Patents

Literature

82results about How to "Quick eject" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

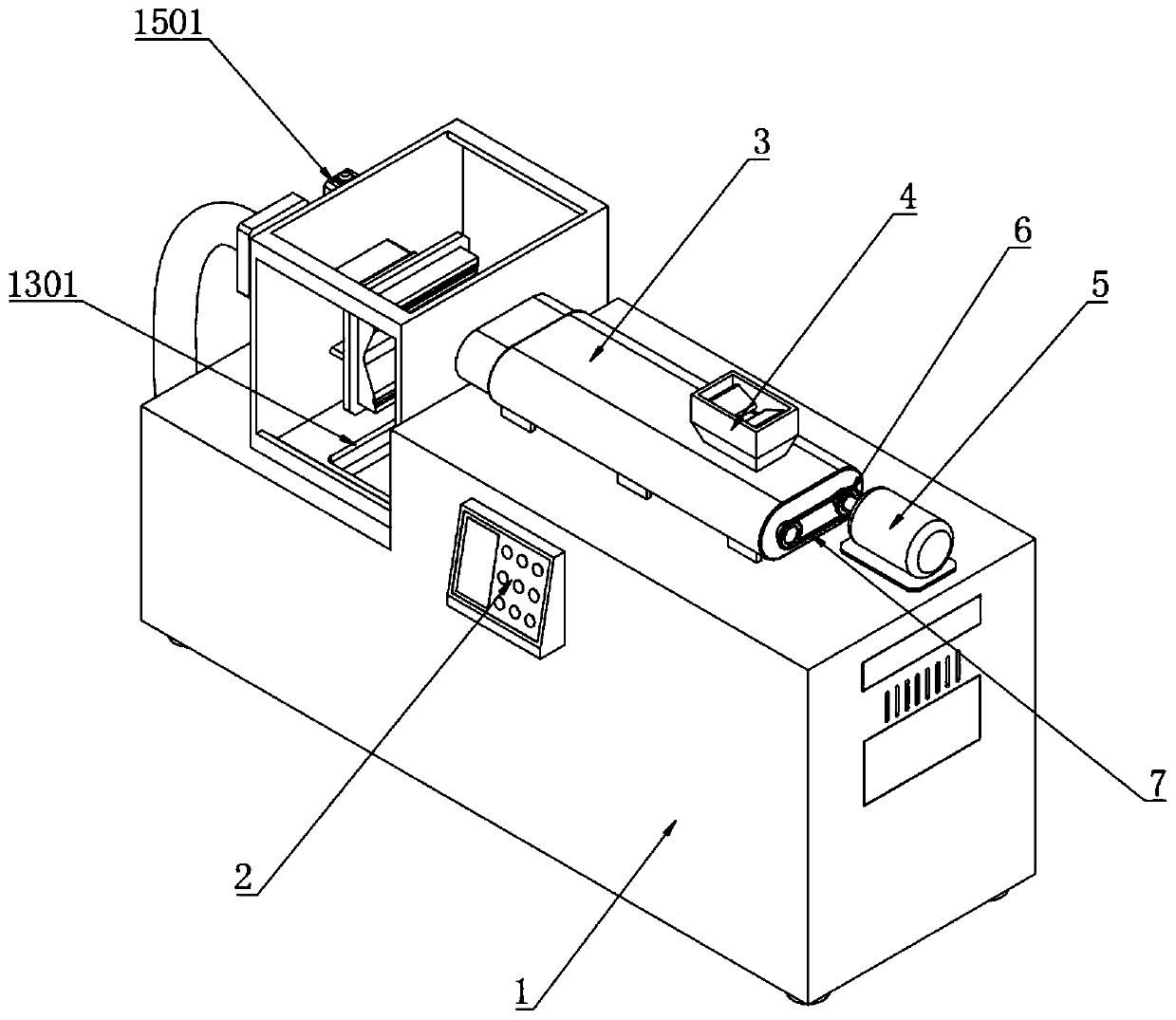

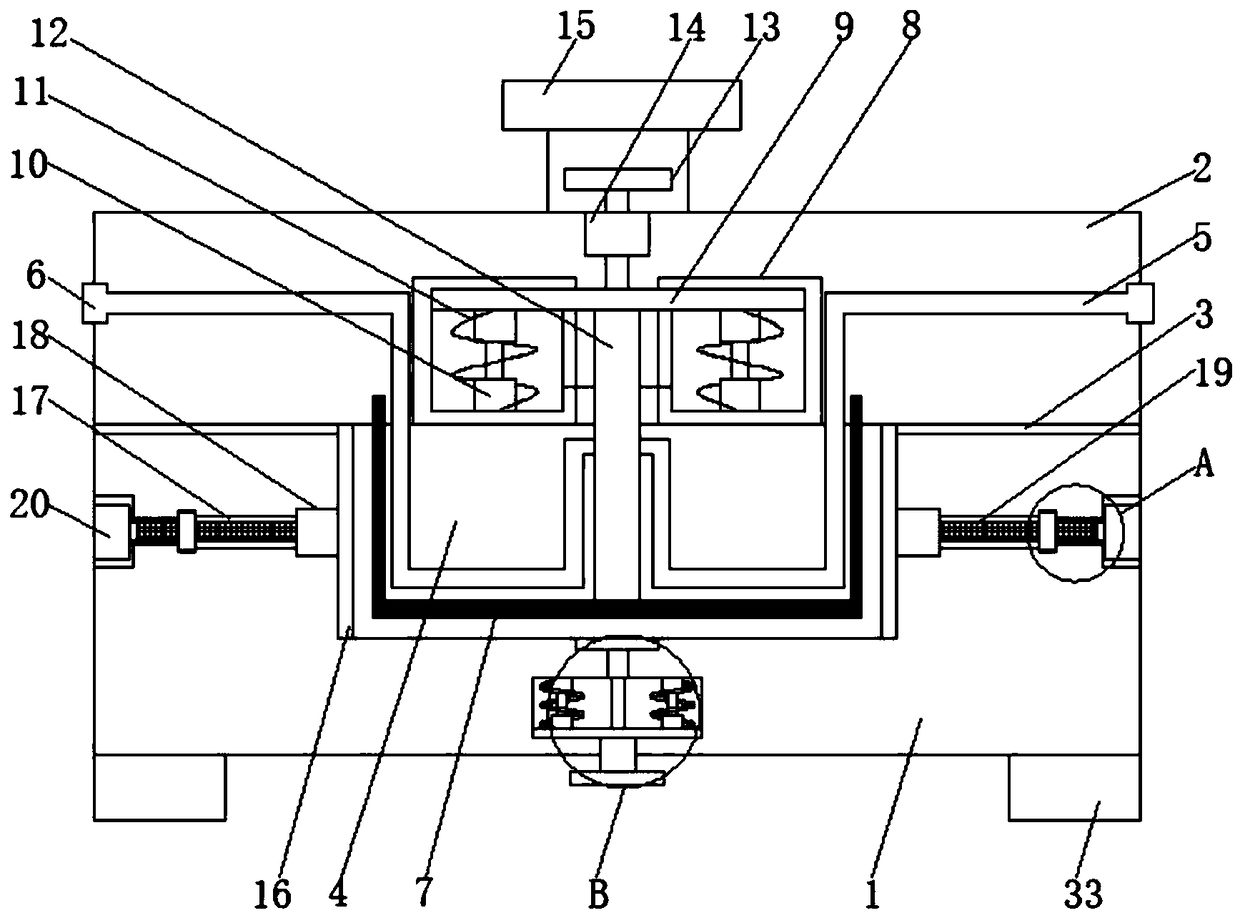

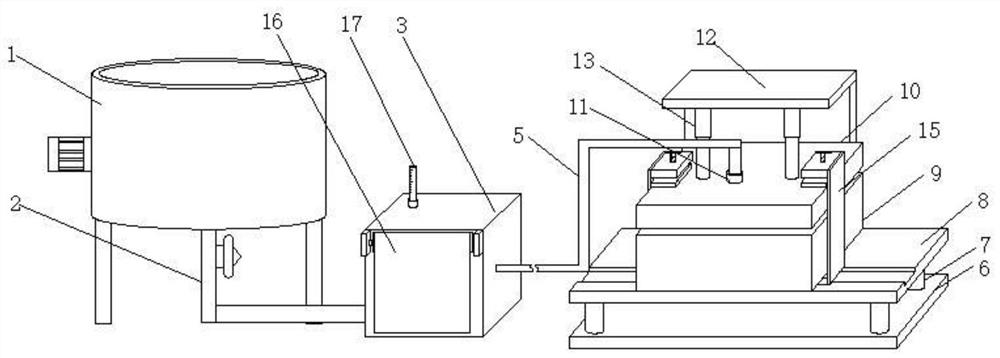

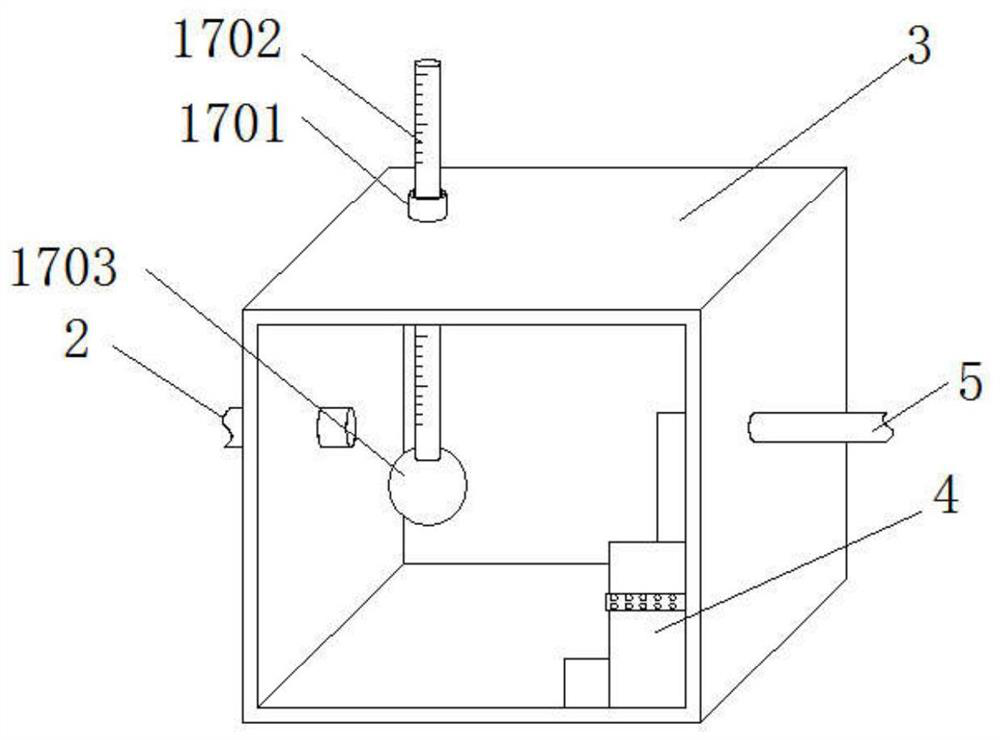

High-efficiency energy-saving type double-screw automatic injection molding machine

InactiveCN111196019AScientific and reasonable structureEasy to useActivated carbonActivated charcoal powder

The invention discloses a high-efficiency energy-saving type double-screw automatic injection molding machine. The high-efficiency energy-saving type double-screw automatic injection molding machine comprises an injection molding box body, one end of the injection molding box body is fixedly provided with a control switch, and the top end of the injection molding box body is connected with an injection molding bin; and the top end of the injection molding bin is connected with a feeding bin. The high-efficiency energy-saving type double-screw automatic injection molding machine is scientific and reasonable in structure, and safe and convenient to use, by arranging a leakage hole, a guide plate, a storage hopper, a cooling fan and a detachable cover, the situation that workpieces adhere toone another because of being overheated can be avoided, the stored workpieces can be quickly taken out, and cooling storage and quick taking out of the workpieces subjected to injection molding are facilitated; by arranging an air exchange fan, air extract holes, an air exchange bin, activated carbon powder bags and an air exhaust hole, air in the injection molding box body can be extracted into the air exchange bin, peculiar smell in the air is absorbed through the activated carbon powder bags, the peculiar smell generated during injection molding can be conveniently absorbed, and the situation that the peculiar smell during injection molding is strong, and the physical health of a user is influenced is avoided.

Owner:山东嘉励智能科技有限公司

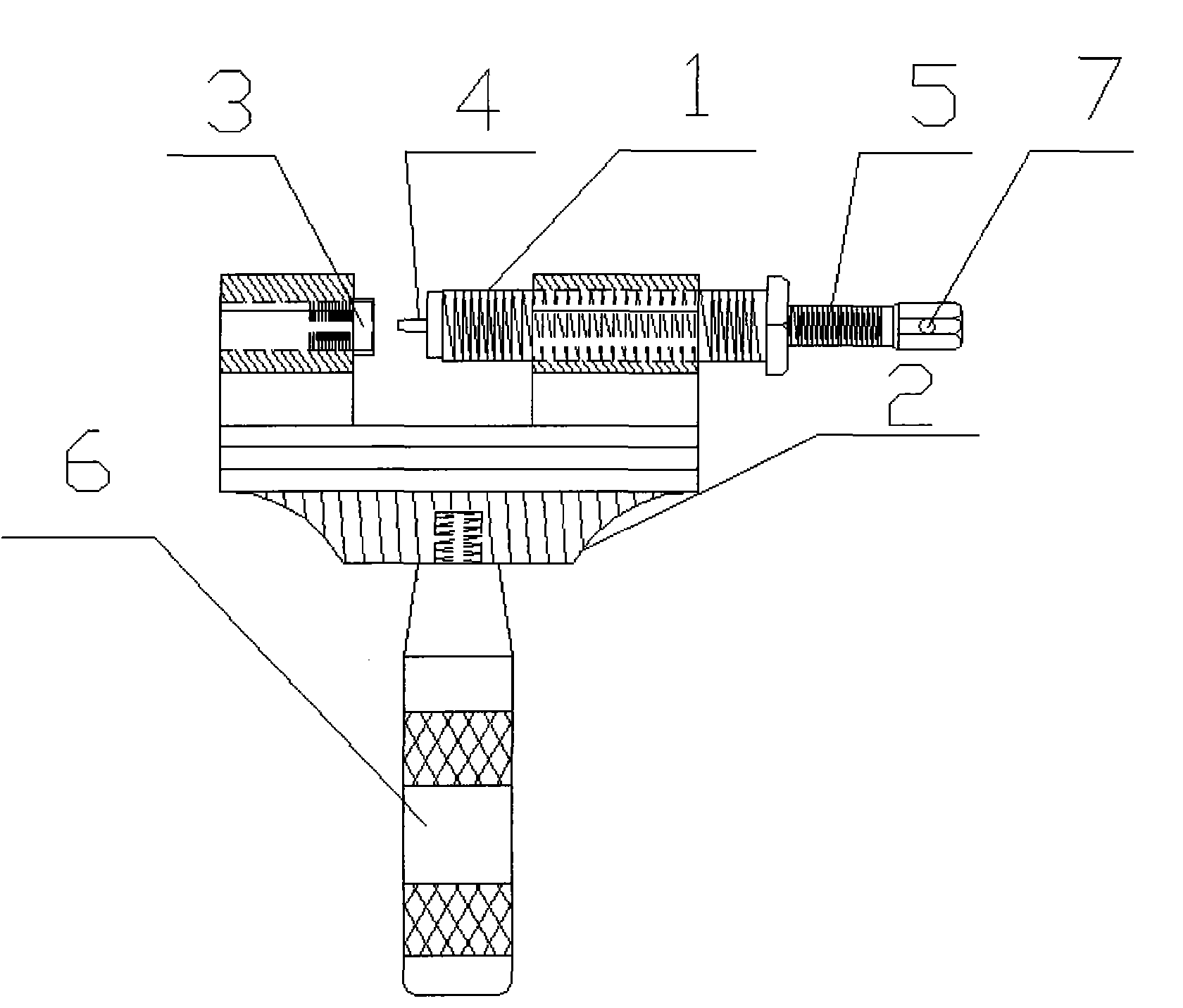

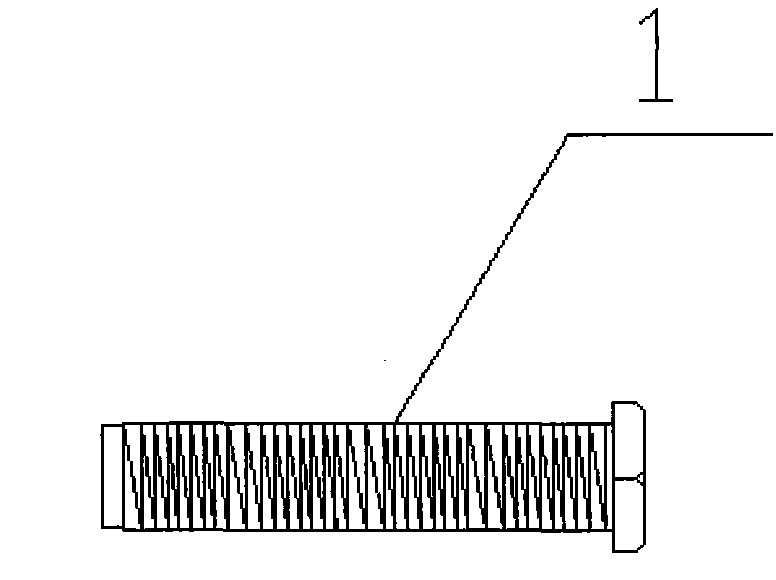

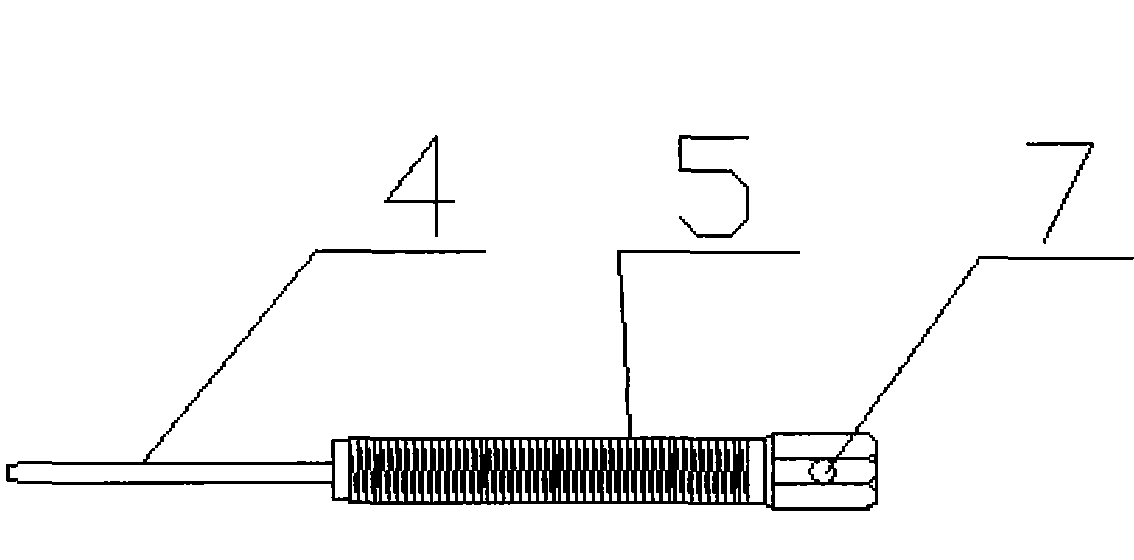

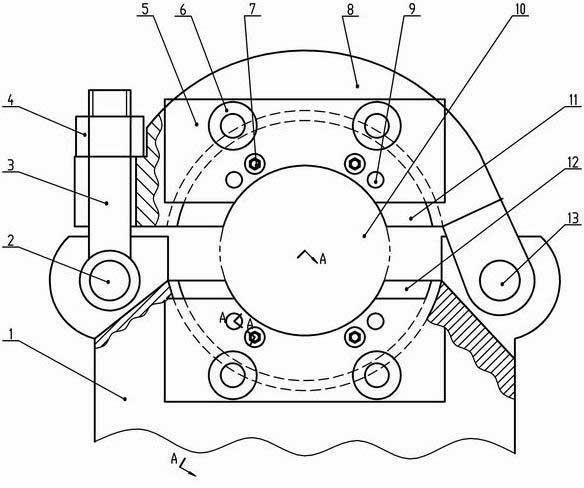

Chain demounting device

The invention relates to a chain demounting device for demounting the driving chain of motor or non-motor vehicle, which comprises a screw and a concave shaped carriage; the screw has a threaded center hole and is screwed in the threaded hole of an end ear of the concave shaped carriage; the rotating arm part 5 of a thimble screw is screwed in the threaded center hole of the screw 1; the other end ear of the concave shaped carriage is formed with a pin locking hole on the inner end face opposite to the thimble of the thimble screw. Advantages: 1, the invention not only realizes the reliable locking to the chain needing demounting, but also realizes easiness, rapid and high efficiency in chain demounting; 2, because the thimble screw is fitted with the screw with center threaded hole by screwing, the force applied on the thimble screw by the rotating arm is applied on the chain pin directly by the thimble, and forces the chain pin contacting the thimble to separate from the outer chain board; 3, the invention achieves the advantages of novel structure design, unique, simple, convenient for hand operation and long service life.

