Patents

Literature

33 results about "Cavity Liner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A material placed between the restoration and the tooth surface.

Remineralizing dental cements

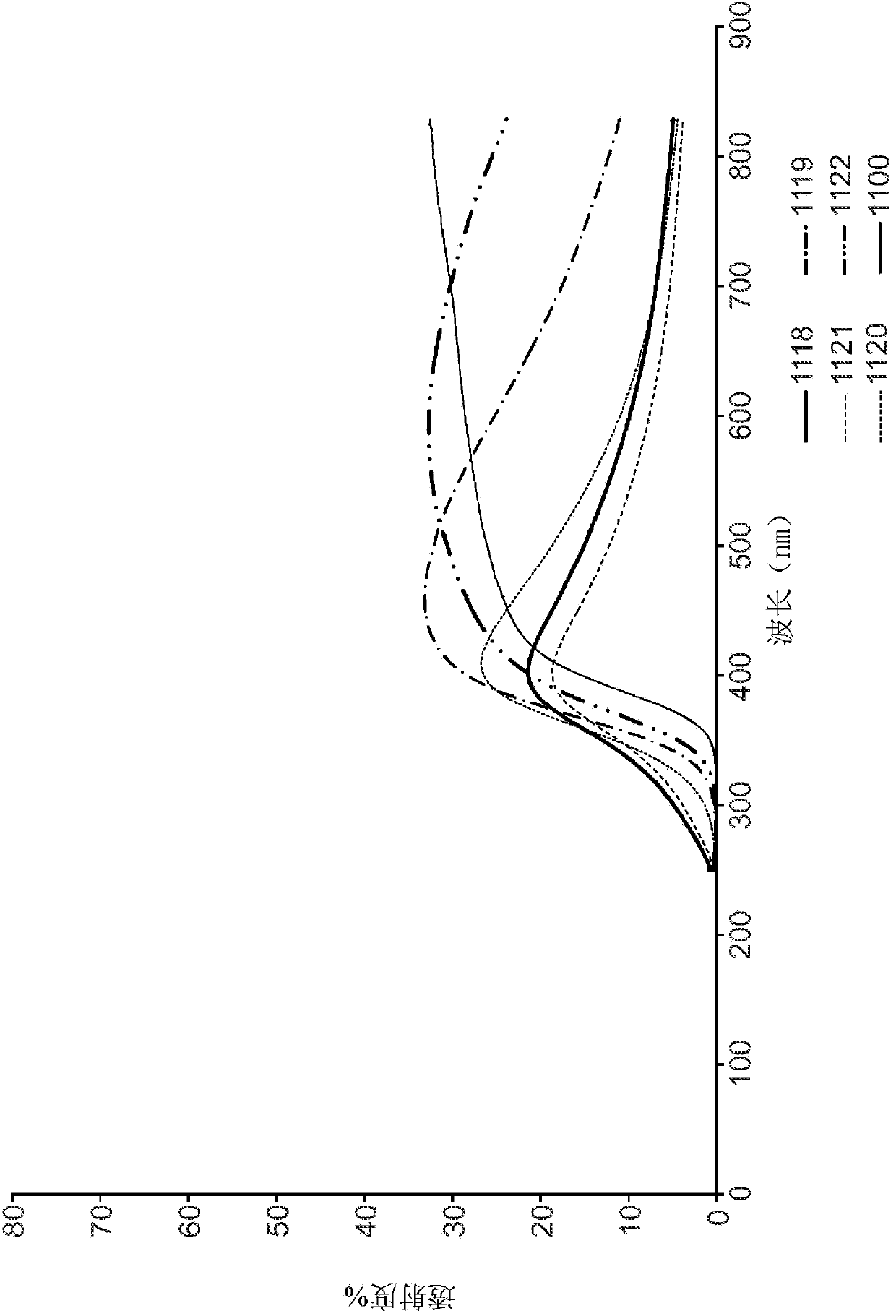

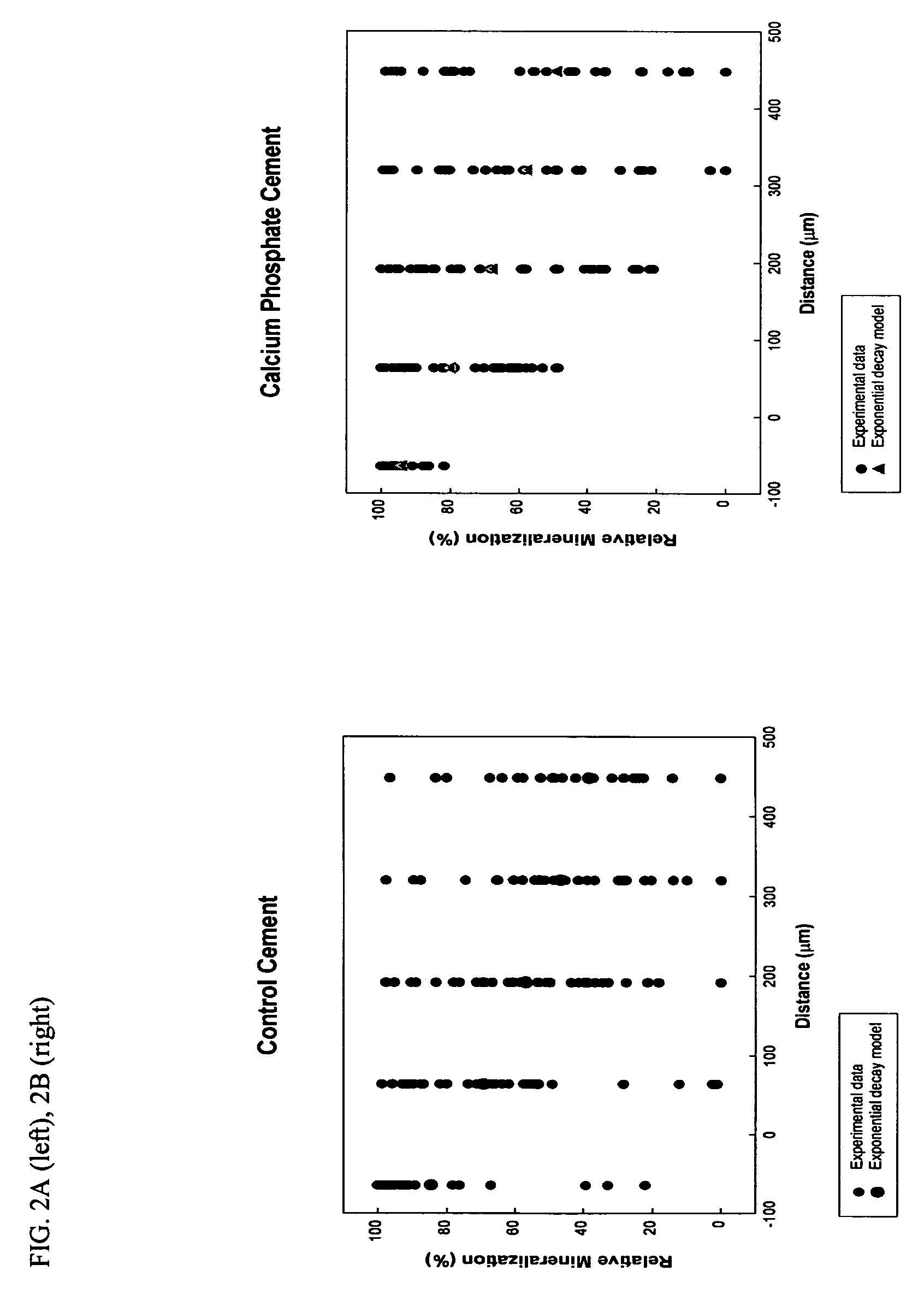

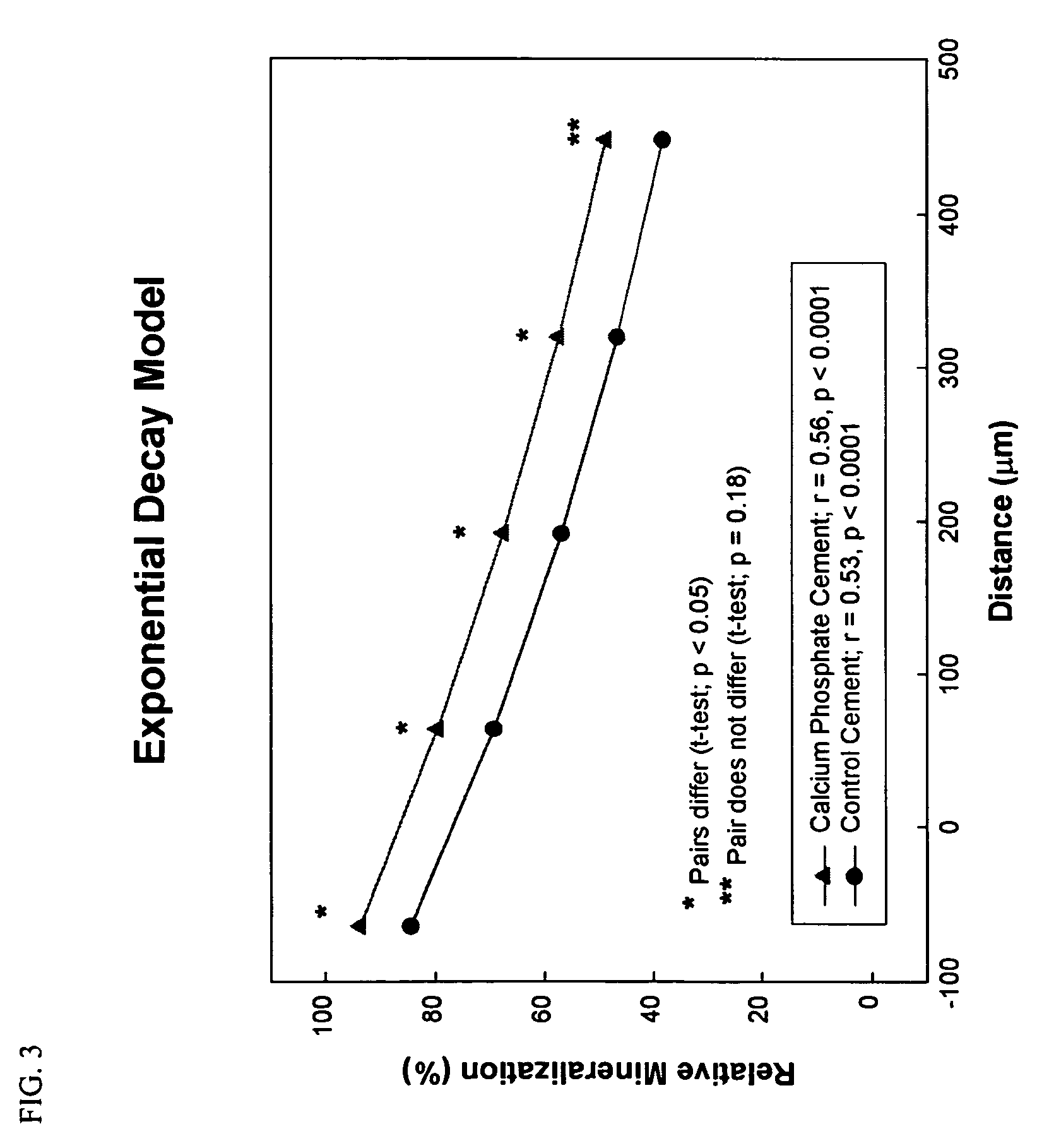

ActiveUS20050020720A1Counteract deleterious effectPromote remineralizationCosmetic preparationsImpression capsPhosphate ionCavity Liner

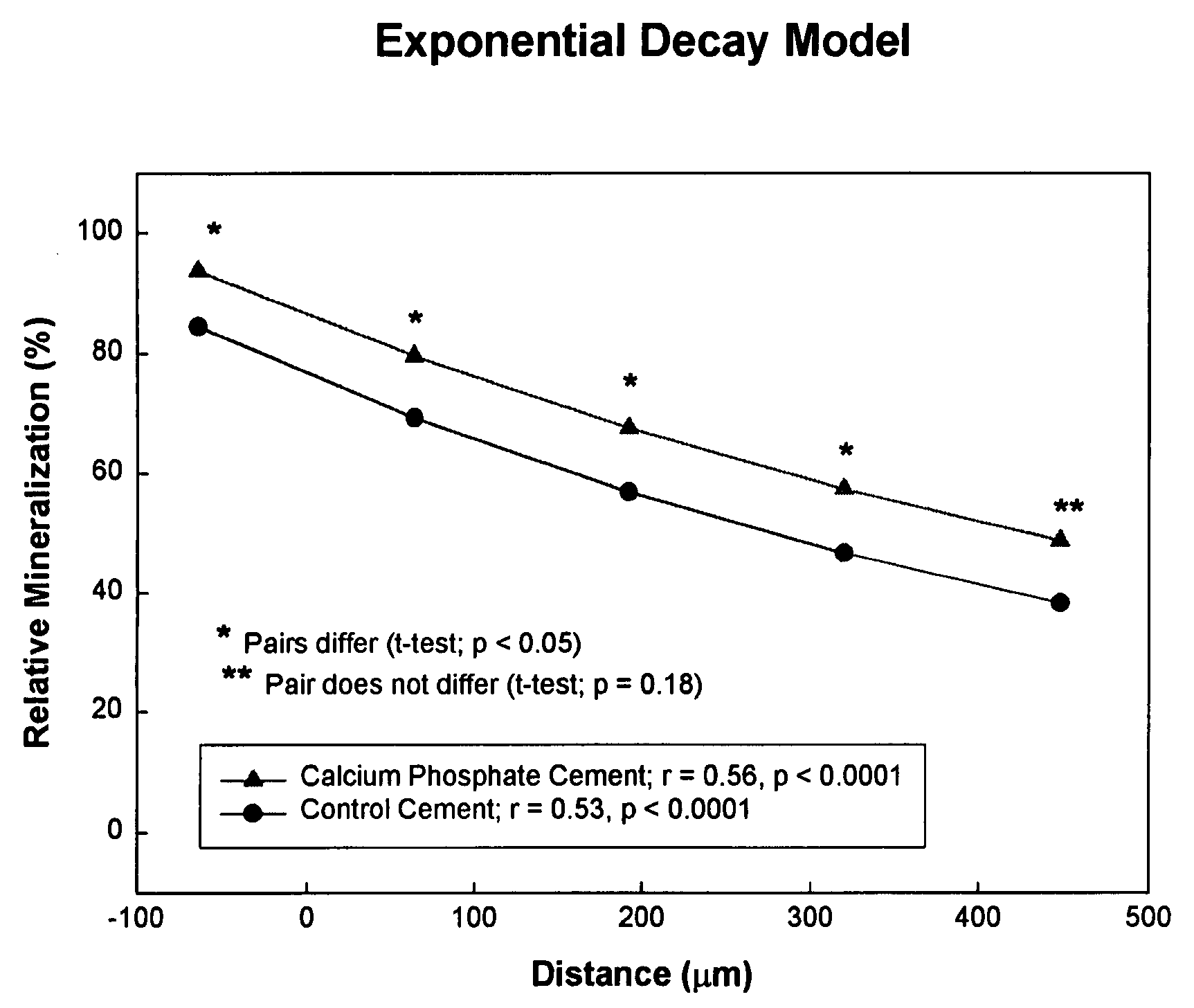

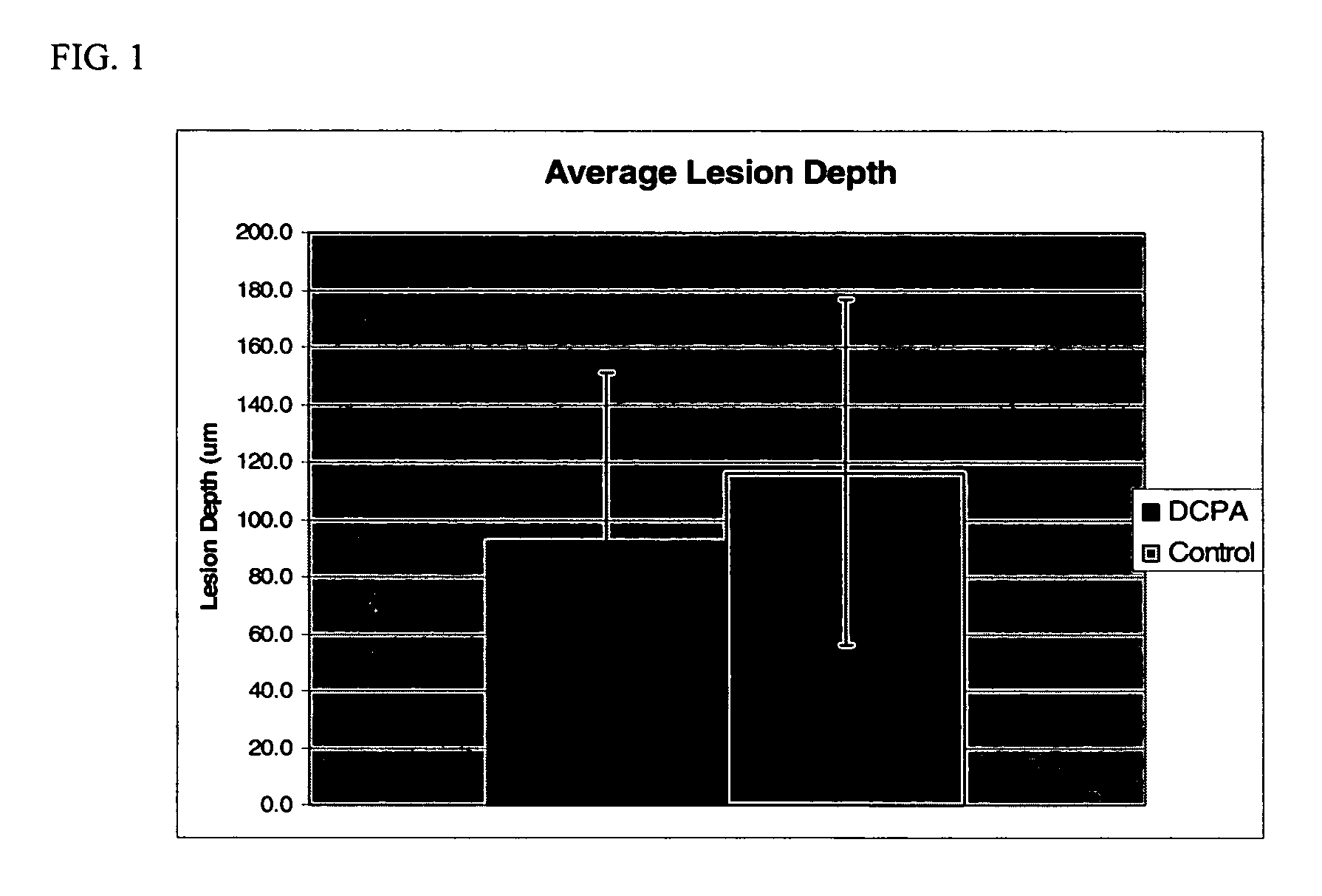

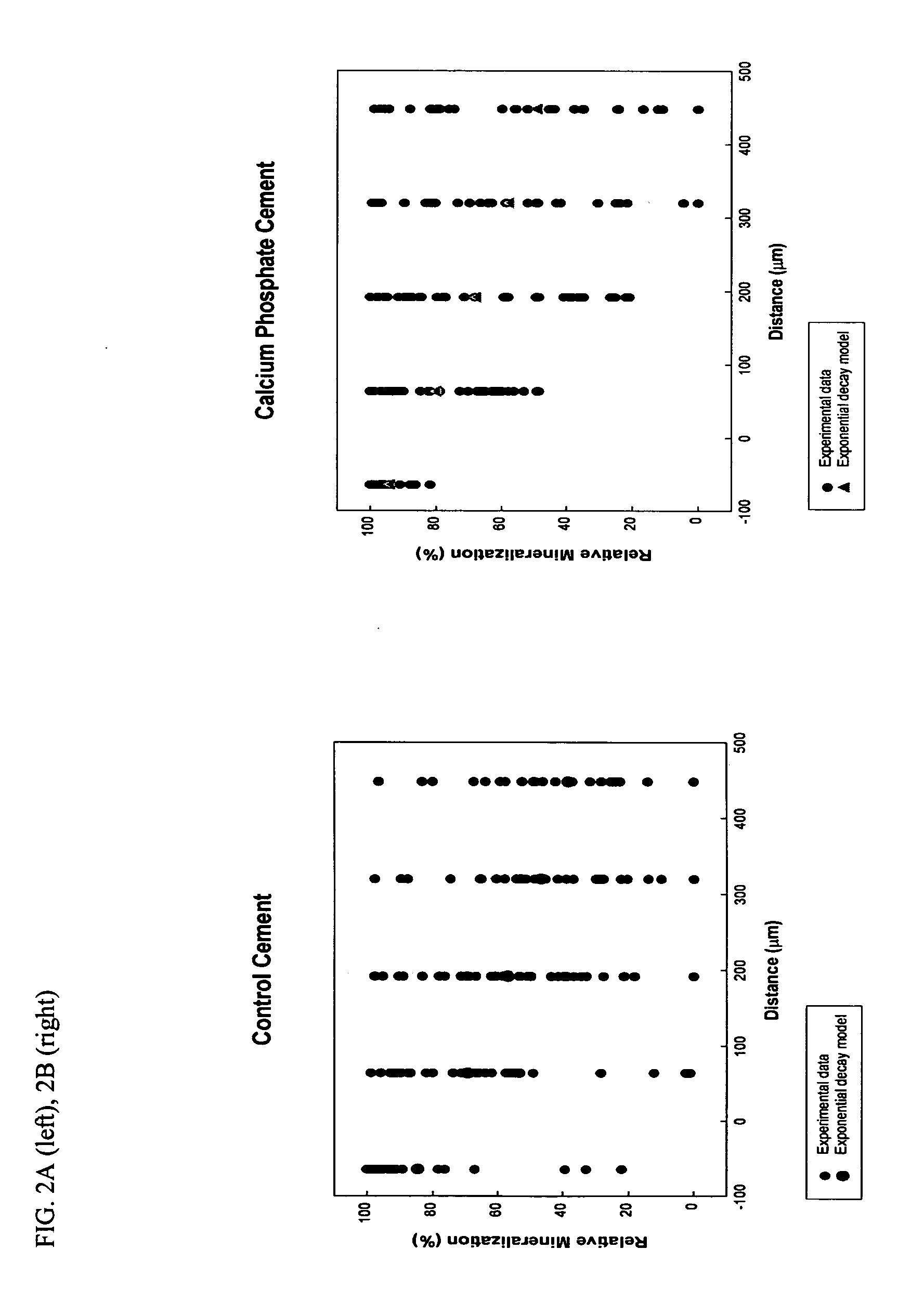

Remineralizing dental cements contain source(s) of calcium and phosphate ions, adhesive resin monomers, reinforcing base resin monomers, and catalysts able to initiate the polymerization of the adhesive and reinforcing base resin monomers. Such dental cements can be used as orthodontic cements, crown and bridge cements, adhesives, sealants, cavity liners, and protective coatings. The release of calcium and phosphate ions and, optionally, fluoride ions, protects tooth structure from demineralization, a precursor of tooth decay.

