Corrosion depth test method for PVC highly-dense viscous steel wire grid

A technology of corrosion depth and testing method, which is applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as ecological grid damage, safety hazards, steel wire grid perforation, etc., and achieve accurate and reliable evaluation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below the present invention will be further described in conjunction with embodiment:

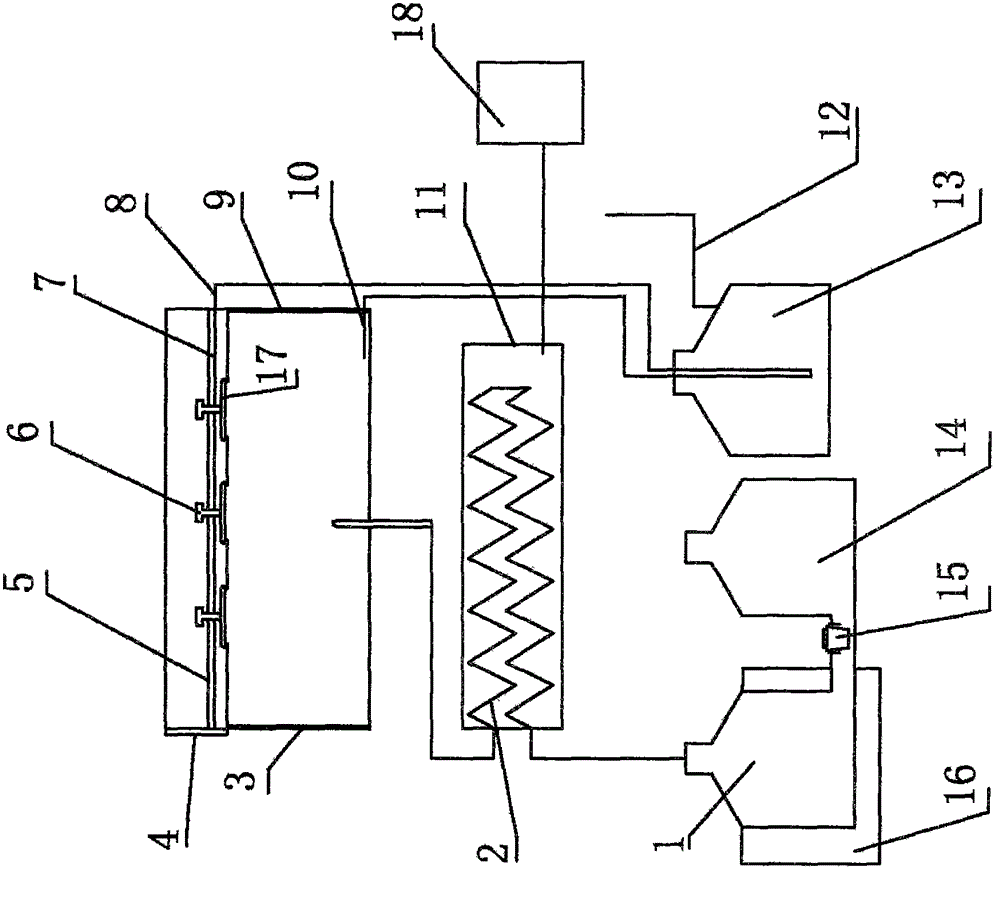

[0025] Such as figure 1 As shown, an experimental device for testing the corrosion depth of a PVC high-density viscous steel wire grid includes an electric heater 16, an evaporator 1, a test chamber and a recovery device 13, and is characterized in that: the evaporator 1 is placed in an electric heating In the device 16, the evaporator 1 is connected to the finned heat exchange tube 2 placed in the steam heater 11 through a glass tube, and then communicated with the test chamber, and the steam heater 11 is connected to the steam drum through a pipe. 18 connection, the test chamber is composed of the test chamber shell 3 and the test chamber liner 9, the inside of the test chamber shell 3 is provided with a fixing device, and the fixing device is arranged at the upper end of the test chamber liner 9, the The top of the test chamber liner 9 is provided with a sample placement device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com