A tablet pressing device and process for precious metal production

A tablet pressing device and precious metal technology, which is applied in the field of tablet pressing devices and processes for precious metal production, can solve the problems of poor quality of precious metal products, low quality of precious metal products, and uncleaning of furnaces, etc., to reduce labor load rate, Beautiful appearance and multi-profit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

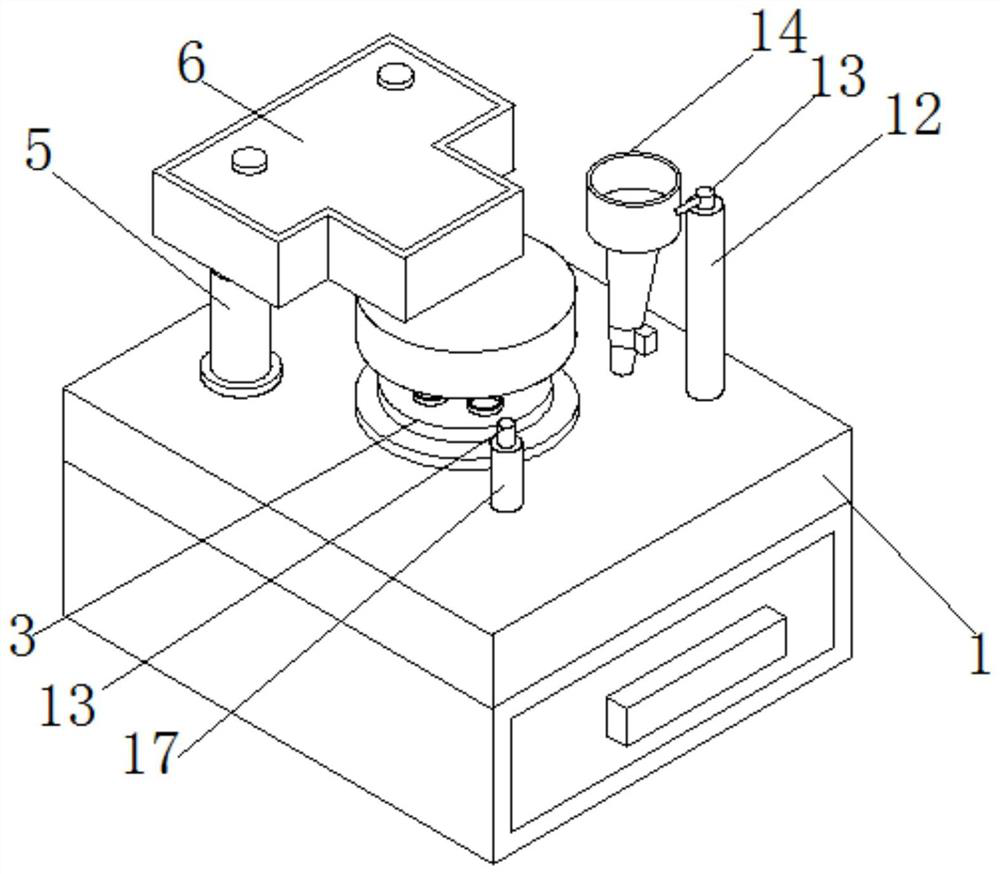

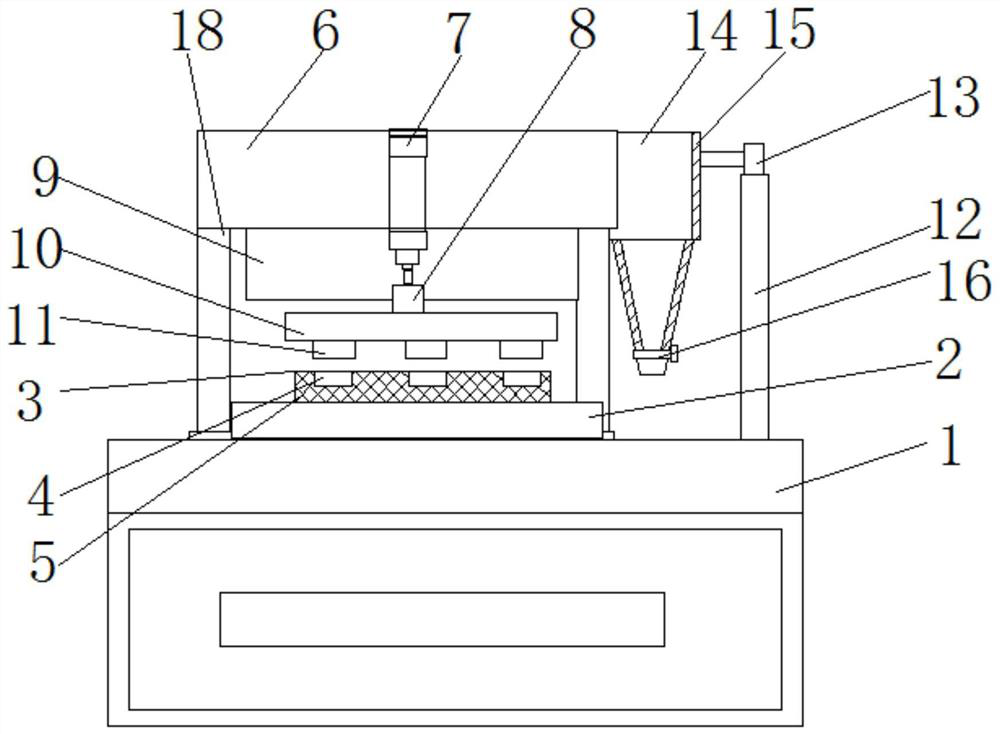

[0023] see Figure 1-2 , a tablet pressing device and process for precious metal production, comprising a base 1, a mounting seat 2 is arranged on the top of the base 1, and a lower groove 3 is arranged on the top of the mounting seat 2, and a lower mold 4 is arranged inside the lower groove 3, and The bottom end of the lower tank 3 is provided with a refrigerant 5, and the two ends of the top of the base 1 are provided with a support rod 18, and the top of the support rod 18 is connected with a mounting block 6, and the inside of the mounting block 6 is provided with a cylinder 7, and the cylinder The output end of 7 is connected with telescopic rod 8, and one end of telescopic rod 8 is connected with upper groove 10, and the bottom end of upper groove 10 is provided with upper mold 11, and one side of base 1 top is provided with connecting rod 12, and connecting rod 12 A rotating shaft 13 is arranged at the top of the connecting rod 12 through which a funnel 14 is rotated an...

Embodiment 2

[0026] Please focus on figure 2 , the base 1 is fixedly connected to the mounting seat 2, and the mounting seat 2 is a cylindrical structure, the number of the lower mold 4 is three sets, and the three sets of lower molds 4 are all cylindrical structures, and the refrigerant 5 is made of ammonium chloride and hydrogen oxide Barium composition.

[0027] In this embodiment: by providing the refrigerant 5, rapid cooling of the precious metal in molten state can be achieved, so that the precious metal can start to form, ensuring the efficiency of tablet forming, and three groups of tablet pressing at the same time can improve the compression rate. The speed of the tablet ensures the cost of the tablet.

Embodiment 3

[0029] Please focus on figure 2 A connection block 9 is connected to the bottom end of the installation block 6, and a telescopic rod 8 is arranged inside the connection block 9, and the connection block 9 is a cylindrical structure.

[0030] In this embodiment: the installation block 6 is to install the cylinder 7 (model is TDA20), which is convenient for pressing with precious metals, and the connecting block 9 is to install the telescopic rod 8 (model is GRA-L50), so that the telescopic The rod 8 and the cylinder 7 can cooperate with the work structure and are simple and easy to operate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com