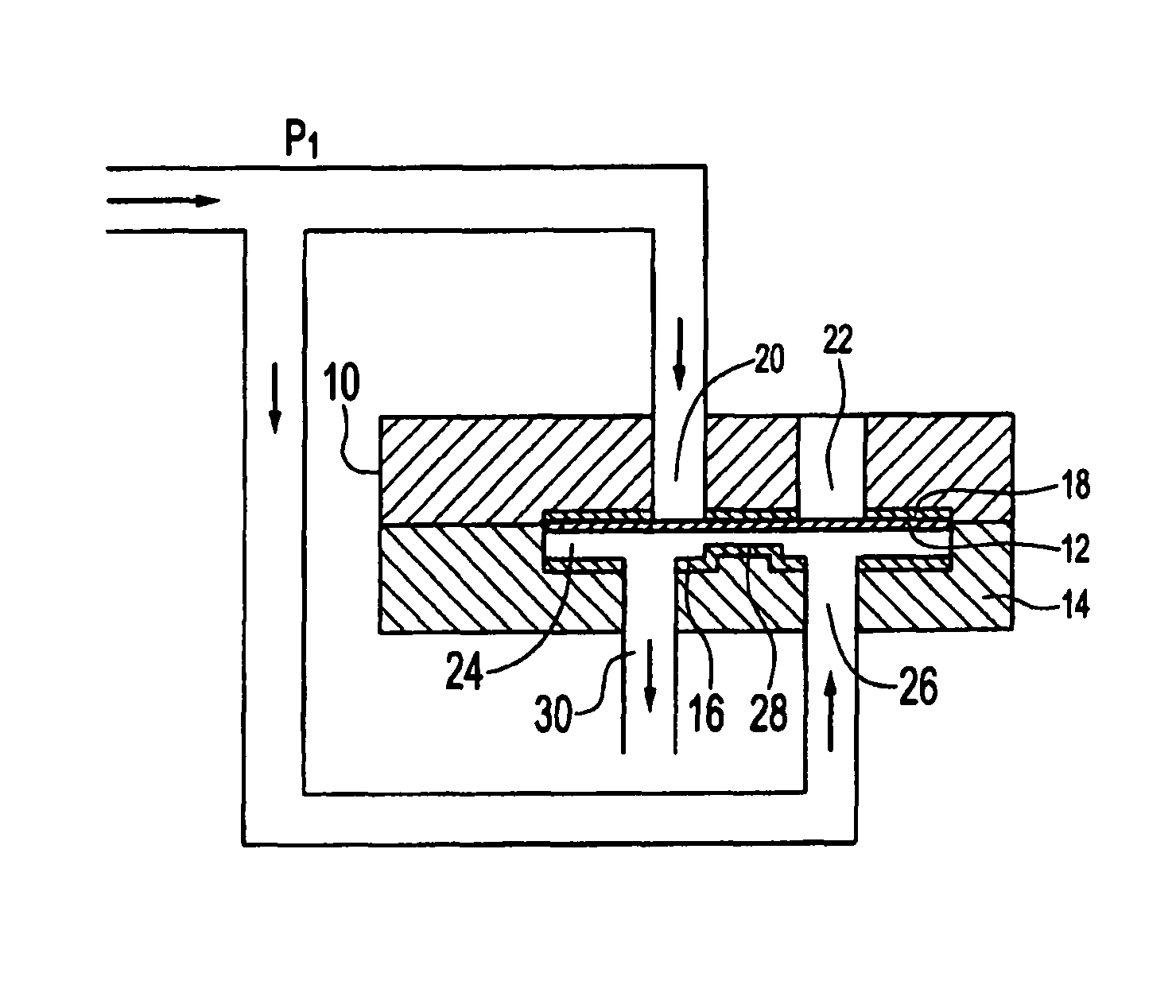

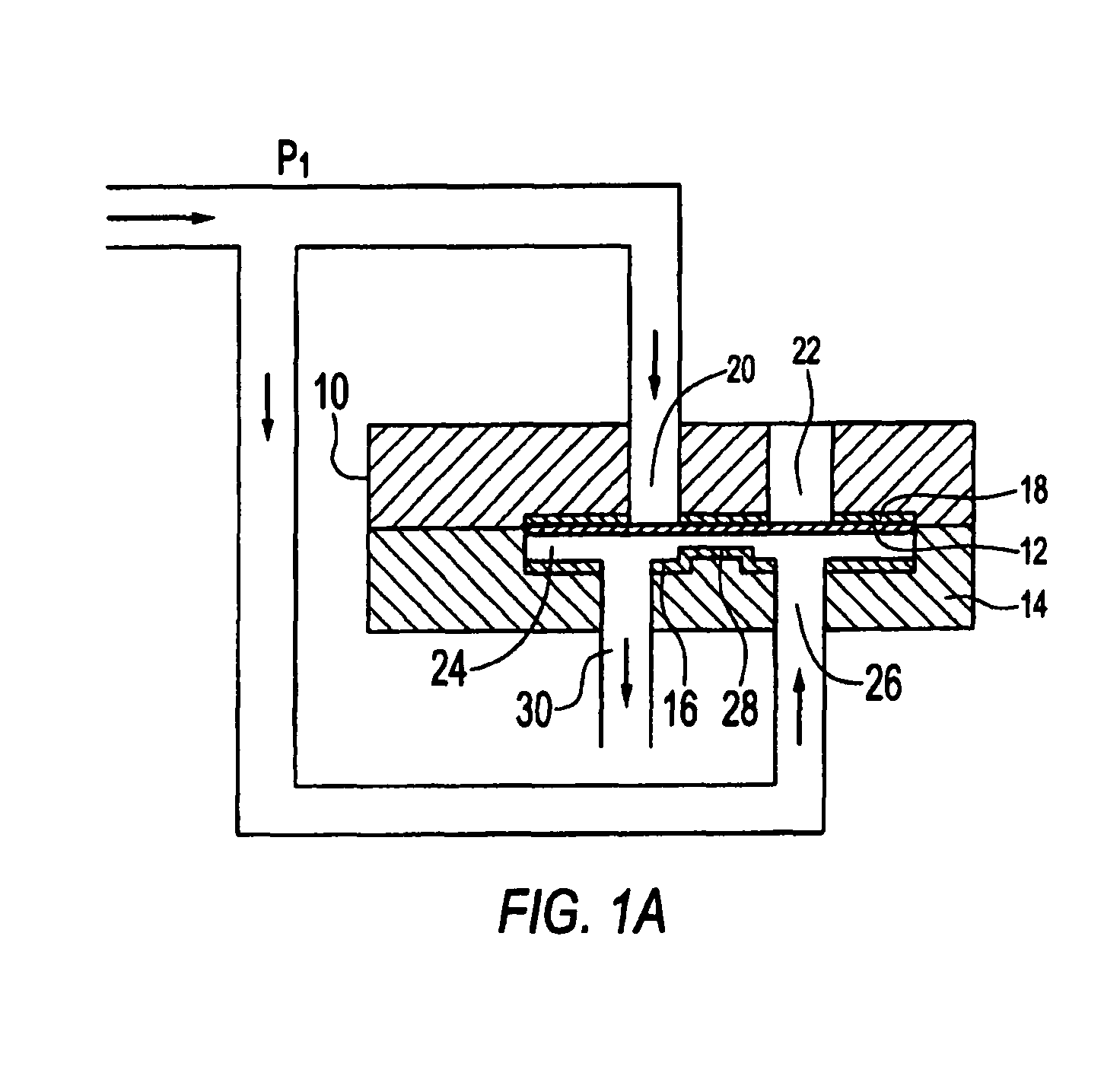

Bi-direction rapid action electrostatically actuated microvalve

PendingUS20070023719A1Start fastReduces film squeezing pressureOperating means/releasing devices for valvesDielectricCross-link

A bi-directional electrostatic microvalve includes a membrane electrode that is controlled by application of voltage to fixed electrodes disposed on either side of the membrane electrode. Dielectric insulating layers separate the electrodes. One of the fixed electrodes defines a microcavity. Microfluidic channels formed into the electrodes provide fluid to the microcavity. A central pad defined in the microcavity places a portion of the second electrode close to the membrane electrode to provide a quick actuation while the microcavity reduces film squeezing pressure of the membrane electrode. In preferred embodiment microvalves, low surface energy and low surface charge trapping coatings, such as fluorocarbon films made from cross-linked carbon di-fluoride monomers or surface monolayers made from fluorocarbon terminated silanol compounds coatings coat the electrode low bulk charge trapping dielectric layers limit charge trapping and other problems and increase device lifetime operation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Enzymatic synthesis of poly(amine-co-esters) and methods of use thereof for gene delivery

ActiveUS9272043B2Increase stability and half-lifeImprove targetingOrganic active ingredientsPowder deliveryDiseaseEnzymatic synthesis

Poly(amine-co-ester) polymers, methods of forming active agent-load nanoparticles therefrom, and methods of using the nanoparticles for drug delivery are disclosed. The nanoparticles can be coated with an agent that reduces surface charge, an agent that increases cell-specific targeting, or a combination thereof. Typically, the loaded nanoparticles are less toxic, more efficient at drug delivery, or a combination thereof compared to a control other transfection reagents. In some embodiments, the nanoparticles are suitable for in vivo delivery, and can be administered systemically to a subject to treat a disease or condition.

