An automatic stirring tablet press machine for mud-like composite materials

A composite material and automatic stirring technology, applied in the field of tablet presses, can solve the problems of difficulty in meeting rapid production, increase labor intensity, and low production efficiency, and achieve the effects of saving manpower, reducing labor costs, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

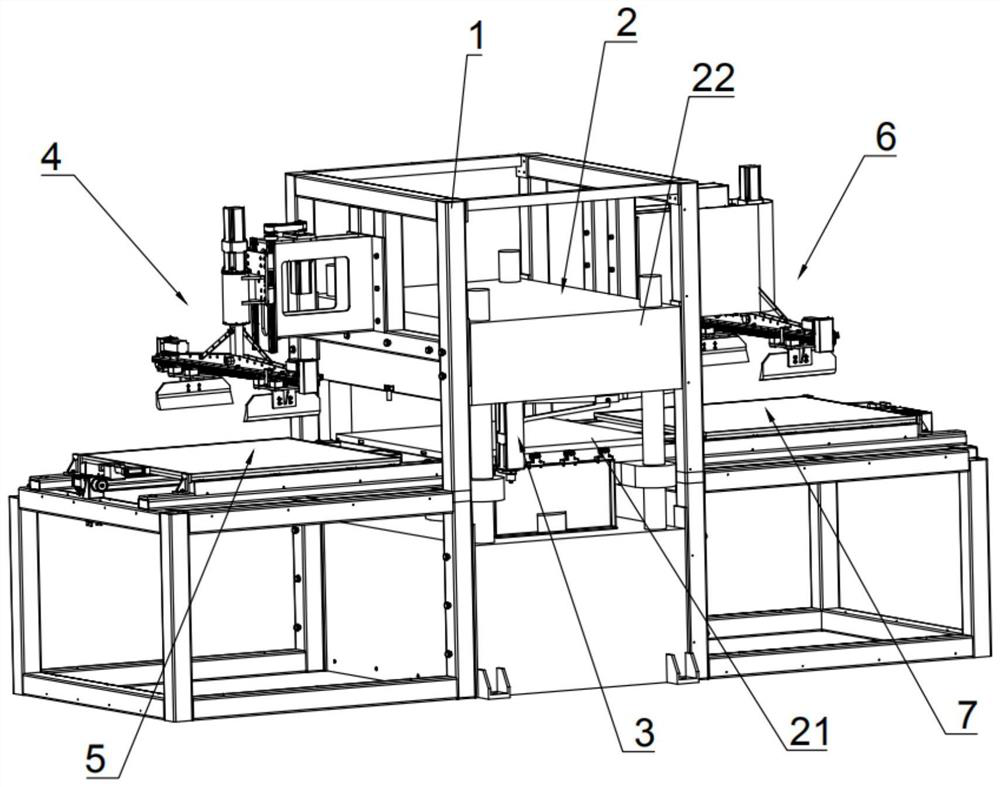

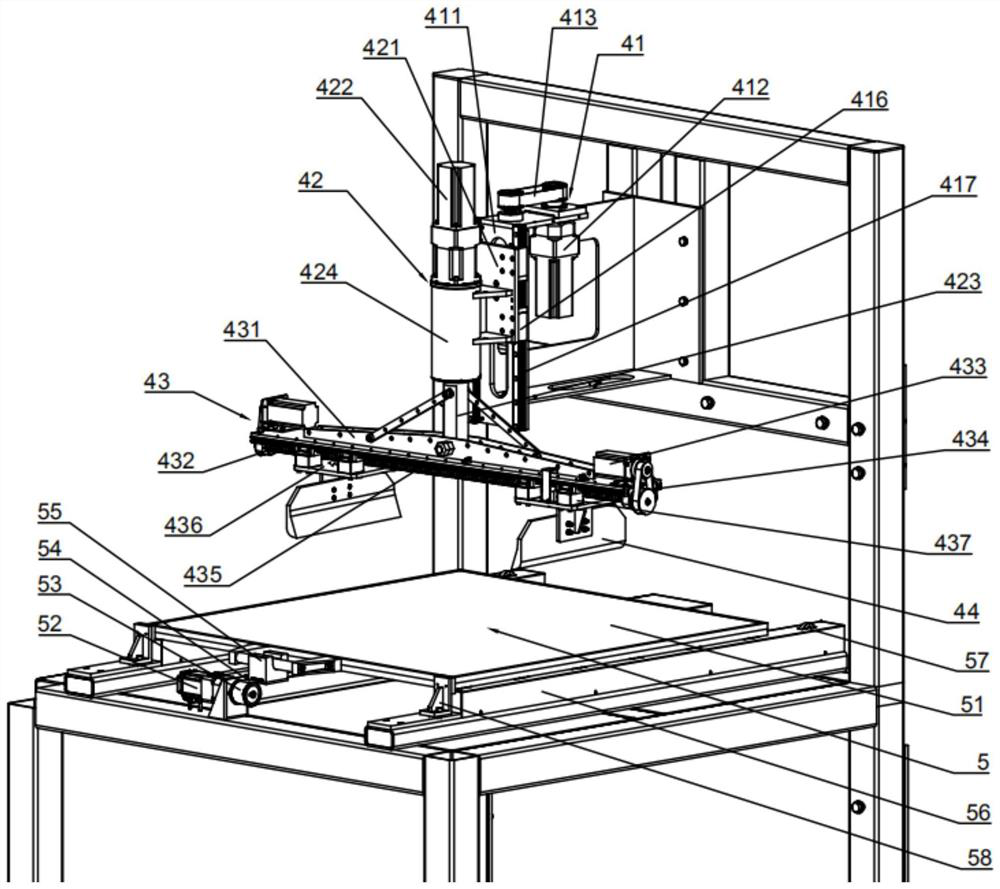

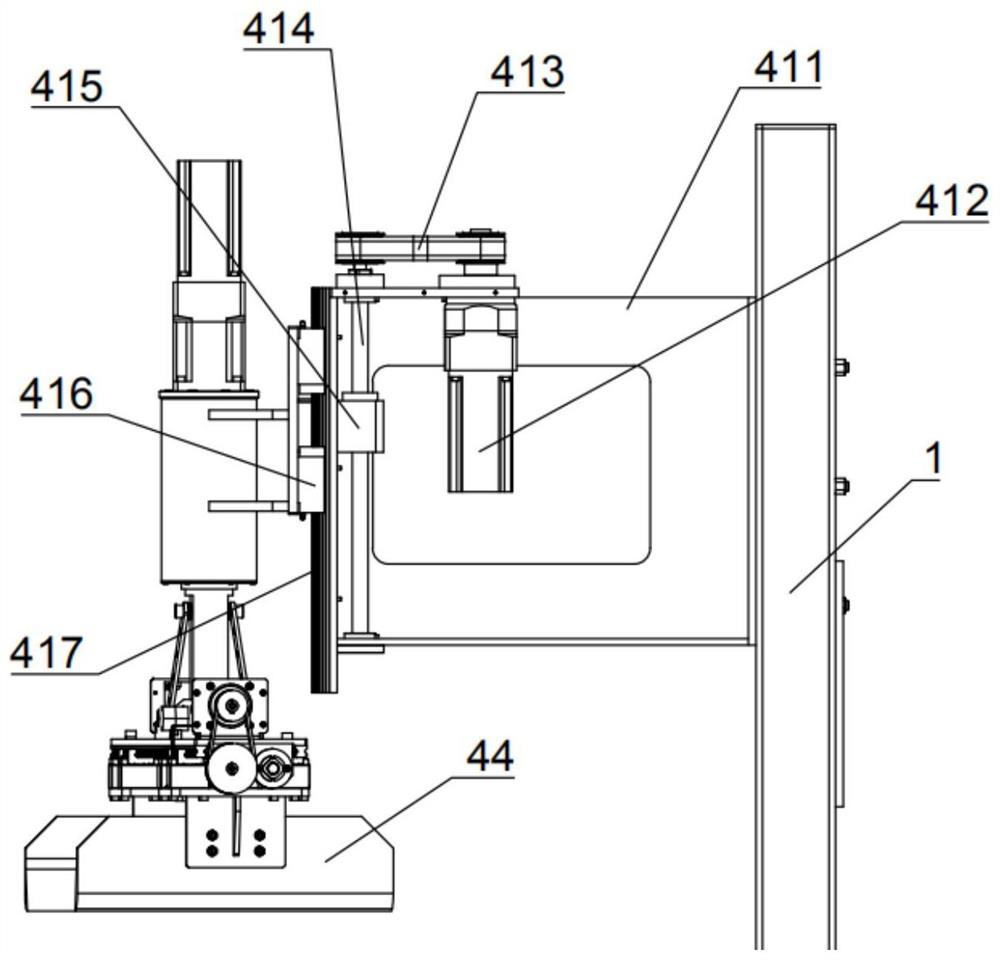

[0027] Such as Figure 1 to Figure 6 As shown, an automatic stirring tablet press machine for mud-like composite materials, including a frame 1, a hydraulic four-column press 2, a cleaning and scraping device, a first scraping device 4, a first slide driving device 5, a second scraping device device 6 and the second slide plate driving device 7, the hydraulic four-column press 2 is located in the middle of the frame 1, and the hydraulic four-column press 2 includes a fixed workbench 22 and a movable workbench 21, and the fixed workbench 22 is located at the movable Above the workbench 21, the first scraping device 4 is arranged on the left side of the frame 1, the first slide plate driving device 5 is arranged at the bottom of the first scraping device 4, and the second scraping device 6 is arranged on the machine On the right side of the frame 1, the second slide plate driving device 7 is arranged at the bottom of the second scraping device 6 , and the cleaning and scraping d...

Embodiment 2

[0044] Such as figure 1 As shown, an automatic stirring tablet press machine for mud-like composite materials, including a frame 1, a hydraulic four-column press 2, a cleaning and scraping device, a first scraping device 4, a first slide driving device 5, a second scraping device device 6 and the second slide plate driving device 7, the hydraulic four-column press 2 is located in the middle of the frame 1, and the hydraulic four-column press 2 includes a fixed workbench 22 and a movable workbench 21, and the fixed workbench 22 is located at the movable Above the workbench 21, the first scraping device 4 is arranged on the left side of the frame 1, the first slide plate driving device 5 is arranged at the bottom of the first scraping device 4, and the second scraping device 6 is arranged on the machine On the right side of the frame 1, the second slide plate driving device 7 is arranged at the bottom of the second scraping device 6 , and the cleaning and scraping device is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com