Owner:HANGZHOU CHIZHENG TECH

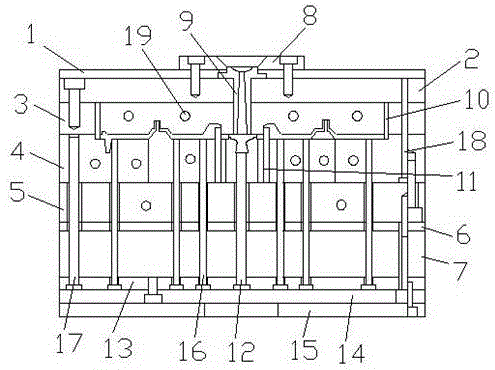

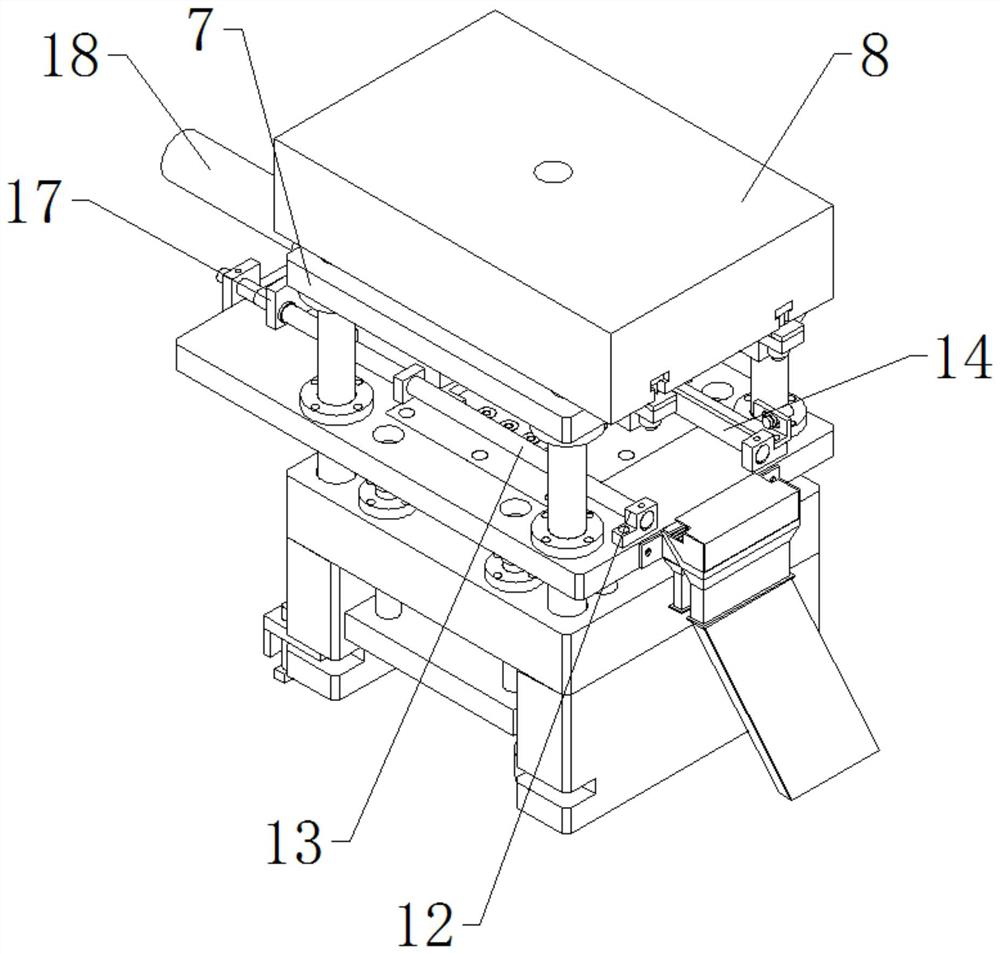

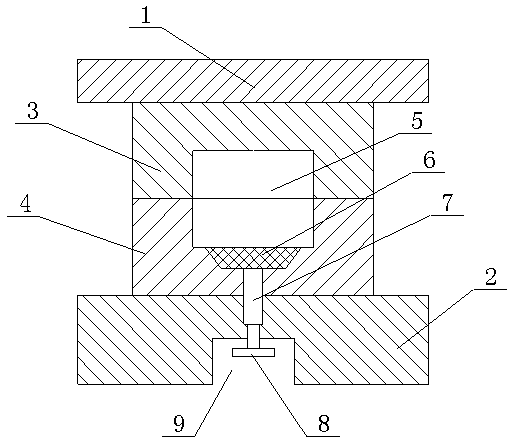

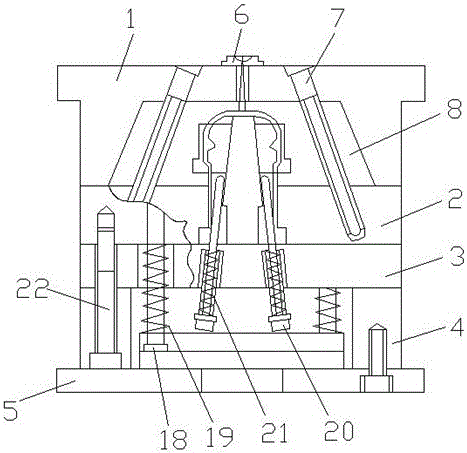

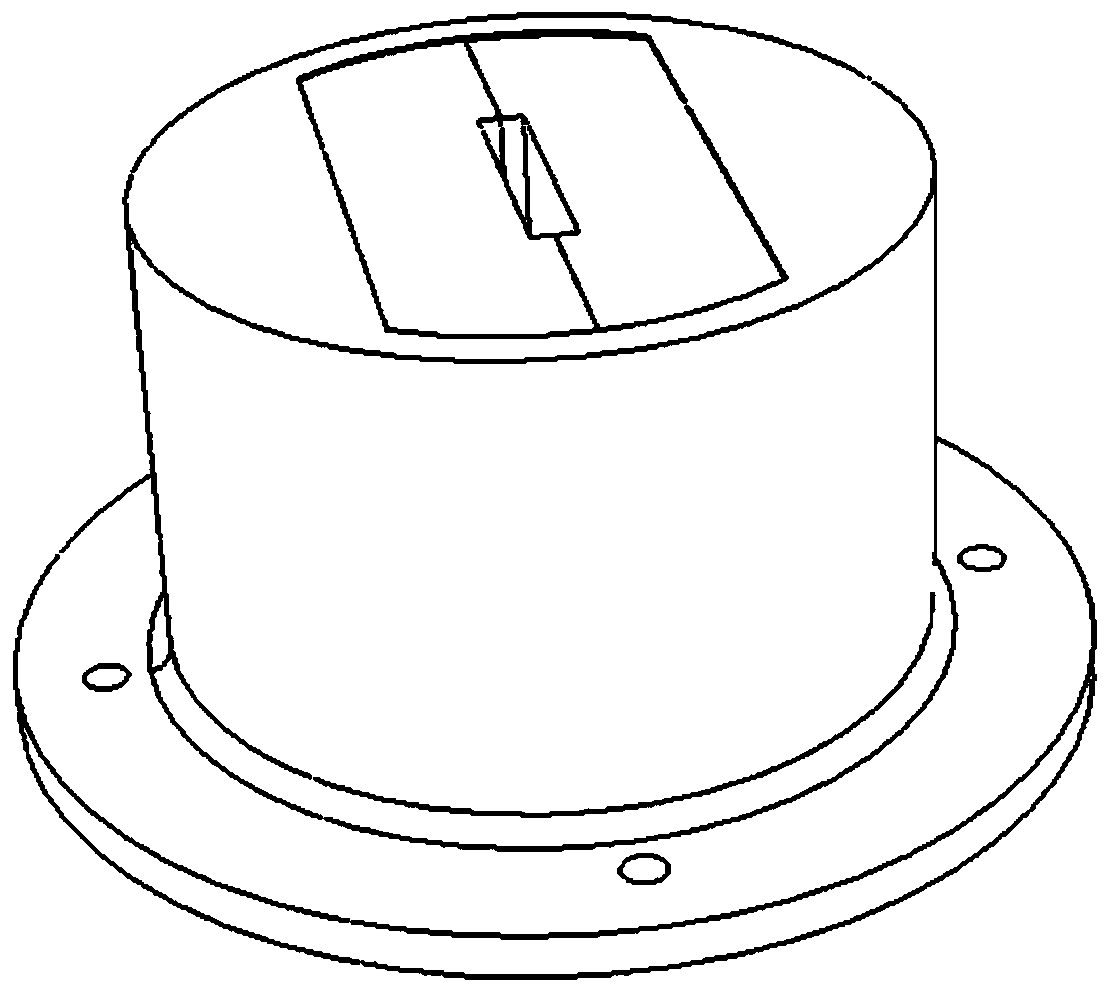

Thermal overload relay base injection mold

The invention discloses a thermal overload relay base injection mold. The thermal overload relay base injection mold comprises a fixed mold thermal insulation plate, a fixed mold bottom plate, a fixed mold plate, a movable mold plate, a movable mold bottom plate, a movable mold thermal insulation plate and a mold leg strip which are sequentially arranged from top to bottom. The fixed mold bottom plate is fixedly connected with the fixed mold plate. A positioning ring is arranged in the middle of the fixed mold thermal insulation plate and is fixedly connected with the fixed mold thermal insulation plate. A sprue bush is arranged in the positioning ring. First forming inserts are arranged at the two ends of the fixed mold plate. A second forming insert is arranged below the sprue bush. The thermal overload relay base injection mold is made of thermoset phenolic plastic through injection molding, the forming temperature is high, manufactured products are good in quality and high in machining accuracy, and mold opening is stable and reliable.

Owner:WUXI YICHEN MOLD TECH

Die for kitchen seasoning storing cup on basis of space variable multi-angle adjustment

InactiveCN108638439AImprove practicalityControl thicknessDomestic articlesMechanical engineeringSingle model

The invention relates to the technical field of die manufacturing and discloses a die for a kitchen seasoning storing cup on the basis of space variable multi-angle adjustment. The die comprises an upper die body and a lower die body. A sealing frame is fixedly connected to the top of the lower die body. The bottom of the upper die body and the top of the sealing frame are connected in an overlapped manner. The die solves the problems that the thickness of a product produced through a single die cannot be adjusted, forming time is long and material stripping cannot be carried out easily. According to the die, the lower die body is improved, rotating and adjusting in the opposite directions are fast, an adjusting block can drive a connecting strip to rotate, thus, thread nuts can rotate accordingly, at the moment, a thread rod can rotate in a sealing sleeve, under the effect of the two rotating thread nuts, an arc-shaped plate can be extruded in the opposite direction, the distance between the inner side wall of the arc-shaped plate and a die core can be controlled, thus, the thickness of the inner wall of a cup body can be controlled, the requirement for producing cups of multiplemodels can be produced, the phenomenon that the single die produces the cups of the single model is avoided, and the application and the requirement of the die are improved.

Owner:芜湖应天光电科技有限责任公司

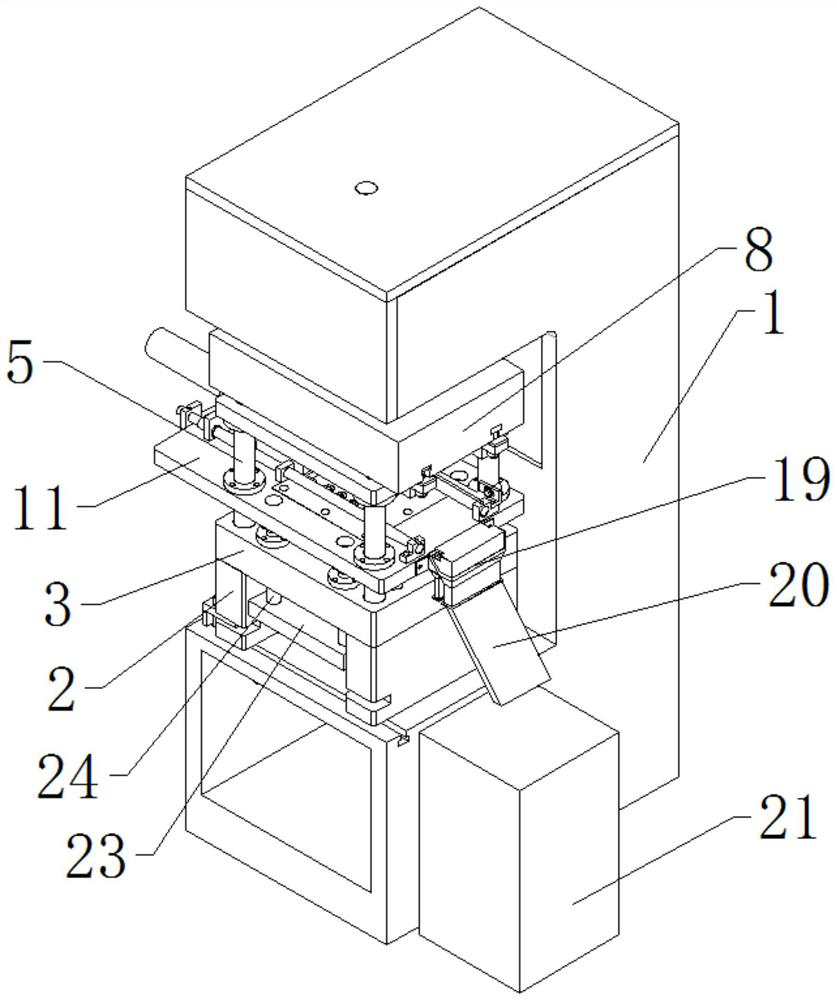

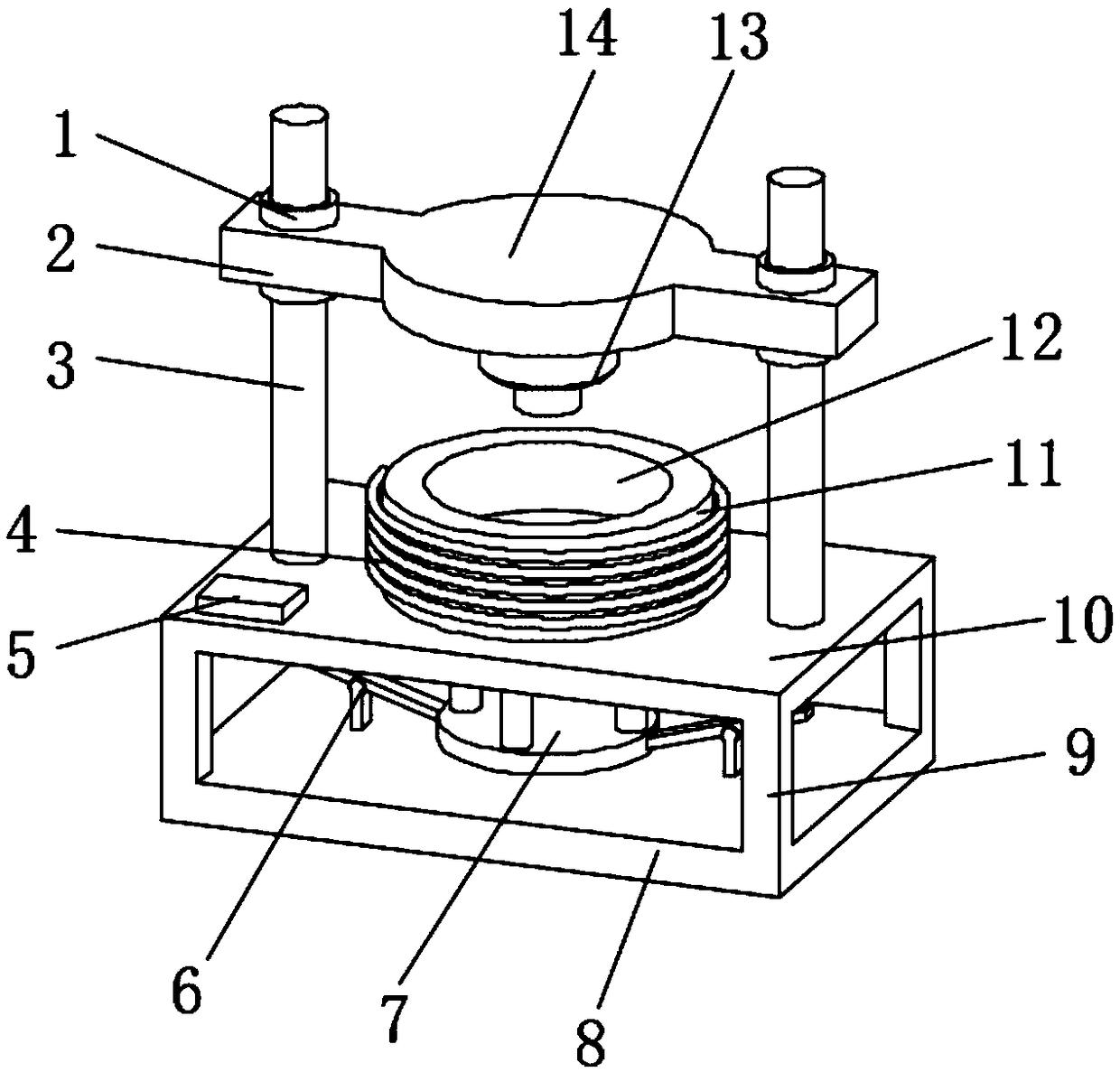

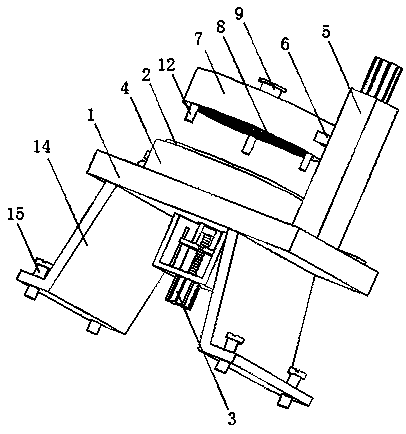

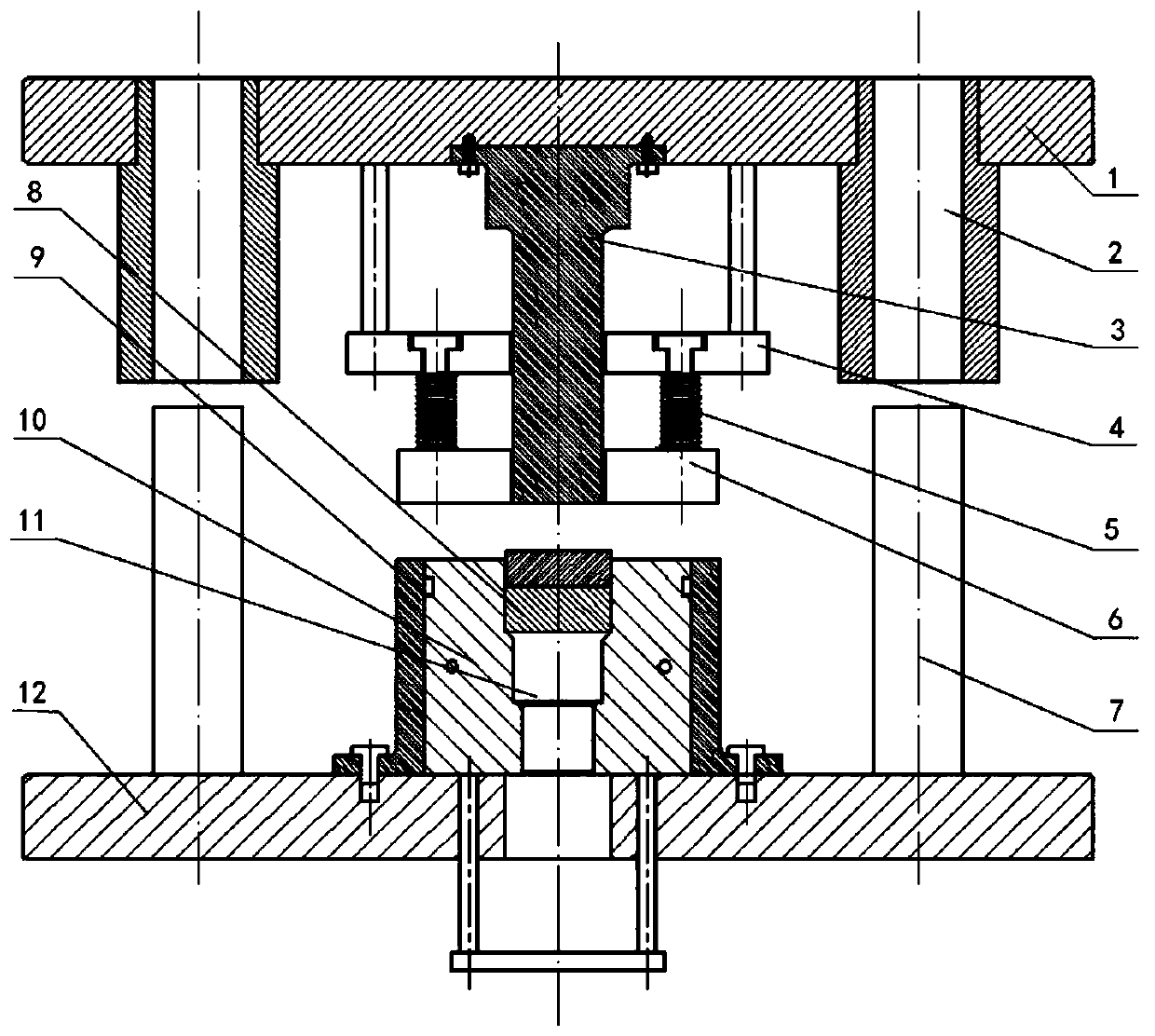

Improved equipment for improving tabletting production capacity

The invention relates to the technical field of tabletting, in particular to an improved device for improving tabletting production capacity. The equipment comprises a rack, a lower mold plate is arranged at the end part of the rack, lower mold heads are uniformly arranged on the base surface of a lower mold plate pressing plate, an upper mold plate is arranged at the end part of a guide column, upper mold heads are uniformly arranged at the bottom of an upper mold plate pressing plate, a middle mold plate is arranged in the middle of a base face of a workbench, material scattering boxes are installed on the outer walls of a first guide polished rod and a second guide polished rod, the middle mold plate can be rapidly filled through the material scattering boxes, feeding of the middle mold plate is simple and convenient, tabletting forming can be rapidly conducted through an arranged upper mold heads, the tabletting efficiency is improved, formed tablets can be rapidly pushed and discharged through the material scattering boxes, feeding and discharging can be carried out at the same time, the overall tablet pressing capacity is improved, the height of the workbench can be controlled through a pull rod, the formed tablets can be rapidly ejected out through the lower mold heads, and the discharging efficiency is improved.

Owner:BEIJING WANHUI DOUBLE CRANE PHARMA

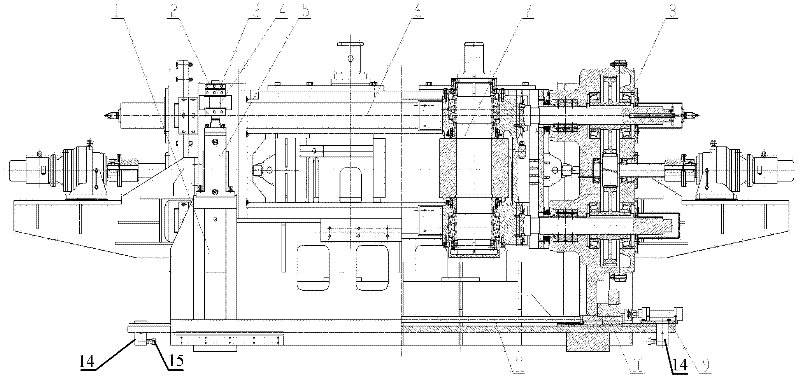

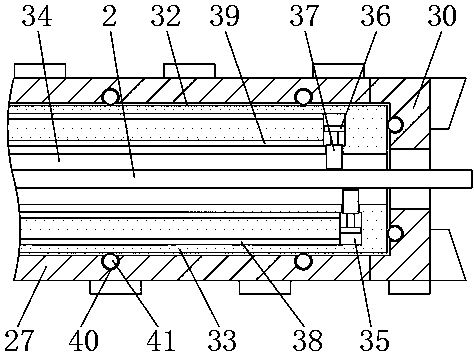

Vertical roll mill capable of vertically shifting roll

InactiveCN102363158ASmall change requestExtended service lifeMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderEngineering

The invention provides a vertical roll mill capable of vertically shifting a roll. The mill comprises a mill body and a lifting device which is enclosed by a pedestal and four upright posts, wherein a lifting hydraulic cylinder is fixedly connected above each upright post; a jacking nut, an isolating sleeve and a locking nut are sleeved on the top of a piston rod of each lifting hydraulic cylinder in sequence; the pedestal is also provided with an elevation adjusting mechanism; the lifting hydraulic cylinders are arranged on the guide posts of the pedestal; and a stand of the mill body adjusts the vertical roll mill body through the lifting hydraulic cylinders and the elevation adjusting mechanism to realize adjustment of a working face of the roll. In terms of the structure, vertical shifting of the roll is realized by integrally lifting the vertical roll mill, the service life of the roll is prolonged, a roll porous mechanism is additionally arranged, and on-line replacement of product specification can be realized. The vertical roll mill and the lifting device can be simultaneously pulled out during roll replacement; the lifting device can be simultaneously applied to replacing the roll by pulling out a steel wire of the vertical roll mill body and replacing the roll by pushing a hydraulic cylinder out; and an operating side and a transmission side of the vertical roll body do not need to be differentiated during assembly.