Owner:ADA FOUND

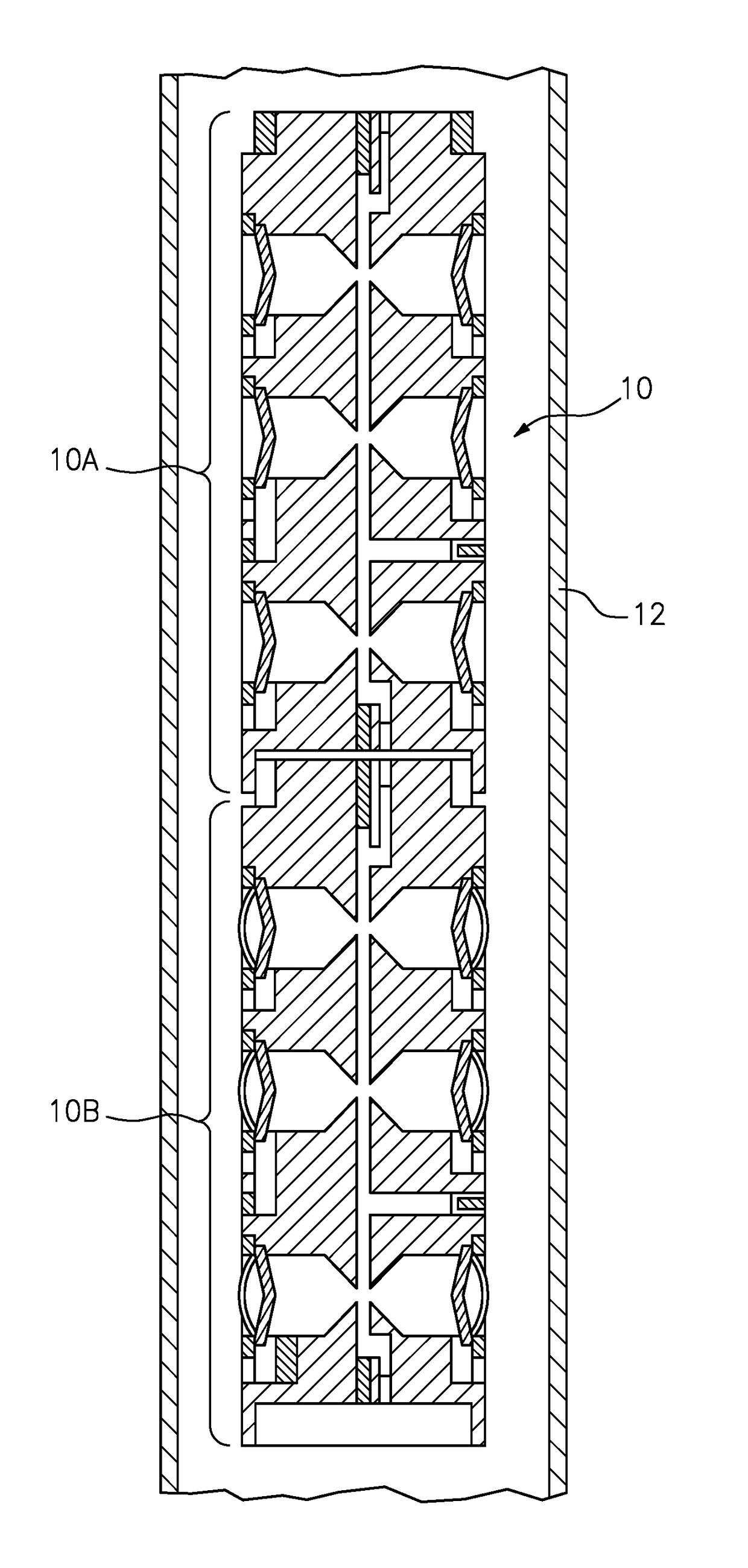

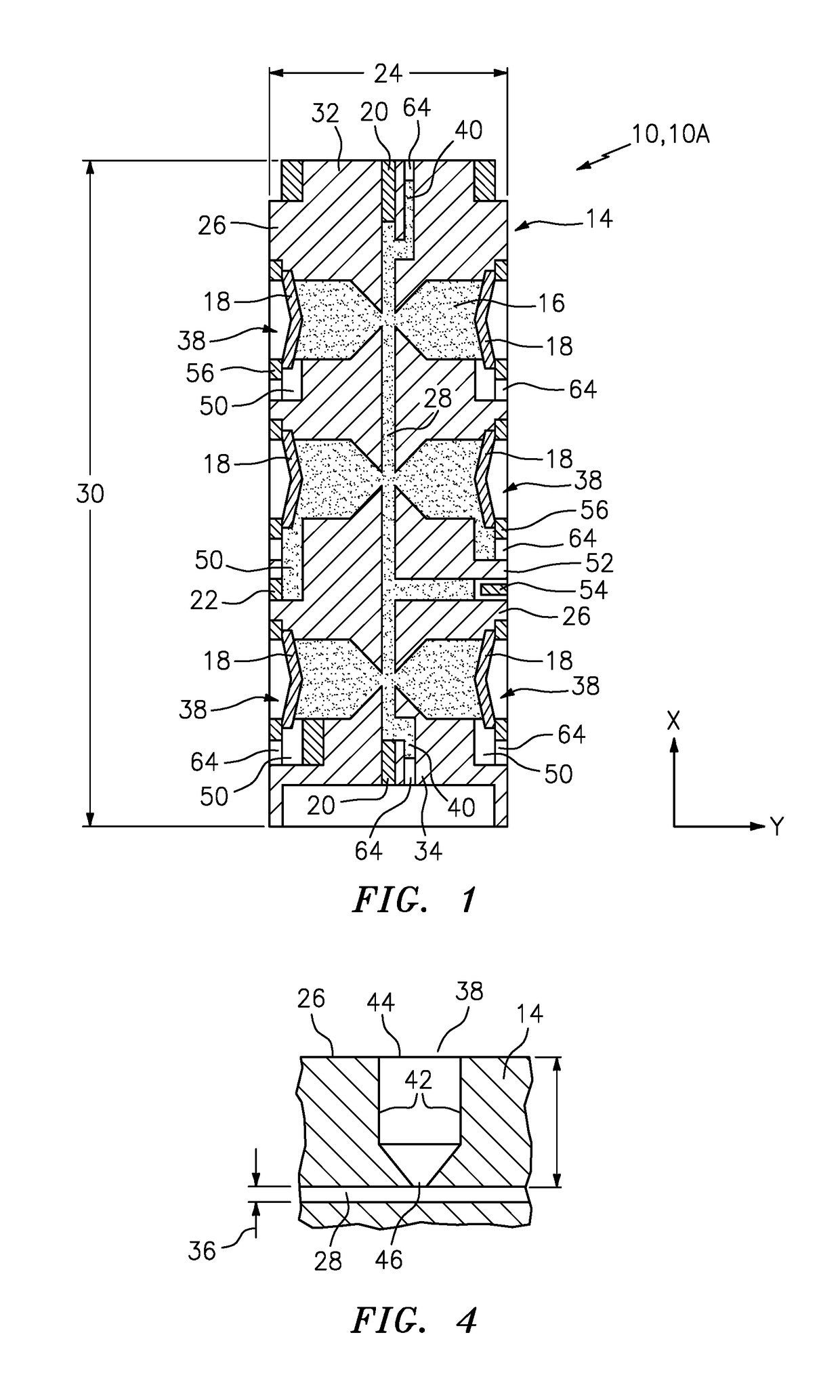

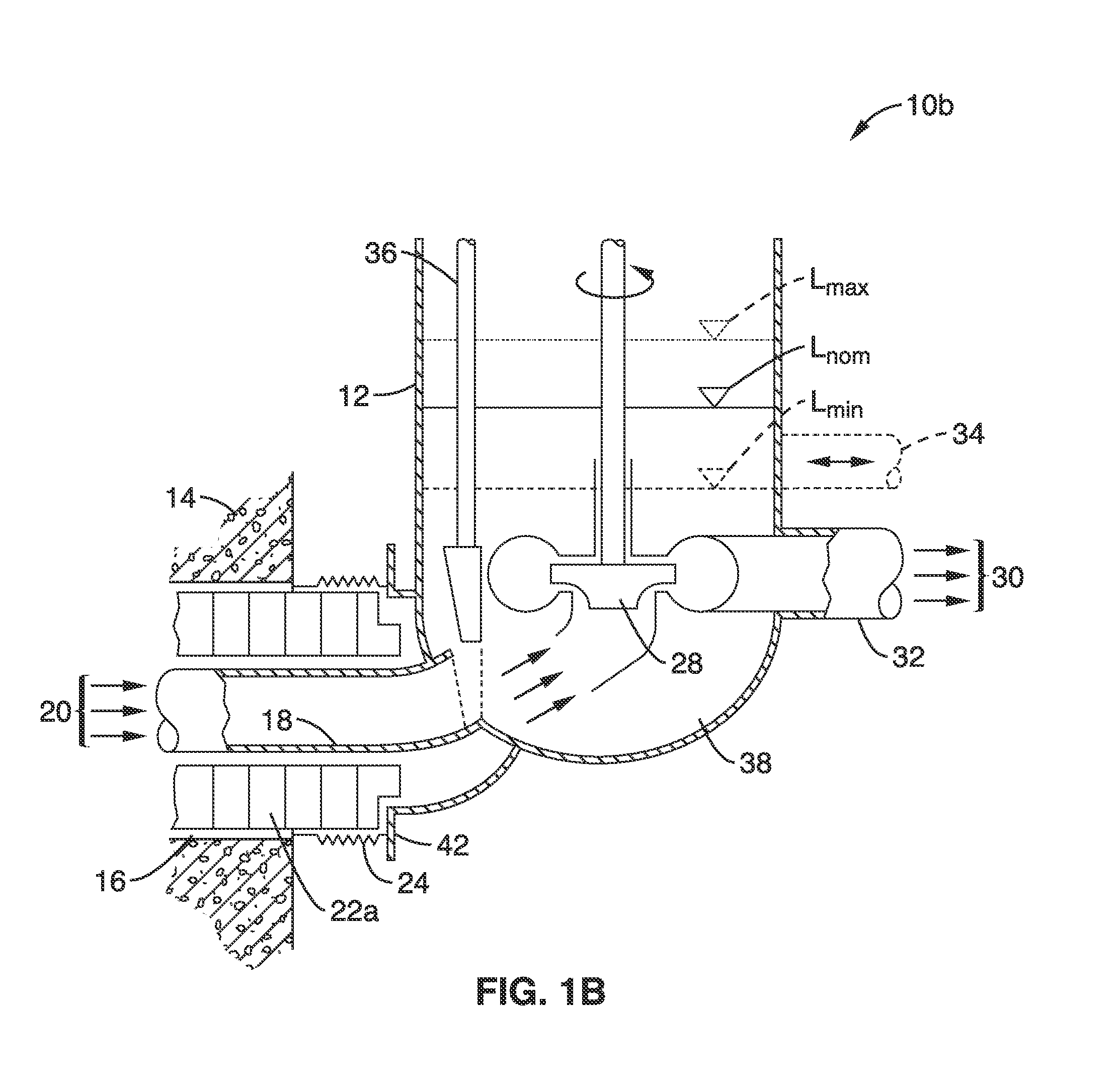

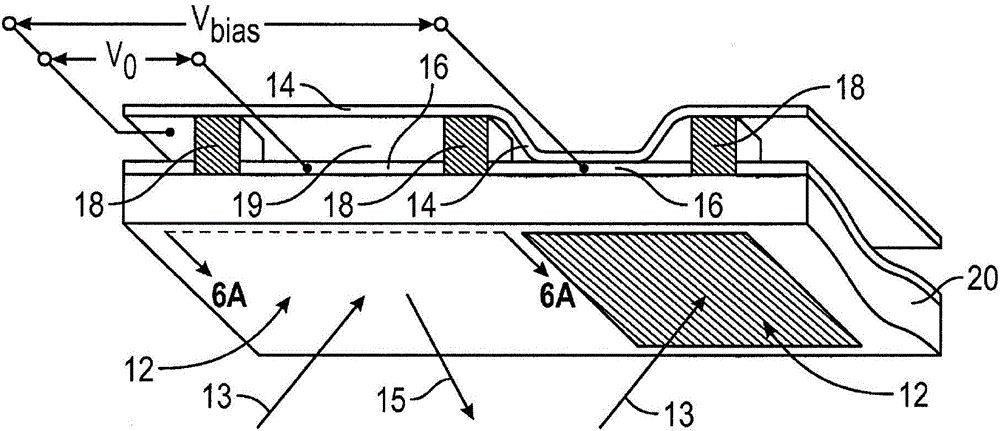

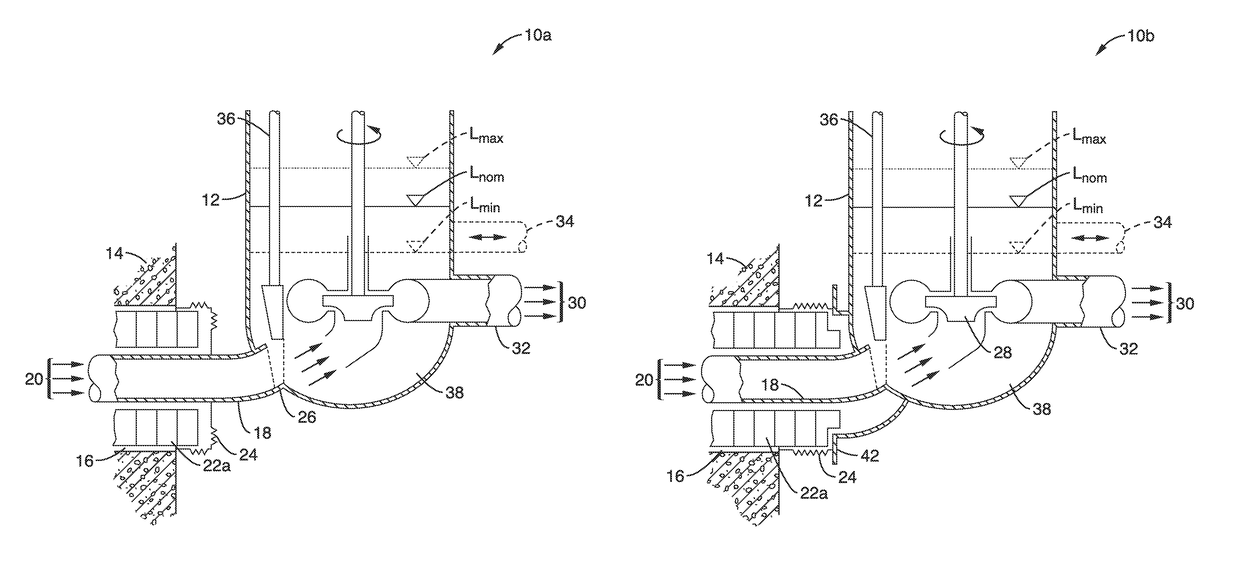

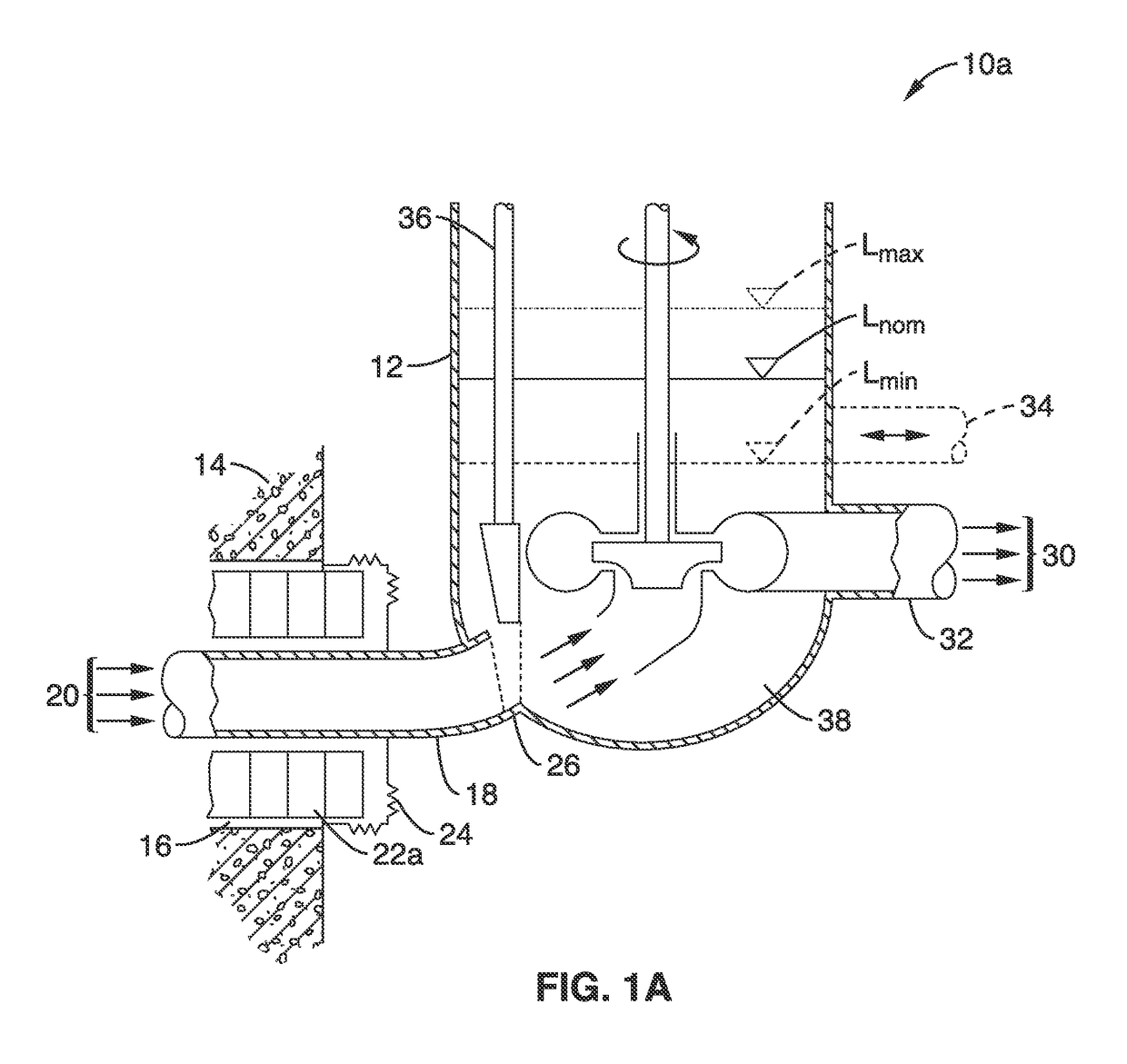

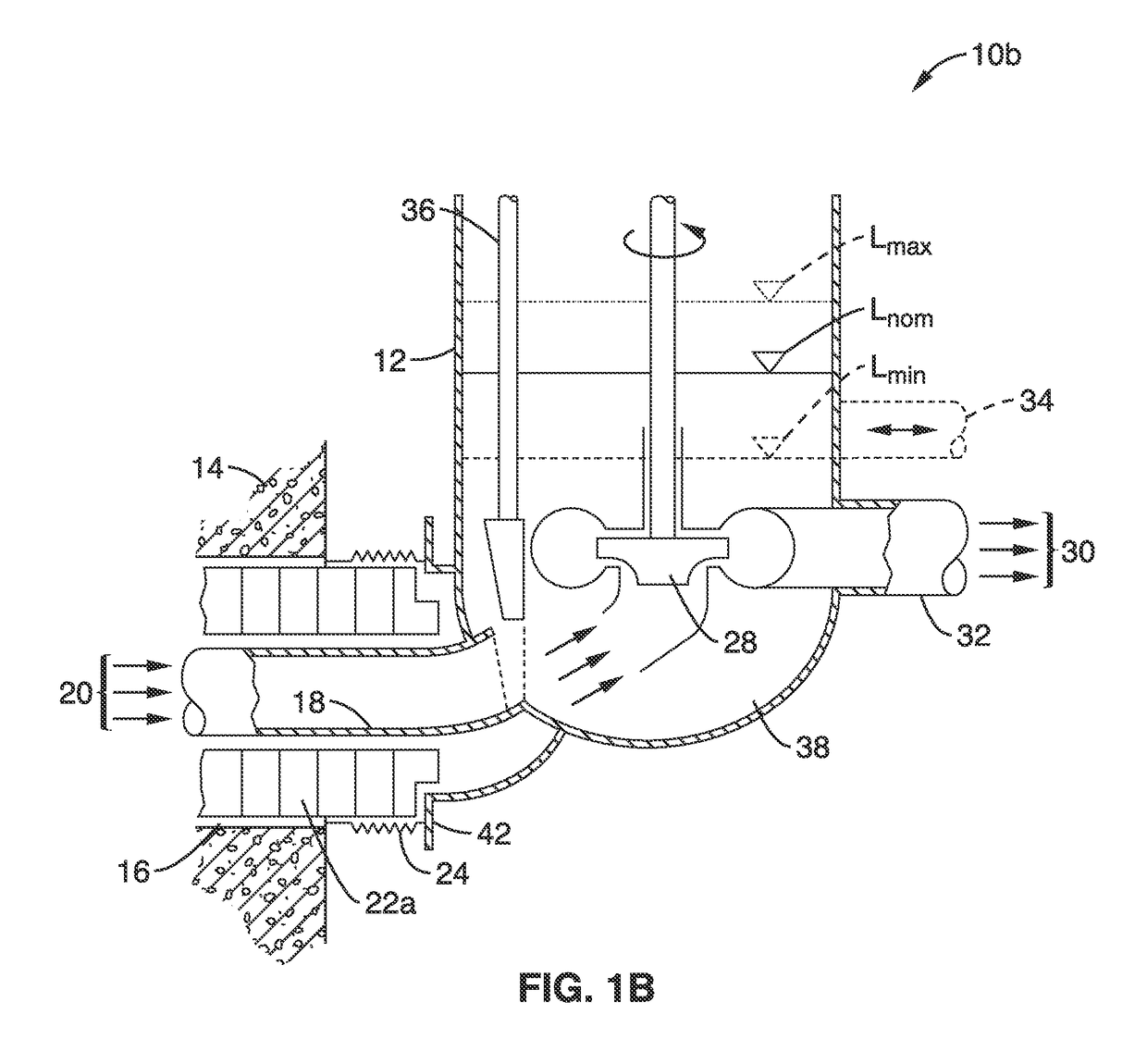

Perforating gun for oil and gas wells

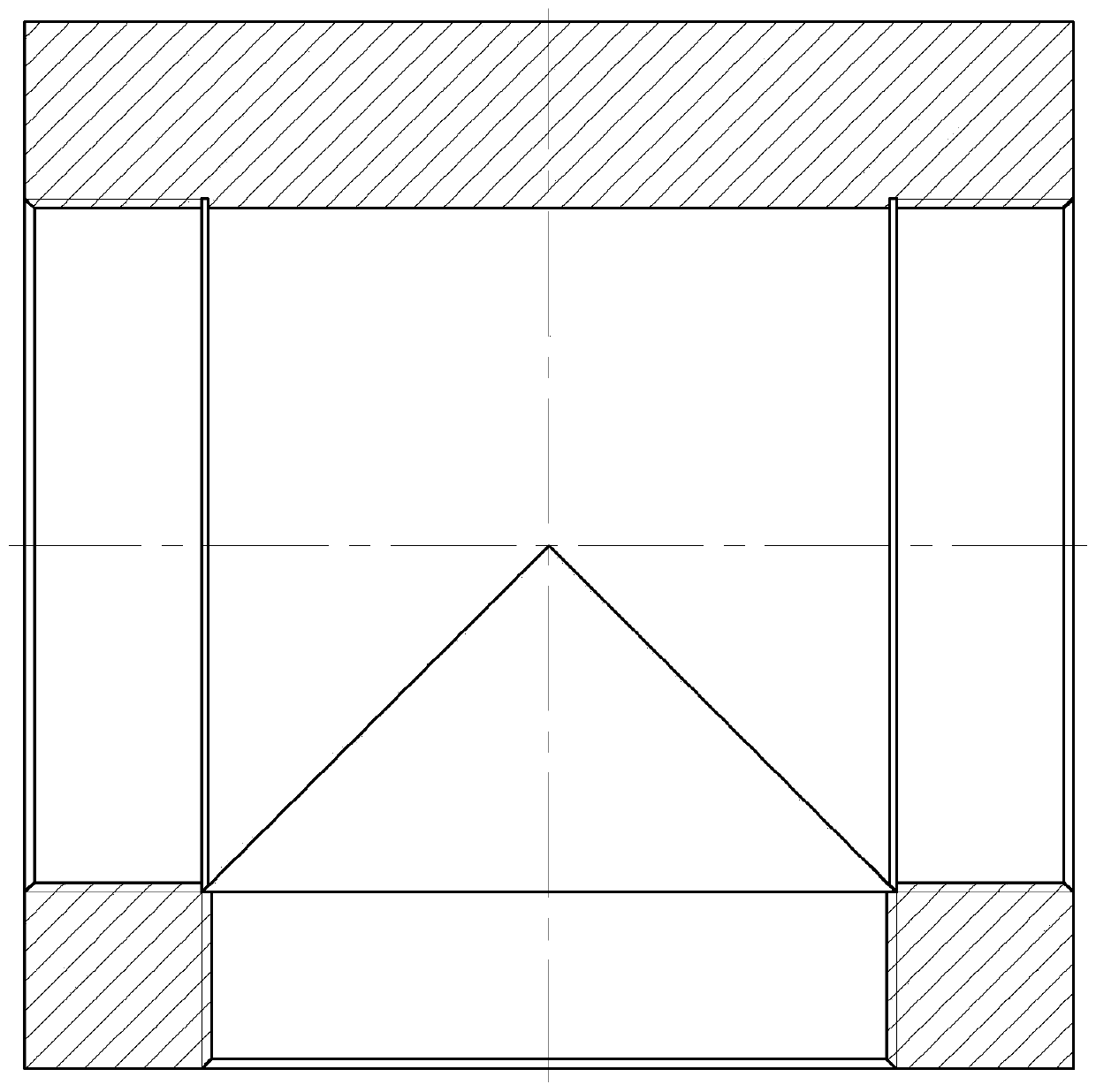

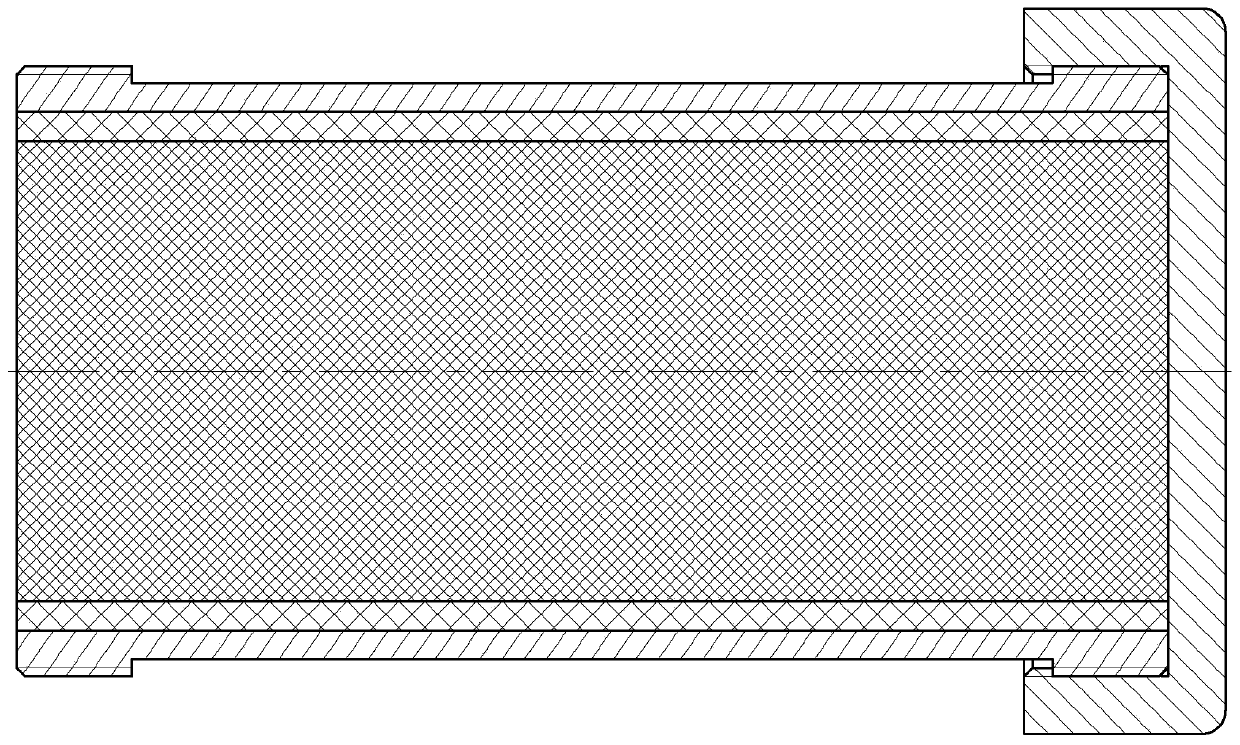

A perforating gun, perforating gun system, and method for producing the same is provided. The perforating gun includes a body and at least one cavity liner. The body has an axial length extending between a first axial end and a second axial end, and an outer radial surface extending between the first and second axial ends, an inner bore, and at least one shaped charge cavity disposed in the outer radial surface. The at least one shaped charge cavity is in fluid communication with the inner bore. The at least one cavity liner is disposed in the shaped charge cavity and is configured to retain an explosive material within the shaped charge cavity.

Owner:EXPRO NORTH SEA

Aerogels, calcined and crystalline articles and methods of making the same

Aerogel, calcined articles, and crystalline articles comprising ZrO2. Exemplary uses of the crystalline metal oxide articles include dental articles (e.g., restoratives, replacements, inlays, onlays, veneers, full and partial crowns, bridges, implants, implant abutments, copings, anterior fillings, posterior fillings, and cavity liner, and bridge frameworks) and orthodontic appliances (e.g., brackets, buccal tubes, cleats, and buttons).