Owner:YALE UNIV

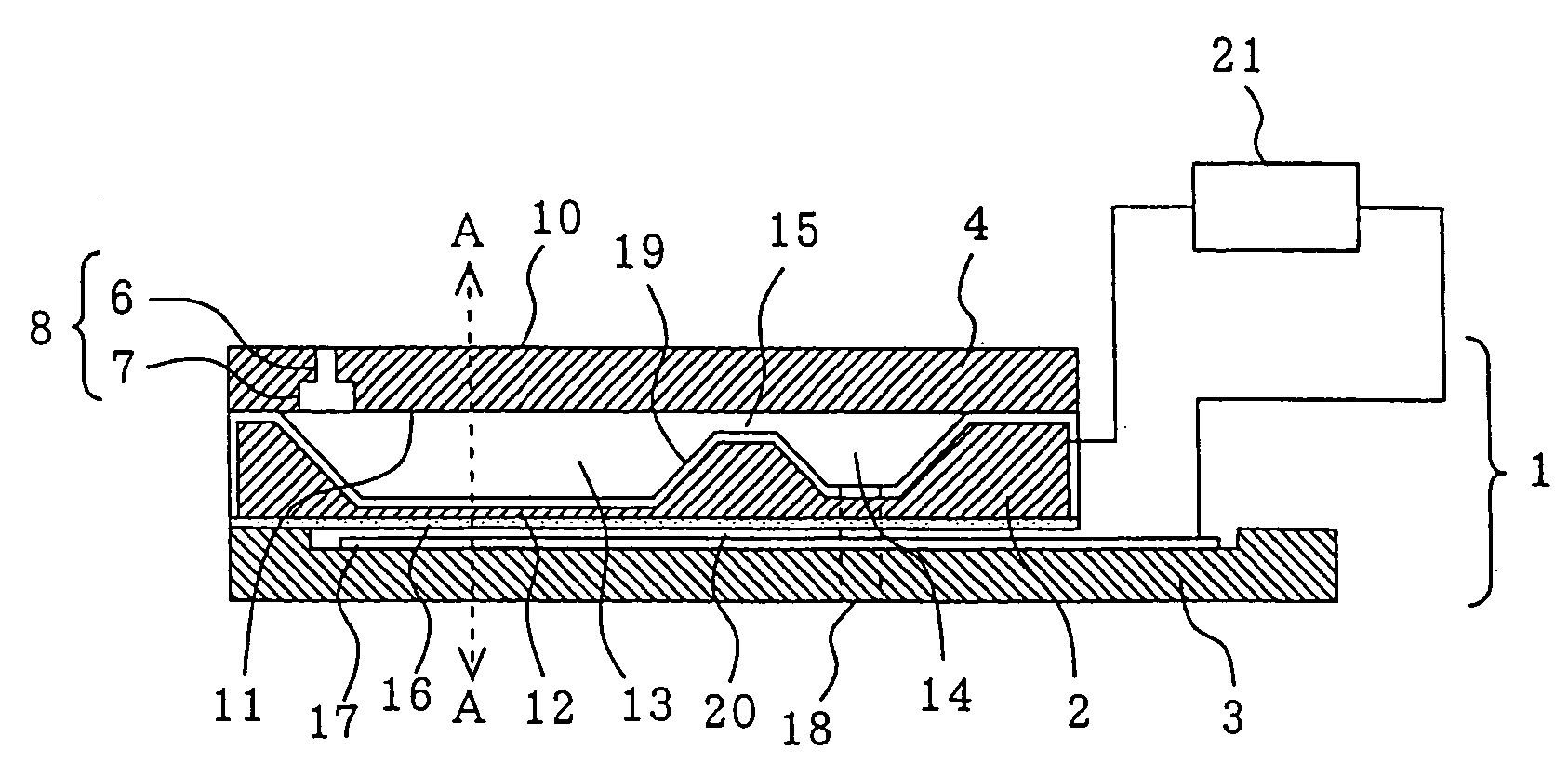

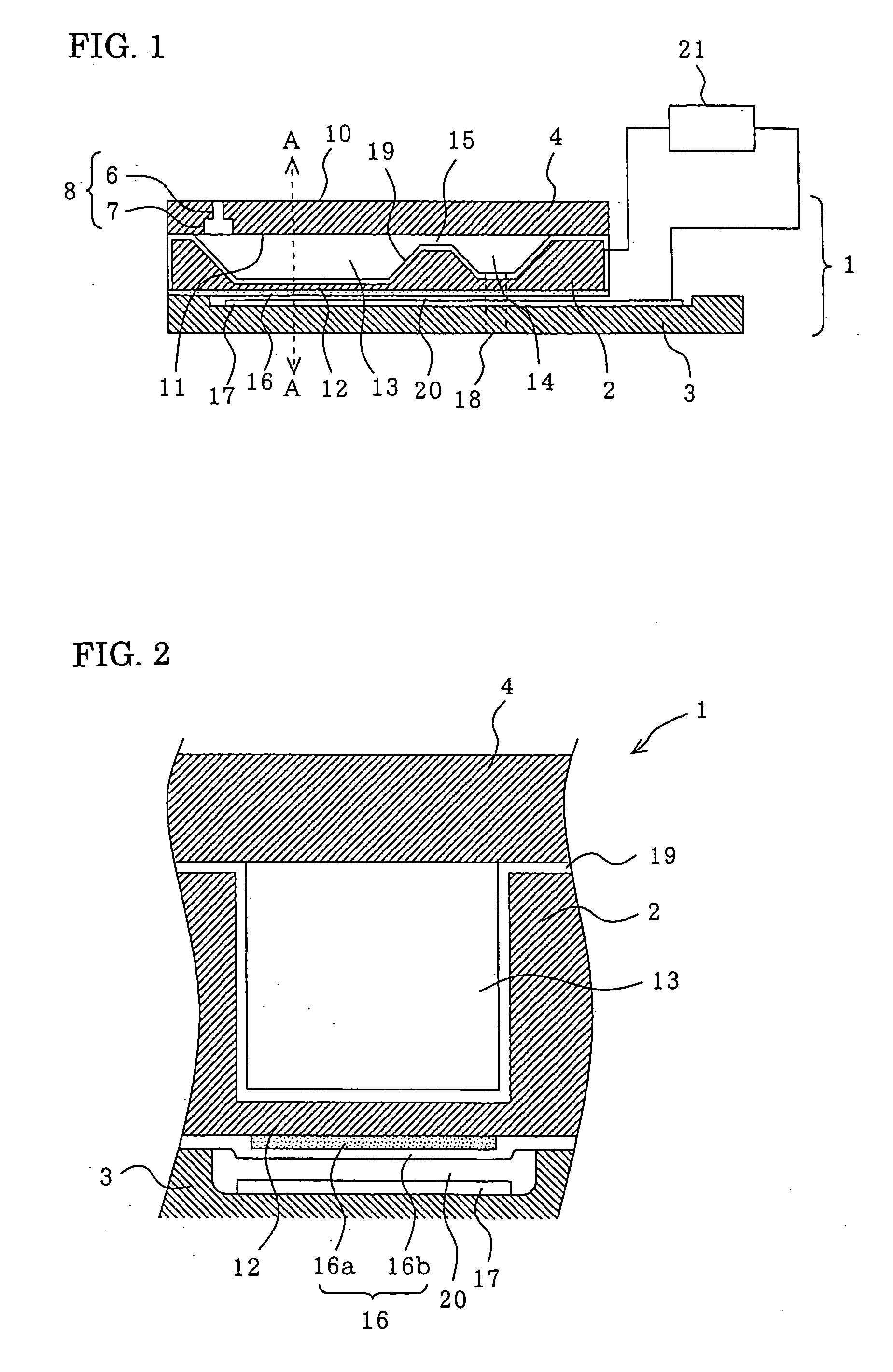

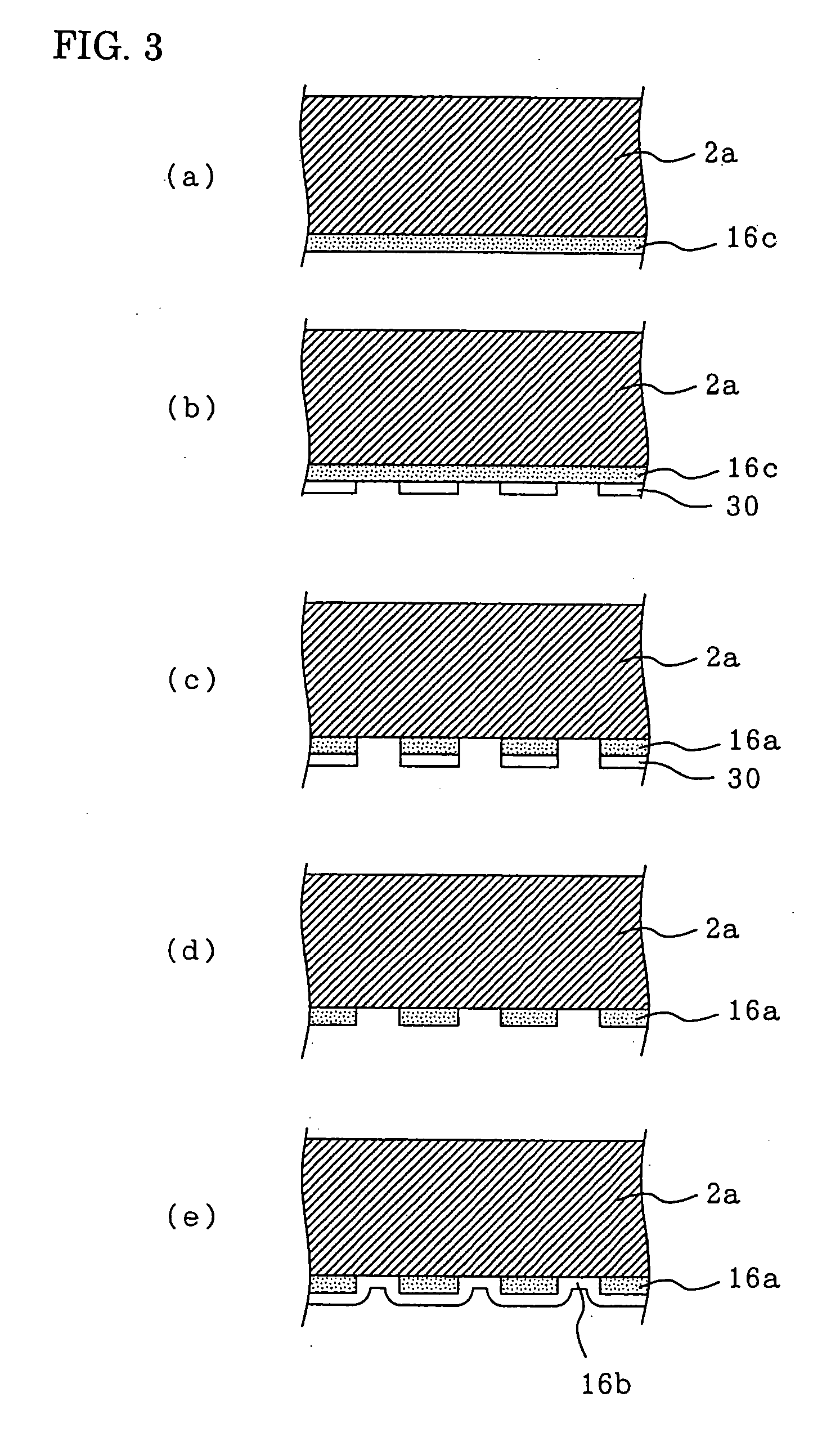

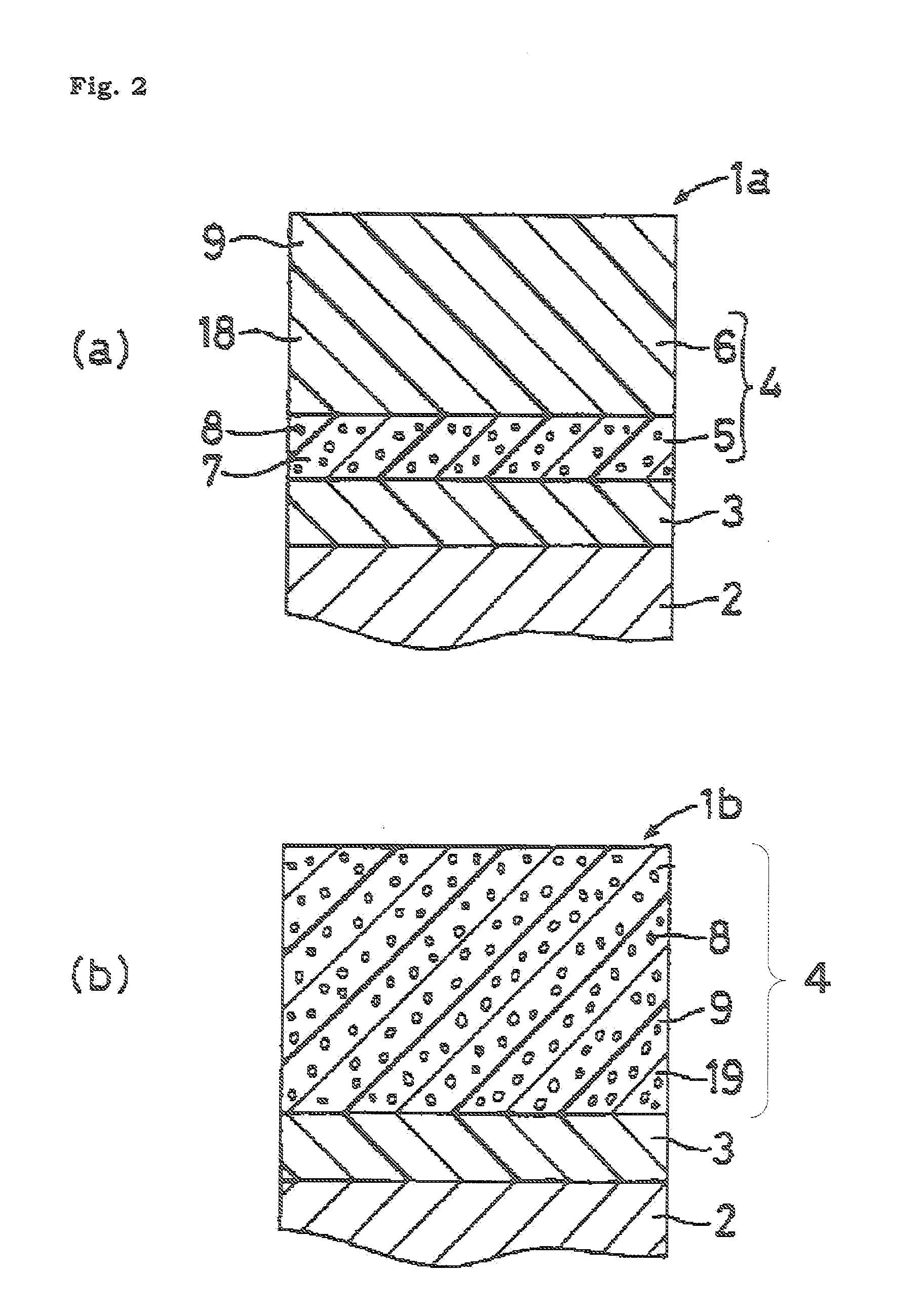

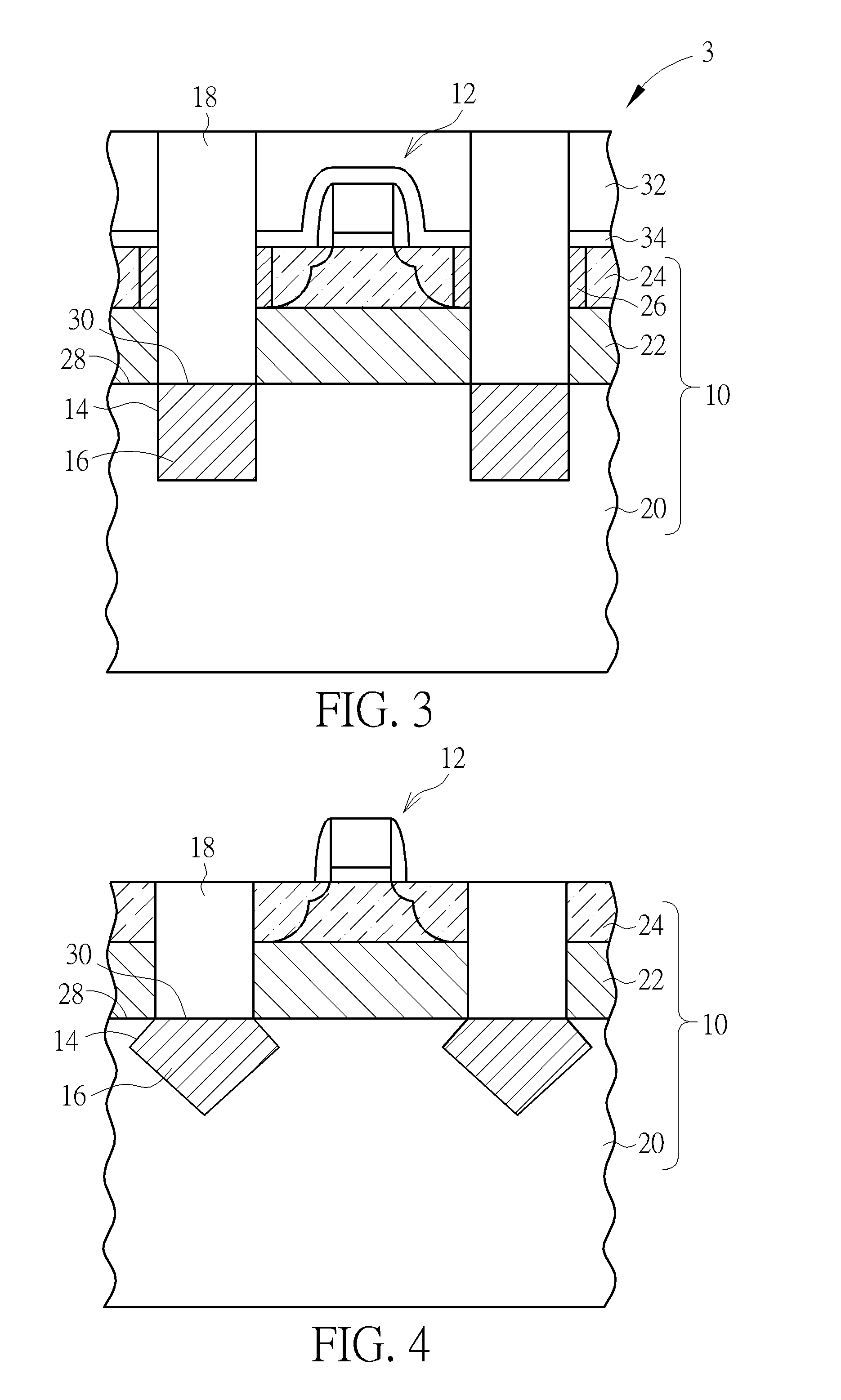

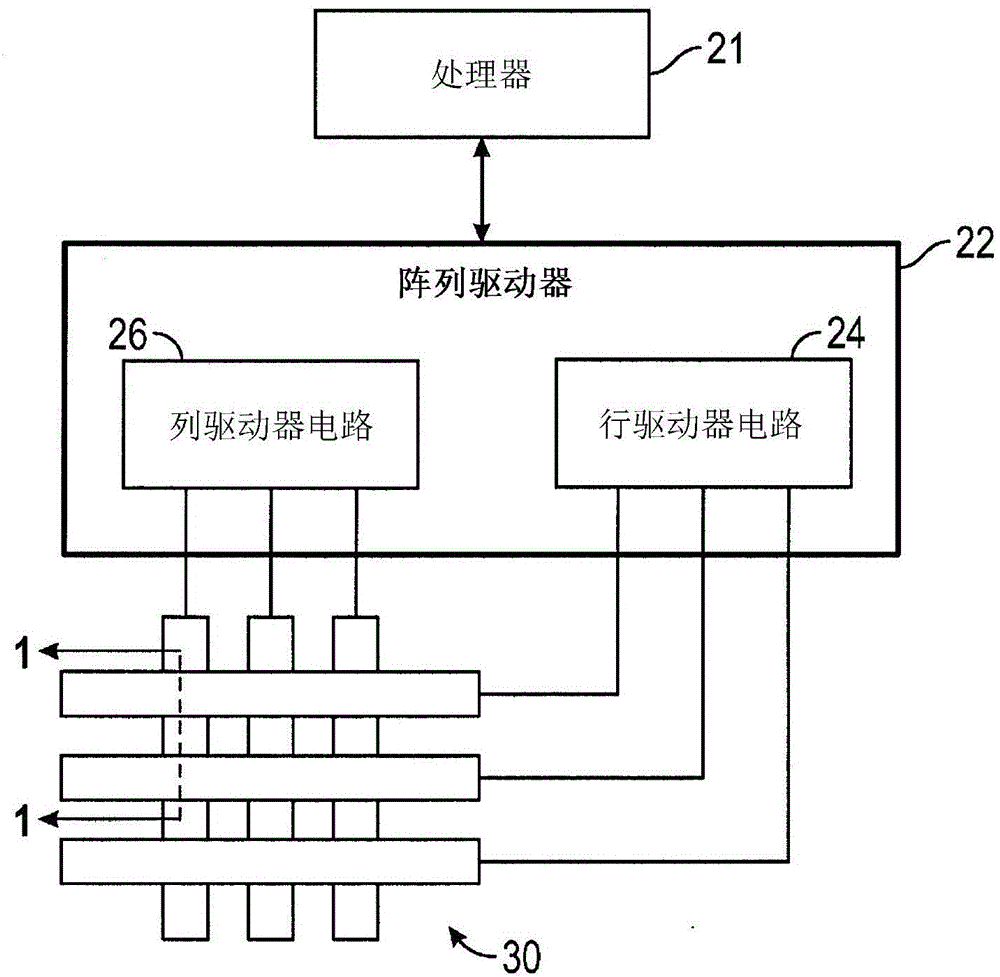

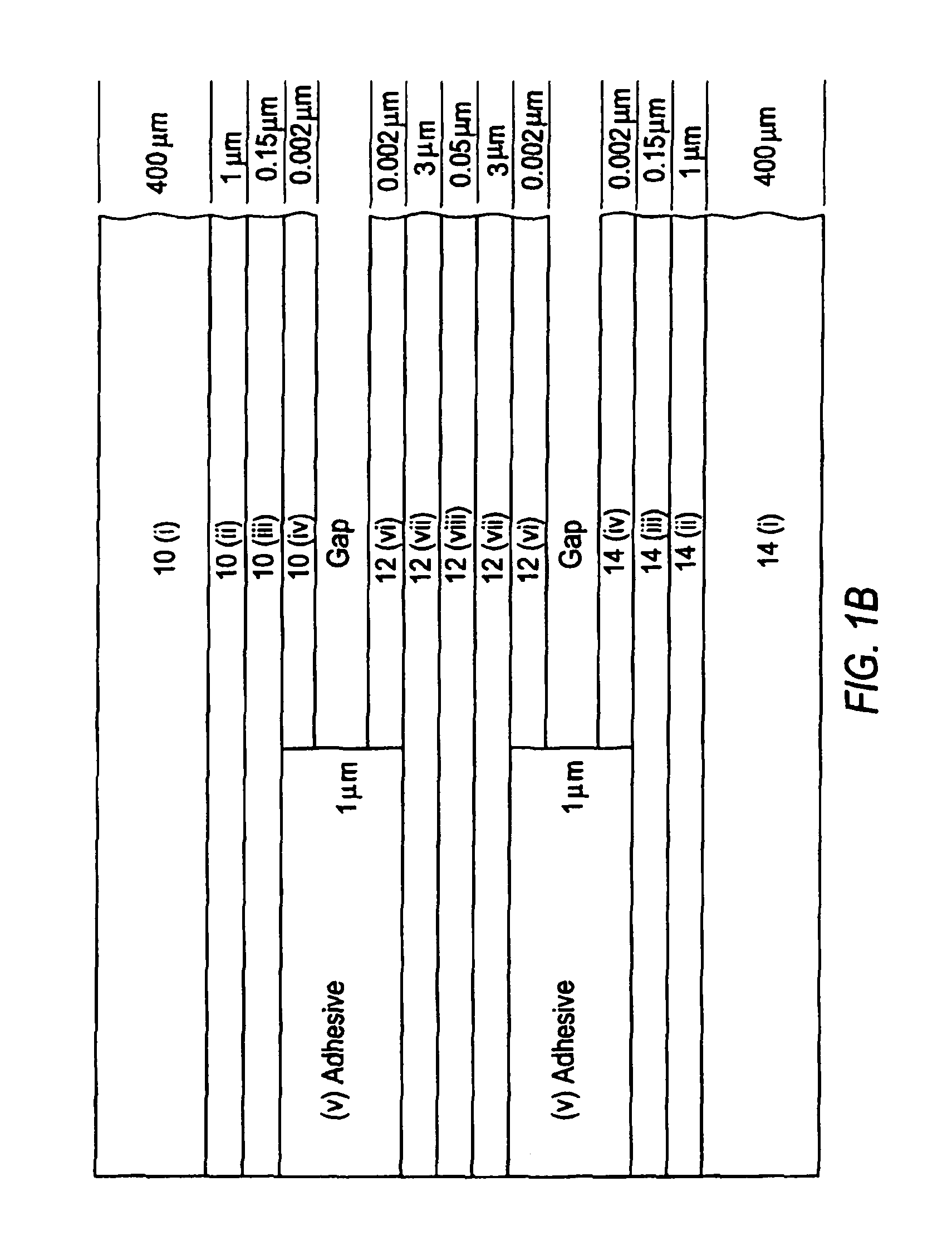

Electrostatic actuator, droplet discharge head and method for manufacturing the droplet discharge head, droplet discharge apparatus, and device

InactiveUS20060125879A1Inhibited DiffusionIncreased durabilityPrintingDielectricElectrostatic actuator

To provide an electrostatic actuator that generates high pressure under a given voltage and includes an insulating film exhibiting excellent insulation resistance, a droplet discharge head that includes the electrostatic actuator and a method for manufacturing the droplet discharge head, a droplet discharge apparatus that includes the droplet discharge head and has excellent printing performance, and a device that includes the electrostatic actuator and has excellent driving performance. A diaphragm 12, a counter electrode 17 opposite to the diaphragm 12 with a gap interposed therebetween, and an insulating film 16 on a surface of the diaphragm 12 opposite to the counter electrode 17 are included. The insulating film 16 includes at least a dielectric film 16a formed of a substance having a higher relative dielectric constant than silicon oxide.

Owner:SEIKO EPSON CORP

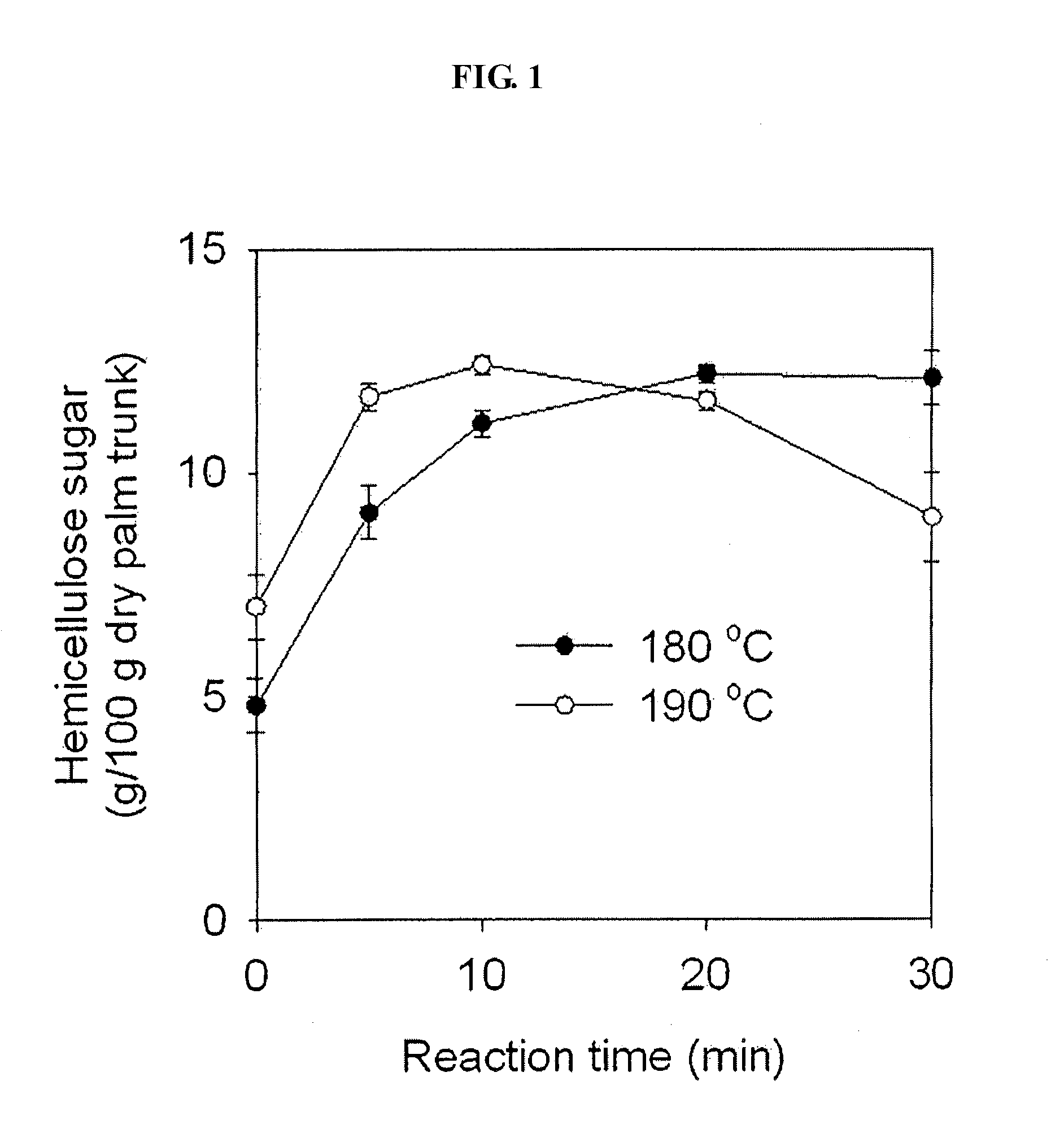

Method for preparing sugar, bioethanol or microbial metabolite from lignocellulosic biomass

ActiveUS20160298142A1Reduce surface chargeHigh puritySugar derivativesBiofuelsChemistryInorganic salts

The present invention relates to a method for preparing bioethanol from lignocellulosic biomass. The method of the present invention is capable of: minimizing the impurity content of an enzymatic saccharification raw material, by extracting biomass using hot water, before pretreatment, and removing extractable substances such as inorganic salts; suppressing, to the greatest extent, the production of overdecomposition products of sugar, by pretreating the biomass, from which the hot water extractable substances have been removed, in a condition for maximizing xylan yield; preparing fermentable sugar at a low cost, without washing a pretreated solid obtained from subsequent solid-liquid separation, but by only concentrating a sugar solution obtained after enzymatic saccharification, using a separation film; and preparing bioethanol therefrom in high yield.

Owner:KOREA RES INST OF CHEM TECH

Electrophotographic photoconductor and image forming apparatus including the same, and coating solution for undercoat layer formation in electrophotographic photoconductor

ActiveUS20120051786A1Inhibit the generation of defectsPrevent image defectsElectrographic process apparatusPolyamide coatingsElectrical conductorOptoelectronics

An electrophotographic photoconductor comprising a conductive support, an undercoat layer and a photosensitive layer, the undercoat layer and the photosensitive layer being formed on the conductive support in sequence, wherein the undercoat layer contains a binder resin, titanium oxide particles surface-treated with at least anhydrous silicon dioxide and titanium oxide particles surface-treated with at least hydrous silicon dioxide.