Owner:中重科技(天津)股份有限公司

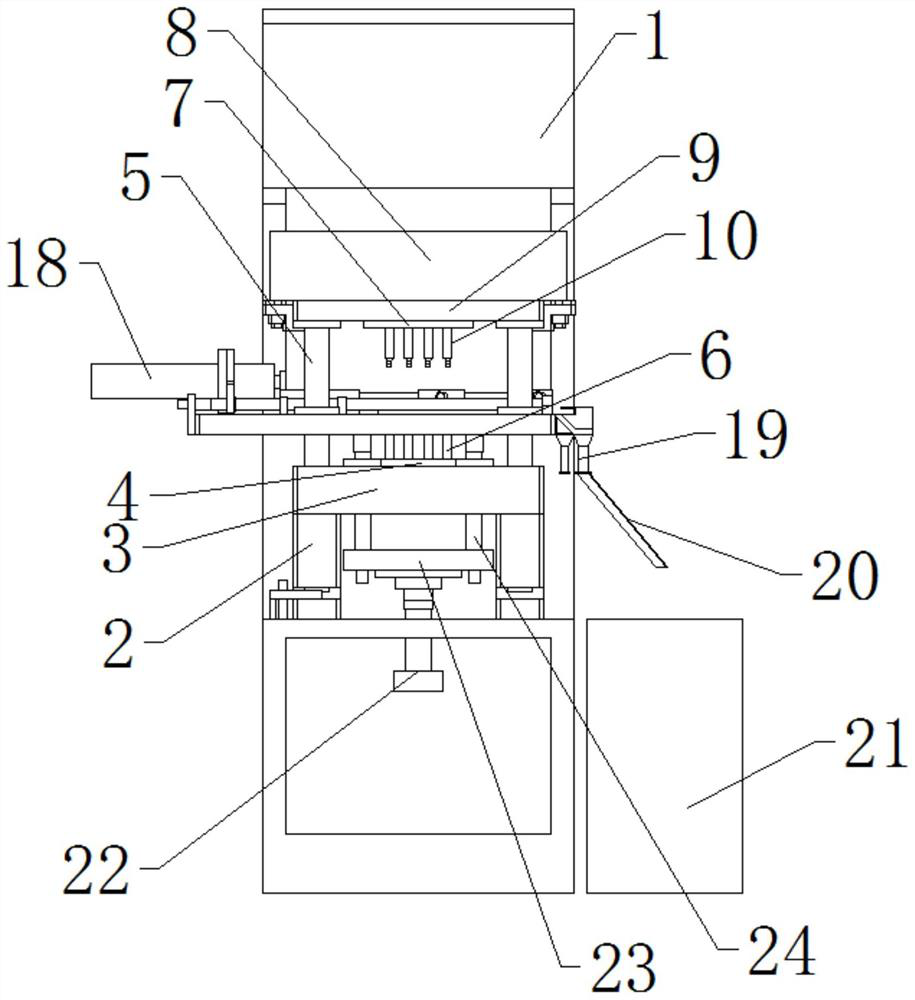

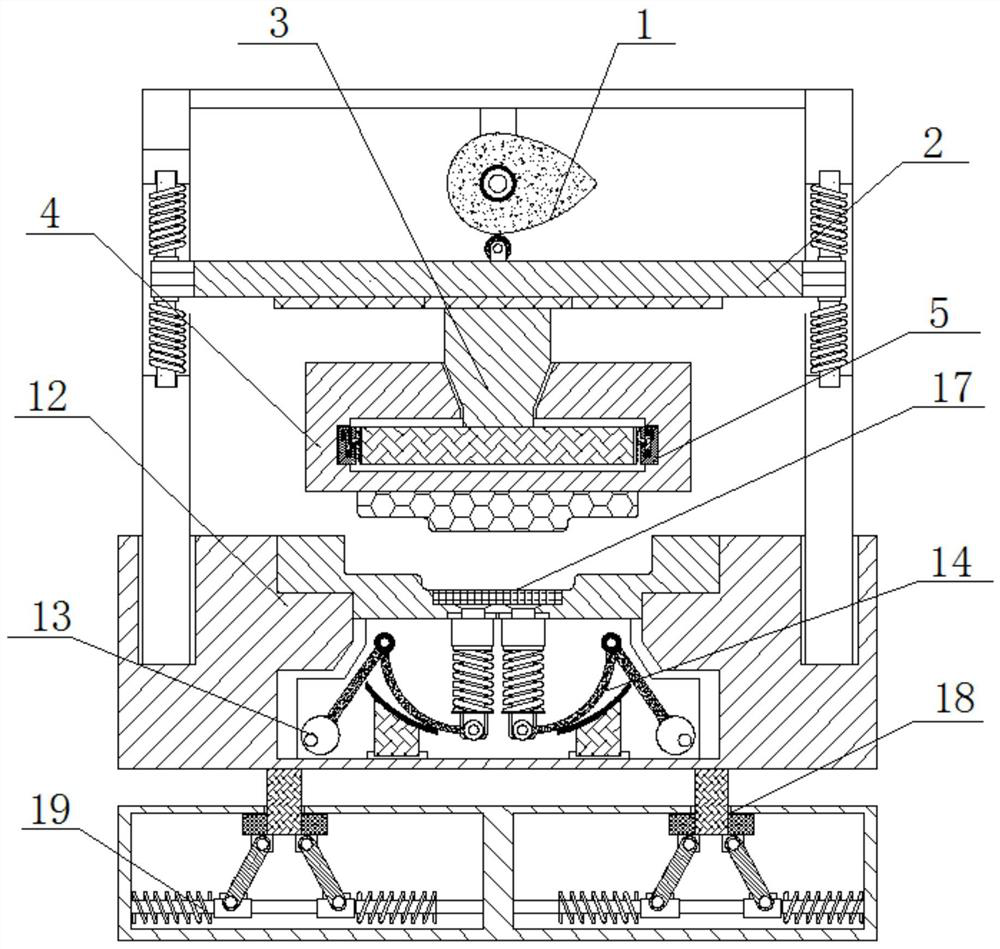

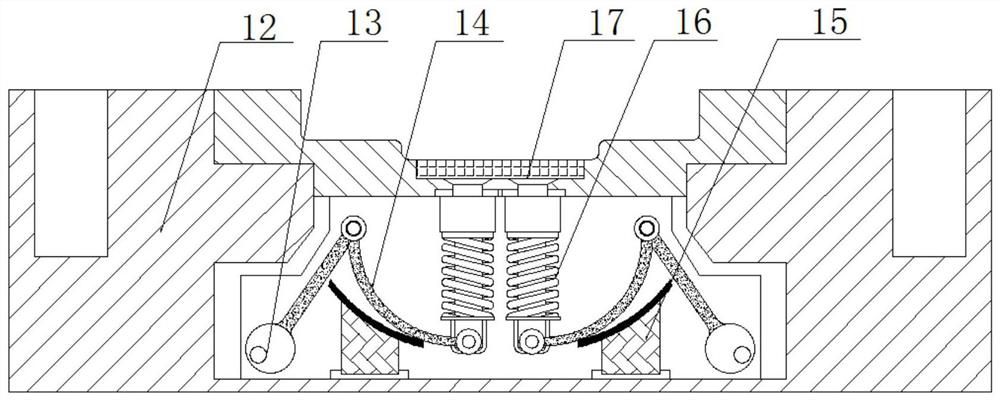

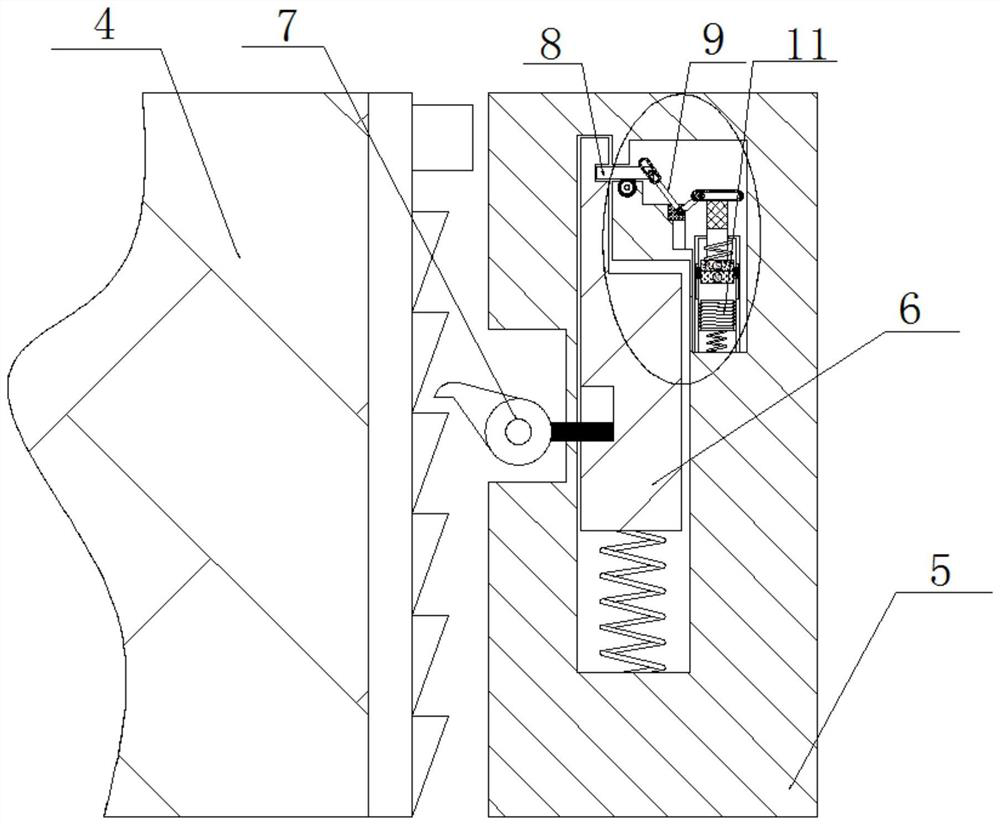

Punch forming equipment for intelligently manufacturing high-stability automobile sheet parts

InactiveCN112517729AHigh precisionNo displacementShaping toolsVehicle componentsRatchetMotor vehicle part

The invention relates to the technical field of automobile part production, and discloses punch forming equipment for intelligently manufacturing high-stability automobile sheet parts. The punch forming equipment comprises a cam, wherein a transverse shaft is movably connected to the lower portion of the cam, a connector is movably connected to the lower portion of the transverse shaft, self-locking of a pawl and a ratchet is matched through the connector and a trapezoid of a male die frame, the connector and the male die frame are fixed and do not move relative to each other, the blanking precision is improved, burrs on the blanking edge are reduced, through cooperation of eccentric wheels, arc-shaped plates and arc-shaped bases, spring shafts drive a push plate to ascend, a formed part is rapidly ejected out, the discharging efficiency is improved, electromagnetic push blocks are powered off, lifting rods drive annular pieces to drive movable pins to move outwards through V-shaped rods, movable blocks move downwards under the action of gravity to drive the pawl to rotate clockwise, the pawl is separated from the ratchet, at the moment, the connector and the male die frame are notfixed any more, and the male die frame can be detached, maintained and replaced.

Owner:田明阳

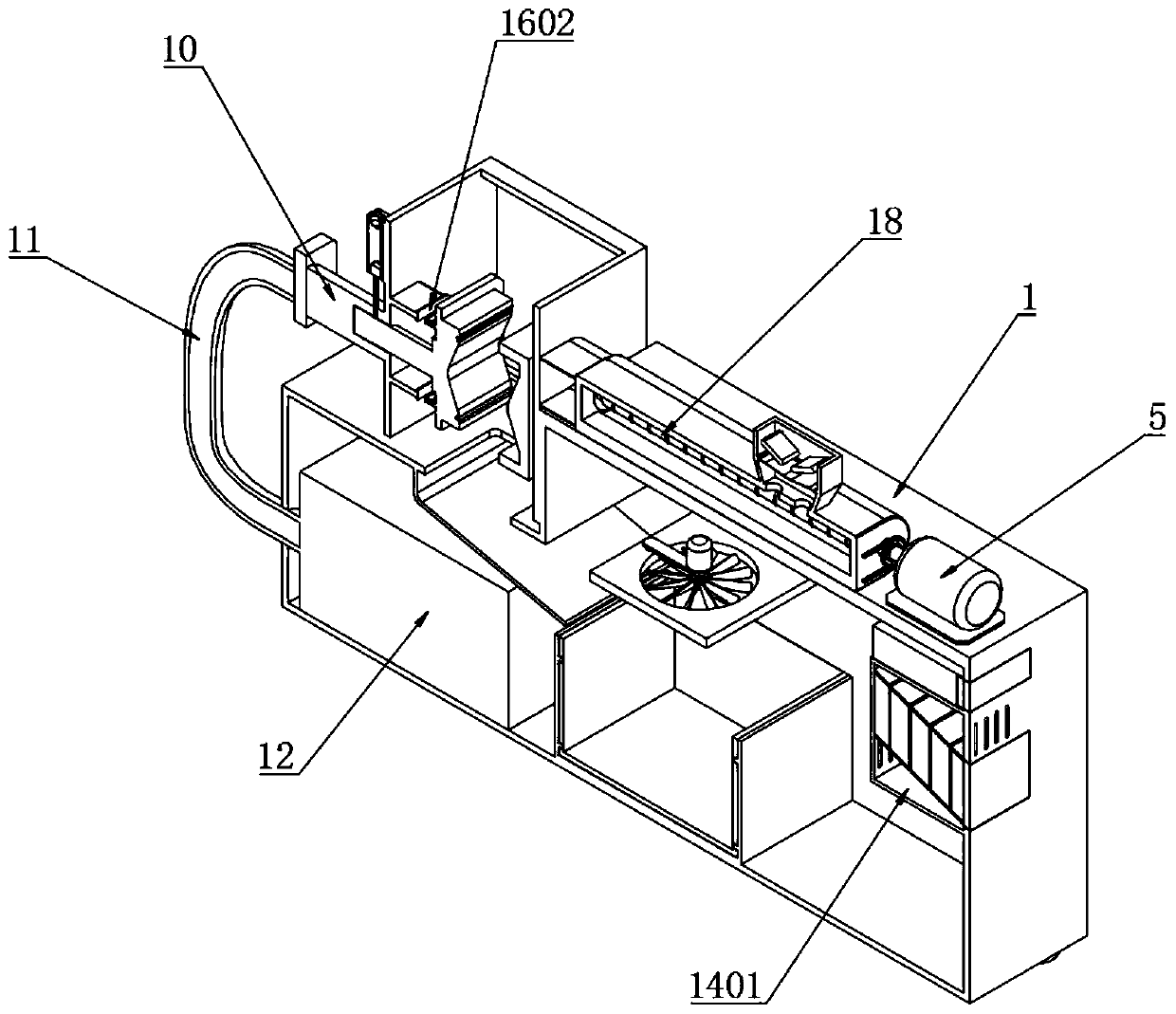

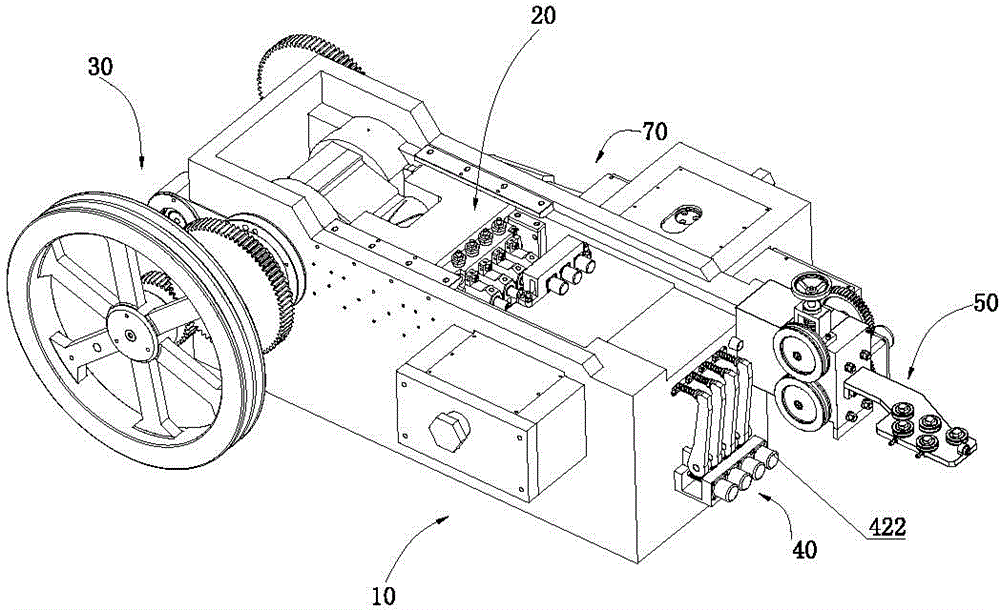

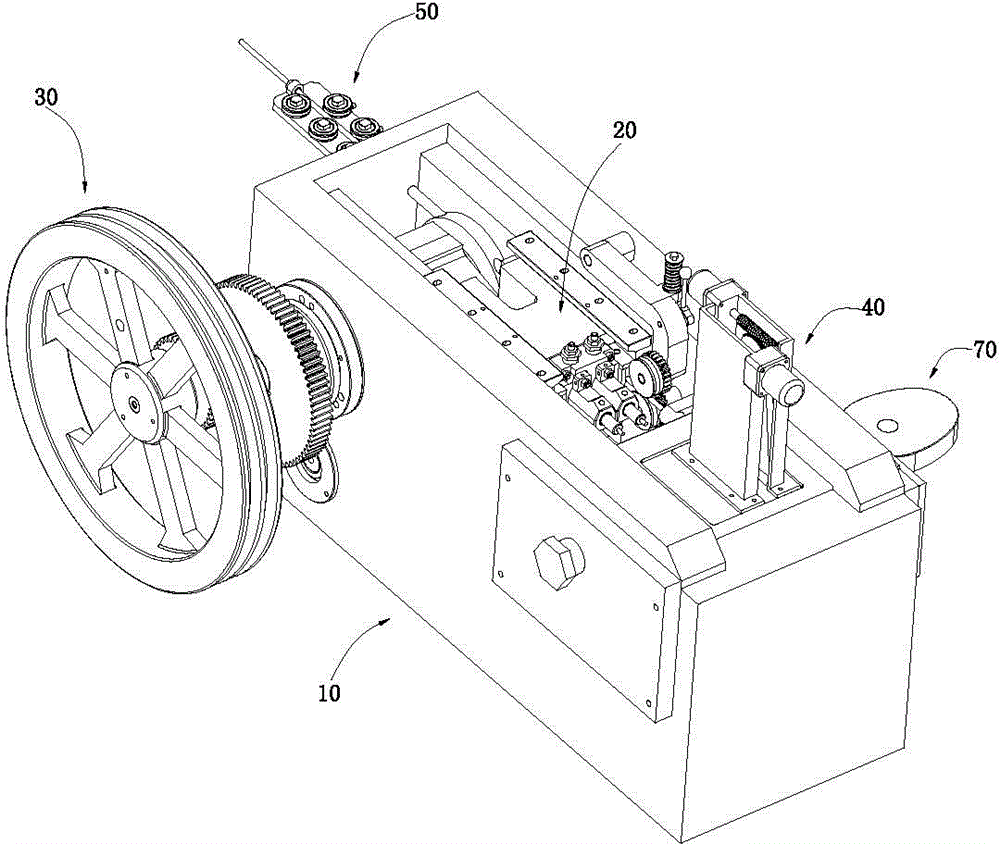

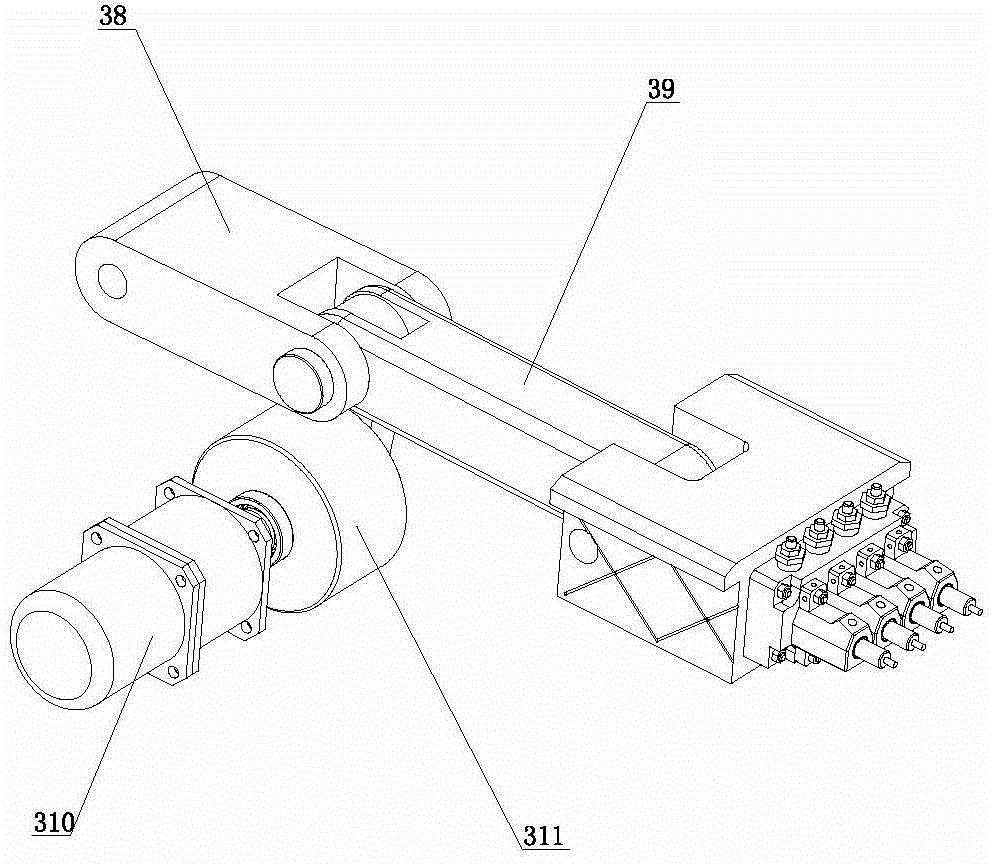

Numerical control upsetting forging press for ejection wires and working method

The invention provides a numerical control upsetting forging press for ejection wires and a working method. An ejection mechanism of the numerical control upsetting forging press for ejection wires is driven by an ejection servo motor and arranged on a press body. An integral main die assembly comprises a main die holder, in which a cutting die installation hole and upsetting concave die installation holes are arranged. The working method comprises following steps: feeding, utilizing translation of the integral main die assembly to achieve displacement full-circle cutting; performing upsetting operation and utilizing the ejection mechanism to eject blank or shaped parts. The working method has following beneficial effects: a cutting mechanism is not needed; replacement and adjustment are carried out for parts in the integral main die assembly outside the press body such that upsetting efficiency is increased; and stroke and position adjustments of the ejection mechanism are made conveniently and flexibly.

Owner:西大(常熟)研究院有限公司

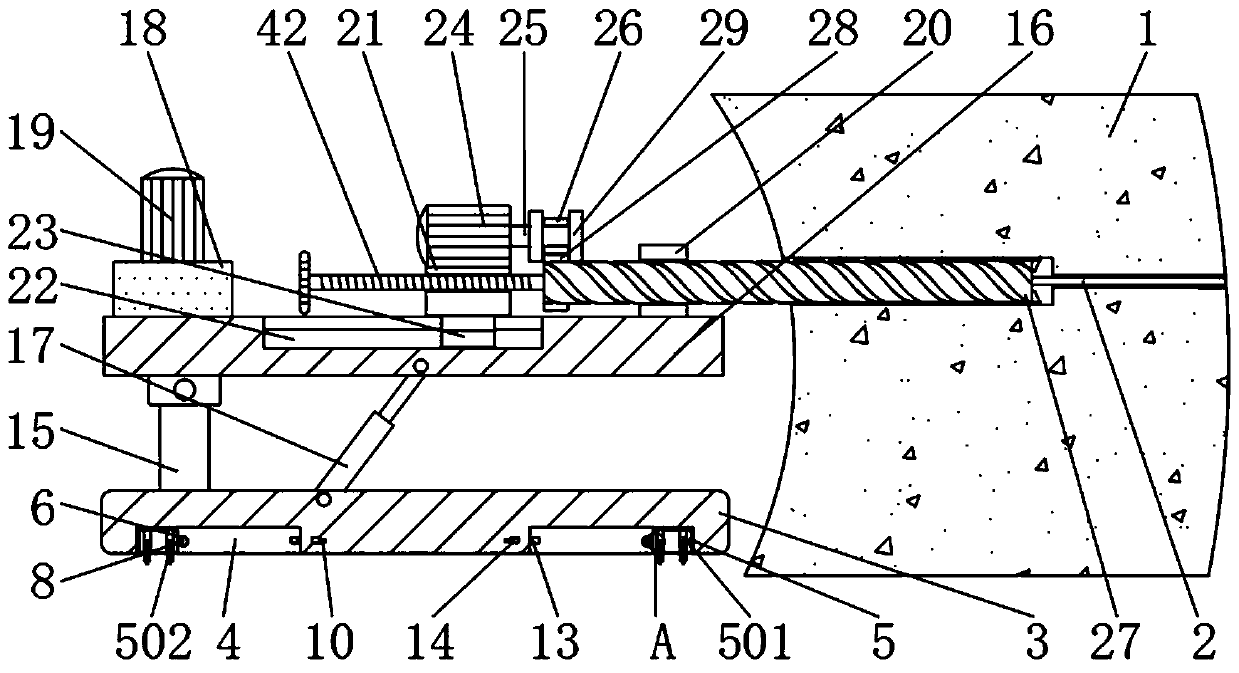

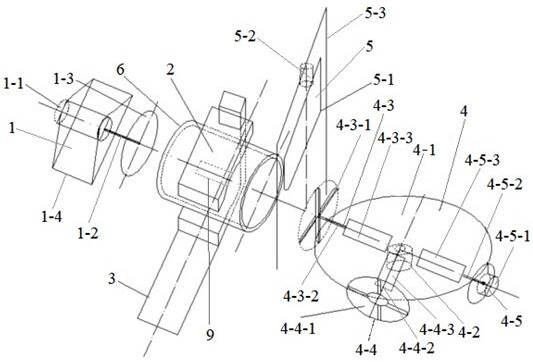

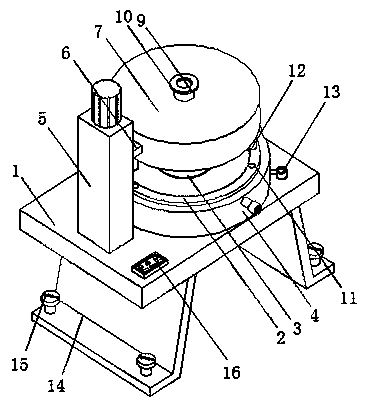

Anchor cable sleeving and taking machine adopting shield method for tunnel crossing anchor cable construction

