Antimony-based compound flame-retardant masterbatch for nylon 66 and preparation method of antimony-based compound flame-retardant masterbatch

A flame-retardant masterbatch and antimony-based technology, applied in the field of flame-retardant materials, can solve problems such as high pollution, and achieve the effects of improving compatibility, improving flame retardancy, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

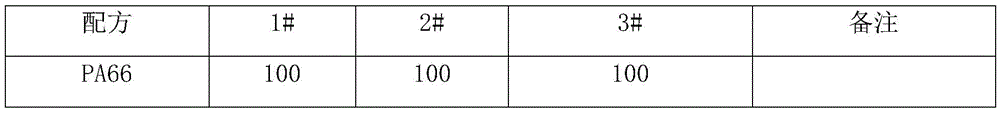

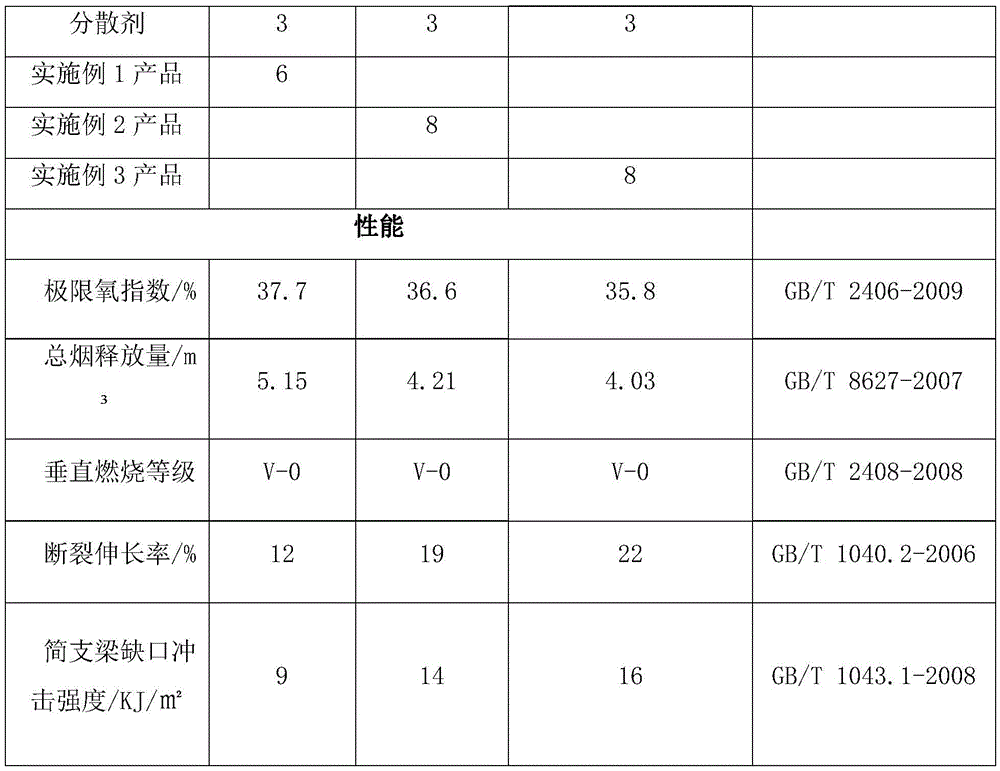

Examples

Embodiment 1

[0032] An antimony-based compound flame-retardant masterbatch for nylon 66, comprising the following raw materials in parts by weight: 15 kg of PA66 carrier resin, 60 kg of antimony trioxide (main content of more than 99.6%, particle size of 0.5 μm), 10 kg of magnesium hydroxide, bromine Chemicalized polystyrene 10kg, zinc stearate 3kg, aluminate 2kg.

[0033] The preparation method of the antimony-based compound flame-retardant masterbatch for the above-mentioned nylon 66: comprises the following steps:

[0034] S1. Drying: Dry the PA66 carrier resin with hot air circulation at a temperature of 110°C and a drying time of 12 hours.

[0035] S2. Surface modification: Weigh antimony trioxide, magnesium hydroxide and aluminate according to the above amounts and put them into a high-speed mixer for modification. The modification temperature is 120°C, the stirring rate is 800rpm / min, and the stirring time is 3.0h. Antimony trioxide and magnesium hydroxide after neutralization.

...

Embodiment 2

[0039] An antimony-based compound flame-retardant masterbatch for nylon 66, comprising the following raw materials in parts by weight: 25 kg of PA66 carrier resin, 40 kg of antimony trioxide (main content of more than 99.6%, particle size of 0.5 μm), 18 kg of aluminum hydroxide, chlorine Polystyrene 12kg, tin stearate 3kg, silane coupling agent 2kg.

[0040] The preparation method of the antimony-based composite flame-retardant masterbatch for the above-mentioned nylon 66 comprises the following steps:

[0041] S1. Drying: Dry the PA66 carrier resin with hot air circulation at a temperature of 100°C and a drying time of 12 hours.

[0042] S2. Surface modification: Weigh antimony trioxide, aluminum hydroxide and silane coupling agent according to the above amount and put them into a high-speed mixer for modification. The modification temperature is 100°C, the stirring rate is 600rpm / min, and the stirring time is 2.0h. Modified antimony trioxide and aluminum hydroxide.

[0043...

Embodiment 3

[0046] An antimony-based compound flame-retardant masterbatch for nylon 66, comprising the following raw materials in parts by weight: 30 kg of PA66 carrier resin, 40 kg of antimony trioxide (main content above 99.6%, particle size 0.5 μm), 15 kg of zinc borate, bromide Polystyrene 10kg, zinc stearate 3kg, aluminate 2kg.

[0047] The preparation method of the antimony-based composite flame-retardant masterbatch for the above-mentioned nylon 66 comprises the following steps:

[0048] S1. Drying: Dry the PA66 carrier resin with hot air circulation at a temperature of 120°C and a drying time of 12 hours.

[0049]S2. Surface modification: Weigh antimony trioxide, zinc borate and aluminate according to the above amounts and put them into a high-speed mixer for modification. The modification temperature is 140°C, the stirring rate is 900rpm / min, and the stirring time is 4.0h. Antimony trioxide and zinc borate after neutralization.

[0050] S3. High-speed thermal mixing: Put the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com