Owner:SHARP KK

Bi-direction rapid action electrostatically actuated microvalve

InactiveUS20080149869A1Reduces film squeeze pressureQuickly actuateAdditive manufacturing apparatusOperating means/releasing devices for valvesSurface energyMicro valve

A bi-directional electrostatic microvalve includes a membrane electrode that is controlled by application of voltage to fixed electrodes disposed on either side of the membrane electrode. Dielectric insulating layers separate the electrodes. One of the fixed electrodes defines a microcavity. Microfluidic channels formed into the electrodes provide fluid to the microcavity. A central pad defined in the microcavity places a portion of the second electrode close to the membrane electrode to provide a quick actuation while the microcavity reduces film squeezing pressure of the membrane electrode. In preferred embodiment microvalves, low surface energy and low surface charge trapping coatings, such as fluorocarbon films made from cross-linked carbon di-fluoride monomers or surface monolayers made from fluorocarbon terminated silanol compounds coatings coat the electrode low bulk charge trapping dielectric layers limit charge trapping and other problems and increase device lifetime operation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

New use of verbascum glycoside

InactiveCN1478479APromote growthLong doubling timeOrganic active ingredientsAntineoplastic agentsIntramuscular injectionGlycoside formation

An application of verbascum glycoside in preparing the medicines for treating cancers by oral application or injection is disclosed.

Owner:LANZHOU UNIVERSITY +1

Cathode material of solid oxide fuel cell and preparation and application thereof

ActiveCN105226294AReduce surface chargeReduce surface stressCell electrodesSputteringScreen printing

The invention discloses a cathode material of a solid oxide fuel cell and a preparation method thereof. The cathode material is characterized in that the cathode material is a composite negative electrode formed by a perovskite oxide and an oxide MO2 modified on the surface of the perovskite oxide, wherein M is Ti, Zr, Nb, Ce, Ru or Sn, the mass content of the oxide MO2 in the composite negative electrode accounts for 1-20%, the particle size of the oxide MO2 is 0.5 to 100 nanometers, and the oxide MO2 in the composite negative electrode coats the surface of the perovskite oxide. The perovskite oxide can be first prepared on the surface of an electrolyte or a partition layer of the battery by methods of coating, silk-screen printing, flow casting and the like, and then the oxide MO2 is modified on the surface of the perovskite oxide in the negative electrode by methods of solution impregnation, sol impregnation, magnetron sputtering and the like. The cathode material disclosed by the invention is endowed with excellent electrochemical performance and favorable stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