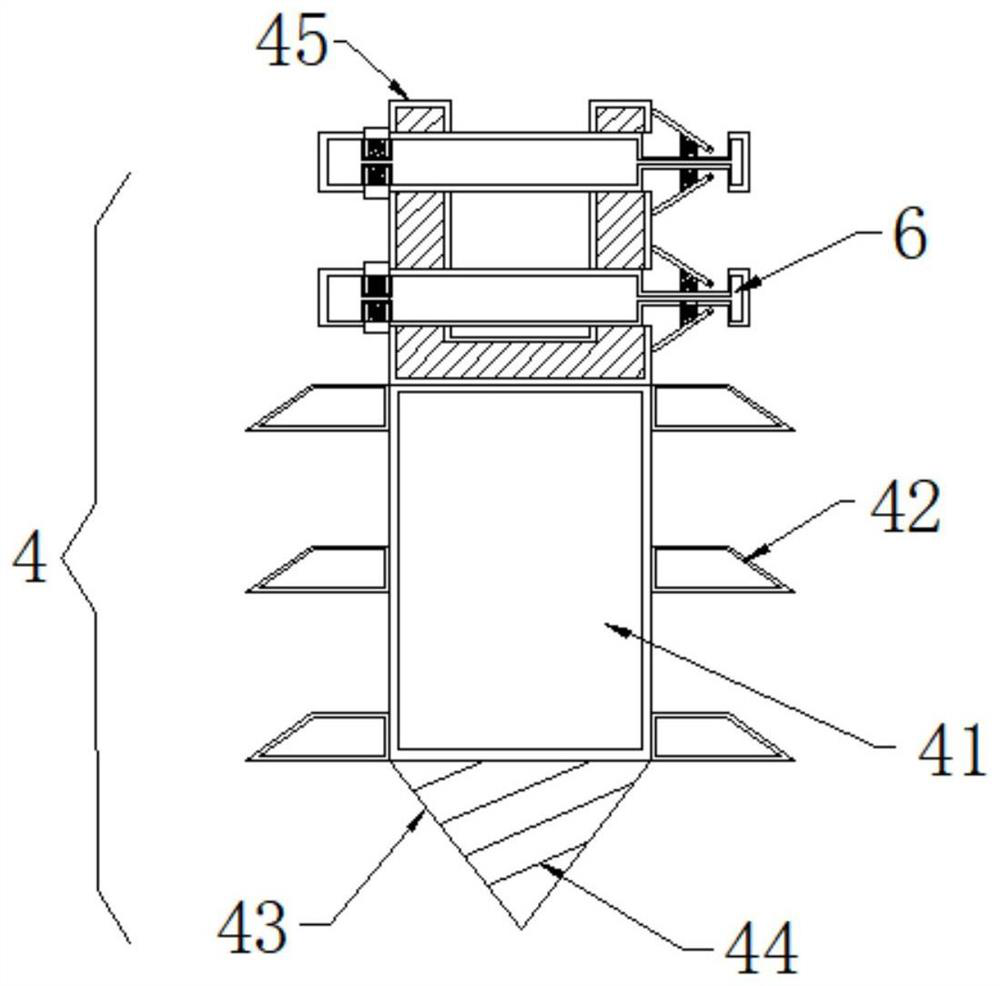

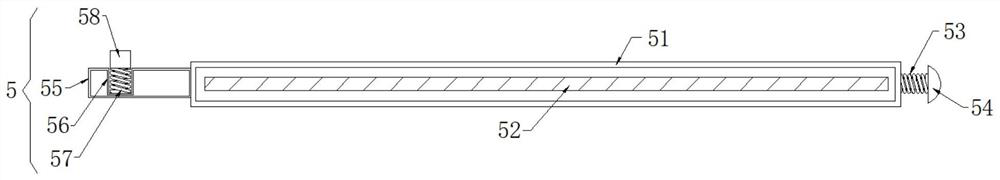

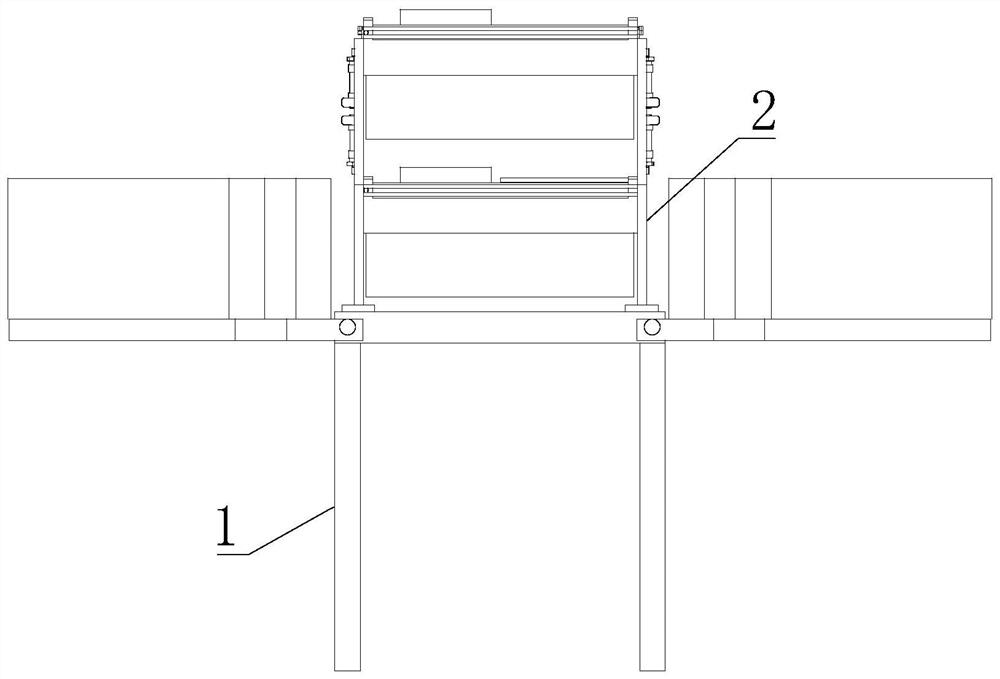

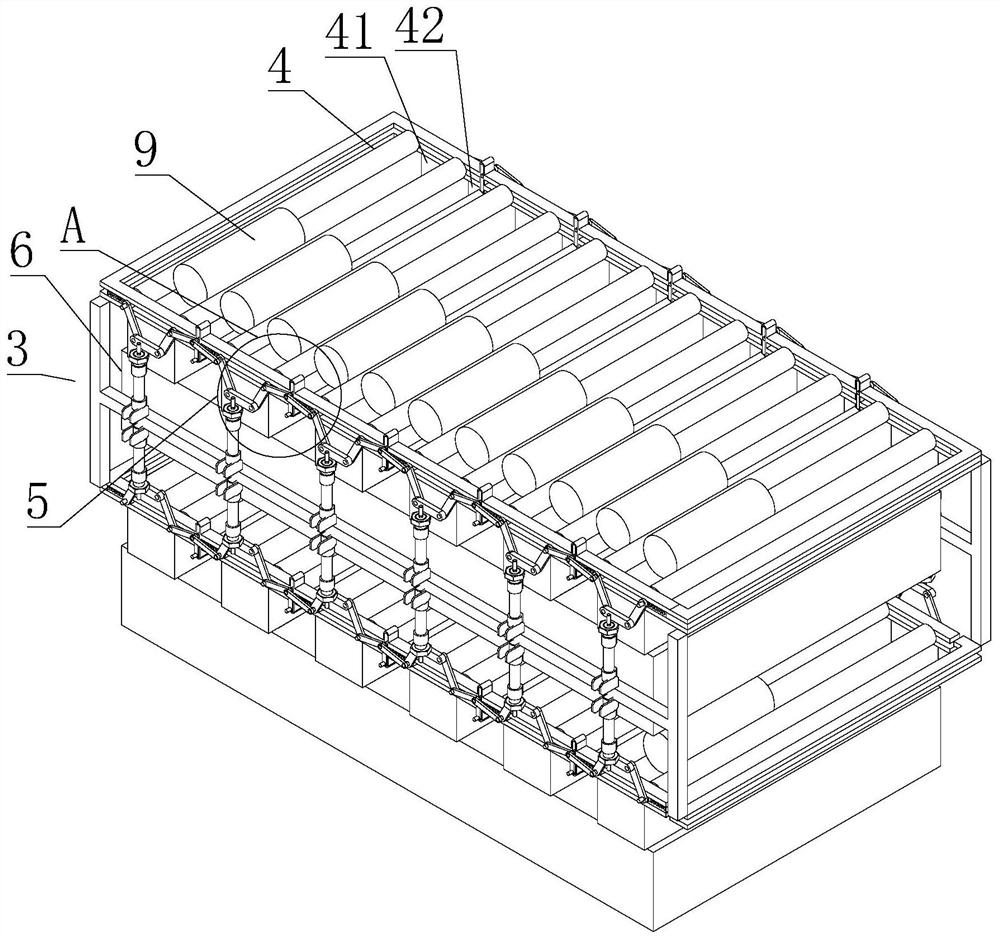

ActiveCN110630196AInhibit injectionQuick ejectBorehole/well accessoriesAnchoring boltsTunnel constructionEngineering

The invention relates to an anchor cable sleeving and taking machine adopting a shield method for tunnel crossing anchor cable construction. The anchor cable sleeving and taking machine comprises a soil layer, a first spring and balls. An anchor cable penetrates through the soil layer. A first base is arranged on one side of the soil layer. Supporting leg grooves are formed in the bottoms of the two sides of the longer side of the first base. Supporting legs are rotatably connected in the supporting leg grooves. Blocking rod grooves are formed in one side, close to the supporting legs, of thefirst base. The anchor cable sleeving and taking machine adopting the shield method for tunnel crossing anchor cable construction is provided with shearing frames. When an anchor cable groove completely sleeves the anchor cable at a tunnel construction site, a hydraulic motor injects hydraulic oil through a first oil groove, so that the hydraulic oil pushes a top plate to move outwards towards a top plate groove, and the top plate drives the shearing frames to move towards the anchor cable. When the shearing frames on the upper and lower sides move simultaneously towards the anchor cable, shearing force is formed between the shearing frames to shear the anchor cable, and meanwhile, the shearing frames prevent the anchor cable from moving out of the anchor cable groove, the anchor cable isdirectly taken out through an anchor cable sleeve, and grouting or injection filling is avoided.

Owner:CHINA CONSTR FOURTH ENG DIV

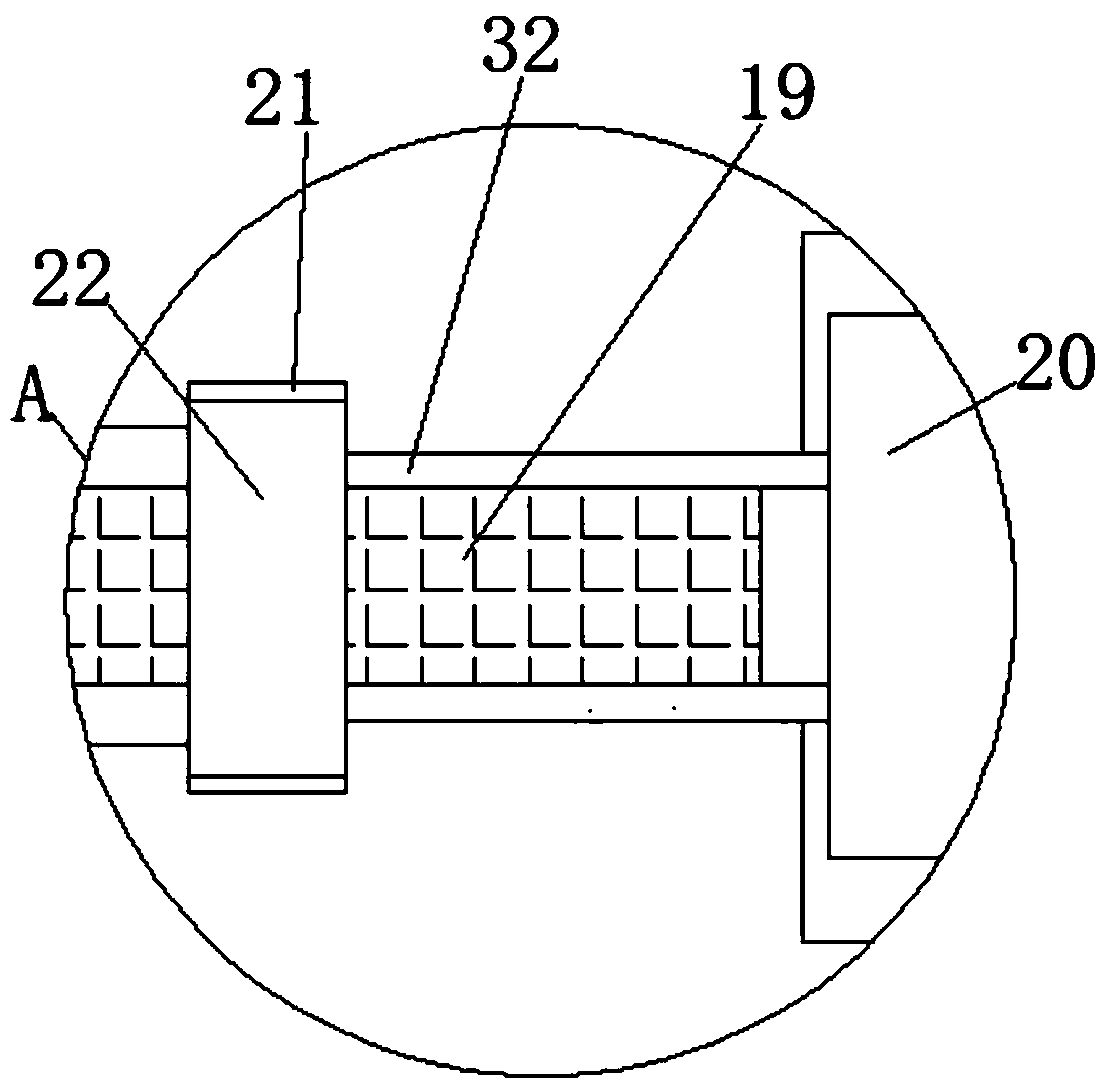

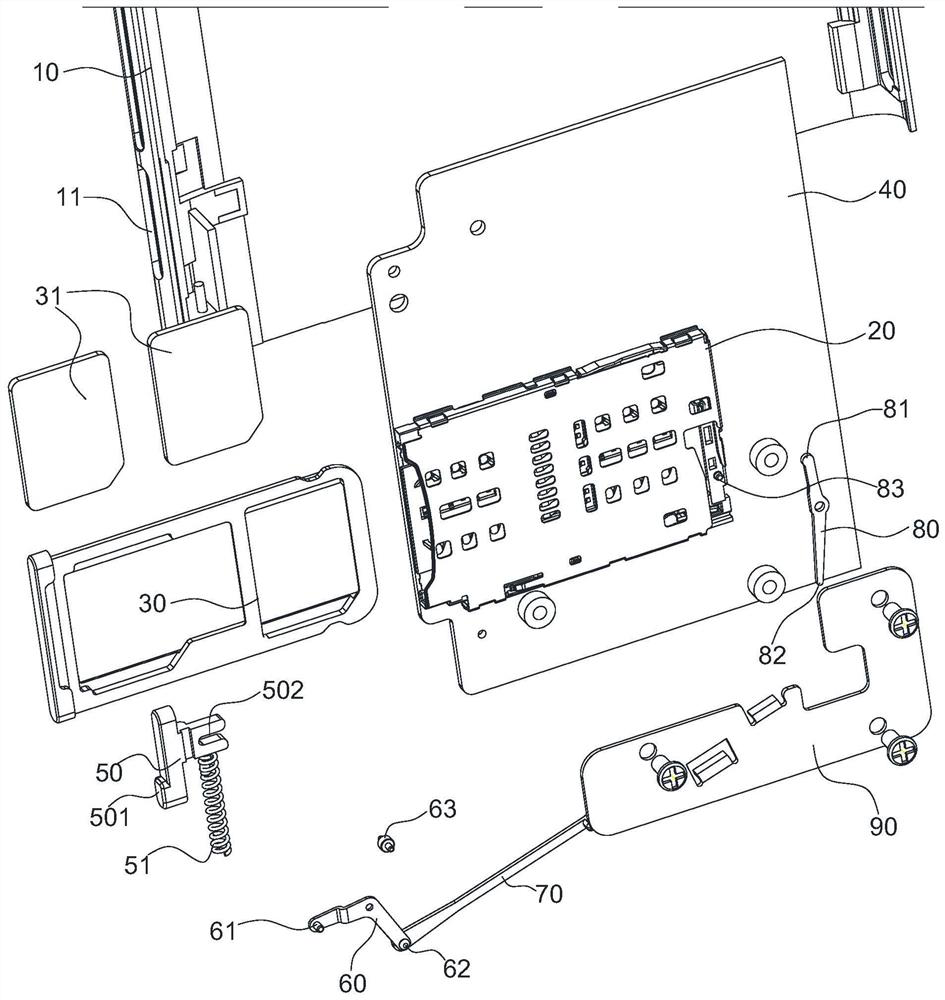

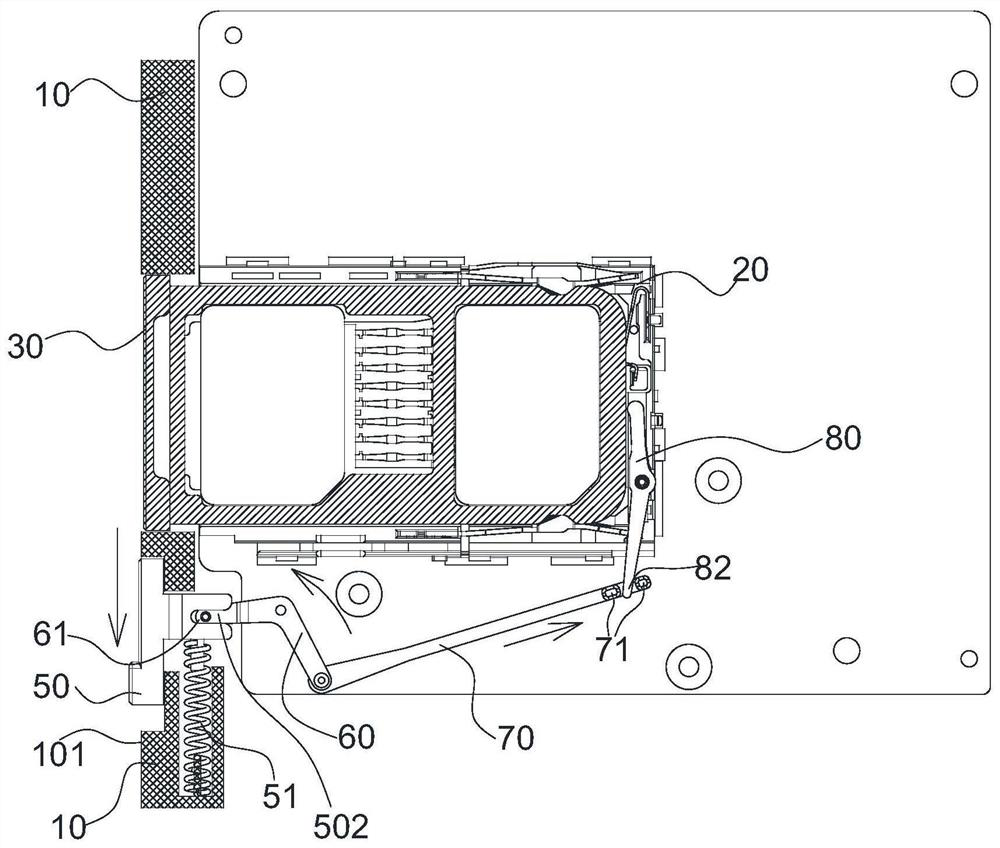

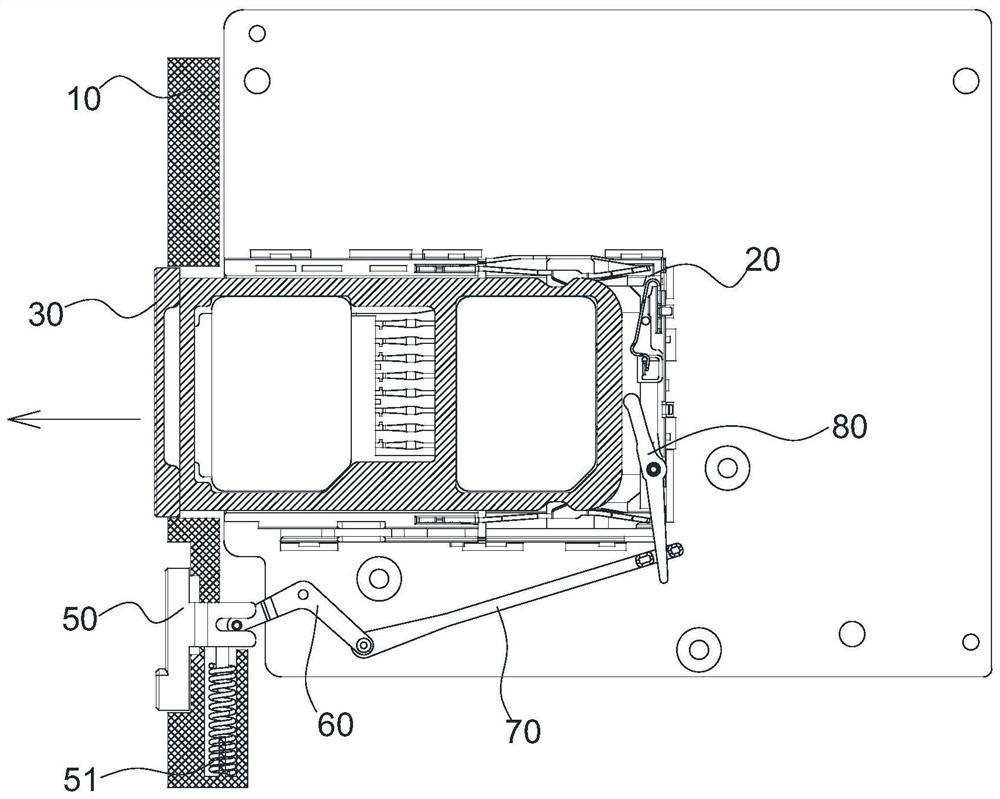

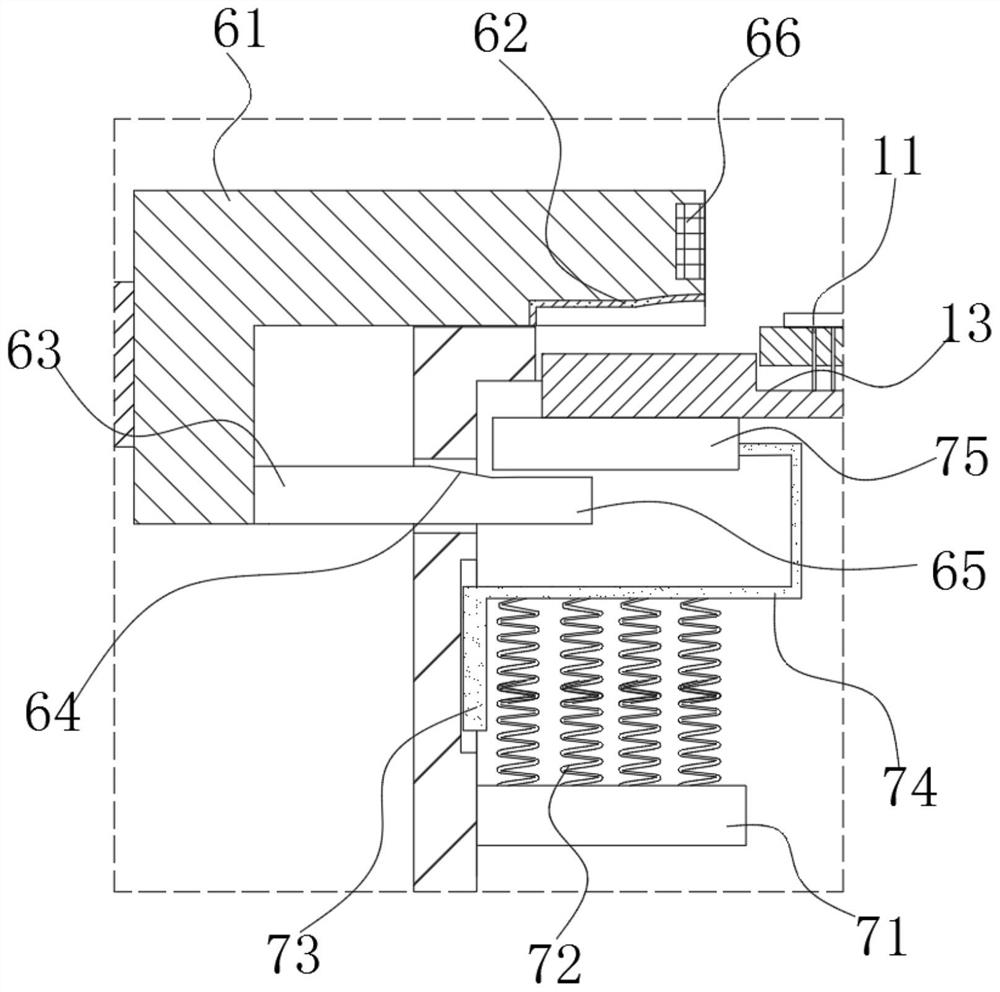

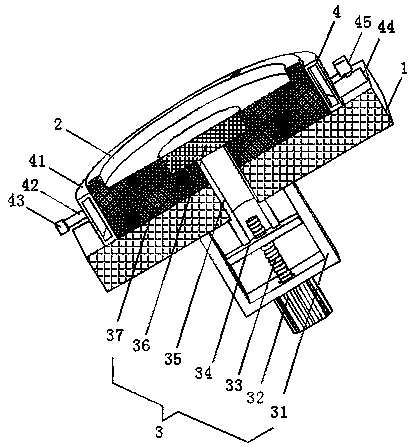

Card tray ejection mechanism and electronic equipment

InactiveCN112490760AEase of ejectionQuick ejectCoupling device detailsKey pressingStructural engineering

The invention discloses a card tray ejection mechanism and electronic equipment. The card tray ejection mechanism comprises a front shell, a card seat and a card tray, the card seat is located in thefront shell, a groove used for containing the card support is formed in the card seat, an opening right facing the groove is formed in the front shell, and the opening is used for allowing the card support to be inserted into the groove. The card tray ejection mechanism further comprises a push rod, a connecting rod assembly and a toggle key, one end of the push rod forms an ejection part which islocated at the inner side end of the card holder to eject the card holder, two ends of the connecting rod assembly are respectively connected with the other end of the push rod and the toggle key, and the toggle key is installed on the front shell in a sliding mode. And the toggle key is provided with a toggle part exposed out of the surface of the front shell, and the toggle part is used for driving the toggle key to move so as to enable the connecting rod assembly to drive the pushing part of the push rod to move. According to the invention, the card tray can be conveniently and rapidly ejected out only by pushing the toggle key without accessories such as a card pin and the like.

