Patents

Literature

38results about How to "Improve tableting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tableting method for sampler wafer with boric acid substrate applied to XRFS analysis

ActiveCN110470685AEasy to smoothImprove tableting efficiencyMaterial analysis using wave/particle radiationProduction rateBoric acid

The invention relates to a tableting method for a sampler wafer with a boric acid substrate applied to XRFS analysis. The technical scheme of the method comprises the steps of putting 2.5-3.5g boric acid into the bottom of a material cavity of a tableting machine, and spreading out to acquire a substrate layer; preparing a thin film material with the thickness of 0.5-1mm into a wafer with a diameter d that is equal to d0-(3-5mm), and thus acquiring a liner film, wherein d0 is the diameter of the material cavity of the tableting machine, mm; then tiling the liner film on the substrate layer, and uniformly spreading 0.5-3g sample powder onto the liner film; and at last floating the sample powder by using a sample spoon, installing a press head of the tableting machine, pressurizing, keepingthe pressure and demolding to acquire the sampler wafer with the boric acid substrate applied to XRFS analysis. The method has the characteristics of being high in efficiency, not prone to generate astripping layer, small in consumption of sample powder, and high in production rate.

Owner:WUHAN UNIV OF SCI & TECH +2

Camellia nitidissima lozenge and preparation method thereof

InactiveCN105725212APrevent oxidationPrevent escapeMetabolism disorderPharmaceutical non-active ingredientsOysterMagnesium stearate

The invention discloses a camellia nitidissima lozenge and a preparation method thereof. The camellia nitidissima lozenge comprises the following components in parts by weight: 40-50 parts of camellia nitidissima, 5-10 parts of spirulina, 15-20 parts of trepan, 20-30 parts of oyster, 3-5 parts of xylitol, 2-3 parts of an arhat fruit extract, 7-9 parts of microcrystalline cellulose and 5-7 parts of magnesium stearate. In the preparation process, a carbon dioxide supercritical extraction method is adopted to extract effective components such as general flavones and tea polyphenol in camellia nitidissima at relatively low temperature, oxidation and diffusion of thermosensitive substances can be effectively prevented, no solvent residue can be generated, and the quality of the camellia nitidissima lozenge can be improved.

Owner:马占平 +2

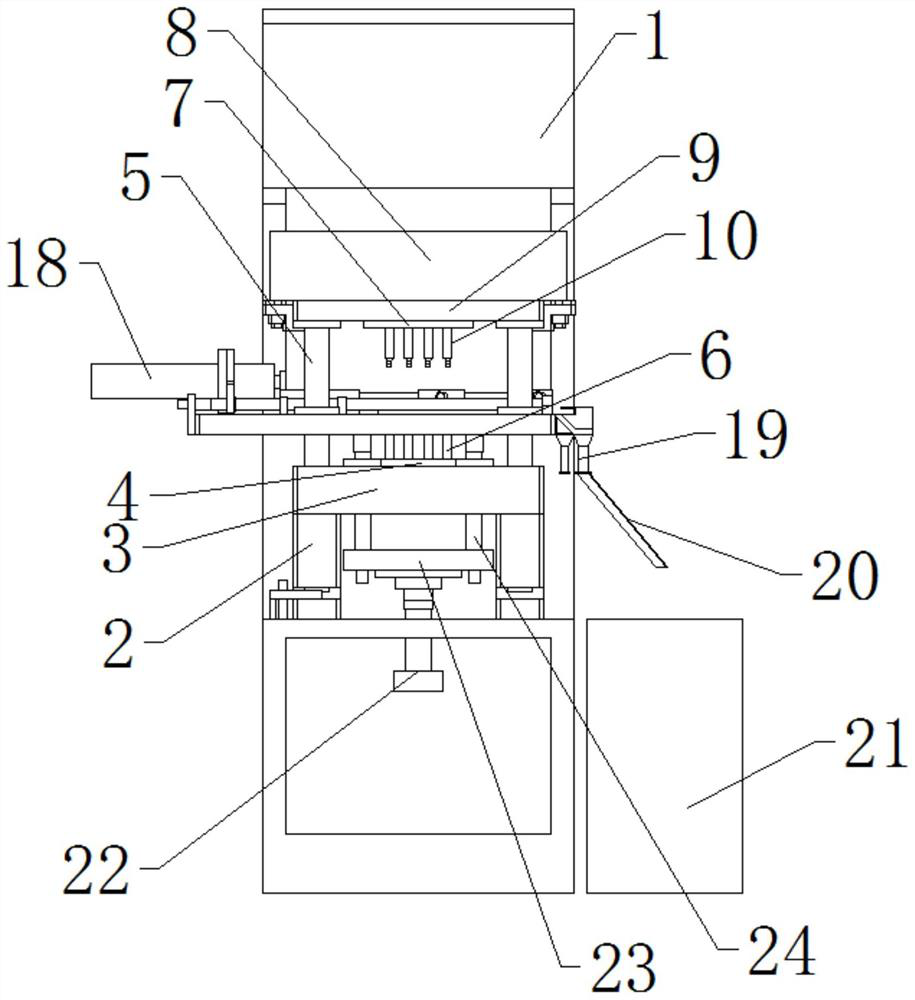

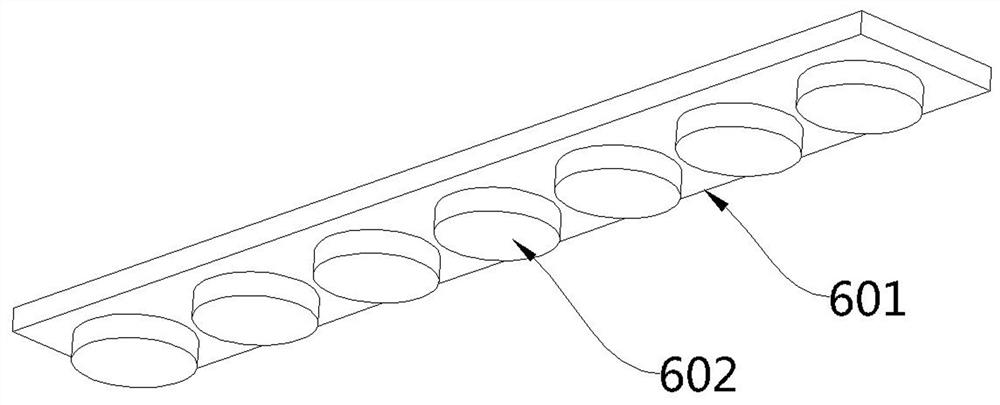

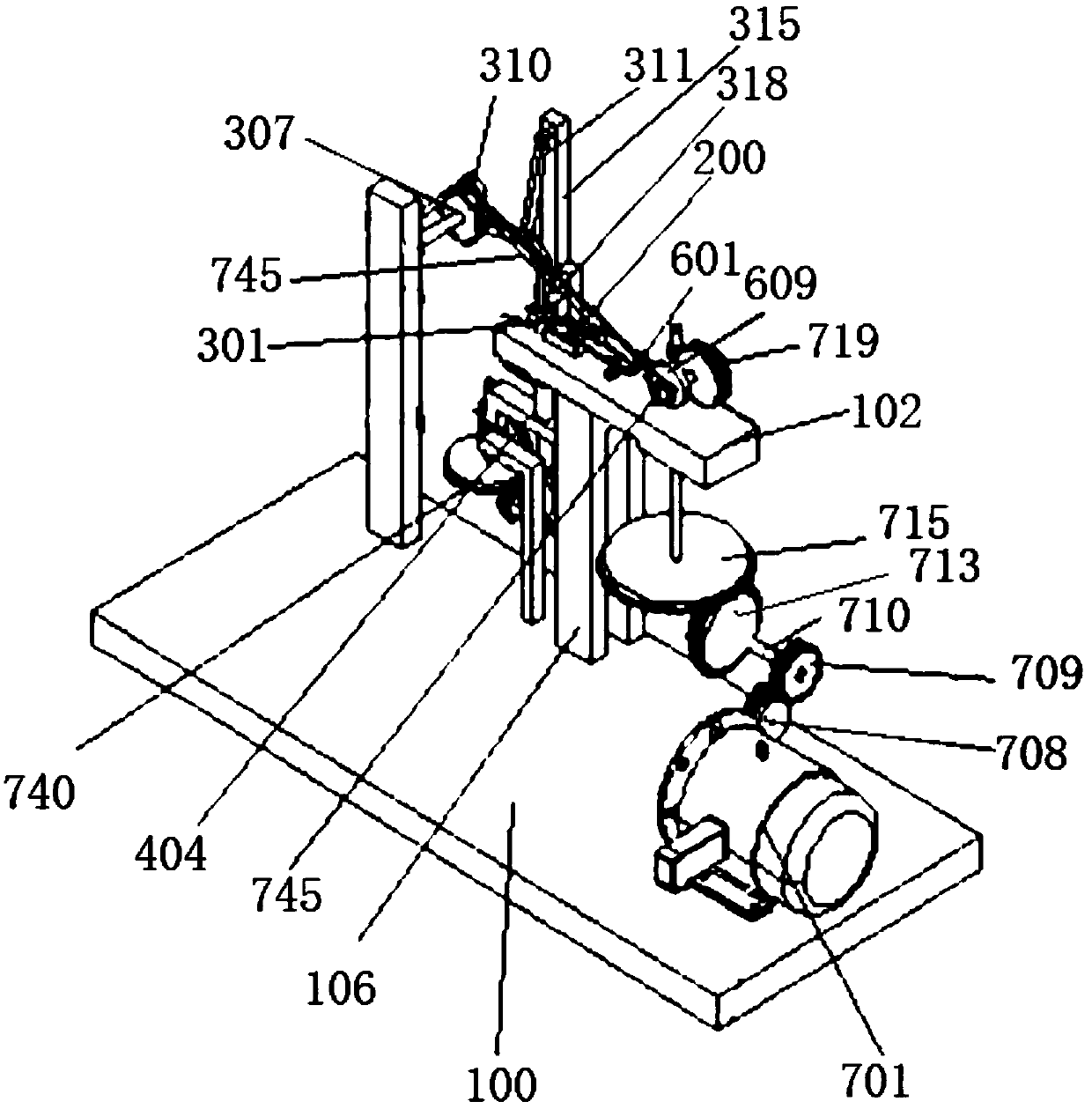

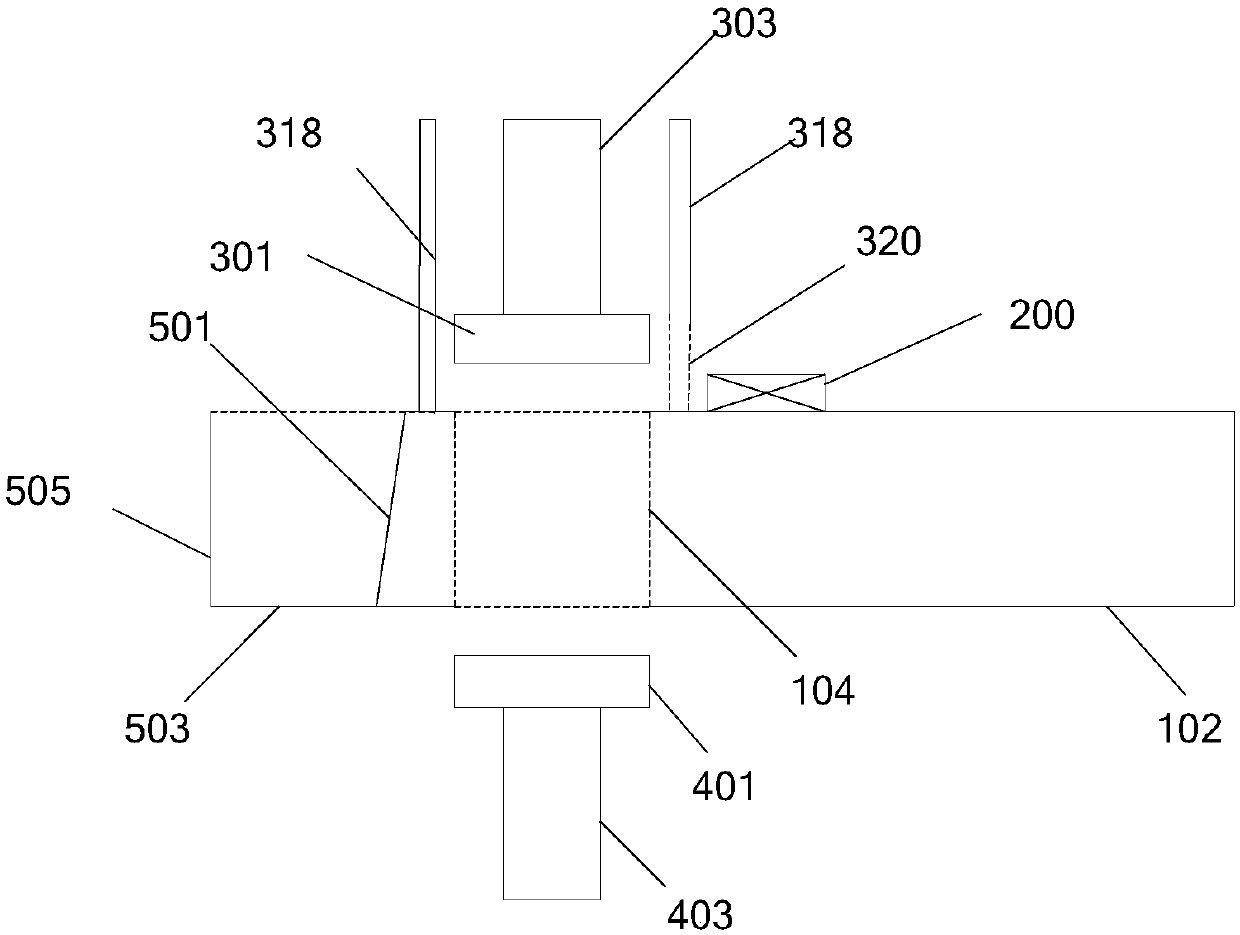

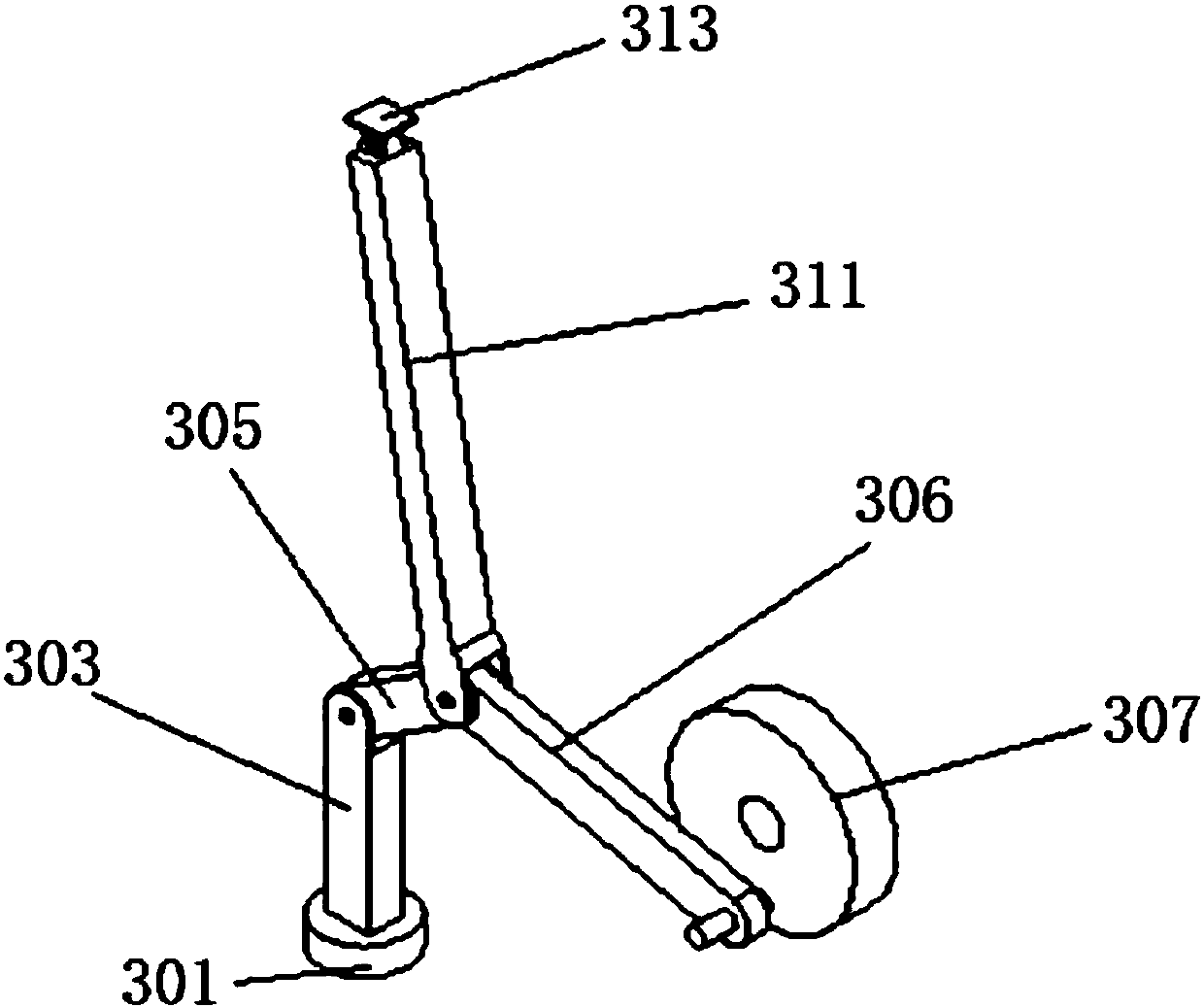

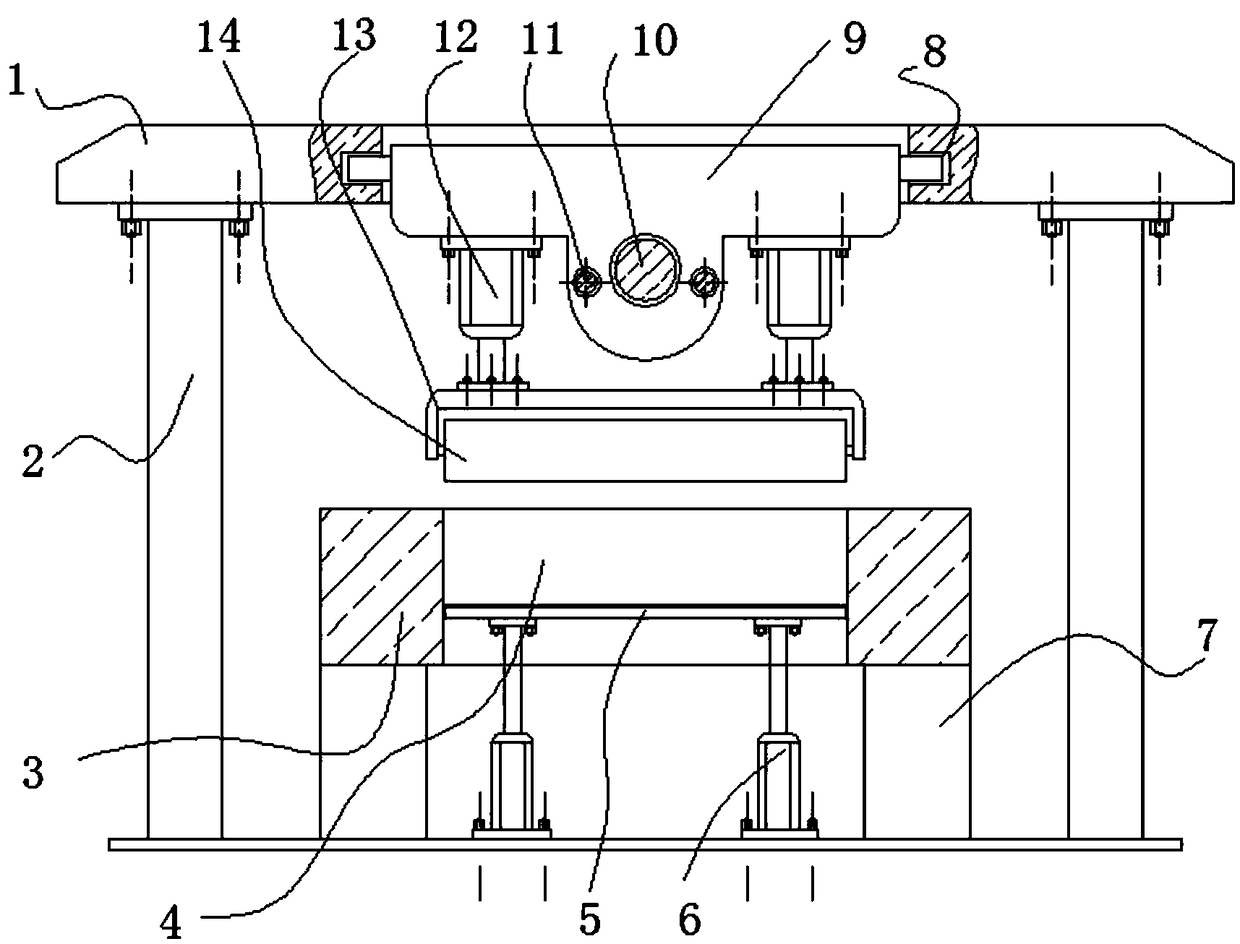

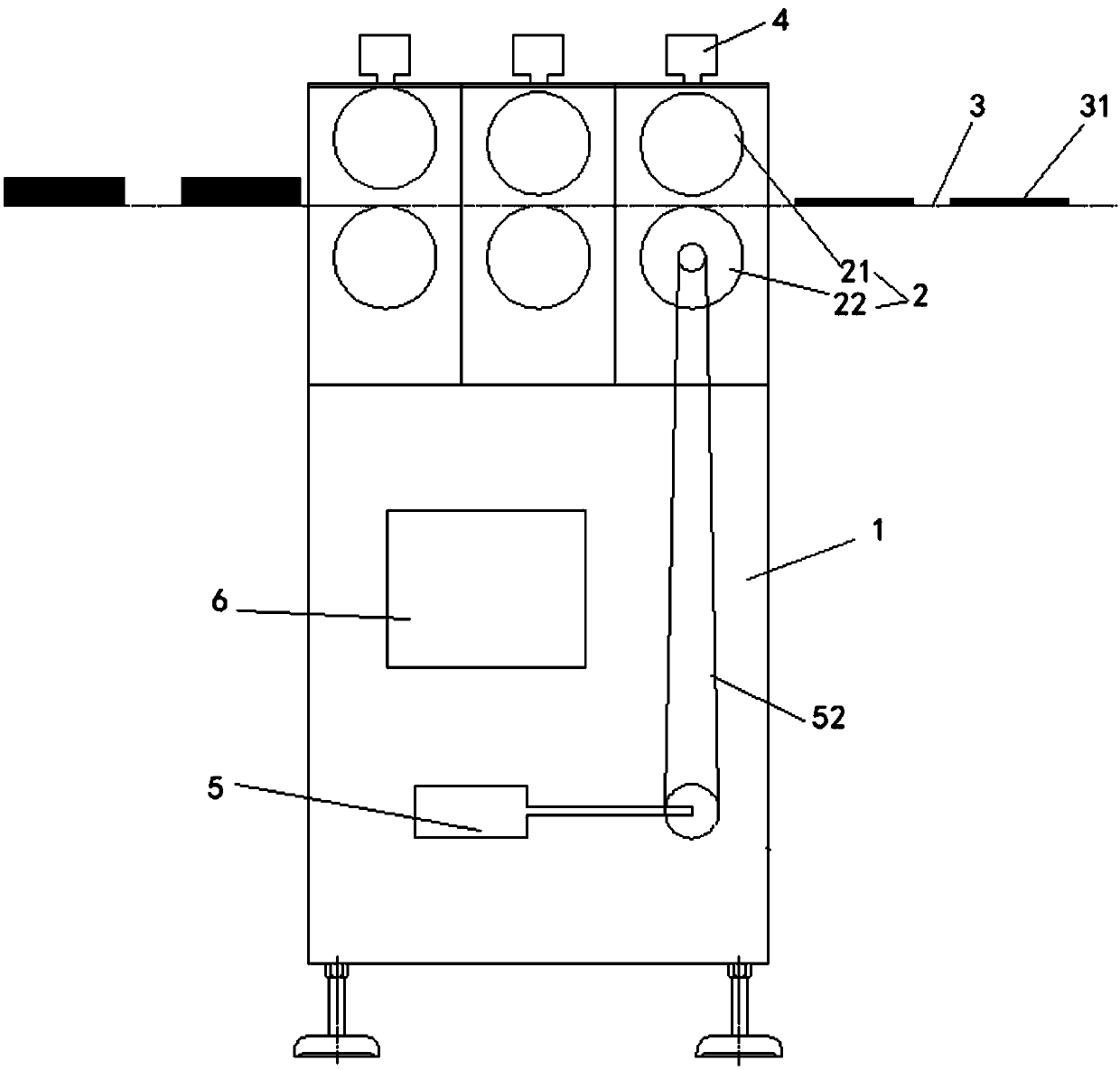

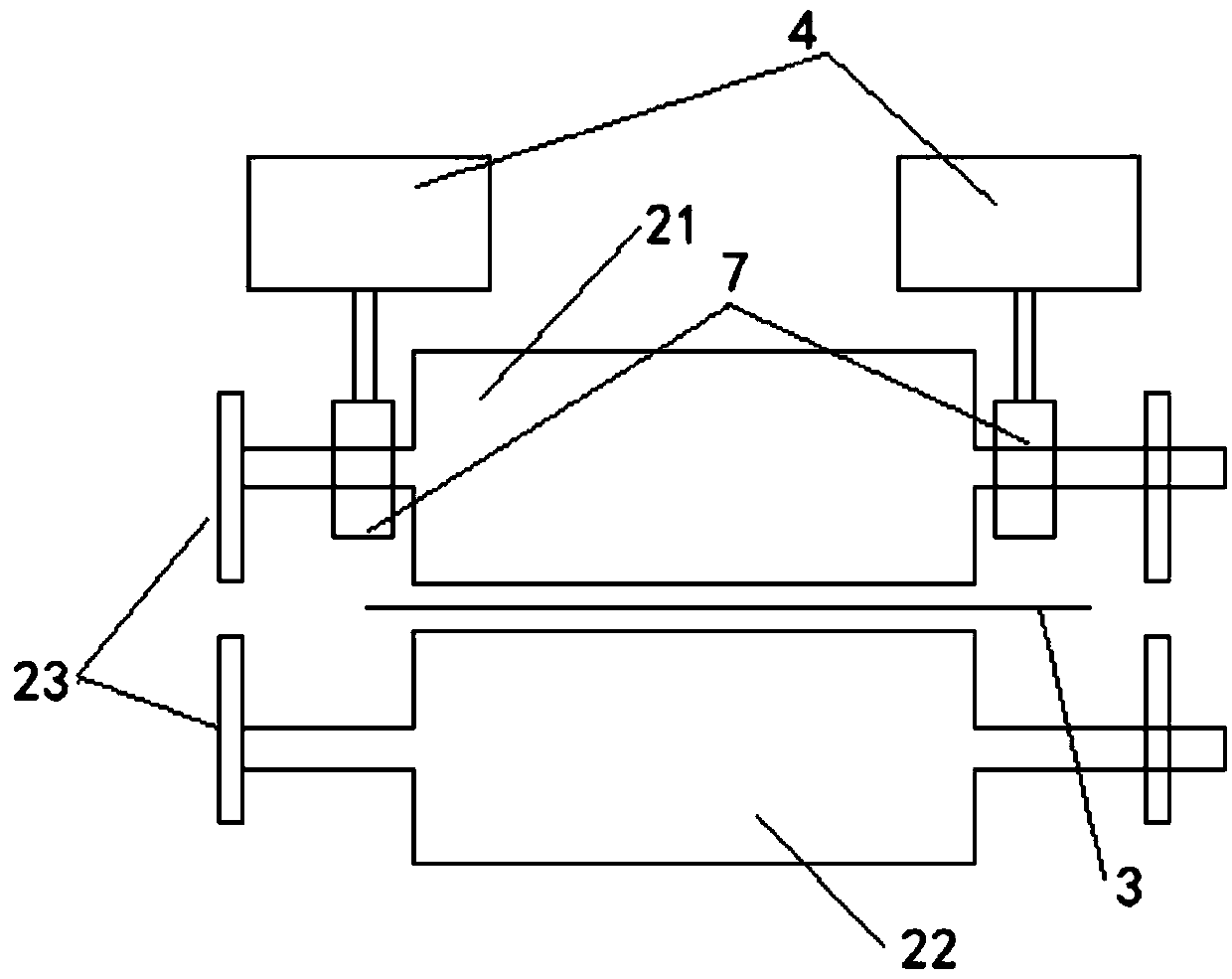

Improved equipment for improving tabletting production capacity

The invention relates to the technical field of tabletting, in particular to an improved device for improving tabletting production capacity. The equipment comprises a rack, a lower mold plate is arranged at the end part of the rack, lower mold heads are uniformly arranged on the base surface of a lower mold plate pressing plate, an upper mold plate is arranged at the end part of a guide column, upper mold heads are uniformly arranged at the bottom of an upper mold plate pressing plate, a middle mold plate is arranged in the middle of a base face of a workbench, material scattering boxes are installed on the outer walls of a first guide polished rod and a second guide polished rod, the middle mold plate can be rapidly filled through the material scattering boxes, feeding of the middle mold plate is simple and convenient, tabletting forming can be rapidly conducted through an arranged upper mold heads, the tabletting efficiency is improved, formed tablets can be rapidly pushed and discharged through the material scattering boxes, feeding and discharging can be carried out at the same time, the overall tablet pressing capacity is improved, the height of the workbench can be controlled through a pull rod, the formed tablets can be rapidly ejected out through the lower mold heads, and the discharging efficiency is improved.