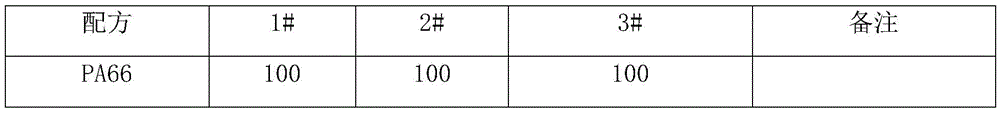

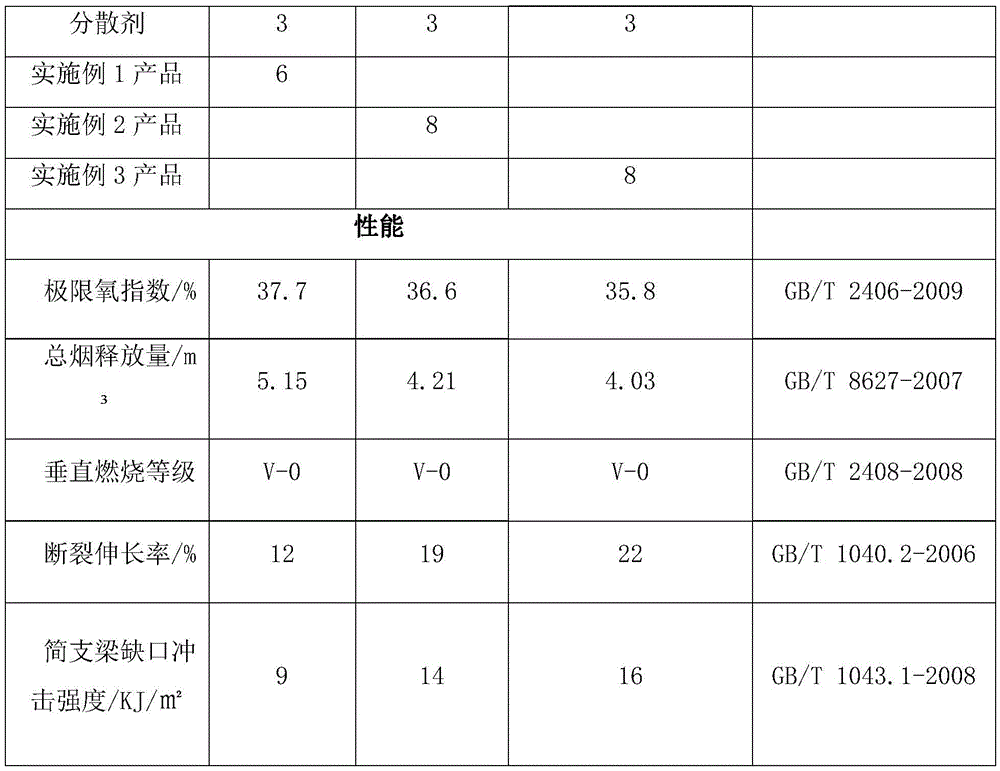

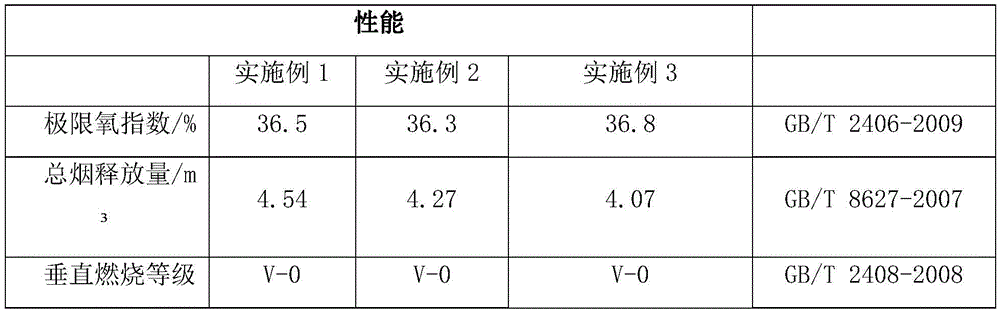

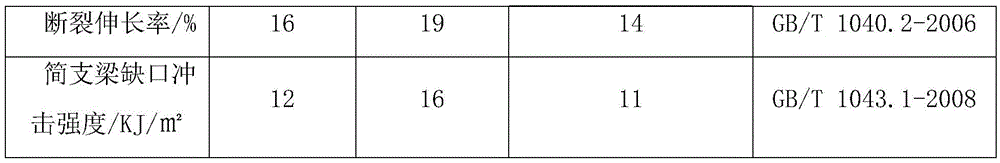

Antimony-based compound flame-retardant masterbatch for nylon 66 and preparation method of antimony-based compound flame-retardant masterbatch

The invention discloses an antimony-based compound flame-retardant masterbatch for nylon 66 (PA66) and a preparation method of the antimony-based compound flame-retardant masterbatch. The flame-retardant masterbatch is prepared form, by weight, 40-60 parts of antimony trioxide, 10-30 parts of a flame retardant A, 10-30 parts of a flame retardant B, 2-5 parts of a coupling agent, 2-6 parts of a lubricant and 15-30 parts of PA66 carrier resin. The flame-retardant masterbatch is prepared through the steps of drying, surface modification, high-speed hot mixing, granulation and the like. The antimony-based compound flame-retardant masterbatch for nylon 66 (PA66) has the advantages of being high in flame-retarding efficiency, good in processability and the like, halogen-free and toxicity-free environment-friendly raw materials and auxiliaries are selected for preparation, a good flame-retarding effect can be achieved without adding halogen-based flame retardants for synergism, and the mechanical property of a composite is hardly influenced.

Owner:广西华锑科技有限公司

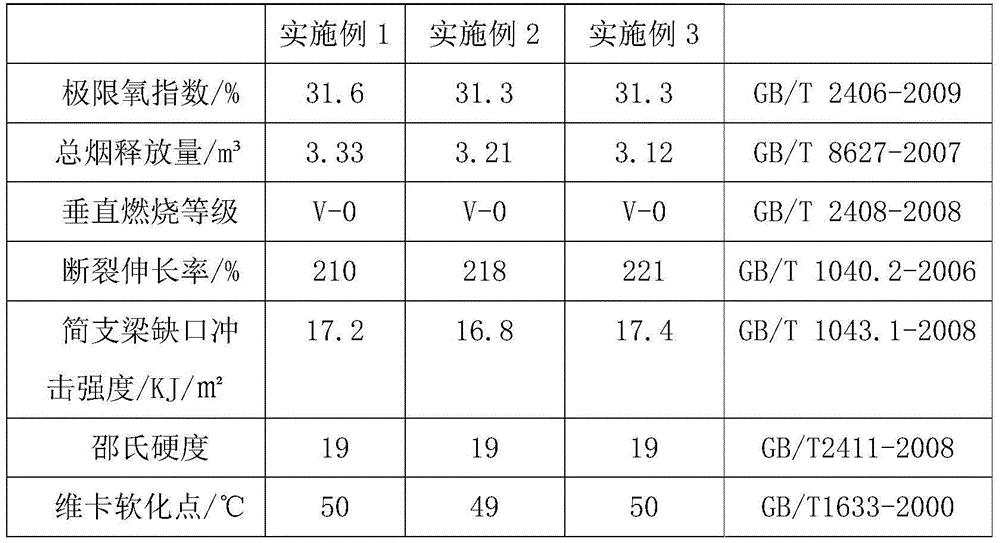

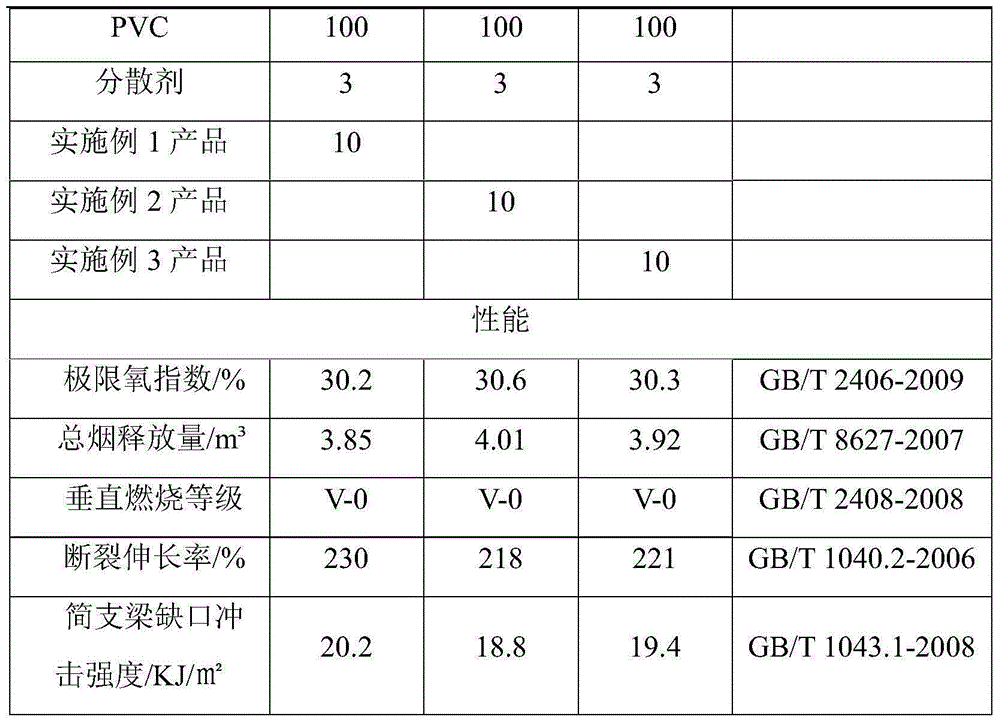

Antimony oxide compound flame-retardant PVC soft composite material and preparation method thereof

The present invention discloses an antimony oxide compound flame-retardant PVC soft composite material and a preparation method thereof. The composite material includes the following materials: PVC (SG-3), a plasticizer, antimony trioxide, ammonium molybdate, montmorillonite, a calcium zinc stabilizer, EVA, epoxy soybean oil, a coupling agent and a dispersing agent. The preparation process of the product is as below: modifying antimony trioxide; mixing the modified antimony trioxide with ammonium molybdate, montmorillonite and EVA; screening the mixture by a vibrating centrifugal screening machine; and drying the screened powder and conducting waterproof packaging. The product of the invention has efficient flame retardant and smoke suppression performance, limiting oxygen index up to 31.6%, elongation at break of 210% and Shore hardness as low as 17, can be used as a direct added raw material for PVC product, or be added as a modification additive, and can also be used as soft fireproof materials, such as PVC leather and protective decoration materials.

Owner:广西华锑科技有限公司

Ultrafast laser system for biological mass spectrometry

ActiveUS9202678B2Reduce surface chargeImproves structural analysisStability-of-path spectrometersIon sources/gunsIon trap mass spectrometryFemto second laser

One aspect of the system provides the use of a laser with a mass spectrometer. Another aspect of the present application employs a laser emitting a pulse of less than one picosecond duration into an ion-trap mass spectrometer. In yet another aspect of the present application, a femtosecond laser beam pulse is emitted upon an ionized specimen to remove at least one electron therefrom.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

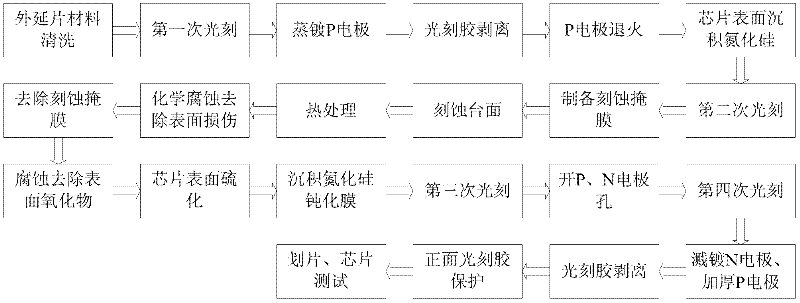

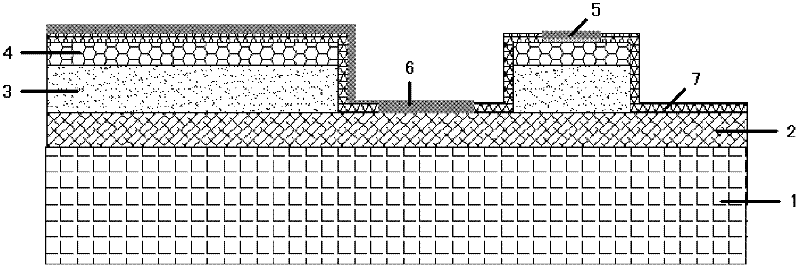

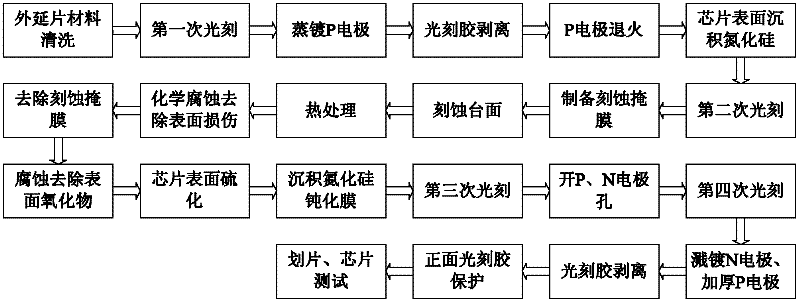

Manufacture method of table surface type indium gallium arsenic detector

ActiveCN102376824AAvoid damageImprove yieldFinal product manufactureSemiconductor devicesVulcanizationIndium

The invention discloses a manufacture method of a table surface type indium gallium arsenic detector, which comprises the step of performing the step of evaporating a P-InP contact electrode and the step of high-temperature quick annealing in advance of the step of passivating silicon nitride. The manufacture method has the advantages that a silicon nitride passivating film is damaged since the surface of a material is polluted or remained with a plurality of particles in the process of high-temperature quick annealing can be avoided, the yield for manufacturing the detector can be improved, the manufacture method is particularly suitable for researching and manufacturing a long linear detector and a plane array detector, and the influence of the process of high-temperature quick annealing to the contact status between the passivating film and the surface of the material can be eliminated; and as a thermal treatment technology is introduced after ion etching, the surface fixed charge introduced into the surface of the material by etching ions can be effectively reduced, the surface oxide can be removed and the crystal lattice damage and the dangling bond of the surface caused by ion etching can be reduced by adopting a chemical corrosion and vulcanization method, the surface state density can be reduced, and the surface composite dark current can be effectively reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

High-toughness antimony system compound flame retardant nylon material and preparation method thereof

The invention discloses a high-toughness antimony system compound flame retardant nylon material and a preparation method thereof. The nylon material is prepared from, by weight, 50-70 parts of nylon 66, 30-50 parts of nylon 6, 3-8 parts of antimony trioxide, 8-15 parts of a flame retardant A, 10-20 parts of a flame retardant B, 3-8 parts of plasticizer, 15-25 parts of a toughening agent, 2-6 parts of a coupling agent, 2-6 parts of a lubricating agent and 1-3 parts of an antioxidant agent. Two resin of nylon 66 and nylon 6 are adopted as composite basic materials, performance advantages of the two resin are combined, the high-toughness antimony system compound flame retardant nylon material has good flame retardant and smoke inhibiting performances and excellent impact resistance and processing performance by optimizing matching and adding auxiliaries for modification. The high-toughness antimony system compound flame retardant nylon material is prepared from halogen-free and nontoxic environment-friendly raw materials and auxiliaries, and the prepared product is an environment-friendly high-toughness antimony system compound flame retardant nylon material.