Owner:WINGTECH COMM

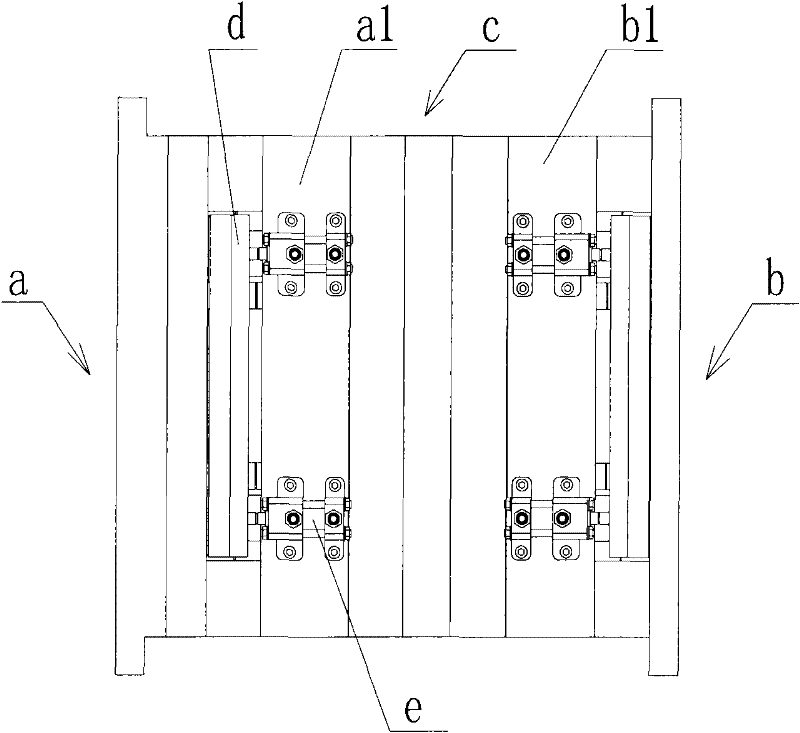

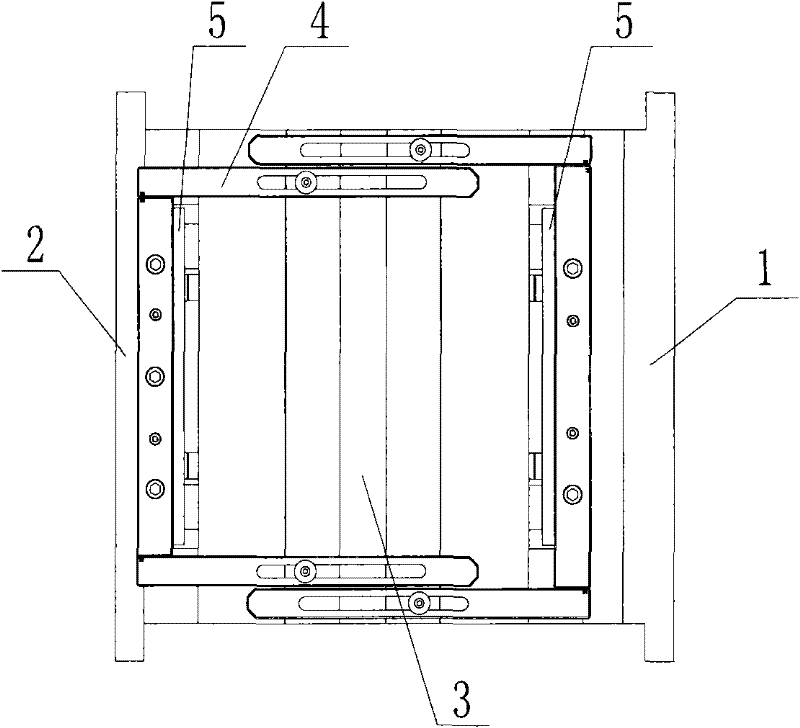

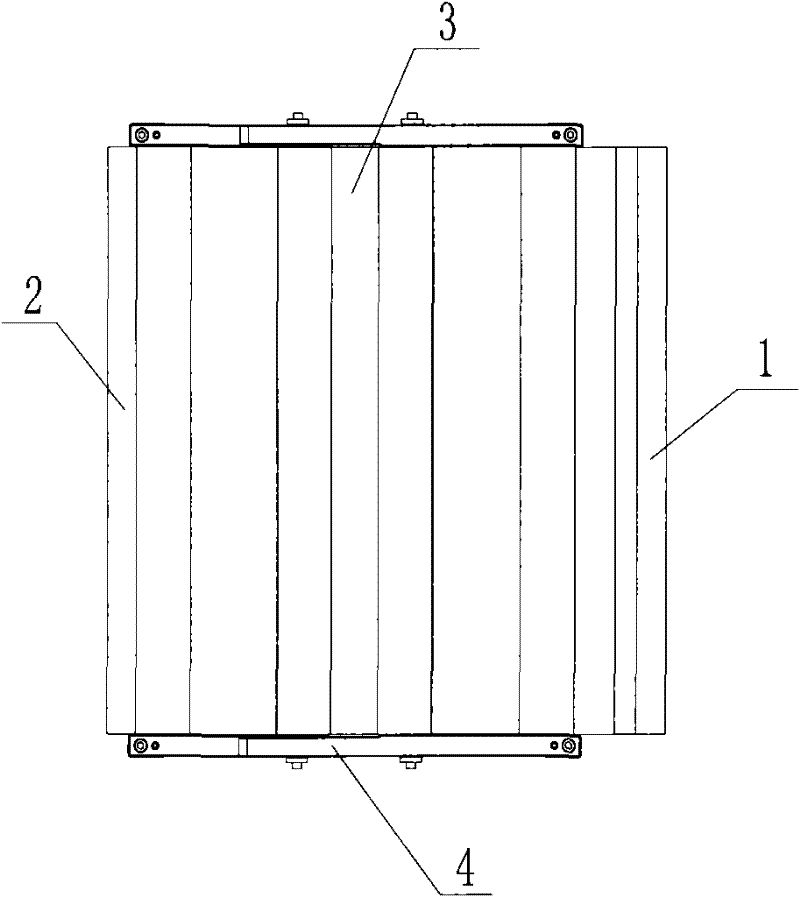

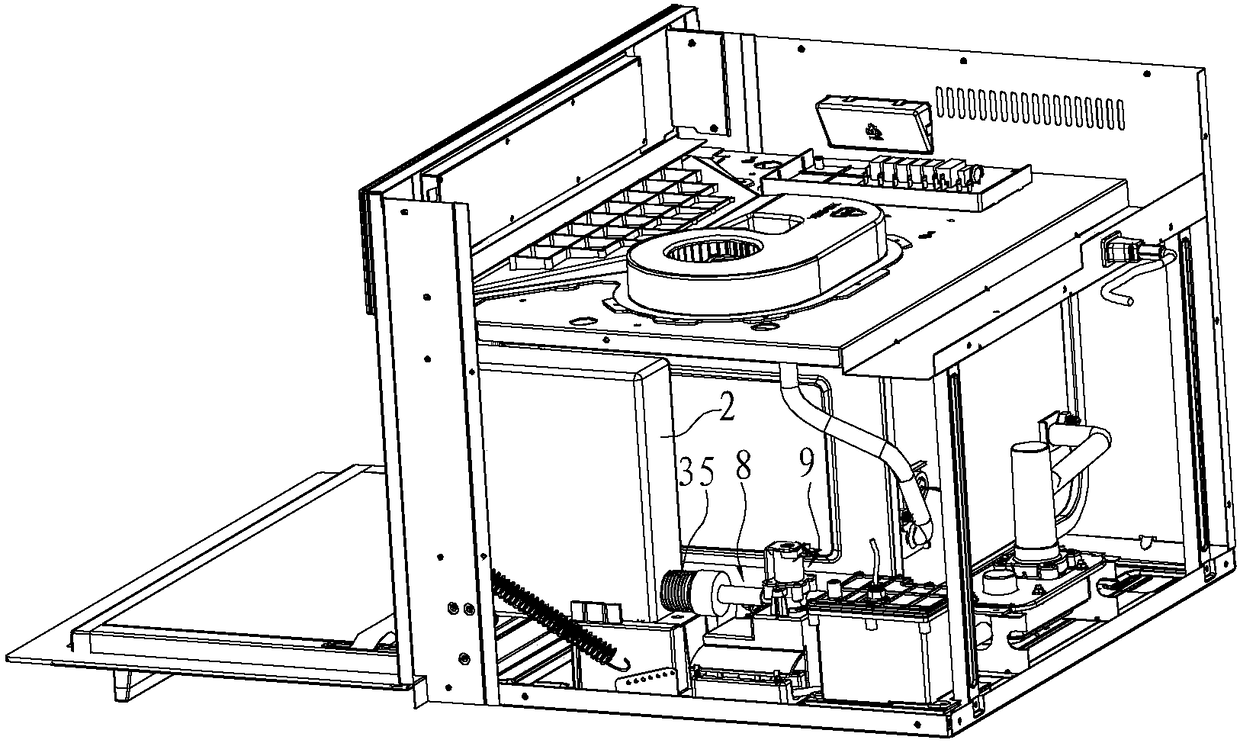

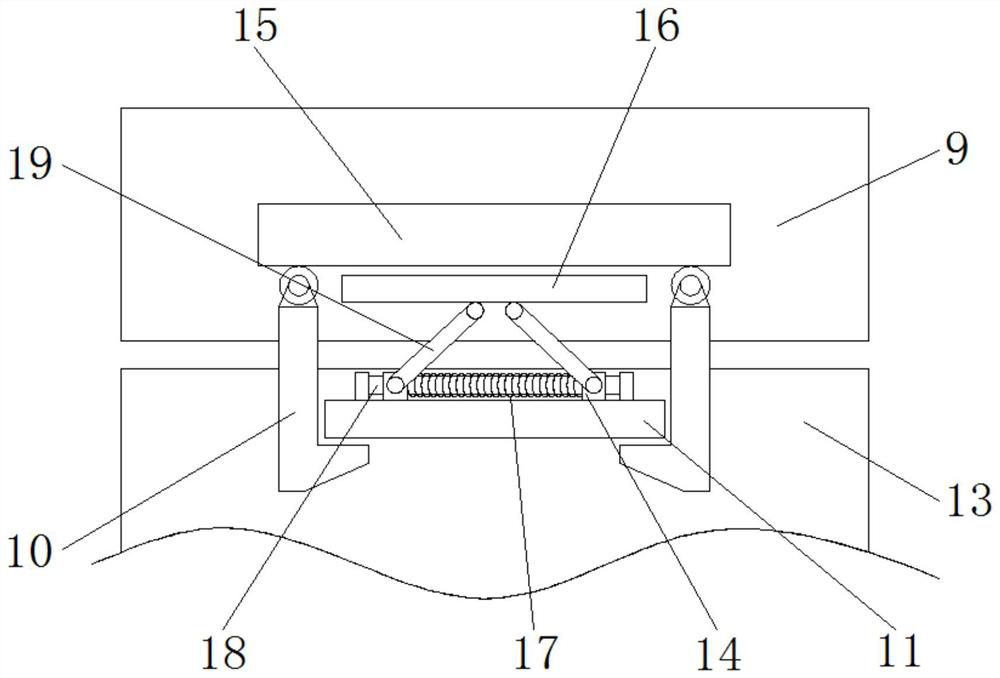

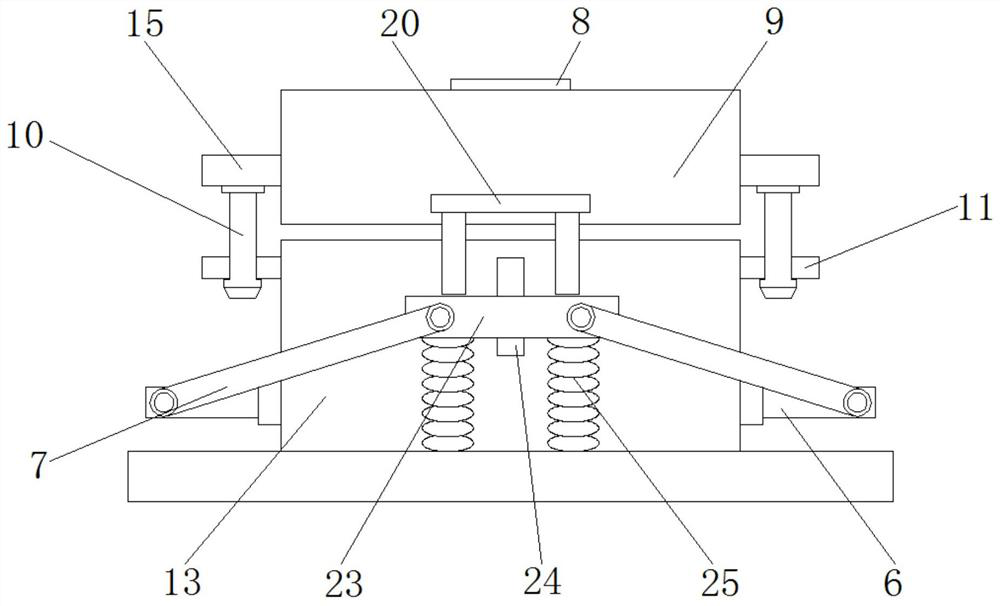

Injection mould with ejection and linkage mechanisms

The invention provides an injection mould with ejection and linkage mechanisms, thus providing a solution to problems of complex oil cylinder structure, high cost and low productivity which exist in present injection moulds employing an oil cylinder ejection mechanism. In the invention, two ejection mechanisms are installed. One end of the ejection mechanisms are connected to liftout plates on the side of the mould core, with the other end connected to one mould side where a cavity is located. The ejection mechanisms are directly driven by mould opening actions of the mould to power the liftout plates so as to eject products. Employing a mechanical structure, the ejection mechanisms of the injection mould are characterized by simple structure, low cost and short injection moulding cycle, and play a key role in achieving fast and efficient manufacturing for the injection mould.

Owner:HAIER GRP CORP +1

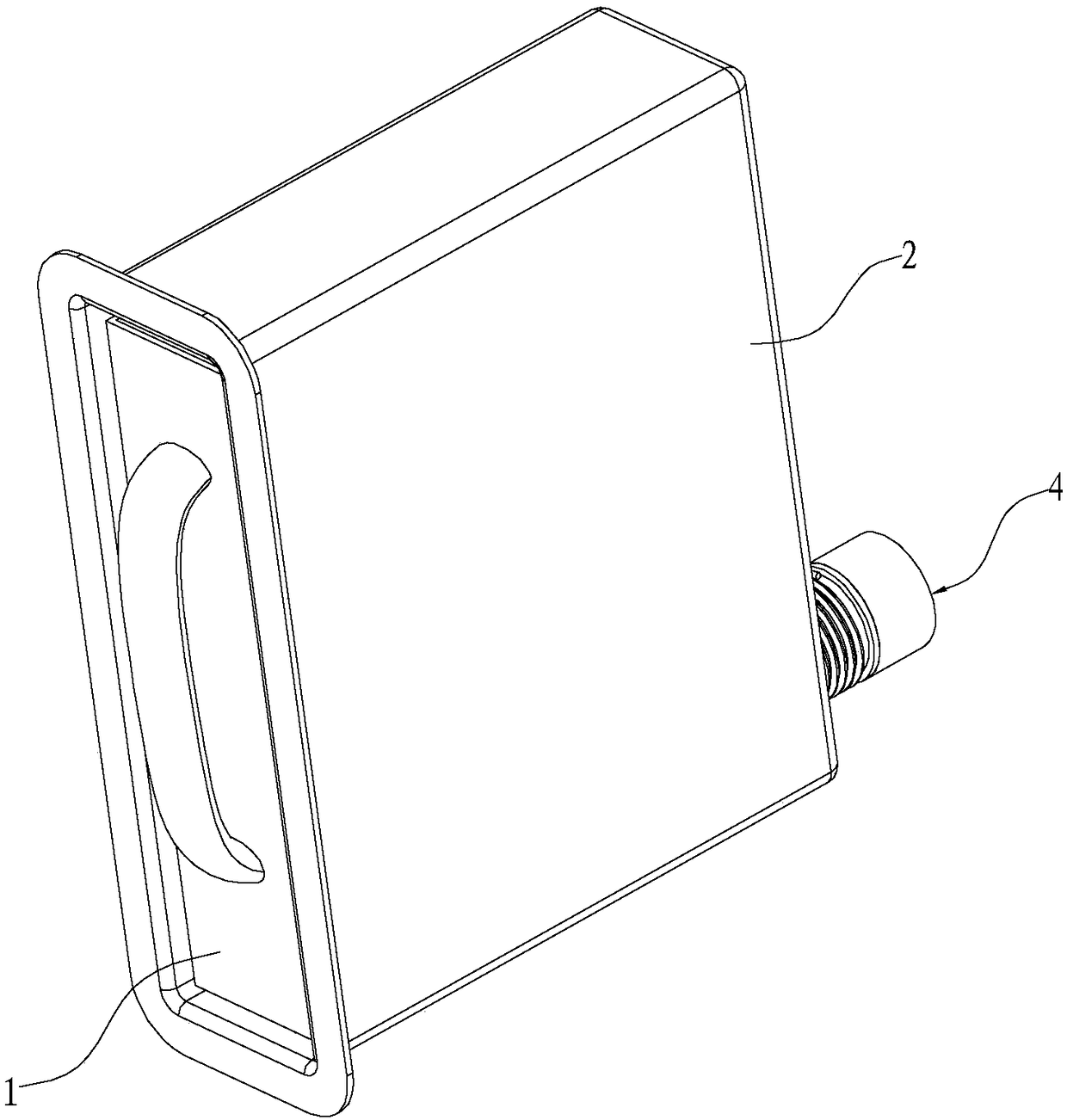

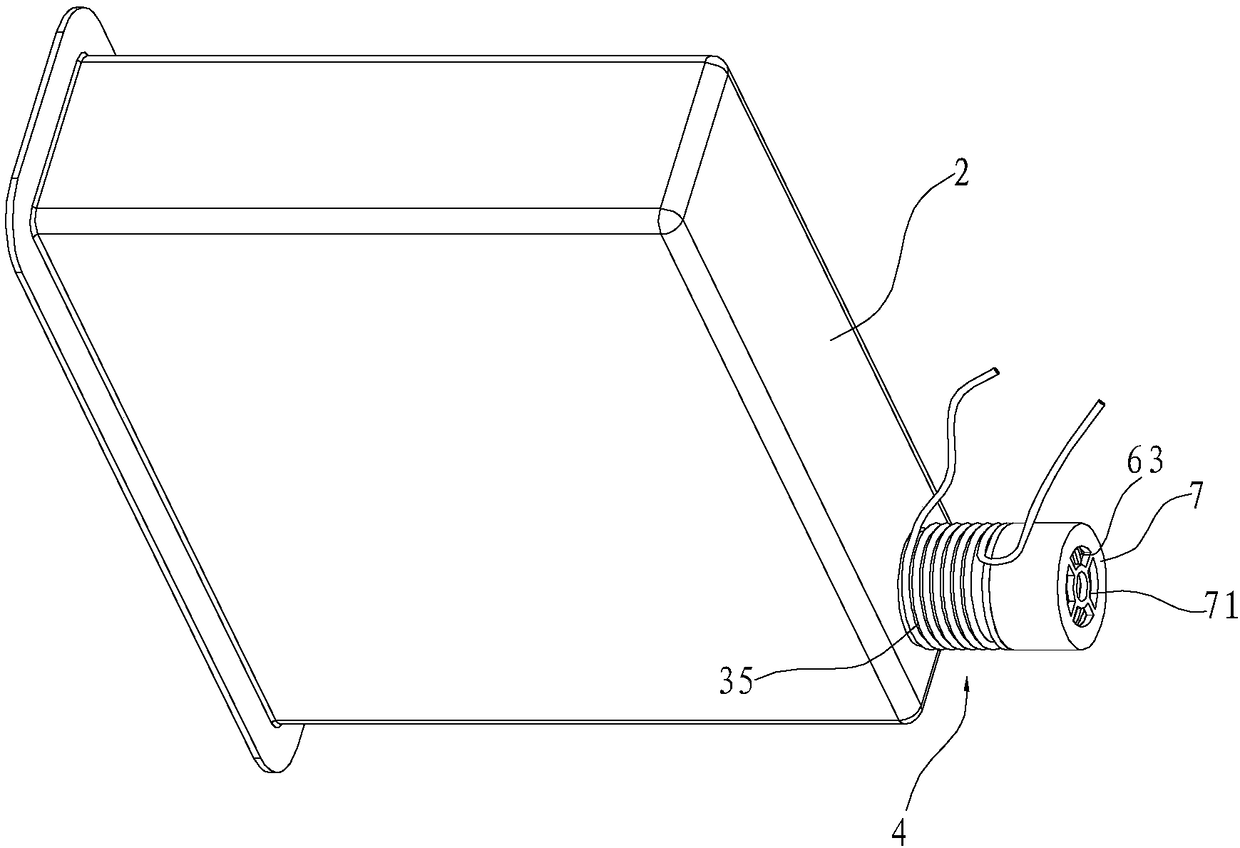

Water tank structure and steaming cooking equipment with same

The invention relates to a water tank structure which comprises a water tank and a water tank base. The water tank base is provided with a water containing opening allowing a water outlet of a water supply box to be inserted, a magnet is installed on the side wall of the water outlet, and an induction coil sleeves the peripheral wall of the portion, at the insertion part of the water outlet, of the water containing opening. The invention further relates to steaming cooking equipment with the water tank structure. Compared with the prior art, whether the water tank is in a pulling state or a take-out state and whether or not pulling / take-out actions are in place are judged according to the change of electromotive force generated by the magnet and the induction coil, not only can operation of a user be facilitated, but also the leakage phenomenon can be further avoided, and meanwhile a magnetic field generated by the induction coil at a water outlet can make water in the water tank generate magnetization; therefore, the solubility of calcium and magnesium in the water is increased, and scale generation is lowered.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