Owner:BEIJING WANHUI DOUBLE CRANE PHARMA

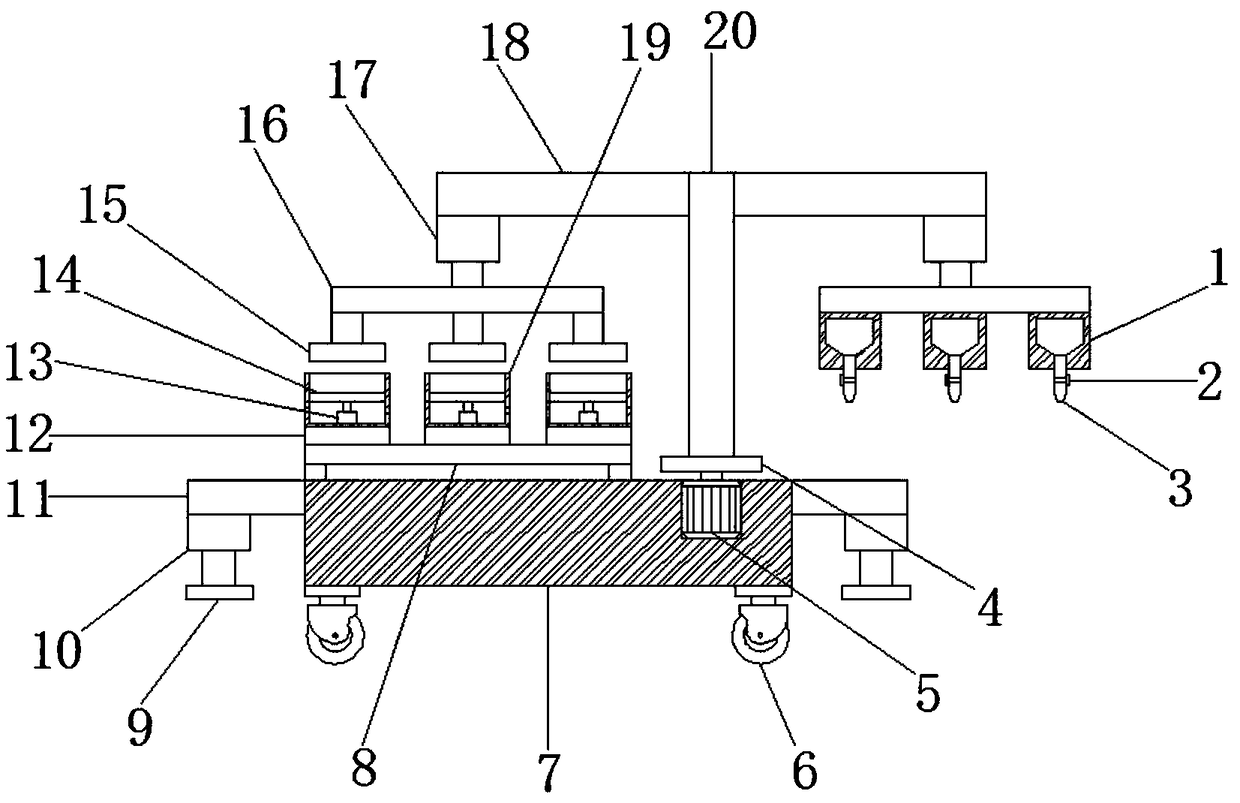

Automatic tabletting device for pharmacy

ActiveCN108891064AImprove tableting efficiencyRealize the integrated production modeShaping pressPharmacyMaterial resources

The invention discloses an automatic tabletting device for pharmacy. The device comprises a base, universal wheels are fixed to the four corners of the outer wall of the base through screws, a workingtable is fixed to one side of the outer wall of the top of the base through the screws, a pressure sensor is fixed to the outer wall of the top of the working table through screws, a tabletting box is arranged on the outer wall of the top of the pressure sensor, an electric telescopic rod is fixed to the inner wall of the bottom of the tabletting box through a screw, a lifting plate is fixed to an output end of the electric telescopic rod through a screw, the lifting plate and the inner wall of the tabletting box form sliding fit, a groove is formed in other side of the outer wall of the topof the base, and a rotating motor is fixed to the inner wall of the bottom of the groove through screws. Accordingly, the integrated production mode from medicine powder filling to tabletting is achieved, the automation degree is high, manpower and material resources are saved, the tabletting efficiency of tablets is significantly improved, the tabletting effect is good, the tabletting quality isimproved, and medicine taking is very convenient.

Owner:张效法

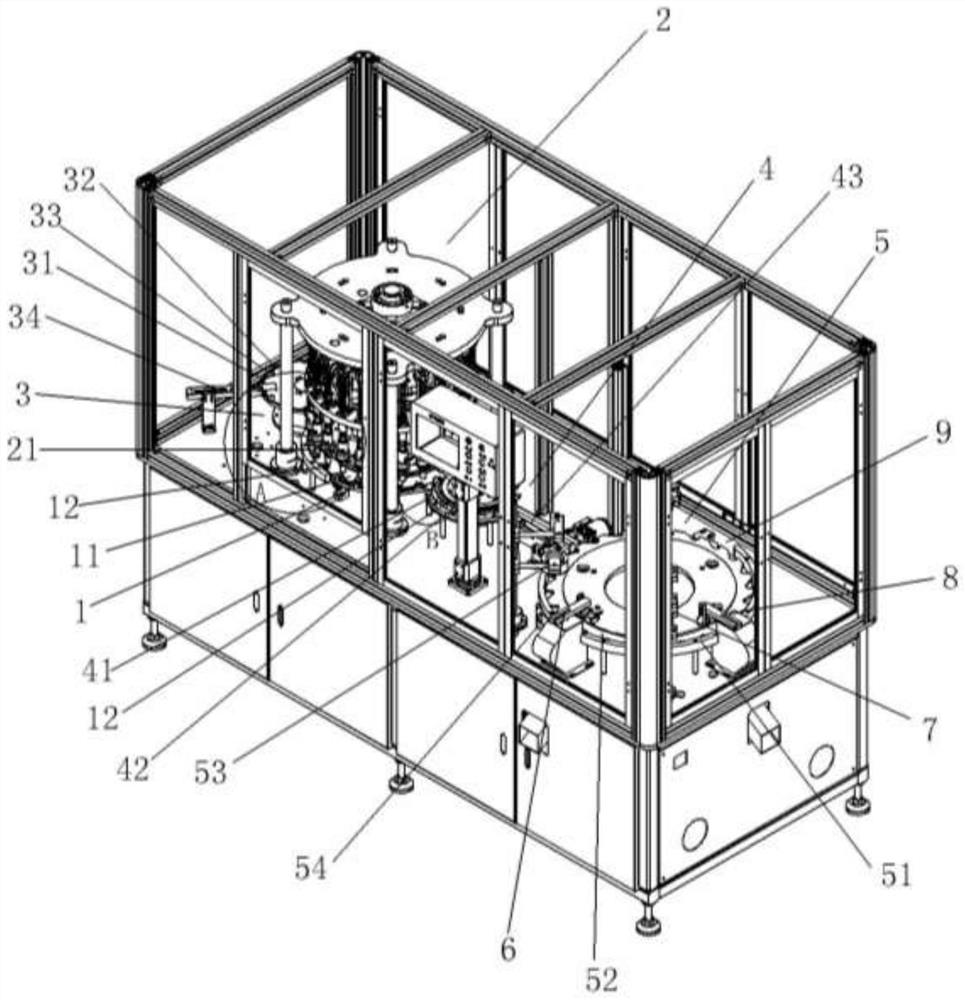

Efficient gasket pressing device for bottle cap inner gasket

ActiveCN111037261AReduce the number of settingsReduce labor intensityMetal working apparatusClassical mechanicsElectric machinery

The invention discloses an efficient gasket pressing device for a bottle cap inner gasket, relates to the technical field of bottle cap machining equipment, and solves problems that a gasket pressingdevice can complete all tabletting processes only through manual multi-time distribution operation, the automation degree is low, operation steps are tedious, labor intensity of workers is high, and tabletting efficiency is low. The device comprises a pushing wheel and a sliding plate, wherein bottle caps are arranged in a long-strip-shaped containing box, a motor is supported and installed on anouter side of a front end of a base plate, a gasket containing barrel is further supported and welded to the middle of the base plate, a jacking round plate is inserted in a supporting and installingplate at the bottom of a rear side of the gasket containing barrel in a jacking and penetrating mode through a spring, a pushing wheel support is located on the left side of the gasket containing barrel, a sliding plate support is located at a top end of the middle position of the base plate. The device is advantaged in that two positioning inserting rods in the device can serve as reference standards, and the long-strip containing box can be conveniently arranged at the preset position of the initial standard in a sliding mode.

Owner:GUANGZHOU SHILI PACKAGING MATERIAL CO LTD

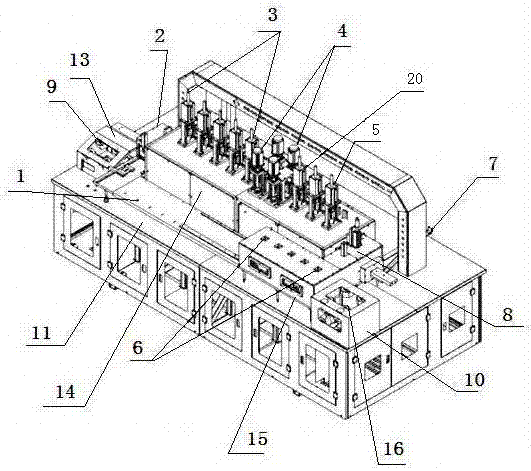

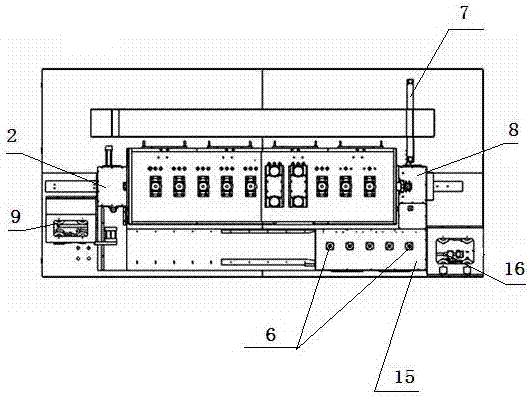

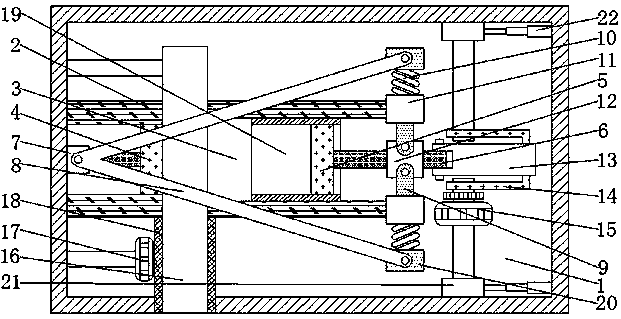

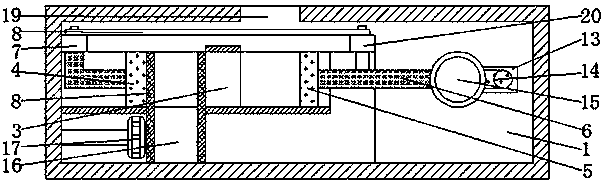

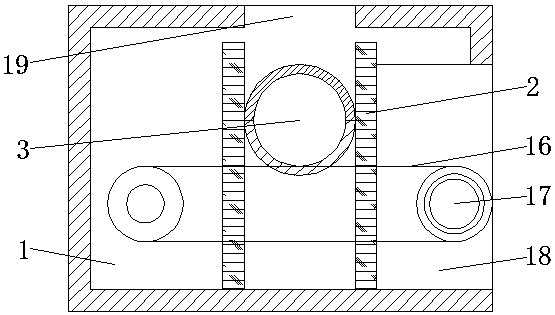

Machine and method for forming free curved surfaces of silicate glass

InactiveCN107129133AImprove insulation effectReduce power consumptionGlass reforming apparatusGlass productionSilicate glassMolding machine

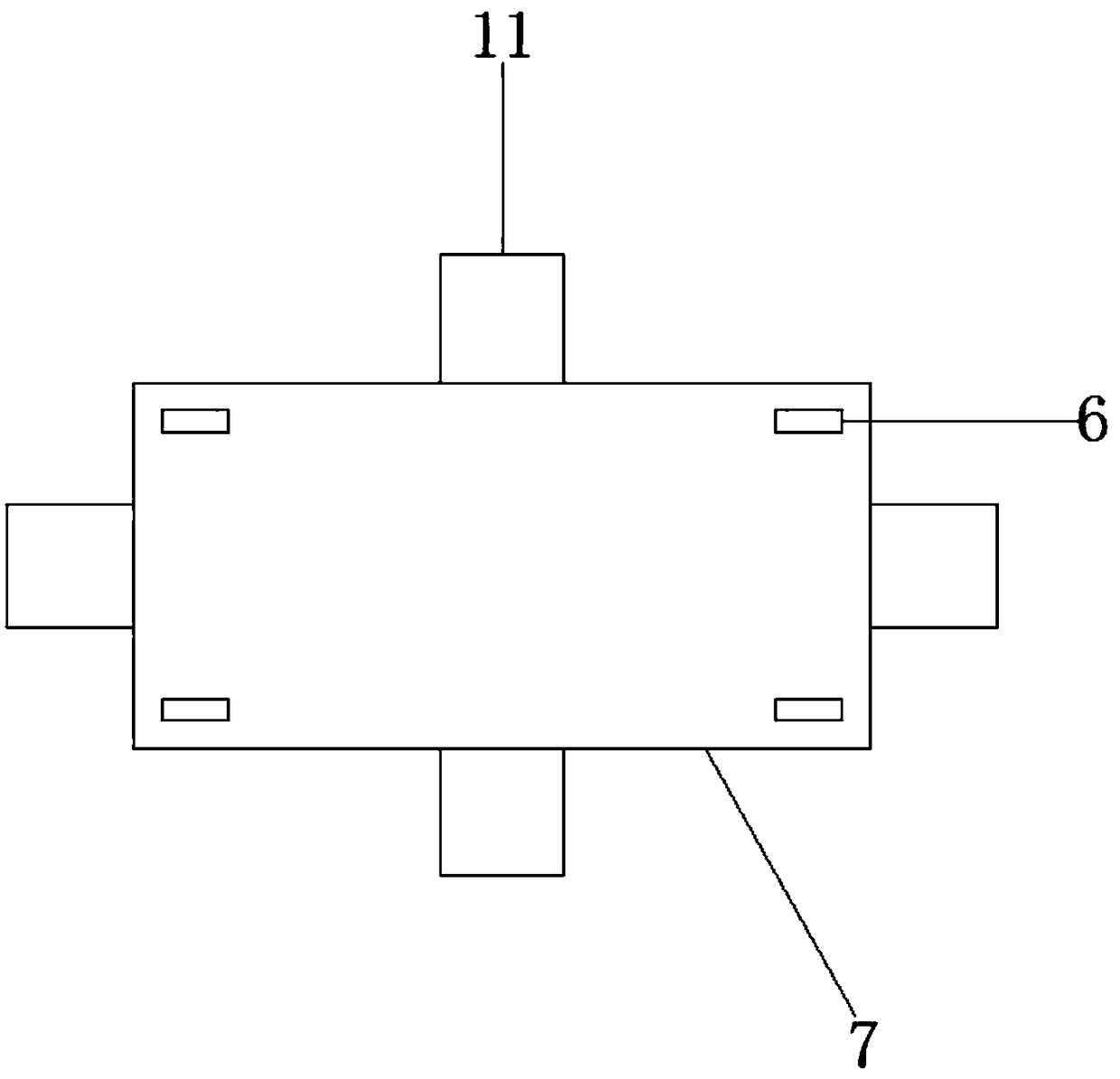

The invention discloses a machine and a method for forming free curved surfaces of silicate glass, and is applicable to machines and methods for forming free curved surfaces of silicate glass. The machine comprises a tank (11). An upper plane of the tank is fixed to a worktable (1), a furnace chamber (14) and a cooling chamber (15) are mounted above the worktable, the cooling chamber is mounted at the front end of the furnace chamber, a feed chamber (2) and a discharge chamber (8) are arranged on two sides of the furnace chamber, a push mechanism B (10) is mounted on the right side of the cooling chamber, the left side of the worktable is connected with a push mechanism A (13) by bolts, preheating devices (3), forming devices (4), a setting device (20) and a slow cooling device (5) are arranged in the furnace chamber, and cooling devices (6) are arranged in the cooling chamber. The machine and the method have the advantage that the problems of explosion and deformation phenomena of glass, decrease of the yield of products and deterioration of the quality of the products due to the fact that existing hot bending machines for the glass with curved surfaces directly enter annealing stations after the glass is formed, molds are excessively high in cooling speeds and the glass is excessively high in temperature difference can be solved.

Owner:HARBIN XINLI PHOTOELECTRIC TECH

Technological method of producing ibuprofen tablets through two times of granulation

InactiveCN109512792AGood dispersionMask bitternessOrganic active ingredientsAntipyreticAcrylic resinBULK ACTIVE INGREDIENT

The invention discloses a technological method of producing ibuprofen tablets through two times of granulation. Silicon dioxide is used for assisting an acrylic resin drug carrier in coating ibuprofenmicro-powder, then one-time granulation is conducted, in the one-time granulation process, colloidal silicon dioxide is taken as an auxiliary material, it is ensured that ibuprofen original drugs isevenly distributed in the granulation process, the flowability of ibuprofen dispersions is improved, and the tabletting efficiency of ibuprofen granules is improved; and the ibuprofen granules obtained through a two-time granulation treatment technology are subjected to tabletting treatment, compared with a technological method in the prior art, the ibuprofen tablets prepared through the technological method is good in flowability, the content of the ibuprofen original medicine in the ibuprofen tablets is maintained, and the obtained tablets have the higher active ingredient dose and have theadvantages of being good in stability, high in bioavailability, not liable to absorb moisture and the like.