Owner:广西华锑科技有限公司

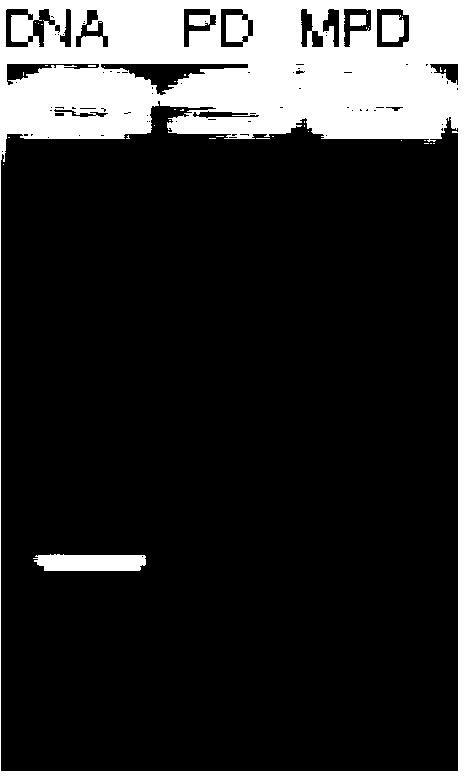

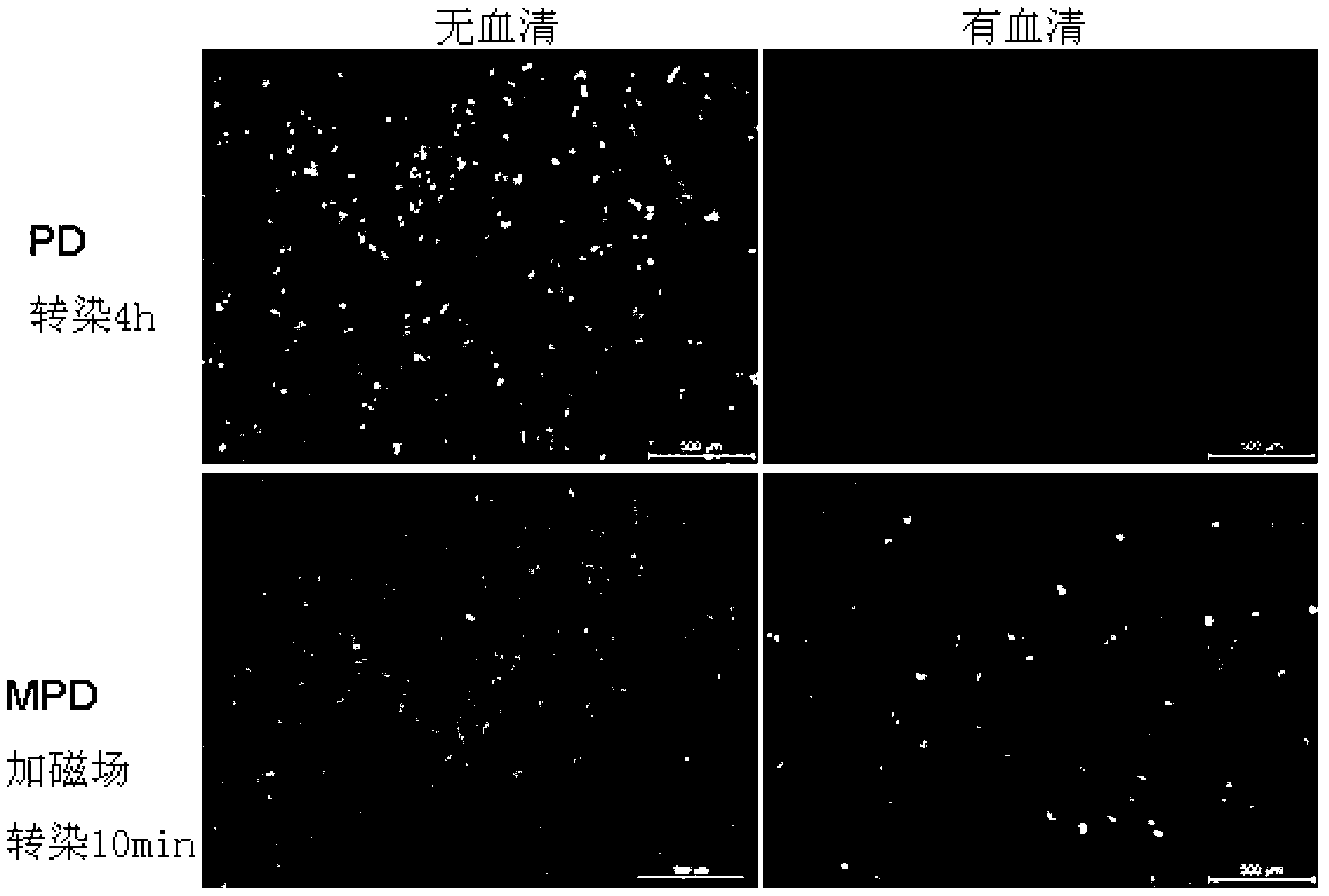

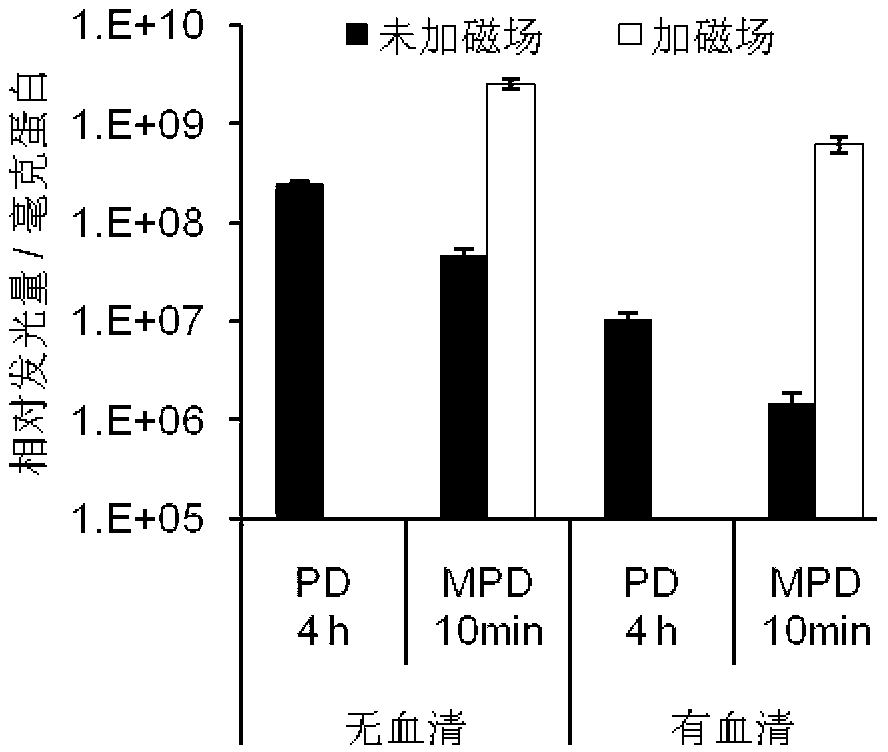

Magnetic nanometer gene vector system as well as preparation method and application thereof

ActiveCN103255175AEasy to prepareFast preparation methodGenetic material ingredientsOther foreign material introduction processesMagnetite NanoparticlesGene vector

The invention discloses a magnetic nanometer gene vector system as well as a preparation method and an application thereof. The gene vector system comprises electronegative magnetic nanoparticles, positive-ion vectors and genes, wherein the three components are prepared into the magnetic nanometer gene vector system according to certain proportions and composite sequences through electrostatic interactions. The magnetic nanometer gene vector system disclosed by the invention is simple in preparation method and has physicochemical properties of small grain diameter and proper surface charge. Compared with non-magnetic nanometer composites, the magnetic nanometer gene vector system has the advantages that the transfection efficiency to cells of the system is remarkably improved under the action of an additional magnetic field; and meanwhile, the cytotoxicity of the system is further reduced.

Owner:SICHUAN UNIV

Antimony-based compounding flame retardant masterbatch for PVC and preparation method thereof

The present invention discloses an antimony-based compounding flame retardant masterbatch for PVC and a preparation method thereof, and belongs to the technical field of flame retardant materials. The masterbatch includes the following raw materials by weight: 25-40 parts of antimony trioxide, 13-25 parts of molybdenum trioxide, 8-13 parts of montmorillonite, 3-8 parts of organic tin, 3-6 parts of a coupling agent, and 20 to 35 parts of a carrier PVC resin. The flame retardant masterbatch is prepared from the steps of antimony trioxide surface modification, raw material mixing and granulation. The present invention employs antimony trioxide, molybdenum trioxide and montmorillonite and other environmentally friendly halogen-free flame retardants as a compounding flame retardant system, integrates the advantages of the system in synergistic flame retardant, and smoke suppression performance, improves the flame retardancy and smoke suppression of the compounding complex retardant masterbatch. Addition of the flame retardant masterbatch can greatly improve the limiting oxygen index of the PVC composite material and reduce the amount of smoke, and the flame retardant masterbatch has the characteristics of high flame retardancy, strong smoke suppression, no additive migration, easiness to use, and easy dispersion.