Owner:3M INNOVATIVE PROPERTIES CO

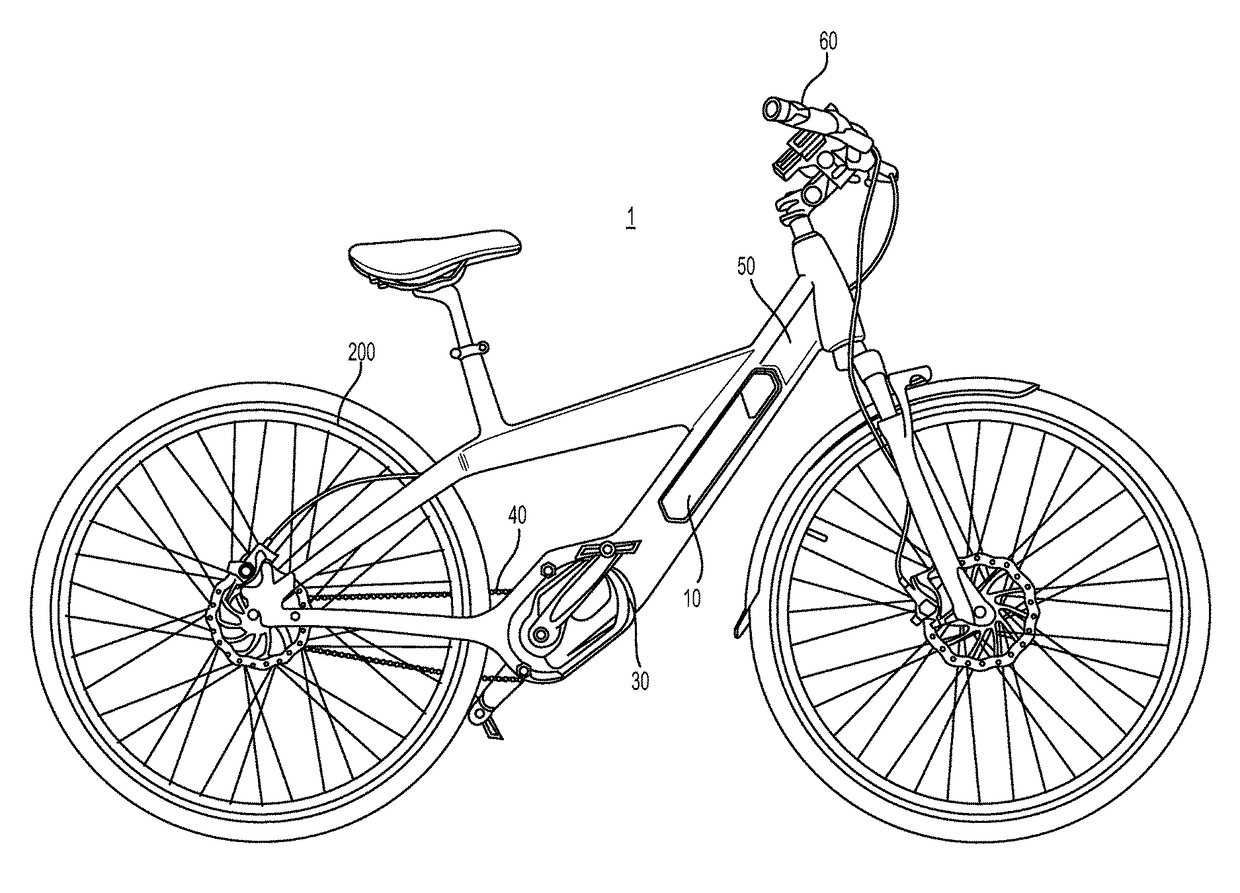

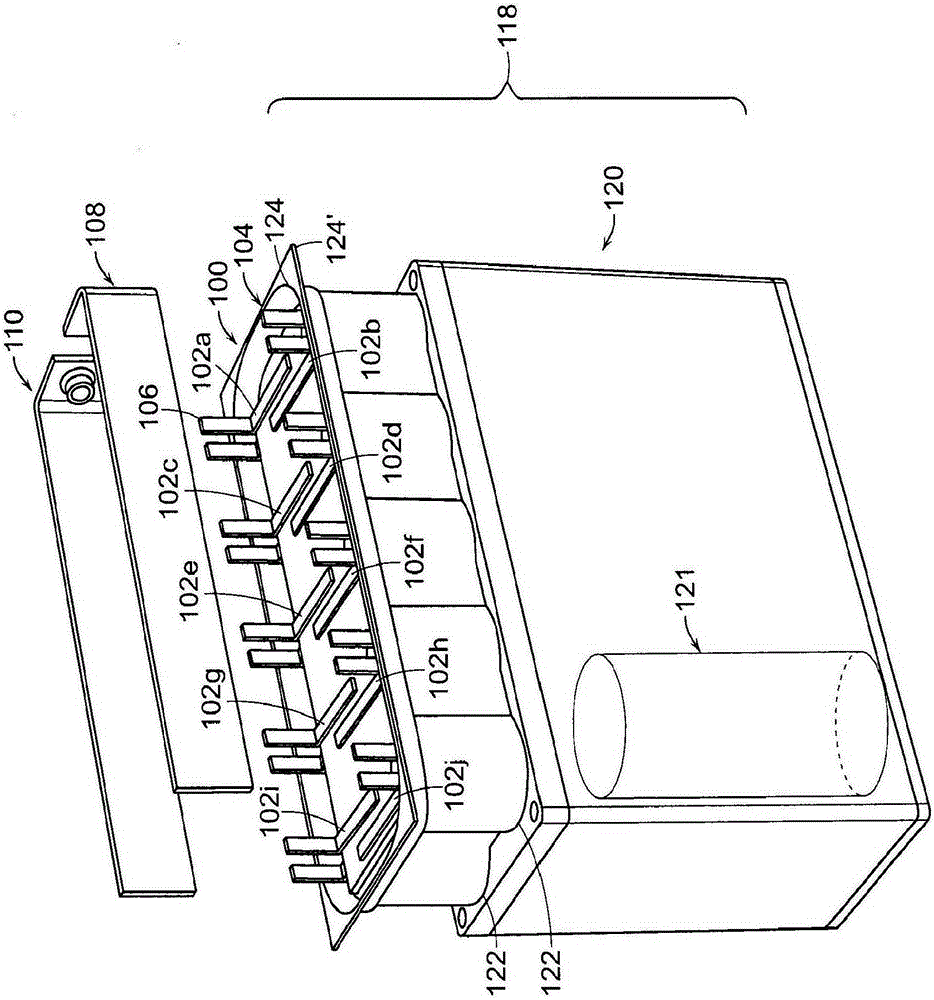

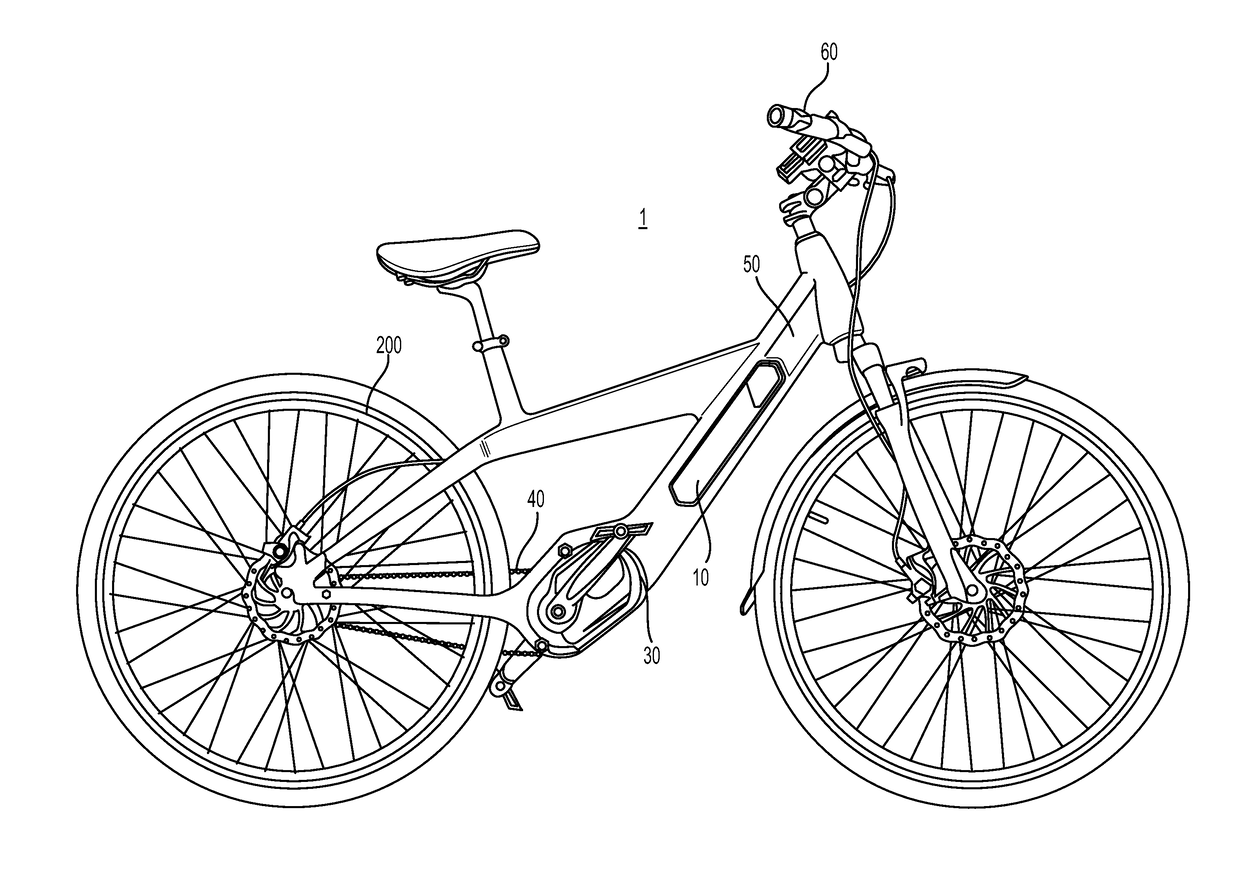

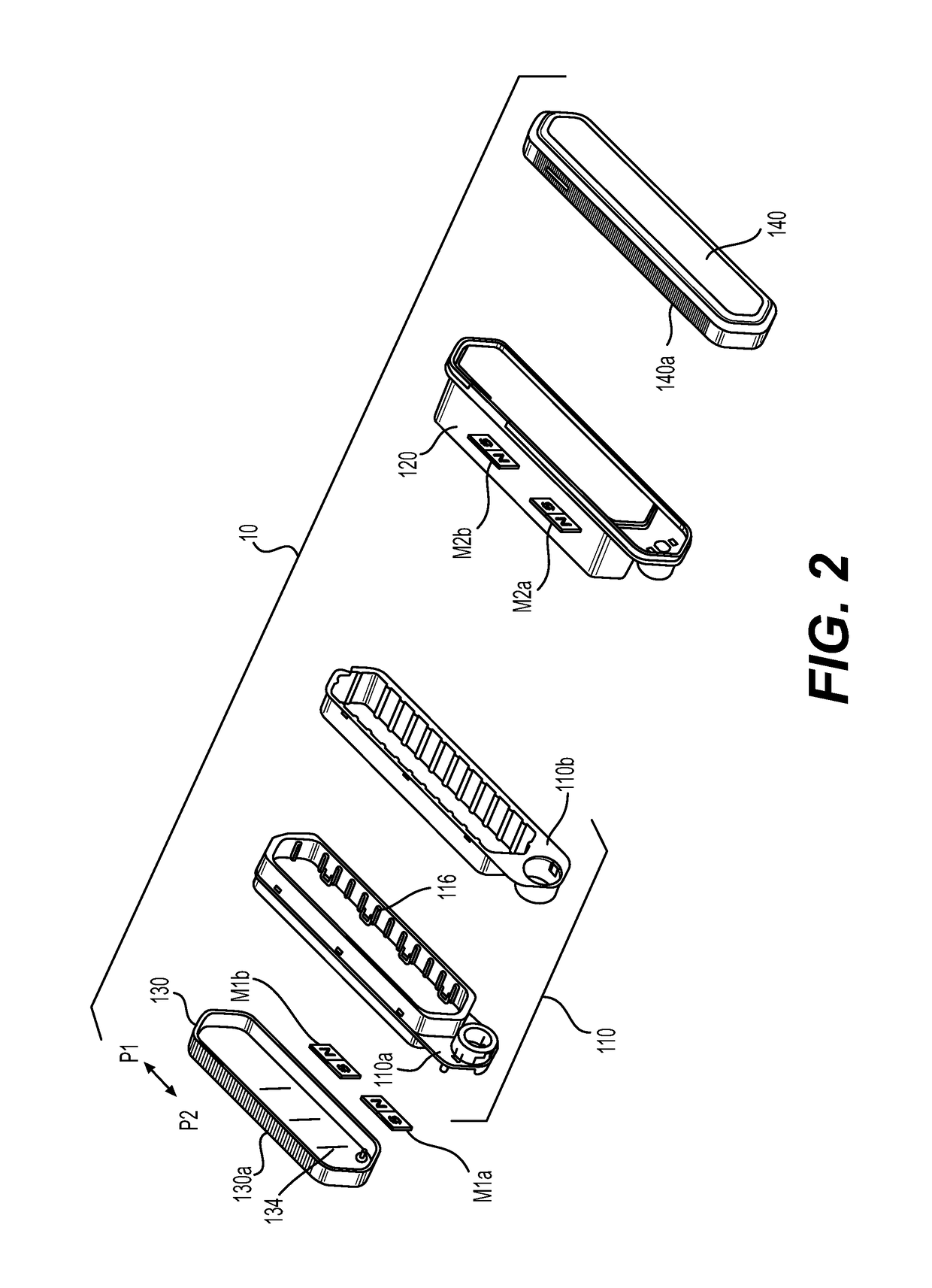

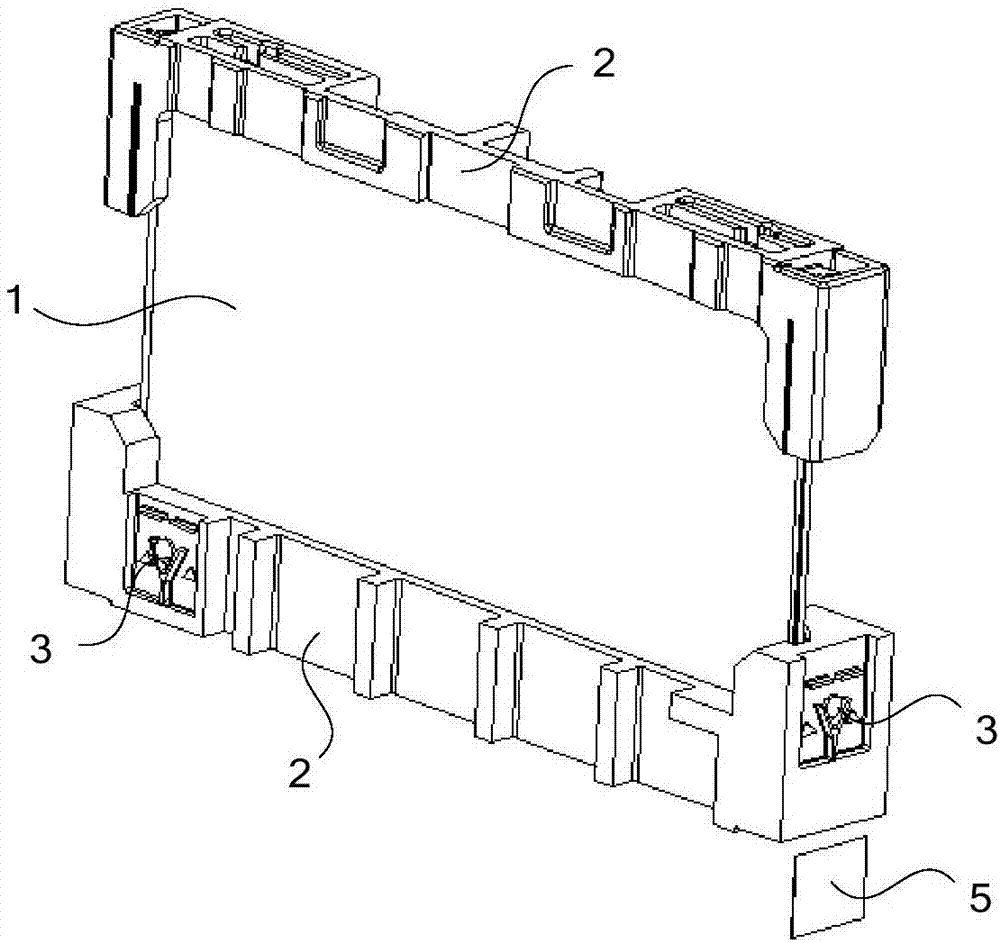

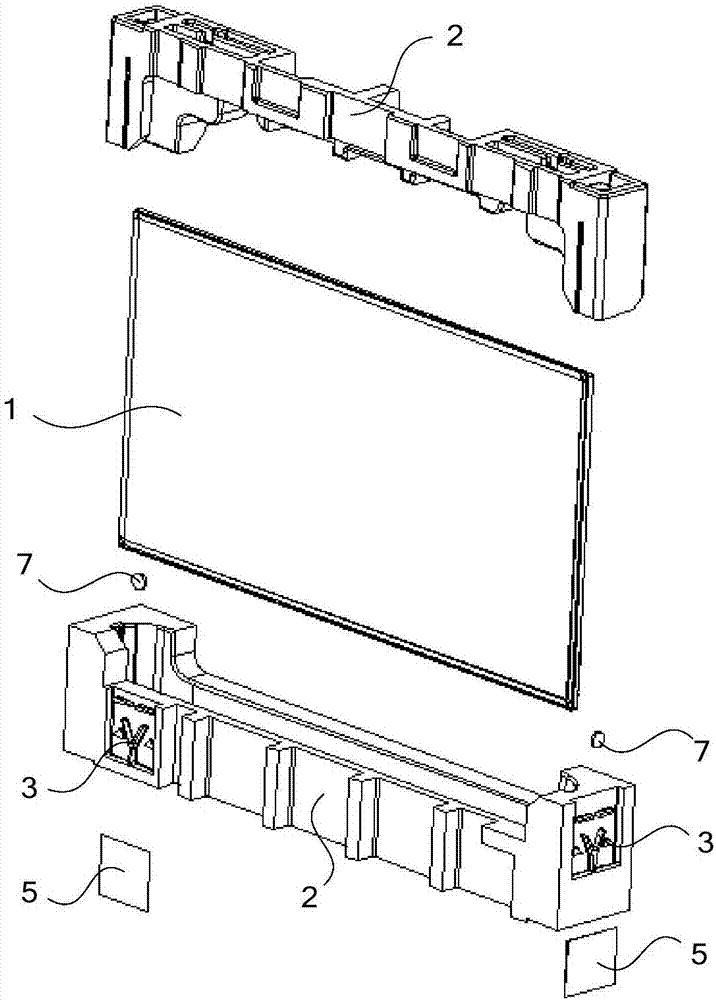

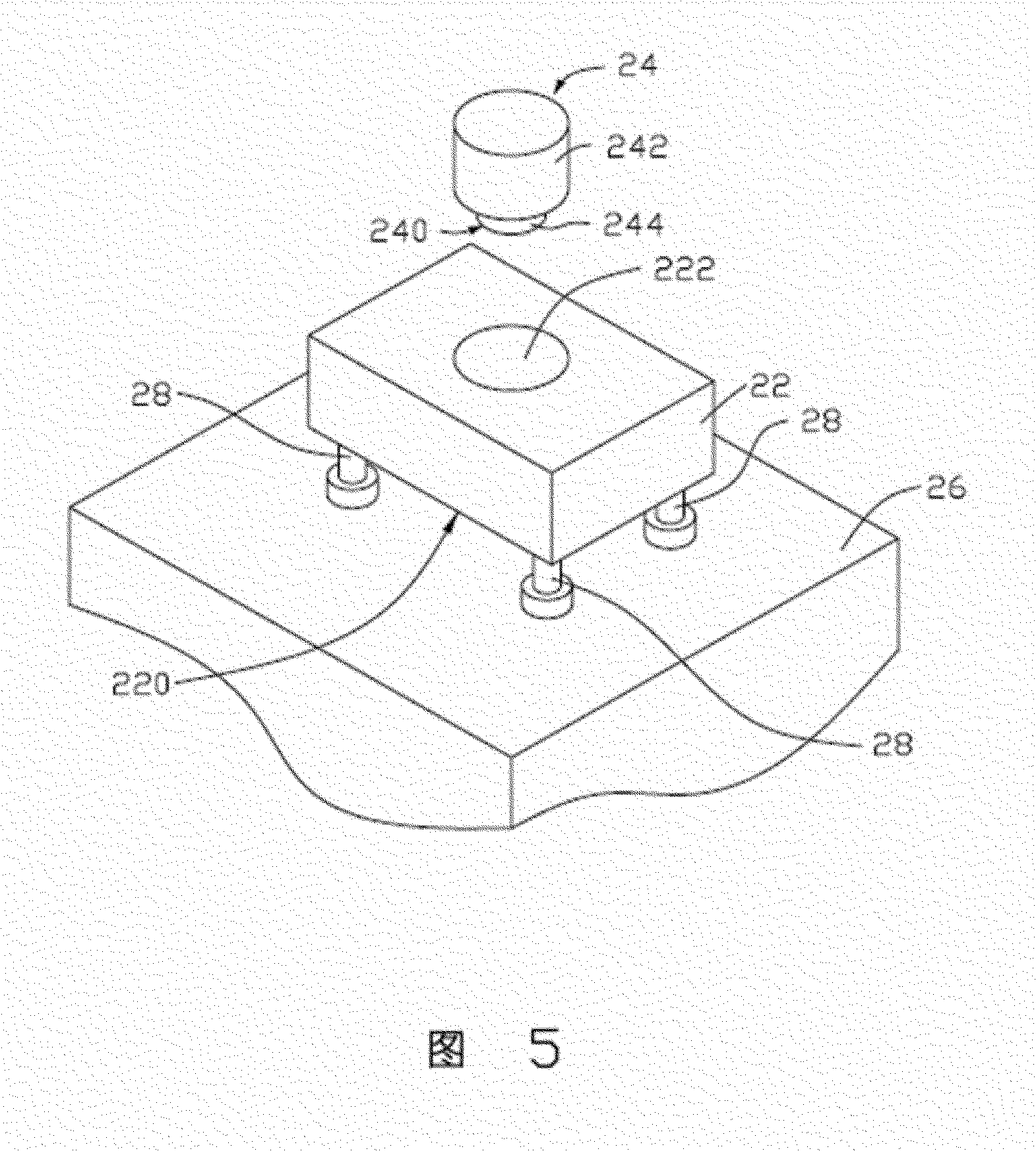

Battery container and bicycle using the same

A battery system assembly for a bicycle is provided. The battery system assembly includes a frame cavity liner, a first cover slideably attached to the frame cavity liner and movable between a first position and a second position with respect to the frame cavity liner, a first magnet interposed between the frame cavity liner and the first cover, a battery container configured to accommodate a rechargeable battery and having a second magnet disposed to face the first magnet, said battery container detachably attached to the frame cavity liner. When the first cover is located at the first position, the frame cavity liner and the battery container are attached one another by magnetic force between an aligned first magnet and second magnet. When the first cover is located at the second position, the first magnet and the second magnet repel each other, thereby detaching the battery container from the frame cavity liner.

