Automatic stirring tablet press for pulpy composite

A composite material and automatic stirring technology, applied in the field of tablet presses, can solve problems such as difficulty in satisfying rapid production, increased labor intensity, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

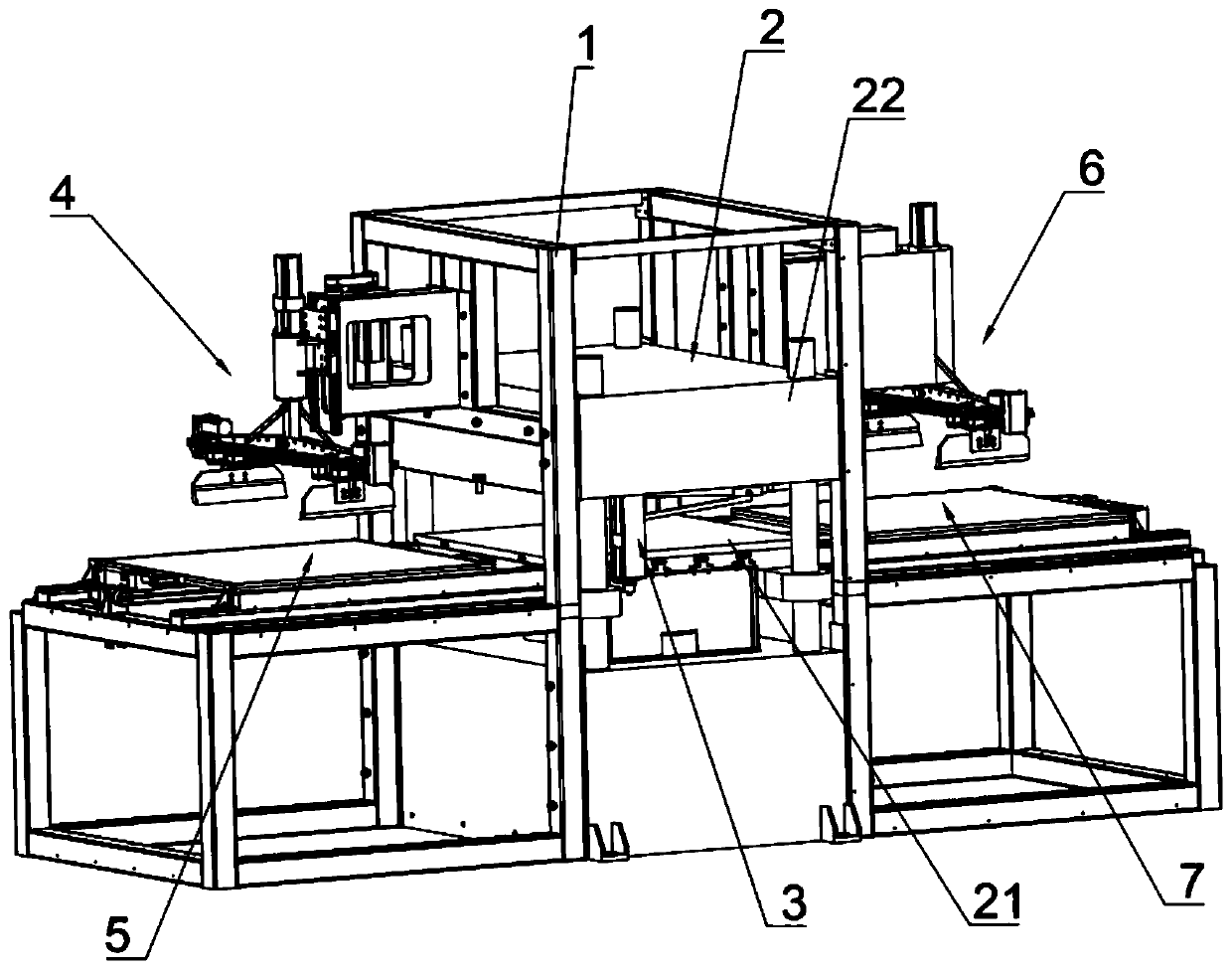

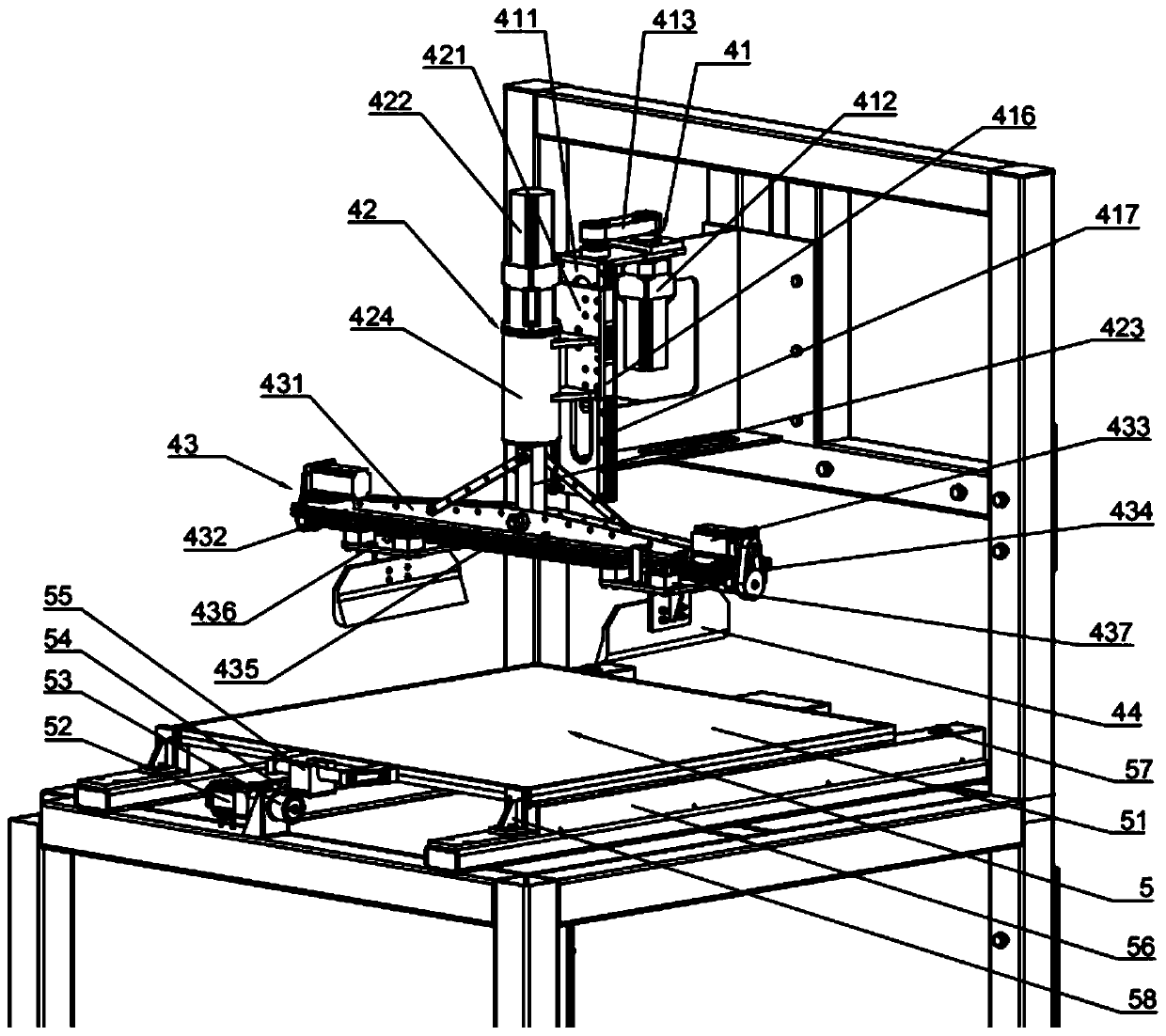

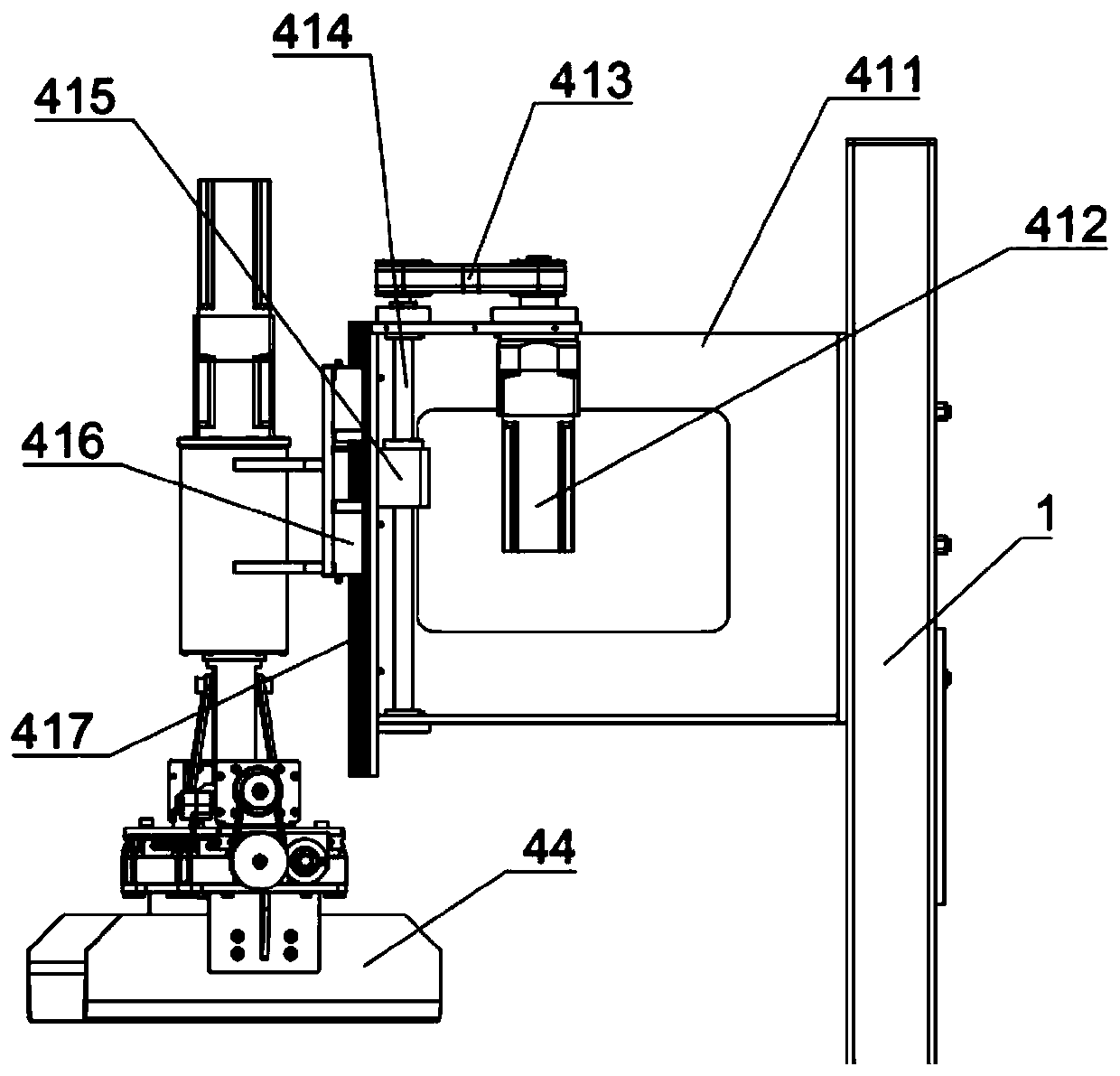

[0027] Such as Figure 1 to Figure 6 As shown, an automatic stirring tablet press machine for mud-like composite materials, including a frame 1, a hydraulic four-column press 2, a cleaning and scraping device, a first scraping device 4, a first slide driving device 5, a second scraping device device 6 and the second slide plate driving device 7, the hydraulic four-column press 2 is located in the