Owner:安徽东盛友邦制药有限公司

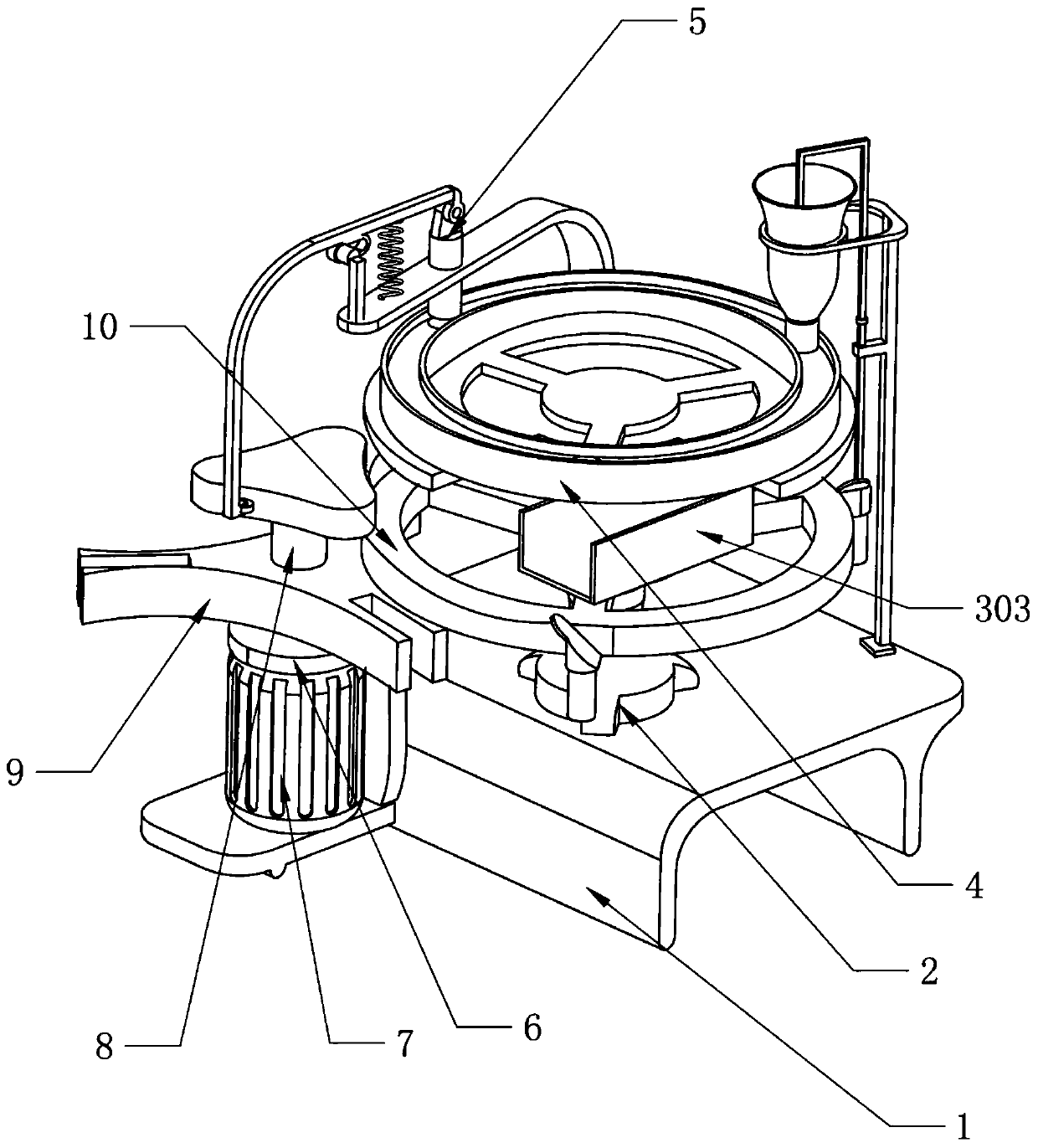

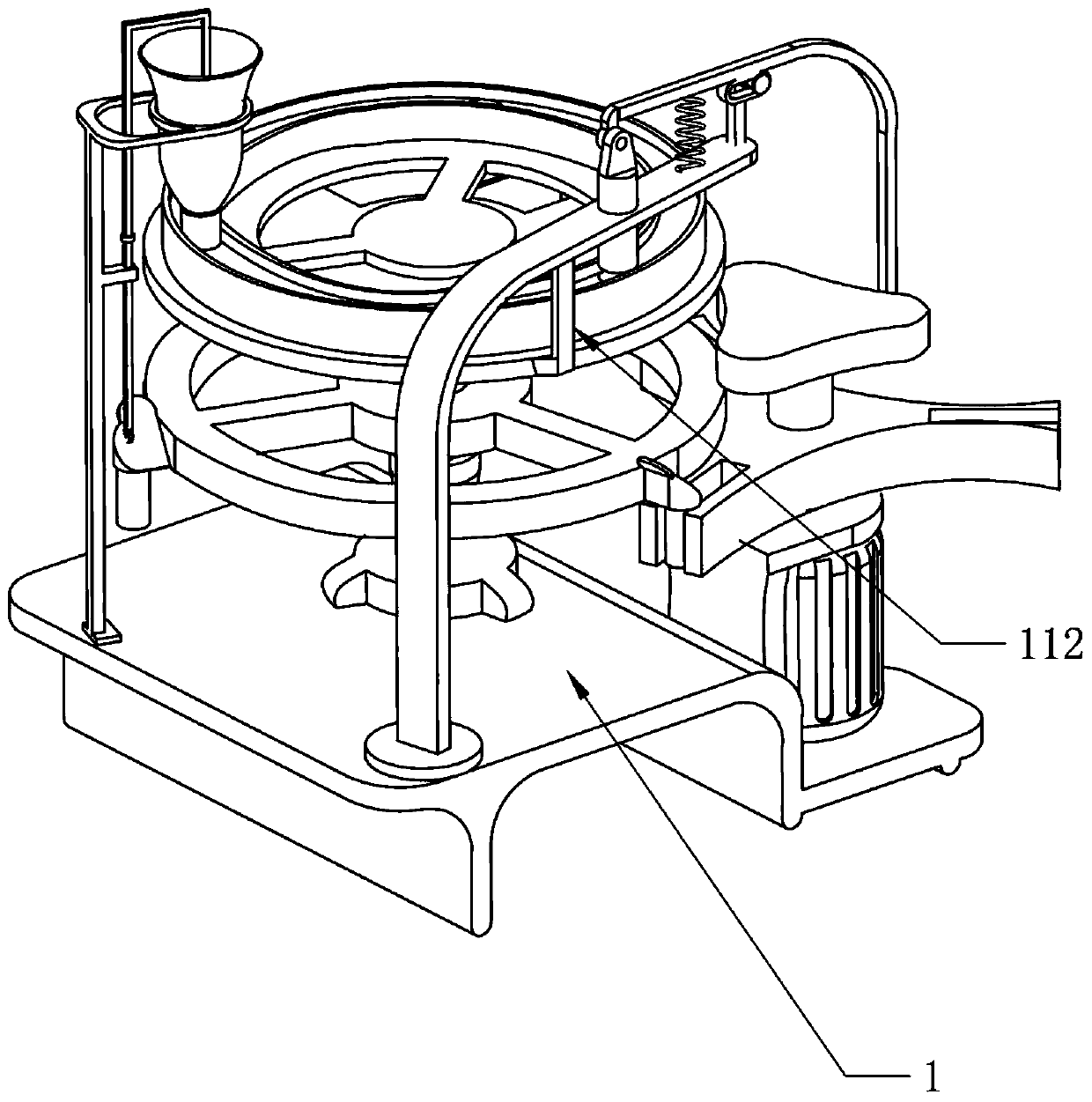

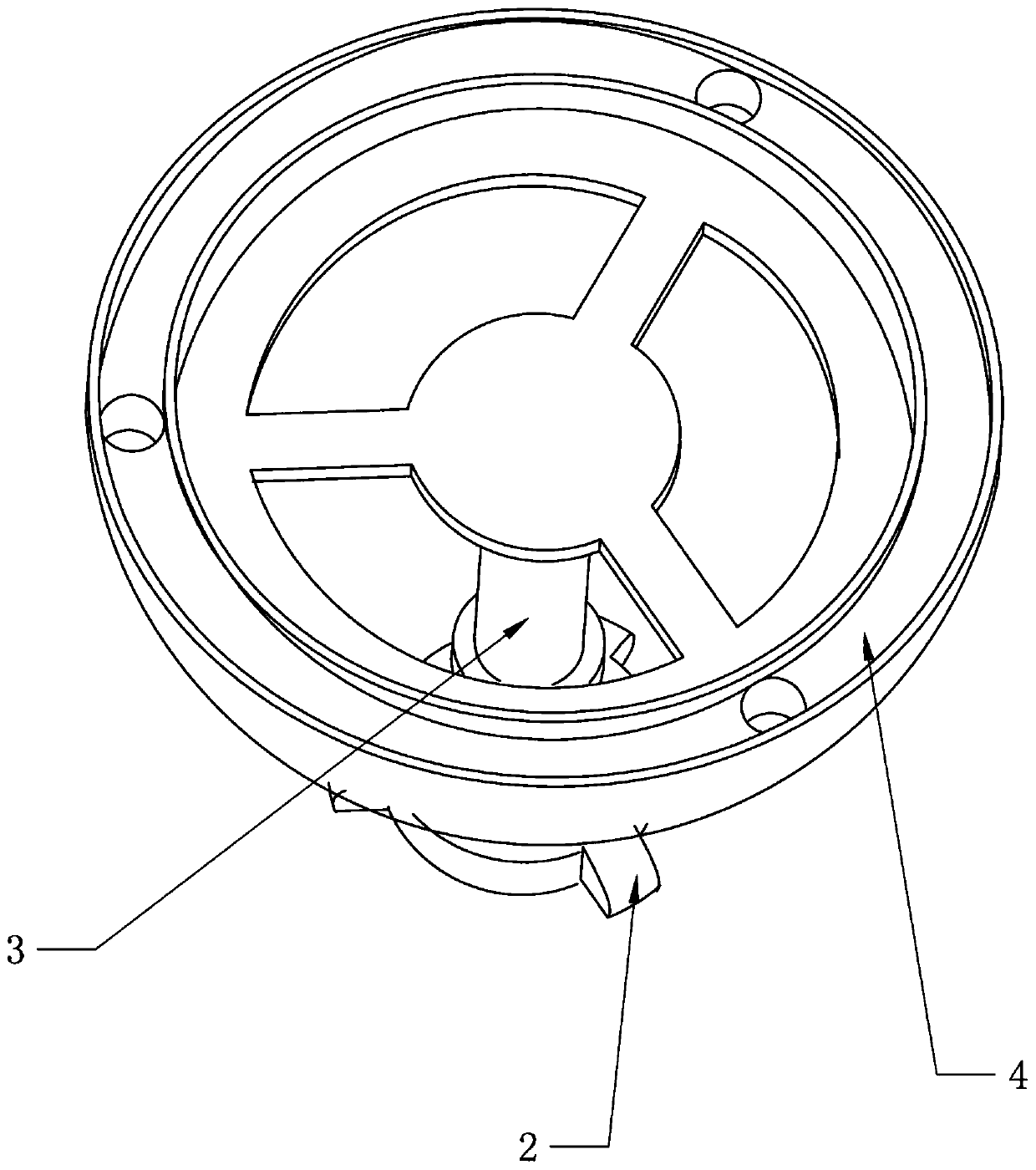

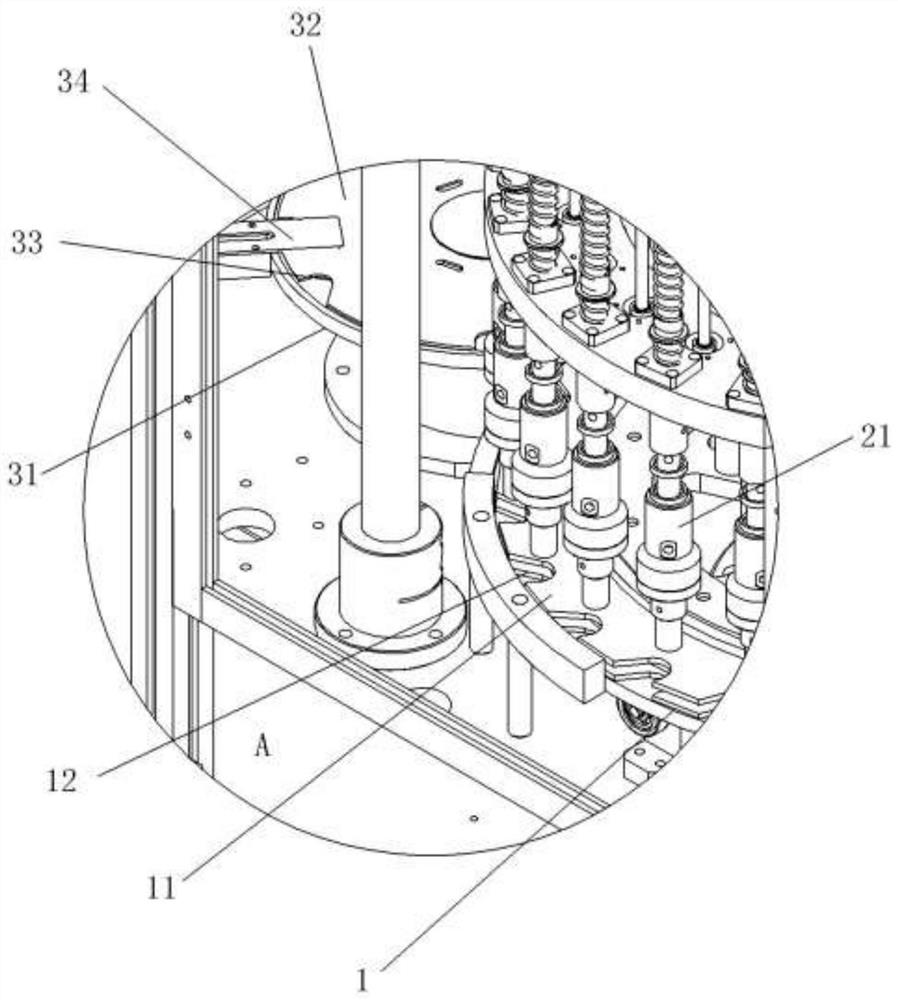

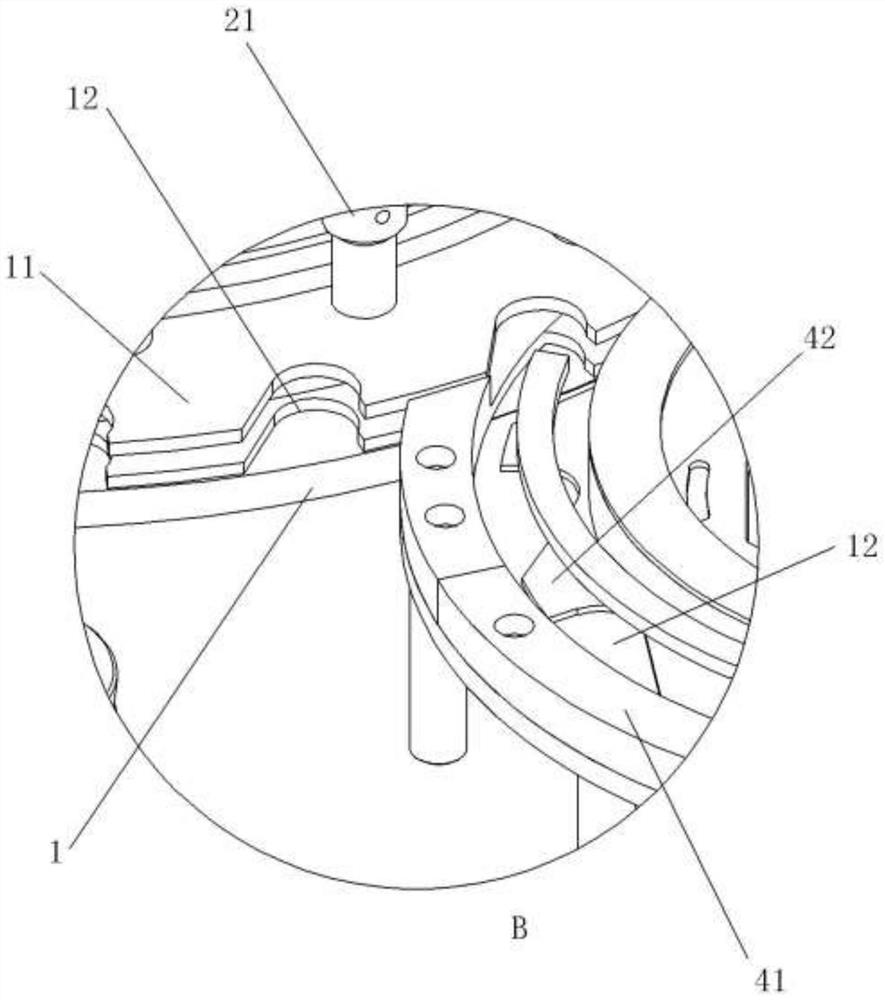

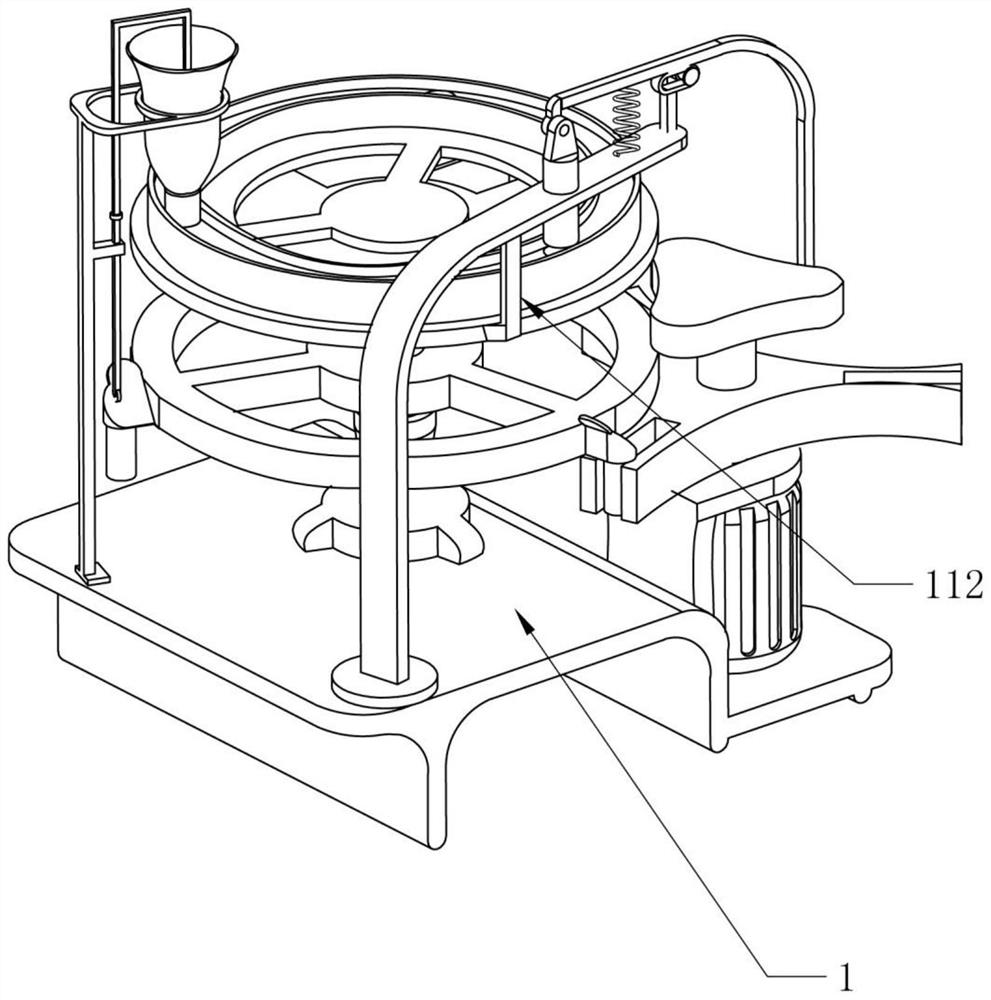

Automatic rotating medicine tablet press

ActiveCN110936652AImprove tableting efficiencyPrecision Tablet SpecificationsPress ramShaping pressTabletingMechanical engineering

The invention relates to a medicine tablet press, in particular to an automatic rotating medicine tablet press, and aims to provide the automatic rotary medicine tablet press which can place medicinepowder into a container to complete tabletting and collection automatically. The automatic rotating medicine tablet press comprises a bottom plate, a rotating base, a conversion shaft, a turntable, atablet pressing rod and the like. The rotating seat is arranged over the bottom plate, the conversion shaft is arranged in the rotating seat, the turntable fixedly sleeves the conversion shaft, a forming hole is formed in the turntable, and the tablet pressing rod matched with the forming hole is arranged on the turntable. According to the medicine tablet press, an operator only needs to put medicine powder into a medicine powder pot and start the motor to automatically tablet the medicine in batches, and compared with the prior art that the medicine is manually tabletted, the medicine tabletpress has the advantages that the tabletting efficiency is improved, the tabletting specification is accurate, pollution and waste are reduced, and the effects of time saving, labor saving, sanitation, environmental protection, convenience and rapidness are achieved.

Owner:JIANGXI JUWANG PHARMA IND

Tabletting device for effervescent tablets

PendingCN114683608ARealize tablet processingTablet effect is goodPharmaceutical product form changeShaping pressEffervescent tabletEngineering

The invention provides a tabletting device for effervescent tablets, and belongs to the technical field of effervescent tablet production, the tabletting device comprises a bottom box, a second driving assembly, a powder storage box, a first driving assembly, a tabletting assembly and an abutting assembly, one side of the bottom box is provided with a through hole matched with the effervescent tablets in shape, the powder storage box is movably arranged on one side of the bottom box, and the first driving assembly is arranged on the other side of the bottom box. The two opposite sides of the powder storage box are open and used for storing powder, the first driving assembly is arranged on one side of the bottom box, and the tabletting assembly is arranged at the output end of the first driving assembly and controlled by the first driving assembly to reciprocate in the direction perpendicular to a through hole. The abutting and supporting assembly is movably arranged on the inner wall of the bottom box. Compared with the prior art, the embodiment of the invention can realize automatic tabletting treatment of the effervescent tablets, and has the advantages of good tabletting effect and high tabletting efficiency.

Owner:汰帮广东日化用品有限公司 +1

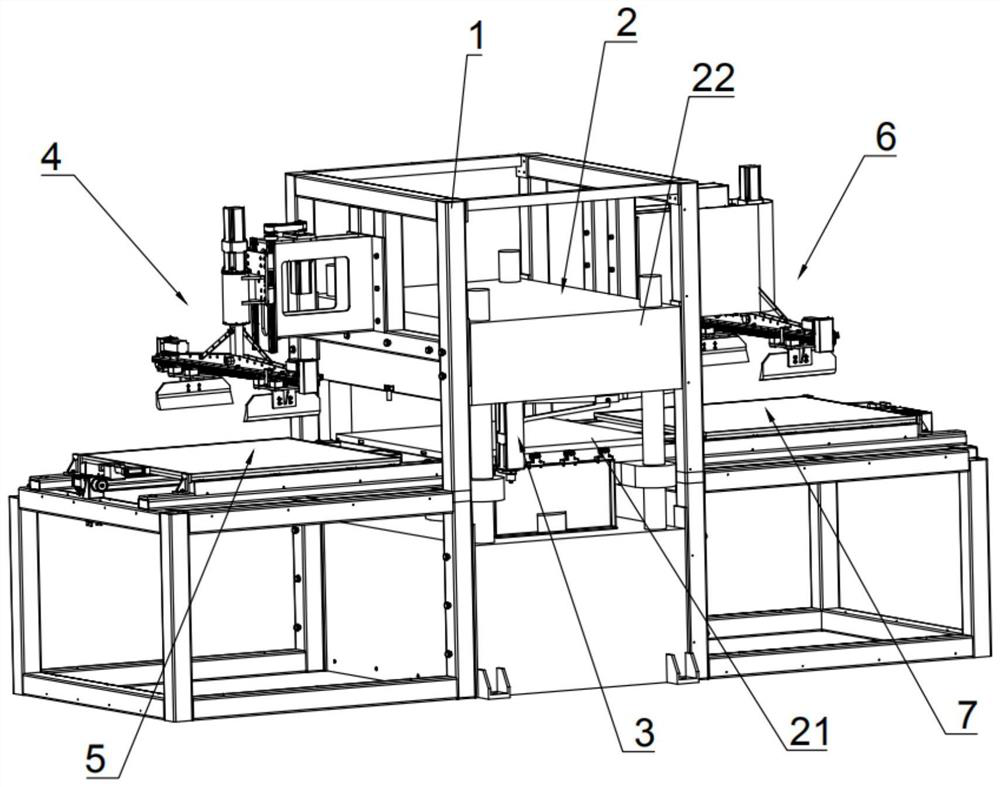

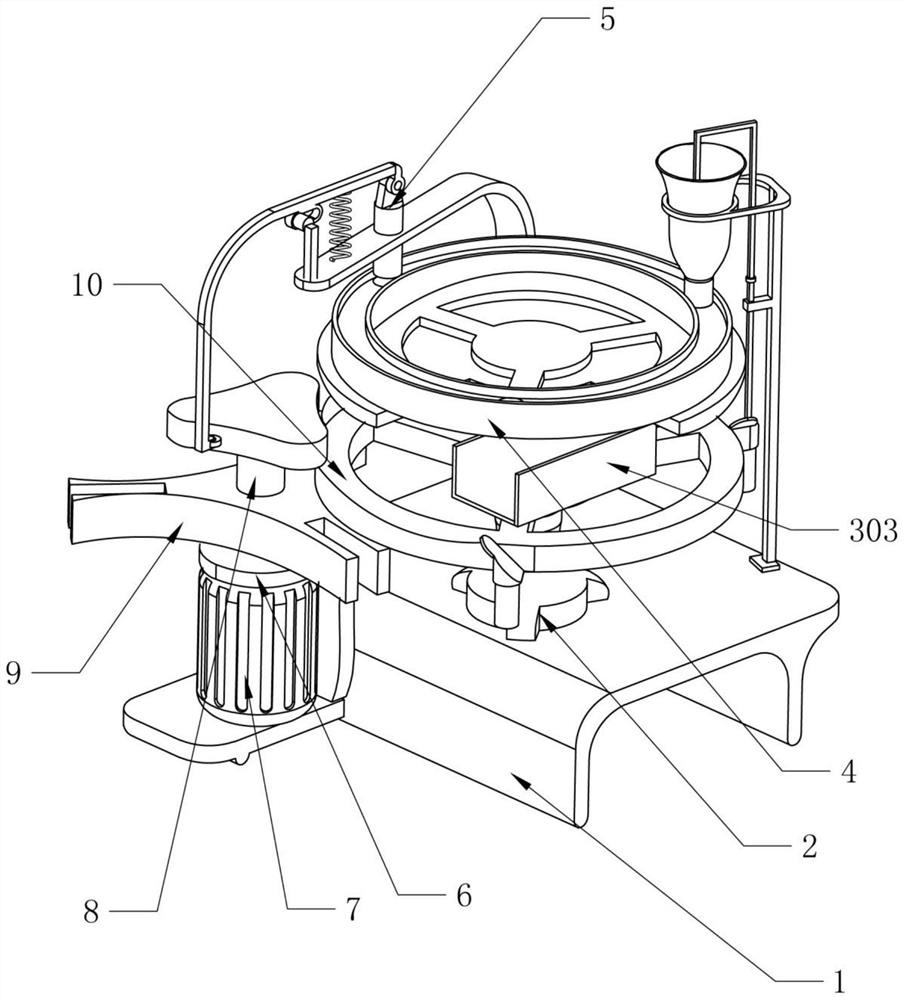

Tabletting forming machine

PendingCN107804017AIncrease productivityIngenious structurePress ramShaping pressPunchingMolding machine

The invention relates to a tabletting forming machine which comprises a base, a punch mechanism, a material screen and a feeding mechanism, wherein the punch mechanism, the material screen and the feeding mechanism are arranged on the base. A tabletting workbench is arranged on the base, and the tabletting workbench is provided with a tabletting cavity which penetrates through the top end face andthe bottom end face of the tabletting workbench. The punch mechanism comprises an upper punching head assembly and a lower punching head assembly, wherein the upper punching head assembly is arrangedabove the tabletting workbench, the lower punching head assembly is arranged below the tabletting workbench, and the upper punch assembly and the lower punch assembly are suitable for stamping raw materials in the tabletting cavity to be formed. The lower punch assembly is further suitable for pushing tablets formed in the tabletting cavity out of the tabletting cavity. The material screen is arranged on the upper end surface of the tabletting workbench, and is suitable for carrying out screening on the raw materials above the tabletting cavity. The feeding mechanism is arranged on the upperend surface of the tabletting workbench and is connected with the material screen so as to be suitable for pushing the material screen to the upper part of the tabletting cavity, so that the raw materials screened by the material screen are scattered into the tabletting cavity. The tabletting machine is ingenious in structure and high in tabletting forming efficiency.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

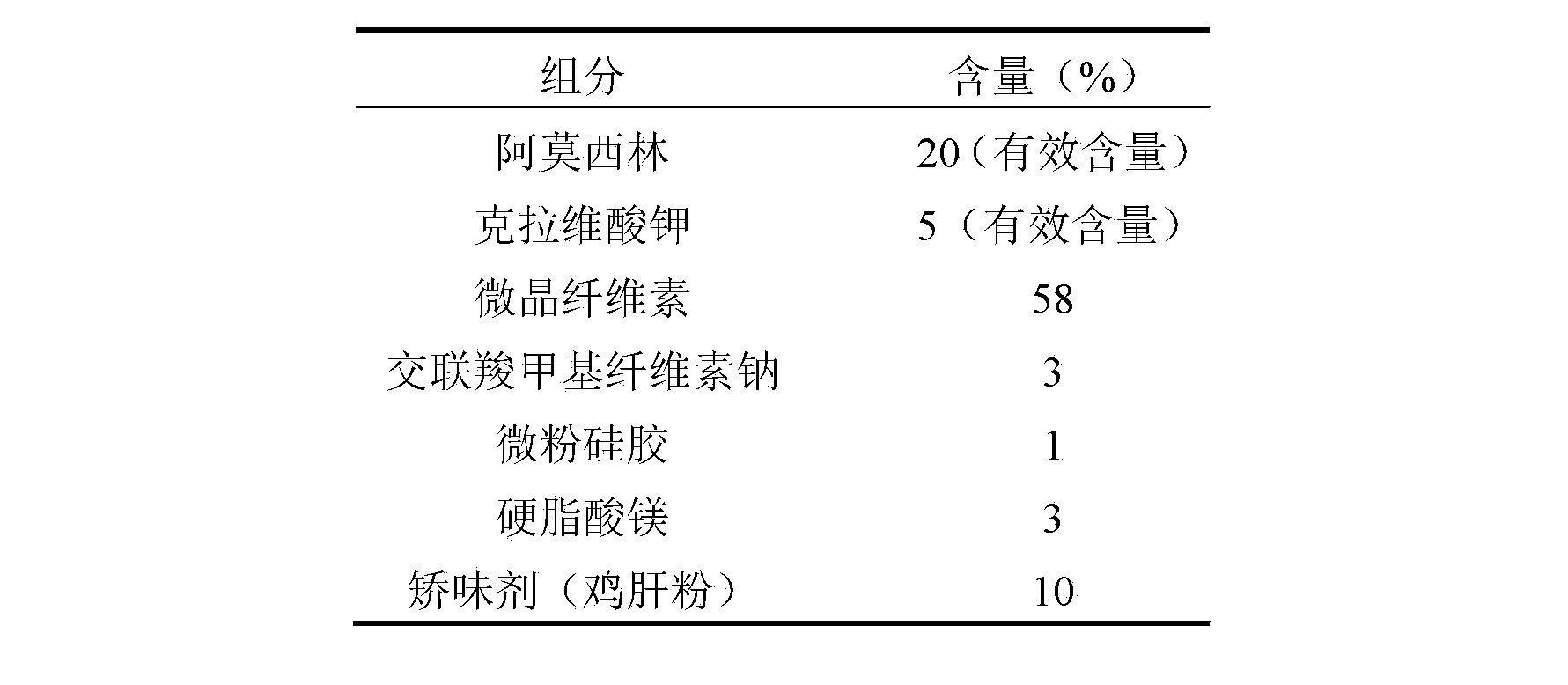

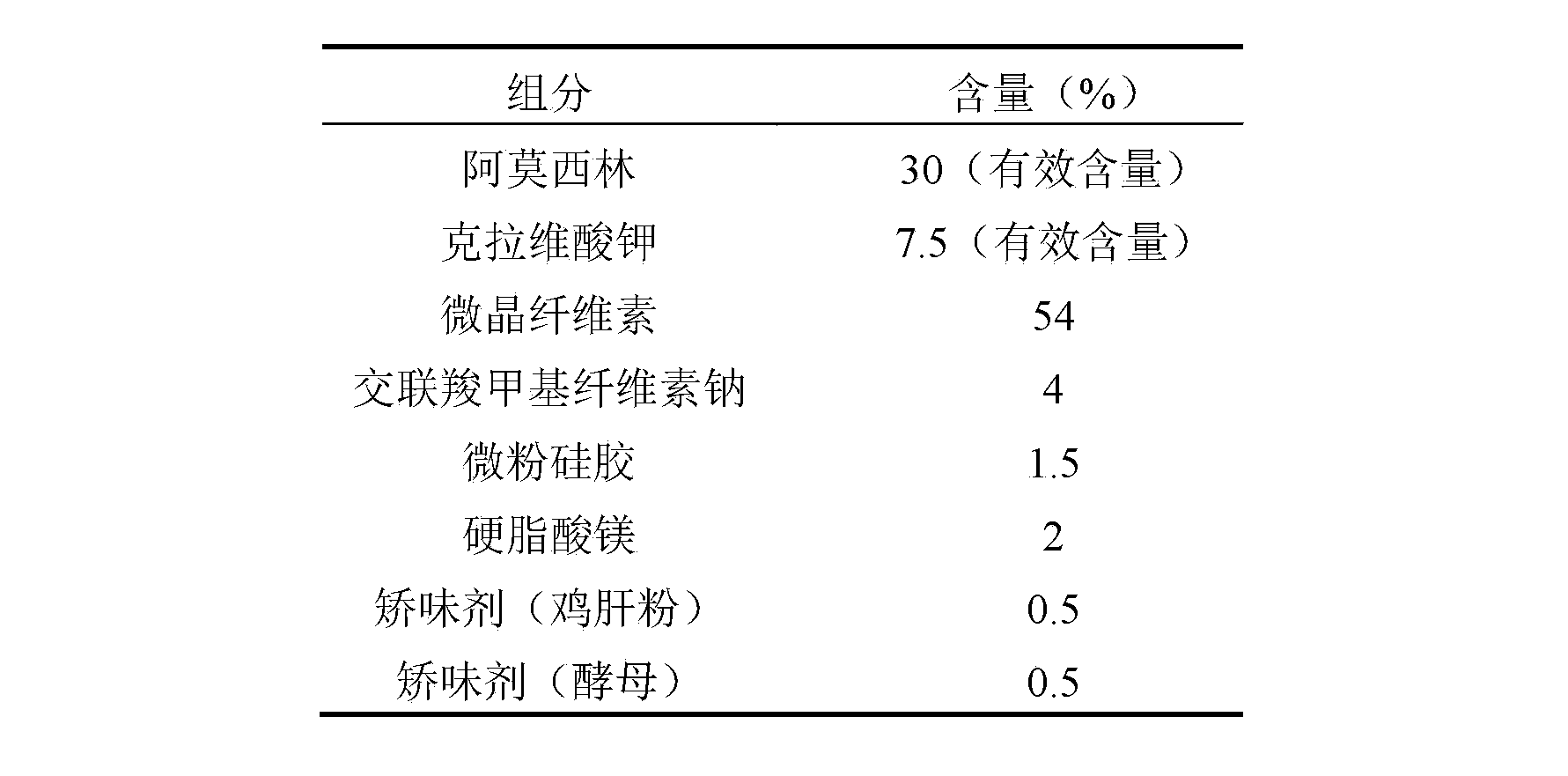

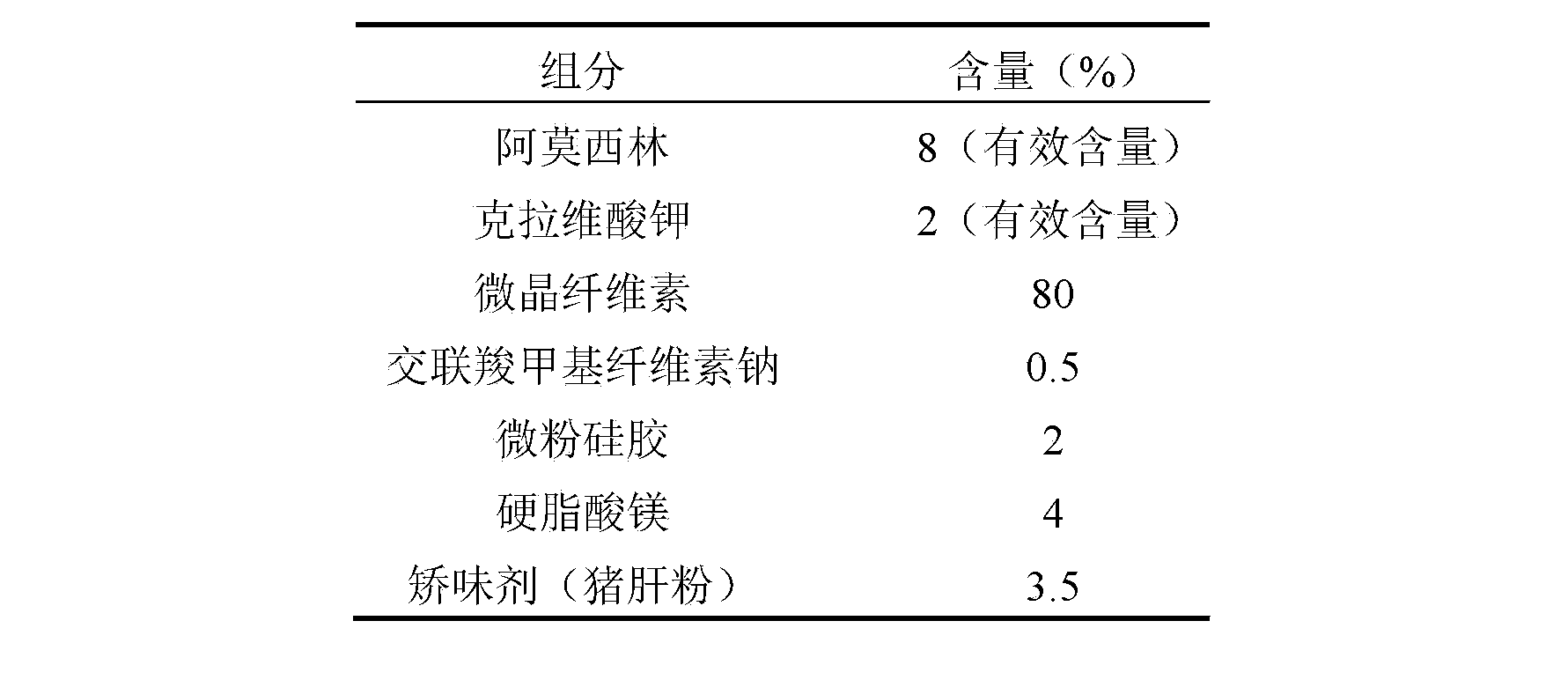

Amoxicillin and clavulanate potassium flavor tablet for pets

InactiveCN104337810AImprove complianceEasy to administerAntibacterial agentsPill deliveryCross-linkFood flavor

The invention discloses an amoxicillin and clavulanate potassium flavor tablet for pets, and its preparation technology. The flavor tablet comprises 8-40% of amoxicillin, 2-10% of clavulanate potassium, 30-80% of microcrystalline cellulose, 0.5-4% of cross-linked carboxymethyl cellulose sodium, 0.5-2% of aerosil, 0.5-4% of magnesium stearate and 1-15% of a flavoring agent. The amoxicillin and clavulanate potassium flavor tablet prepared in the invention is a tablet specially designed for solving the palatability of pets, can satisfy taste demands of the majority of pets, and has the characteristics of convenient administration, rapid action, high blood concentration and stable curative effect.