Owner:FAR EAST ELECTRIC BICYCLE CO LTD

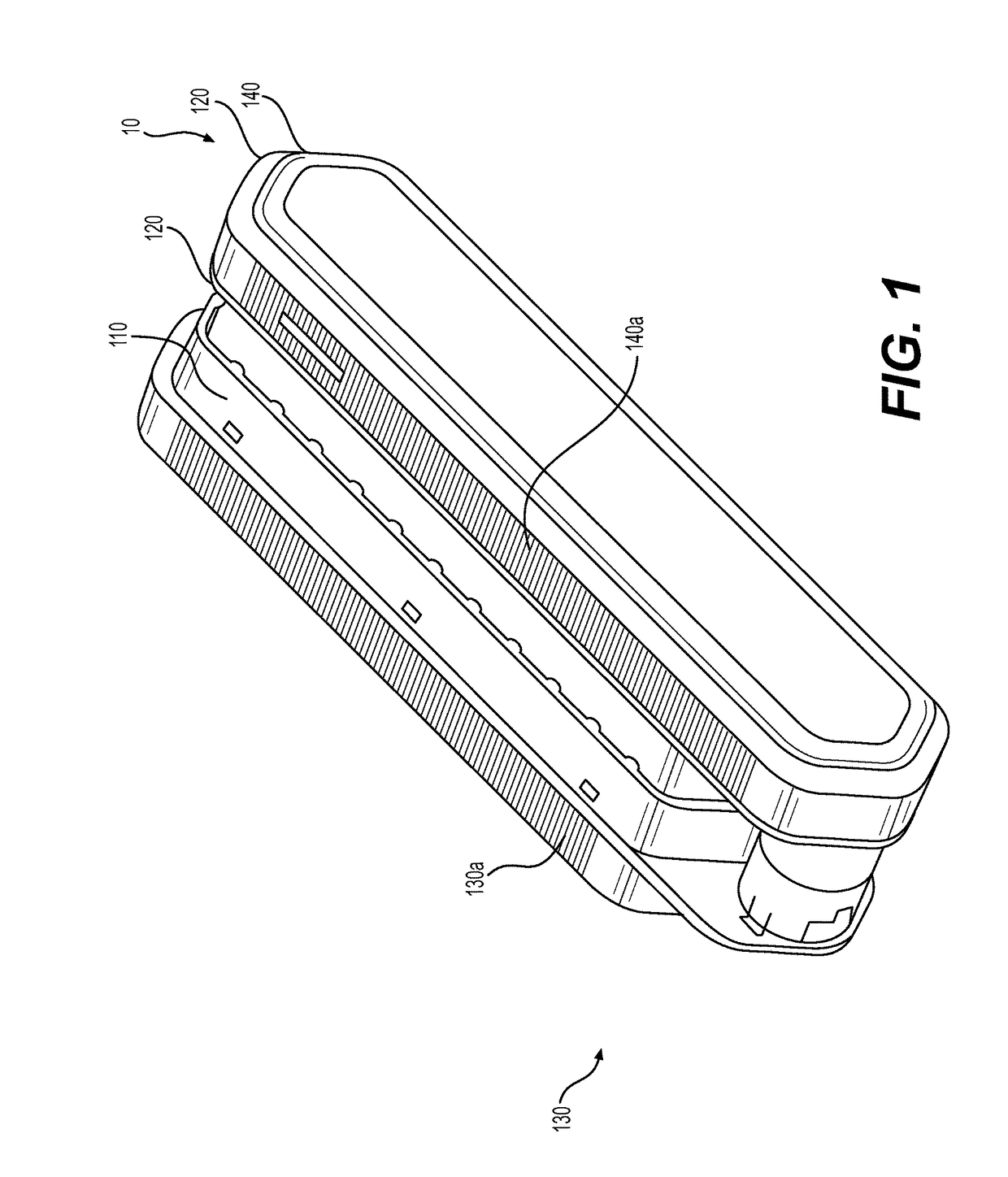

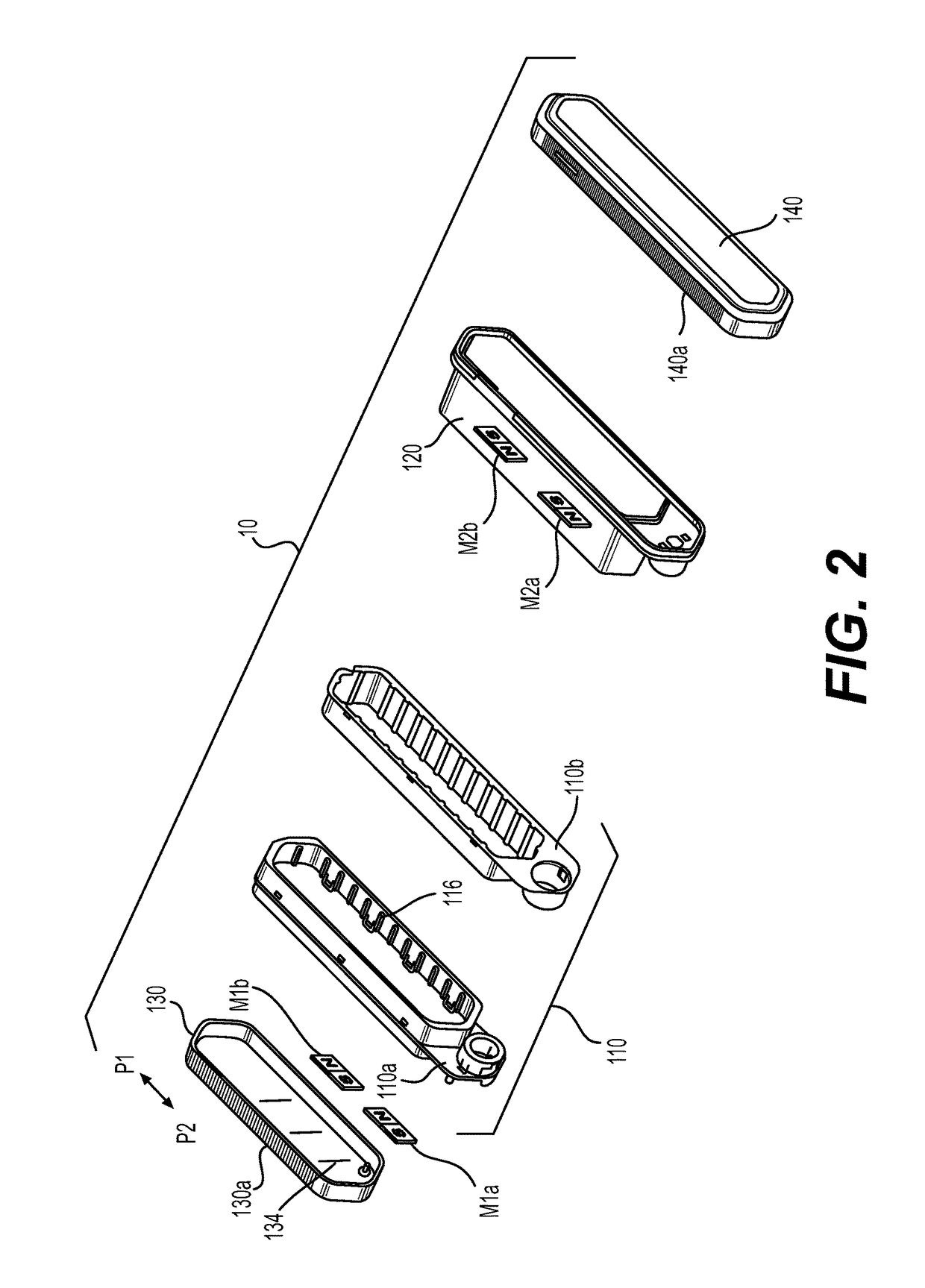

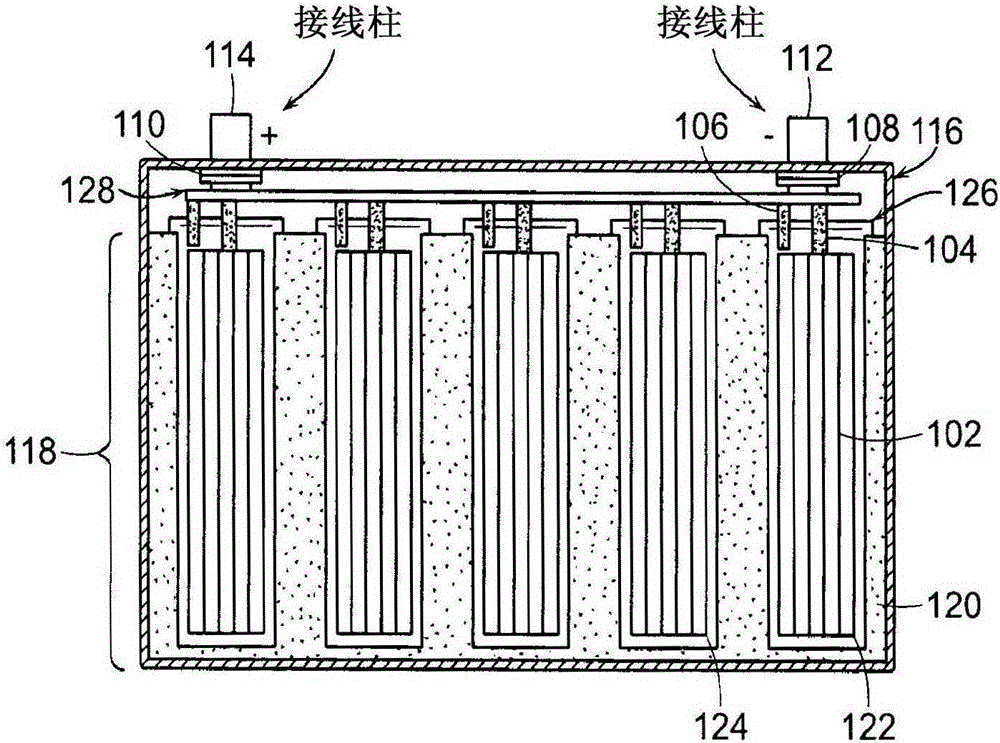

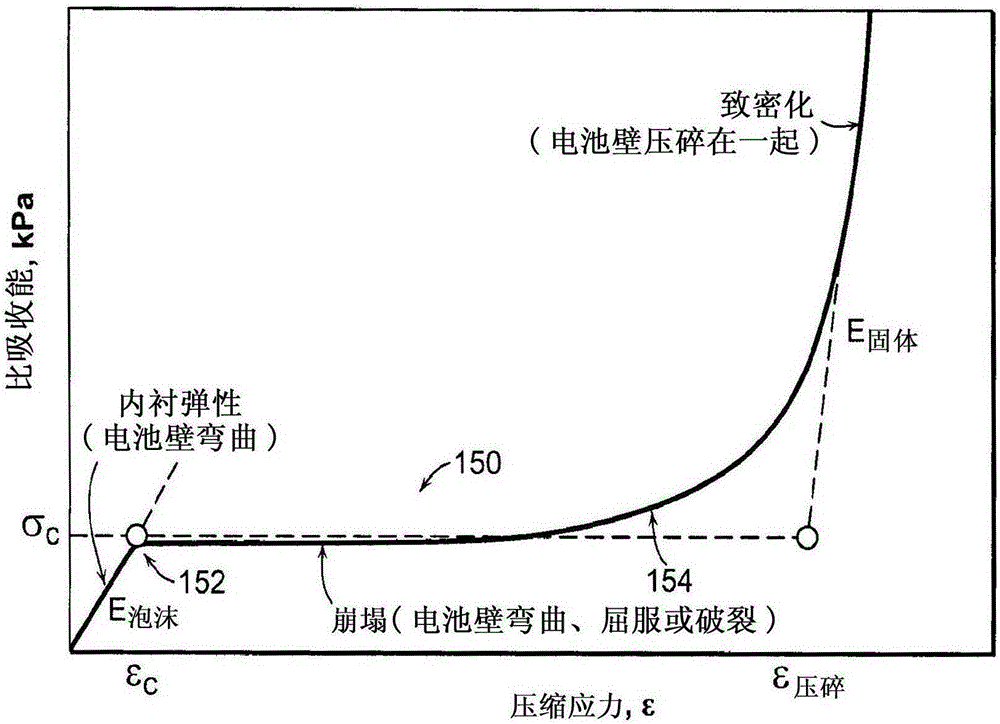

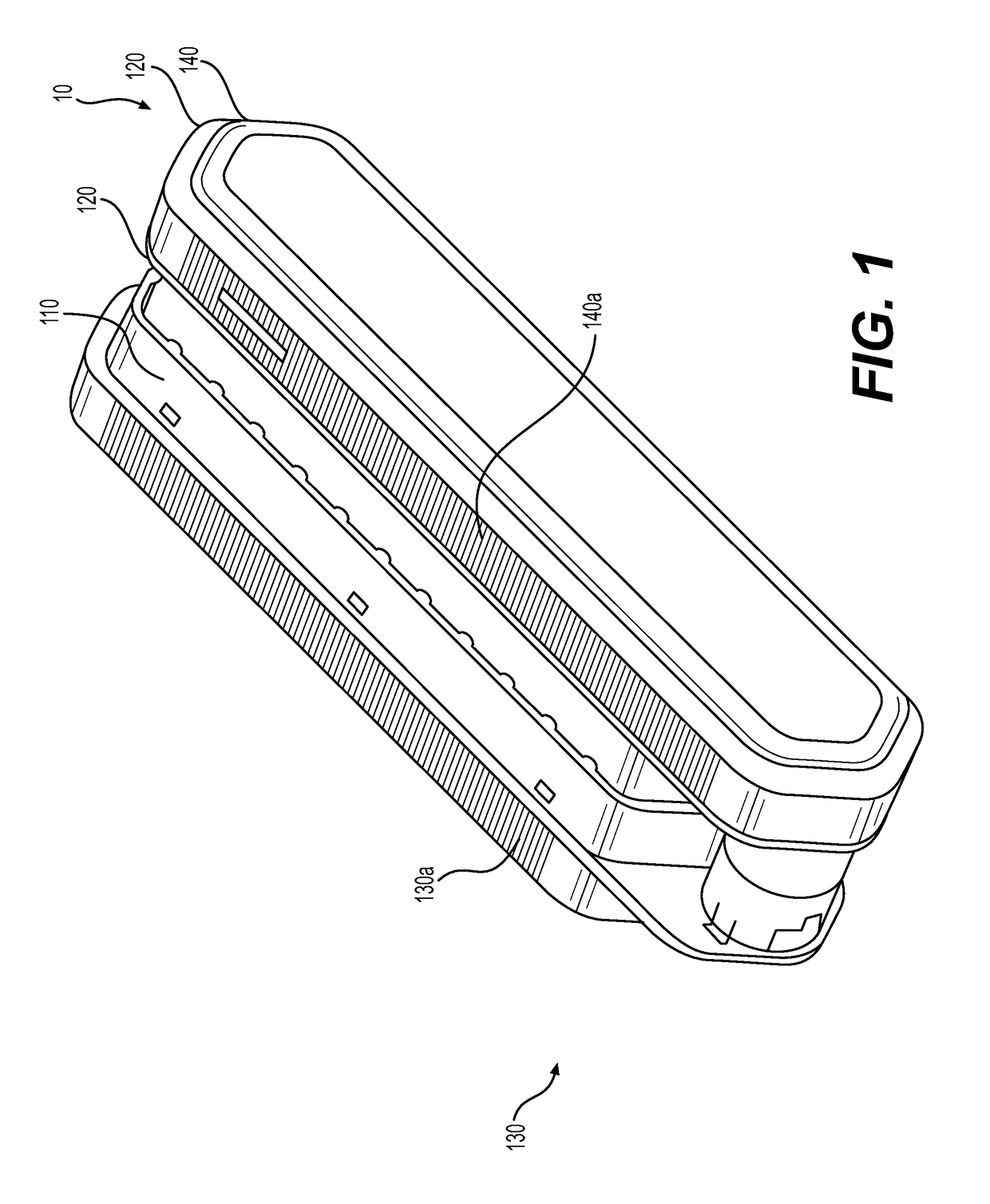

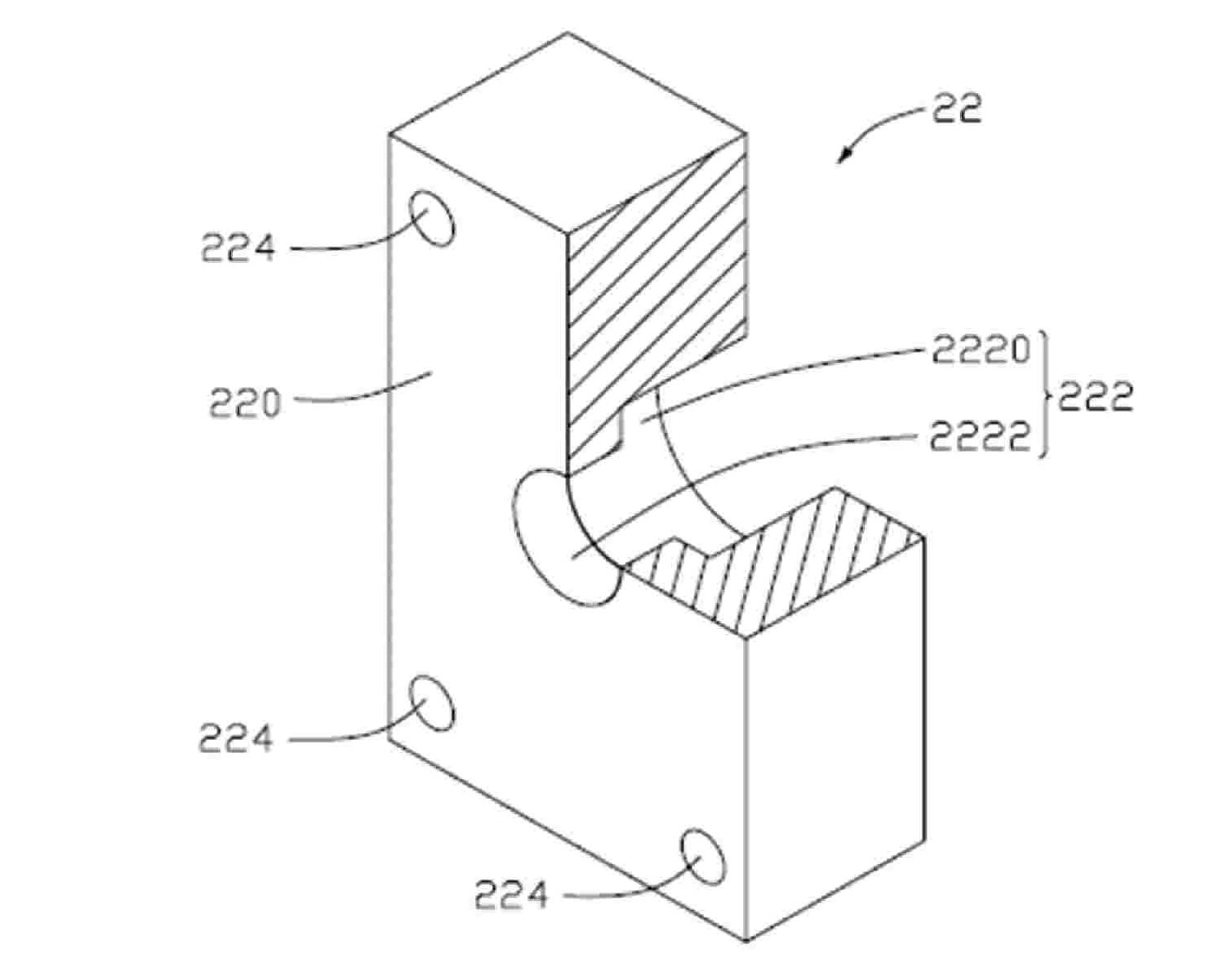

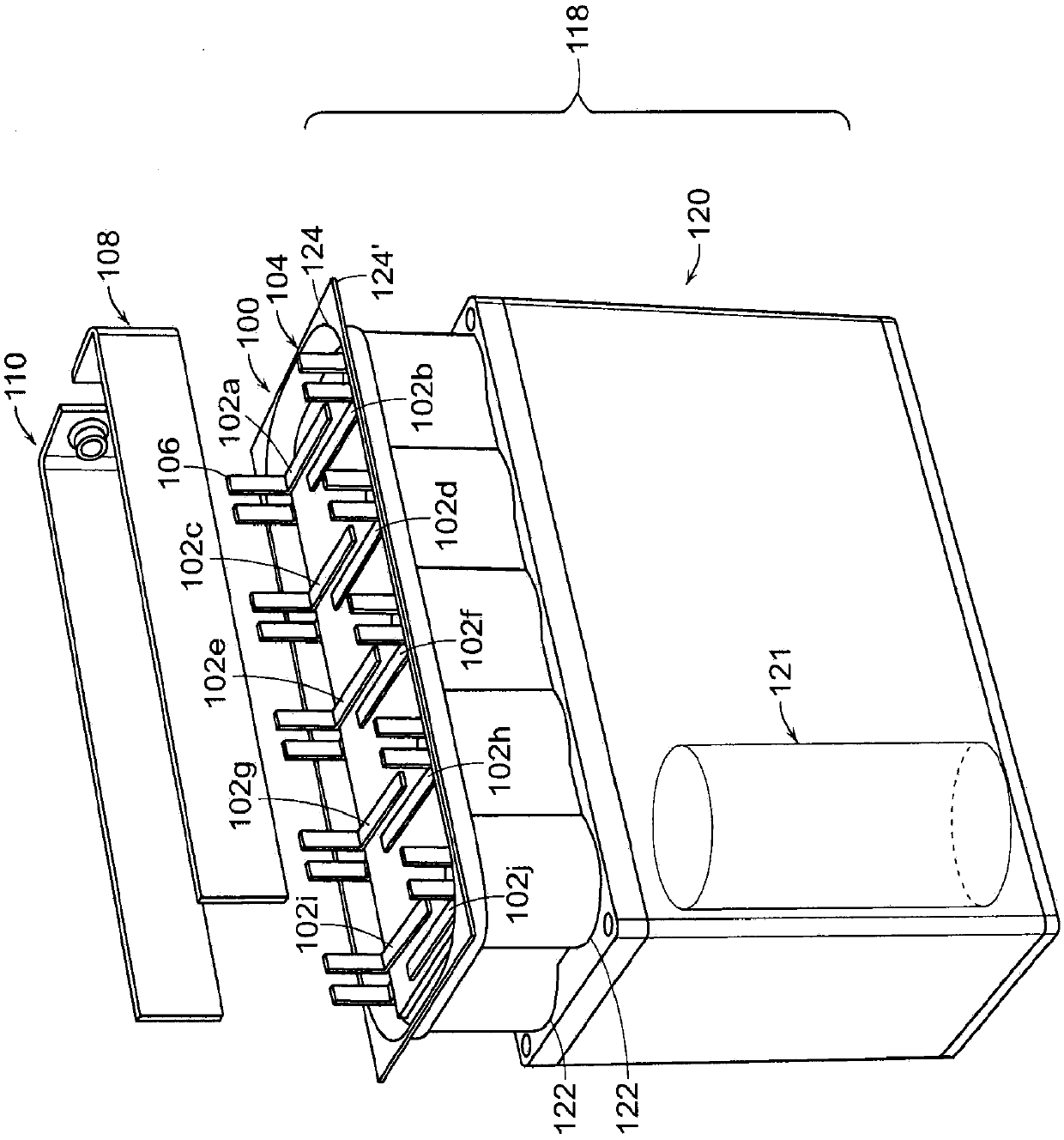

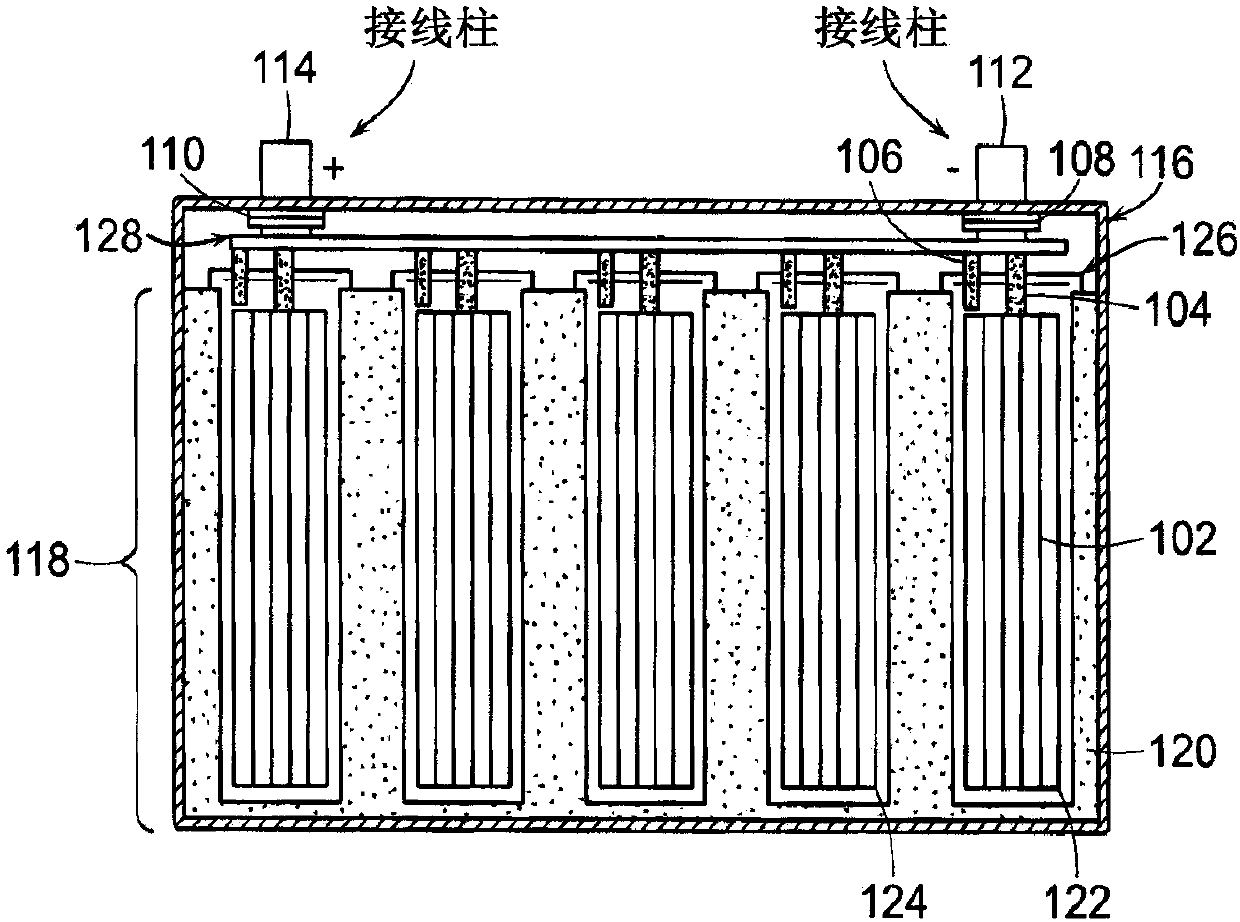

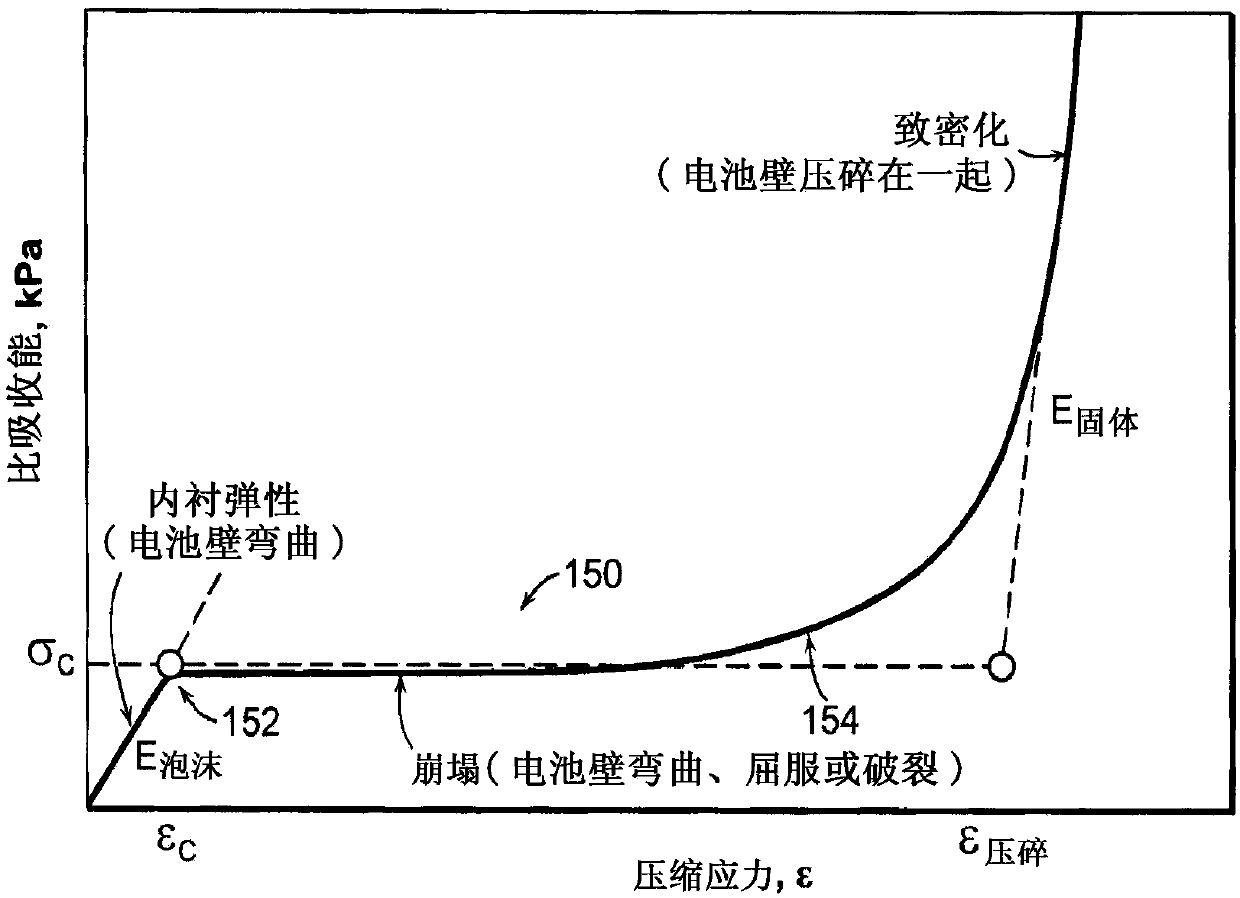

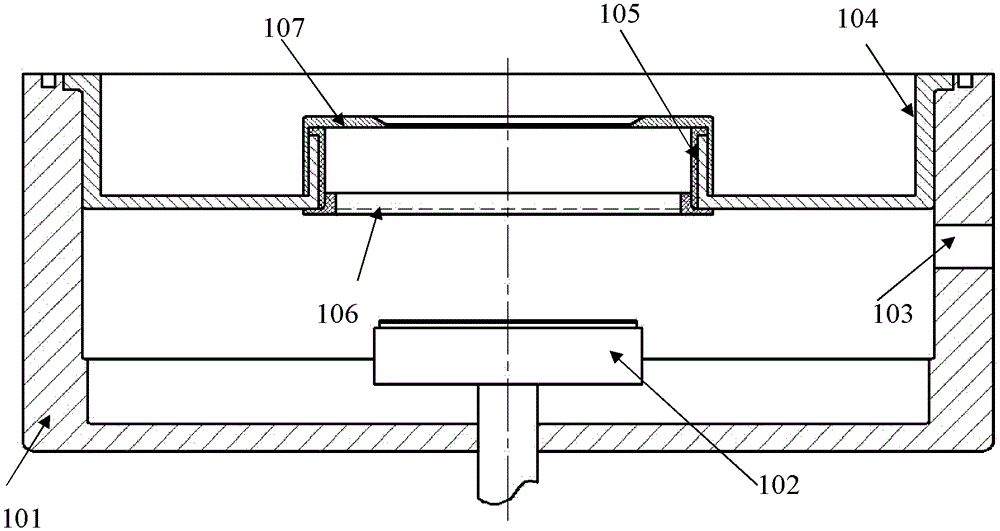

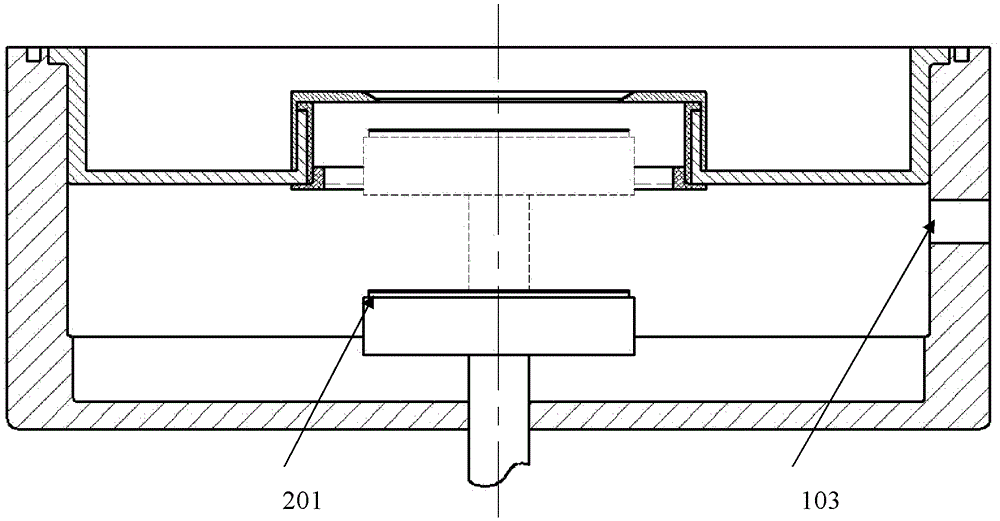

Lithium ion battery

A multi-core lithium ion battery (100) includes a sealed enclosure (116) and a support member (120) disposed within the sealed enclosure (116). The support member (120) includes a plurality of cavities and a plurality of lithium ion core members (102) which are disposed within the plurality of cavities. The battery further includes a plurality of cavity liners (124), each of which is positioned between a corresponding one of the lithium ion core members (102) and a surface of a corresponding one of the cavities.

Owner:CADENZA INNOVATION INC

Remineralizing dental cements

ActiveUS7619016B2Counteract deleterious effectPromote remineralizationCosmetic preparationsImpression capsPhosphate ionCavity Liner

Remineralizing dental cements contain source(s) of calcium and phosphate ions, adhesive resin monomers, reinforcing base resin monomers, and catalysts able to initiate the polymerization of the adhesive and reinforcing base resin monomers. Such dental cements can be used as orthodontic cements, crown and bridge cements, adhesives, sealants, cavity liners, and protective coatings. The release of calcium and phosphate ions and, optionally, fluoride ions, protects tooth structure from demineralization, a precursor of tooth decay.

Owner:ADA FOUND

Battery container and bicycle using the same

A battery system assembly for a bicycle is provided. The battery system assembly includes a frame cavity liner, a first cover slideably attached to the frame cavity liner and movable between a first position and a second position with respect to the frame cavity liner, a first magnet interposed between the frame cavity liner and the first cover, a battery container configured to accommodate a rechargeable battery and having a second magnet disposed to face the first magnet, said battery container detachably attached to the frame cavity liner. When the first cover is located at the first position, the frame cavity liner and the battery container are attached one another by magnetic force between an aligned first magnet and second magnet. When the first cover is located at the second position, the first magnet and the second magnet repel each other, thereby detaching the battery container from the frame cavity liner.

Owner:FAR EAST ELECTRIC BICYCLE CO LTD

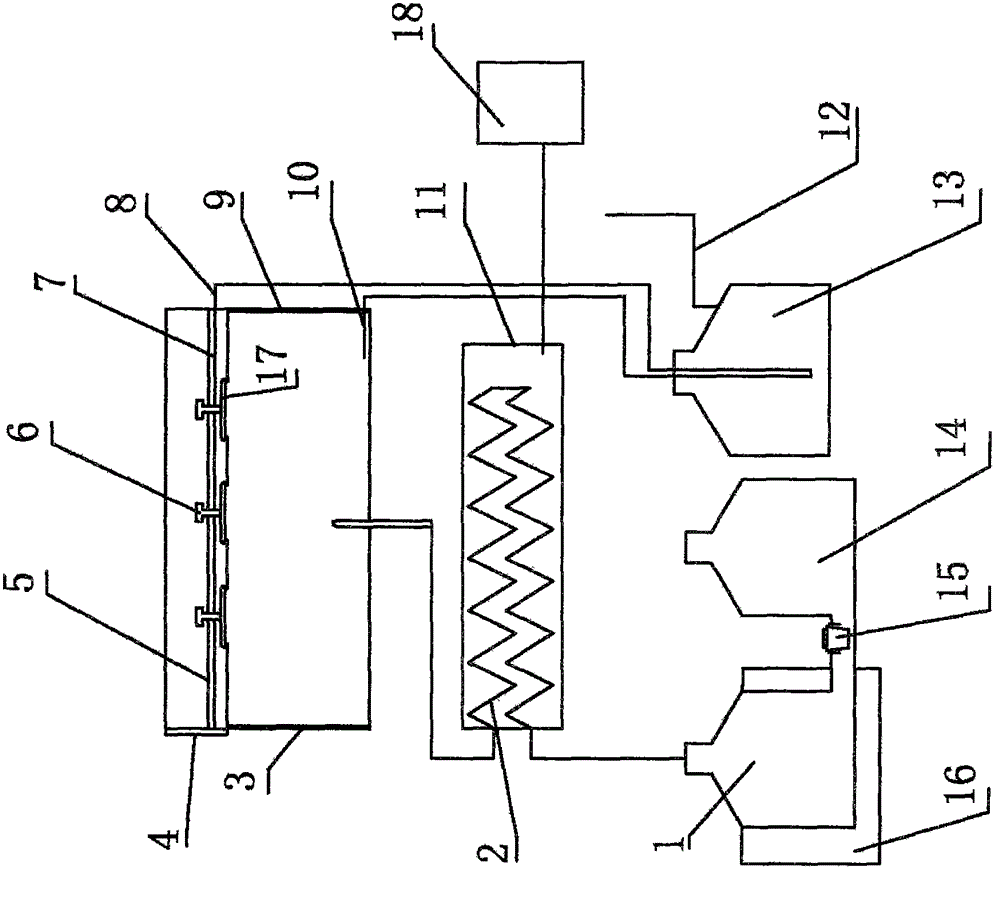

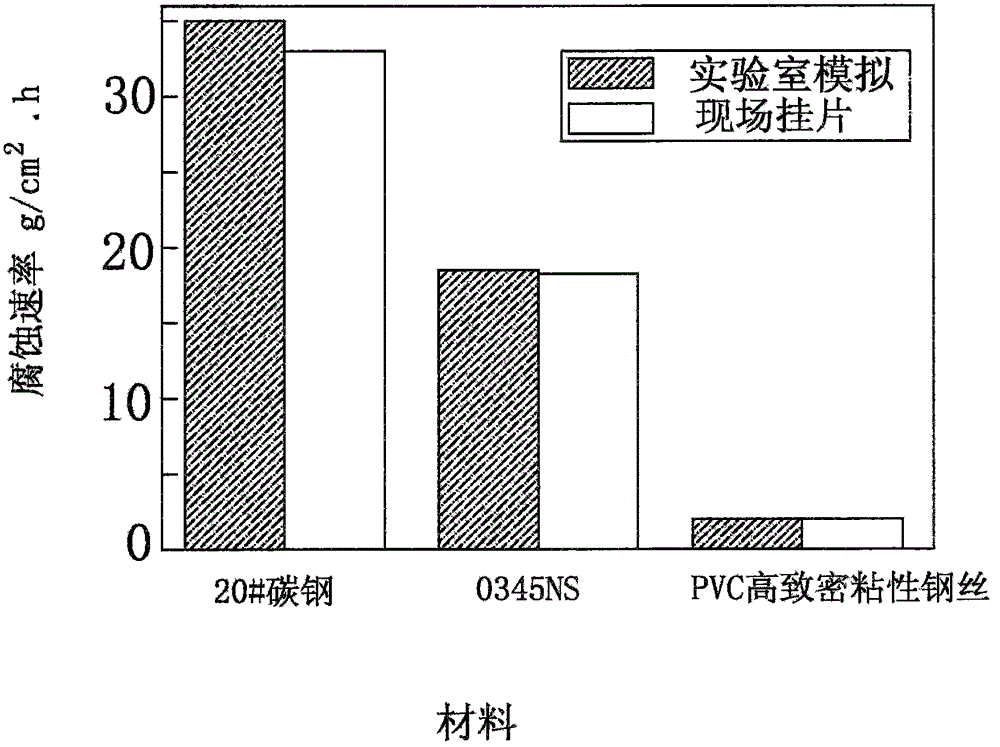

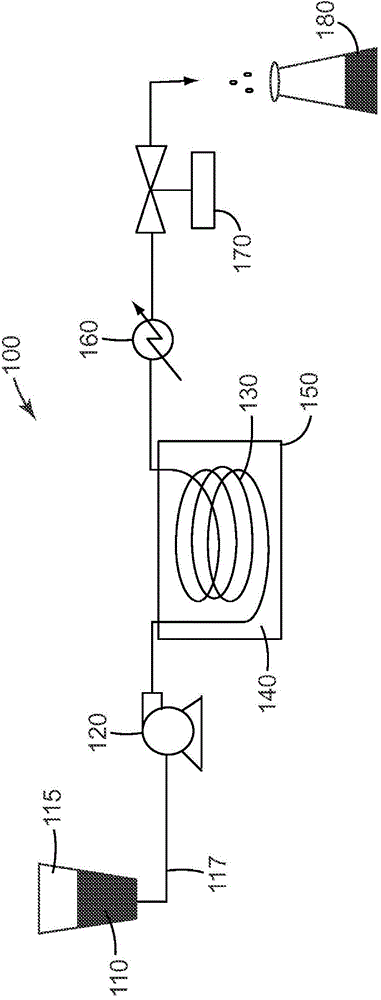

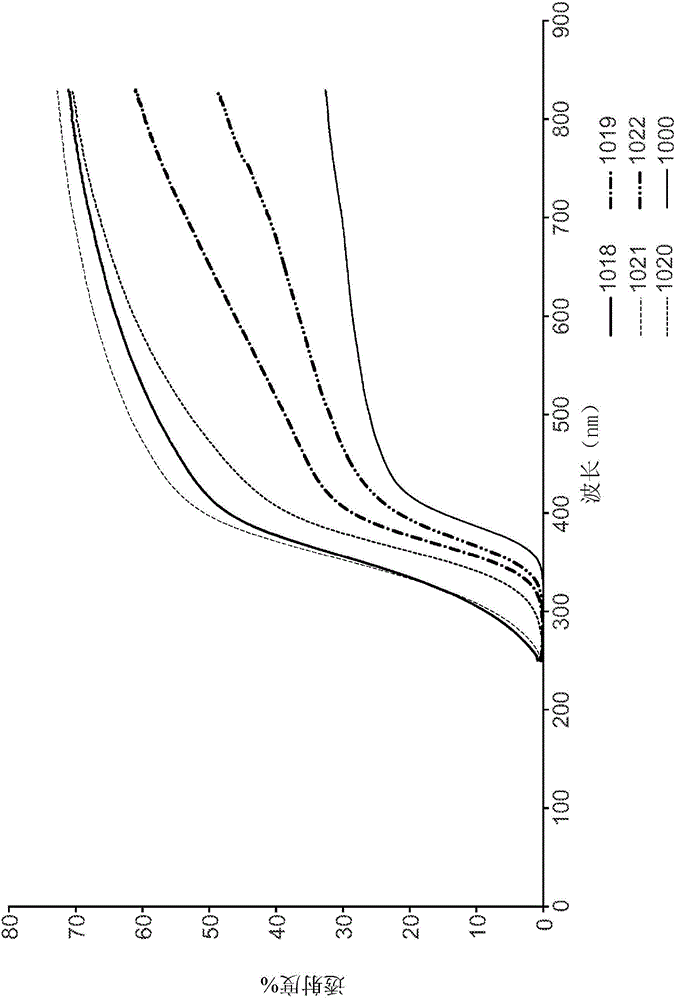

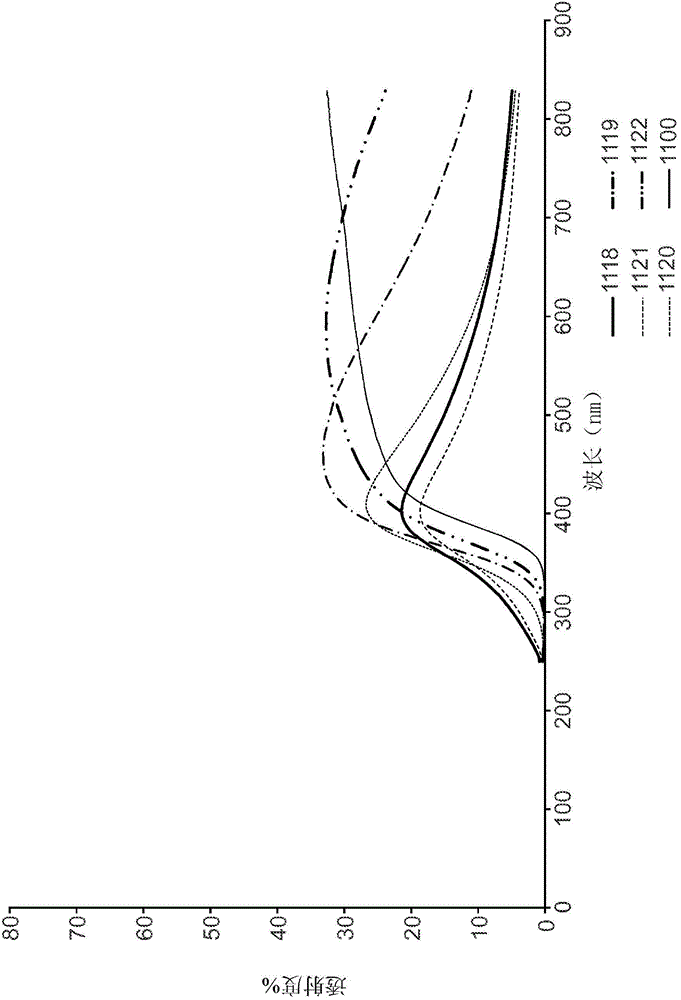

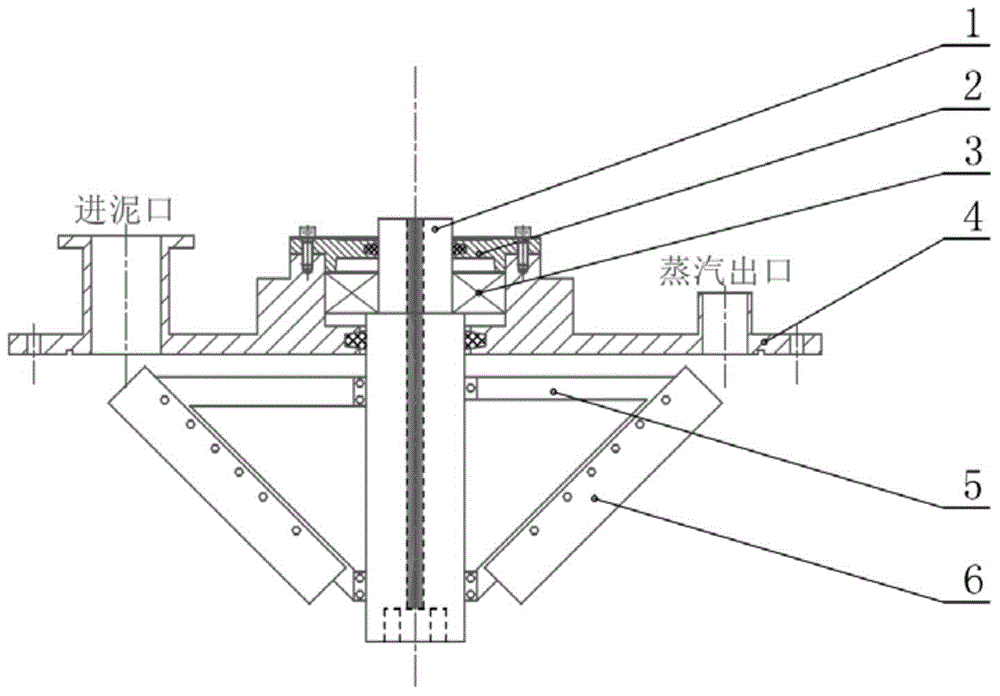

Corrosion depth test method for PVC highly-dense viscous steel wire grid

InactiveCN106290122AAdjustable temperatureThe evaluation results are accurate and reliableWeather/light/corrosion resistanceElectricityWire grid

The invention relates to a corrosion depth test method for a PVC highly-dense viscous steel wire grid. The method includes the steps that firstly, a sample to be tested is installed at the top of a test cavity liner and fixed through fixing bolts, a sulfuric acid solution is put into an evaporator and a liquid storage tank, a valve is switched on, an electric heater is started to heat the evaporator, liquid in the evaporator boils and then generates corrosive gas, the generated corrosive gas enters a test cavity through finned heat exchange tubes arranged in a steam heater, redundant corrosive gas in the test cavity enters a recovery device through an air outlet, and liquid condensed on the test cavity liner enters the recovery device through a liquid discharge port, wherein the controlled temperature of the electric heater is 100-150 DEG C, the controlled temperature of the steam heater is 80-160 DEG C, and a calcium hydroxide solution with the mass concentration of 10% is used for treating waste liquid and tail gas. The method provides a fast, simple and convenient test means for studying the corrosion mechanisms of various steel wire grids and evaluating corrosion-resistant steel wire grid materials.