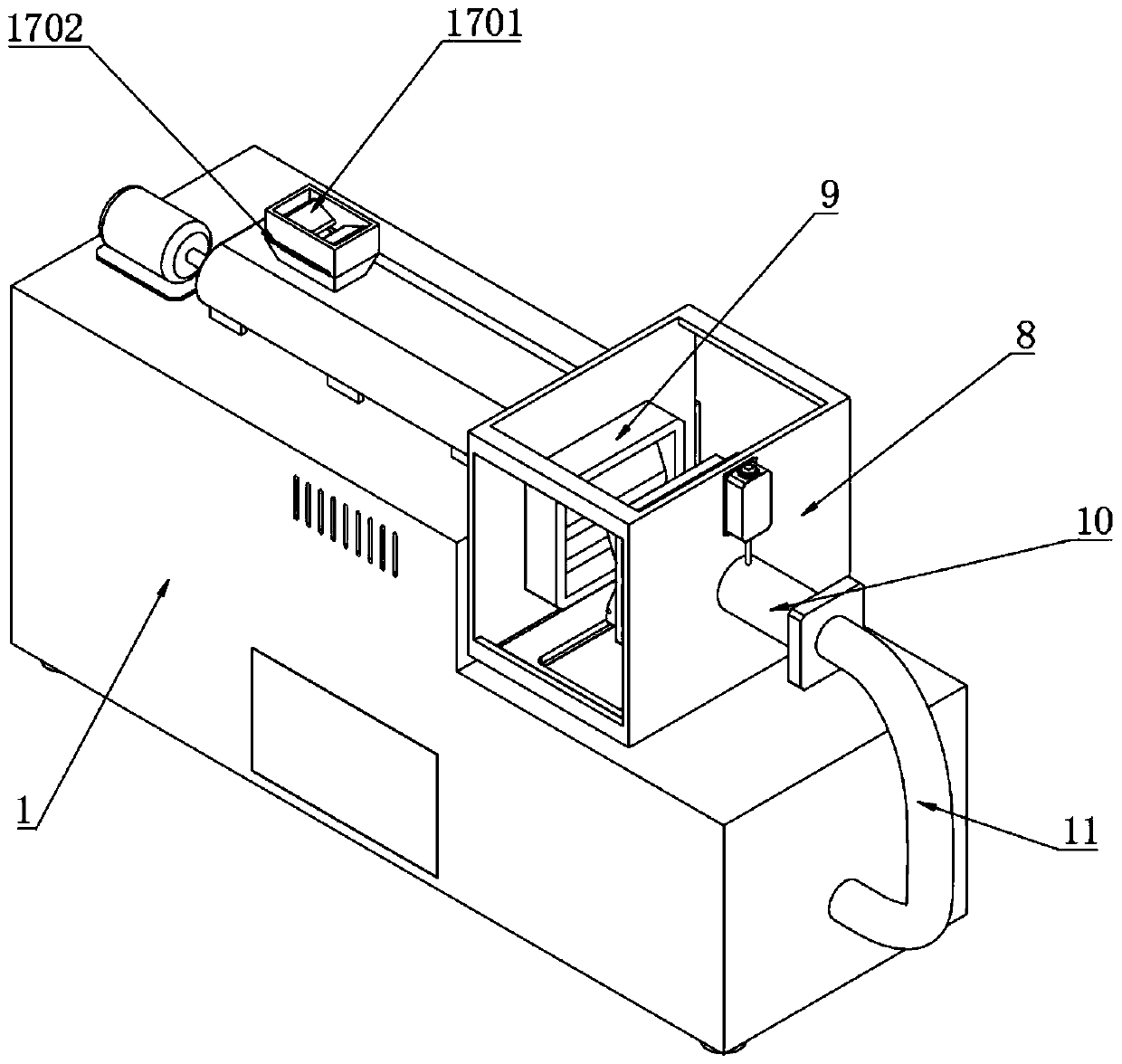

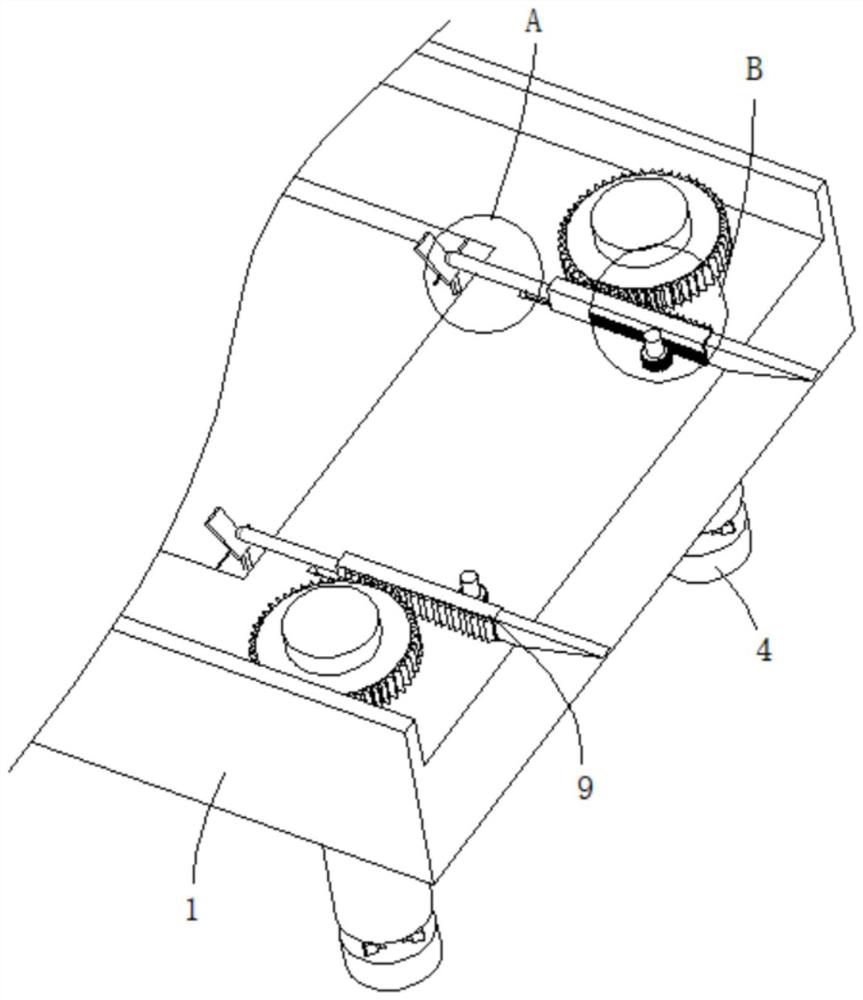

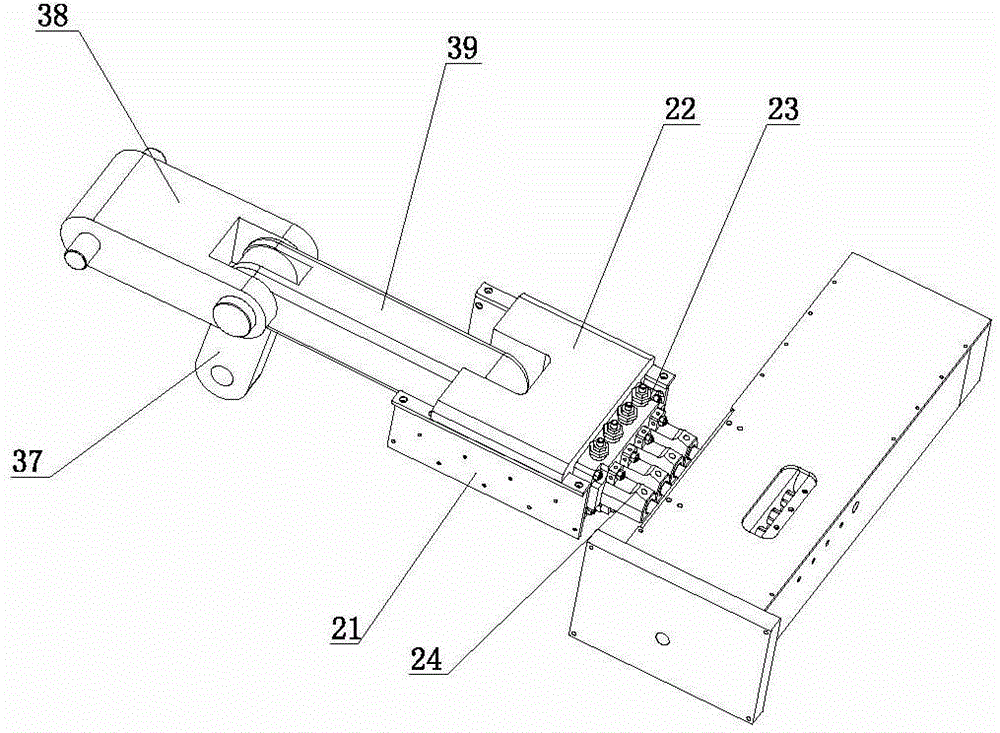

Automatic cutting and sampling device for original soil sample preparation box and use method

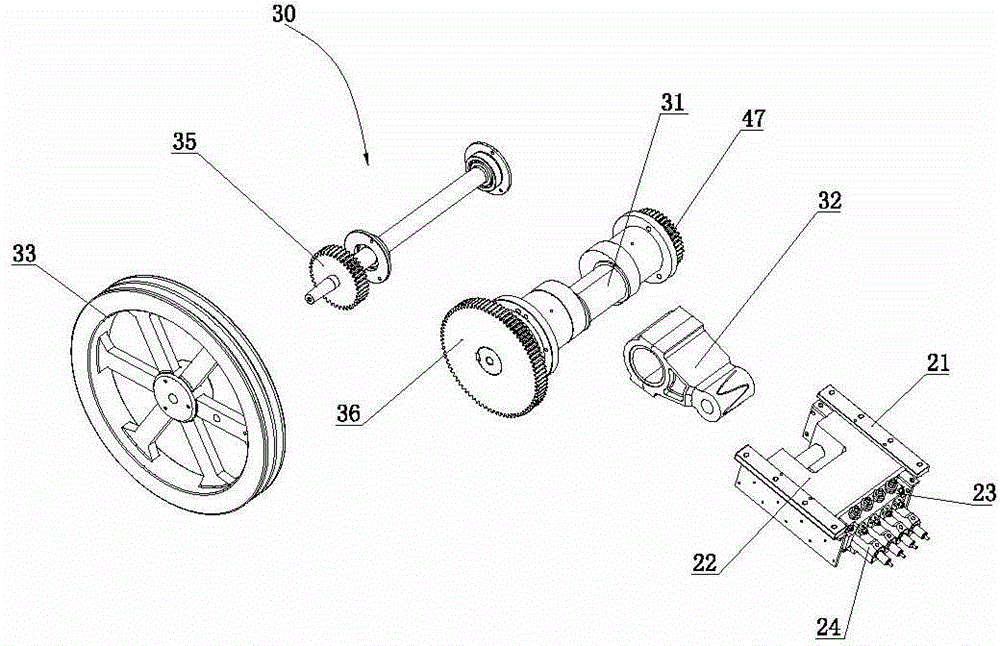

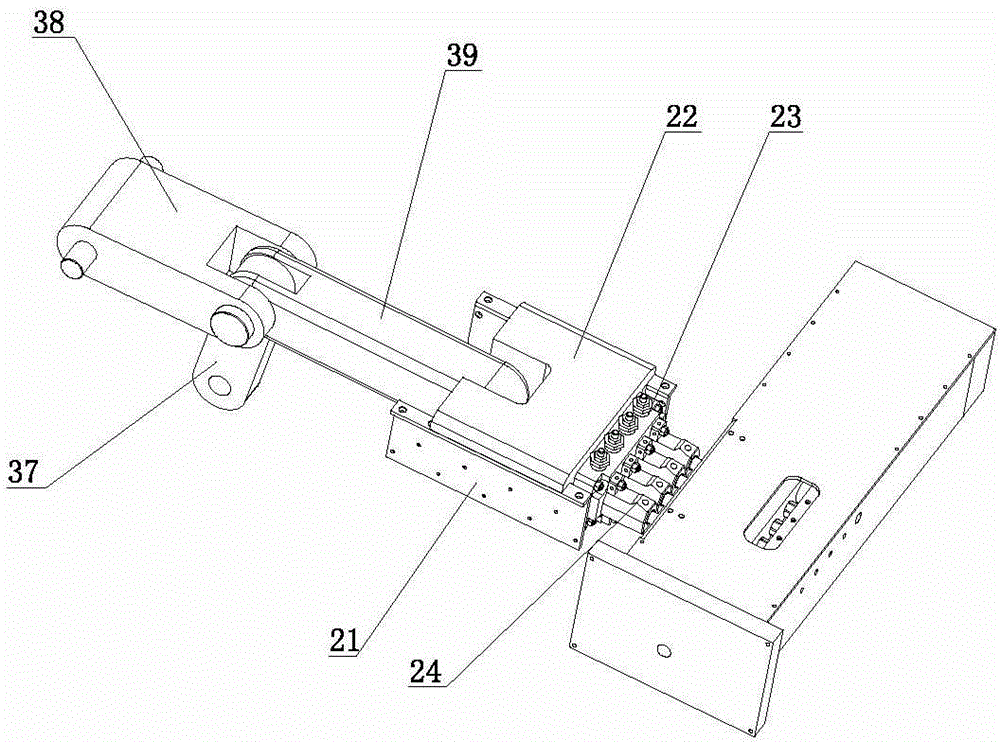

PendingCN112798323AFully automatedImprove sample preparation efficiencyWithdrawing sample devicesGear wheelAgricultural engineering

The invention discloses an automatic cutting and sampling device for an original soil sample preparation box and a use method. The automatic cutting and sampling device comprises a push rod assembly, a clamping assembly, a conveying guide rail, a sampling assembly, a cutting assembly and a control assembly, wherein the clamping assembly clamps the sample preparation box, a tooth-shaped rail is arranged on the upper end face of the conveying guide rail, and a gear motor is fixed to the lower end face of the clamping assembly; the gear motor is matched with the tooth-shaped rail, the push rod assembly is arranged on one side of the conveying guide rail in the width direction, the sampling assembly is arranged on the other side of the conveying guide rail in the width direction, the cutting assembly is arranged between the conveying guide rail and the sampling assembly, and the center of the push rod assembly and the center of the sampling assembly are located on the same straight line; the push rod assembly and the sampling assembly are both perpendicular to the conveying guide rail, the centers of the push rod assembly, the sampling assembly and the sample preparation box are located on the same plane, and the push rod assembly, the clamping assembly, the gear motor, the sampling assembly and the cutting assembly are electrically connected with the control assembly.

Owner:XIAN CHANGQING TECH ENG +1

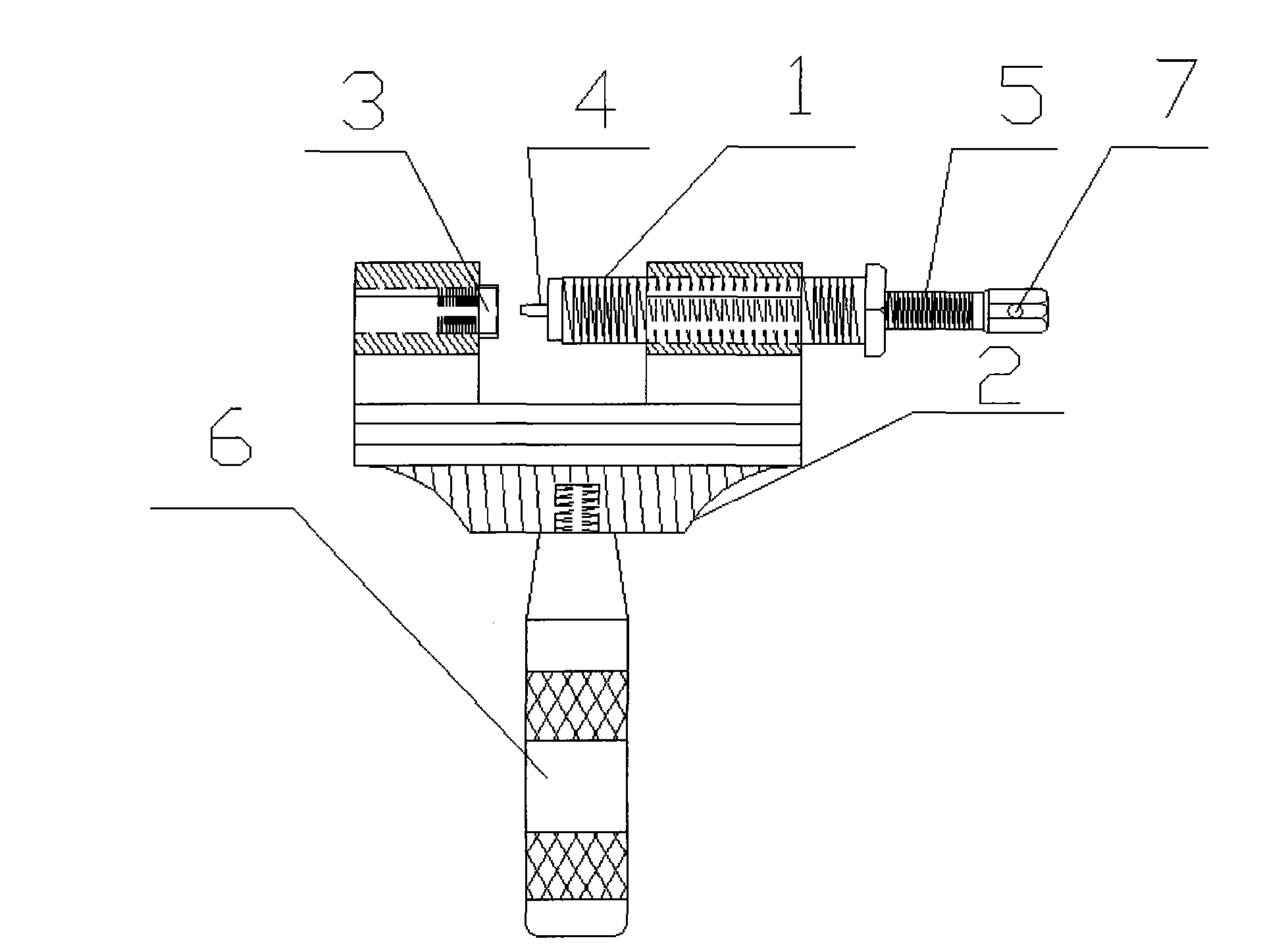

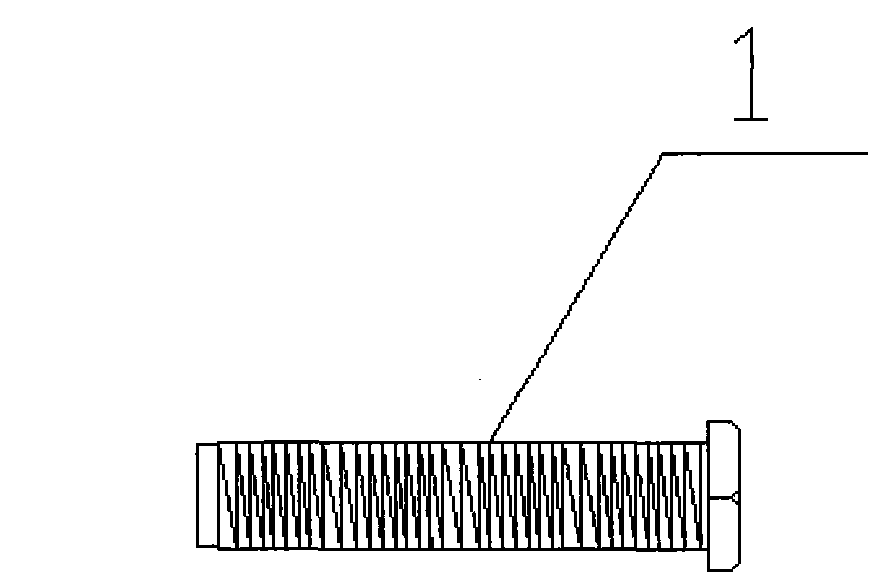

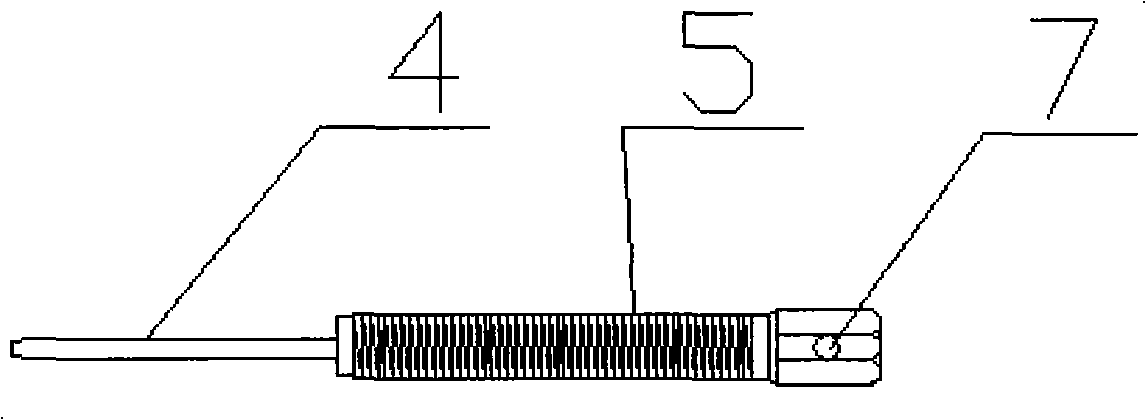

Chain demounting device

The invention relates to a chain demounting device for demounting the driving chain of motor or non-motor vehicle, which comprises a screw and a concave shaped carriage; the screw has a threaded center hole and is screwed in the threaded hole of an end ear of the concave shaped carriage; the rotating arm part 5 of a thimble screw is screwed in the threaded center hole of the screw 1; the other endear of the concave shaped carriage is formed with a pin locking hole on the inner end face opposite to the thimble of the thimble screw. Advantages: 1, the invention not only realizes the reliable locking to the chain needing demounting, but also realizes easiness, rapid and high efficiency in chain demounting; 2, because the thimble screw is fitted with the screw with center threaded hole by screwing, the force applied on the thimble screw by the rotating arm is applied on the chain pin directly by the thimble, and forces the chain pin contacting the thimble to separate from the outer chainboard; 3, the invention achieves the advantages of novel structure design, unique, simple, convenient for hand operation and long service life.

Owner:HANGZHOU CHIZHENG TECH

Die casting mould

The invention relates to a die casting mould. The die casting mould comprises a movable mould set, a fixed mould set, a movable mould base, a fixed mould base and a cavity, wherein an ejection block is arranged on the lower portion of the cavity and is connected with an ejection rod; the ejection rod is a telescopic rod; one end of the ejection rod is connected with a hydraulic cylinder; the section of the ejection block is trapezoidal; and the end, which faces the cavity, of the ejection block is a large-diameter end. When die casting of a product is finished by the die casting mould, the product can be ejected out quickly, so that the production efficiency is improved.