Owner:RINGPU TIANJIN BIOLOGICAL PHARMA

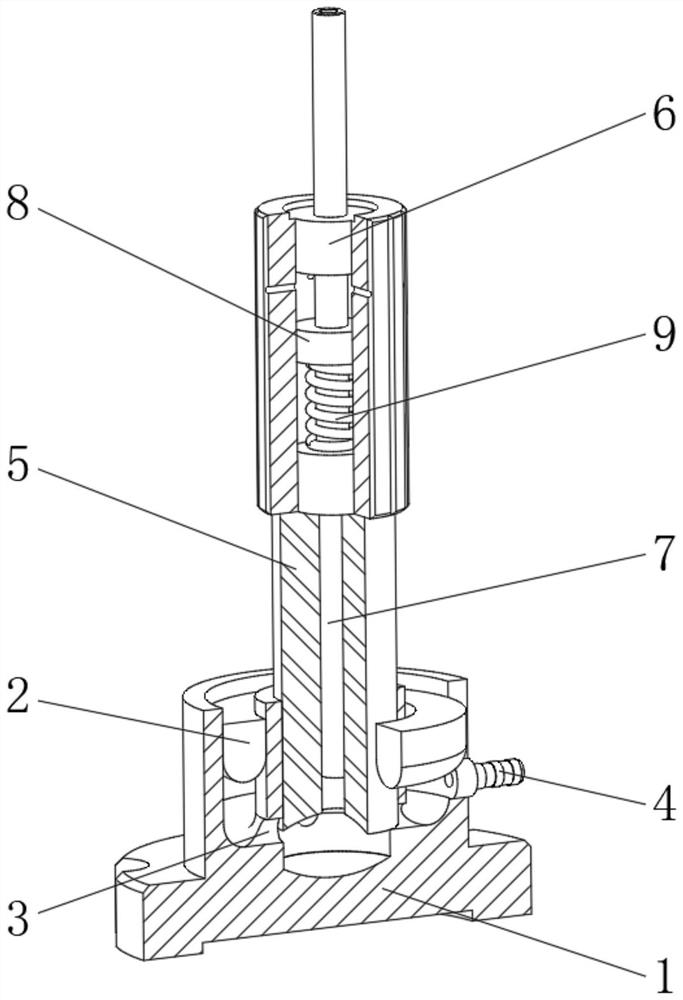

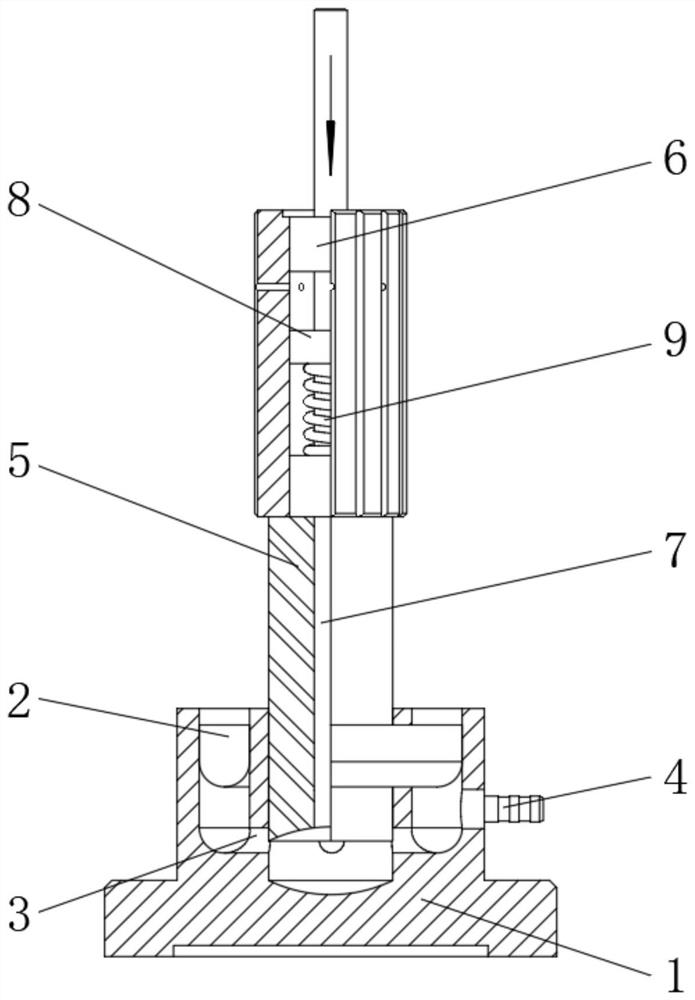

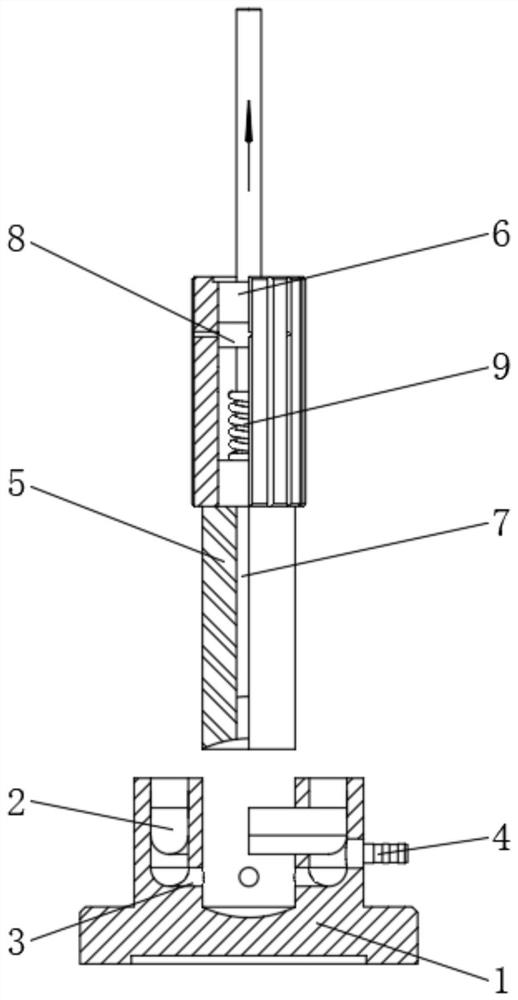

Powder tablet pressing and taking-out mechanism

The invention relates to the technical field of tablet pressing equipment, and discloses a powder tablet pressing and taking-out mechanism which comprises a lower mold. A counterweight pressing ring is movably connected in an inner cavity of the top of the lower mold in a sleeved mode, a communicating groove communicating with a middle cavity of the lower mold is formed in the inner cavity of the top of the lower mold, a conveying pipeline is arranged on one side of the top cavity of the lower mold, an extrusion sleeve is fixedly installed at the top end of an upper mold, and a movable connecting rod communicating to the top of the extrusion sleeve is movably connected into the upper mold in a sleeved mode. According to the powder tablet pressing and taking-out mechanism, the upper mold, the extrusion sleeve and the movable connecting rod are arranged, in the upward moving process of the extrusion sleeve, the upper mold and the movable connecting rod on the upper mold can be staggered with each other under the elastic force action of an adsorption spring, then negative pressure is formed in an inner cavity of the upper mold, the pressed tablets are sucked out from the inner cavity of the middle part of the lower mold, and the device is simple in structure and convenient to use.

Owner:湖南嘉恒制药有限公司

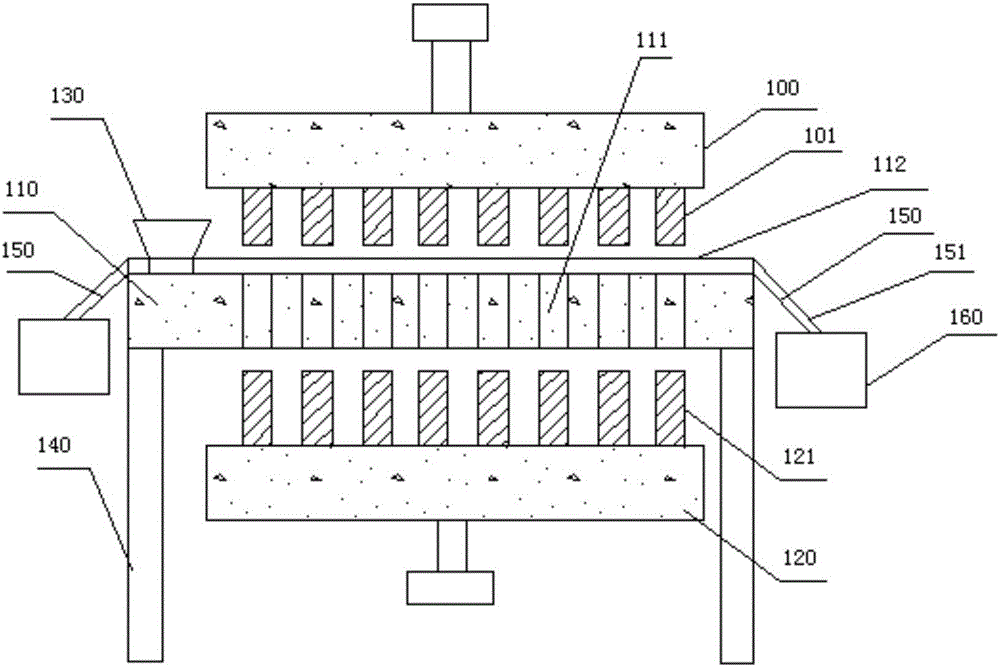

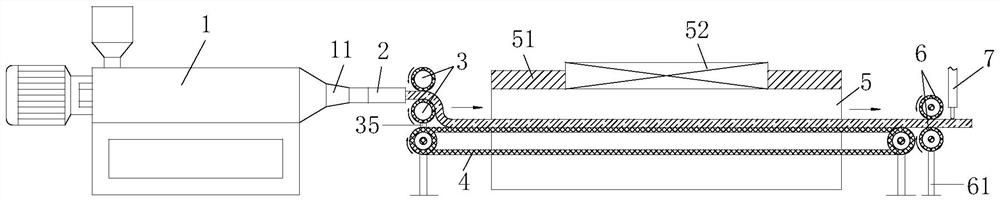

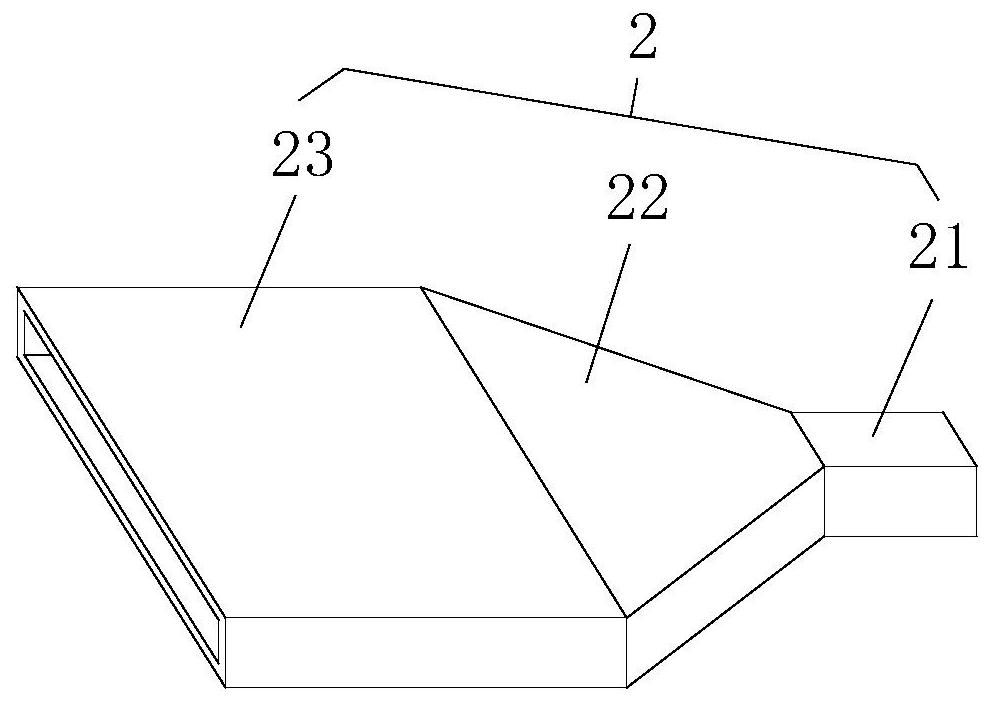

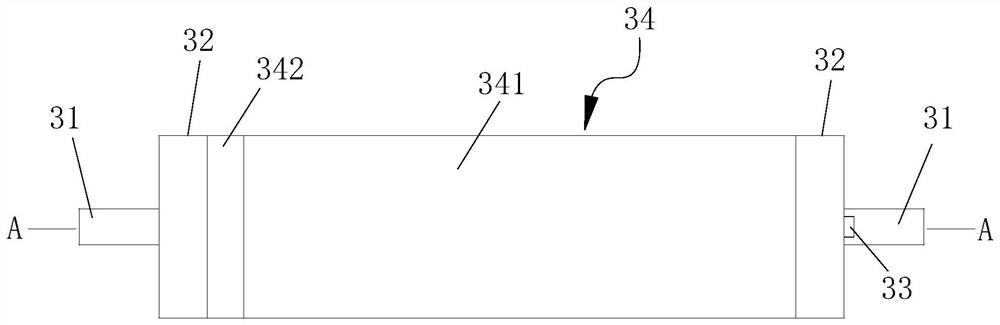

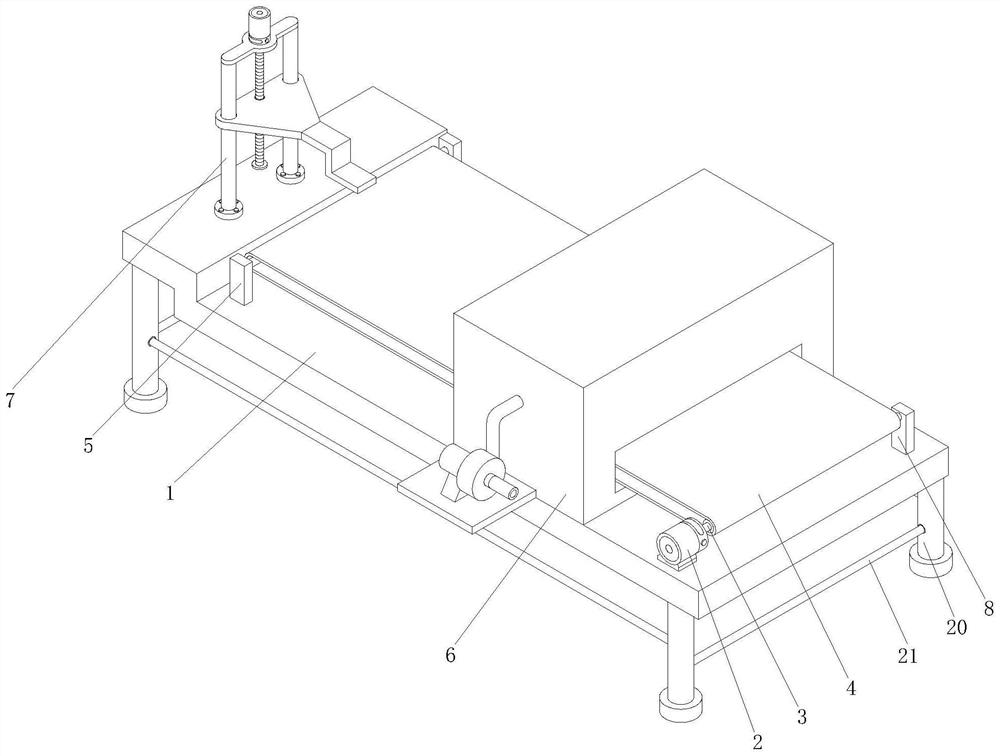

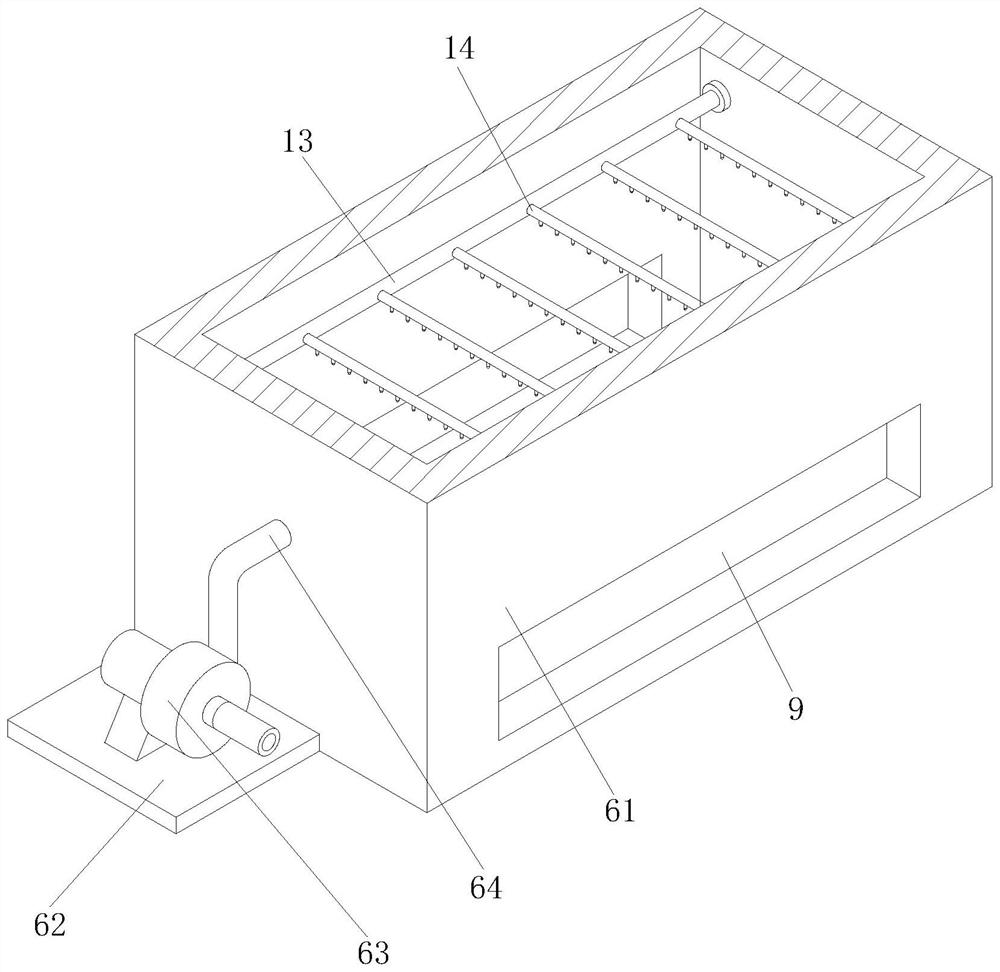

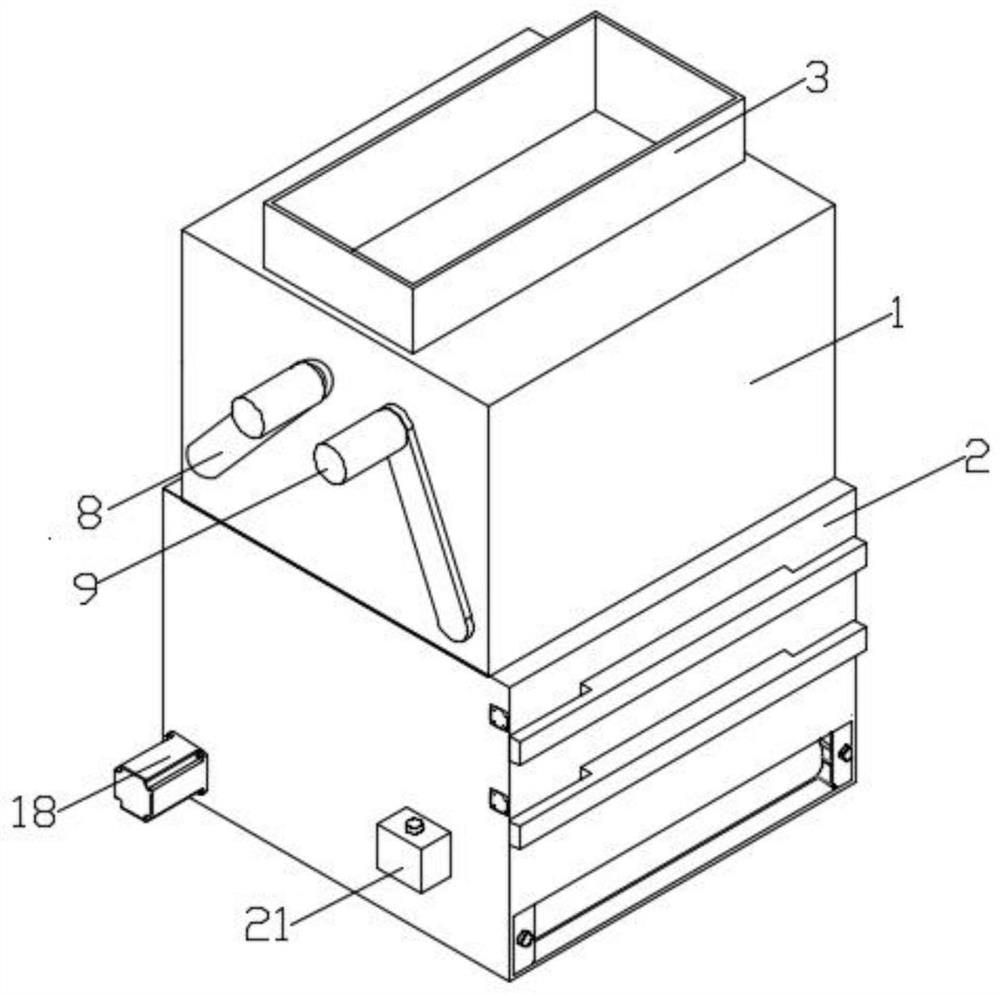

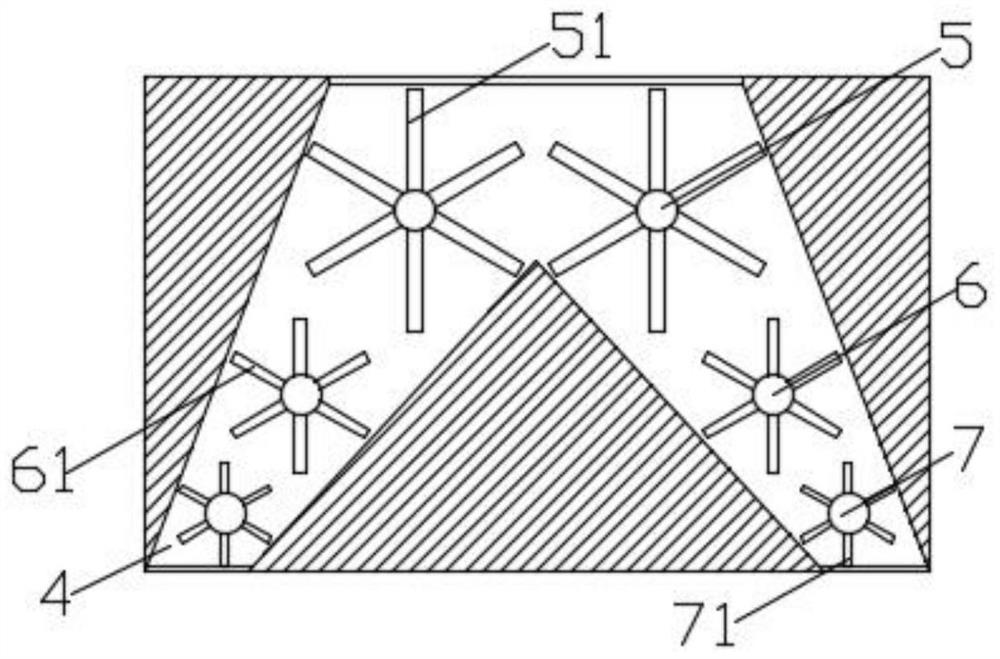

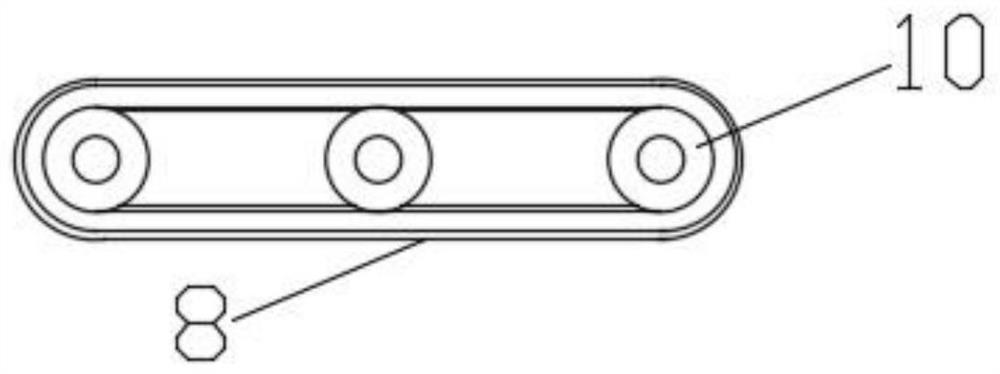

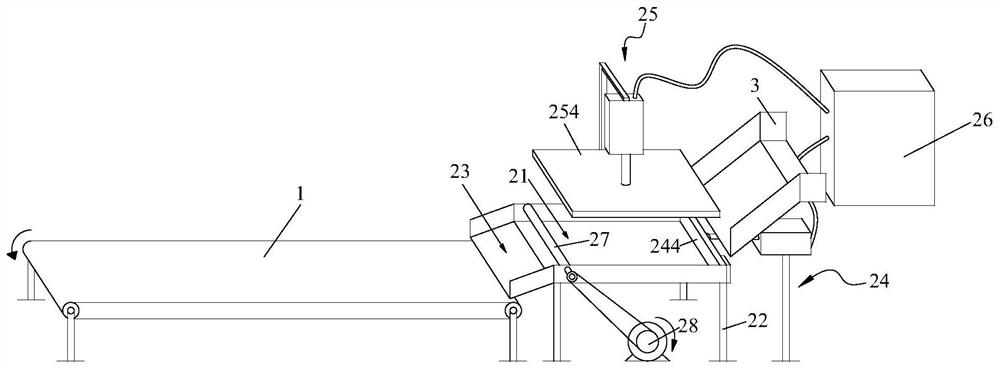

Melt extruding, shaping and slicing system for powder coating processing

The invention relates to a melt extruding, shaping and slicing system for powder coating processing. The melt extruding, shaping and slicing system for the powder coating processing comprises an extruder used for extruding a melt material, a discharging port of the extruder is horizontally in butt joint with a discharging die cavity used for flattening the melt material, and a set of cooling sheeting rollers which are parallel to one another and internally provided with freezing media are arranged on the discharging end side of the discharging die cavity in an up-down spaced mode. A conveying belt is horizontally placed below the cooling sheeting rollers, an air cooling tunnel is erected on the conveying belt, the end face of the air cooling tunnel is of a door-shaped structure, a heat dissipation fan is arranged on a top plate of the air cooling tunnel, a set of parallel guide rollers are arranged on the discharging side of the conveying belt in an up-down spaced mode, and a cutting machine is arranged on the outer sides of the guide rollers. According to the melt extruding, shaping and slicing system for the powder coating processing, the flatness of the produced melt material can be effectively improved, the continuous degree is relatively high, and the subsequent sheeting efficiency can be improved. In the short-distance conveying process, the melt material cooling and shaping effect is good, and the slicing efficiency of a subsequent cutting machine is improved.

Owner:马鞍山睿诚科技信息咨询有限公司

Automatic surface mounting device based on integrated circuit design

InactiveCN113976543AAchieve dust removal effectFix damageDirt cleaningCleaning using gasesSurface mountingElectric machine

The invention provides an automatic surface mounting device based on integrated circuit design. The device comprises a workbench, the top of the workbench is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a rotating rod, the outer side of the rotating rod is in transmission connection with a conveying belt, the inner wall of one end of the conveying belt is rotationally connected with a first fixing block through a rotating shaft, a dust removal assembly is arranged above the conveying belt, a surface mounting assembly is arranged at the top, away from the first motor, of the workbench, a dust removal box is fixedly connected to the top of the workbench and located on the outer side of the conveying belt, and one side of the dust removal box is fixedly connected with a supporting plate, and the top of the supporting plate is fixedly connected with a suction fan. The automatic surface mounting device based on the integrated circuit design has the advantages of being simple in design, convenient to use, capable of improving the working efficiency and capable of removing dust on an integrated circuit board.