Owner:无锡金利达生态科技股份有限公司

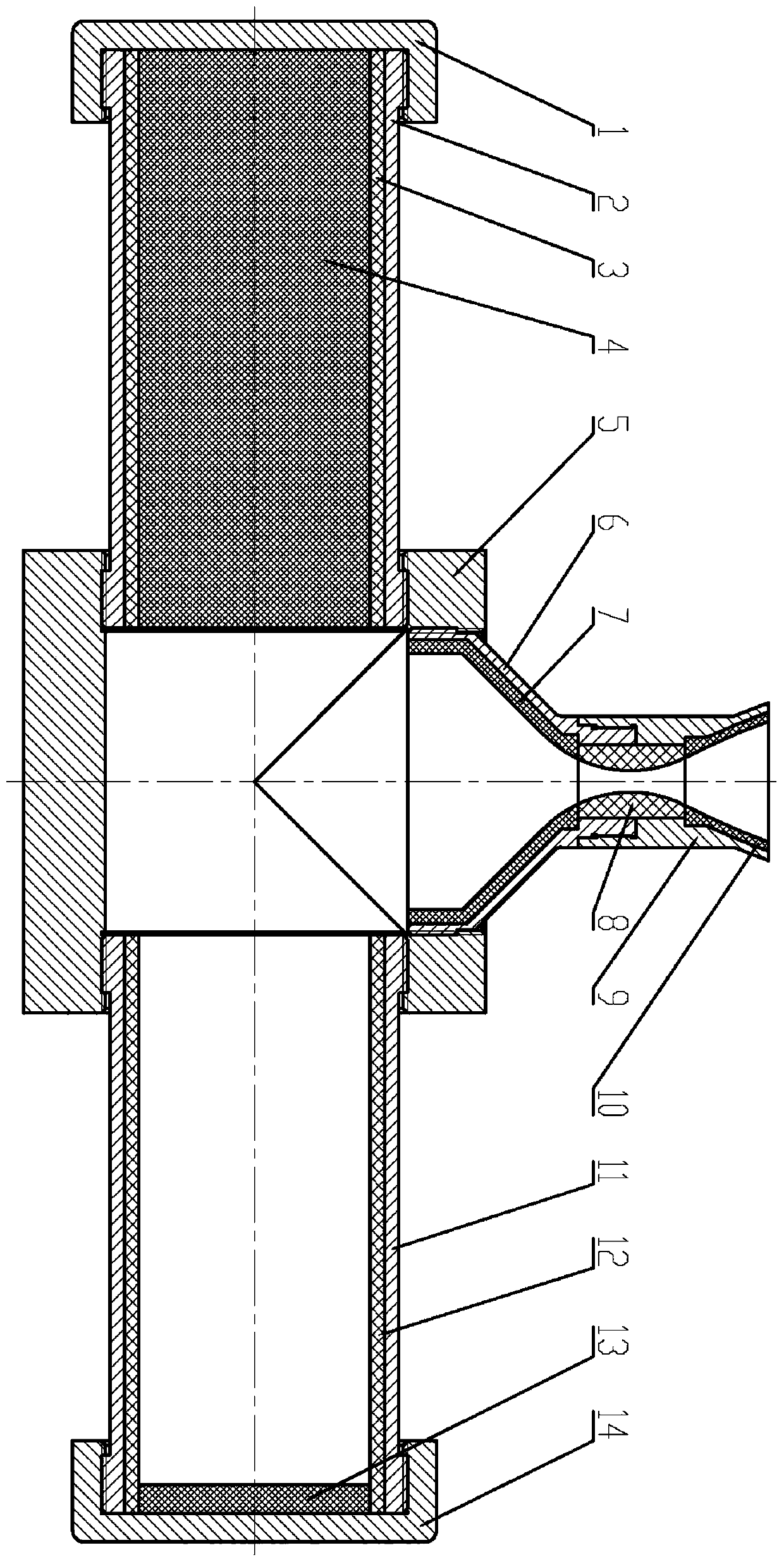

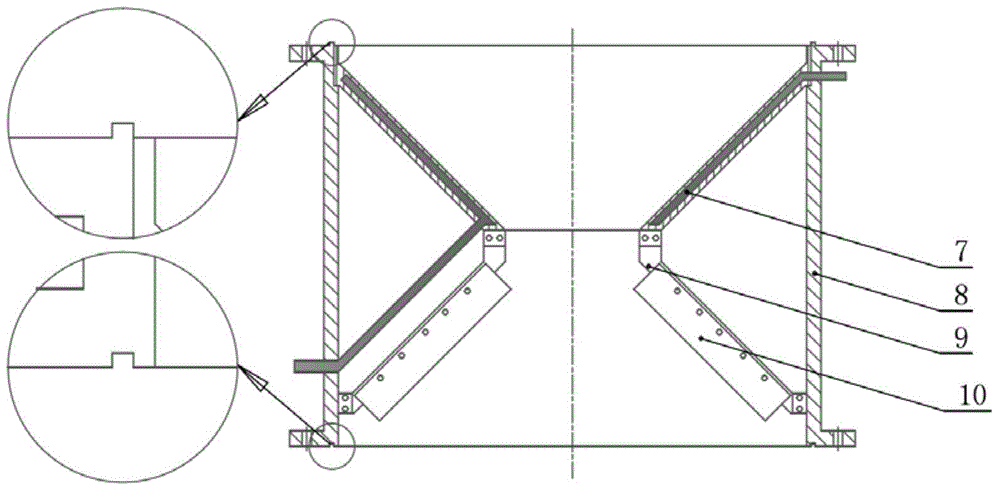

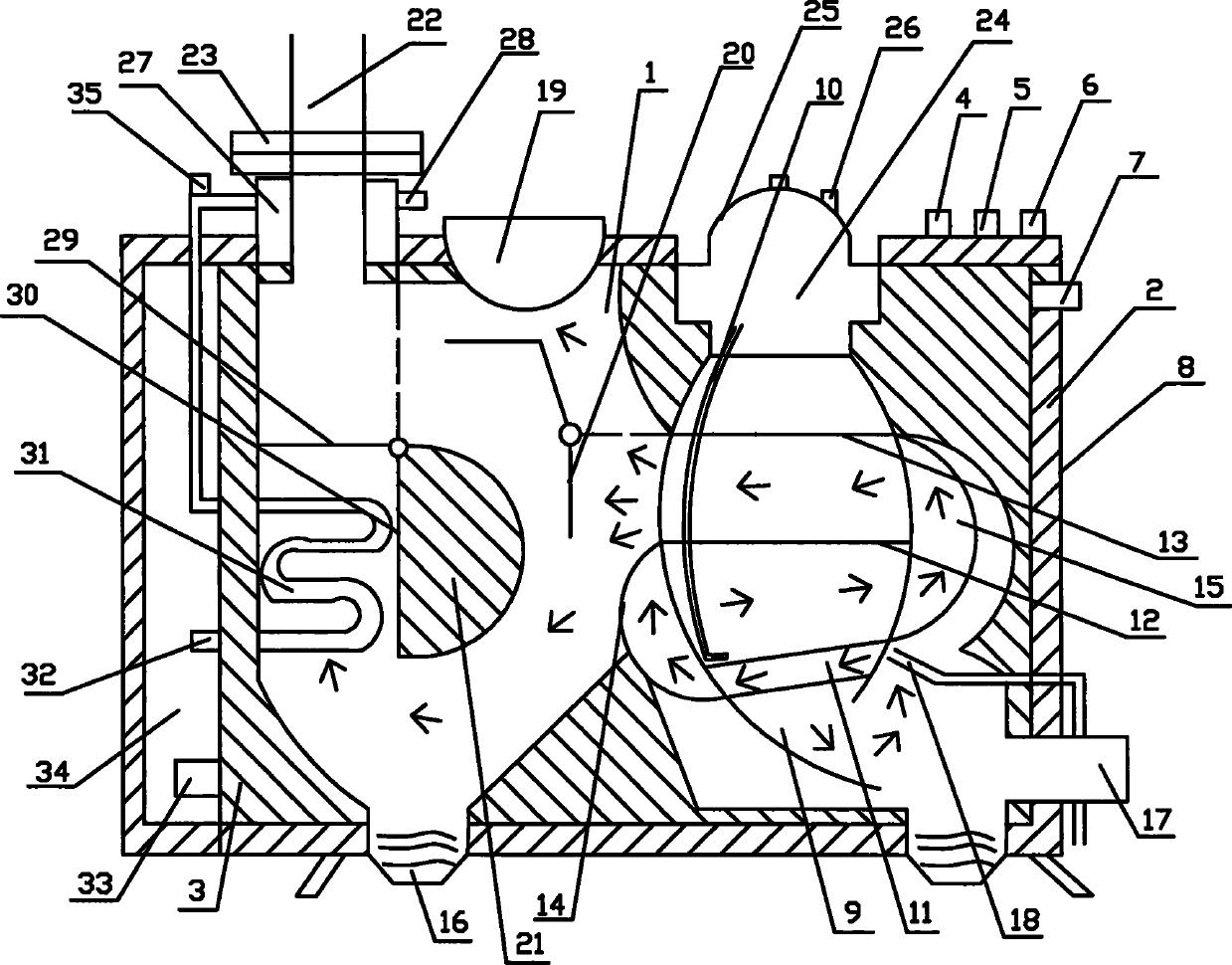

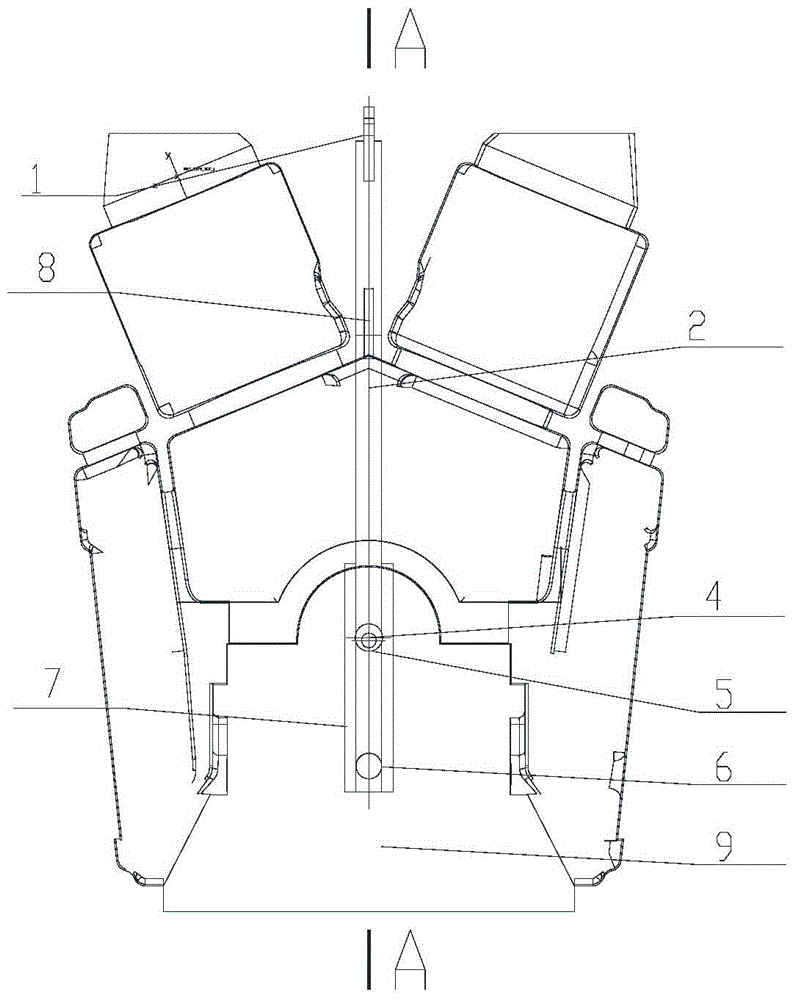

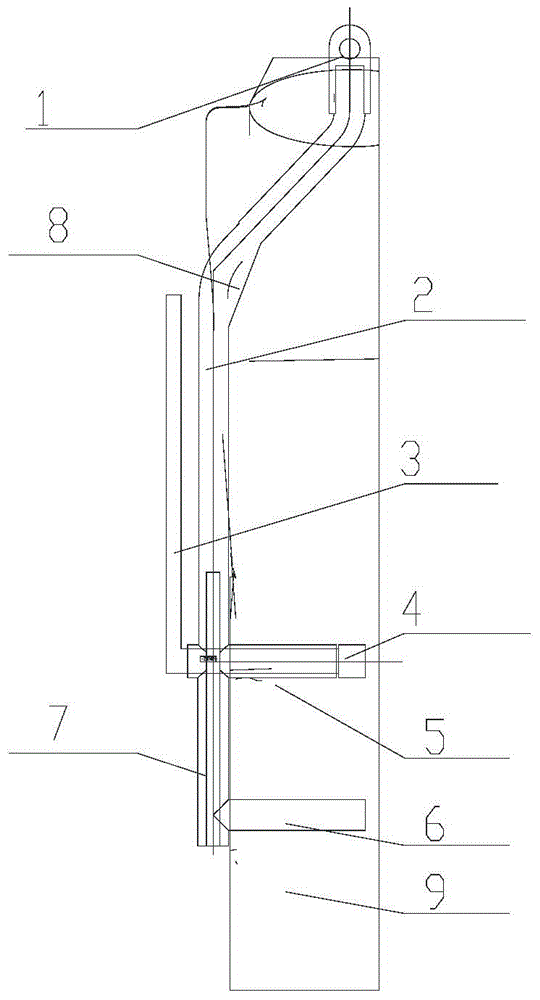

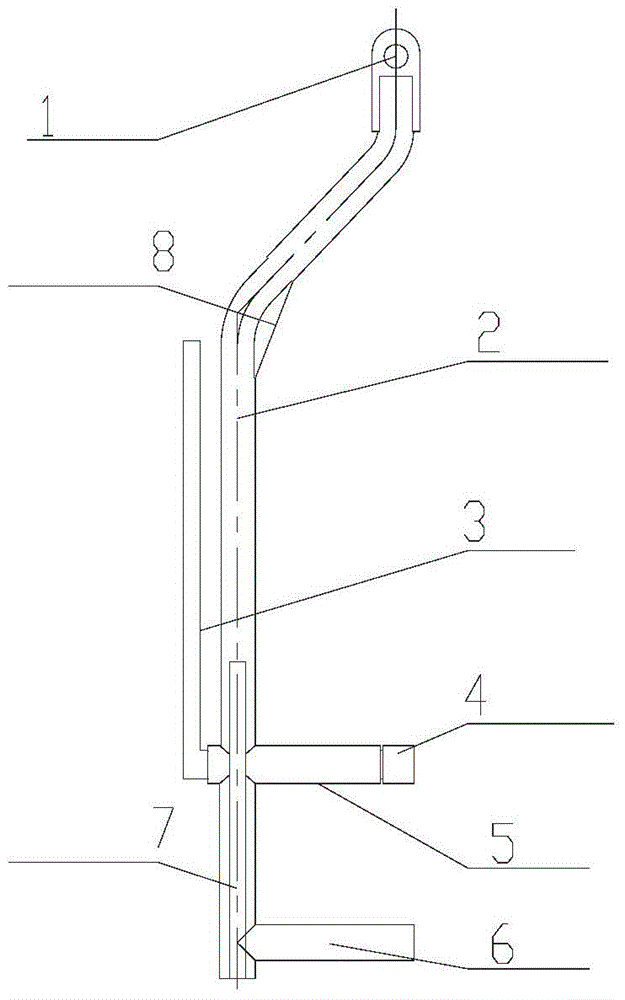

Dual-pulse solid rocket engine soft interlayer ablation test device

ActiveCN110425058ANo accelerationReal-time monitoring of flow fieldRocket engine plantsThroatCombustion

Owner:NANJING UNIV OF SCI & TECH

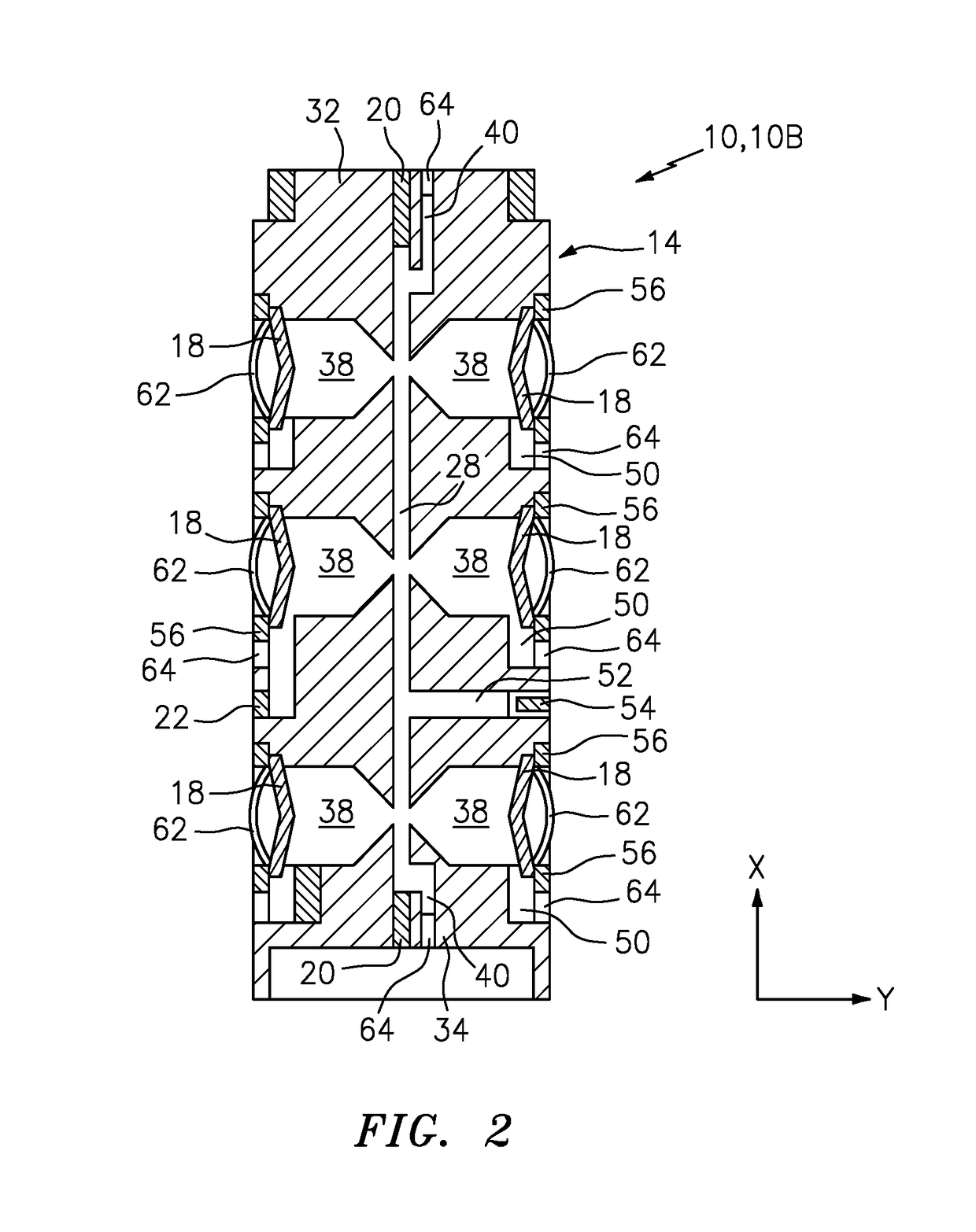

Systems and methods for enhancing isolation of high-temperature reactor containments

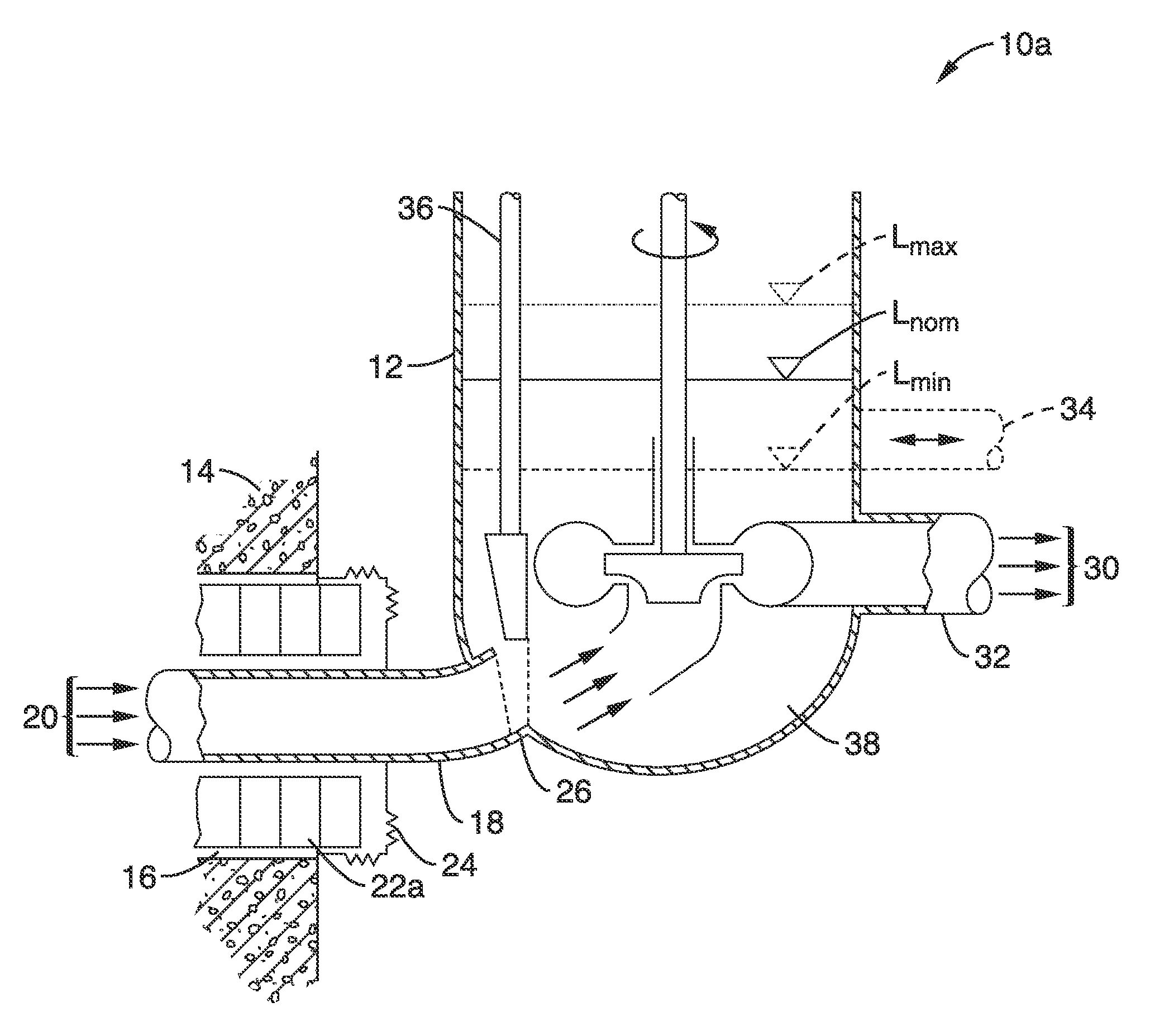

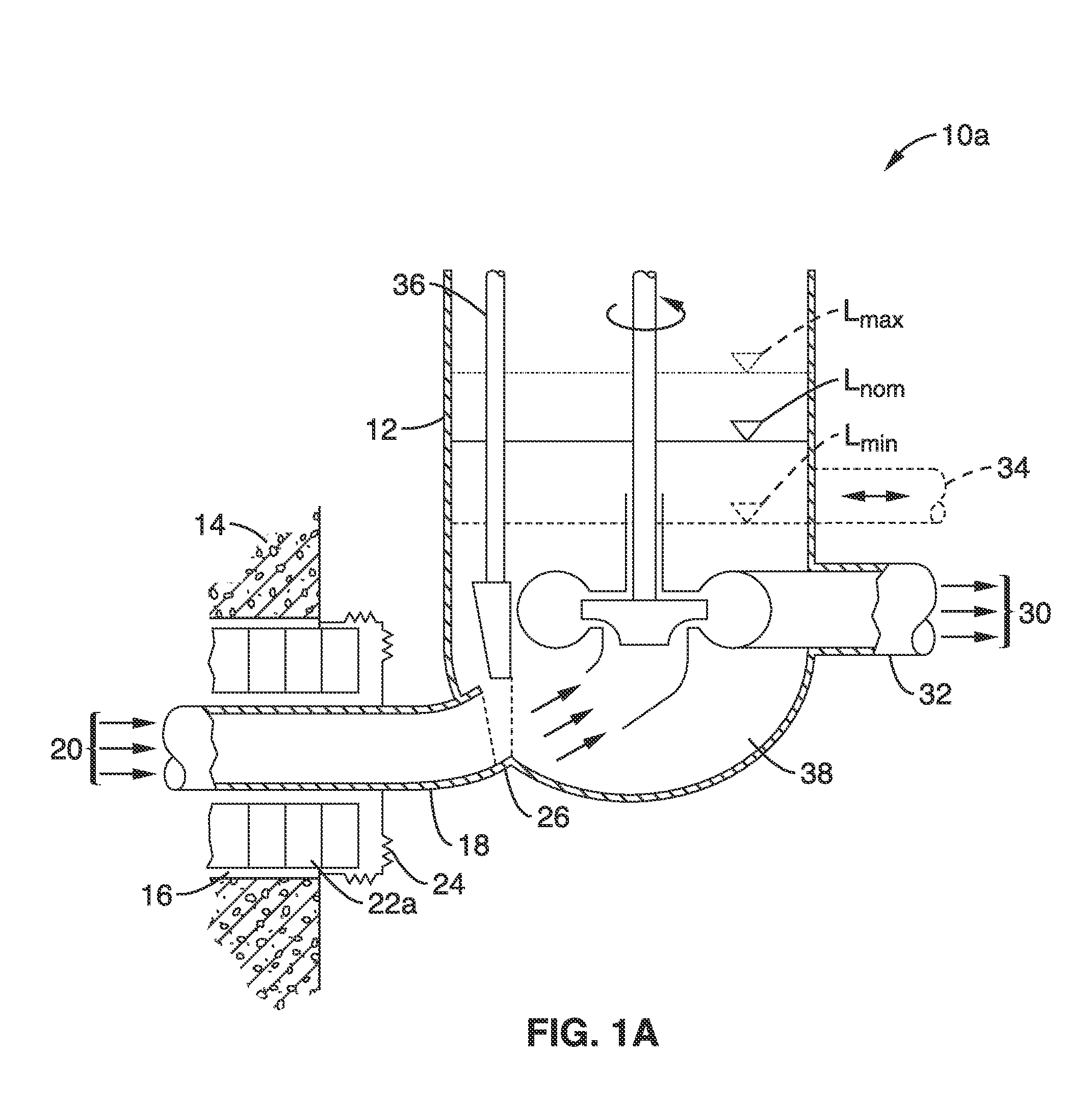

ActiveUS20150124922A1Avoid spreadingLower the volumeNuclear energy generationShieldingCoolant flowLiquid metal

A high-temperature containment-isolation system for transferring heat from a nuclear reactor containment to a high-pressure heat exchanger is presented. The system uses a high-temperature, low-volatility liquid coolant such as a molten salt or a liquid metal, where the coolant flow path provides liquid free surfaces a short distance from the containment penetrations for the reactor hot-leg and the cold-leg, where these liquid free surfaces have a cover gas maintained at a nearly constant pressure and thus prevent high-pressures from being transmitted into the reactor containment, and where the reactor vessel is suspended within a reactor cavity with a plurality of refractory insulator blocks disposed between an actively cooled inner cavity liner and the reactor vessel.