Owner:广西华锑科技有限公司

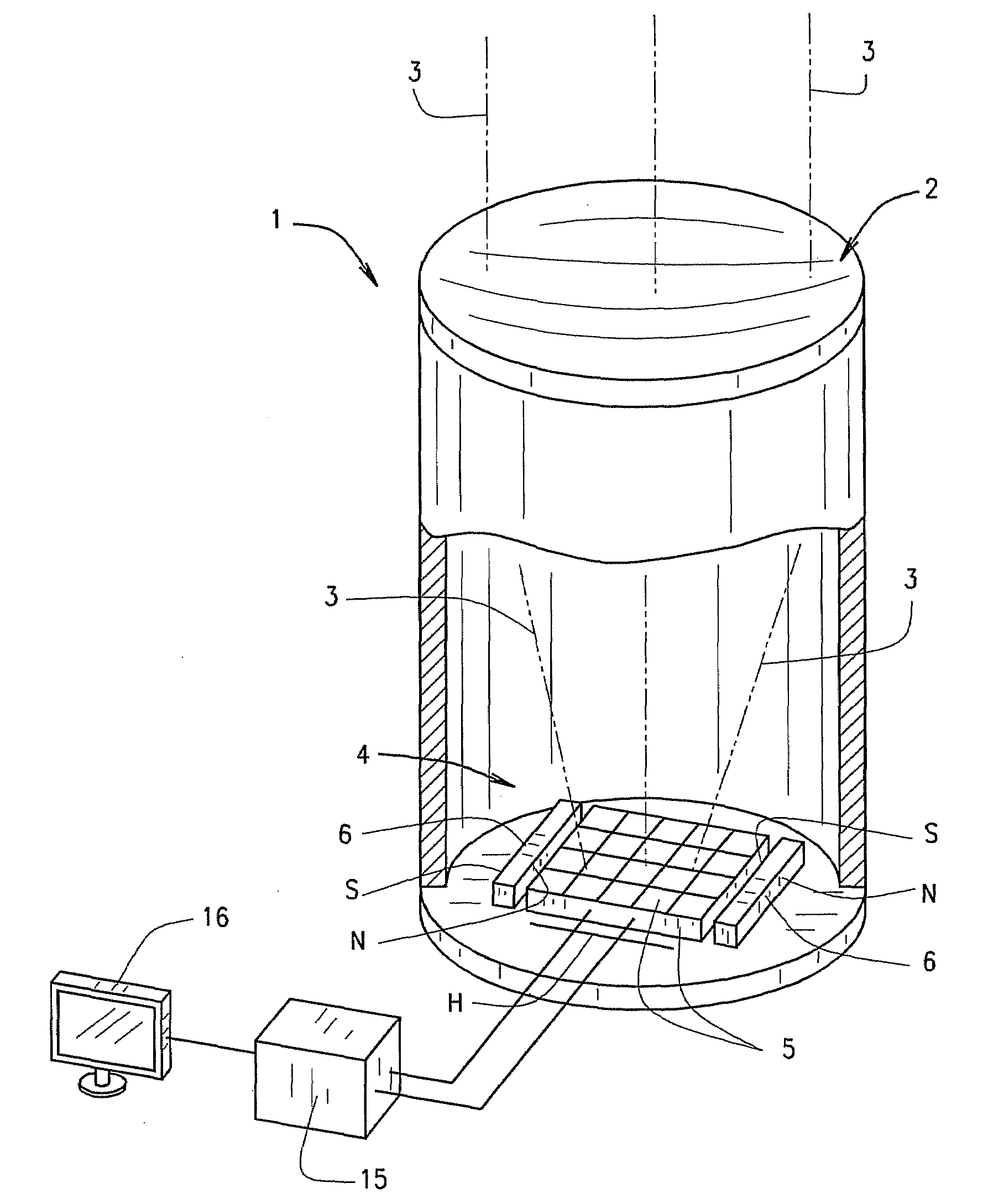

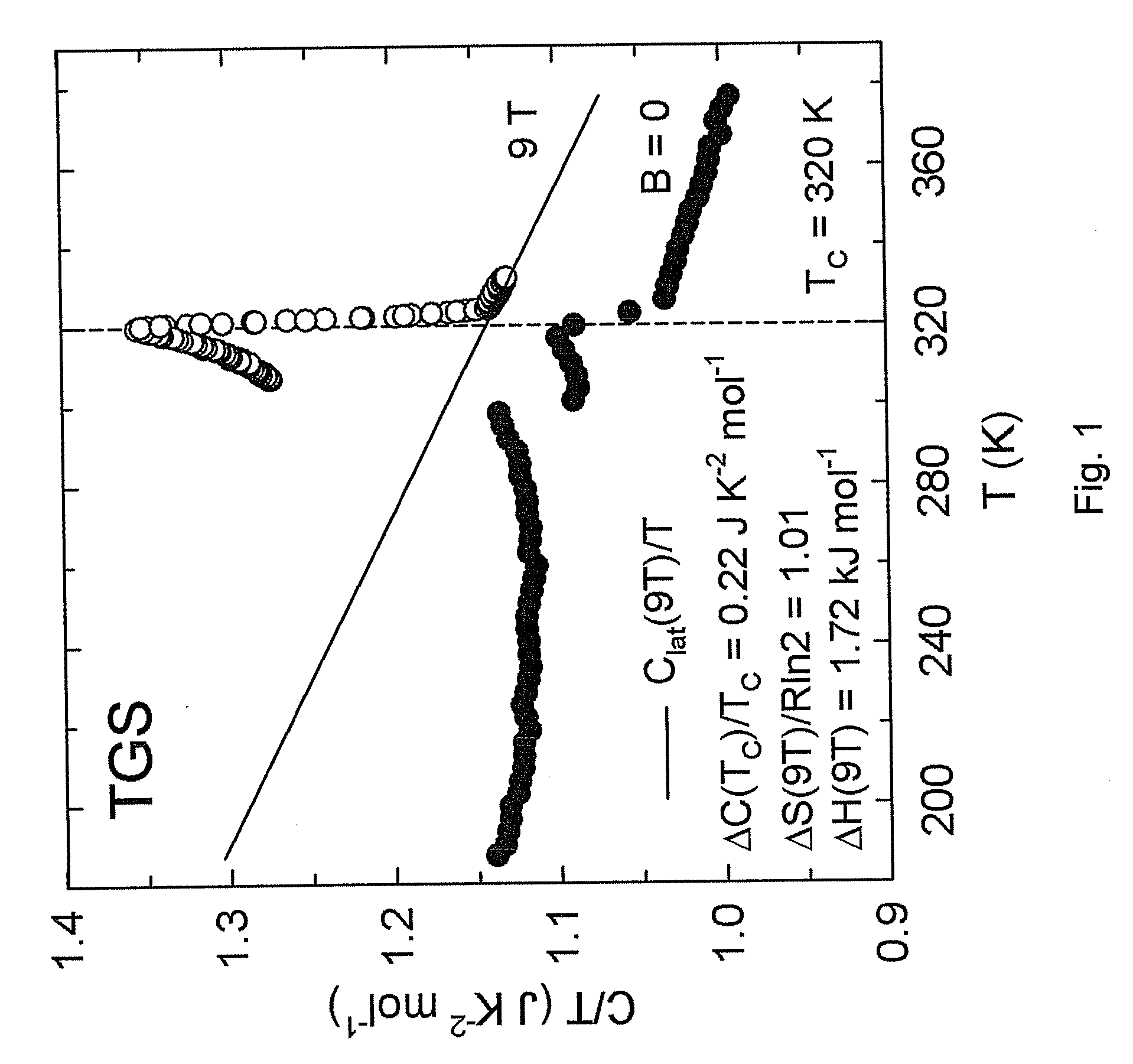

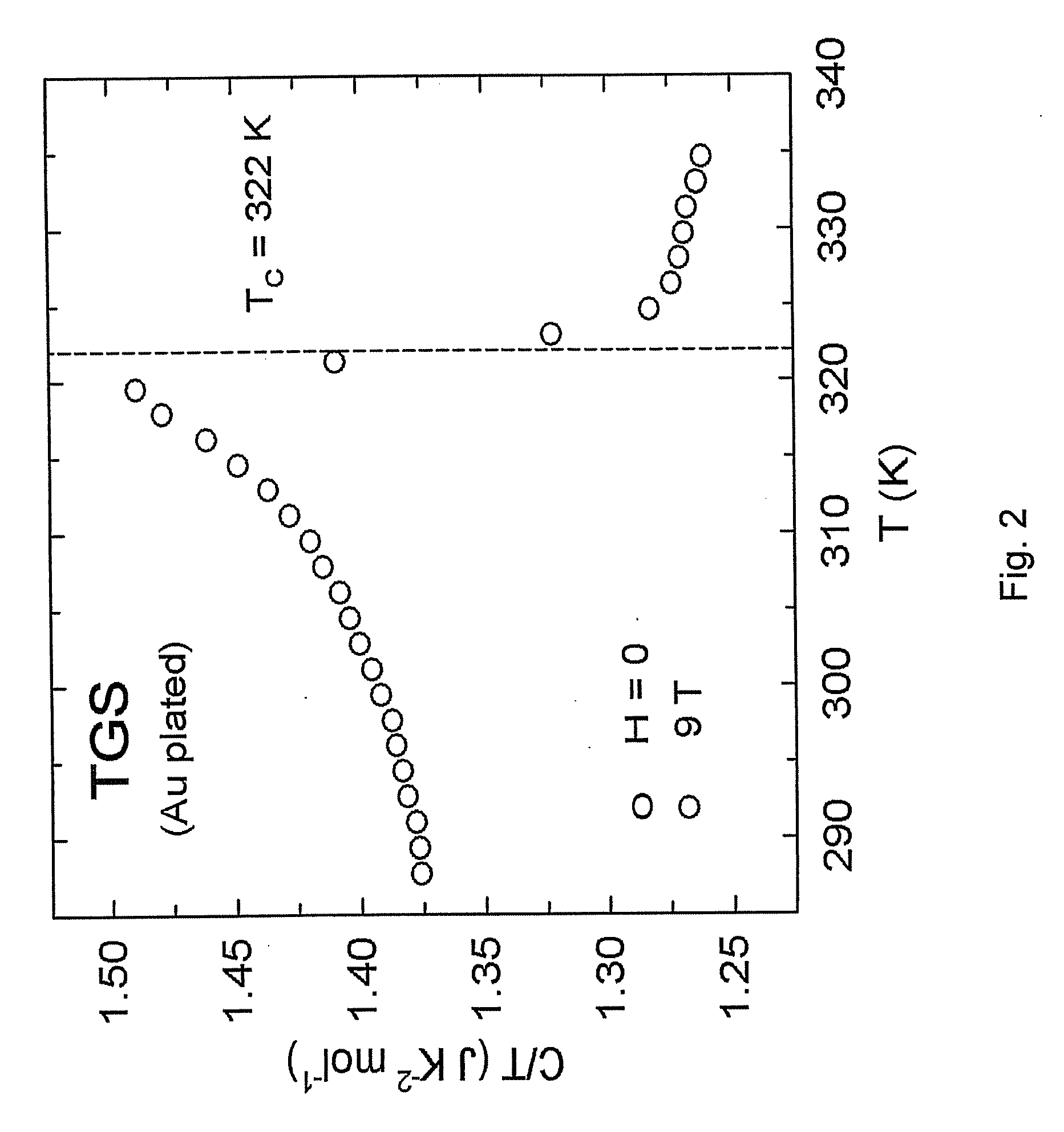

Infrared detector and method

InactiveUS20080185523A1Improve efficiencyReduce surface chargeThermoelectric device with dielectric constant thermal changeMaterial analysis by optical meansCurie temperatureSurface charge

An apparatus and method are provided for sensing infrared radiation. The apparatus includes a sensor element that is positioned in a magnetic field during operation to ensure a λ shaped relationship between specific heat and temperature adjacent the Curie temperature of the ferroelectric material comprising the sensor element. The apparatus is operated by inducing a magnetic field on the ferroelectric material to reduce surface charge on the element during its operation.

Owner:LOS ALAMOS NATIONAL SECURITY

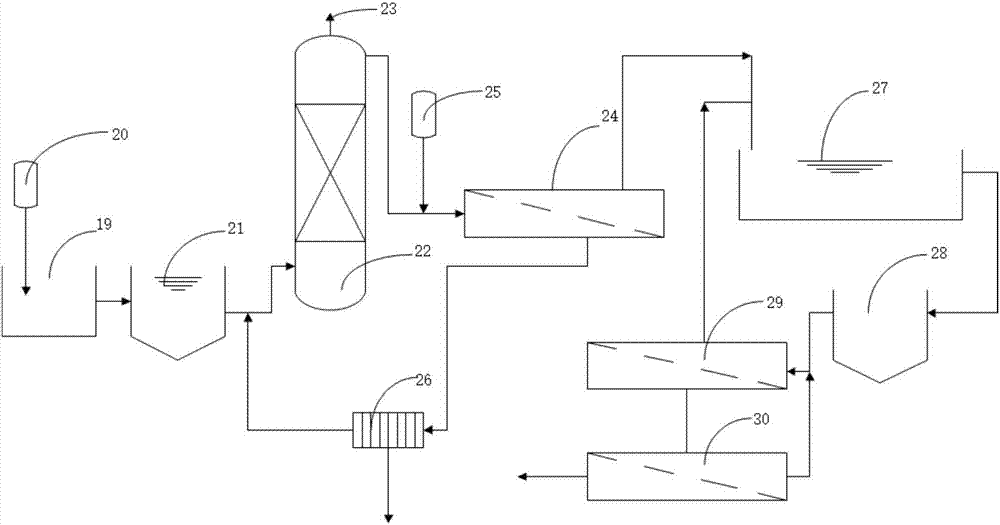

Disposing method and device of papermaking waste water

ActiveCN107311391AAvoid destructionReduce pollutionWater contaminantsTreatment involving filtrationFiltration membraneReverse osmosis

The invention relates to a disposing method and device of papermaking waste water, and belongs to the technical field of water disposal. The disposing method includes steps of initially settling waste water for pulping and papermaking, and then adding biodegradable flocculating agent to perform the flocculating reaction; settling the flocculate; delivering the disposed waste water to an anaerobic reaction tower to react; after adding sodium carbonate precipitant in the produced water at the upper part of the anaerobic reaction tower, delivering to a tubular ceramic micro-filtration membrane filter to filter; delivering concentrated fluid of the tubular ceramic micro-filtration membrane filter to a plate frame type filter to perform filter pressing; returning the waste water after filter pressing to an anaerobic reaction tower to dispose; delivering the produced water of the tubular ceramic micro-filtration membrane filter to an aerobiotic pond to react; after settling the produced water of the aerobiotic pond through a settling pond, delivering the waste water to the ceramic micro-filtration membrane filter to filter; delivering penetrated liquid of the ceramic micro-filtration membrane filter to a reverse osmosis membrane to filter.