Owner:炬为微电子(上海)有限公司

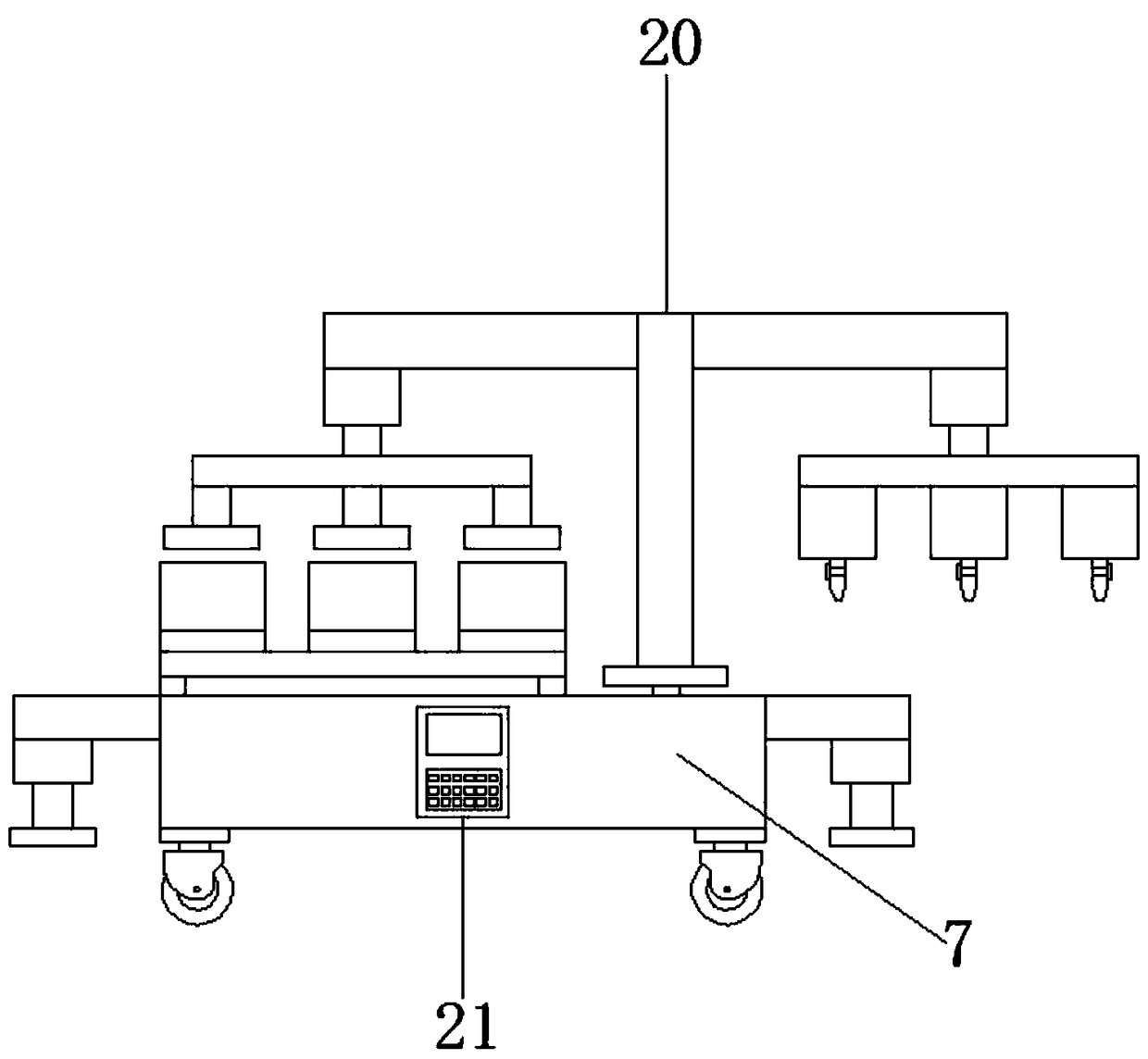

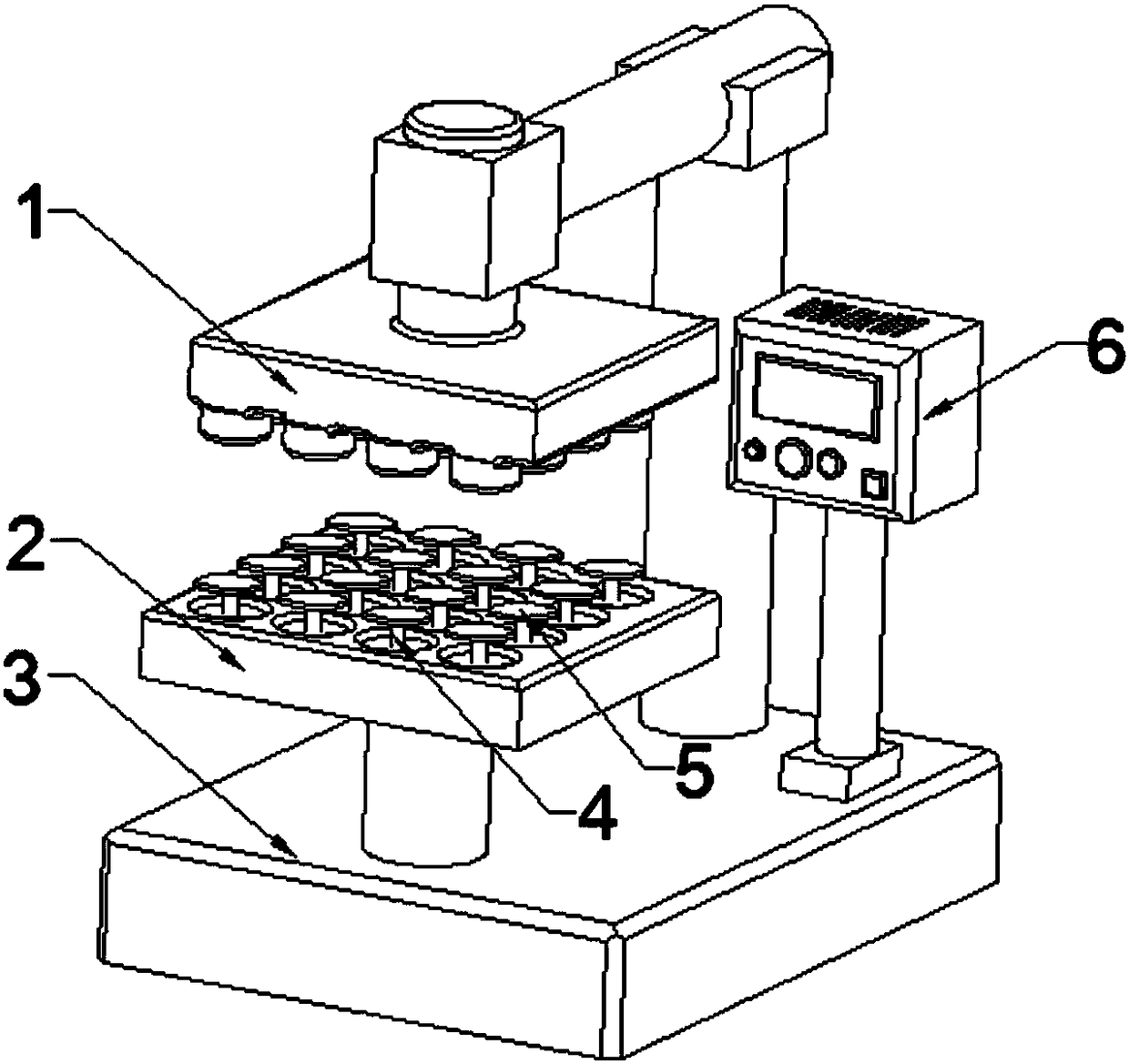

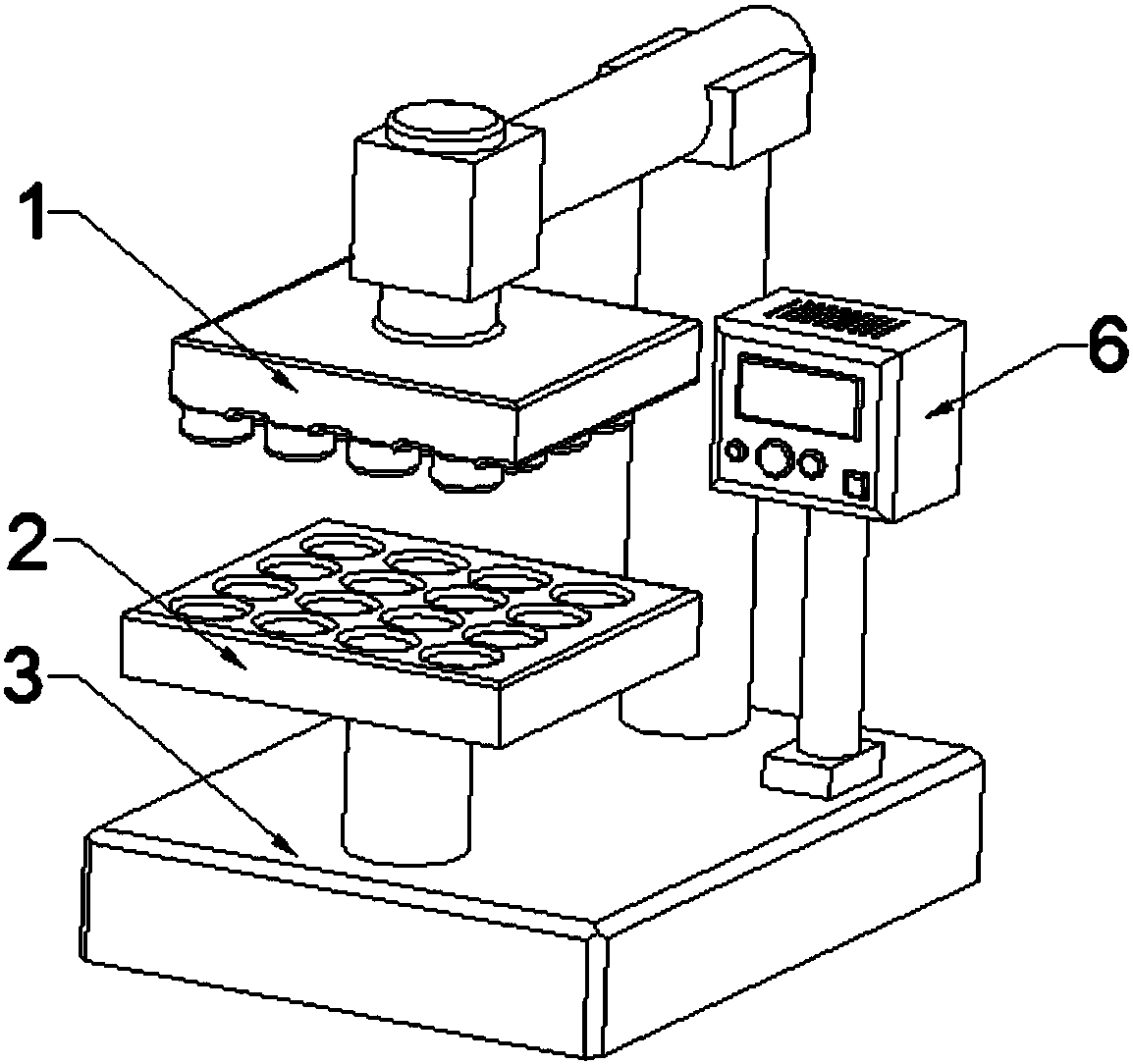

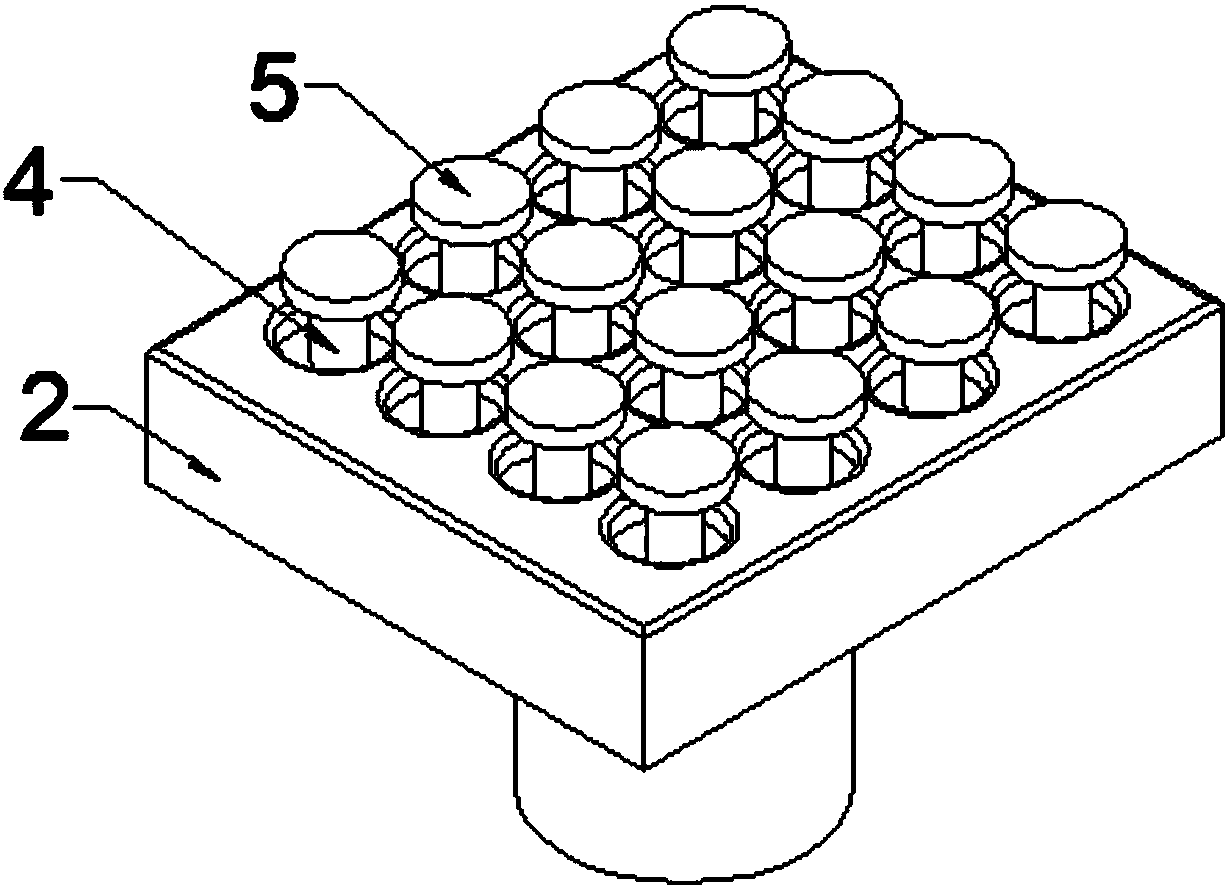

Tablet compressing device with rapid tablet taking function

The invention provides a tablet pressing device with a rapid tablet taking function. The tablet pressing device comprises an upper die plate and a lower die plate, wherein lifting rods are installed on the upper end face of the upper die plate and the lower end face of the lower die plate, and a base is arranged below the upper die plate and the lower die plate; a power device and an adjusting device are arranged in the base, the tail ends of the lifting rods are fixedly connected with the power device, and a controller electrically connected with the adjusting device is further arranged on the upper end face of the base; grooves for containing materials are formed in the lower die plate, and protrusions capable of being sleeved with the grooves are arranged in the upper die plate; top plates are arranged at the bottoms of the grooves, and the top plates are movably connected with the side walls of the grooves; and top rods capable of ascending and descending are arranged on the lowerend faces of the top plates, and the top rods are connected with the power device through the lifting rods. The tablet pressing device with the rapid tablet taking function has the beneficial effectsthat the tablet taking speed is increased, the bottoms of the tablet materials are uniformly stressed, and therefore, integrity of the tablet materials during taking out is improved.

Owner:天津椿盟科技有限公司

Composite hydrogel material for adsorbing heavy metals and preparation method of composite hydrogel material

InactiveCN111729657AImprove adsorption efficiencyLarge adsorption capacityOther chemical processesWater contaminantsTabletingComposite hydrogels

The invention discloses a composite hydrogel material for adsorbing heavy metals and a preparation method of the composite hydrogel material. A conveying channel is designed to be wide in the upper portion and narrow in the lower portion. Meanwhile, a first stirring blade, a second stirring blade and a third stirring blade with different sizes are matched, so a primary product is subjected to physical mixing treatment again after ultrasonic mixing; the narrowing design of the conveying channel ensures that the primary product can be in full contact with the stirring blades with different sizes; two layers of filter plates are designed to ensure that impurities in a primary product are filtered; an automatic drawing filter plate is designed, the filter plate can be conveniently cleaned, thecomposite hydrogel material can be rapidly obtained through ethanol spraying and tabletting pressing after the primary product is filtered, the tabletting efficiency of the primary product is effectively improved through the double tabletting design, the composite hydrogel material is cut while tabletting is performed, and the practicality is high.

Owner:杭州凯博特环保科技开发有限公司

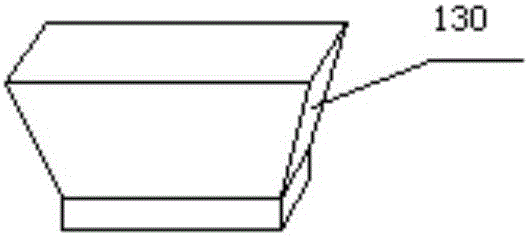

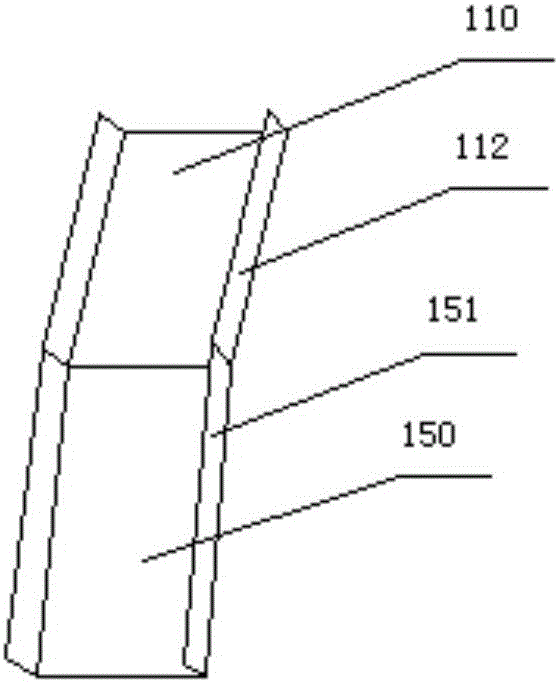

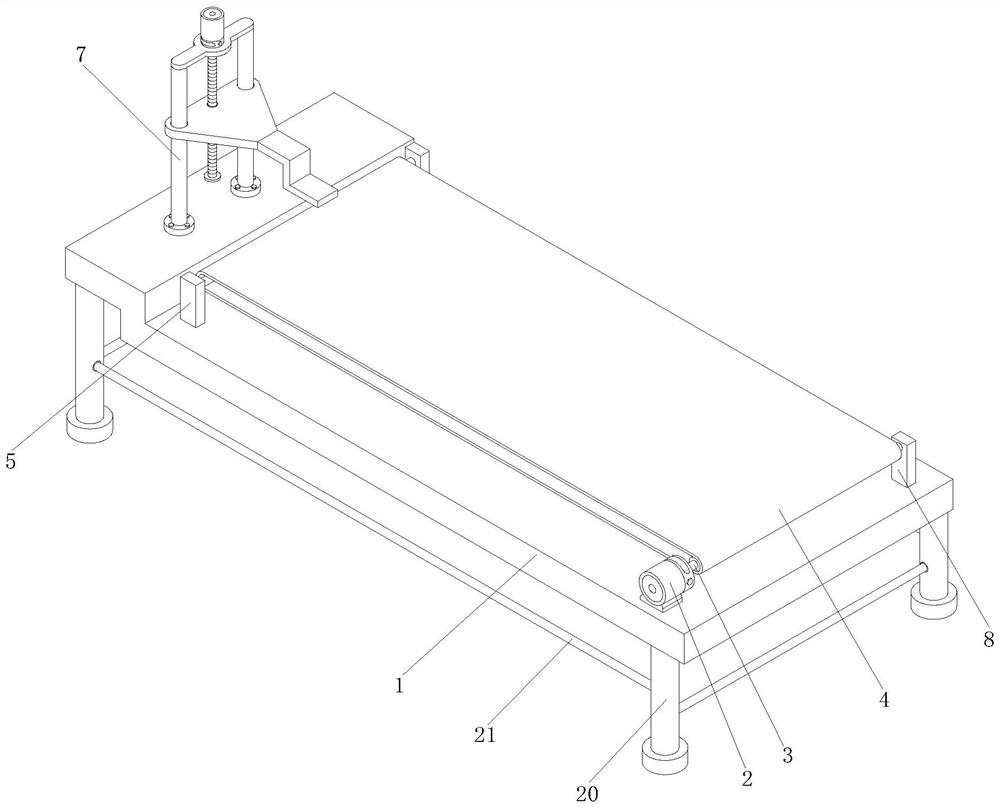

Molten material flattening and conveying device for powder paint processing

InactiveCN112693809AImprove tableting efficiencyConveyorsConveyor partsElectric machineryEngineering

A molten material flattening and conveying device for powder paint processing comprises a conveying belt, and a molten material flattening mechanism is arranged at one end of the conveying belt. The molten material flattening mechanism comprises a horizontally-placed square tank, one end of the square tank is in butt joint with an inclined tank, the inclined tank is arranged above one end portion of the conveying belt, the square tank is fixedly supported through a first support, and a pushing component capable of moving transversely is arranged at the other end of the square tank in a telescopic mode. A flattening component capable of moving longitudinally in a telescopic mode is arranged over the square tank, a guide pressing roller is horizontally arranged on the upper portions of the two side walls of the joint of the square tank and the inclined tank, and one end of the guide pressing roller is connected with an external speed reduction motor through a belt in a rotating mode. By arranging the molten material flattening mechanism, a molten material can become relatively flat and then is conveyed to a tabletting roller of the next procedure through the conveying belt to be tabletted, and the tabletting efficiency of the tabletting roller is greatly improved.

Owner:马鞍山睿诚科技信息咨询有限公司

High-speed bottle cap two-dimensional code chip adding machine

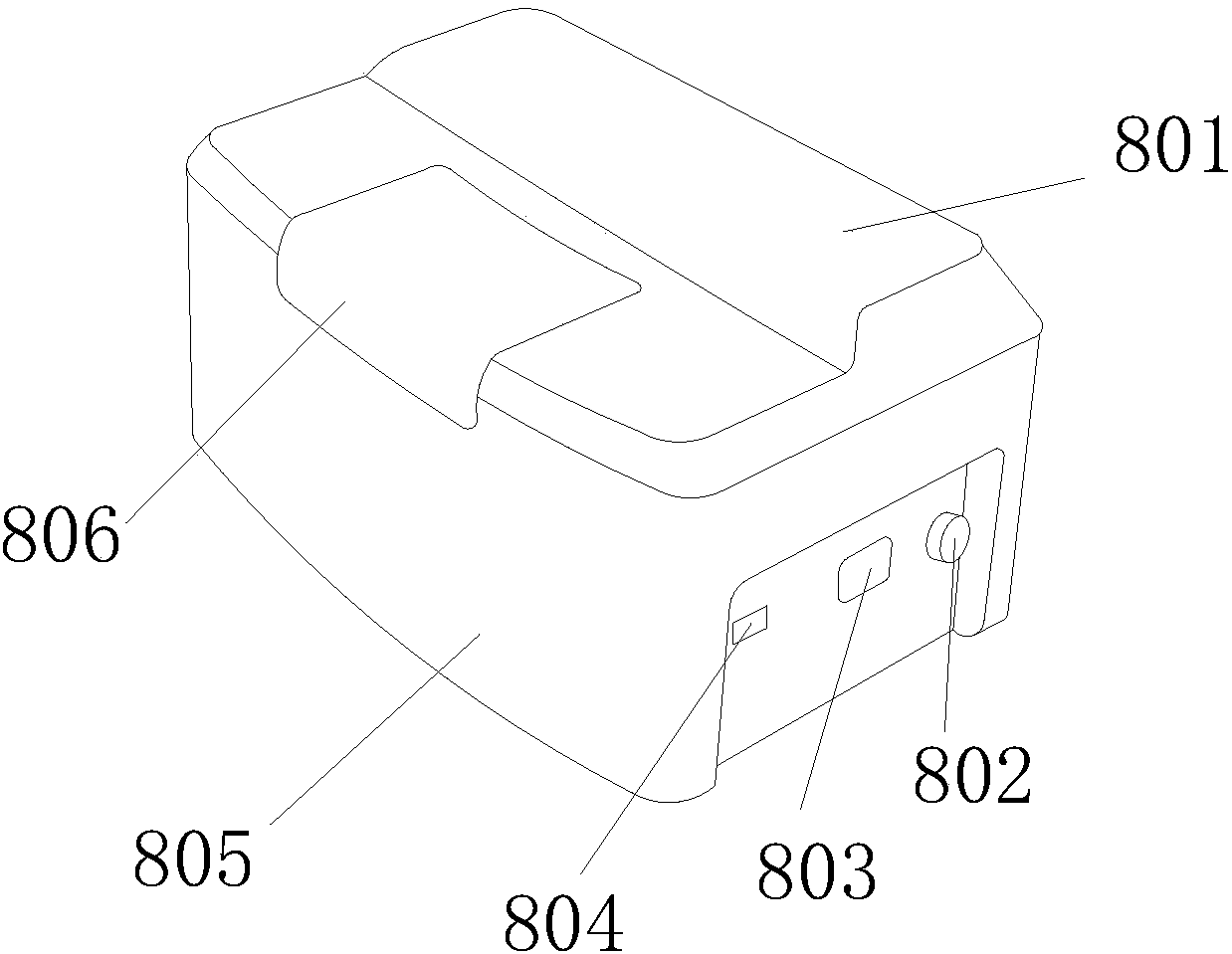

PendingCN114290027AImprove tableting efficiencySolve the technical problem of low tablet compression efficiencyMetal working apparatusEngineeringBottle cap

The high-speed bottle cap two-dimensional code chip adding machine comprises a first fixing disc, a first bottle cap rotating disc is arranged at the top of the first fixing disc, and bottle cap containing grooves are evenly formed in the outer edge of the first bottle cap rotating disc in the circumferential direction; a cap pressing mechanism is arranged above the multiple bottle cap containing grooves, and the portion, corresponding to the upper portion of each bottle cap containing groove, of the cap pressing mechanism is provided with an adsorption press-fit assembly capable of moving up and down. A two-dimensional code piece feeding mechanism is arranged on the outer side of the first bottle cap rotating disc, and the feeding position of the two-dimensional code piece feeding mechanism is located between one adsorption press-fit assembly and the bottle cap containing groove. Through the structural arrangement, the operation of pressing the two-dimensional code piece into the bottle cap is carried out in the rotating process of the first bottle cap rotating disc, the piece pressing efficiency is improved, and the technical problem that in the prior art, the piece pressing efficiency is low is effectively solved.

Owner:深圳圣鑫自动化设备有限公司

Tablet pressing device for medicine production

InactiveCN108995280AImprove tableting efficiencyQuality improvementPharmaceutical product form changeShaping pressMedical equipmentMedicine

The invention discloses a tablet pressing device for medicine production, and relates to the field of medical equipment. The device comprises a medicine lifting table and a medicine pressing mechanismlocated above the medicine lifting table, the medicine lifting table is manufactured from supporting feet, the medicine lifting table is provided with an up-down through groove, a horizontal lower supporting die is arranged inside the through groove, a vertical first lifting assembly is arranged below the medicine lifting table, the lifting end of the first lifting assembly is in fastened connection with the lower end face of the lower supporting die, the side wall of the lower supporting die makes sliding contact with the inner wall of the through groove, the medicine pressing mechanism is composed of a walking assembly and a pressing assembly, the walking assembly is composed of a walking guide rail, a motor, a lead screw and a sliding base, and the pressing assembly comprises a secondlifting assembly and a pressing roller. The structure is simple, the tablet pressing efficiency and quality are improved, the production efficiency is improved, and the production cost is reduced.