Owner:RGT UNIV OF CALIFORNIA

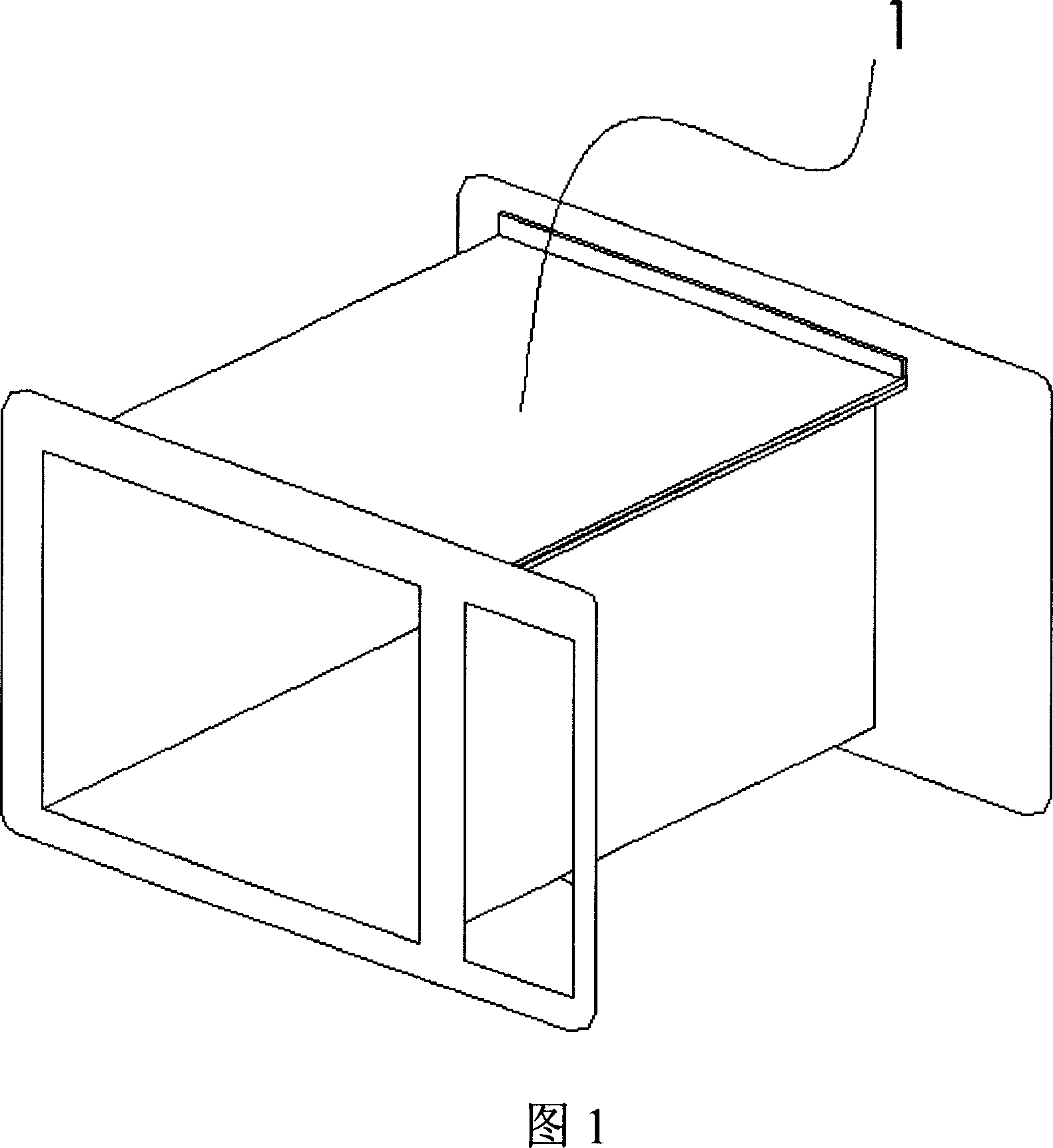

Micro-wave oven furnace chamber inner container and processing method

InactiveCN101116934ALow costSimple processDomestic stoves or rangesLighting and heating apparatusMicrowave ovenCavity Liner

The invention provides a microwave oven cavity liner and processing method, which comprises a microwave oven cavity liner body and a support connecting plate. The microwave oven cavity liner body is a whole, which consists of a body front plate and a cavity body. The support connecting plate is fixed in the lower end of the microwave oven cavity liner body. A rivet hole is arranged on the lower end of the microwave oven cavity liner body. The support connecting plates are connected by rivets. The lower end of the microwave oven cavity liner body may be connected with the support connecting plate by welding. Therefore, the producing process is simplified. The percent of pass of product and producing efficiency are improved. The strength of microwave oven cavity liner is improved.

Owner:HAIER GRP CORP +1

Dental releasing materials

InactiveUS20070123604A1Improve fracture toughnessSuperior strength toughnessImpression capsMedical preparationsAdhesivePhosphate

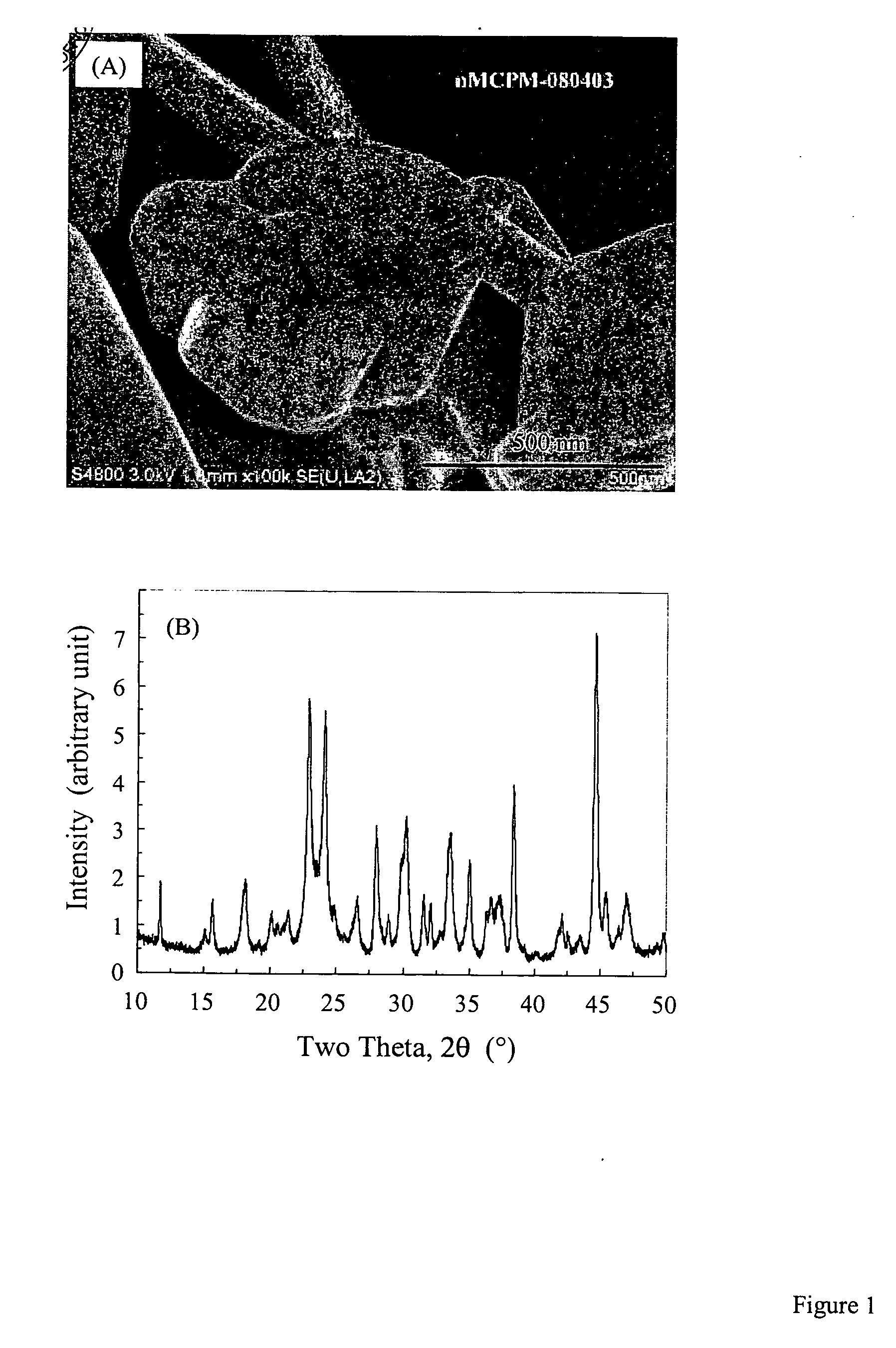

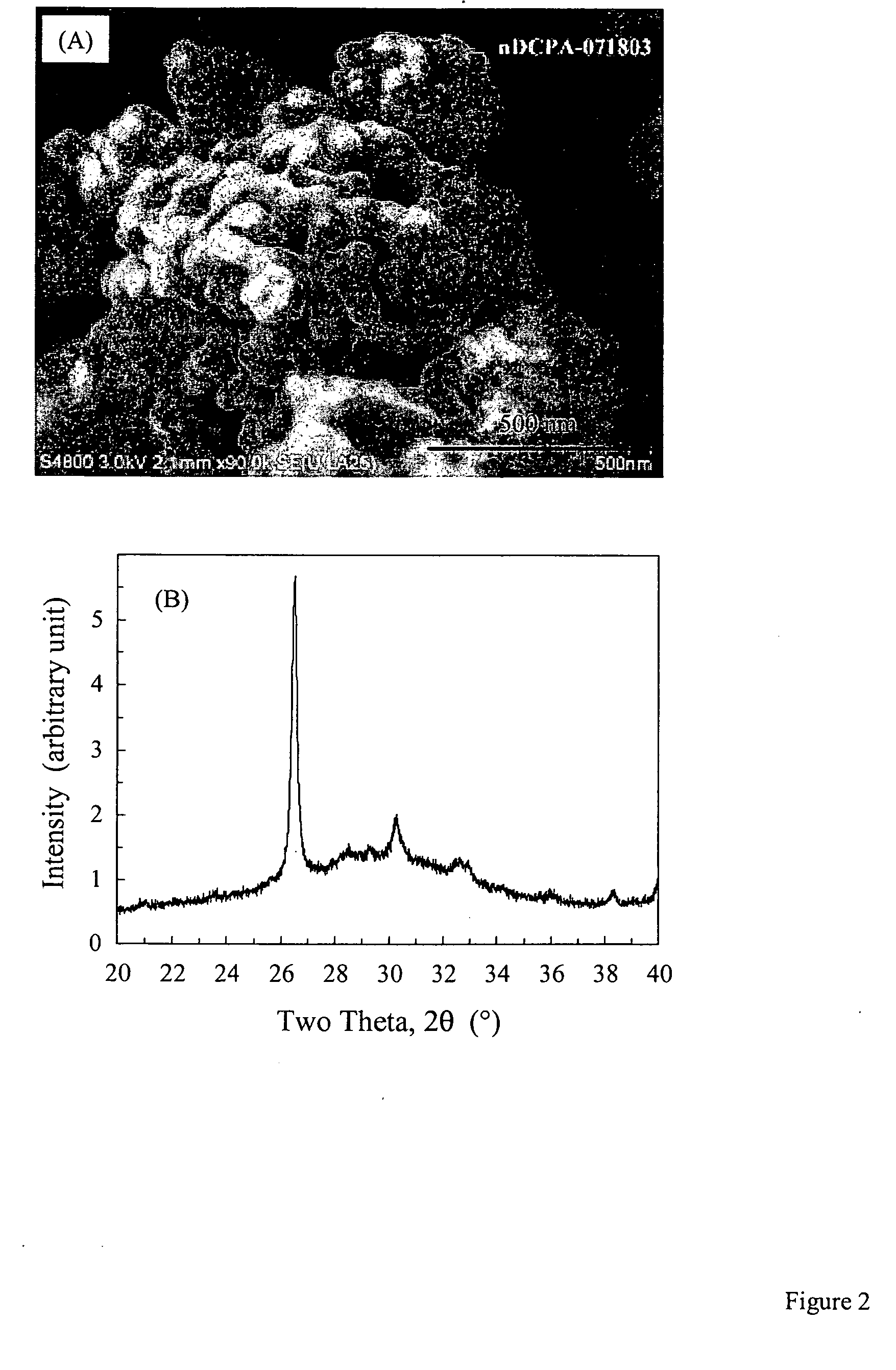

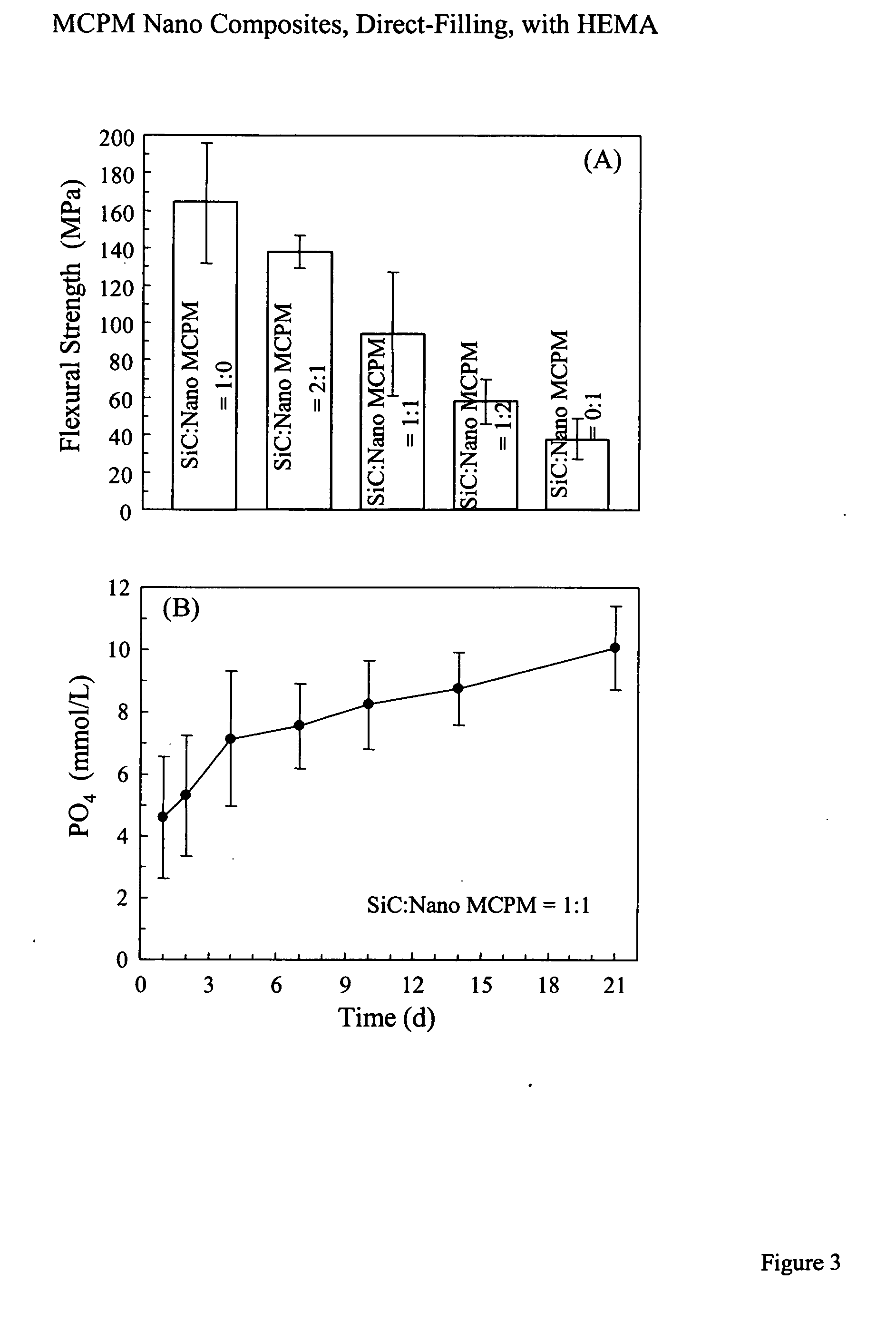

The present invention relates to methods and compositions of dental materials containing nano-sized calcium phosphate and other fillers that release calcium, phosphate and fluoride. This invention further relates to dental compositions for restorations, stress-bearing applications, artificial crowns, anterior and posterior tooth fillings, adhesives, cavity liners, cements, bases, orthodontic devices, prostheses, and sealants utilizing high stress-bearing materials that release materials for the remineralization of decayed tooth structures.

Owner:ADA FOUND

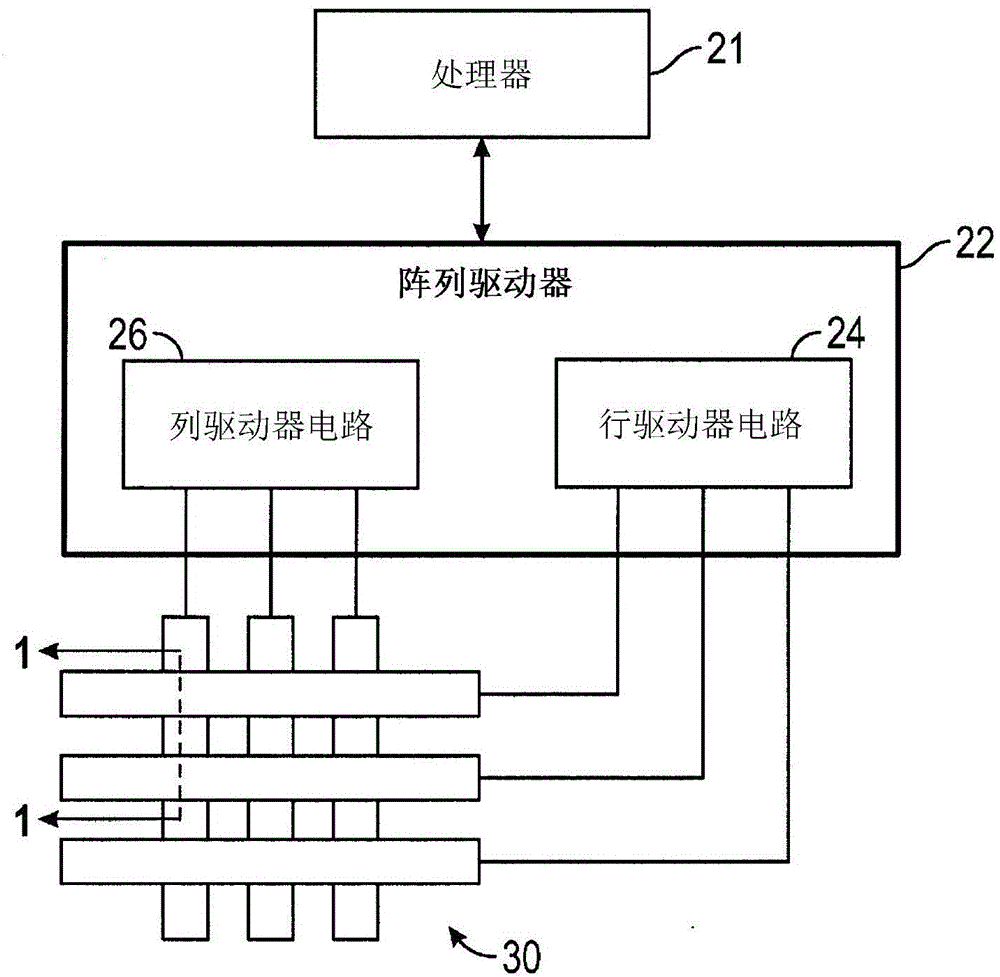

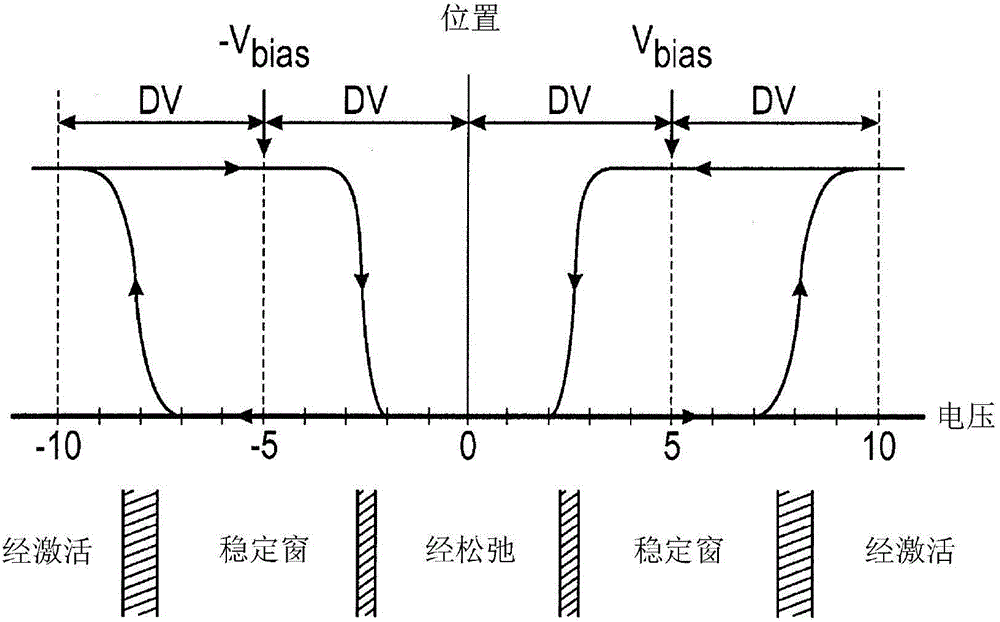

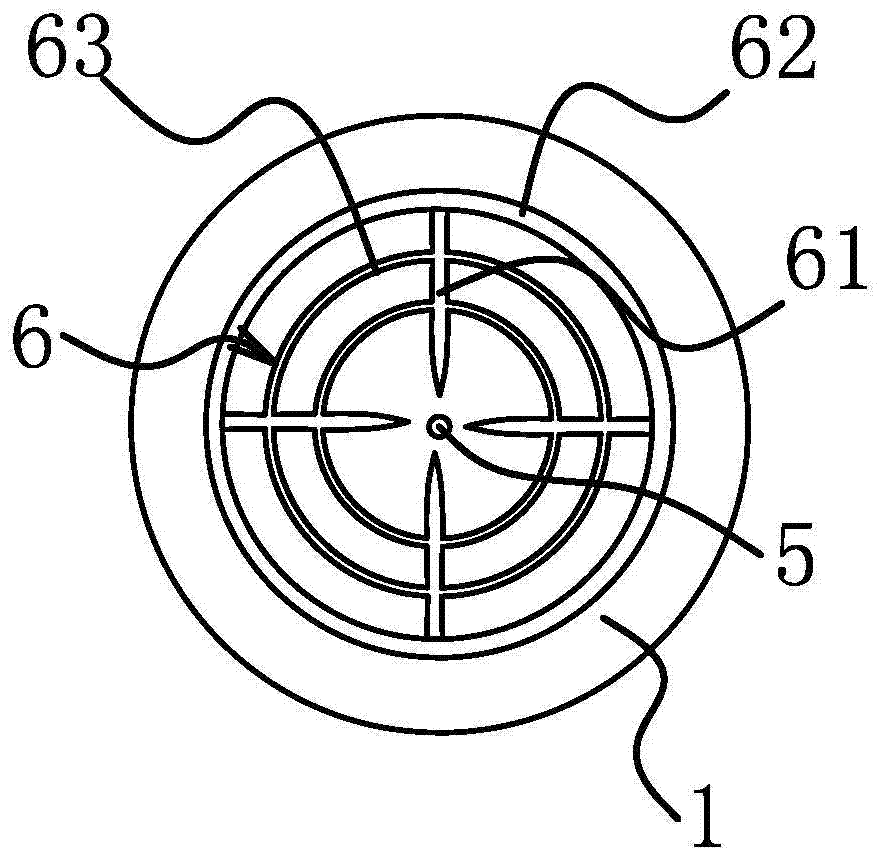

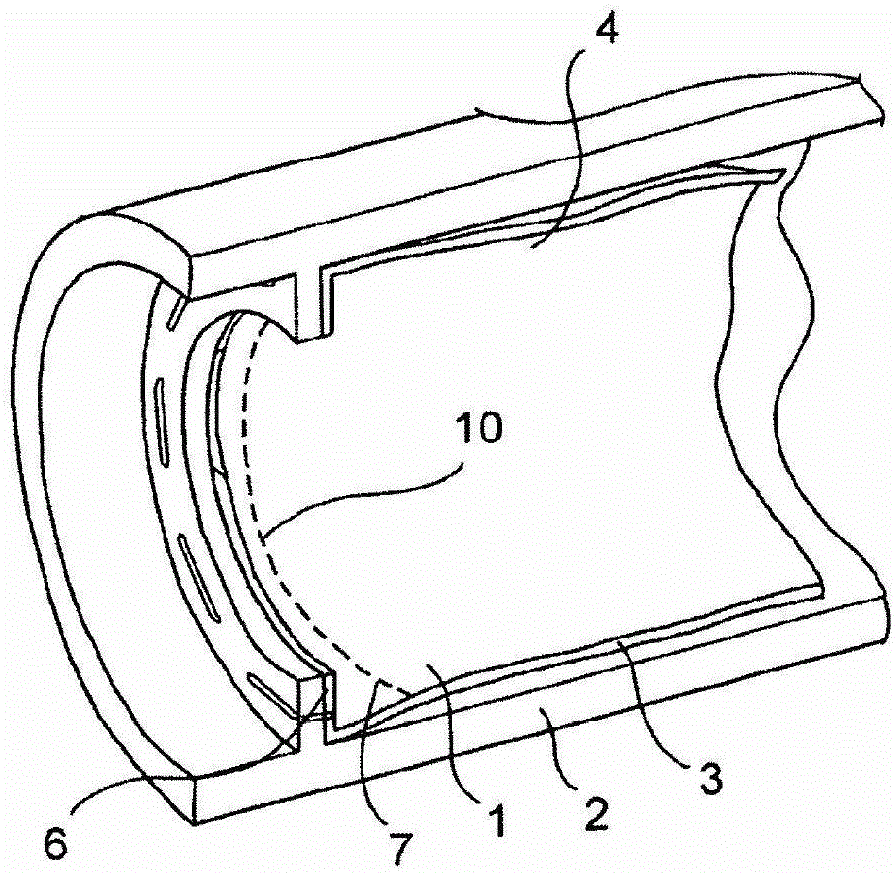

Cavity liners for electromechanical systems devices

InactiveCN104428240ARetain roughnessImprove performancePiezoelectric/electrostrictive devicesFlexible microstructural devicesCavity LinerSelf-assembled monolayer

This disclosure provides systems, methods and apparatus for electromechanical systems devices with improved electrical properties and device life span. In one aspect, a conformal antistiction layer is formed within a cavity of an electromechanical systems apparatus over a roughened surface. The conformal antistiction layer can include a dielectric layer. The conformal antistiction layer can include a self-assembled monolayer (SAM) formed over the dielectric layer. The conformal antistiction layer can replicate the roughness of the surface that it is deposited on.

Owner:SNAPTRACK

Construction method of furnace cavity liner of garbage incinerator

The invention discloses a construction method of a furnace cavity liner of a garbage incinerator, comprising the following steps: material proportioning, ramming construction, anchoring and drying, wherein ramming materials in the material proportioning step comprise the following components in percentage by weight: 1.2-1.5% of Fe2O3, 7-10% of Al2O3, 72-85% of SiC and 5-17% of silicates couplant;and the drying temperature is a constant temperature of 250 DEG C in the drying step. The ramming materials have excellent chemical stability, abrasion resistance, anti-strip property and heat shock resistance, obviously enhanced abrasion resistance and heat conductivity, enhanced compressive strength and apparent porosity, simple construction and material saving; in addition, the constructed liner has the advantages of compact combination, difficult deformation after being formed, and the like; the service life of the liner of the garbage incinerator is prolonged; and the using and maintenance costs are saved.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Systems and methods for enhancing isolation of high-temperature reactor containments

ActiveUS9773574B2Avoid spreadingLower the volumeNuclear energy generationShieldingShortest distanceCoolant flow

A high-temperature containment-isolation system for transferring heat from a nuclear reactor containment to a high-pressure heat exchanger is presented. The system uses a high-temperature, low-volatility liquid coolant such as a molten salt or a liquid metal, where the coolant flow path provides liquid free surfaces a short distance from the containment penetrations for the reactor hot-leg and the cold-leg, where these liquid free surfaces have a cover gas maintained at a nearly constant pressure and thus prevent high-pressures from being transmitted into the reactor containment, and where the reactor vessel is suspended within a reactor cavity with a plurality of refractory insulator blocks disposed between an actively cooled inner cavity liner and the reactor vessel.