Owner:昆山旭龙精密机械有限公司

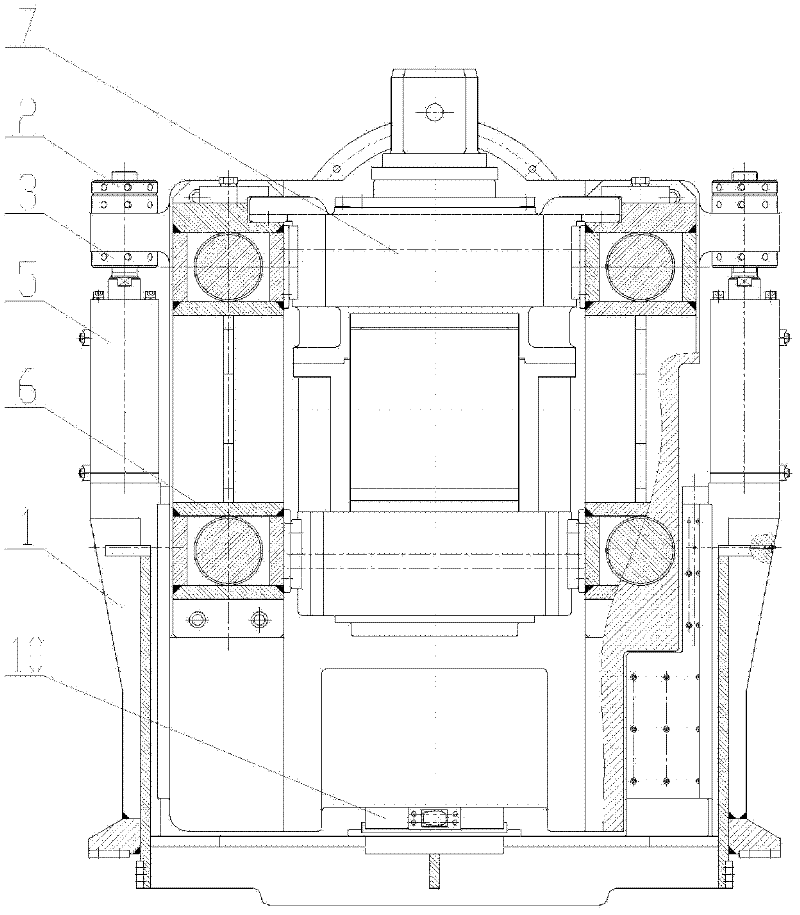

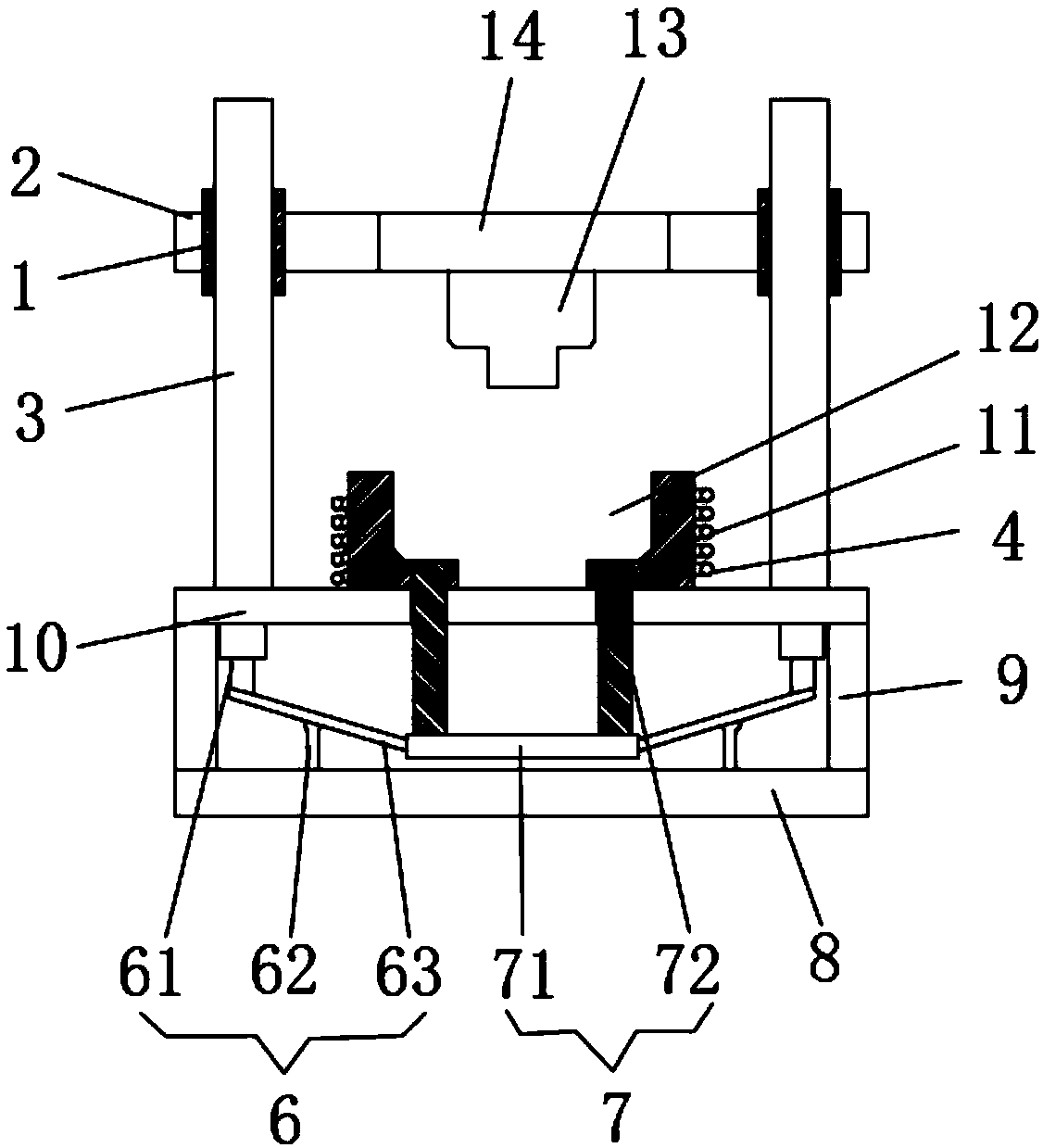

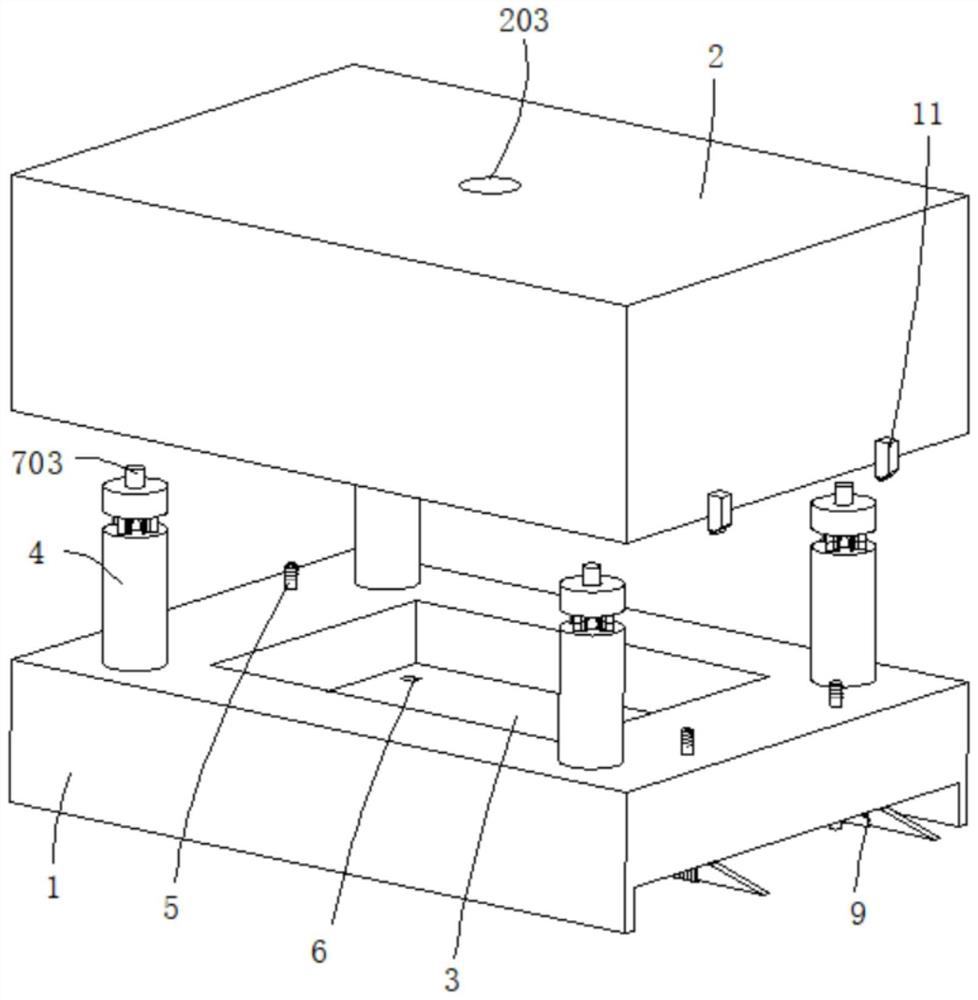

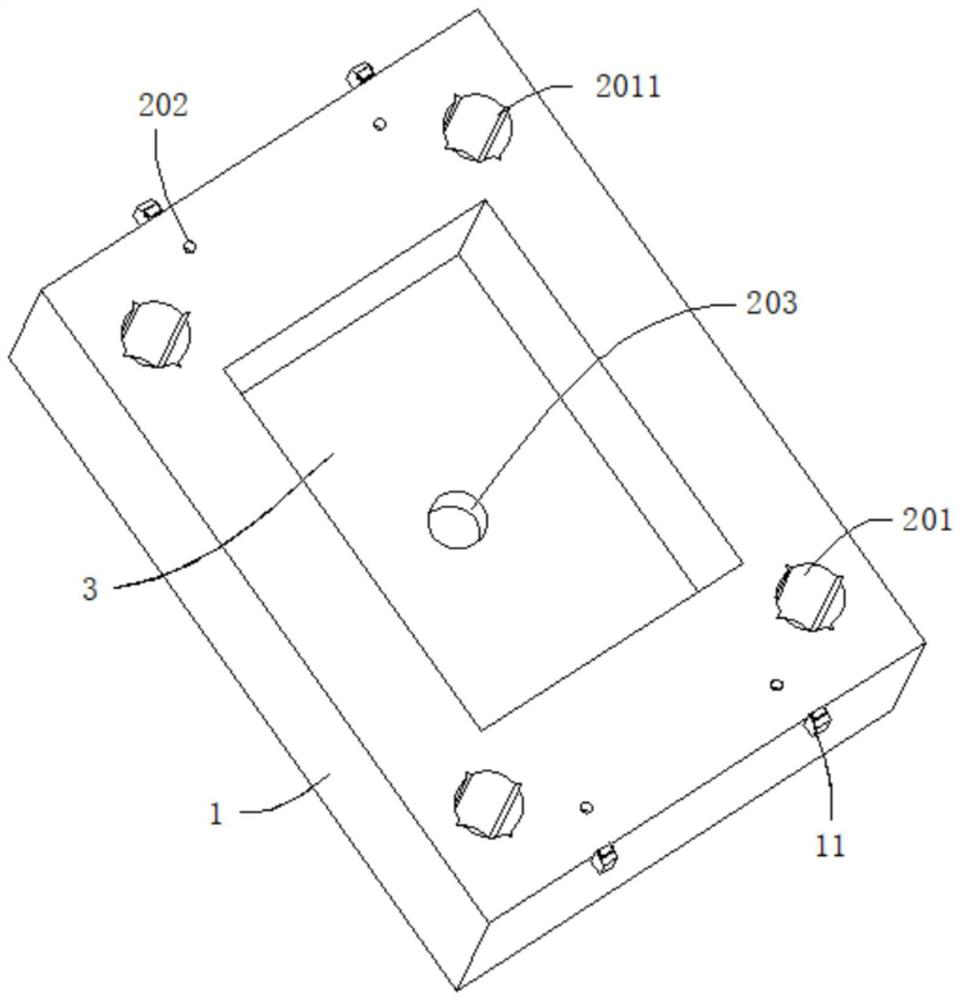

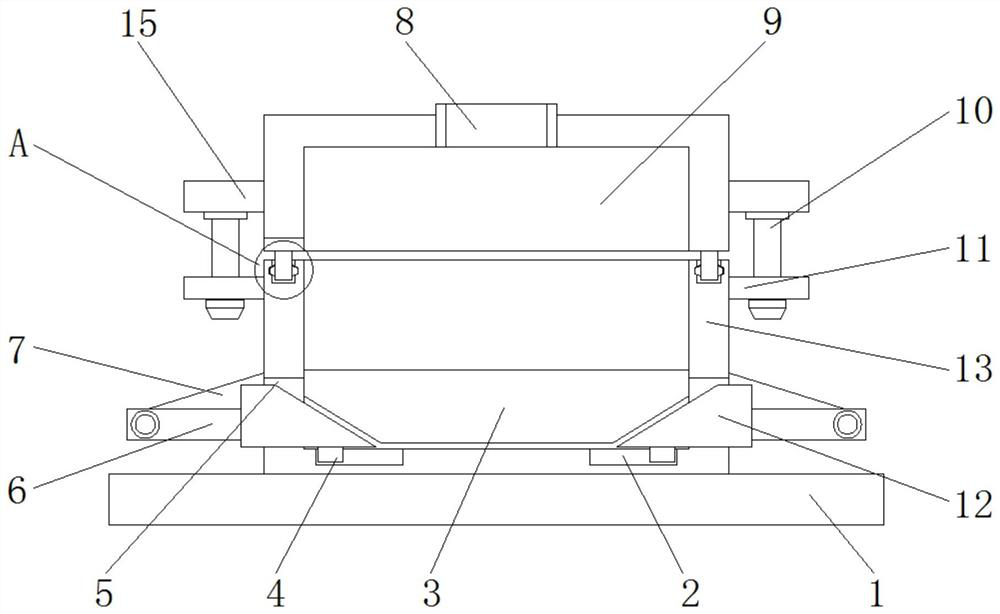

Precision shaping die for forge piece for outer ring of automobile hub

InactiveCN108723277AEasy to process and produceEasy to useForging/hammering/pressing machinesHeating/cooling devicesElectromagnetic inductionEngineering

The invention discloses a precision shaping die for a forge piece for an outer ring of an automobile hub. The precision shaping die comprises a bottom board and an upper die. One side of the upper surface of the bottom board is equipped with a control switch. An input end of the control switch is electrically connected with an output end of an external power supply. A lower die is arranged in themiddle of the upper surface of the bottom board. The lower outer surface of the lower die is equipped with an electromagnetic induction heater. An input end of the electromagnetic induction heater iselectrically connected with an output end of the control switch. The interior of the lower die is equipped with a die cavity. The lower surface of the upper die is provided with a die cover matching the die cavity. Support columns are arranged at four corners of the lower surface of the bottom board. The base is arranged at bottom ends of the four support columns. An ejection mechanism is arrangedon the upper surface of the base. The precision shaping die for the forge piece for the outer ring of the automobile hub is convenient to use. The upper die and the lower die are prevented from beingvertically shaped not on the same plane during production. The electromagnetic induction heater can heat the lower die at higher speed, which is convenient for hot forging. The forge piece is quicklyto eject out and convenient to machine and produce.

Owner:阜阳裕晟电子科技有限公司

Clamping device for slitting of computer display card cooling fins

The invention discloses a clamping device for slitting of computer display card cooling fins. The clamping device comprises a base, a mounting seat, movable arms, locking assemblies, top bracing assemblies and a machining table. The mounting seat is fixed to the base, the mounting seat is of a hollow cavity, an opening is formed in the top of the mounting seat, and the mounting seat is used for enabling the machining table to move up and down along the position of the opening of the mounting seat. A containing groove is formed in the middle of the machining table, vertically-put pit molding needles are evenly distributed at the bottom of the containing groove, and the upper faces of the pit molding needles are in round ball shapes and are used for containing the to-be-slit cooling fins. The movable arms capable of moving horizontally are symmetrically arranged on the two sides of the mounting seat, one locking assembly is arranged on each movable arm, when the to-be-slit cooling fins are clamped and locked, the locking assemblies can lock the to-be-slit cooling fins in the pit molding needles while ejecting the machining table upwards through the top bracing assemblies, and therefore pits in the to-be-slit cooling fins are molded.

