On-assembly-line sheeting machine for operation towels

A technology of tablet press and surgical drape, which is applied in the fields of surgery, medical science, and surgical drape, can solve the problems of high labor cost and slow manual tablet compression efficiency, and achieve the goals of saving labor costs, improving tablet compression efficiency, and saving space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

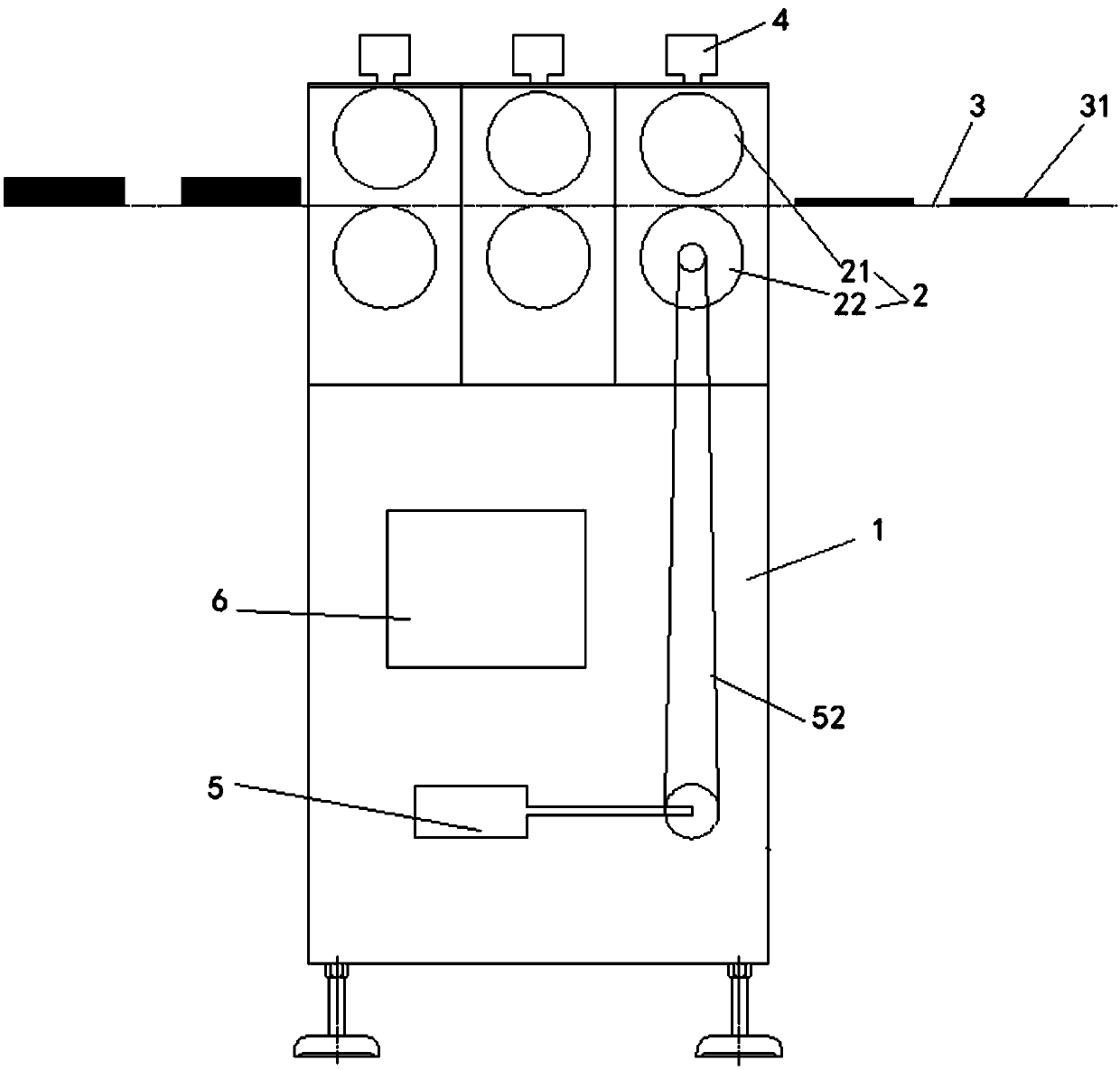

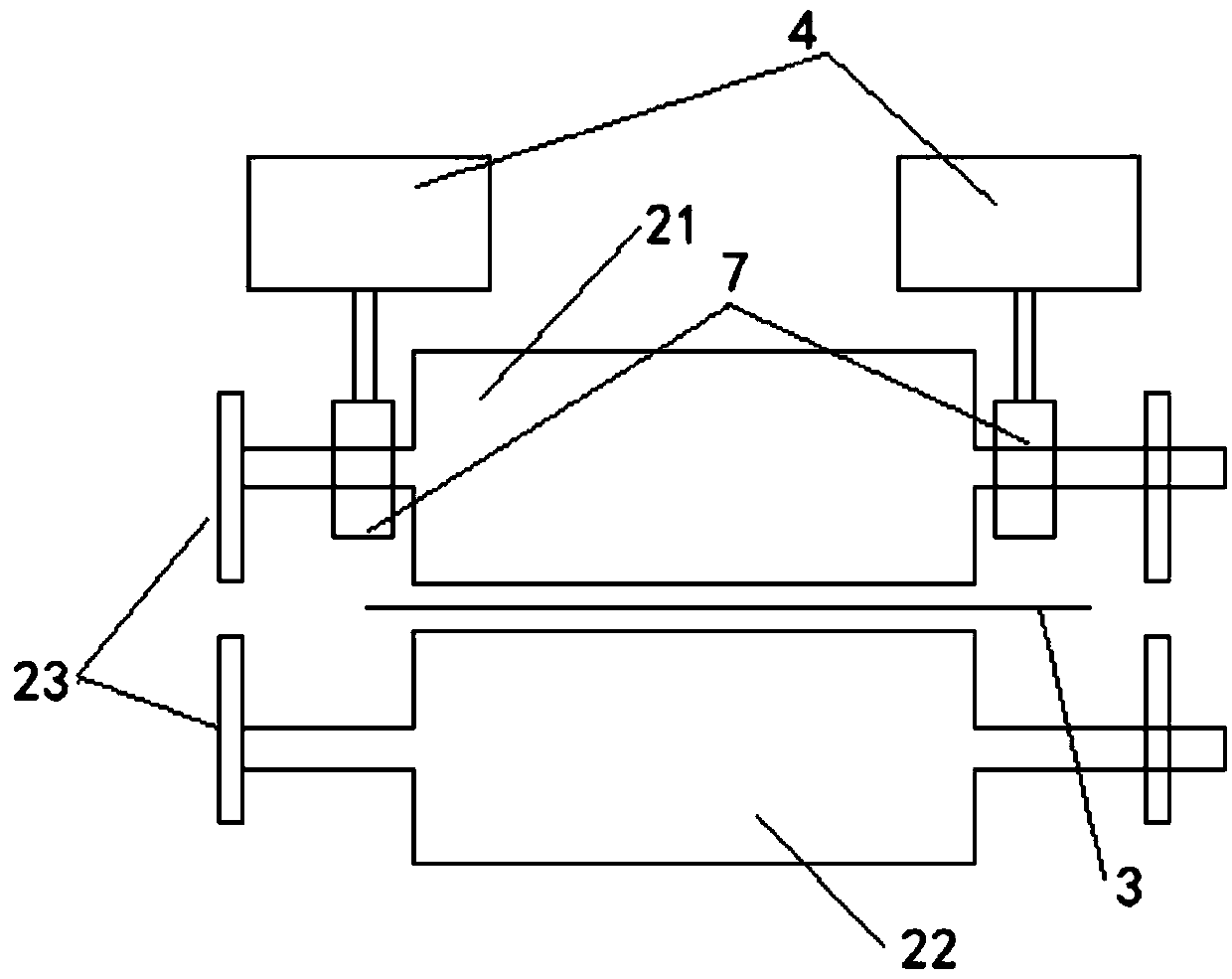

[0018] This embodiment provides an online tablet press for surgical towels, such as figure 1 and figure 2 , including a frame 1, on the frame 1, multiple groups of pressure rollers 2 are installed at equal intervals, wherein each group of pressure rollers 2 includes an upper pressure roller 21 and a lower pressure roller 22 arranged symmetrically, and an upper pressure roller 21 and a lower pressure roller 22 Being on the same central axis in the vertical direction, the distance between the upper pressing roller 21 and the lower pressing roller 22 is pre-adjusted according to the requirements of tablet pressing.

[0019] Wherein, the online tablet press machine also includes a driving device installed on the frame 1, which is used to drive multiple groups of pressing rollers 2 to rotate synchronously to complete the automatic ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com