Vertical type sludge thin layer drying device

A thin-layer and equipment technology, applied in the field of vertical sludge thin-layer drying equipment, can solve the problems of large heat loss, low heat transfer efficiency, and high dust volume, and achieve the effect of low heat loss and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

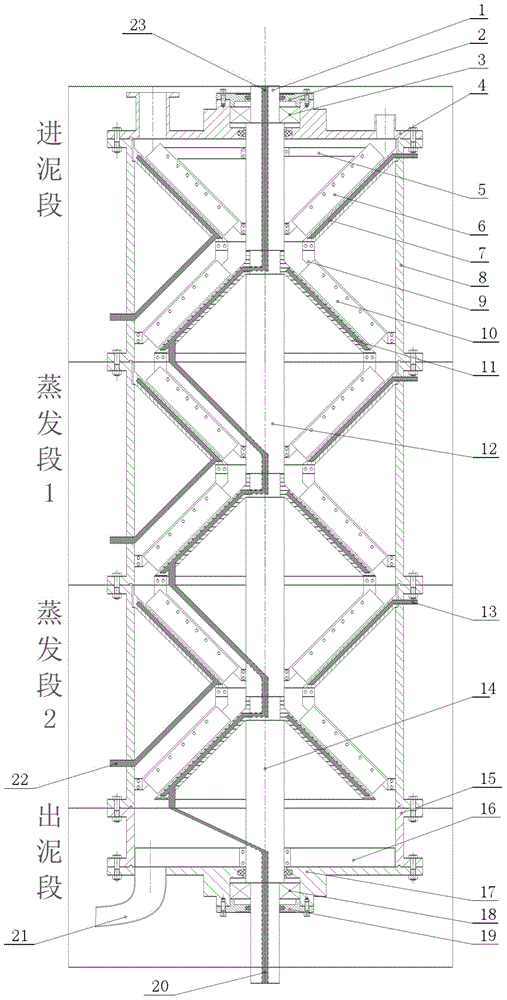

[0019] The thin-layer sludge drying equipment involved in this embodiment is an example of a sewage treatment plant treating sludge with a moisture content of 85% to 70%. The overall structure of the equipment is as follows figure 1 As shown, the equipment consists of a mud inlet section, an evaporation section and a mud outlet section:

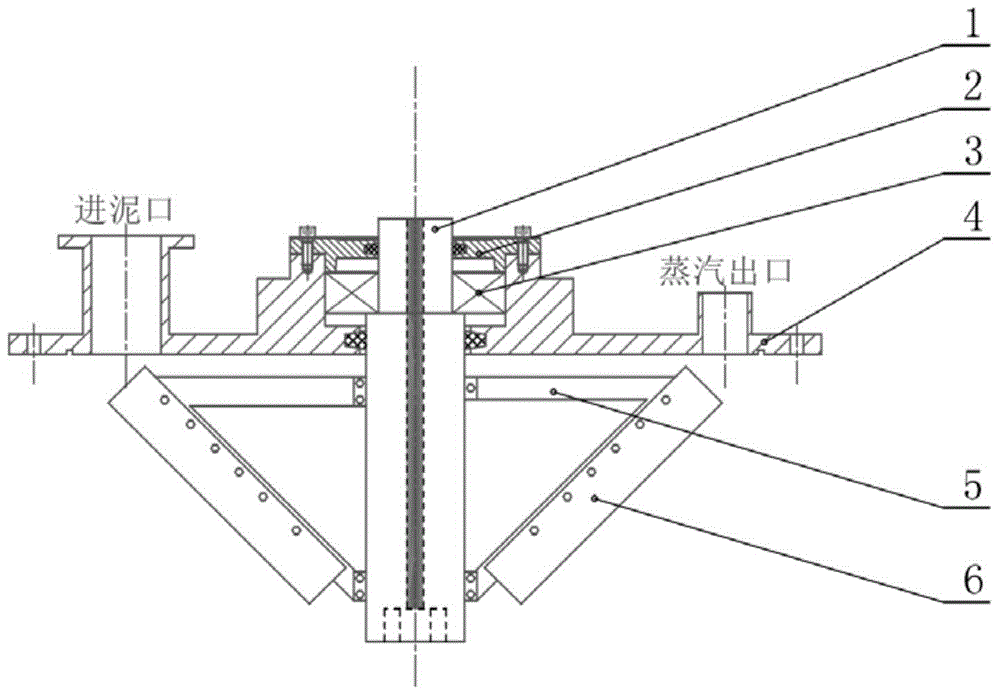

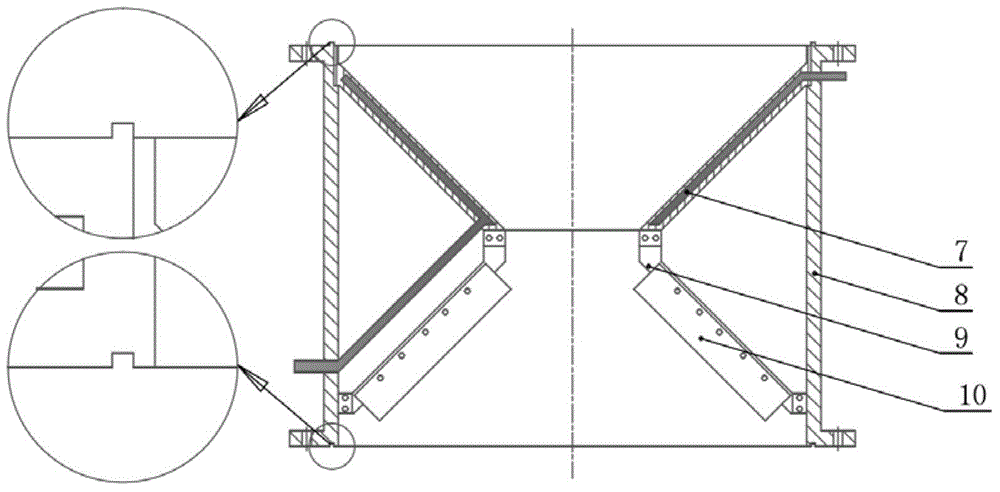

[0020] The mud inlet section is composed of mud inlet flange 4, evaporation tube 8, oil chamber outer liner 7, oil chamber inner liner 11, fixed scraper 10, rotating scraper 6, mud inlet section shaft 1, evaporation section shaft 12, The mud inlet flange 4 and the mud inlet section shaft 1 are connected by a mud inlet section bearing 3. The mud inlet flange 4 is provided with a mud inlet and a steam outlet, and an oil circuit is arranged in the mud inlet section shaft 1 The first part is provided with a rotating heat conduction oil outlet 23, the mud inlet flange 4 and the evaporator 8 are connected by screws, the upper part of the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com