Improved equipment for improving tabletting production capacity

A technology of production capacity and equipment, applied in presses, material forming presses, manufacturing tools, etc., can solve the problems of low feeding and unloading efficiency of tablet presses and low tablet production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

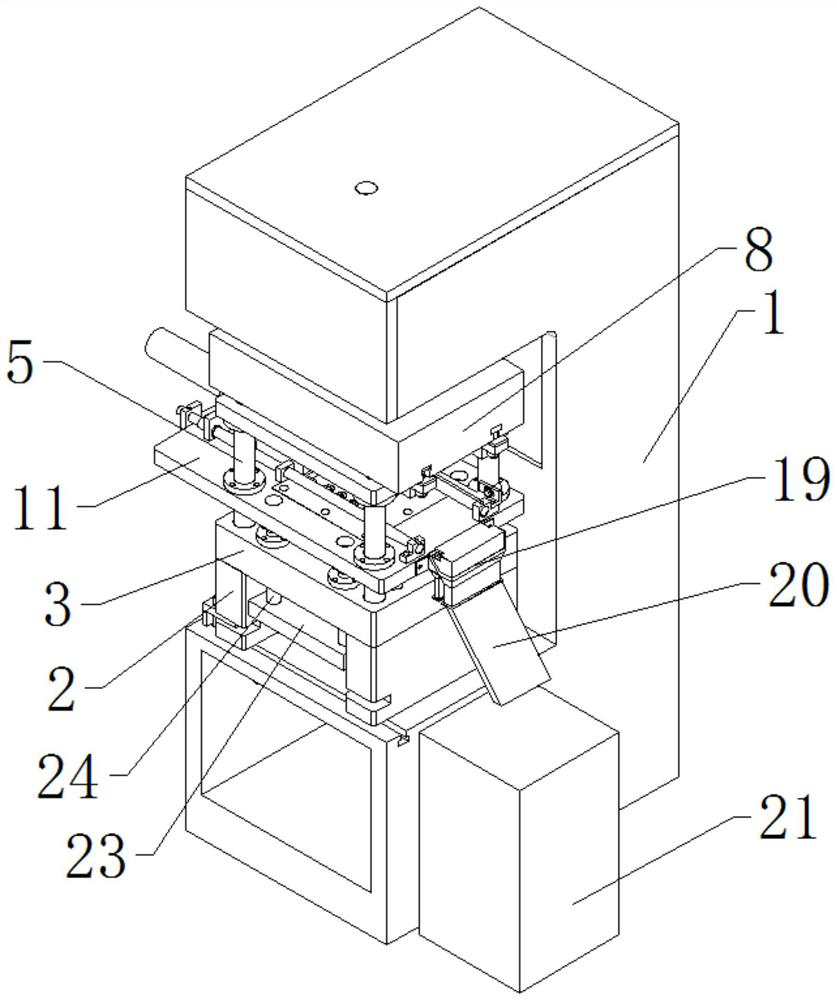

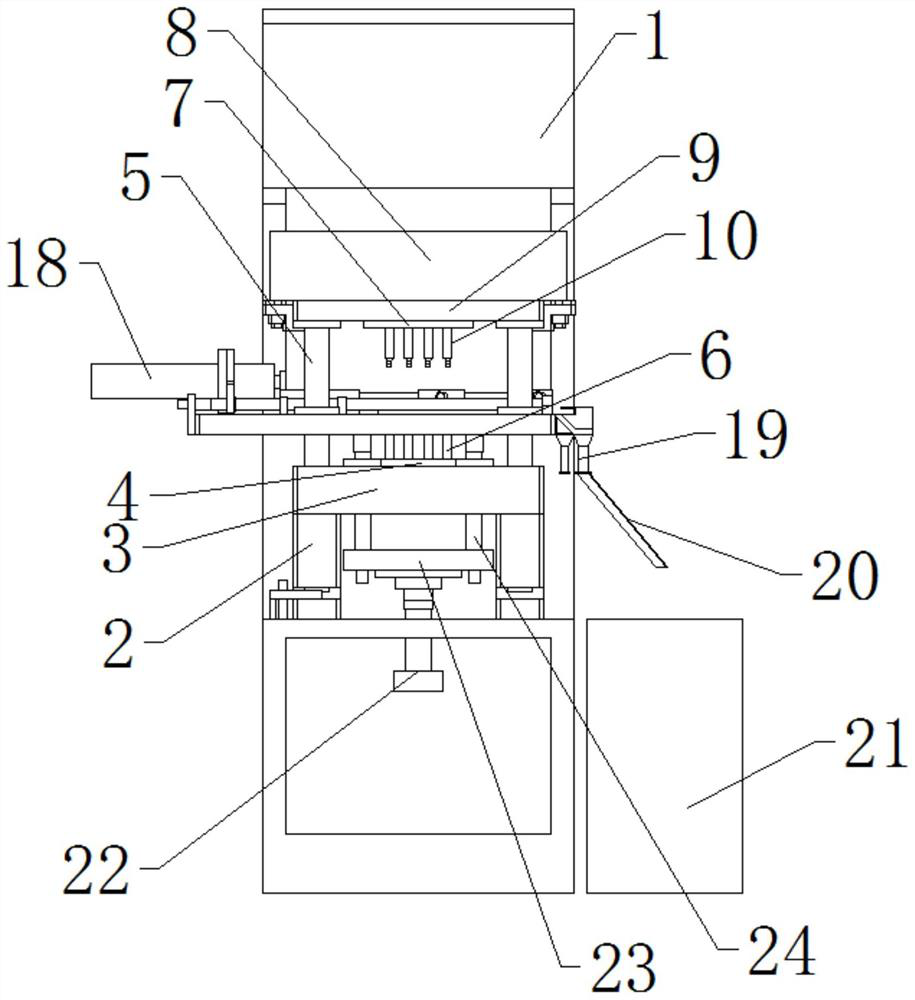

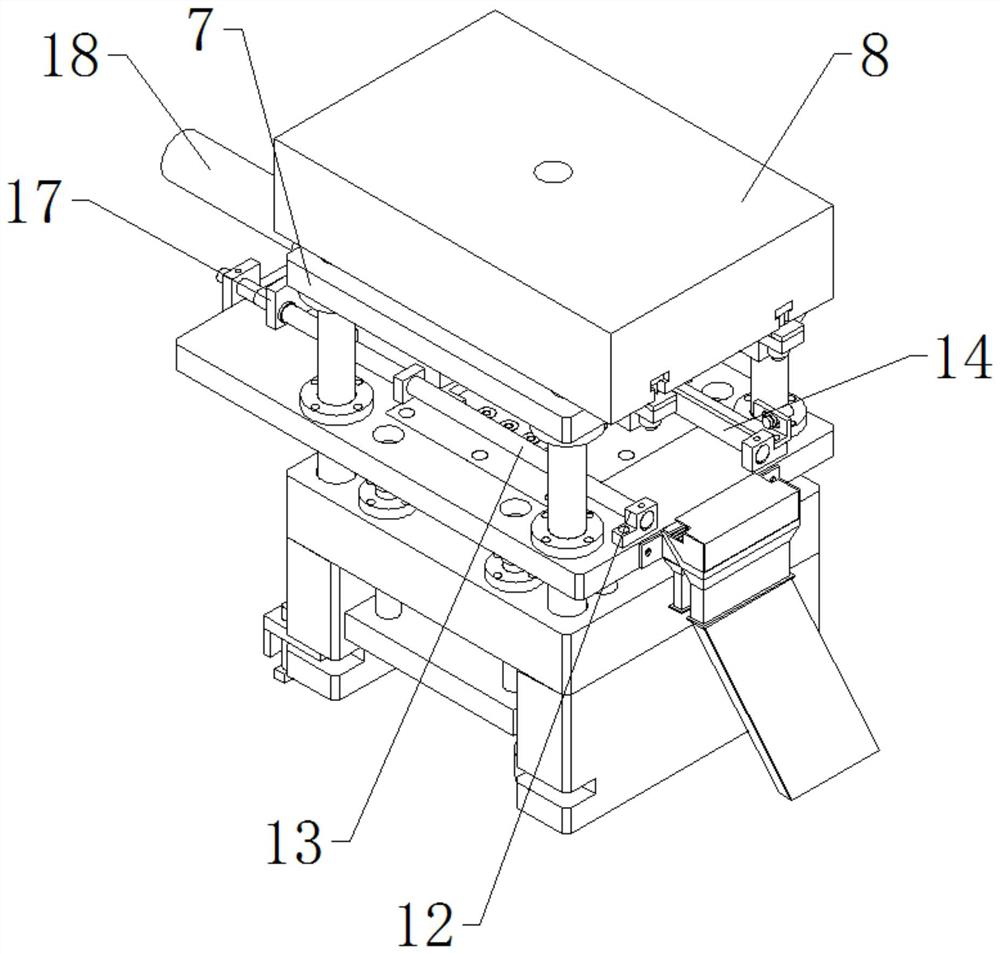

[0022] Example 1, see Figure 1-5 , an equipment improvement for increasing tablet production capacity, comprising a frame 1, a bracket 2 is arranged on the inner lower side of the frame 1, a lower template 3 is arranged at the end of the bracket 2, and a lower template 3 is arranged at the middle of the base surface of the lower template 3 The lower formwork platen 4 and the corner of the base surface of the lower formwork 3 are provided with guide columns 5, the base surface of the lower formwork platen 4 is evenly provided with a lower die head 6, the end of the guide column 5 is provided with an upper formwork 7, and the upper formwork 7 The base surface is provided with an indenter 8, the upper template platen 9 is arranged in the middle of the bottom of the upper template 7, the upper die head 10 is evenly arranged on the bottom of the upper template platen 9, and the outer wall of the guide column 5 is provided with a working plate near the end of the lower template 3. ...

Embodiment 2

