Assembling method of mold-cavity liner

A technology of mold core insertion and assembly method, applied in the field of mold assembly, can solve the problems of air dust pollution, deterioration of optical lens quality, low stability of mold core body 12, etc., and achieves the effects of less wear and avoidance of mold eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

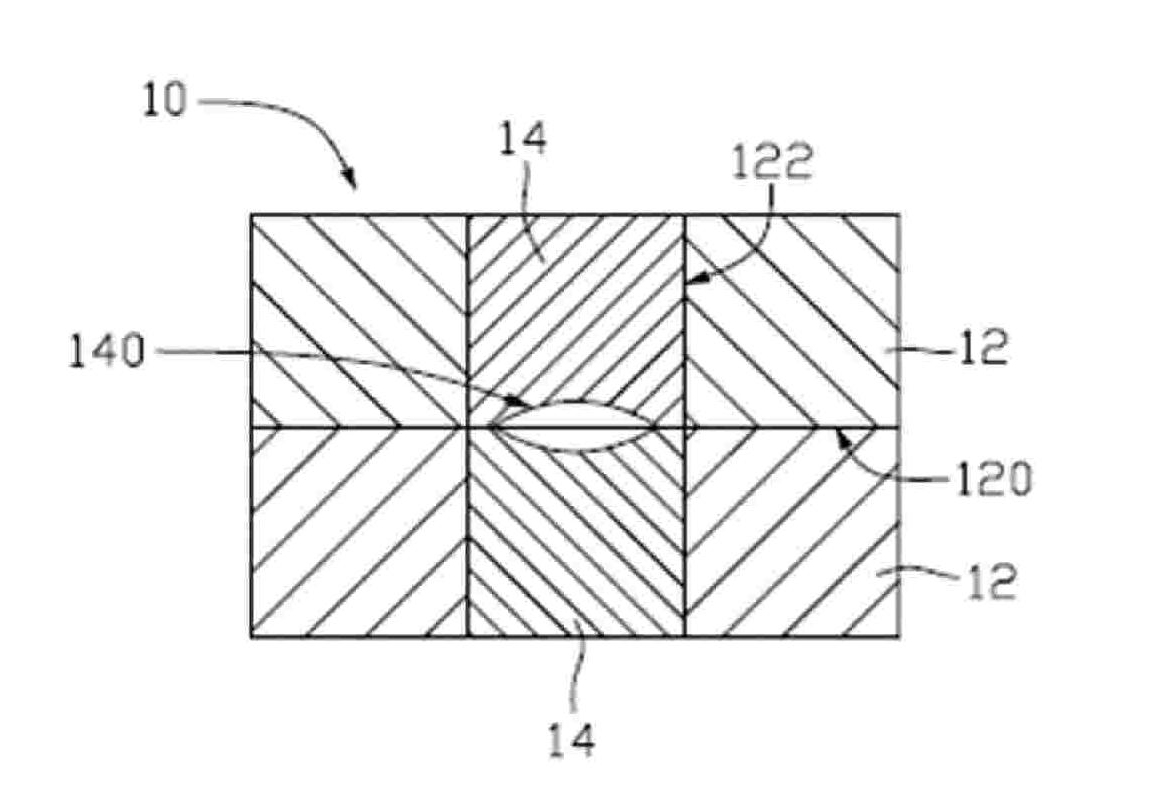

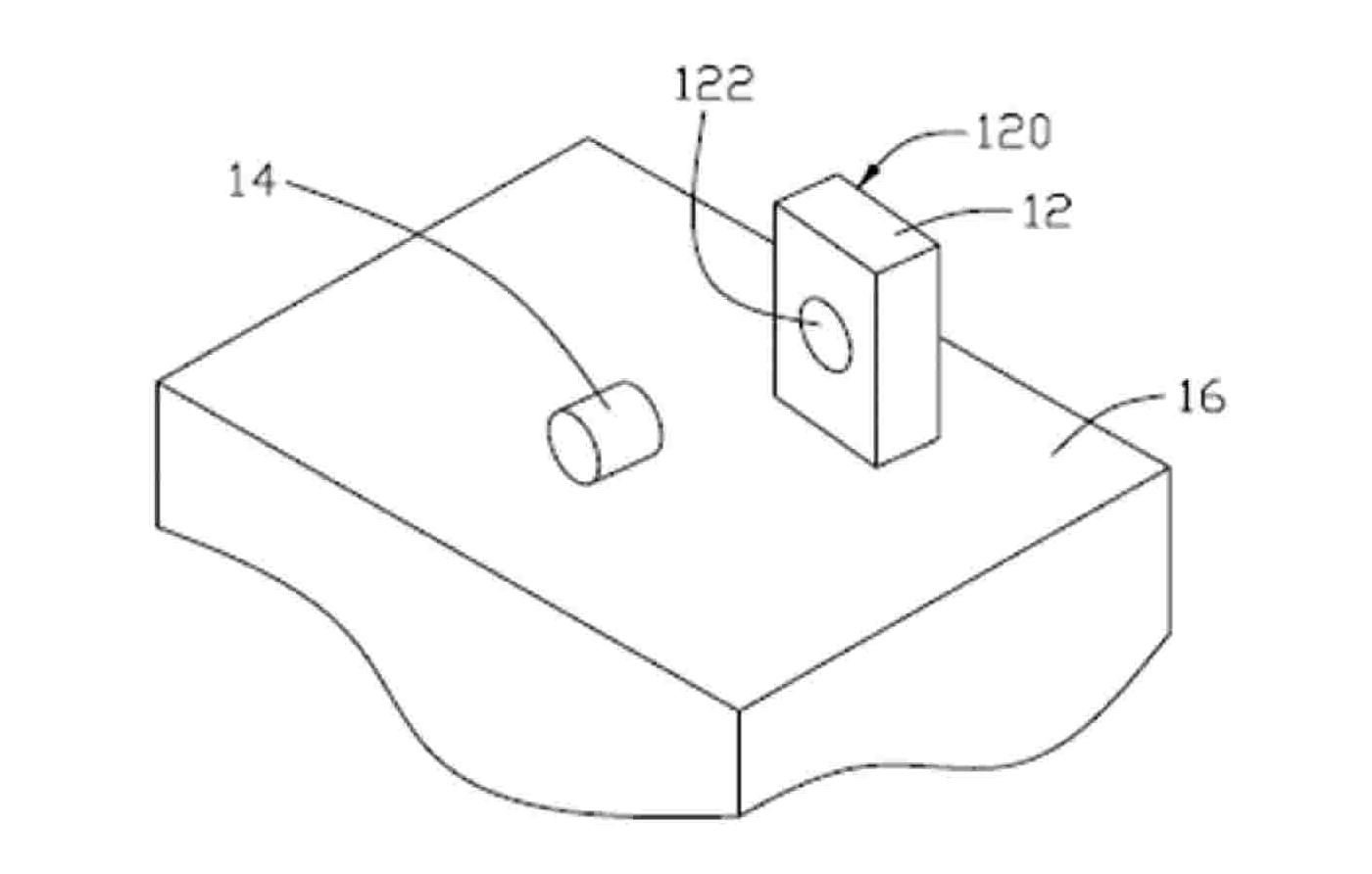

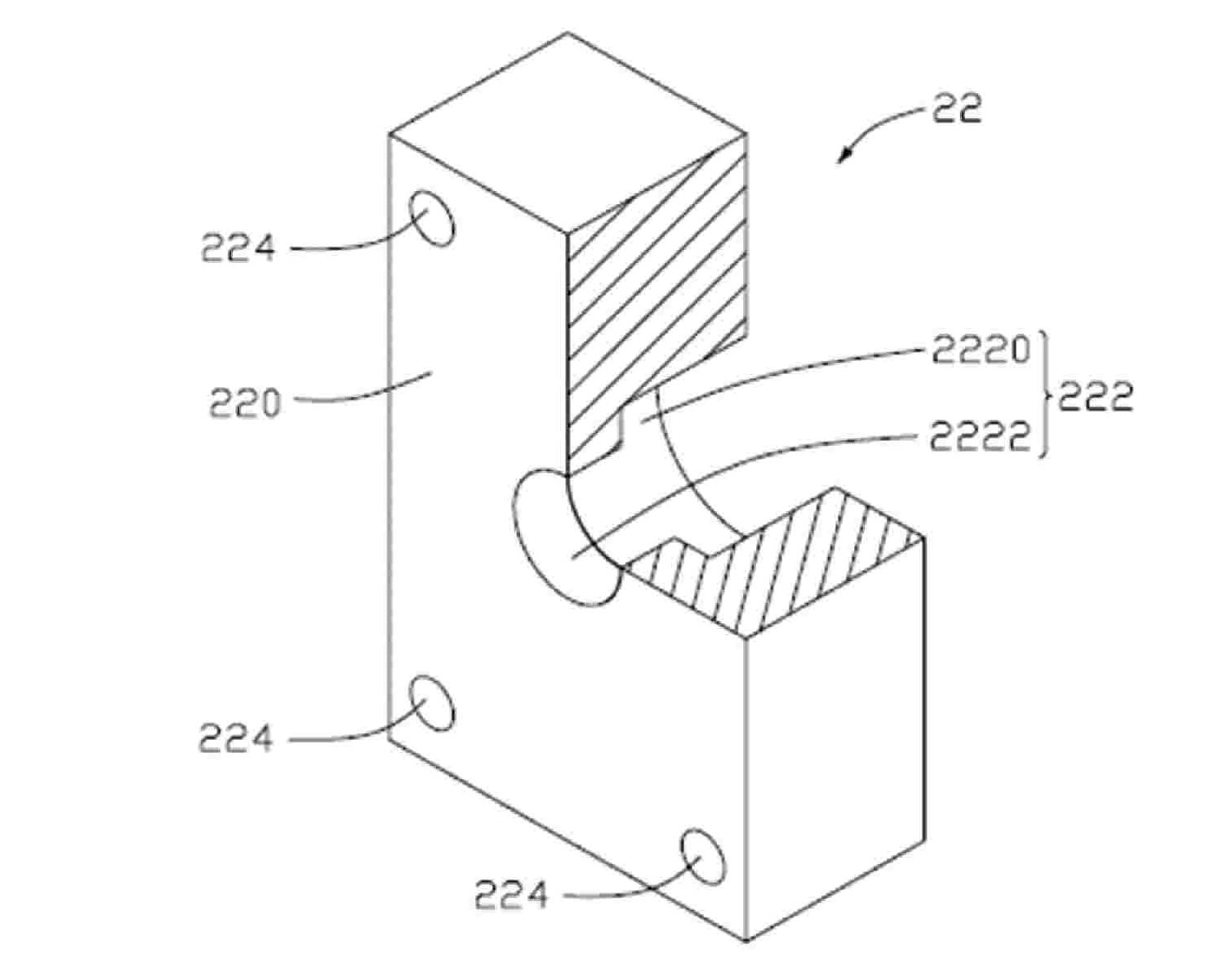

[0016] The first embodiment of the present invention provides a method for assembling a mold core insert, which mainly includes the following steps: 1). Provide a mold core base body and a mold core insert with a molding surface, the mold core base body has A clamping surface with several screw holes formed on the clamping surface, and the base of the mold core also has a cavity for inserting the core through the base of the mold core; 2). Drill the screw into the screw hole of the base of the mold core ; 3). Place the base of the mold core horizontally on the workbench, with the clamping surface of the base of the mold core facing the workbench, and adjust the height of the screw so that the base of the mold core is placed horizontally on the workbench; 4). Put the core of the mold into the Assemble the mold core into the sub-cavity with the molding surface facing the workbench; 5). Take out the screws.

[0017] The method in this embodiment will be described in detail below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com