Owner:RGT UNIV OF CALIFORNIA

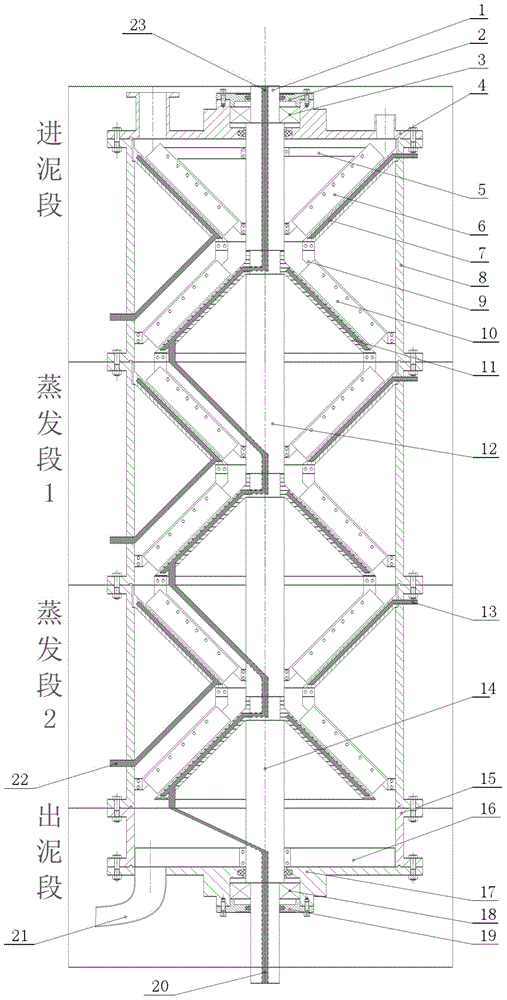

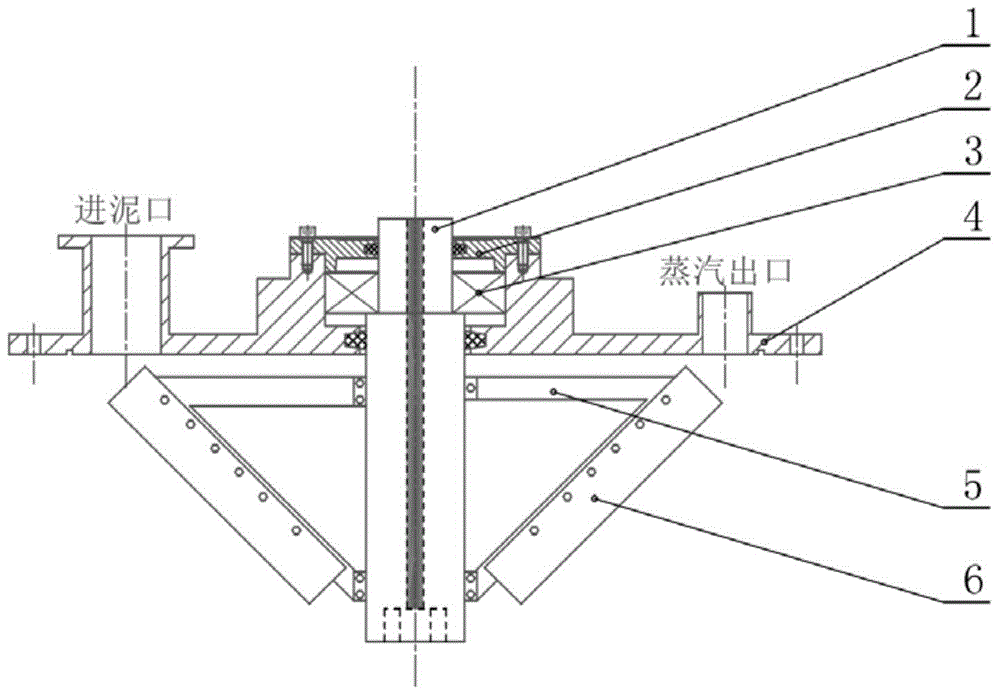

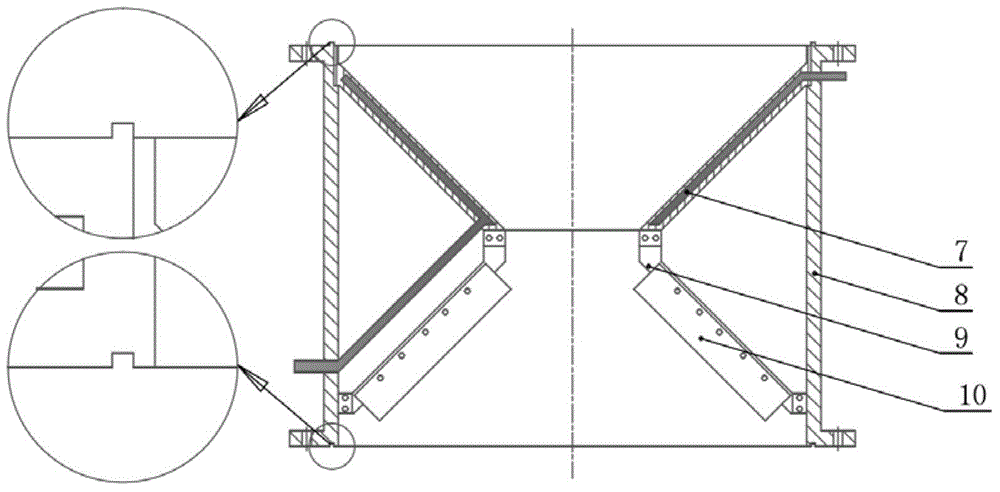

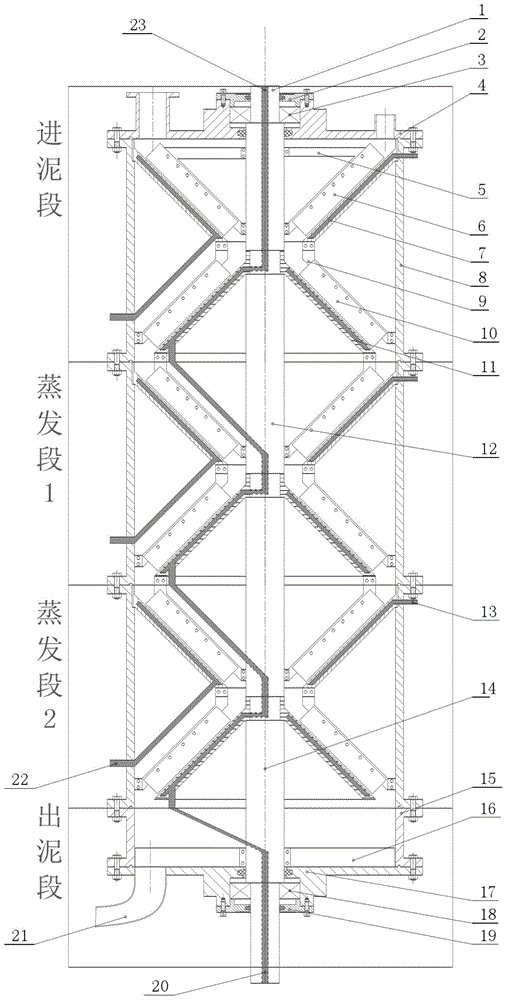

Vertical type sludge thin layer drying device

ActiveCN104016563AImprove heat transfer efficiencyReduce lossesSludge treatment by de-watering/drying/thickeningCavity LinerSludge

The invention discloses a vertical type sludge thin layer drying device, which comprises a sludge inlet section, an evaporation section, a sludge outlet section and a heat conduction oil pipe, wherein the sludge inlet section and the evaporation section form a heating cabin, a rotary main shaft with a rotary scraper and an oil cavity liner is arranged in the heating cabin, the rotary main shaft is composed of a sludge inlet section shaft, an evaporation section shaft and a sludge outlet section shaft, an evaporation cylinder of the heating cabin is provided with a fixed scraper, the evaporation cylinder is provided with an oil cavity outer container, and a fixed heat conduction oil inlet in the evaporation cylinder, a fixed heat conduction oil outlet in the evaporation cylinder, the oil cavity outer container and an oil pipe form a fixed oil line system; an oil line is arranged in the evaporation section shaft, the sludge inlet section shaft is provided with a rotary heat conduction oil outlet, the sludge outlet section shaft is provided with a rotary heat conduction oil inlet, and the rotary heat conduction oil inlet, the rotary heat conduction oil outlet, the oil line in the shaft, an oil cavity container and an oil pipe form a rotary oil path system; a flange of the sludge inlet section is provided with a sludge inlet and a steam outlet, and a flange on the sludge outlet section is provided with a sludge outlet. The heat transfer efficiency in the drying process is high, the heat loss is relatively low, the dust is basically avoided, the drying process is independent of dry sludge backmixing, and the sludge with water content of 85-70% can be dried to water content of 50-35%.

Owner:CHONGQING UNIV

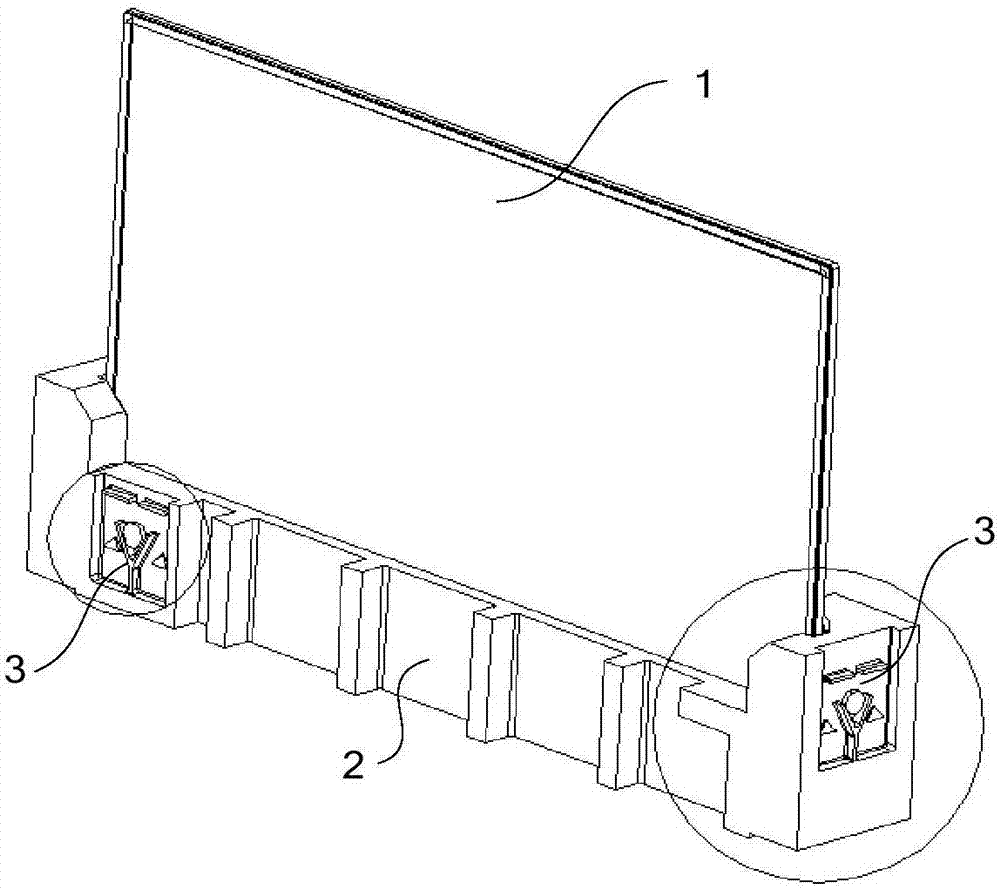

Television packaging device

The invention provides a TV packaging device, which relates to the technical field of TV, and is invented for monitoring the impact of the TV during transportation and standardizing logistics operations. The packaging device includes a liner for fixing the TV. The liner is provided with a monitoring assembly. The monitoring assembly includes a cavity arranged on the side wall of the liner. The cavity is covered with a cover plate. Between the cavity and the cover plate A baffle is arranged along the horizontal direction, and the left and right ends of the baffle extend toward the top of the TV to form a concave portion, and a metal sheet is arranged in the concave portion of the baffle, and there are gaps between the left and right ends of the baffle and the side walls of the cavity for use The metal sheet passes through the gap. When the liner falls to a specific angle with the TV, the metal sheet is affected by gravity, slides out along one end of the baffle, and slides down to the bottom of the baffle through the gap.

Owner:HISENSE VISUAL TECH CO LTD

Aerogels, calcined and crystallized articles and methods of making them

Aerogel, calcined articles, and crystalline articles comprising ZrO2. Exemplary uses of the crystalline metal oxide articles include dental articles (e.g., restoratives, replacements, inlays, onlays, veneers, full and partial crowns, bridges, implants, implant abutments, copings, anterior fillings, posterior fillings, and cavity liner, and bridge frameworks) and orthodontic appliances (e.g., brackets, buccal tubes, cleats, and buttons).

Owner:3M INNOVATIVE PROPERTIES CO

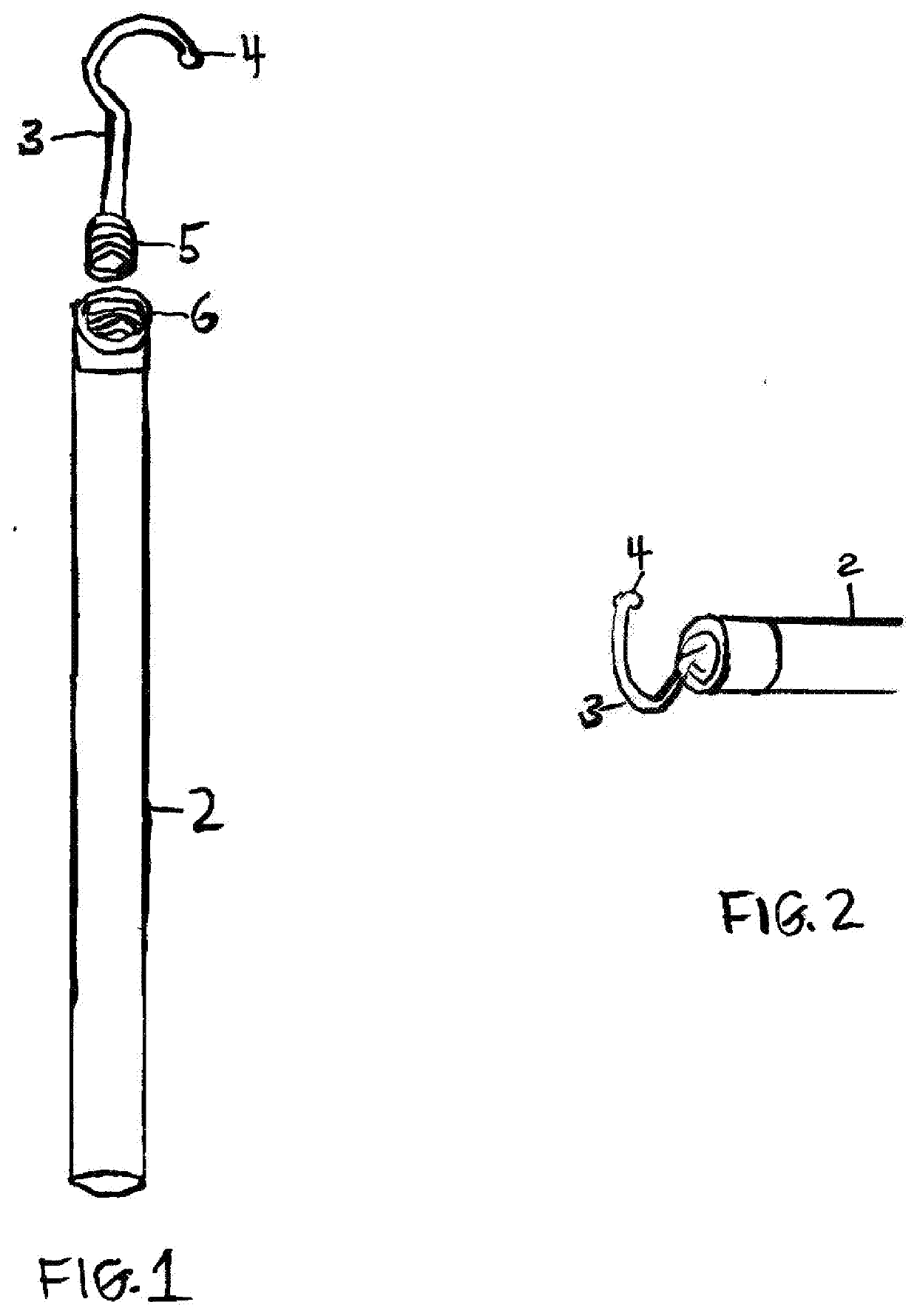

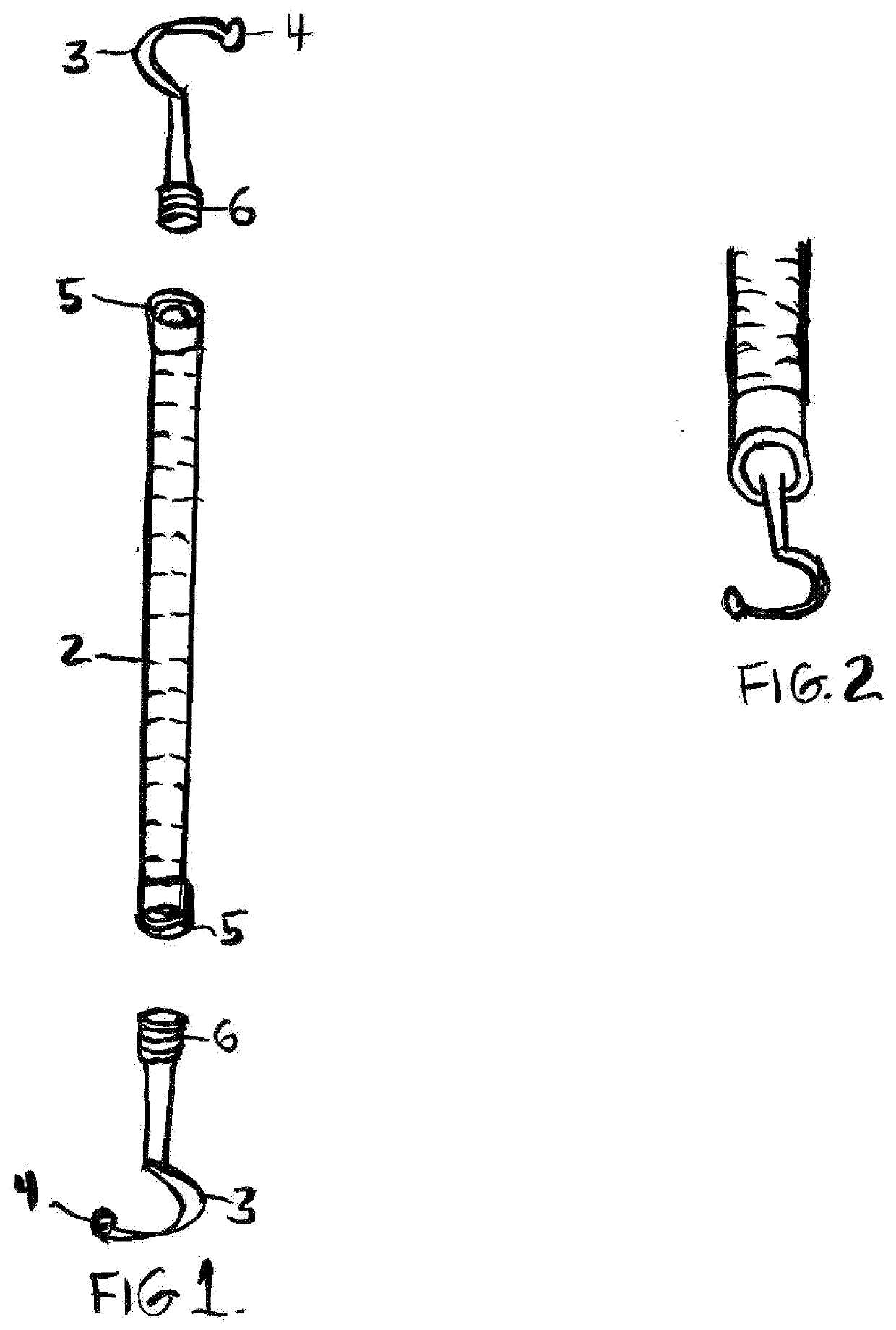

Interim therapeutic restoration and cavity liner placement (ITR) instrument description

This invention is a classic dental shepherd's hook explorer that has been fitted with a dycal style ball on the end, for a completely new instrument designed to facilitate exacting placement of cavity liners and bases, spreading flowable composite underneath fillings by the Dentist, and placing Interim Therapeutic Restorations (ITR) such as fluoride releasing glass ionomer by the Dentist or Registered Dental Hygienist Expanded Functions (RDHEF).Doctors then can reach over matrix bands and apply dental bases and liners, or spread flowable composite directly to the axial wall and pulp floor of their preps, and RDHEF's can access hard to reach interproxirnal, root and furcation areas to apply glass ionomer or other Interim Therapeutic Restorations where incipient caries have been hand excavated.

Owner:AYERS EVELYN ANNE BAUSCHKA

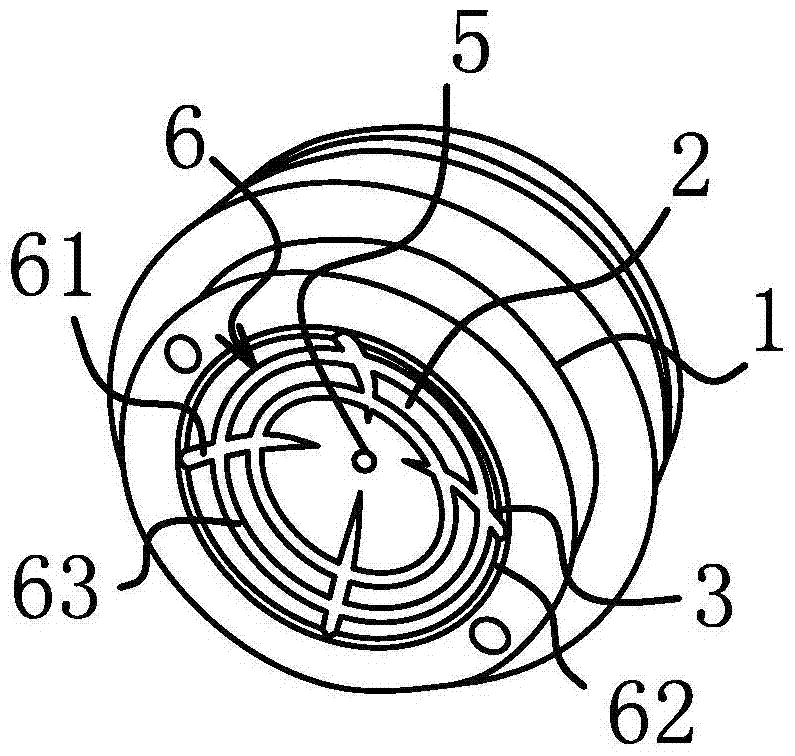

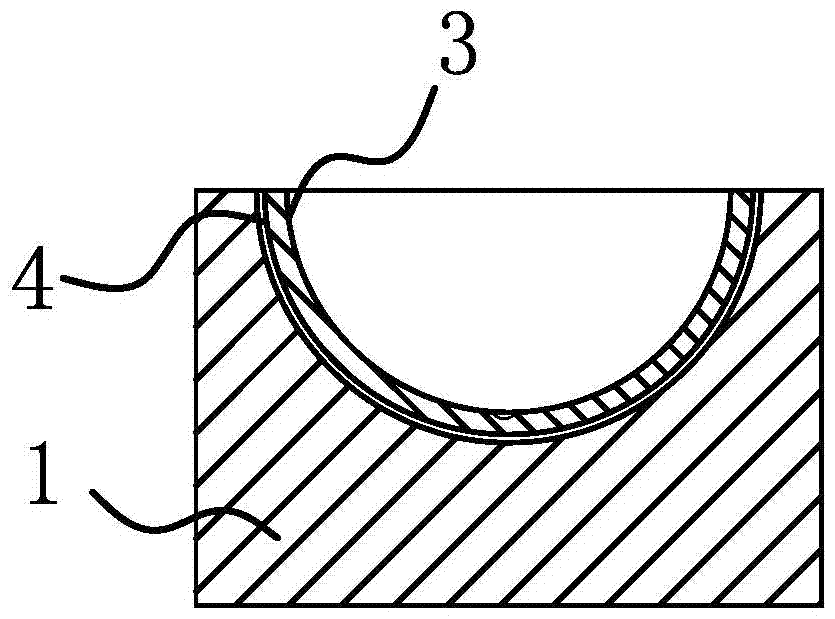

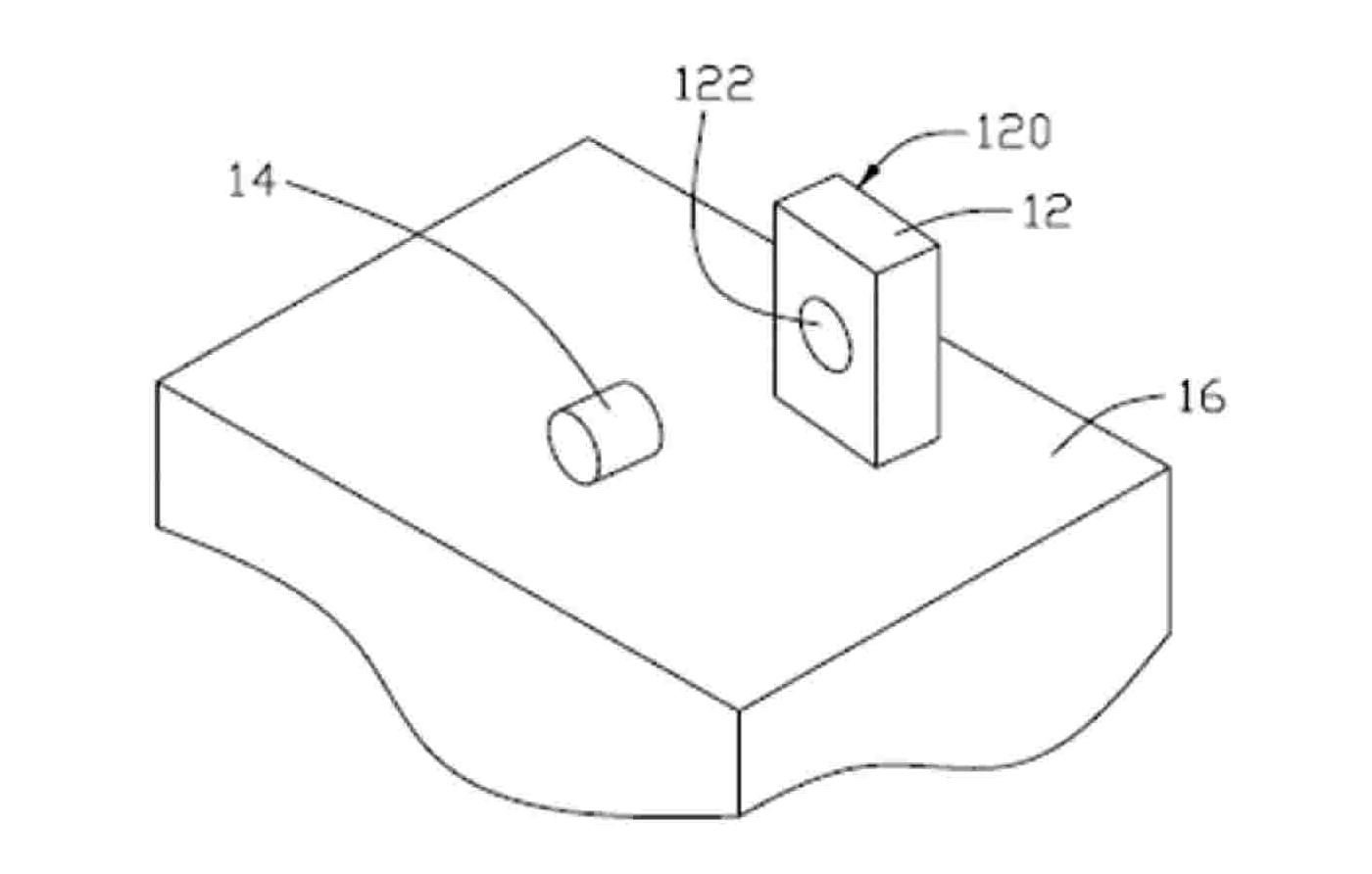

Ball bowl of press slider assembly and its processing method

ActiveCN103994141BReasonable designThe preparation method is reasonableBearing componentsPivotal connectionsManufacturing cost reductionCavity Liner

The invention belongs to the technical field of mechanical equipment, and relates to a press slide block assembly, in particular to a ball bowl of a press slide block assembly and a processing method thereof. It solves technical problems such as unreasonable existing technologies. It includes a cylindrical base, and a bowl cavity is provided at one end of the base. It is characterized in that the base is made of steel, and a bowl made of copper is cast in the bowl cavity. A bushing, a steel-copper interpenetration layer is formed between the bowl-shaped bushing and the bowl cavity, and the center of the inner bottom of the bowl-shaped bushing is provided with an oil storage and dirt storage depression, and the inner side of the bowl-shaped bushing is provided There is a lubricating groove structure located above the oil storage and dirt storage depression. Compared with the existing technology, the advantages of the ball bowl of the press slider assembly and its processing method are: reasonable design, simple structure, high mechanical strength, can greatly reduce manufacturing costs, and only need to replace the bowl after wear and tear The type bushing can be reused after repairing, without the need for complete replacement, so the cost of use is also greatly reduced.