Owner:贵州西部环保科技股份有限公司

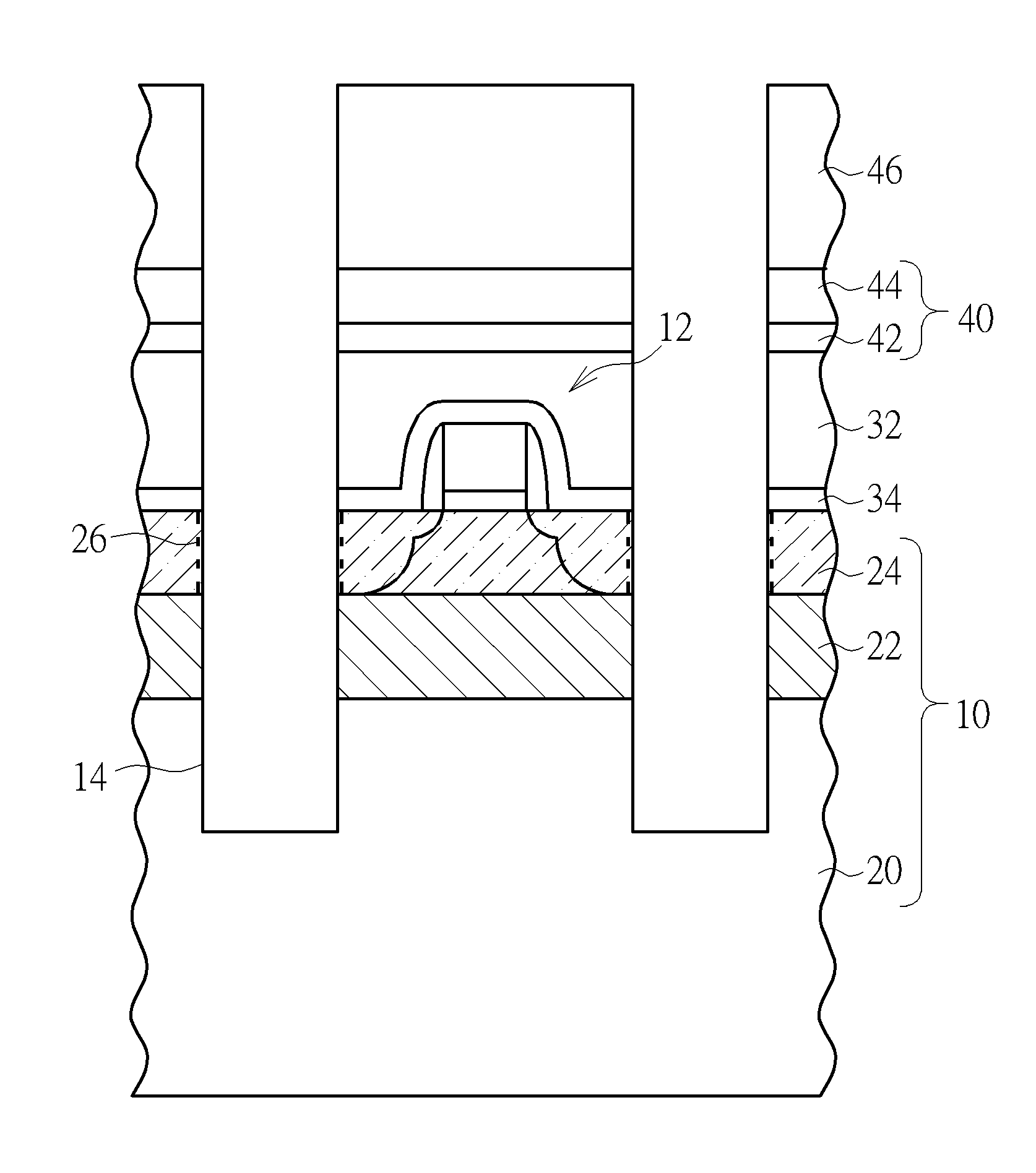

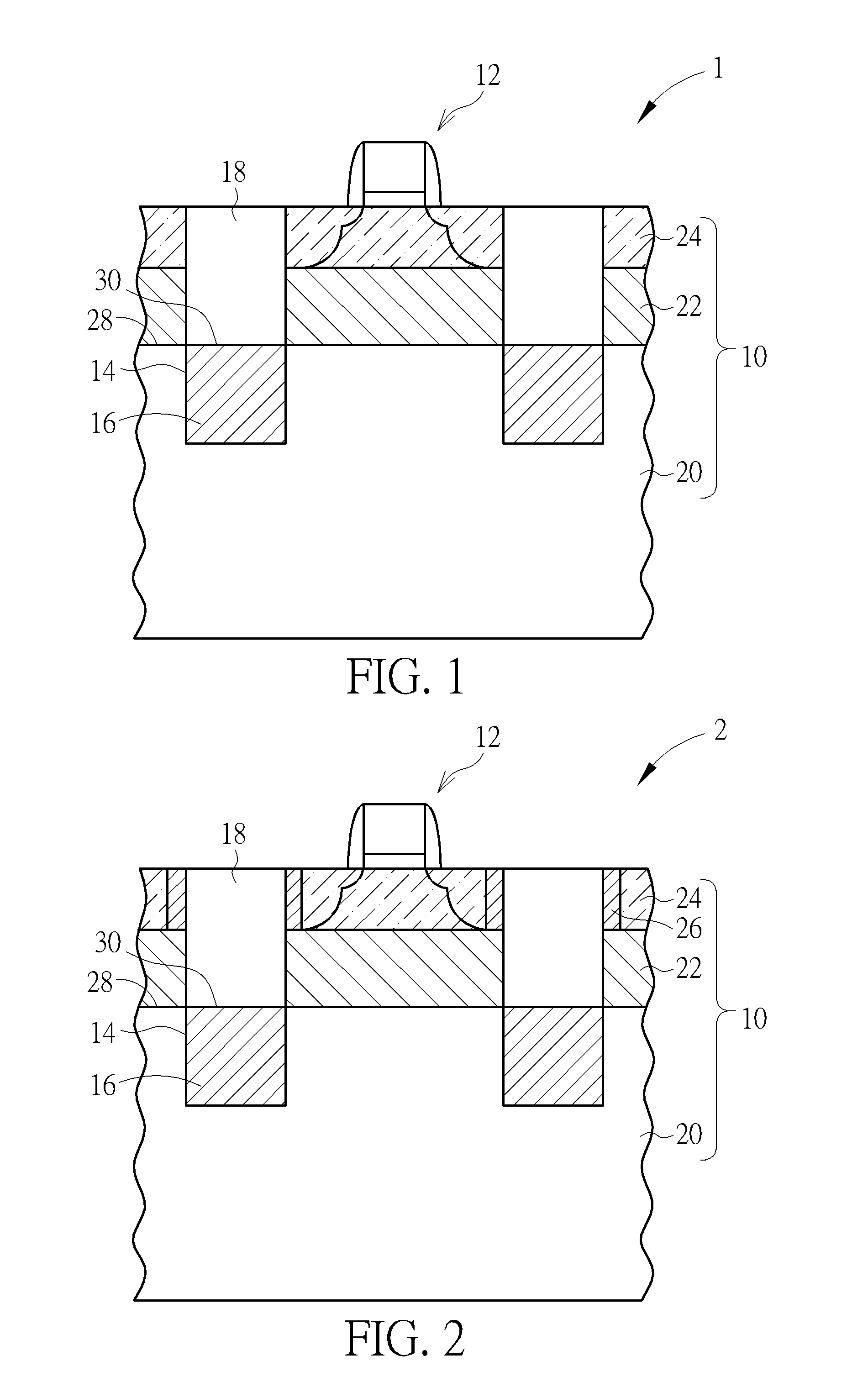

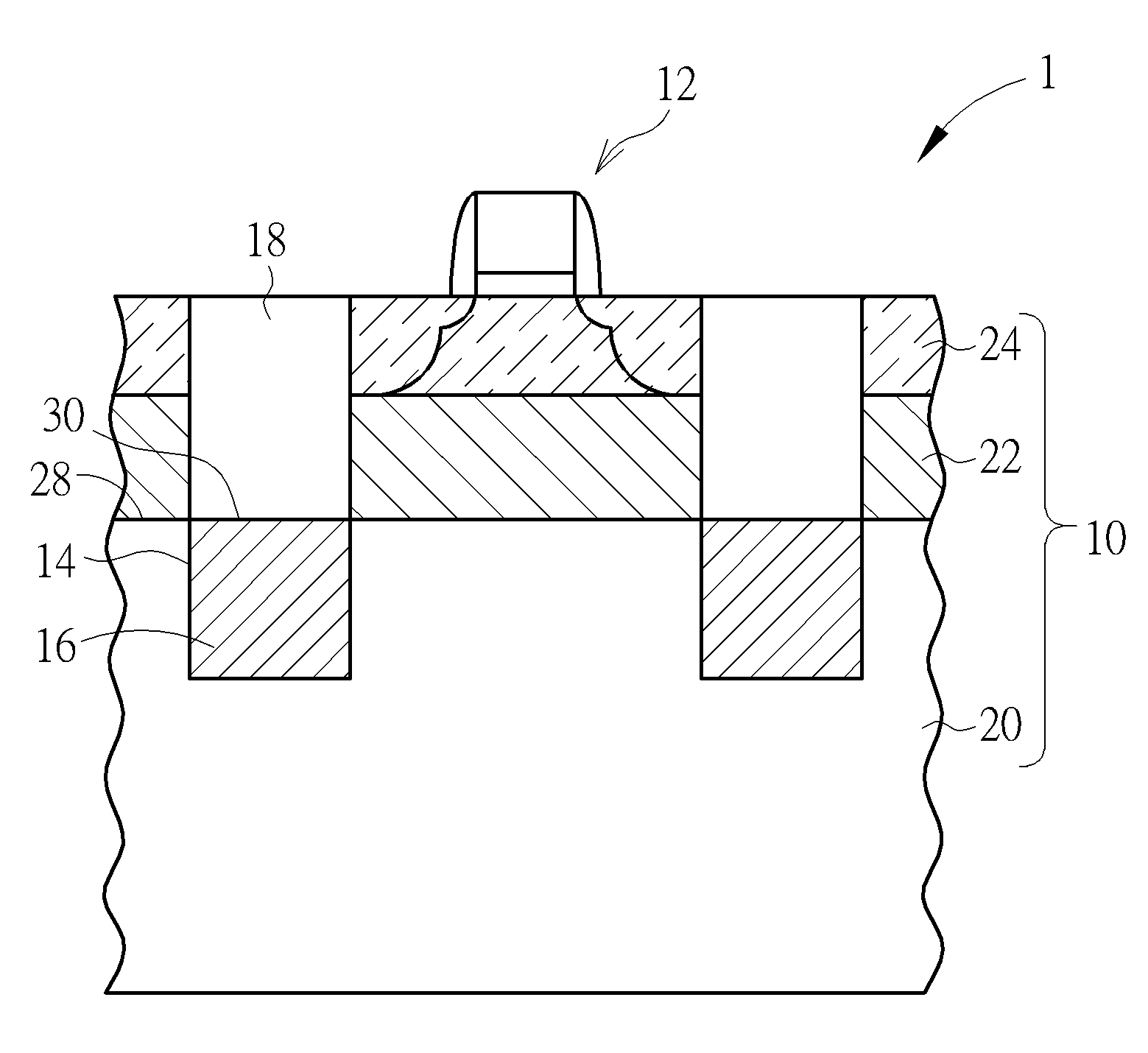

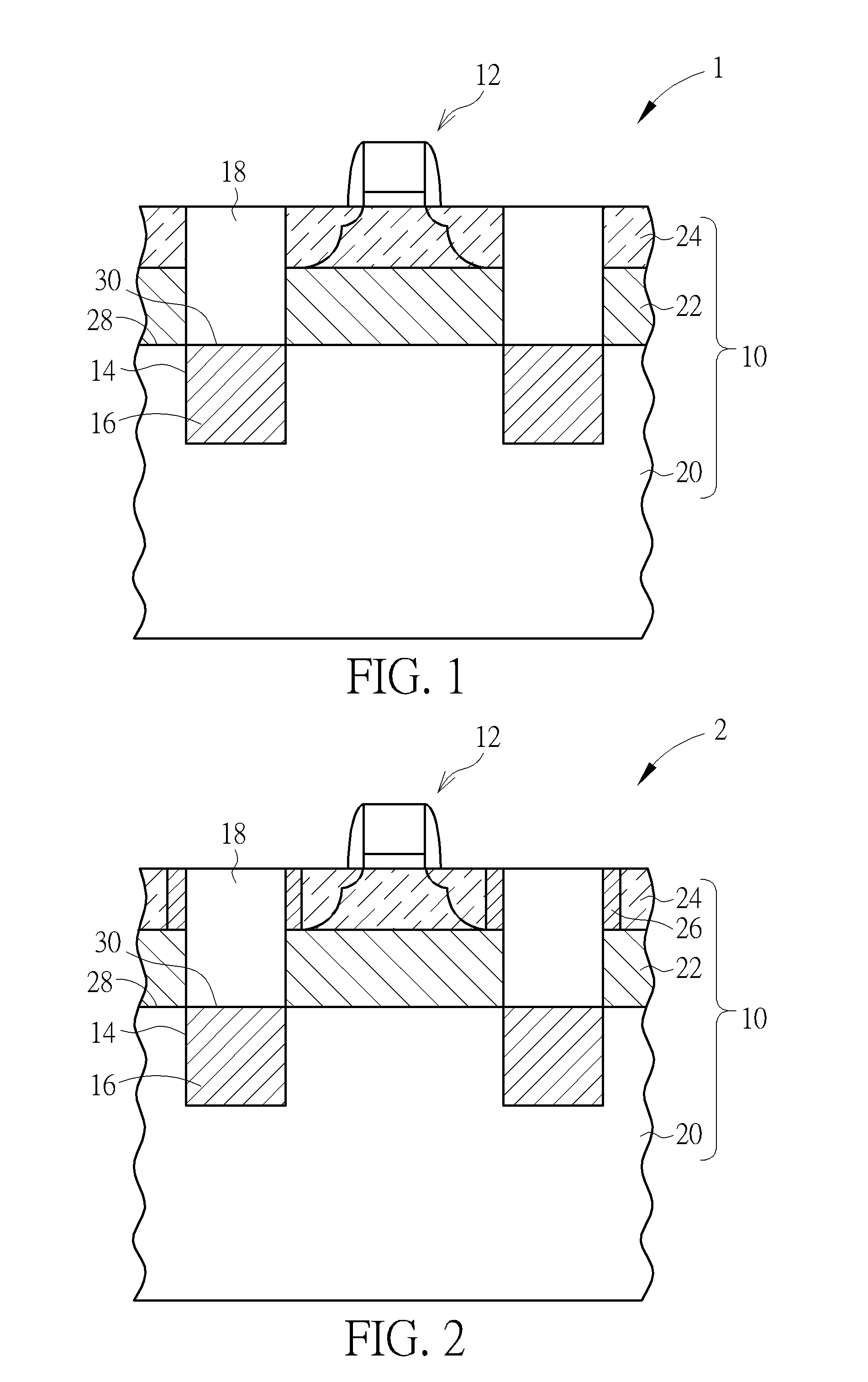

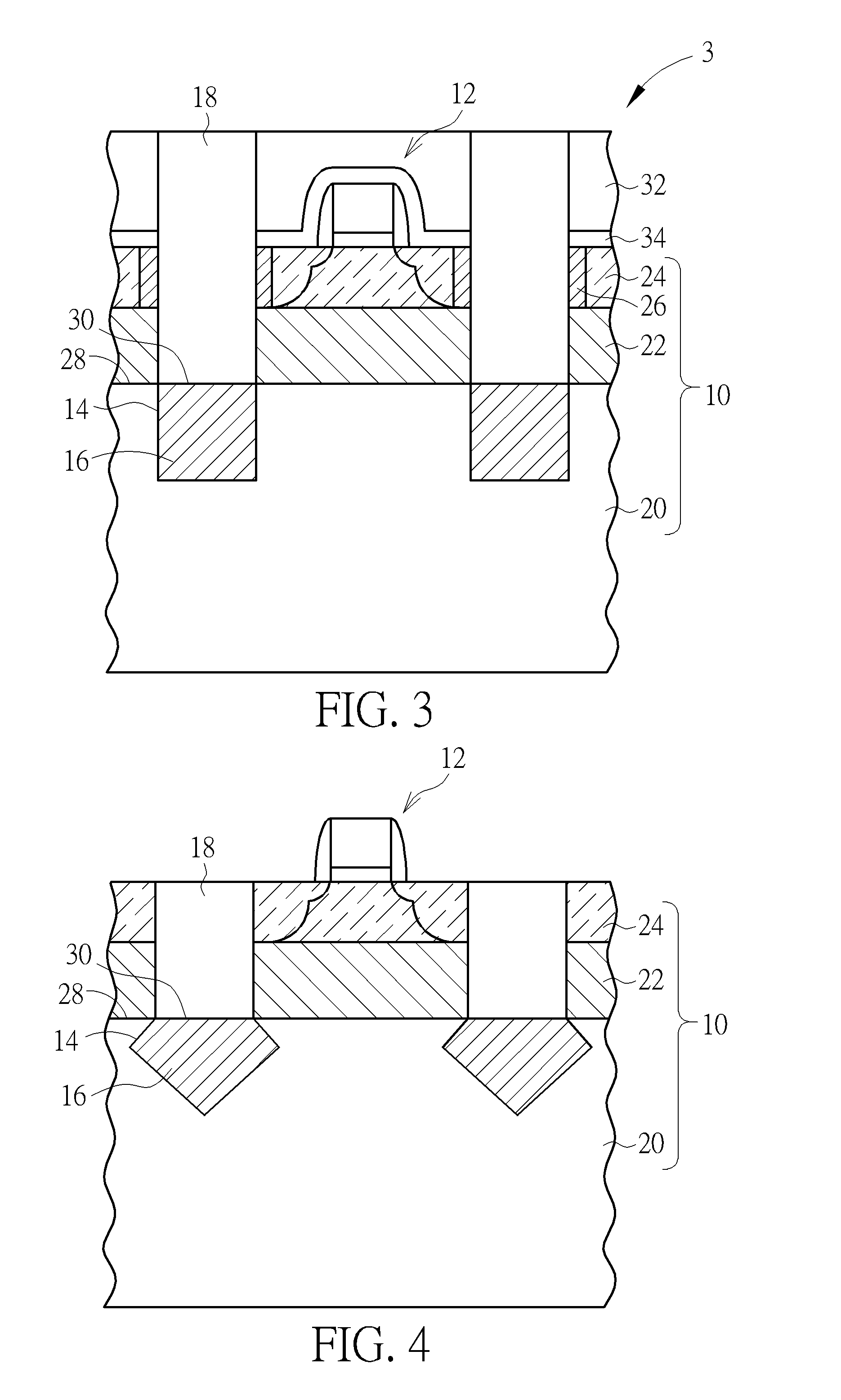

Semiconductor structure and method of forming a harmonic-effect-suppression structure

ActiveUS20150001670A1Alleviate parasitic surface charge issueReduce harmonic effectsSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureDielectric layer

A semiconductor structure includes a SOI / BOX semiconductor substrate, a device, a deep trench, a silicon layer, and a dielectric layer. The deep trench is adjacent to the device and extends through a shallow trench isolation layer within the SOI layer and the BOX layer and into the base semiconductor substrate. The silicon layer is disposed within a lower portion of the deep trench. The silicon layer has a top surface height substantially the same as or lower than a top surface height of the base semiconductor substrate. The dielectric layer is disposed within the deep trench and on the silicon layer. The deep trench can be formed before or after formation of an interlayer dielectric.

