Tablet press device for semiconductor chamber

A technology of tablet pressing device and semiconductor, applied in semiconductor/solid-state device manufacturing, discharge tube, electrical components, etc. Tablet quality and tableting efficiency, improving structural stability, and increasing the effect of tablet feeding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

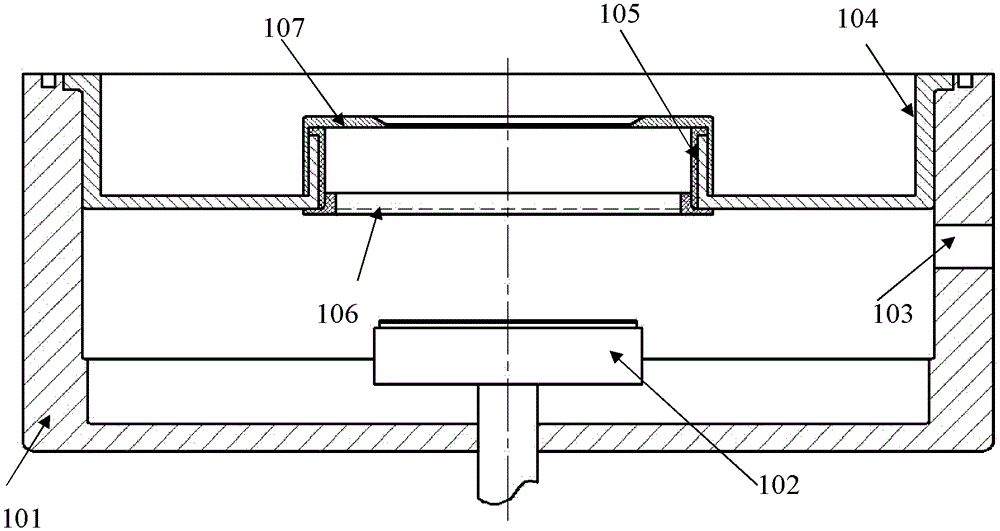

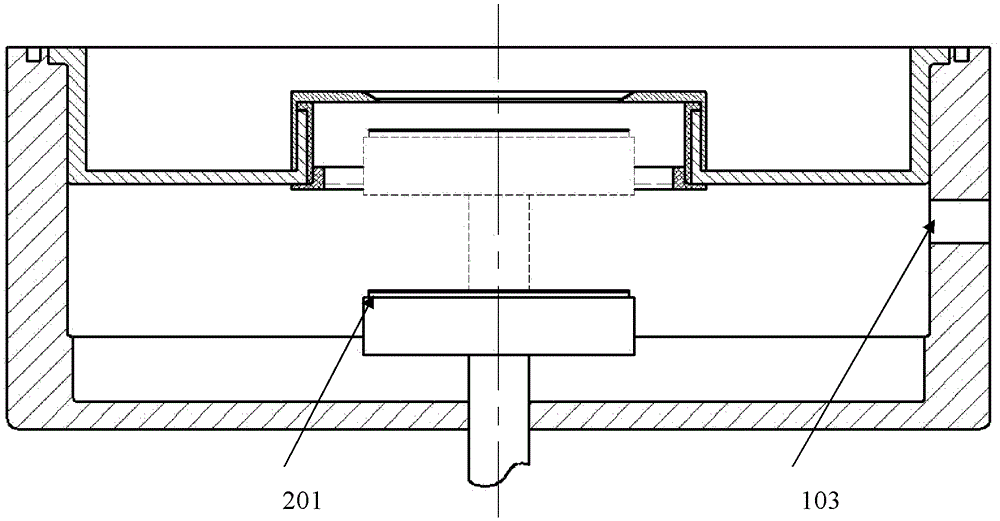

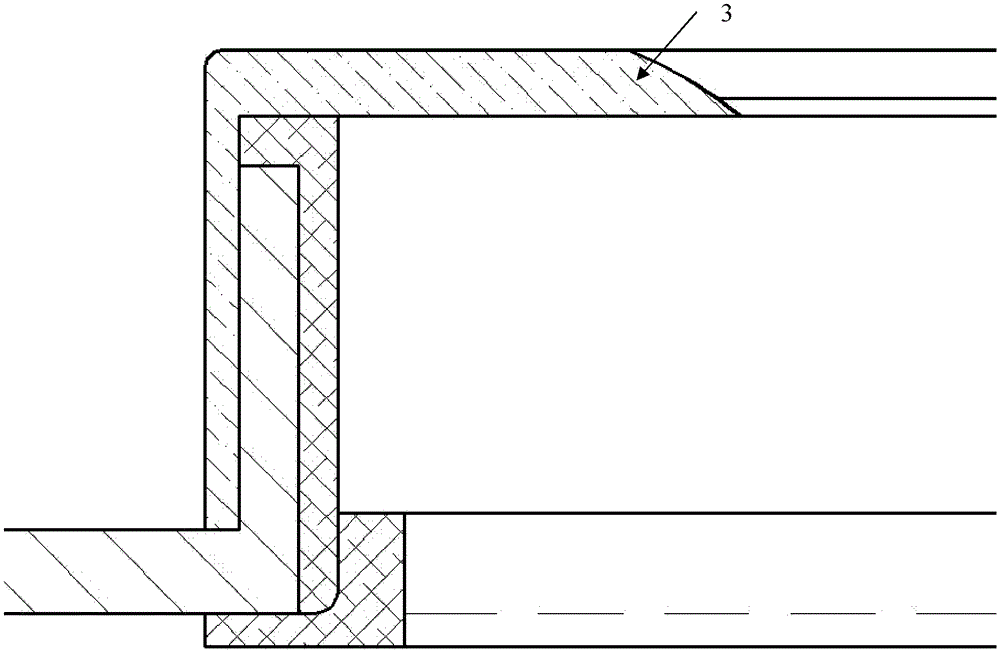

[0023] See figure 1 A tablet pressing device for a semiconductor chamber provided by an embodiment of the present invention includes a reaction chamber 101, a chamber lining 104, a tablet holder 107, a polytetrafluoroethylene protective cover 105, a support bracket 106, and a slide mechanism 102. The reaction chamber 101 is provided with a film feeding hole 103. The slide mechanism 102 is an electrostatic chuck or a slide table. The tablet press rack 107 is arranged in the upper half of the reaction chamber 101. The height of the tablet press rack is low, which makes the film feeding space large, which is beneficial to the smooth and rapid progress of the film feeding process of the film feeding mechanism, and also provides a certain amount of the film feeding mechanism. Independent design space. The tablet press frame 107 is in a "concave" shape, the two ends of the tablet press frame 107 have through holes, and the cavity lining 104 is inserted into the through holes. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com