Owner:WUHU KANGQI PHARMA

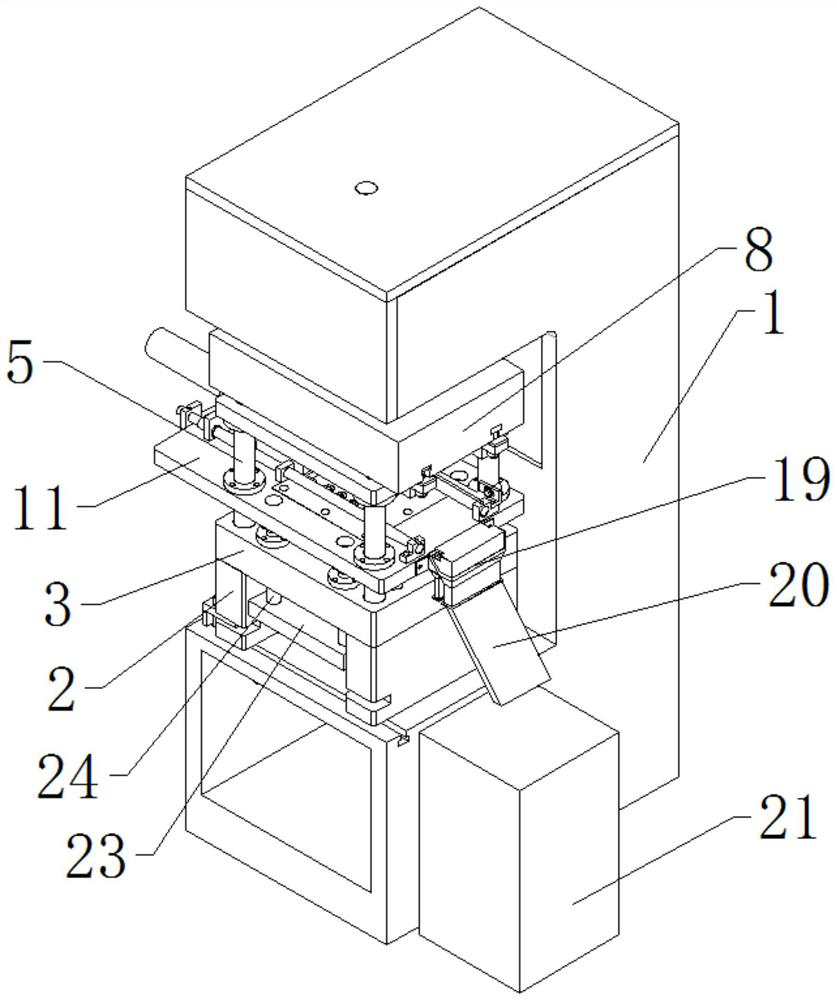

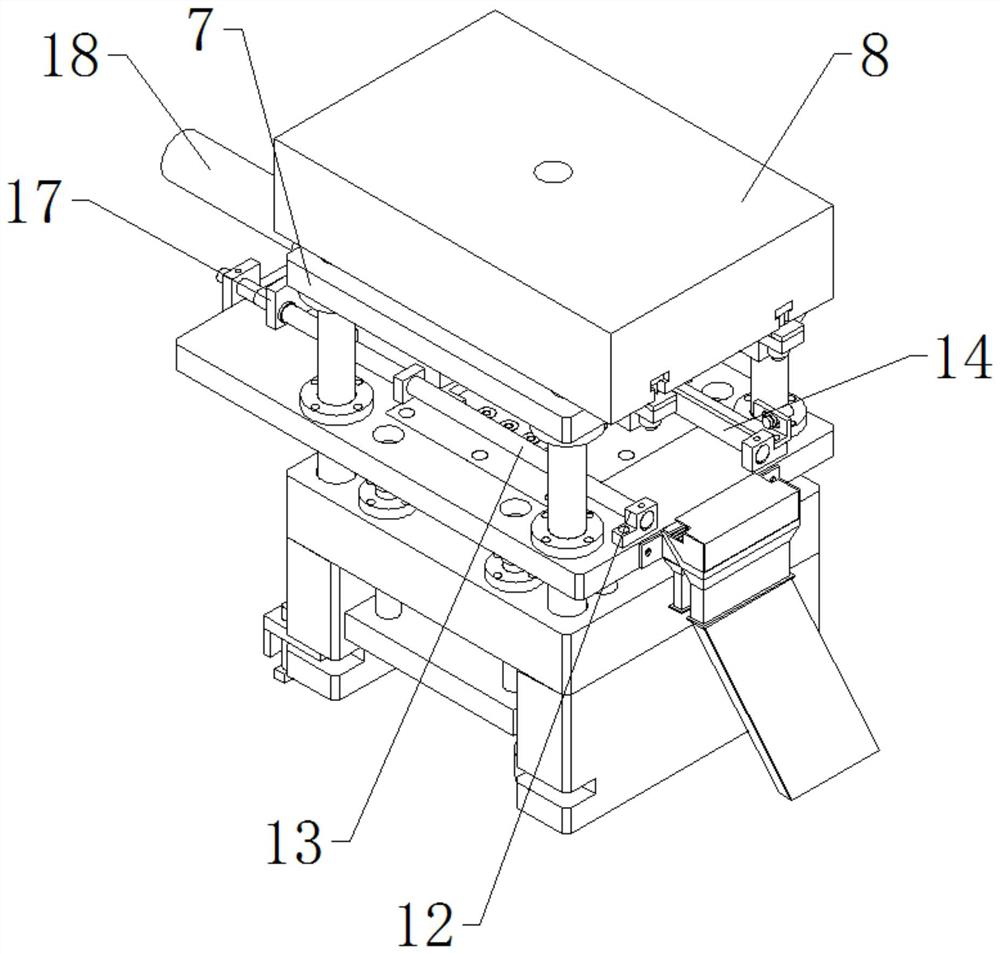

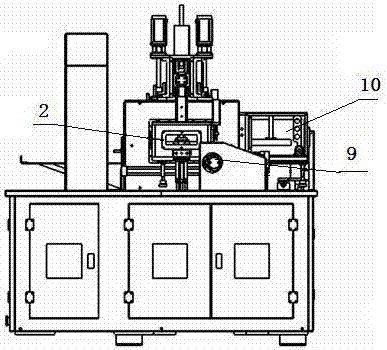

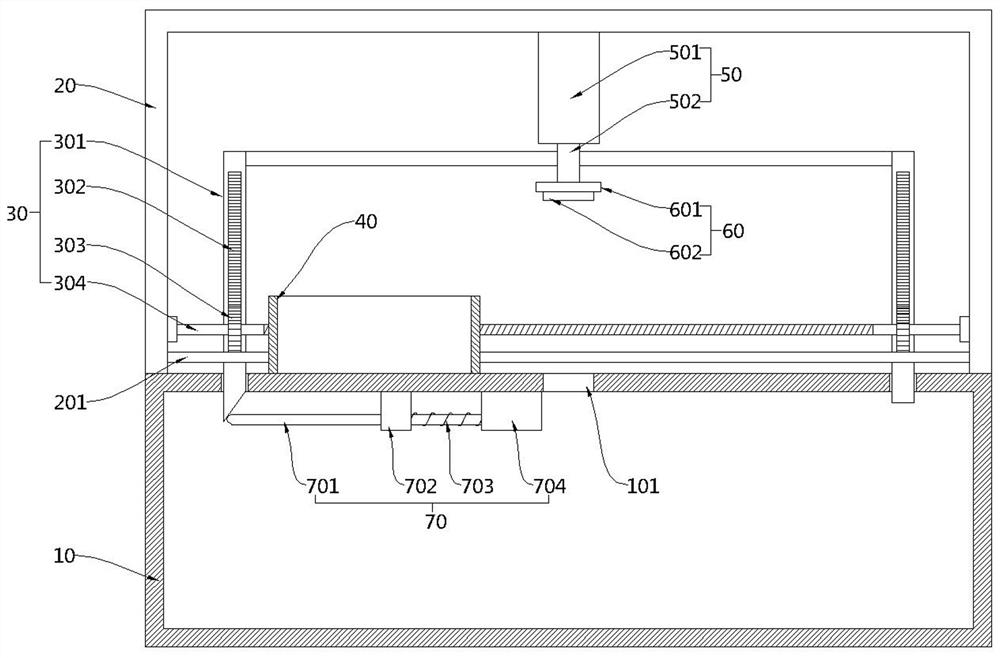

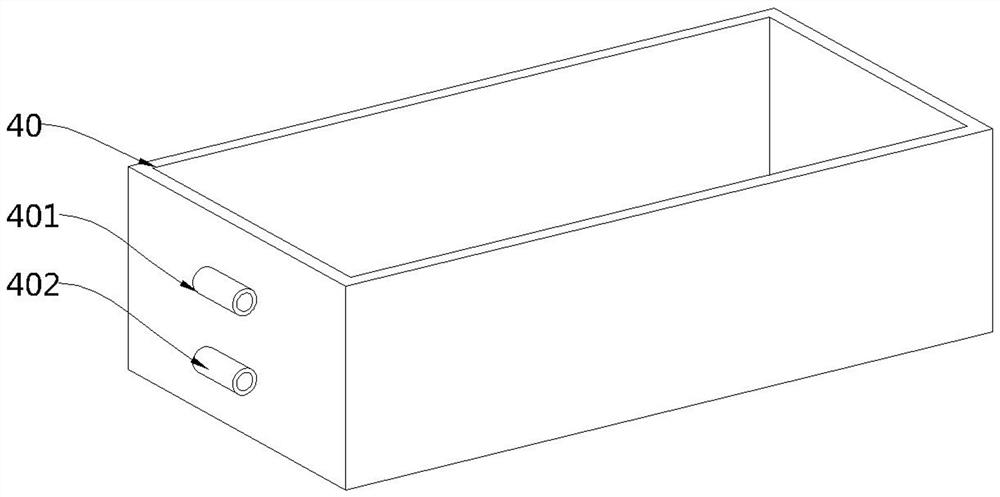

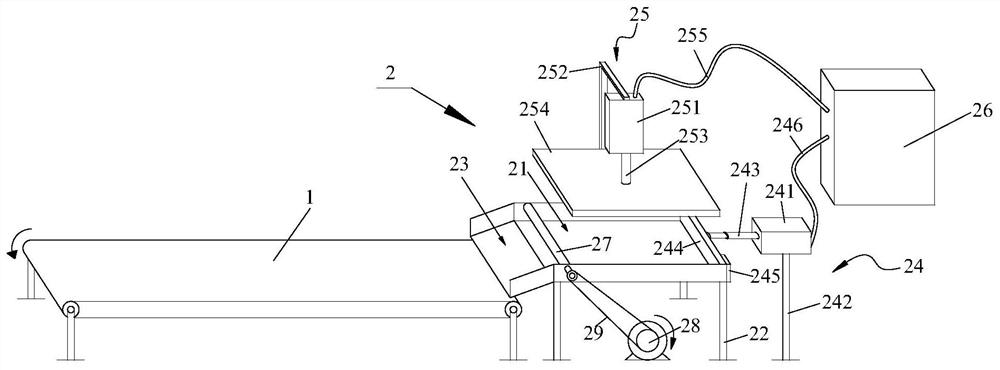

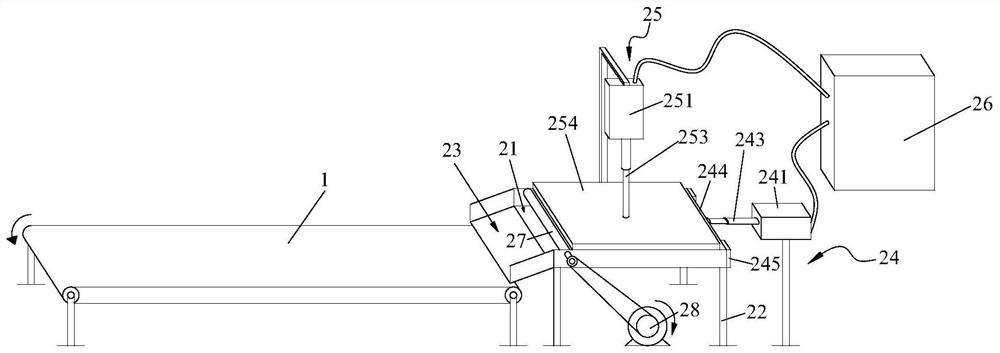

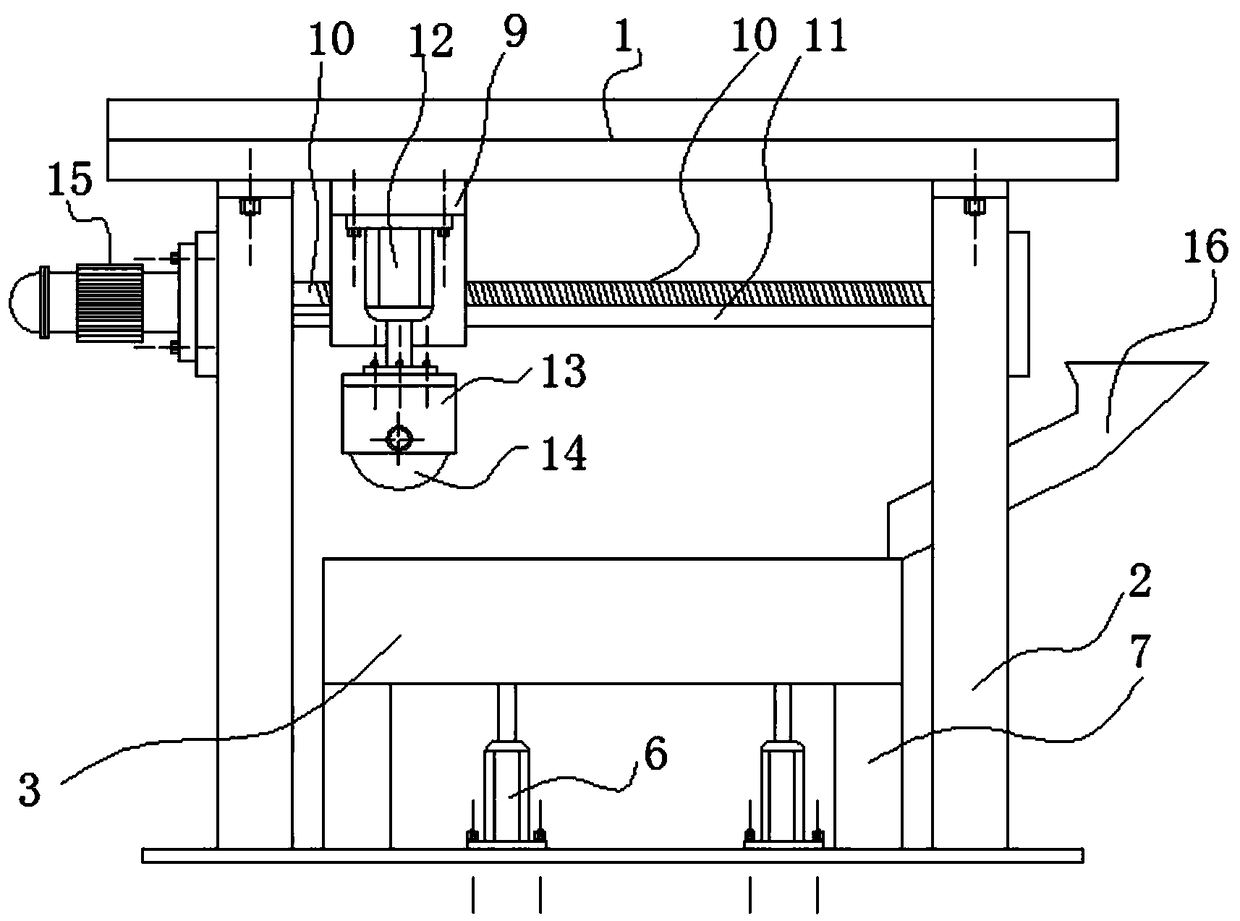

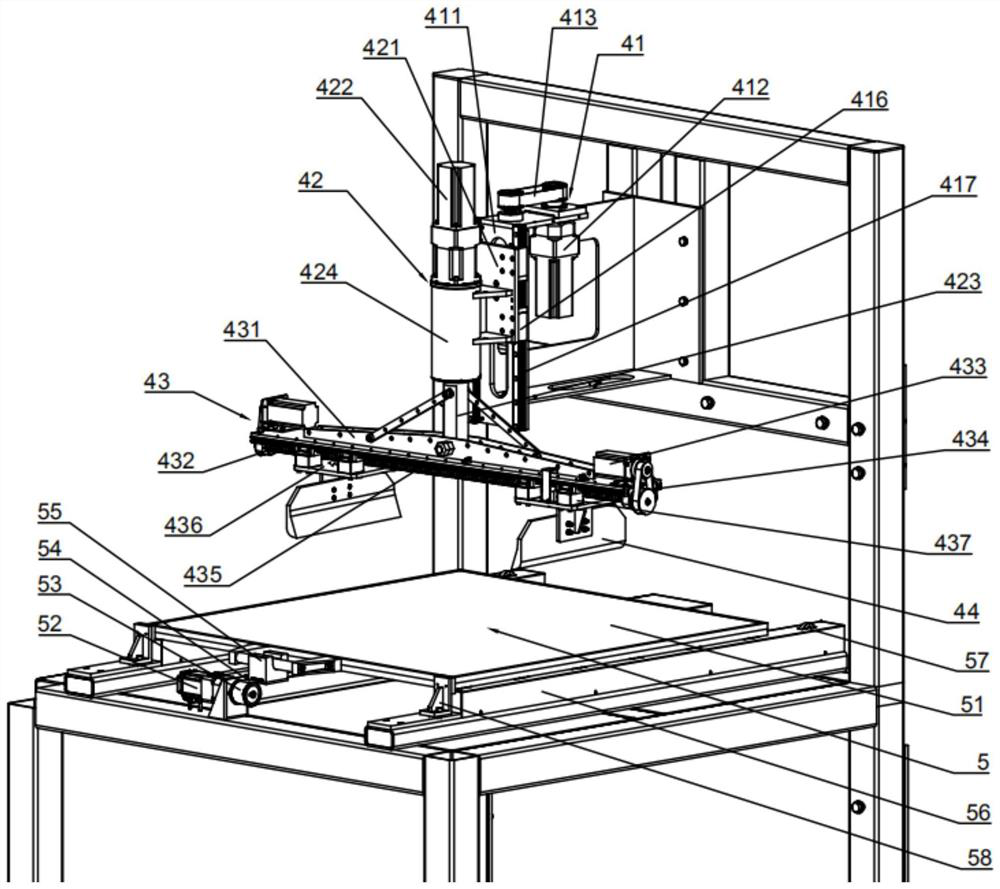

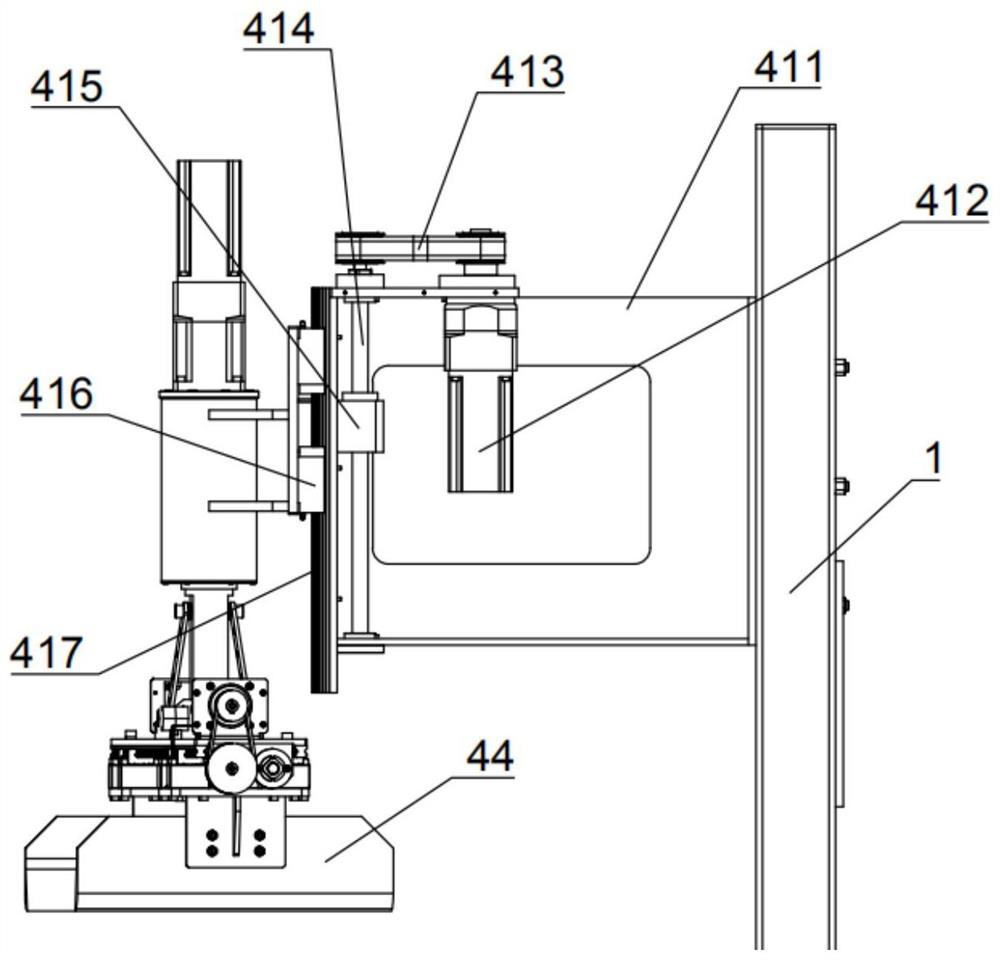

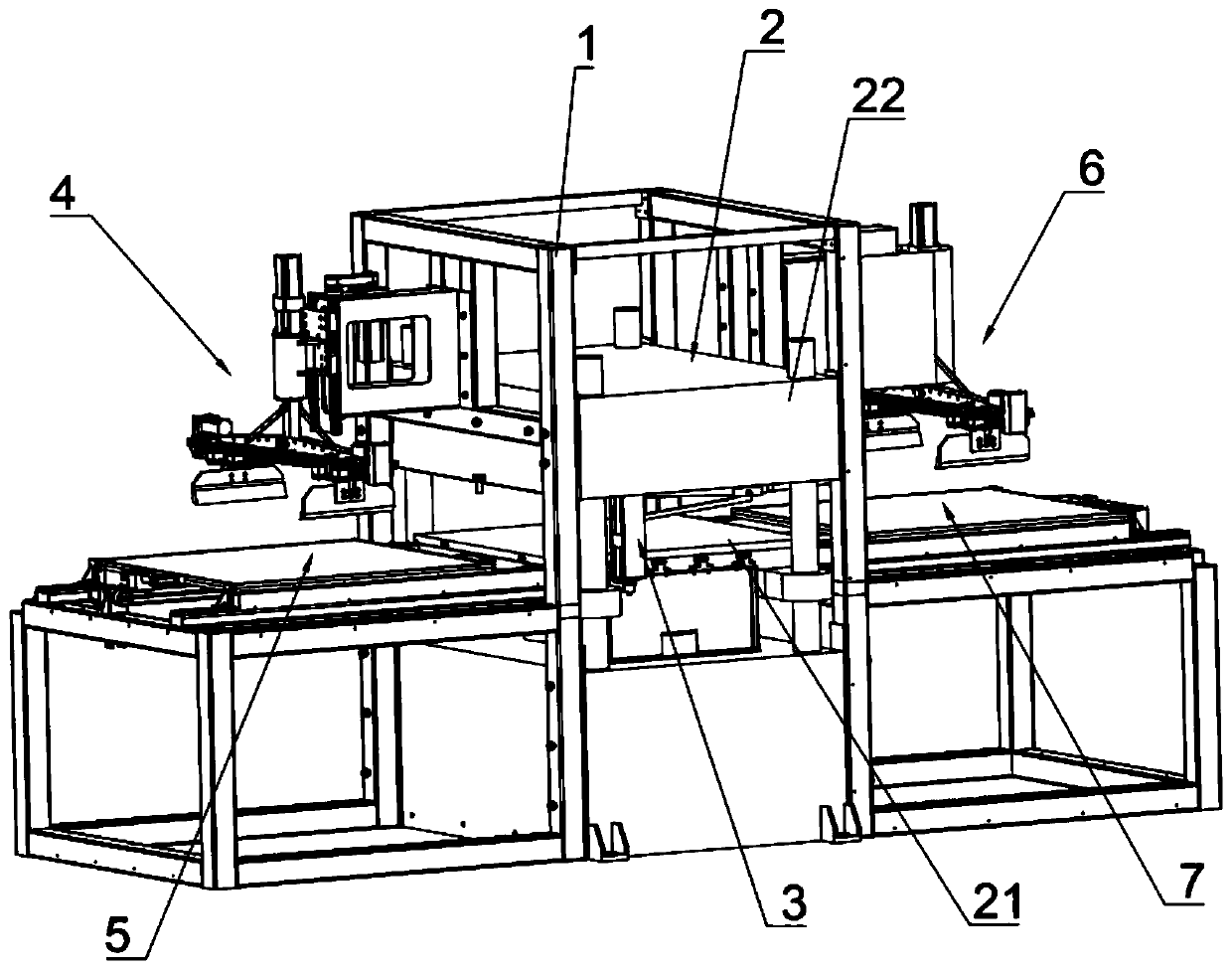

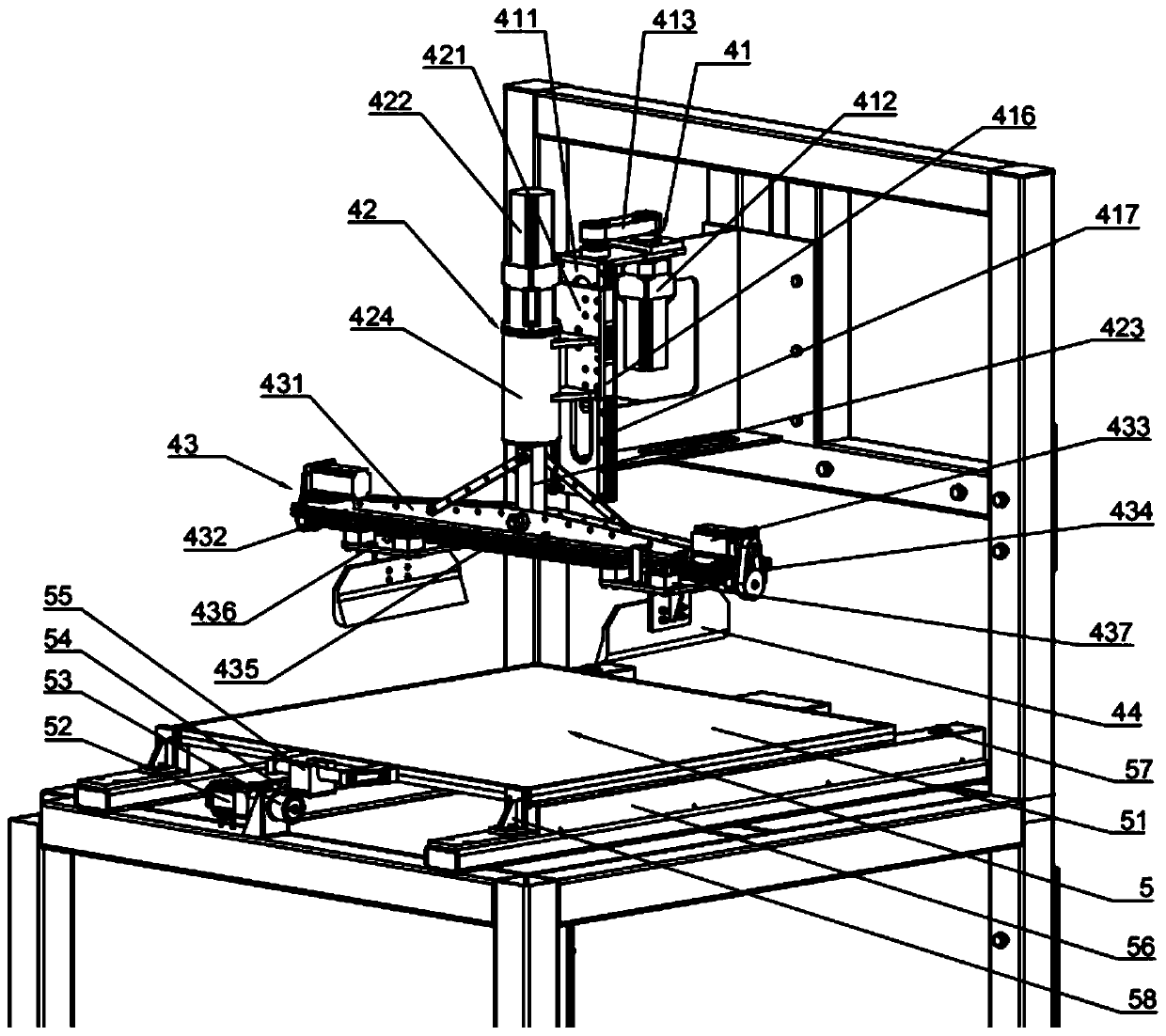

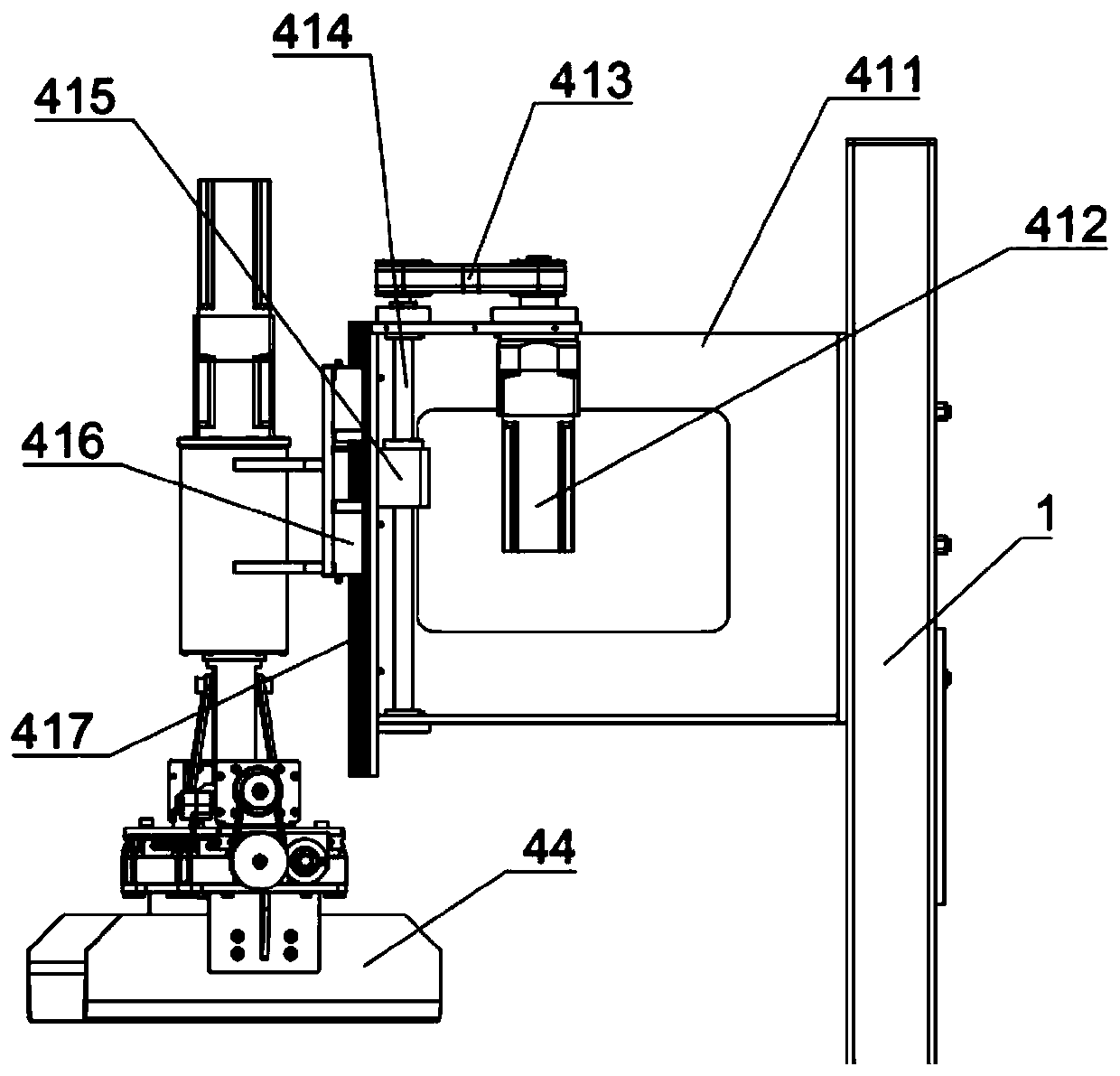

An automatic stirring tablet press machine for mud-like composite materials

ActiveCN110696423BSave human effortImprove work efficiencyCleaning using toolsPressesSlide plateTableting

The invention discloses an automatic stirring tablet press machine for mud-like composite materials, which includes a frame, a hydraulic four-column press, a cleaning and scraping device, a first scraping device, a first sliding plate driving device, a second scraping device and a second scraping device. Two slide plate driving devices, the hydraulic four-column press is set in the middle of the frame, the first scraping device is set on the left side of the frame, the first slide plate driving device is set at the bottom of the first scraping device, and the first scraping device is set at the bottom of the first scraping device. The second scraping device is arranged on the right side of the frame, and the second slide plate driving device is arranged at the bottom of the second scraping device. The present invention uses the first scraping device or the second scraping device to stir and gather the mud-like composite material into agglomerates, and then send it to a hydraulic four-column press for tableting, reciprocating multiple times until the mud-like composite material is uniformly pressed, and the whole The process is automatic, saving manpower; the hydraulic four-column press can work simultaneously with the first scraping device or the second scraping device, and the two stations are carried out simultaneously to improve work efficiency and save costs.