[0023] Example 2, see Figure 1-5 , the corner of the upper formwork 7 is connected with the pressure head 8 through the connecting block, the workbench 11 is slidably connected with the guide column 5 through the guide sliding sleeve, and the driving end of the push cylinder 18 is connected with the spreading box 16, the lower formwork 3 and the upper formwork 7 Corresponding to the middle template 15, through the sliding connection between the workbench 11 and the guide column 5, when the push-down cylinder 22 and the pull rod 24 can control the workbench 11, the operation of the workbench 11 is simple, and the stability is high, and the pressure is increased. The efficiency and quality of sheet blanking.

Embodiment 3

[0024] Example 3, see Figure 4-5 , the inside of the spreading box 16 is provided with a partition corresponding to the middle template 15, and the right side of the spreading box 16 is provided with a material limit frame, the end of the pull rod 24 is connected with the workbench 11, and the pull rod 24 passes through the guide slide The cover is slidably connected with the lower template 3, the left side of the material receiver 19 is provided with a filter material tube, the right side of the material receiver 19 is provided with a material lowering tube, and the end of the filter material tube is provided with a filter screen, through the provided sprinkling The material box 16 can quickly push and unload the formed tablet, and can realize loading and unloading simultaneously, improving the overall tablet pressing ability. The height of the workbench 11 can be controlled by the pull rod 24 provided to make the lower die head 6 Quickly eject the formed compressed tablet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com