Owner:UNITED MICROELECTRONICS CORP

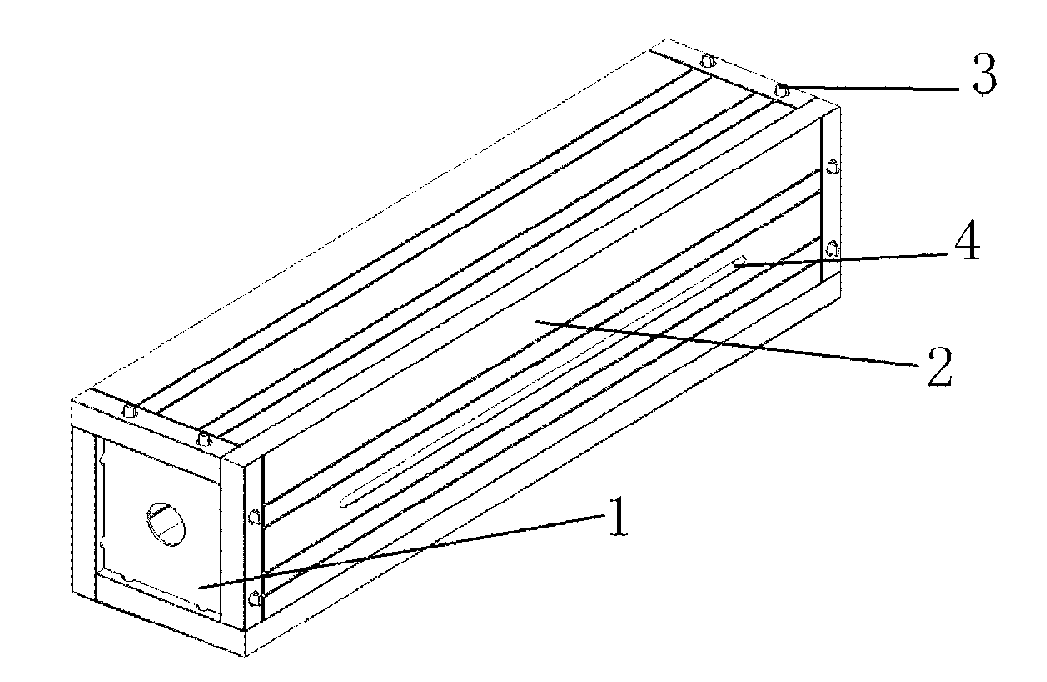

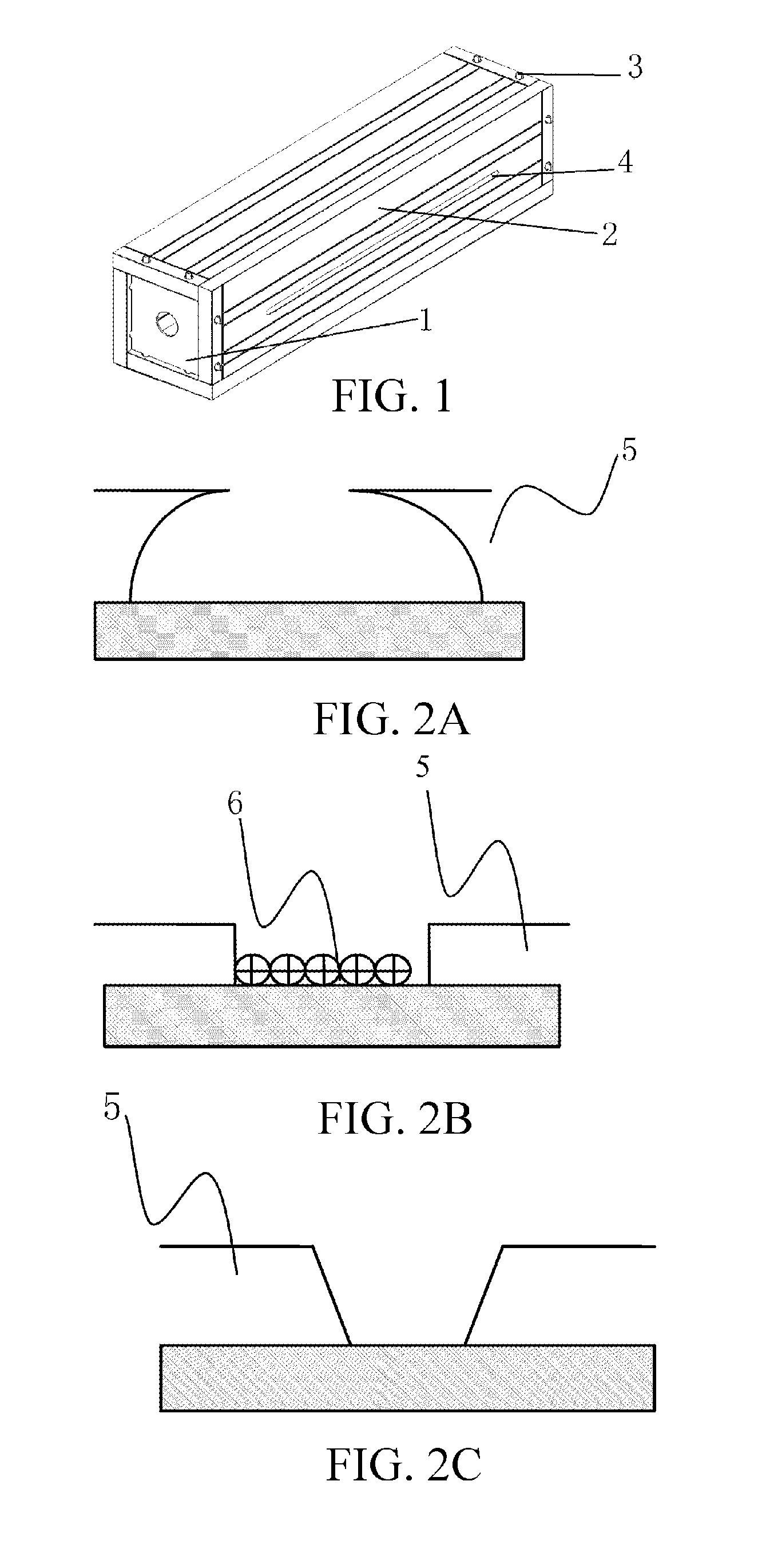

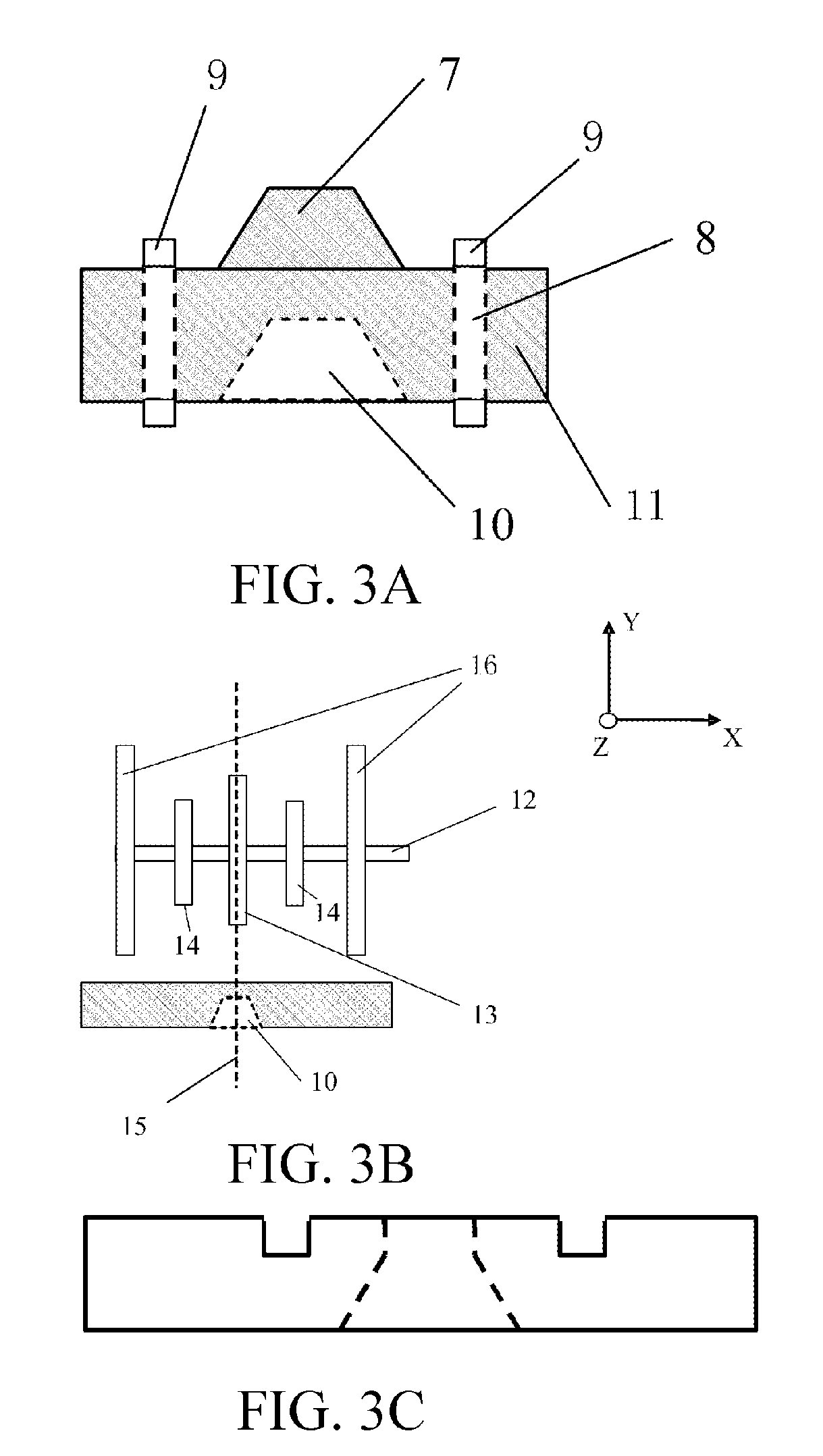

Method for manufacturing ion optical device

ActiveUS20140087063A1High precisionImprove accuracyParticle separator tubesVacuum evaporation coatingIonOptoelectronics

The present invention provides a method for preparing an ion optical device. A substrate is fabricated with a hard material adapted for a grinding process, the substrate at least including a planar surface, and including at least one insulating material layer. Next, one or more linear grooves are cut on the planar surface, to form multiple discrete ion optical electrode regions on the planar surface separated by the linear grooves. Then, conductive leads are fabricated on other substrate surfaces than the planar surface and in a through hole inside the substrate, to provide voltages required on ion optical electrodes. By using high-hardness materials in cooperation with high-precision machining, higher precision and a desired discrete electrode contour can be obtained.

Owner:SHIMADZU RES LAB SHANGHAI

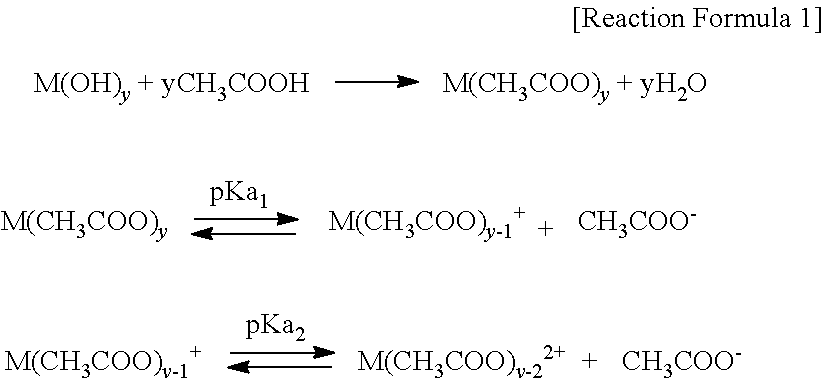

Environment-friendly cation emulsified water-based cutting fluid and preparation method thereof

InactiveCN101760294AImprove solubilityReduce the critical micelle concentration cmc valueLubricant compositionSolubilityWater based

The invention relates to an environment-friendly cation emulsified water-based cutting fluid and a preparation method thereof. The preparation method is characterized by comprising the following steps: preparation of a component A: respectively adding 3-8% of quaternary ammonium salt, 5-8% of Tween -40, 0.05-0.2% of calcium chloride, 0.01-0.08% of magnesium sulfate, 16-30% of gear oil 200# and 54-76% of deionized water into a reaction kettle for uniformly stirring, heating the mixture until the temperature is within 45-65 DEG C, and keeping the temperature for 20-30 minutes to obtain the component A; preparation of a component B: respectively adding 20-40% of extreme pressure antiwear additive, 2-10% of preservative, 5-20% of antirust, 0.04-0.3% of calcium chloride, 0.01-0.06% of magnesium sulfate and 30-72% of the deionized water into the reaction kettle for uniformly stirring, heating the mixture until the temperature is within 55-75 DEG C, and keeping the temperature for 25-35 minutes to obtain the component B; and after the component A and the component B are prepared, mixing and stirring the component A and the component B according to the mass ratio of 2:1-1:2 to be invalid, heating the mixture until the temperature is within 65-80 DEG C, keeping the temperature for 35-45 minutes, and then cooling to normal temperature to obtain the product of the invention. The product of the invention has the advantages of high wear resistance, water solubility and lubricating property, good anti-rust property, no corrosion, good cooling property, convenient cleaning, cheap price and the like.

Owner:SHUNDE POLYTECHNIC

Preparation method of flocculating agent used for treating oily sewage

ActiveCN107879447AEnhanced ability to absorb oilGood removal effectCopper organic compoundsDisinfectantsAluminium saltsChemistry

The invention discloses a preparation method of a flocculating agent used for treating oily sewage, which is mainly characterized in that chitosan is used as the main material, meanwhile, poly-ferricsulfate, poly-aluminum sulfate, poly (diallyldimethylammonium chloride) and thiocarbanilide copper complex are added in the preparation process to perform modification treatment, and a steady chelatecompound is formed by amino groups and carboxy groups in chitosan molecules and mercury, lithium, copper, lead, silver and other heavy metal ions in sewage, so as to remove and recycle metal ions in waste water. The flocculating agent prepared according to the invention has a good adsorption effect, and the better the biocompatibility is, the stronger the adsorption effect for grease dirt is. Theflocculating agent can also be used for decoloration of waste water in sewage treatment, and adsorption and flocculating reaction and the like of waste water in industrial production, thus having goodpopularization and application values.

Owner:菏泽衡巽环保科技有限公司

Semiconductor structure and method of forming a harmonic-effect-suppression structure

ActiveUS9048285B2Reduce surface chargeEliminate the effects ofSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricSemiconductor structure

Owner:UNITED MICROELECTRONICS CORP

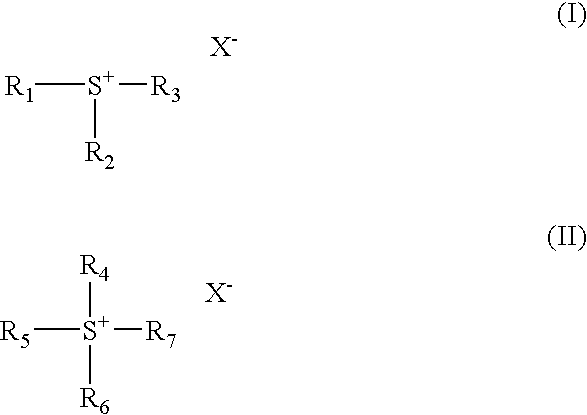

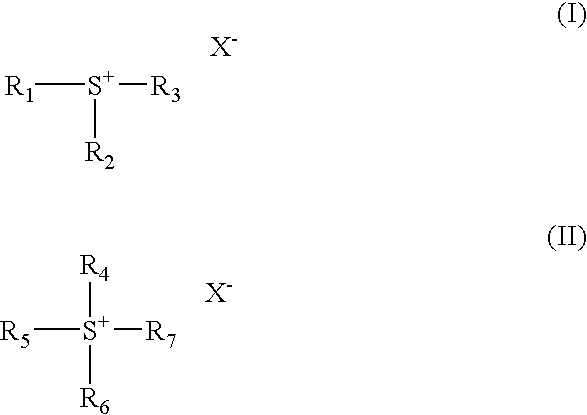

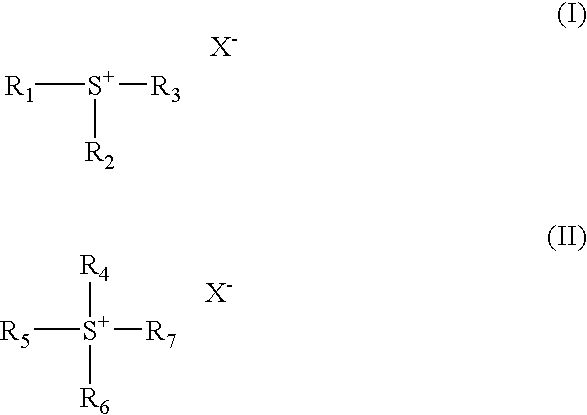

Thermally developable materials processable at lower temperatures

InactiveUS20060093974A1Shorten the overall cycleReduce the temperatureMulticolor photographic processingPhotothermographic systemsPhosphonium saltSulfonium

Black-and-white direct thermographic materials and photothermographic materials can be processed or developed at lower temperatures because of the incorporation of a tertiary sulfonium or quaternary phosphonium salt in an amount of at least 0.5 mol % based on total silver in the material.

Owner:EASTMAN KODAK CO

Formulations for targeted release of agents under low ph conditions and methods of use thereof

ActiveUS20170360959A1Easy to optimizeEfficient deliveryOrganic active ingredientsPowder deliveryNanoparticleMedicine

Poly(amine-co-ester-co-ortho ester) polymers, methods of forming active agent-load nanoparticles therefrom, and methods of using the nanoparticles for drug delivery are disclosed. The nanoparticles can be coated with an agent that reduces surface charge, an agent that increases cell-specific targeting, or a combination thereof. Typically, the loaded nanoparticles are less toxic, more efficient at drug delivery, or a combination thereof compared to a control or other transfection reagents.

Owner:YALE UNIV

Cavity liners for electromechanical systems devices

InactiveCN104428240ARetain roughnessImprove performancePiezoelectric/electrostrictive devicesFlexible microstructural devicesCavity LinerSelf-assembled monolayer

This disclosure provides systems, methods and apparatus for electromechanical systems devices with improved electrical properties and device life span. In one aspect, a conformal antistiction layer is formed within a cavity of an electromechanical systems apparatus over a roughened surface. The conformal antistiction layer can include a dielectric layer. The conformal antistiction layer can include a self-assembled monolayer (SAM) formed over the dielectric layer. The conformal antistiction layer can replicate the roughness of the surface that it is deposited on.

Owner:SNAPTRACK

Bi-direction rapid action electrostatically actuated microvalve

InactiveUS8628055B2Reduces film squeezing pressureStart fastAdditive manufacturing apparatusOperating means/releasing devices for valvesCross-linkTrapping

A bi-directional electrostatic microvalve includes a membrane electrode that is controlled by application of voltage to fixed electrodes disposed on either side of the membrane electrode. Dielectric insulating layers separate the electrodes. One of the fixed electrodes defines a microcavity. Microfluidic channels formed into the electrodes provide fluid to the microcavity. A central pad defined in the microcavity places a portion of the second electrode close to the membrane electrode to provide a quick actuation while the microcavity reduces film squeezing pressure of the membrane electrode. In preferred embodiment microvalves, low surface energy and low surface charge trapping coatings, such as fluorocarbon films made from cross-linked carbon di-fluoride monomers or surface monolayers made from fluorocarbon terminated silanol compounds coatings coat the electrode low bulk charge trapping dielectric layers limit charge trapping and other problems and increase device lifetime operation.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com