Owner:深圳市华阳通达精密机械有限公司 +1

Rapid medicinal yeast tabletting device

InactiveCN108016078AExtended service lifeAvoid deformationShaping pressYeastAgricultural engineering

The invention discloses a rapid medicinal yeast tabletting device. The rapid medicinal yeast tabletting device comprises an inner cavity. The inner wall of one side of the inner cavity is fixedly connected with one ends of clamping plates. An extrusion barrel is arranged between the two clamping plates. A first extrusion plate and a second extrusion plate are arranged at the two ends of the extrusion barrel correspondingly. Push rods are arranged on one side of the first extrusion plate and one side of the second extrusion plate. The tops of the two push rods are connected with the bottom of afirst fixing seat and the bottom of a second fixing seat correspondingly. The top of the second fixing seat is rotationally connected with one end of a first connecting rod through a connecting shaft. According to the rapid medicinal yeast tabletting device, medicinal yeast is tabletted through extrusion force, and the service life of the tabletting device is prolonged. After extrusion forming, formed medicinal yeast tablets are conveyed out through a conveying belt, deformation of the formed medicinal yeast tablets is avoided, the quality of extrusion tabletting of the medicinal yeast is improved, and therefore the tabletting efficiency of the medicinal yeast is improved.

Owner:扬州起航机械有限公司

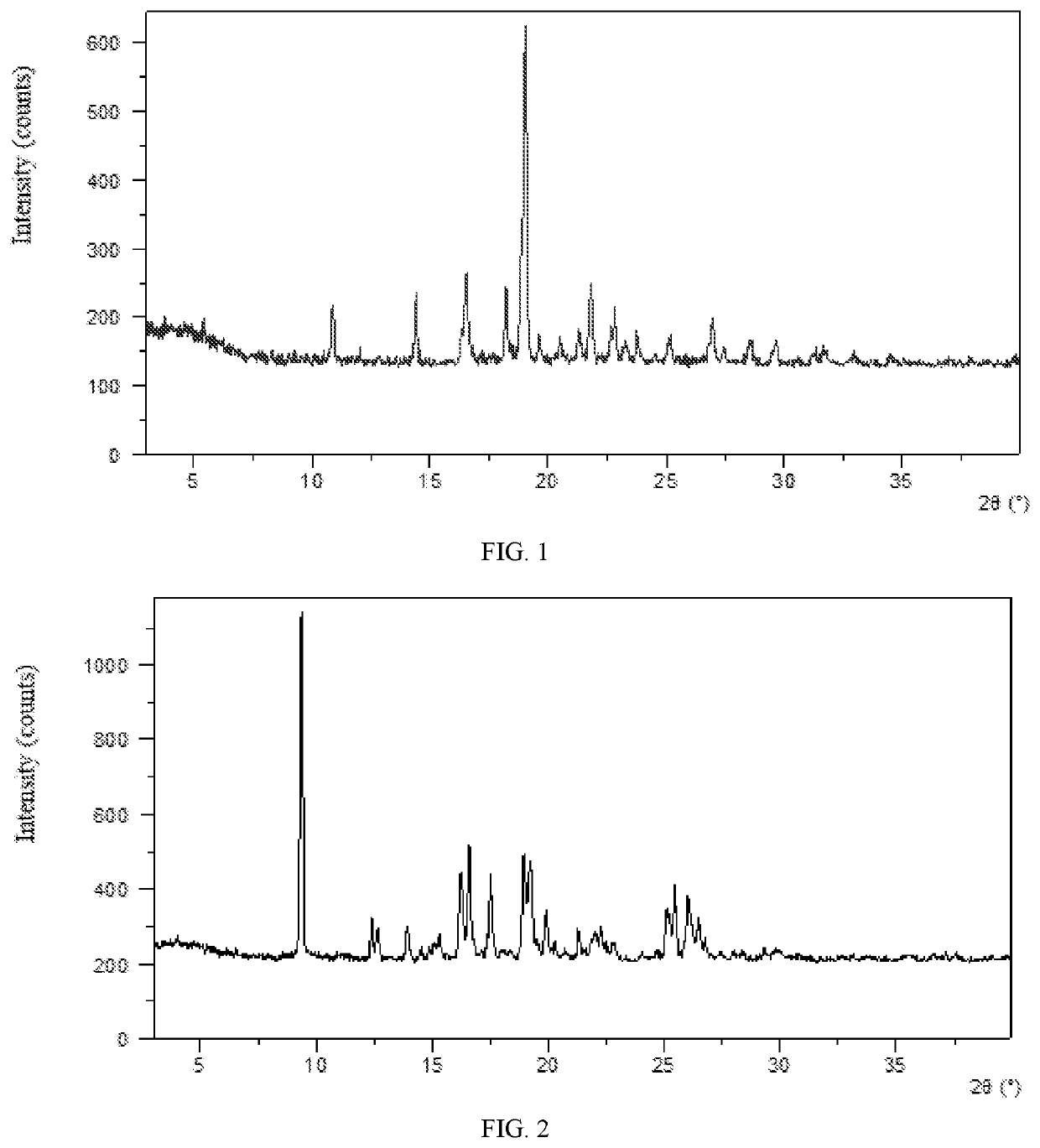

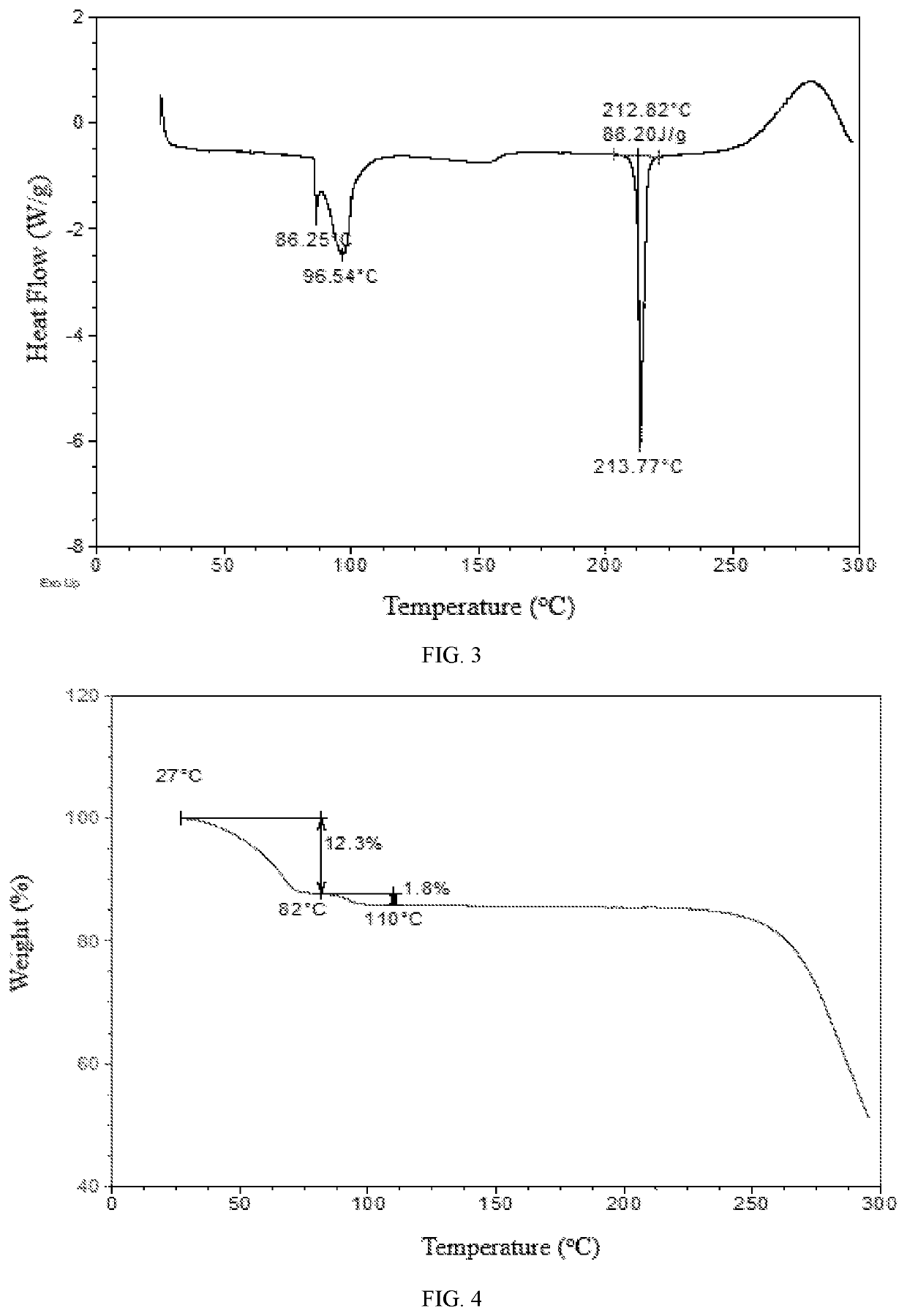

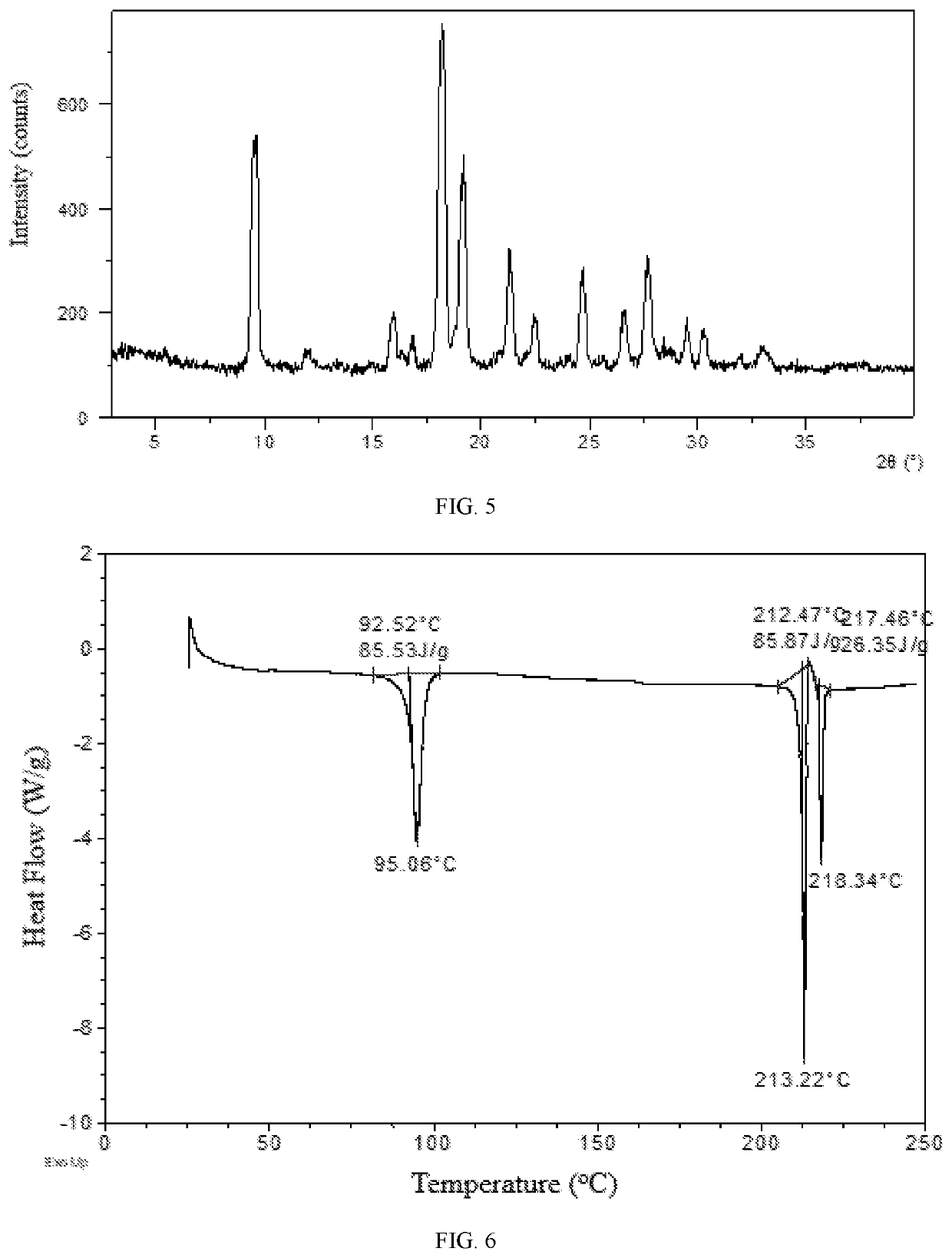

Crystal form of Baricitinib and preparation method thereof

ActiveUS11124517B2Improve solubilityImprove drug bioavailabilityOrganic active ingredientsAntipyreticPharmaceutical drugCombinatorial chemistry

The present disclosure relates to crystalline forms of Baricitinib and processes for preparation thereof. The present disclosure also relates to pharmaceutical composition containing these crystalline forms and use of these crystalline forms for preparing JAK inhibitor drugs and preparing drugs treating rheumatoid arthritis. The crystalline forms of the present disclosure have one or more improved properties compared with crystalline forms of the prior art and have significant values for future drug optimization and development.

Owner:CRYSTAL PHARMA CO LTD

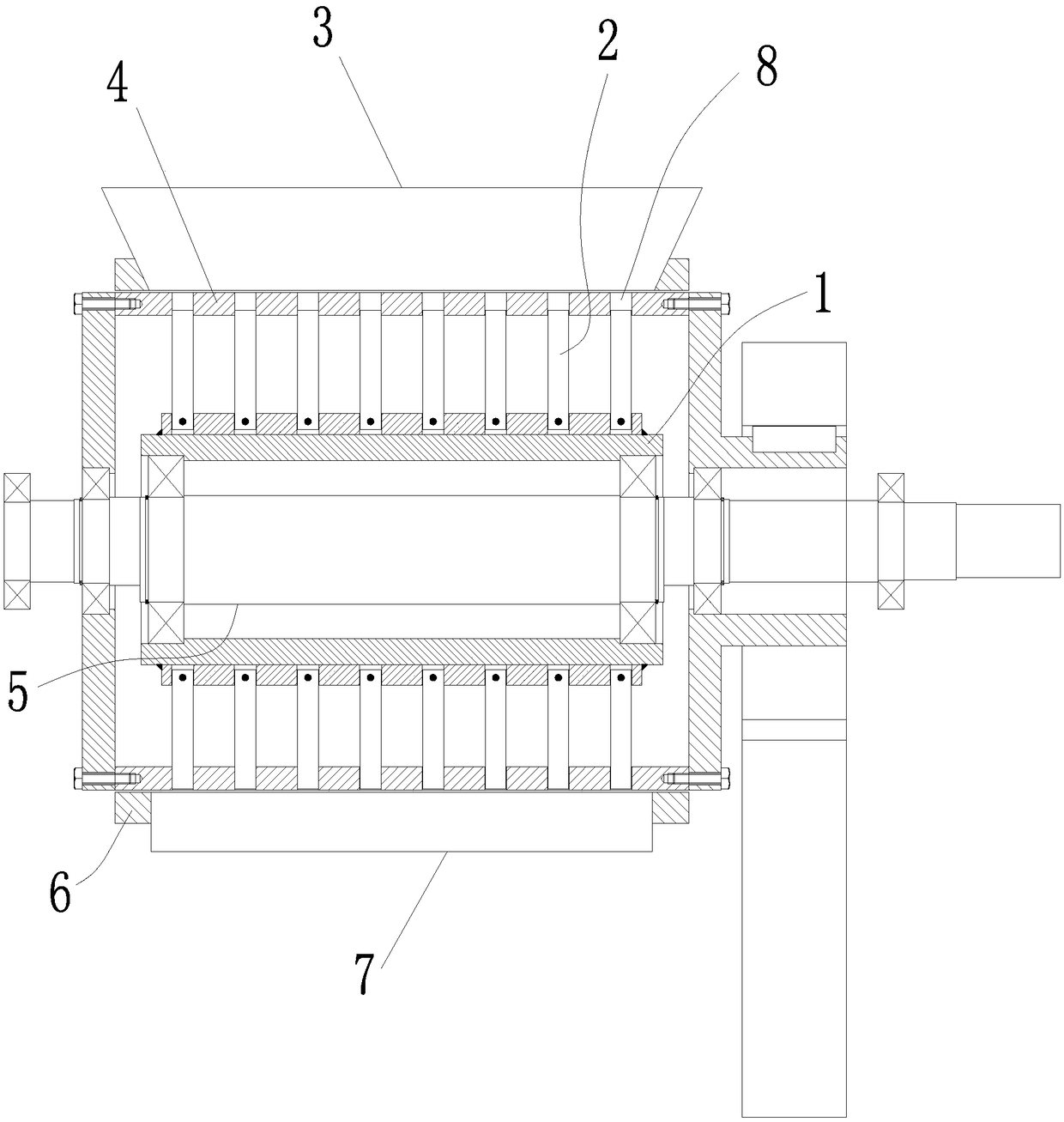

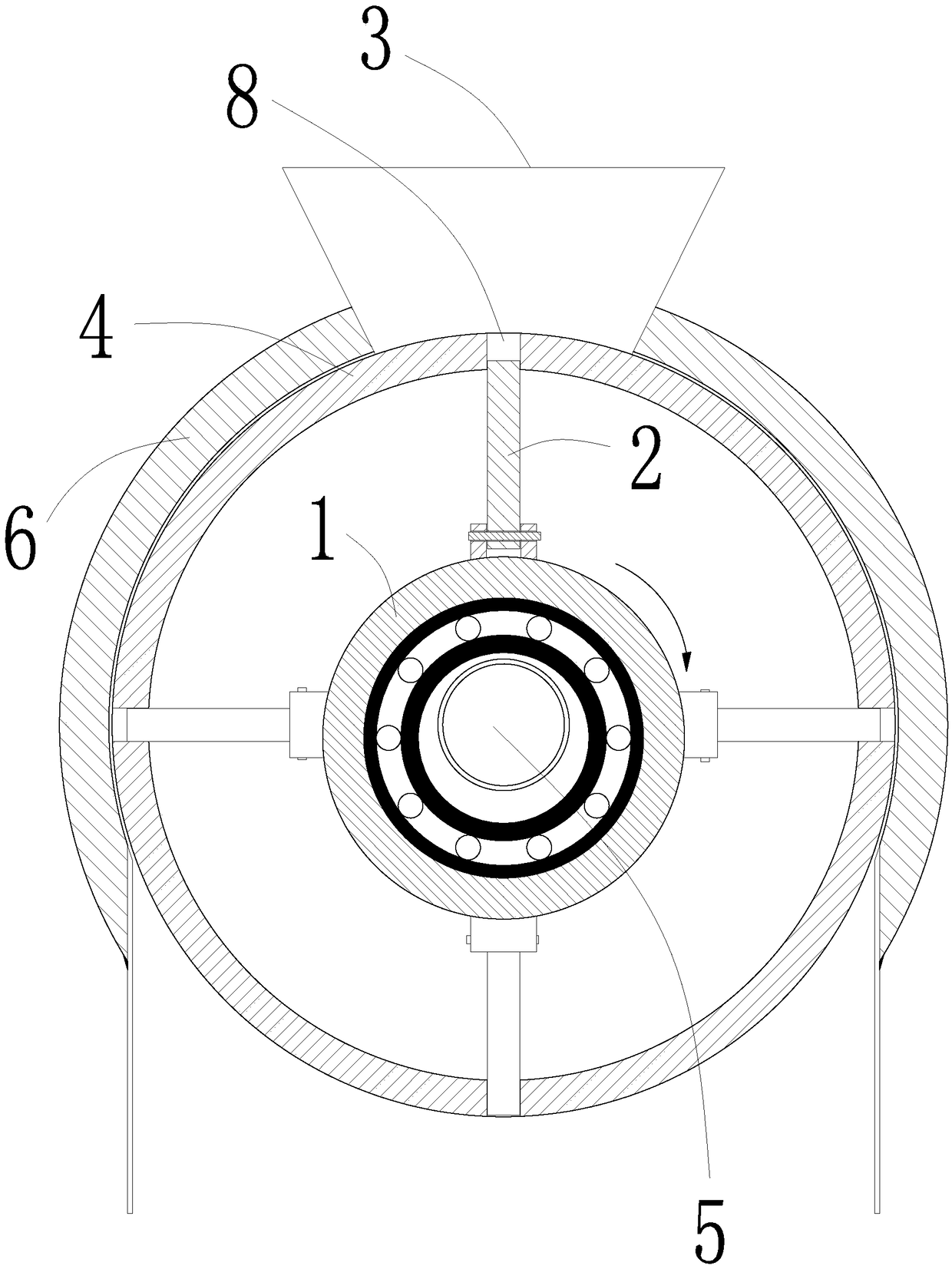

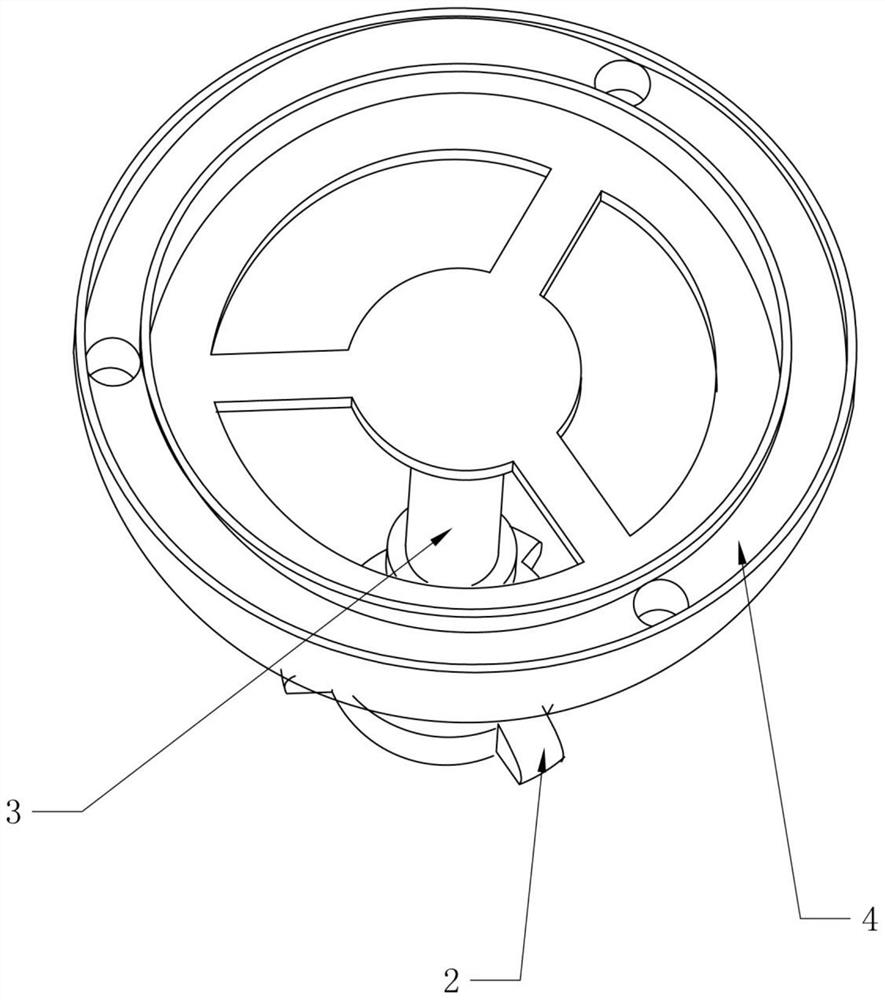

Rotary Fertilizer Press

The invention provides a rotation chemical fertilizer pressing machine. The rotation chemical fertilizer pressing machine comprises an inner rolling barrel and an outer rolling barrel. The inner rolling barrel axially penetrates the outer rolling barrel. The outer wall of the inner rolling barrel and the inner wall of the outer rolling barrel are matched with each other to achieve rolling sheet manufacturing. A feeding hopper is arranged at the upper end of the outer rolling barrel. A discharging port is formed in the lower end of the outer rolling barrel. The inner rolling barrel is arranged on a main shaft through a bearing. The right end of the inner rolling barrel is connected with a power mechanism. An eccentric part is arranged at the middle section of the main shaft and provided with a shaft sleeve through a bearing. Four rows of ejector rods are annularly arranged on the outer wall of the shaft sleeve. Grooves corresponding to the ejector rods in a one-to-one manner are formed in the inner wall of the inner rolling barrel. One ends of the ejector rods are fixed to the outer wall of the shaft sleeve, and the other ends of the ejector rods are inserted in the grooves. According to the rotation chemical fertilizer pressing machine, rolling is achieved in the manner of cooperation of the inner rolling barrel and the outer rolling barrel, and the tabletting efficiency is high; feeding and discharging can be synchronously finished while tabletting is achieved, the fit clearance between the inner rolling barrel and the outer rolling barrel is controlled by the eccentric part of the main shaft, stability is good, and clearance control is accurate.