Owner:ZHEJIANG WANZHONG MACHINERY MFG

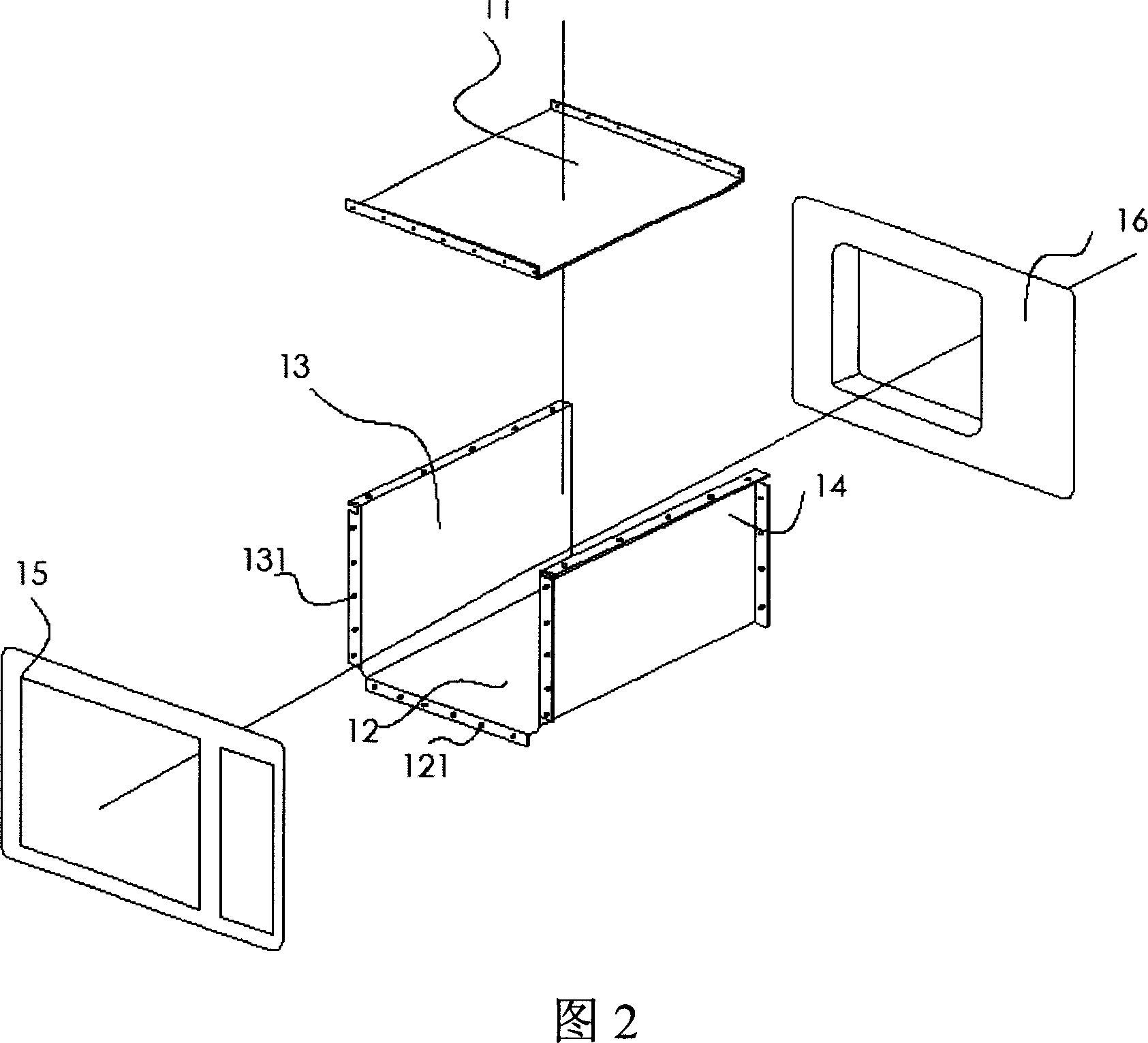

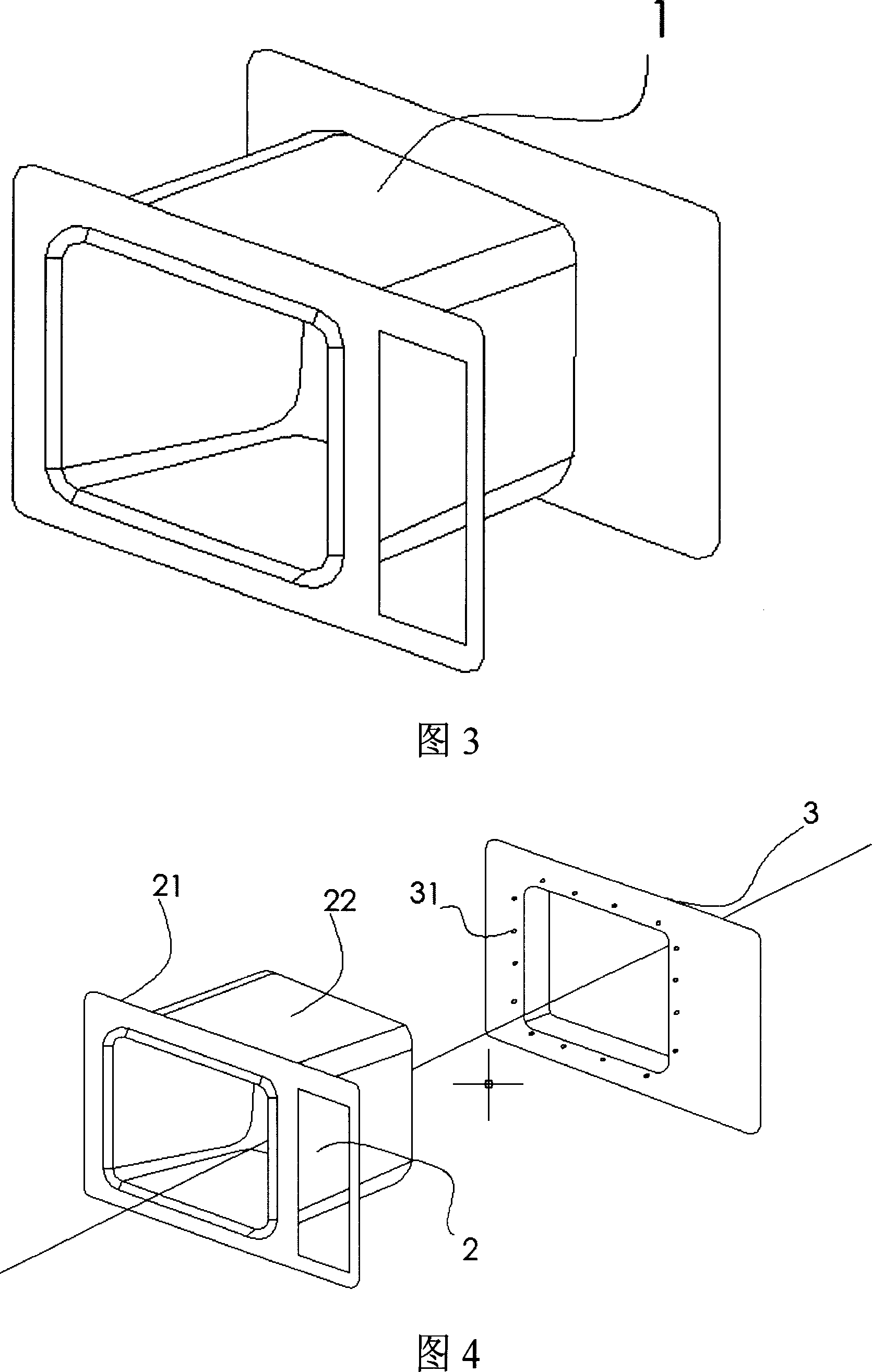

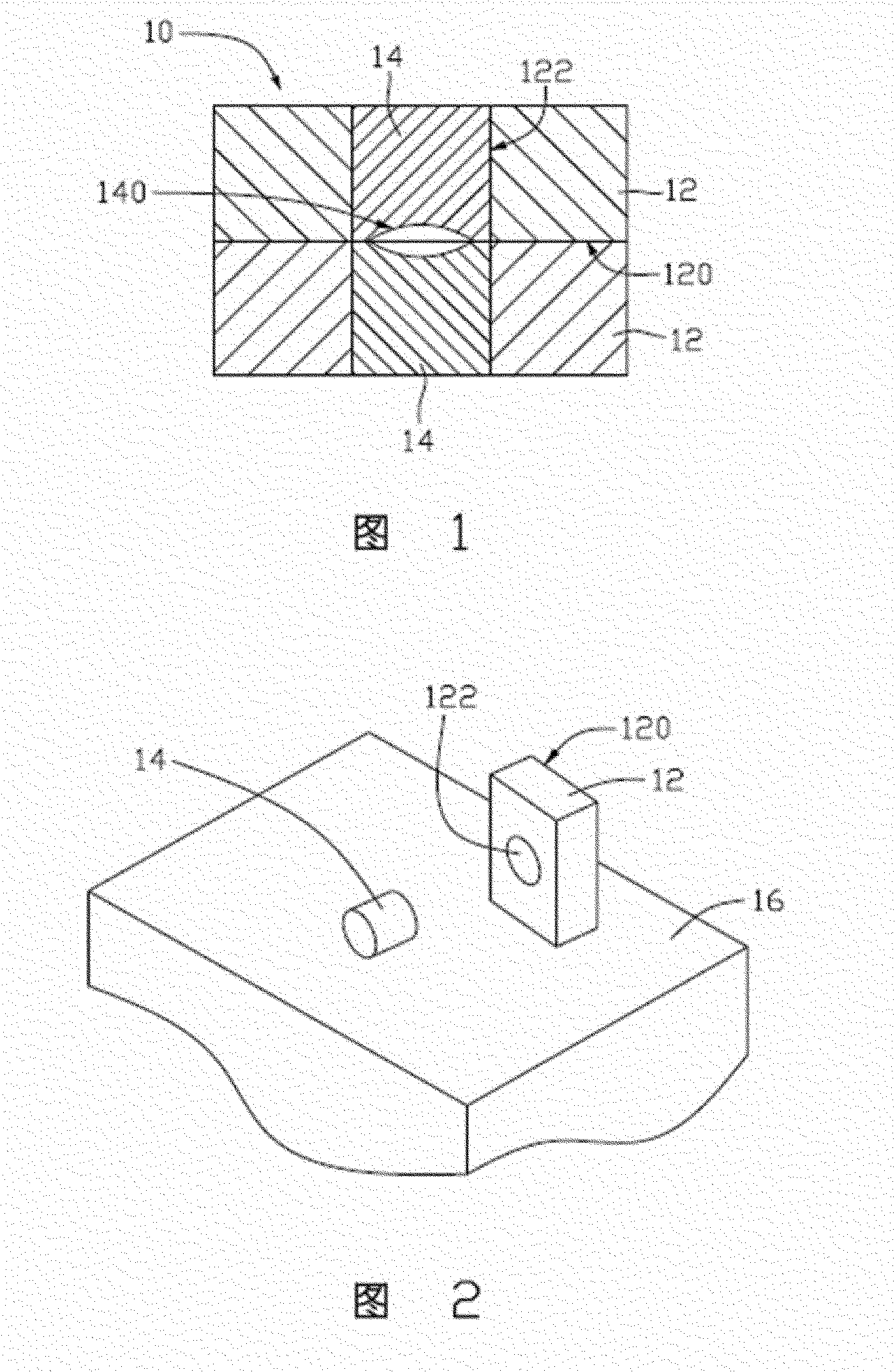

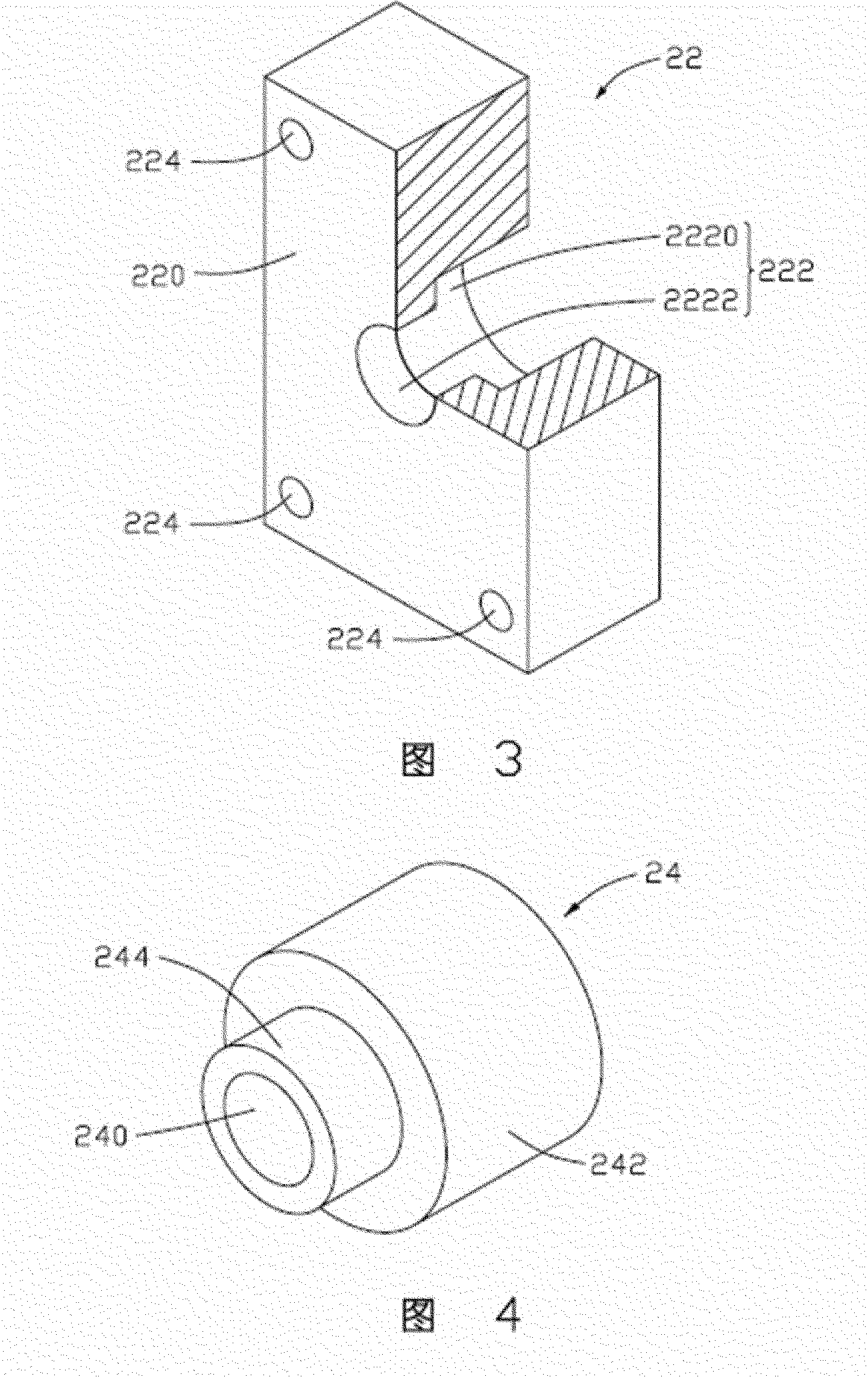

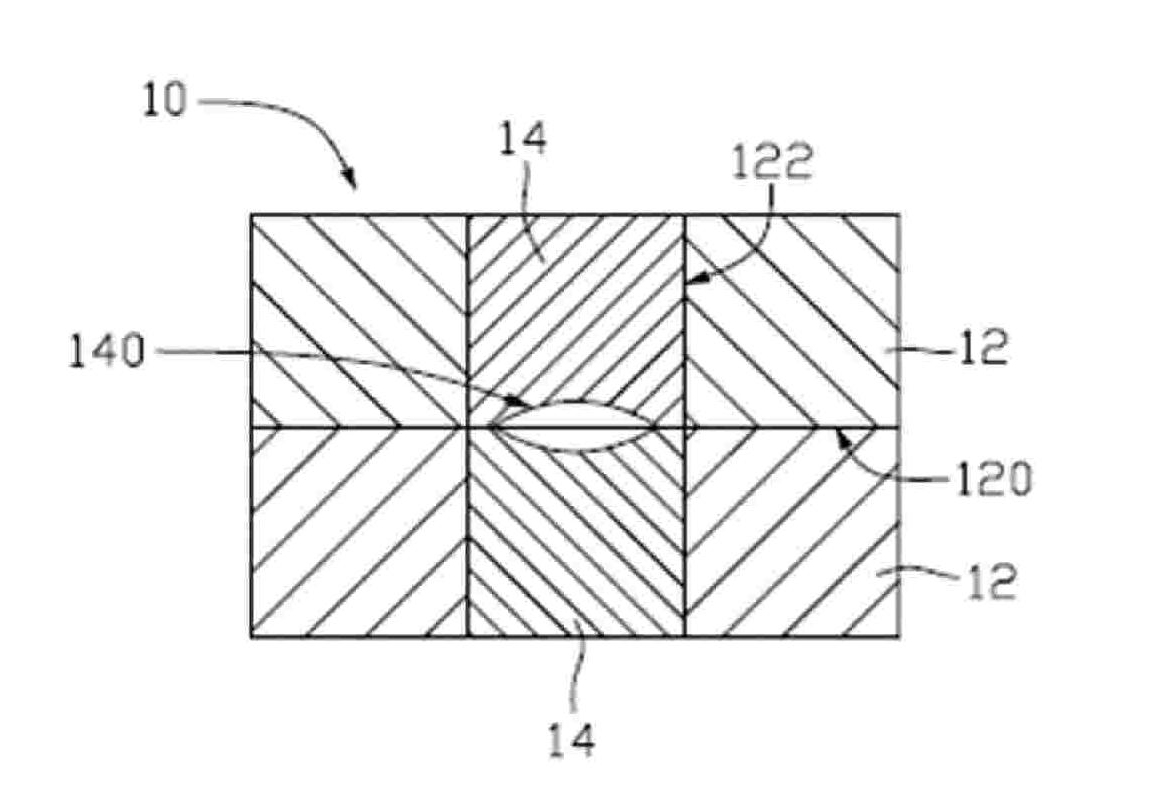

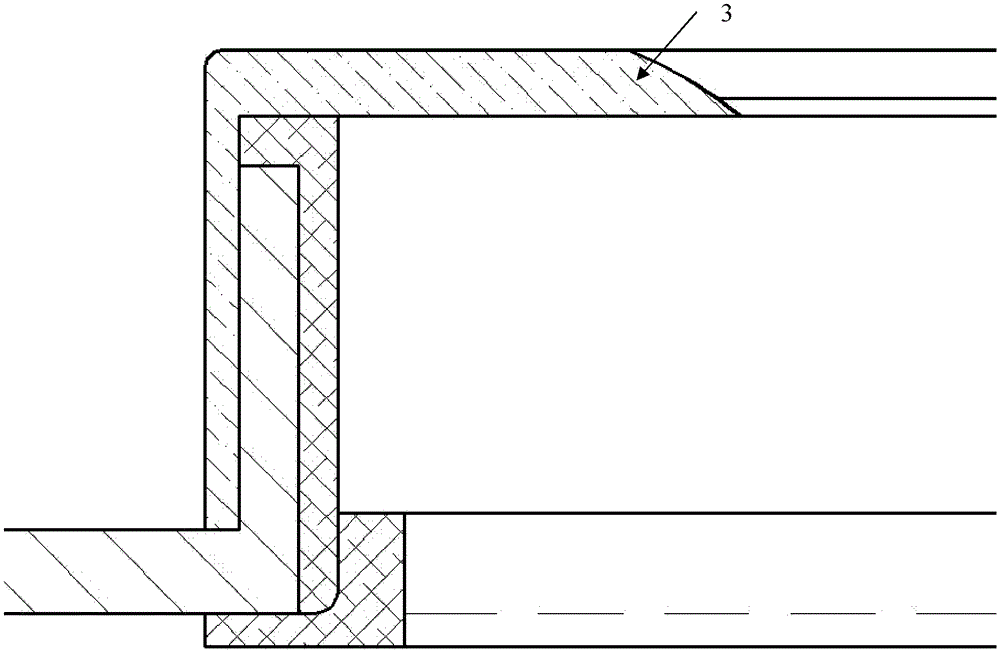

Assembling method of mold-cavity liner

The invention relates to a die cavity core assembly method, comprising the steps as follows: a die cavity substrate and a die cavity core with forming surfaces are provided; the die cavity substrate is provided with a die closing surface; the die cavity substrate is also provided with a die core cavity which passes through the die cavity substrate; the die cavity substrate is horizontally arranged on a workbench; the die closing surface of the die cavity substrate faces to the workbench; furthermore, a plurality of supporting parts with the same height are arranged between the die closing surface and the workbench of the die cavity substrate; the forming surface of the die cavity core faces to the workbench; furthermore, the die cavity core is arranged into the die core cavity.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Interim Provisional Restoration Placement Instrument-#1

InactiveUS20200046457A1Hard to areaPrecise curvatureTooth pluggers/hammersTeeth fillingGlass ionomersIonomer

This invention is a classic dental cow horn explorer that has been fitted with dycal style balls on the ends, for a completely new instrument designed to facilitate exacting placement of cavity liners and bases, spreading flowable composite underneath fillings by the Dentist, and placing Interim Therapeutic Restorations (ITR) such as fluoride releasing glass ionomer by the Dentist or Registered Dental Hygienist Expanded Functions (RDHEF).Doctors then can reach over matrix bands and apply dental bases and liners, or spread flowable composite directly to the axial wall and pulp floor of their preps, and RDHEF's can access hard to reach interproximal, root and furcation areas to apply glass ionomer or other Interim Therapeutic Restorations where incipient caries have been hand excavated.

Owner:AYERS EVELYN ANNE BAUSCHKA

Vertical type sludge thin layer drying device

ActiveCN104016563BImprove heat transfer efficiencyReduce lossesSludge treatment by de-watering/drying/thickeningSludgeCavity Liner

The invention discloses a vertical type sludge thin layer drying device, which comprises a sludge inlet section, an evaporation section, a sludge outlet section and a heat conduction oil pipe, wherein the sludge inlet section and the evaporation section form a heating cabin, a rotary main shaft with a rotary scraper and an oil cavity liner is arranged in the heating cabin, the rotary main shaft is composed of a sludge inlet section shaft, an evaporation section shaft and a sludge outlet section shaft, an evaporation cylinder of the heating cabin is provided with a fixed scraper, the evaporation cylinder is provided with an oil cavity outer container, and a fixed heat conduction oil inlet in the evaporation cylinder, a fixed heat conduction oil outlet in the evaporation cylinder, the oil cavity outer container and an oil pipe form a fixed oil line system; an oil line is arranged in the evaporation section shaft, the sludge inlet section shaft is provided with a rotary heat conduction oil outlet, the sludge outlet section shaft is provided with a rotary heat conduction oil inlet, and the rotary heat conduction oil inlet, the rotary heat conduction oil outlet, the oil line in the shaft, an oil cavity container and an oil pipe form a rotary oil path system; a flange of the sludge inlet section is provided with a sludge inlet and a steam outlet, and a flange on the sludge outlet section is provided with a sludge outlet. The heat transfer efficiency in the drying process is high, the heat loss is relatively low, the dust is basically avoided, the drying process is independent of dry sludge backmixing, and the sludge with water content of 85-70% can be dried to water content of 50-35%.

Owner:CHONGQING UNIV

Assembling method of mold-cavity liner

The invention relates to a die cavity core assembly method, comprising the steps as follows: a die cavity substrate and a die cavity core with forming surfaces are provided, wherein the die cavity substrate is provided with a die closing surface, the die cavity substrate is also provided with a die core cavity, the die core cavity is formed by the side of the die cavity substrate opposite to the die closing surface and extending towards the die closing surface, and the die core cavity passes through the die cavity substrate; the die cavity substrate is horizontally arranged on a workbench; the die closing surface of the die cavity substrate faces to the workbench; furthermore, a plurality of supporting parts with the same height are arranged between the die closing surface and the workbench of the die cavity substrate; the forming surface of the die cavity core faces to the workbench; furthermore, the die cavity core is perpendicular to the workbench and is arranged into the die core cavity.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

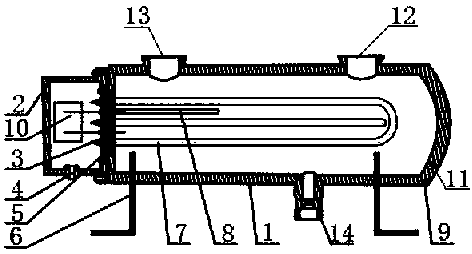

Auxiliary electric heater for air conditioner

InactiveCN107702302AImprove protectionImprove insulation effectSpace heating and ventilation detailsWater heatersTemperature controlElectricity

The invention discloses an auxiliary electric heater for air conditioners, which comprises an electric heater shell (1), a sealing end cover (2), a wiring board (3), a lead coil (4), a flange plate (5), an electric heater Heater base (6), temperature control tube (7), electric heater (8), liner (9), overheating protector (10) and insulation layer (11), the upper part of the electric heater shell is provided with a water inlet port (12) and water outlet port (13), one end of the electric heater casing is connected to the sealing end cover through a flange, the electric heater base is provided at the lower end of the electric heater casing, and a matching liner is provided inside the electric heater casing There are temperature control tubes and electric heaters in the cavity of the liner, and a terminal board and an overheat protector are provided in the sealed end cover. The terminal board is connected with the overheat protector, the terminal board is connected with the electric heater, and the sealed end A lead wire is provided on one side of the cover, and an insulating layer is provided on the inner and outer walls of the liner. The invention adopts the auxiliary electric heater for the air conditioner, and the structure design is reasonable.

Owner:朱小平

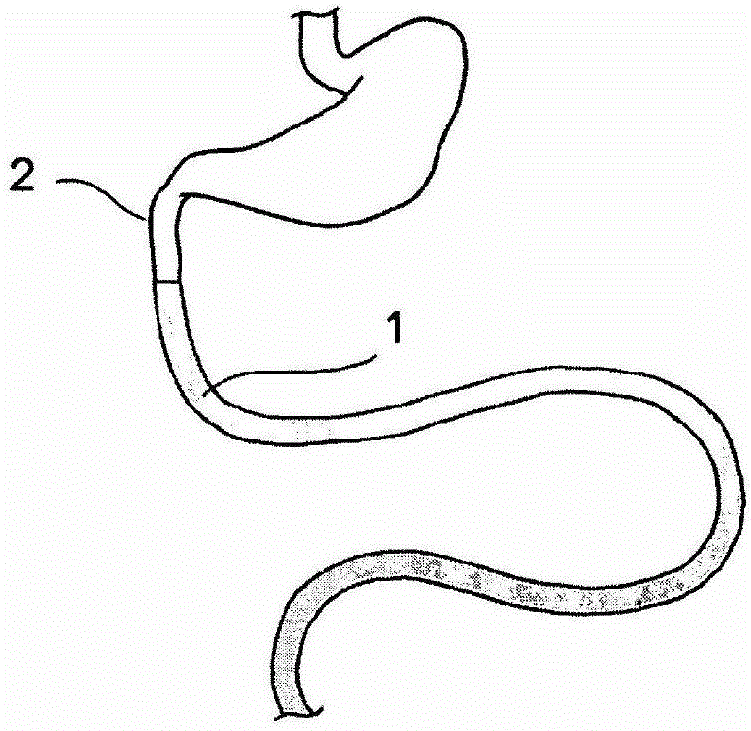

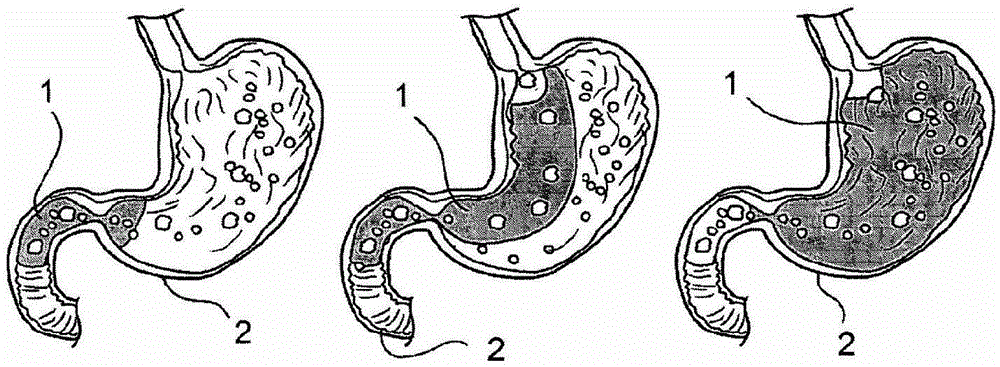

Cavity liners and methods of lining hollow organ cavities

Owner:ETHICON ENDO SURGERY INC

Li-ion battery pack

A multi-cell lithium-ion battery pack (100) includes a sealed housing (116) and a support member (120) disposed within the sealed housing (116). The support member (120) includes a plurality of cavities and a plurality of lithium ion core members (102) disposed within the plurality of cavities. The battery pack further includes a plurality of cavity liners (124), each of which is disposed between a respective one of the lithium ion core members (102) and a surface of a respective one of the cavities.

Owner:CADENZA INNOVATION INC

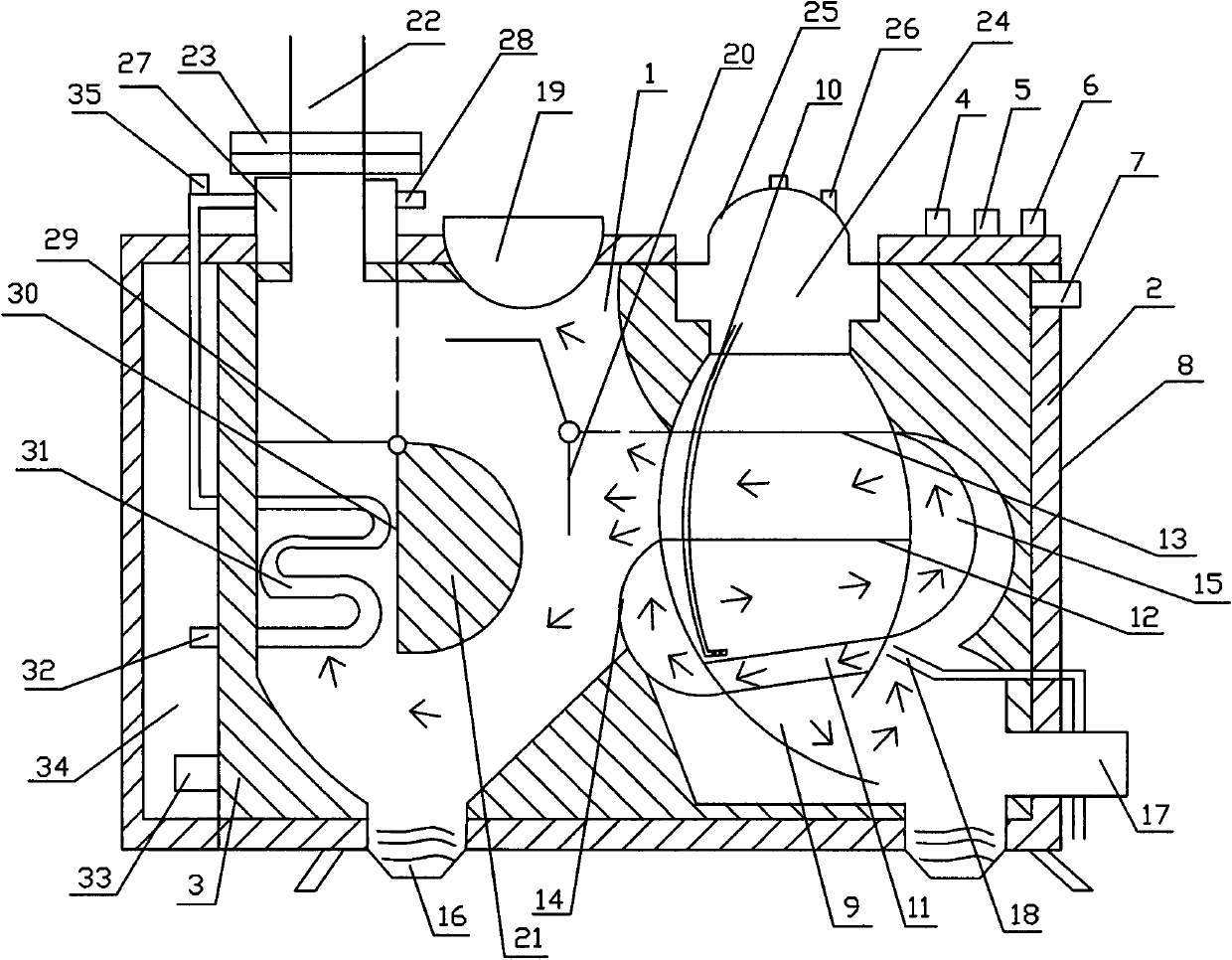

Multi-functional heating furnace

InactiveCN102705870ABurn fullyReduce usageLighting and heating apparatusStove/ranges for heating waterSlagCavity Liner

The invention relates to a multi-functional heating furnace comprising a main heating furnace body, a coaling port, a heating water outlet, a heating water inlet, a heating water jacket, a smoke outlet and a slag removal port, wherein an unsealed furnace cavity is connected below the coaling port; the smoke outlet is provided with a radiator; the furnace cavity is internally provided with a tubular grate smoke guide pipe and is formed into an independent furnace cavity liner; the periphery and the bottom of the main heating furnace body are provided with a heat preserving layer and a shell; the outer surface of the furnace cavity liner is provided with baffle plates (1, 2); the smoke outlet of the furnace cavity liner is communicated with a smoke gas inlet of the tubular grate smoke guide pipe; a smoke gas outlet of the tubular grate smoke guide pipe is connected with an arc-shaped plate (1), and the arc-shaped plate(1) is respectively connected with the baffle plate (1) and the outer wall of the furnace cavity liner, which is positioned at one side of the smoke gas outlet of the tubular grate smoke guide pipe; the baffle plate (2) is connected with an arc-shaped plate (2), and the arc-shaped plate (2) is connected with the outer wall of the furnace cavity liner, which is positioned at one side of the smoke gas inlet of the tubular grate smoke guide pipe; and the heating water jacket is separated from the furnace cavity liner through air. The invention has the advantages of good heat preserving effect, civil and industrial use, energy saving, environmental protection and convenience for use.

Owner:李虹

Tablet press device for semiconductor chamber

ActiveCN103165375BImprove structural stabilityIncrease the feeding spaceElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorCavity Liner

The invention discloses performing device for a semiconductor cavity. The performing device for the semiconductor cavity comprises a reaction cavity, a preforming frame and a chip-mounting mechanism. The preforming frame is arranged at the upper portion of the reaction cavity. A cavity liner is arranged inside the reaction cavity and connected with the preforming device. The chip-mounting mechanism is arranged at the lower end of the preforming frame. The performing device for the semiconductor cavity not only increases chip-sending space, enables chip-sending to be fast, improves stability of structure of the preforming frame, and further improves preforming quality and efficiency.

Owner:中科九微科技有限公司

Diesel engine body crankshaft cylinder liner cavity sand core hoisting sling

The invention discloses a sand core hoisting sling for a crankshaft cylinder liner cavity of a diesel engine body. The upper part of the tubular sling main body is bent, and the bent position bypasses the plane of the sand core and is in the middle of the "V"-shaped cylinder liner cavity of the sand core. , the difference between the bend and the plane is greater than half the thickness of the sand core, the top of the main body of the spreader is fixed with lifting lugs, and the bottom of the spreader is installed horizontally and forwardly from top to bottom. The distance between the pipe strings is equal to the distance between the upper pipe string lifting hole and the lower pipe string lifting hole in the middle of the crankshaft cavity at the lower part of the sand core. The rear part of the tool body passes through the center hole of the upper pipe string and is connected with the external eccentric rod. The diameter of the eccentric rod is consistent with the diameter of the upper pipe string and can be inserted into the lifting hole of the upper pipe string. The lower pipe string can be inserted To the lifting hole of the lower pipe, the surface of the eccentric column is threaded. The sand core hoisting sling for the crankshaft cylinder liner cavity of the diesel engine body is easy to manufacture, simple to operate, economical and practical.

Owner:CRRC DALIAN CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com