Cavity liners for electromechanical systems devices

A technology of electromechanical systems and electrode devices, applied in the direction of microelectronic microstructure devices, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

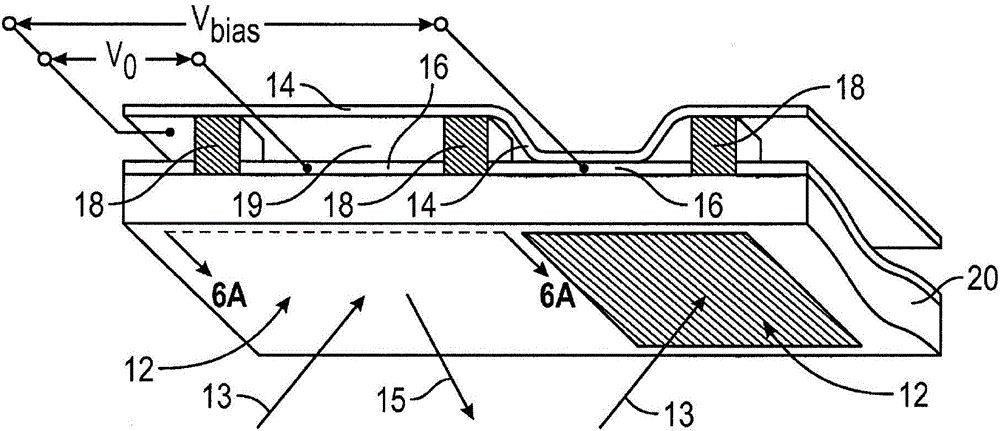

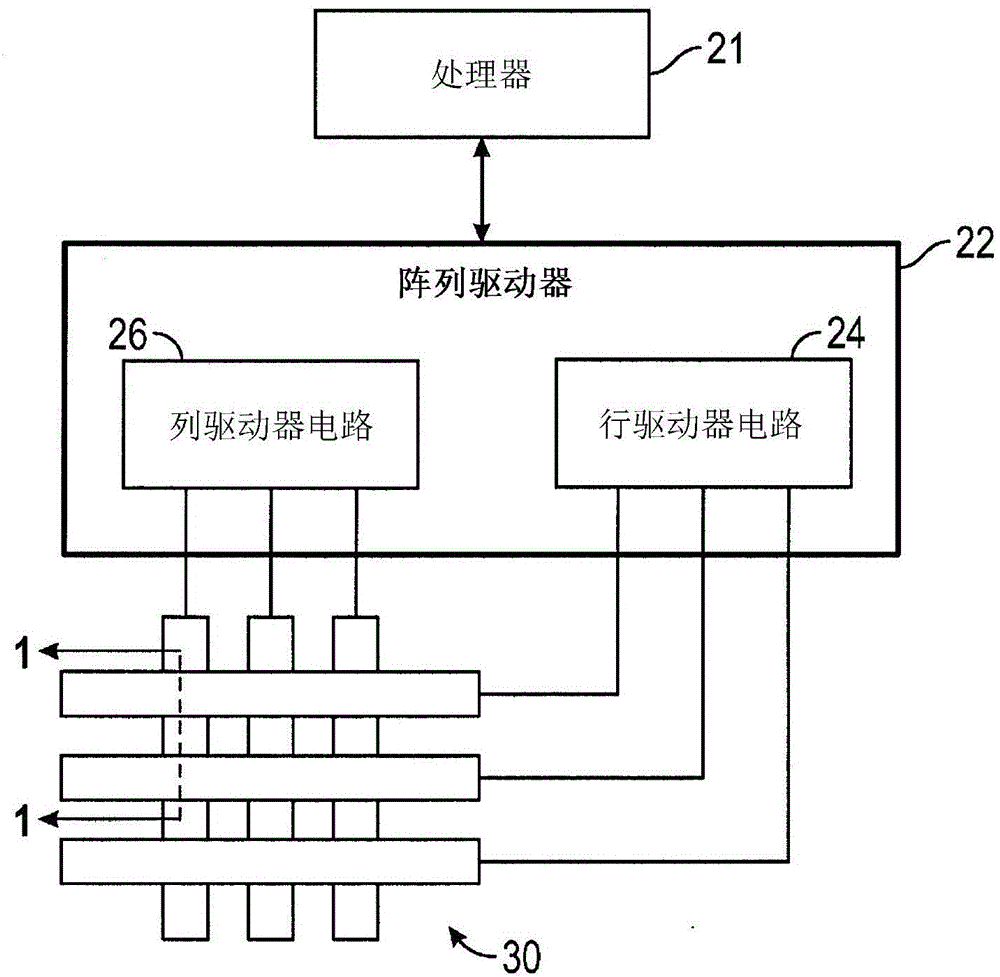

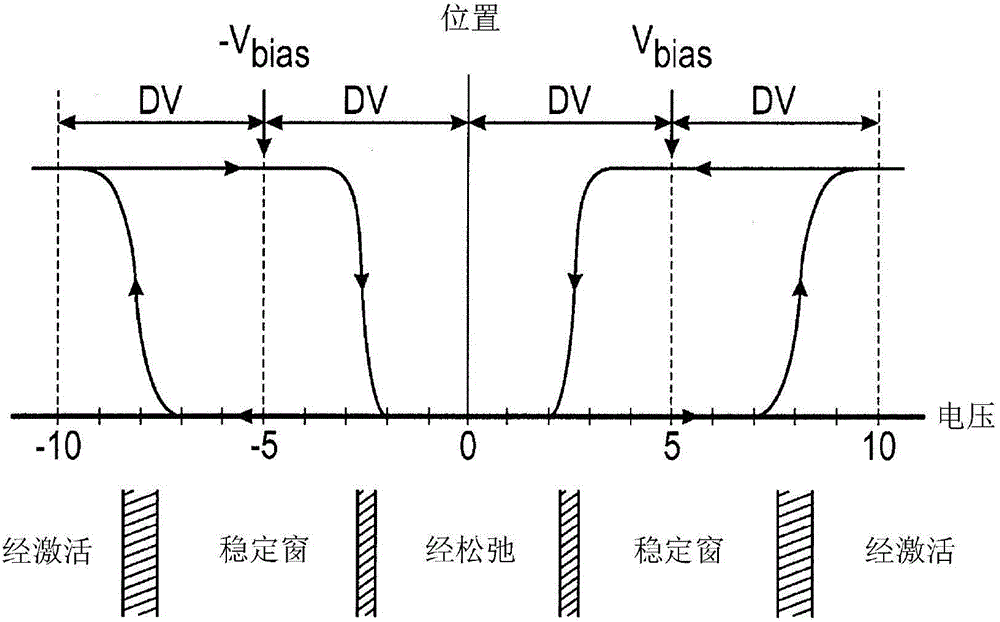

[0026] The following detailed description is directed to some implementations for the purposes of describing innovative aspects. However, the teachings herein can be applied in many different ways. The described implementations can be implemented in any device configured to display images, whether in motion (eg, video) or still images (eg, still images), and whether textual, graphical, or pictorial. More particularly, it is contemplated that the implementations may be implemented in or associated with a variety of electronic devices such as, but not limited to, mobile telephones, multimedia Internet enabled cellular Telephones, mobile TV receivers, wireless devices, smart phones, Devices, Personal Data Assistants (PDAs), Wireless Email Receivers, Handheld or Laptop Computers, Netbooks, Notebooks, Smartbooks, Tablet Computers, Printers, Copiers, Scanners, Fax Devices, GPS Receivers / Navigators, Cameras , MP3 players, video cameras, game consoles, wrist watches, clocks, calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| General hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com