Owner:安徽省锦艺农业科技开发有限公司

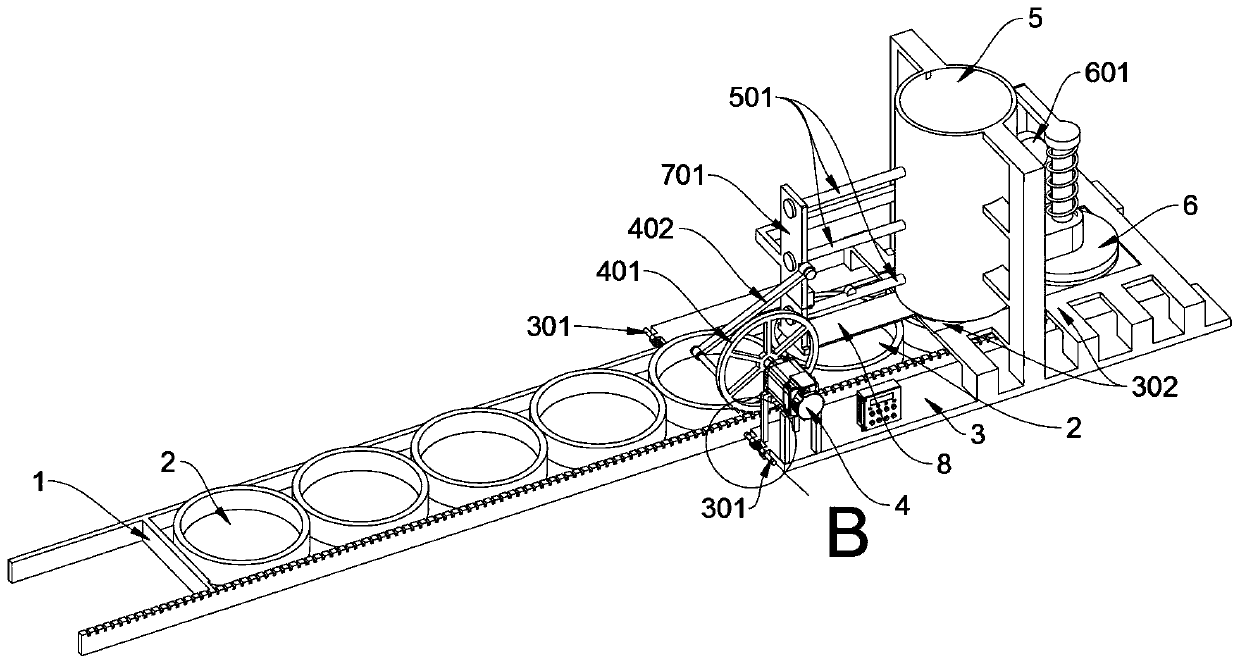

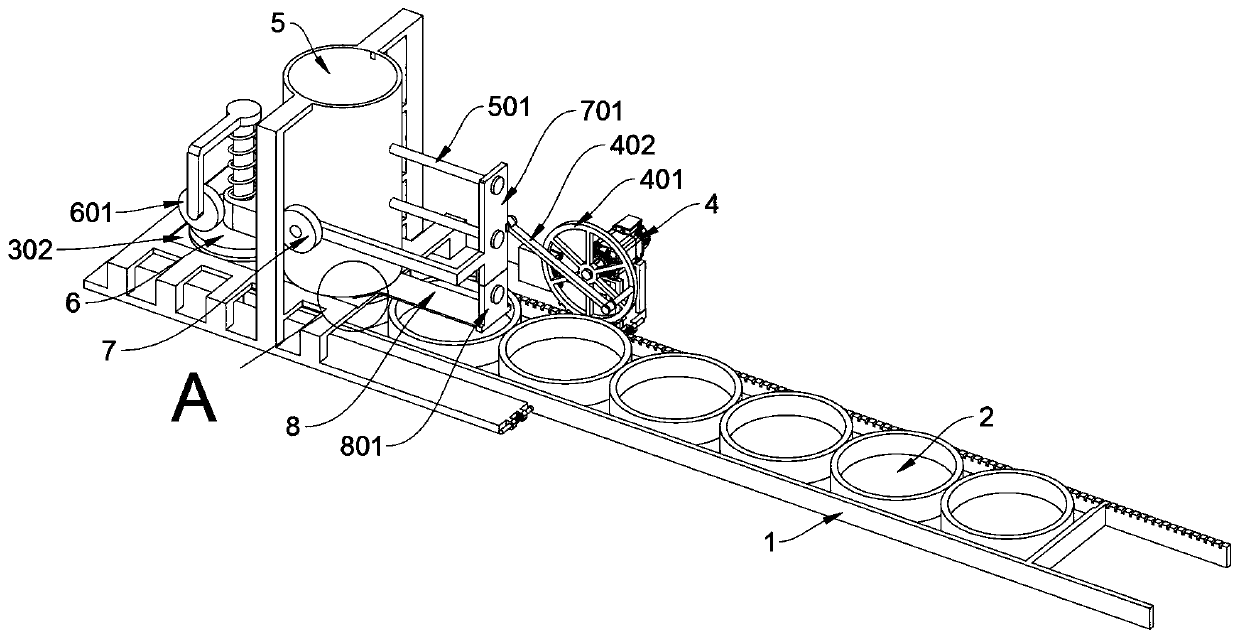

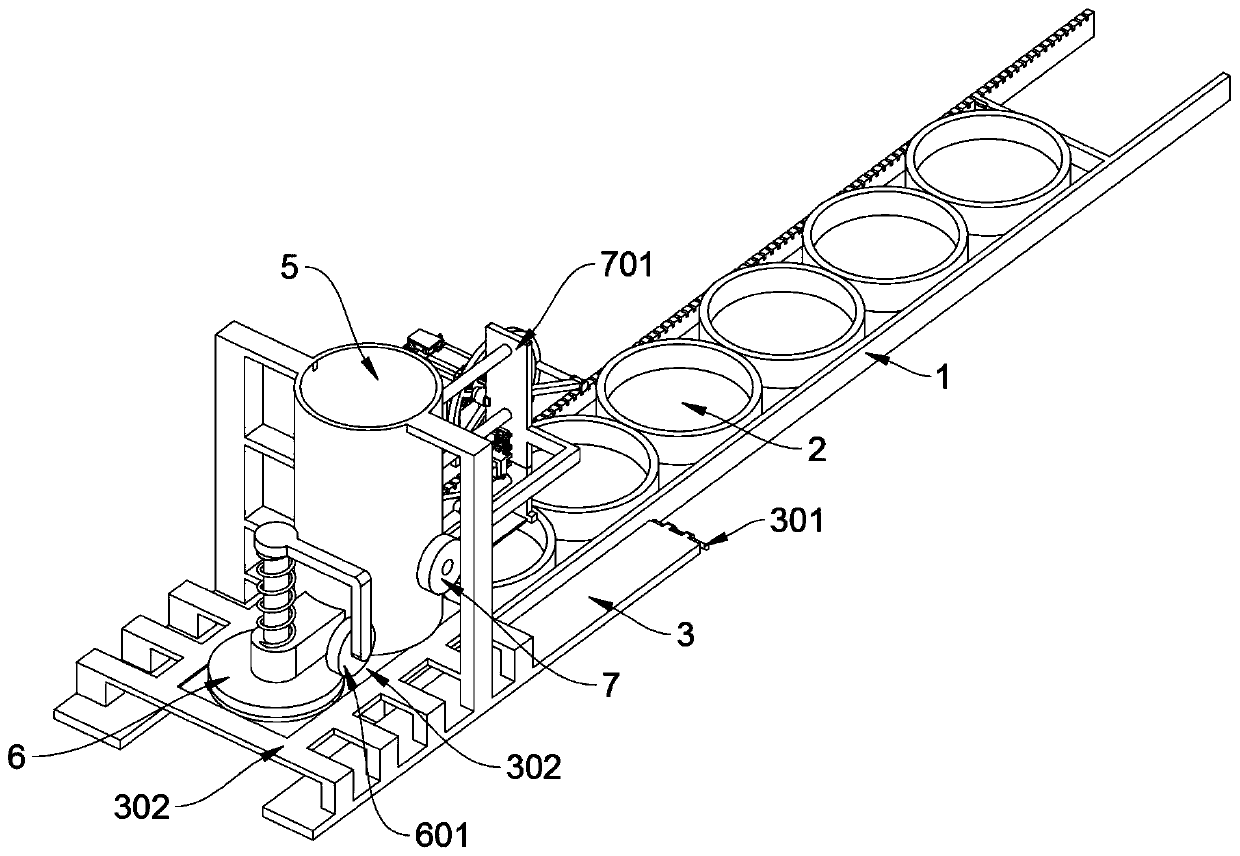

Automatic stirring tablet press for pulpy composite

ActiveCN110696423ASave human effortImprove work efficiencyCleaning using toolsPressesEngineeringSlide plate

The invention discloses an automatic stirring tablet press for a pulpy composite. The automatic stirring tablet press comprises a machine frame, a hydraulic four-column press, a sweeping and scrapingdevice, a first scraping device, a first slide plate driving device, a second scraping device and a second slide plate driving device. The hydraulic four-column press is arranged in the middle of themachine frame. The first scraping device is arranged on the left side of the machine frame. The first slide plate driving device is arranged at the bottom of the first scraping device. The second scraping device is arranged on the right side of the machine frame. The second slide plate driving device is arranged at the bottom of the second scraping device. The pulpy composite is stirred and gathered into a lump through the first scraping device or the second scraping device and then the lump is conveyed into the hydraulic four-column press for tabletting in this way repeatedly until the pulpycomposite is evenly pressed, the whole process is automatically carried out, and labor is saved; and the hydraulic four-column press can work together with the first scraping device or the second scraping device synchronously at two stations, work efficiency is improved, and cost is saved.

Owner:深圳市华阳通达精密机械有限公司 +1

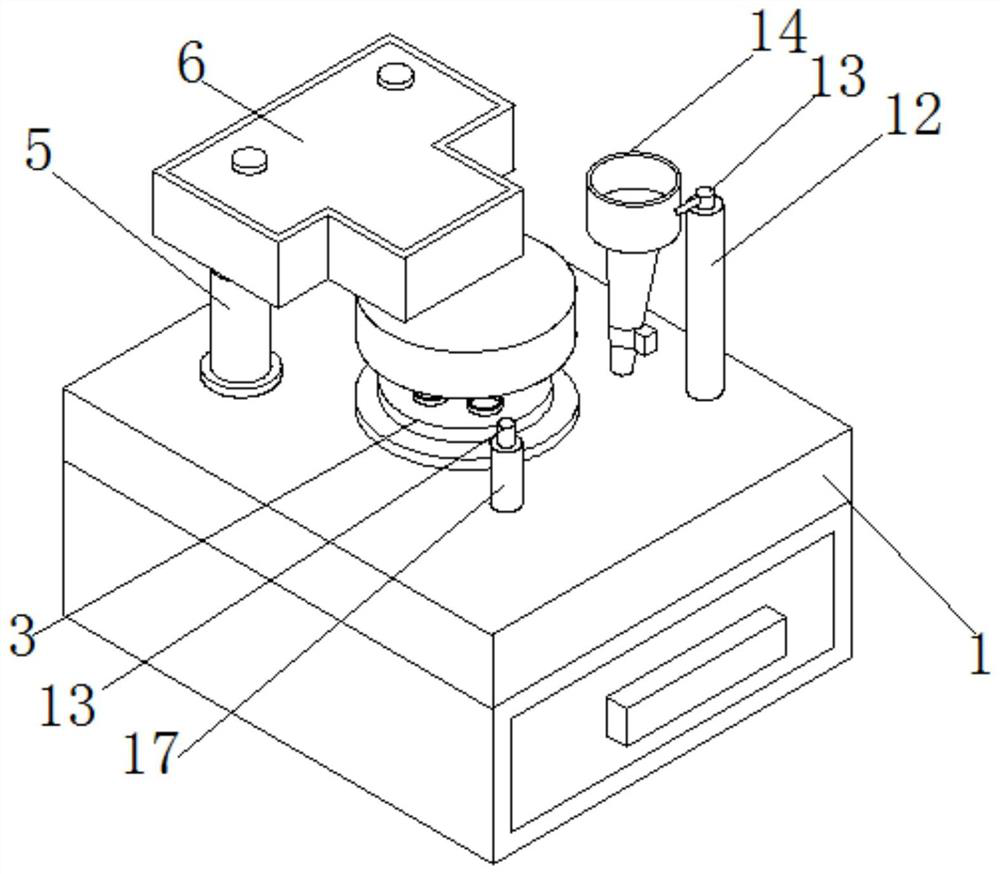

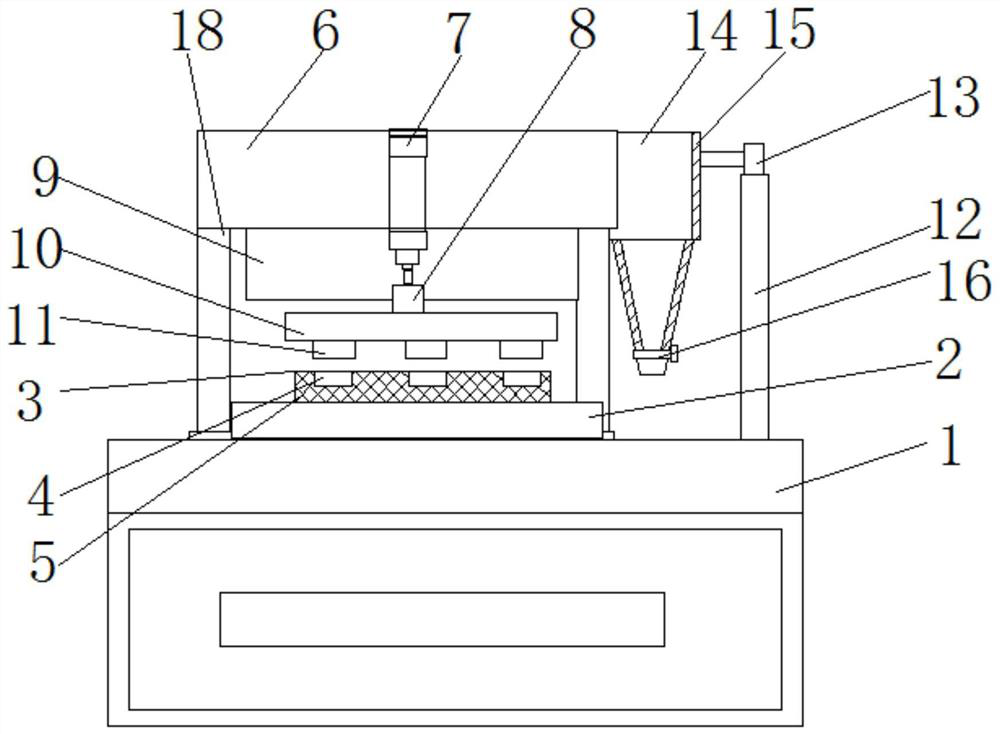

A method and device for displaying hard tissue pathological slices

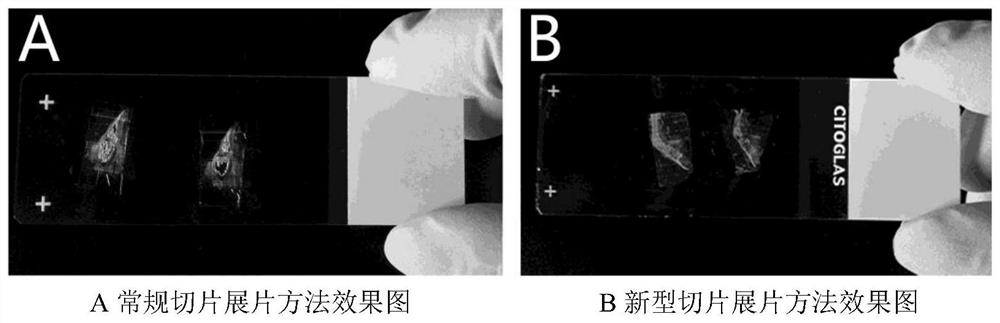

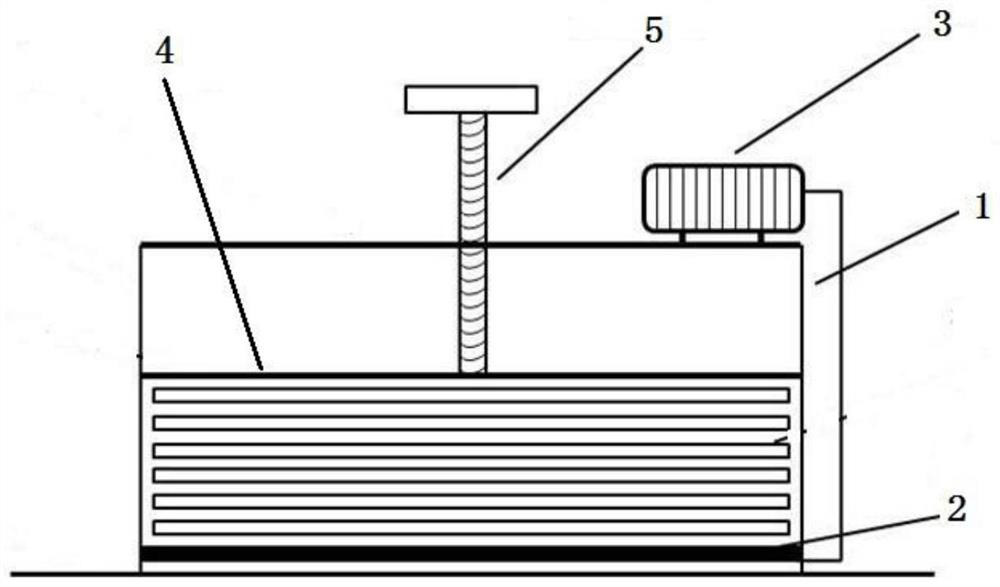

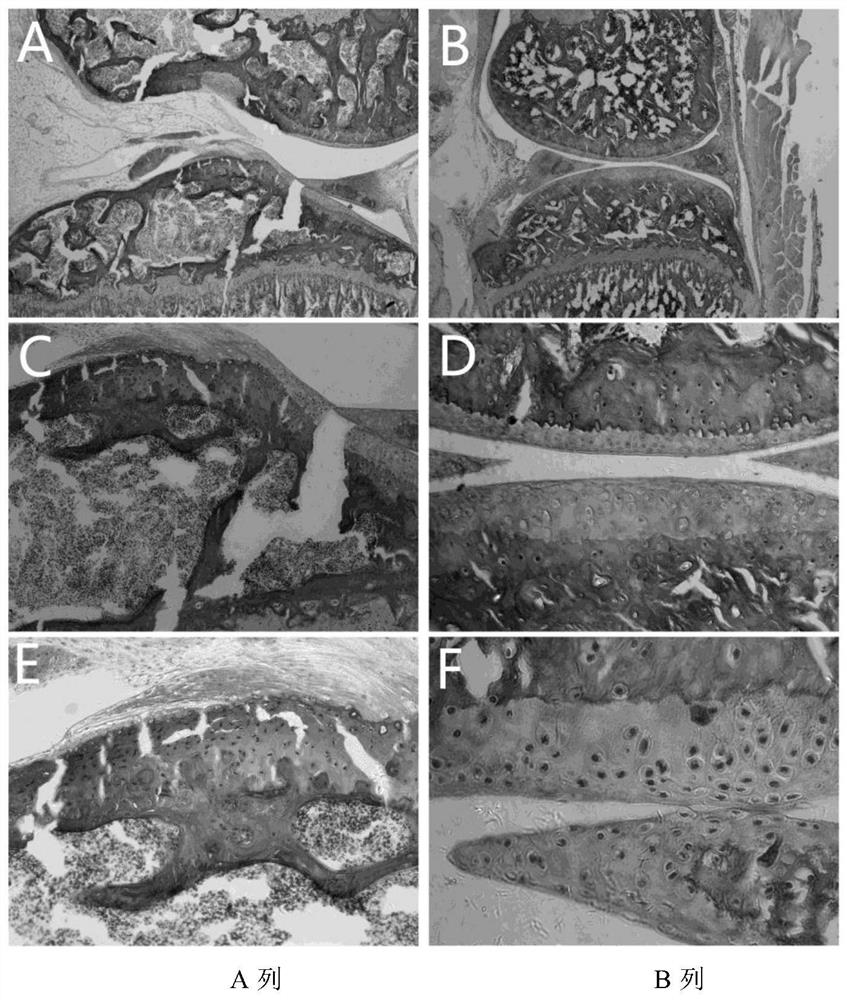

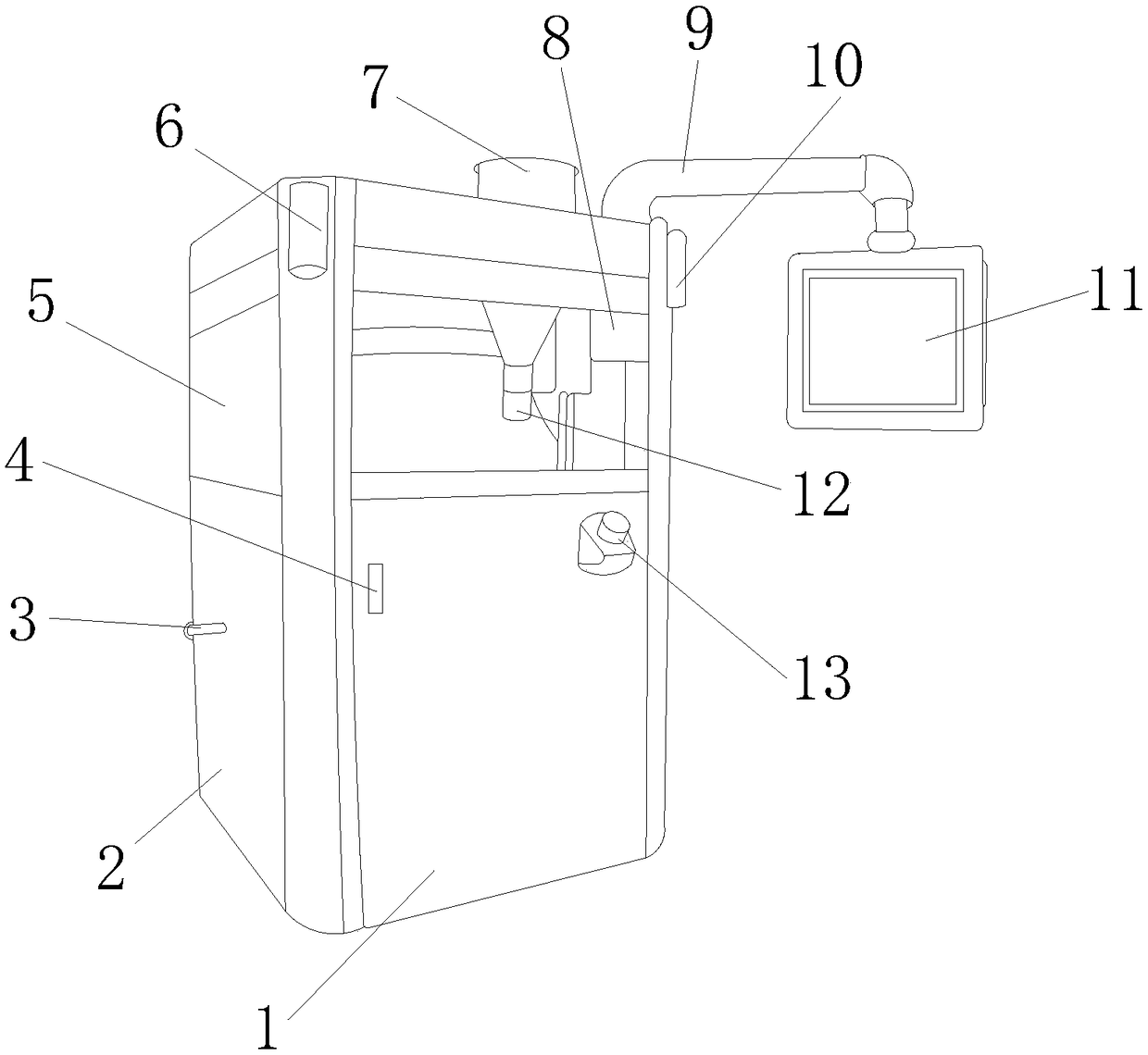

ActiveCN109187118BHigh hardnessEasy to apply pressure evenlyPreparing sample for investigationXylyleneGlass cover

The invention discloses a method and a device for spreading a hard tissue pathological section. The method comprises the following steps: 1) fixing a material, dehydrating, clearing, permeating, embedding and trimming with a grinding wheel; 2) uniformly coating an OCT embedding medium on the surface of the hard section and then slicing; 3) putting the sliced hard tissue section into hot water at 45-52 DEG C and spreading the tissue section; 4) using a glass slide coated with chrome alum gelatin for fishing out the hard tissue section; 5) uniformly coating vaseline on a cover glass and placingon the glass slide adhered to the tissue section; 6) placing the glass slide into a pressing device, uniformly applying a pressure, putting the pressing device with the glass slide into an oven at 60DEG C and baking for 2 hours; and 7) taking the glass slide out of the oven, removing the cover glass, putting into xylene for removing vaseline, and naturally airing for later use. The method and thedevice for spreading the hard tissue pathological section disclosed by the invention have the advantages that the operation is convenient, the repeatability is high, the problems of shrinking, shedding, and the like, of the hard tissue section can be effectively avoided, the spreading effect is obviously promoted and the method and the device are suitable for different tissue-engineered bone researches.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Tabletting machine for infrared spectrum analysis

InactiveCN109263126AEasy to take outImprove follow-up test accuracyPreparing sample for investigationMaterial analysis by optical meansInfraredEngineering

The invention discloses a tabletting machine for infrared spectrum analysis. The machine structurally comprises a box body, a fixing base, an adjusting block, a positioning block, a tabletting chamber, an indicating scaleplate, a feeding port, an infrared spectrum analysis device, a supporting beam, a spring, a displaying screen, a discharging port and a controller, the box body is fixedly connected with the fixing base, the adjusting block is arranged on the fixing base, the spring is connected with the box body, and the displaying screen is connected with the controller through the box body.The tabletting machine has the advantages that the infrared spectrum analysis device is arranged, the tabletting machine is firstly controlled through the controller and the adjusting block to put amaterial into the feeding port, the tabletting strength is controlled by a strength regulator and a tabletting state displaying board, so that circular tablets are not bonded in a mold and are easilytaken out, the tabletting is uniform, subsequent testing accuracy is improved, labor force is replaced with a time controller to control time, molding is conducted by the tabletting machine by remaining unchanged after certain pressure is reached by automatic pressing, tablets are discharged from the discharging port, and the tabletting efficiency is improved.

Owner:TIANJIN XIANNQUAN IND & TRADE DEV

An automatic rotary medicine tablet press machine

ActiveCN110936652BImprove tableting efficiencyPrecision Tablet SpecificationsPress ramShaping pressDrug productTableting

The invention relates to a medicine tablet press machine, in particular to an automatic rotary medicine tablet press machine. The object of the present invention is to provide an automatic rotary medicine tablet press machine which can automatically finish tableting and collecting the medicine powder after placing it in the container. An automatic rotary drug tablet press, including a bottom plate, a rotating seat, a conversion shaft, a turntable, a tablet pressing rod, etc.; a rotating seat is installed above the bottom plate, and a conversion shaft is installed inside the rotating seat; A forming hole is opened, and a tablet pressing rod matched with the forming hole is arranged on the turntable. The invention only needs the operator to put the medicine powder into the medicine powder pot and turn on the motor to automatically compress the medicine in batches. Tablet specifications, and reduce pollution and waste, to save time and effort, health and environmental protection, convenient and quick effect.

Owner:JIANGXI JUWANG PHARMA IND

On-assembly-line sheeting machine for operation towels

PendingCN109549707ARealize automatic tablet pressingAdjustable spacingSurgical drapesAssembly lineRisk stroke

The invention relates to the technical field of the production of operation towels, in particular to an on-assembly-line sheeting machine for operation towels. The sheeting machine comprises a machineframe, a plurality of groups of press rollers arranged on the machine frame, and a driving device, wherein each group of the press rollers comprise an upper press roller and a lower press roller which are symmetrically arranged; each upper press roller and the corresponding lower press roller are at the same axle wire in the vertical direction; the driving device is used for driving the press rollers to synchronously rotate; and a feeding opening of the sheeting machine is in on-assembly-line linkage with a discharging opening of a folding machine through a conveyor belt. Through the adoptionof the on-assembly-line sheeting machine disclosed by the invention, the on-assembly-line linkage of the folding and the sheeting of the operation towels is realized; compared with a conventional manual sheeting manner, the on-assembly-line sheeting machine has the advantages that the sheeting efficiency is improved, and labor cost is saved; besides, off-assembly-line sheeting by a mechanical sheeting machine can be performed without manual working procedure transferring, so that the site is saved; and in addition, the stroke of an air cylinder can be adjusted, so that the spacing between each upper press roller and the corresponding lower press roller is adjustable, and the sheeting machine can be suitable for on-assembly-line sheeting of the operation towels having different thickness and different sheeting requirements.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

A method for pressing samples for xrfs analysis of boric acid substrates

InactiveCN110470685BEasy to smoothImprove tableting efficiencyMaterial analysis using wave/particle radiationThin membraneTableting

The invention relates to a method for pressing a sample sheet for XRFS analysis of a boric acid substrate. Its technical proposal is: put 2.5-3.5g of boric acid into the bottom of the charging chamber of the tablet press and spread it flat to obtain the substrate layer; 0 ‑(3~5mm) discs, that is, the backing film; where: d 0 Indicates the diameter of the charging cavity of the tablet press, mm; then spread the backing film on the substrate layer, spread 0.5-3g of sample powder evenly on the backing film; finally use a sample spoon to The powder of the sample is smoothed, the press head of the tablet press is installed, the pressure is applied, the pressure is maintained, and the mold is demoulded to obtain a sample for XRFS analysis of the boric acid substrate. The invention has the characteristics of high efficiency, no peeling layer, small sample powder consumption and high sheet forming rate.

Owner:WUHAN UNIV OF SCI & TECH +2

A tablet pressing device and process for precious metal production

The invention discloses a tablet pressing device and process for precious metal production, comprising a base, a mounting seat is provided at the top of the base, a lower groove is arranged at the top of the mounting seat, a lower mold is arranged inside the lower groove, and Refrigerant is provided at the bottom end inside the lower tank, support rods are provided at both ends of the top of the base, and the top ends of the support rods are connected with mounting blocks. The present invention realizes that solid precious metals can be placed and melted inside the funnel by providing a funnel, and the inside of the funnel is provided with an anti-adhesion coating, so that it will not stick to the precious metal and at the same time facilitate cleaning, so that no impurities will be generated inside the funnel, Therefore, the inside of the precious metal does not contain impurities, and the appearance is beautiful. By setting the lower groove and the rotating shaft, the precious metal in the molten state can be directly poured into the mold, without manual metal transfer, and the contact between the precious metal and the air is reduced. Reduce oxidation and particle adhesion, resulting in better quality precious metals.

Owner:山东金艺珠宝有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com