middle of the frame 1, and the hydraulic four-column press 2 includes a fixed workbench 22 and a movable workbench 21, and the fixed workbench 22 is located at the movable Above the workbench 21, the first scraping device 4 is arranged on the left side of the frame 1, the first slide plate driving device 5 is arranged at the bottom of the first scraping device 4, and the second scraping device 6 is arranged on the machine On the right side of the frame 1, the second slide plate driving device 7 is arranged at the bottom of the second scraping device 6 , and the cleaning and scraping d...

Embodiment 2

[0044] Such as figure 1 As shown, an automatic stirring tablet press machine for mud-like composite materials, including a frame 1, a hydraulic four-column press 2, a cleaning and scraping device, a first scraping device 4, a first slide plate driving device 5, a second scraping device device 6 and the second slide plate driving device 7, the hydraulic four-column press 2 is located in the middle of the frame 1, the hydraulic four-column press 2 includes a fixed workbench 22 and a movable workbench 21, and the fixed workbench 22 is located at the movable Above the workbench 21, the first scraping device 4 is arranged on the left side of the frame 1, the first slide plate driving device 5 is arranged at the bottom of the first scraping device 4, and the second scraping device 6 is arranged on the machine On the right side of the frame 1, the second slide plate driving device 7 is arranged at the bottom of the second scraping device 6 , and the cleaning and scraping device is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com