Ball bowl of press slider assembly and its processing method

A processing method and press technology, applied to mechanical equipment, bearing components, shafts and bearings, etc., can solve the problems of complex overall structure and high manufacturing cost, and achieve the effects of reasonable preparation method, high manufacturing efficiency and reduced use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

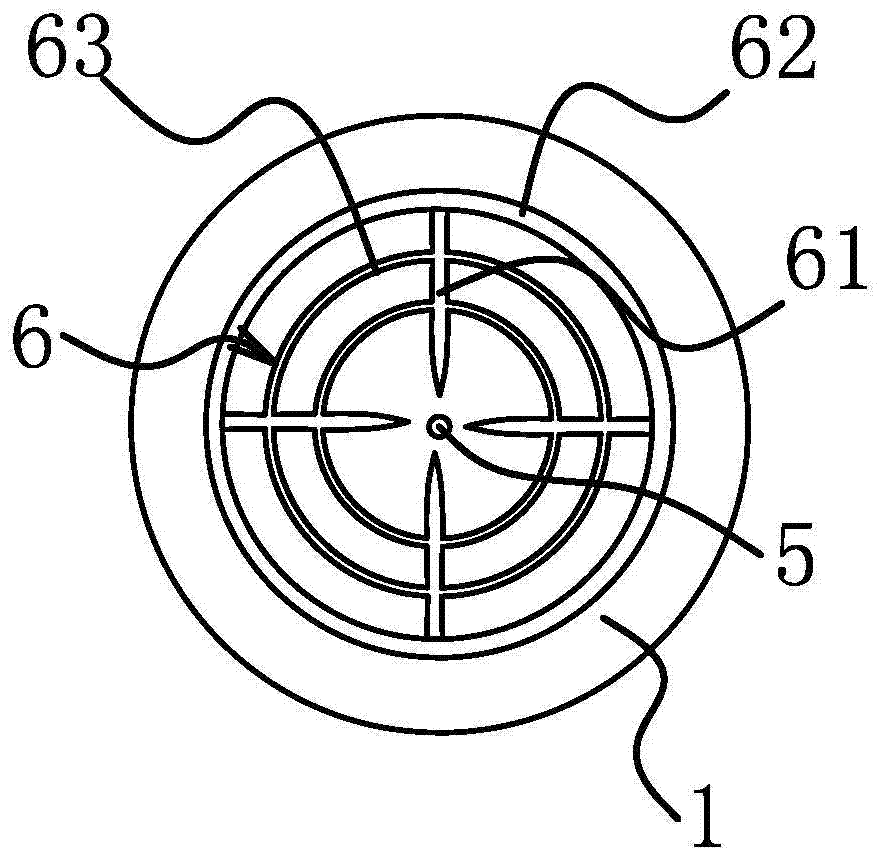

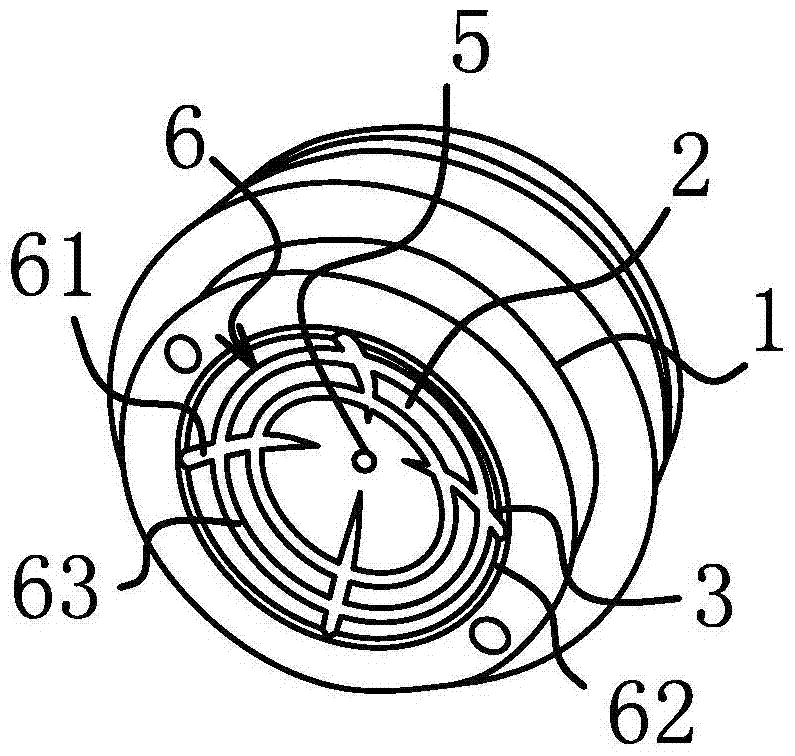

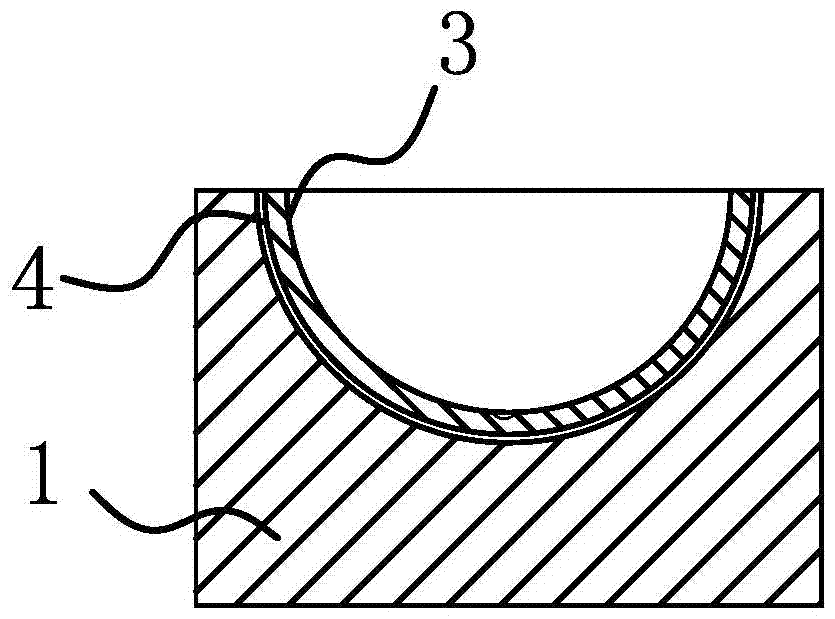

[0028] Such as Figure 1-3 As shown, the ball bowl of the press slider assembly includes a cylindrical base 1, a bowl cavity 2 is provided at one end of the base 1, the base 1 is made of steel, and the bowl cavity 2 is cast There is a bowl-shaped bush 3 made of copper, a steel-copper interpenetration layer 4 is formed between the bowl-shaped bush 3 and the bowl cavity 2, and an oil storage and dirt storage depression 5 is provided in the center of the inner bottom of the bowl-shaped bush 3. The inner side of the bowl-shaped bush 3 is provided with a lubricating groove structure 6 above the oil and dirt storage depression 5 .

[0029] The lubricating groove structure 6 includes a number of longitudinal grooves 61 extending longitudinally along the inner wall of the bowl-shaped bush 3 , the longitudinal grooves 61 are evenly distributed in the circumferential direction, and the lower ends of the longitudinal grooves 61 are closed to the oil and dirt storage of the bowl-shaped bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com