Owner:GUIZHOU INST OF TECH

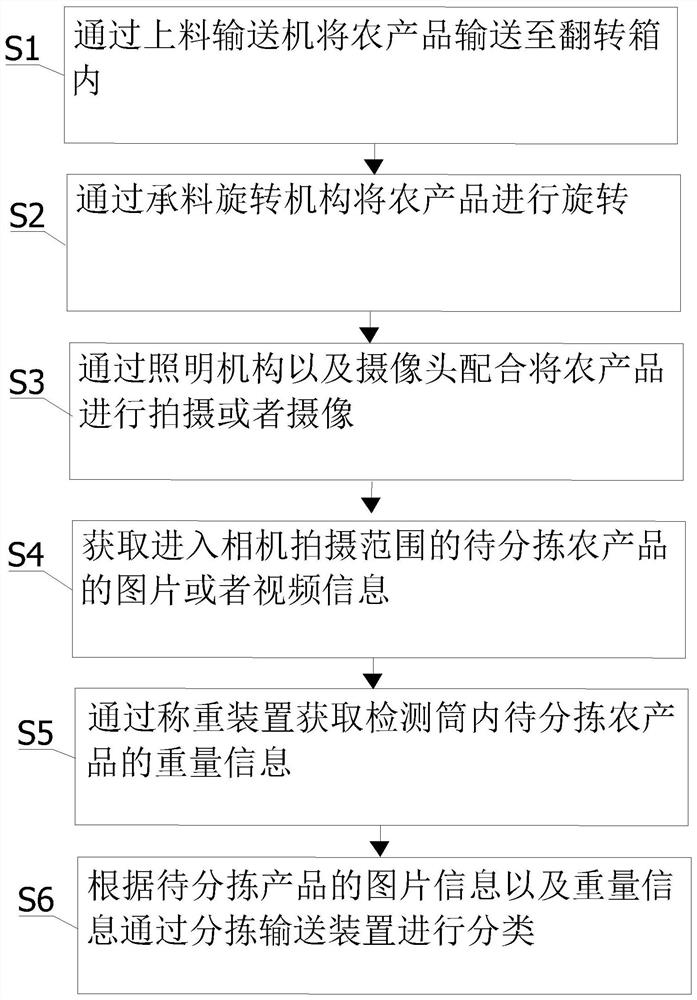

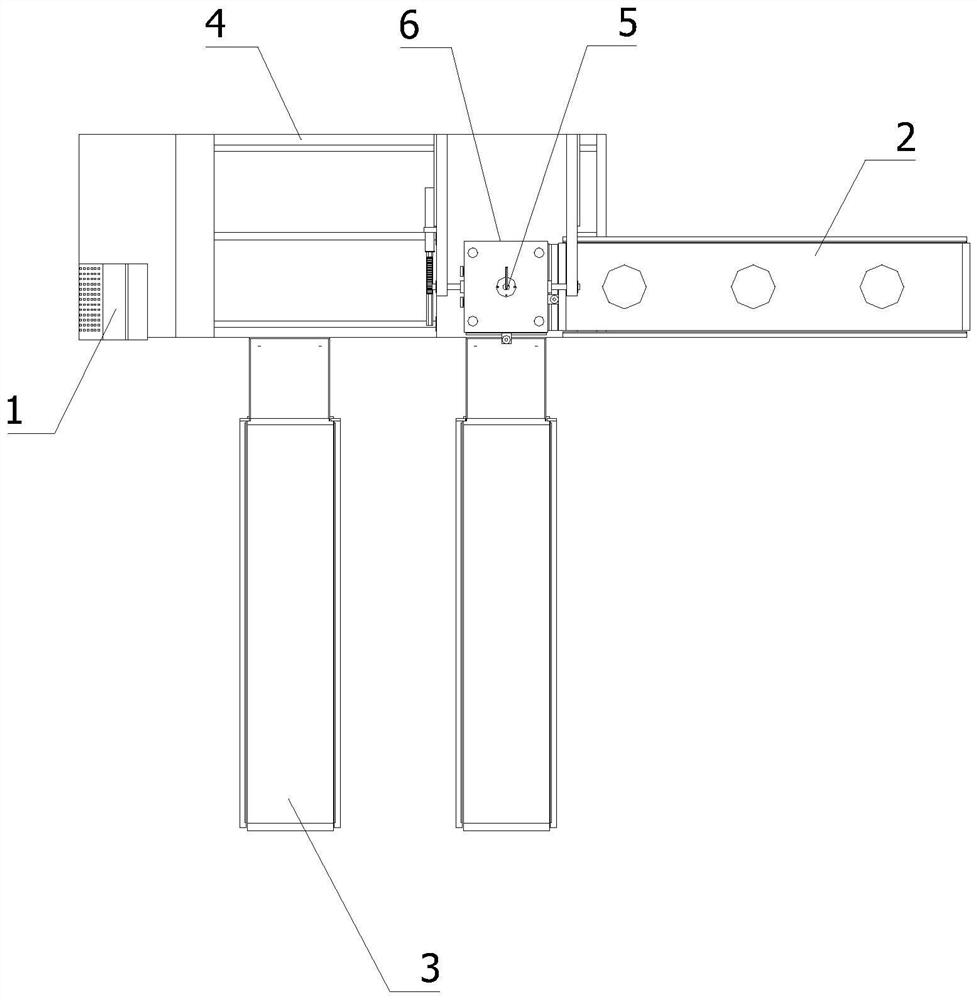

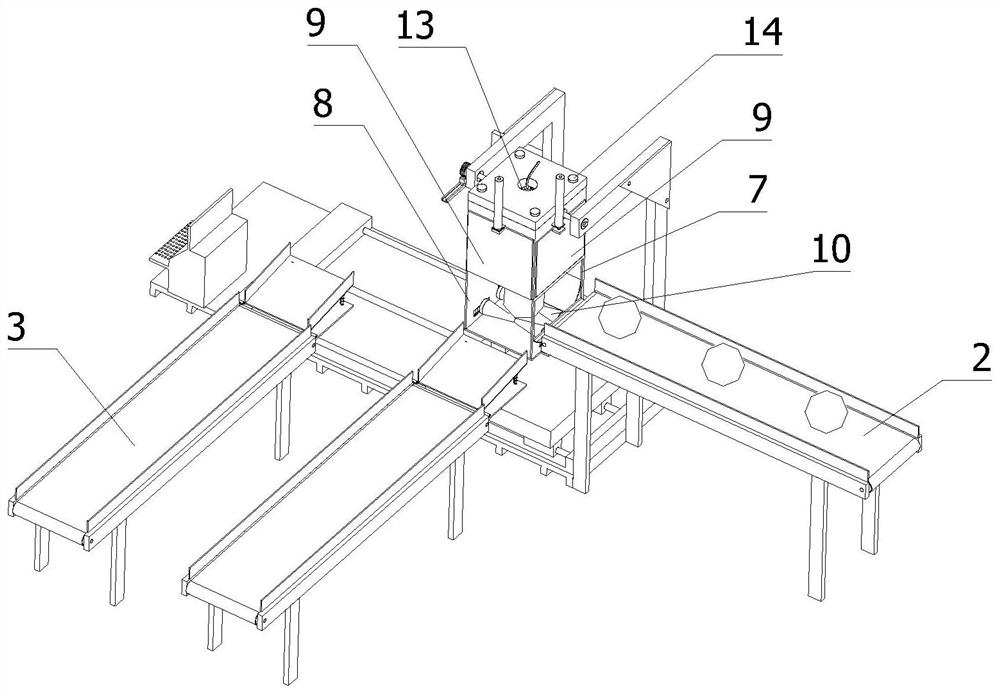

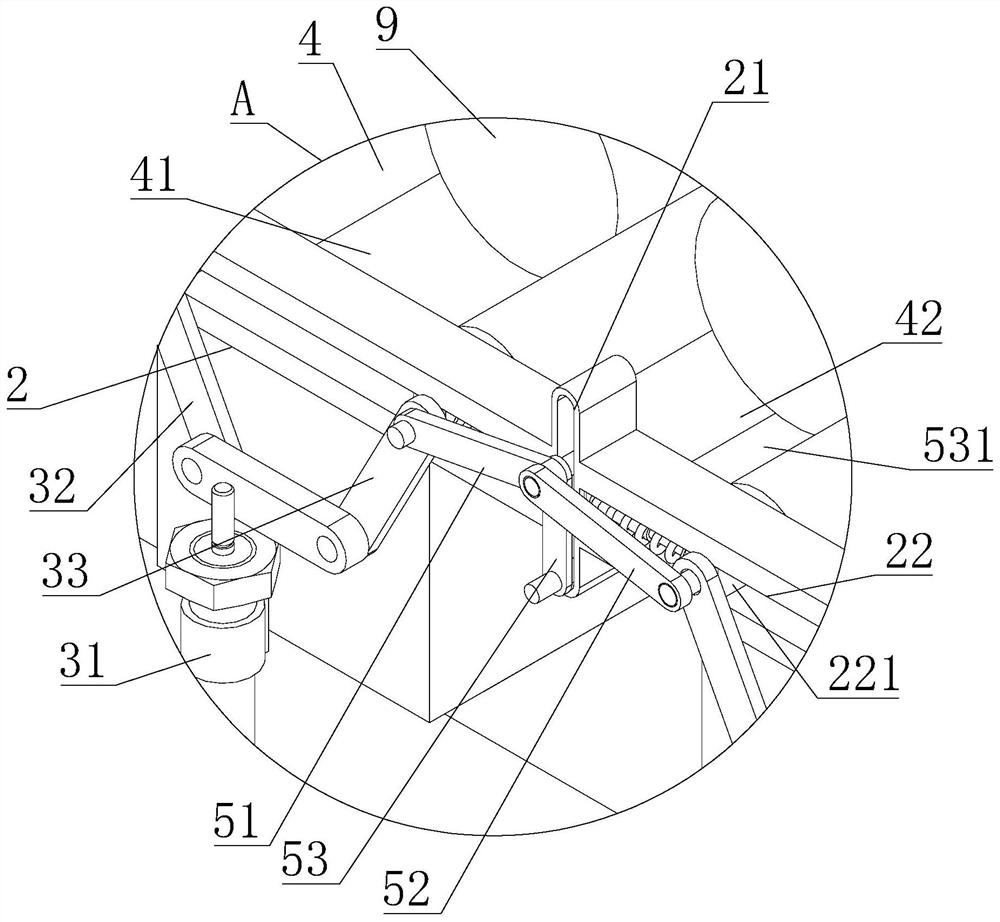

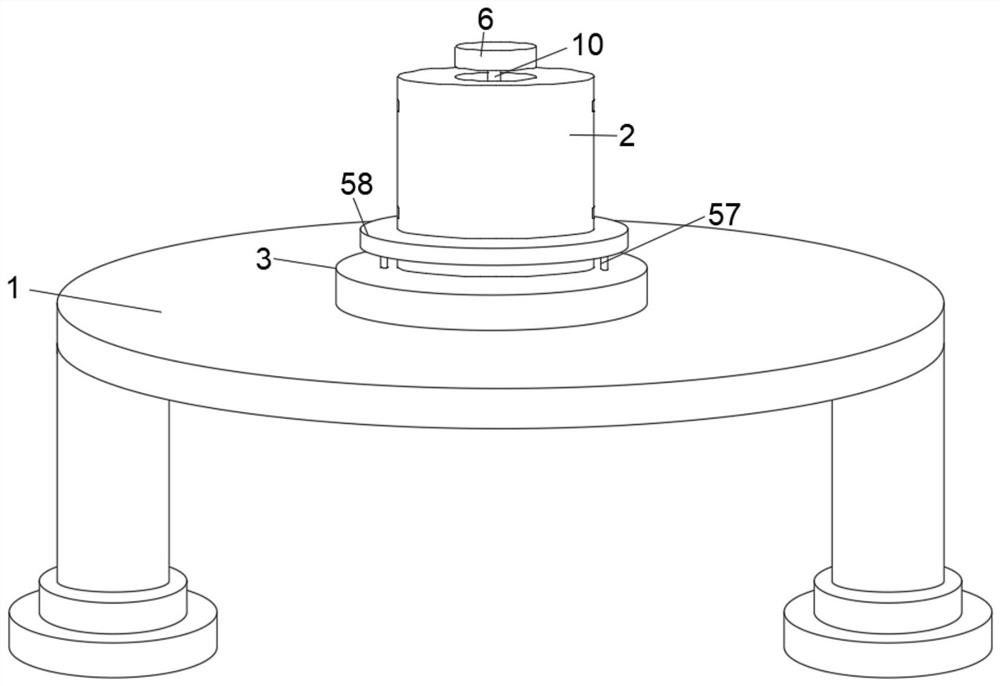

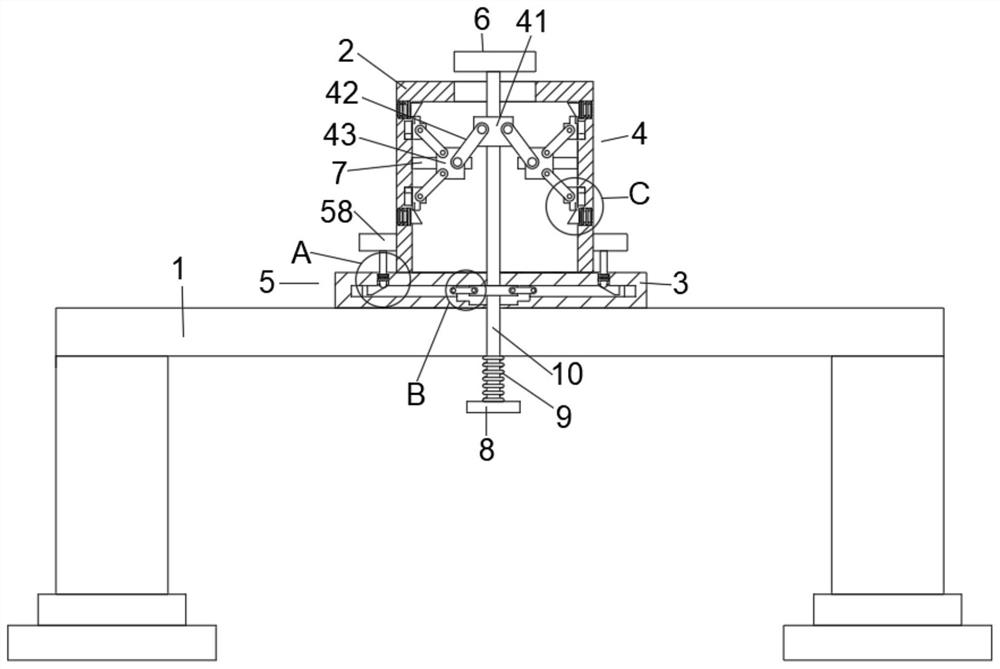

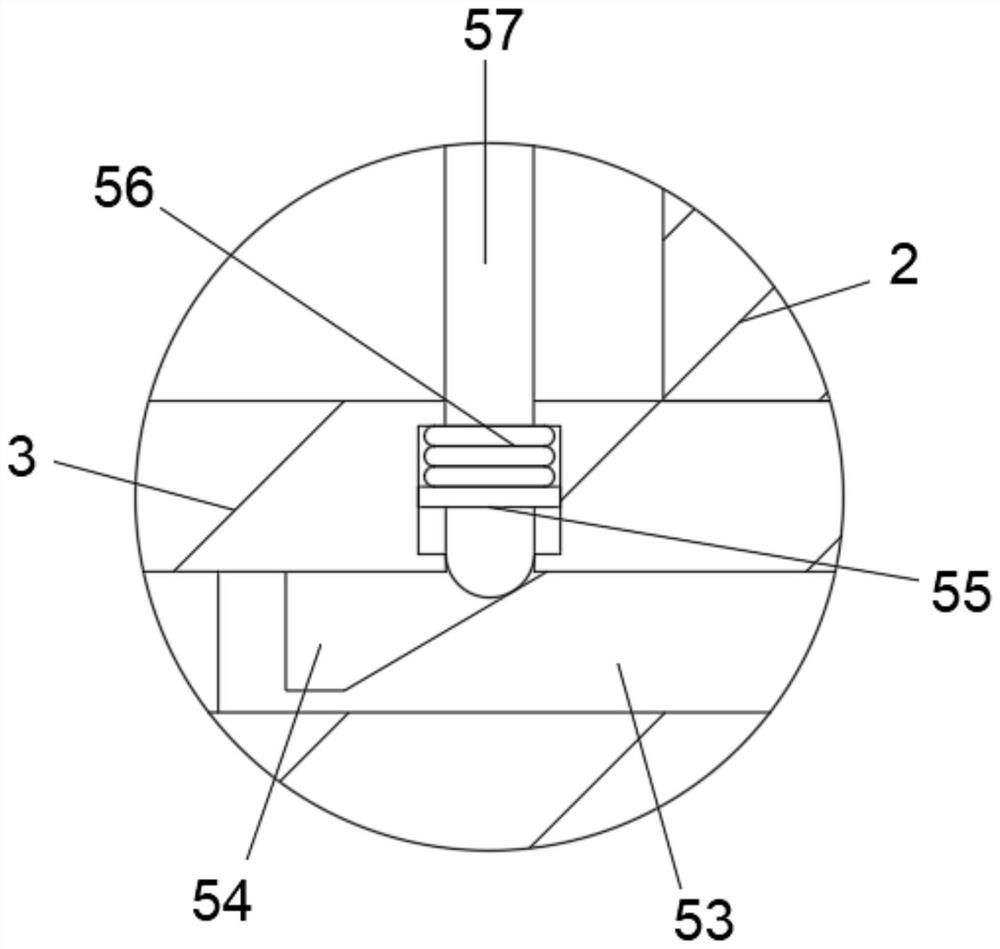

Automatic sorting device and method for agricultural products

PendingCN113751337AImprove the shooting effectReduce detection impactSortingAgricultural engineeringAgricultural science

The invention relates to the technical field of agricultural product sorting, and particularly relates to an automatic sorting device for agricultural products. The invention further relates to an implementation method of the automatic sorting device for the agricultural products. The automatic sorting device comprises a control unit, a feeding conveyor, a plurality of discharging conveyors and a horizontal material moving mechanism arranged between the feeding conveyor and the multiple discharging conveyors. The automatic sorting device is characterized by further comprising an overturning box, a material bearing rotating mechanism, a shooting head, a weighing mechanism and an illuminating mechanism, wherein the overturning box is arranged on the horizontal material moving mechanism in an overturning manner, a feeding opening and a discharging opening are formed in the overturning box, and material baffles capable of moving up and down are arranged on the feeding opening and the discharging opening; and the material bearing rotating mechanism, the shooting head, the weighing mechanism and the illuminating mechanism are arranged in the overturning box, and the material bearing rotating mechanism comprises a first roller and a second roller which are arranged in the overturning box in parallel. By means of the device, influences of light source light leakage and ambient light on fruit and vegetable spectrum detection are effectively reduced, the agricultural products can be overturned through the material bearing rotating mechanism, the shooting range is enlarged, and the sorting precision is improved.

Owner:广东广垦绿色农产品有限公司

Processing method for accelerating germination of peanut seeds

InactiveCN107810680ADry evenlyPromote germinationBio-organic fraction processingSeed and root treatmentPorosityRadicle

The invention mainly relates to the technical field of planting and discloses a processing method for accelerating germination of peanut seeds. The processing method includes the steps of drying, seeddressing, germination accelerating, and sowing. The method is simple, the processing time of peanuts is 1 to 2 days, and germination and seedling emergence appear 3 to 4 days after sowing, and the germination rate reaches 100%, and therefore the method significantly improves the planting efficiency of peanuts. In the method, the seeds of peanuts are lyophilized in a lyophilizer until a small amount of water dissipates, so that the seeds can be dried quickly and uniformly, and the stress resistance of seed radicles and germs is enhanced, the radicles and germs are accelerated to growth, and also the porosity of the seed coats can be increased, thereby facilitating absorption of water and nutrients in the external environment in a later period and accelerating germination of seeds. After drying, a ferrous sulfate solution is added to the seeds for seed dressing, thereby promoting growth of the radicles, facilitating absorption of nutrients from outside, enhancing the strength of the hypocotyls and the ability of cell elongation, enabling the germs to be pushed out of soil quickly, and shortening the germination and emergence time of the seeds.

Owner:全椒县大地种植专业合作社

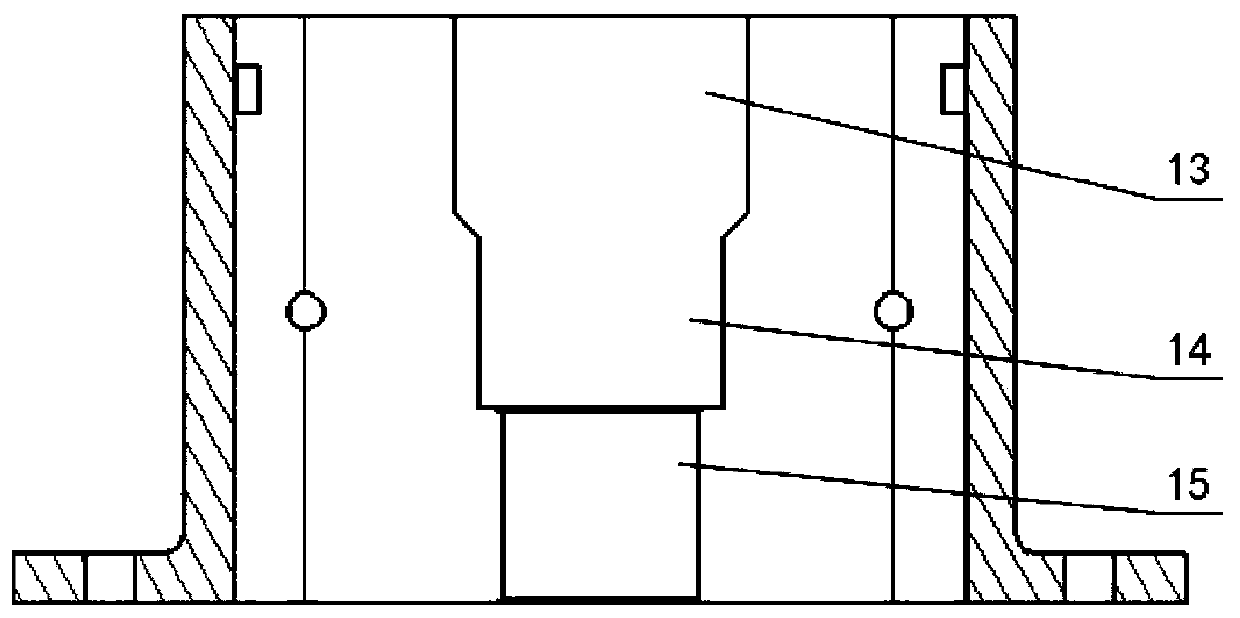

Injection mold of water meter shell

InactiveCN105128279ASafe and reliable classificationSafe and reliable core pulling actionMaterials science

The invention discloses an injection mold of a water meter shell. The injection mold comprises a fixed mold plate, a movable mold plate, a movable mold bottom plate, a mold foot strip and a mold foot plate, all of which are sequentially arranged from top to bottom. A sprue bush and inclined guide columns are arranged on the fixed mold plate. A half sliding block is arranged in the fixed mold plate and movably connected with the inclined guide columns. Sliding blocks, molding cores and inserts are arranged in the middles of the inclined guide columns and are sequentially and fixedly connected. Main cores are arranged in the inserts. Main core sleeves and ejector rods are arranged outside the main cores. The main cores are fixedly connected with the movable mold bottom plate. The ejector rods are connected with the inserts. Cylindrical pins are arranged outside the main core sleeves. A rear ejector plate and a front ejector plate are arranged on the mold foot plate. The injection mold of the water meter shell is safe and reliable in parting and core drawing motion, good in processing effect, compact in structure, good in stability and convenient to operate.

Owner:WUHU HENGFENG TECH

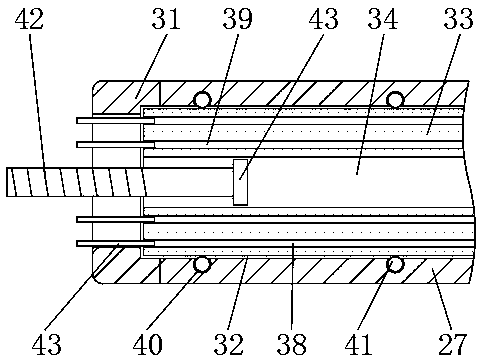

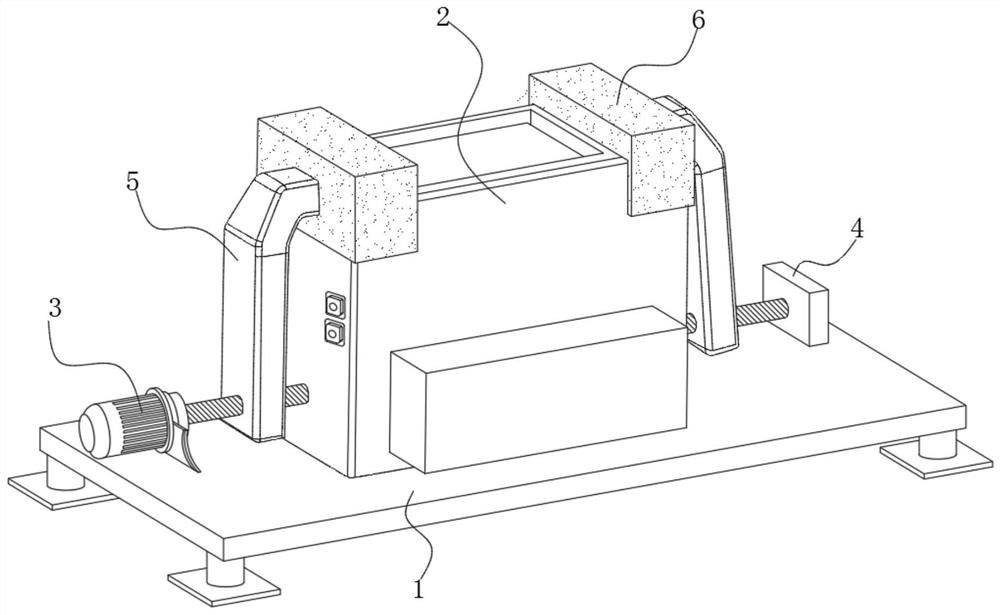

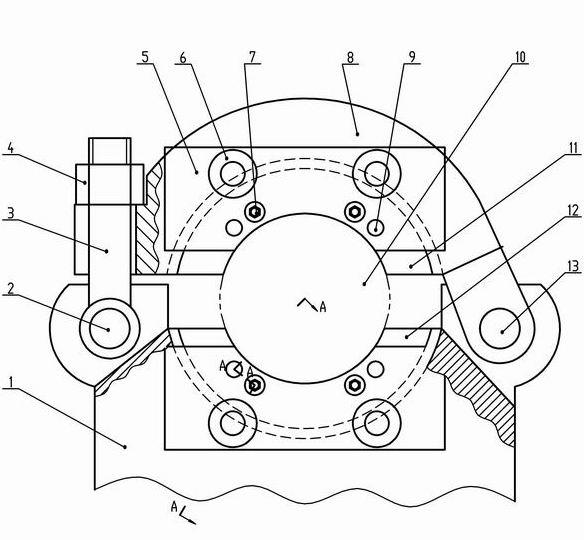

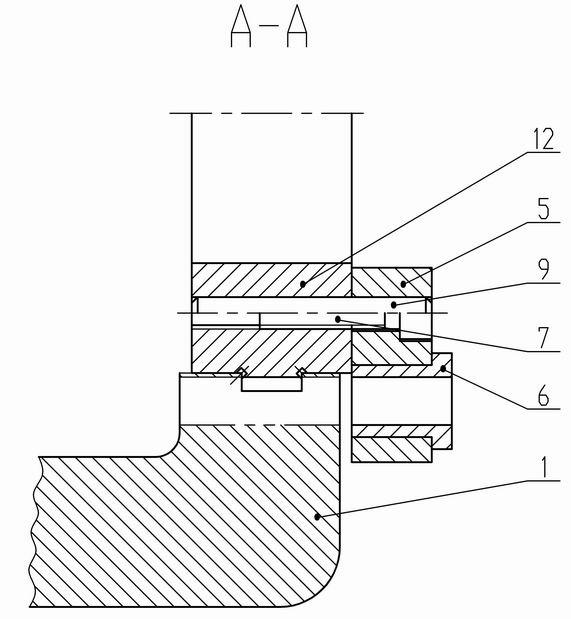

A quick-release slip drilling template

The invention relates to a drilling jig for drilling on a quick-release slip. The drilling jig comprises a clamp body, a lower lining tile, a gland, an upper lining tile, a lining column, a drilling jig plate and a drill bushing, wherein grooves are arranged on the clamp body and the gland, bosses are correspondingly arranged on the lower lining tile and the upper lining tile in the circumferential direction, the lower lining tile and the upper lining tile are closely fitted and embedded in the grooves of the clamp body and the gland respectively, one end of the gland is connected with one side of the clamp body through a hinge pin, a U-shaped port is arranged at the other end of the gland, a flat head bolt and a compression nut are used for connection, the lining column is tightly clamped between the lower lining tile and the upper lining tile, screw holes and pin holes are arranged on the side surfaces of the upper lining tile and the lower lining tile, a countersunk hole and a pin hole are correspondingly arranged on the drilling jig plate and fixed with the upper lining tile and the lower lining tile respectively through a screw and a positioning pin, and a drill bushing is fixedly mounted on the drilling jig plate. The drilling jig is reasonable in structure, simple for manufacturing and convenient for mounting and clamping, and can realize drilling of circular holes on the clamp body and the inner edge of the gland; furthermore, the positions of the drilled holes are accurate, and the drilling jig is suitable for the quick-release slips and can be applied to quick changeovers.

Owner:TIANRUN IND TECH CO LTD

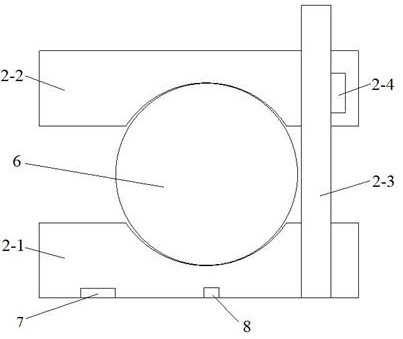

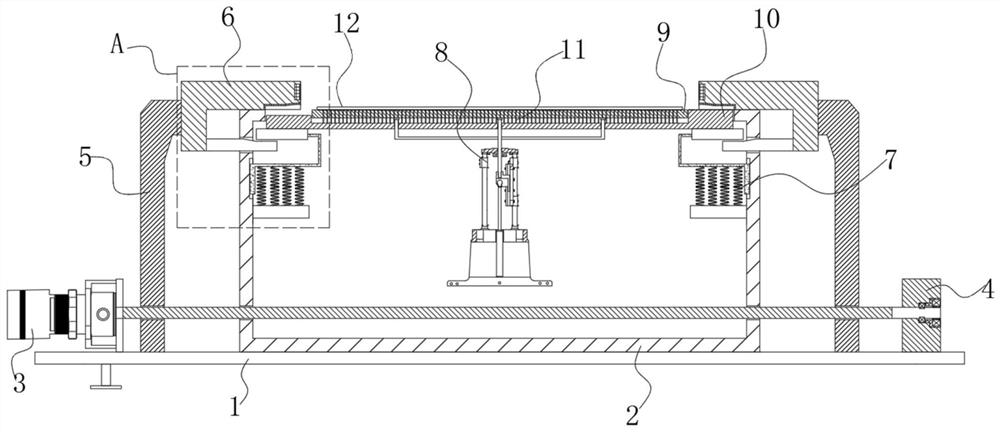

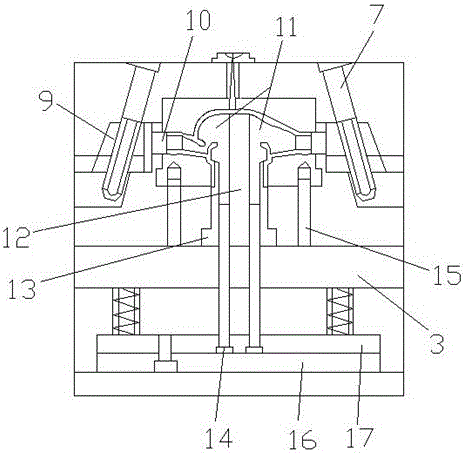

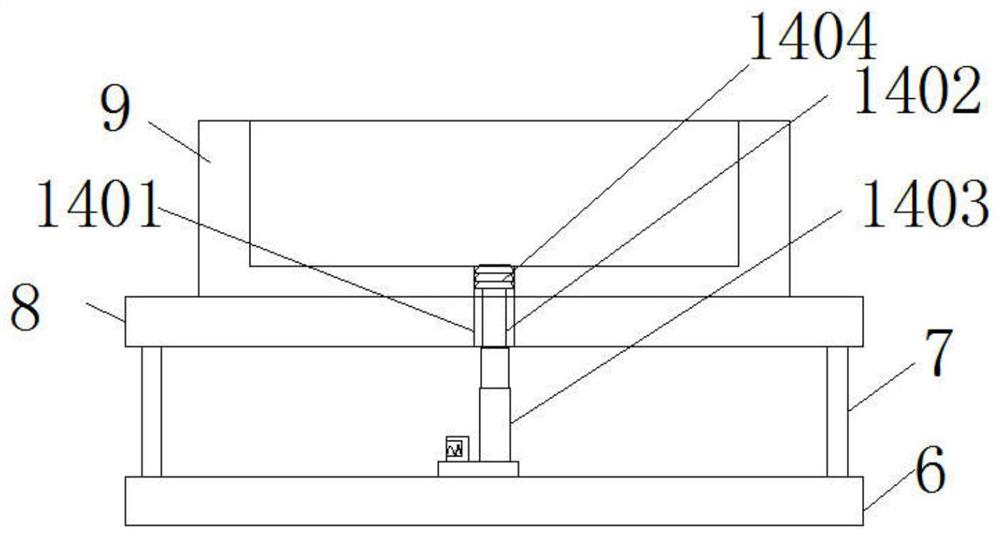

Advanced ceramic part injection mold and injection molding method

ActiveCN109648684ASimple structureUniform and efficient injectionDischarging arrangementInjection molding machineMaterials science

The invention discloses an advanced ceramic part injection mold and injection molding method. The advanced ceramic part injection mold comprises a base plate. A lower mold plate is arranged at the right side of the upper end of the base plate. An ejection device is arranged inside the lower mold plate. The outer surface of the lower mold plate is provided with a cooling device. A closed separatingdevice is arranged at the left side of the upper end of the base plate. A connecting plate is arranged at the side, close to the center of the lower mold plate, of a support block in the closed separating device. Under the effect of locating pillars and locating holes, an upper mold plate and the lower mold plate are closed through the closed separating device; mixed and compounded slurry is located and guided through a locating annular piece. According to the advanced ceramic part injection mold and injection molding method, the injection mold is simple in structure and convenient to operate; the slurry is injected uniformly and efficiently; the mold can achieve rapid cooling and molding, and materials are convenient and fast to pick; the injection molding method is reasonable and efficient; the injection molding quality of parts is guaranteed; the work load of personnel is lowered; and the injection and molding efficiency is improved.

Owner:湖南犀鸟陶瓷有限公司

Asymmetric continuous large-deformation extrusion die for magnesium alloy

The invention discloses a magnesium alloy asymmetric continuous large-deformation extrusion processing die, and belongs to the field of non-ferrous metal plastic forming. The asymmetric continuous large-deformation extrusion processing die comprises an upset-extruding cavity at the upper part and an extruding cavity at the lower part, and a forming channel hole can be designed to be in an asymmetric type. The extrusion deformation of one side of a casting material is large while the extrusion deformation at the other side is small, so that the deformation is intensified. Die cores are detachable, and various types of die cores which can be suitable for different sizes are designed, so that different production requirements can be met. After one casting material is deformed, the casting material can be quickly replaced with the next casting material, so that continuous production is realized. The die is mainly used for realizing continuous extrusion forming of a sheet of a magnesium alloy sheet-shaped casting material, and the magnesium alloy sheet-shaped part which is uniform in structure and optimized in performance can be obtained through the processing technology.

Owner:JILIN UNIV

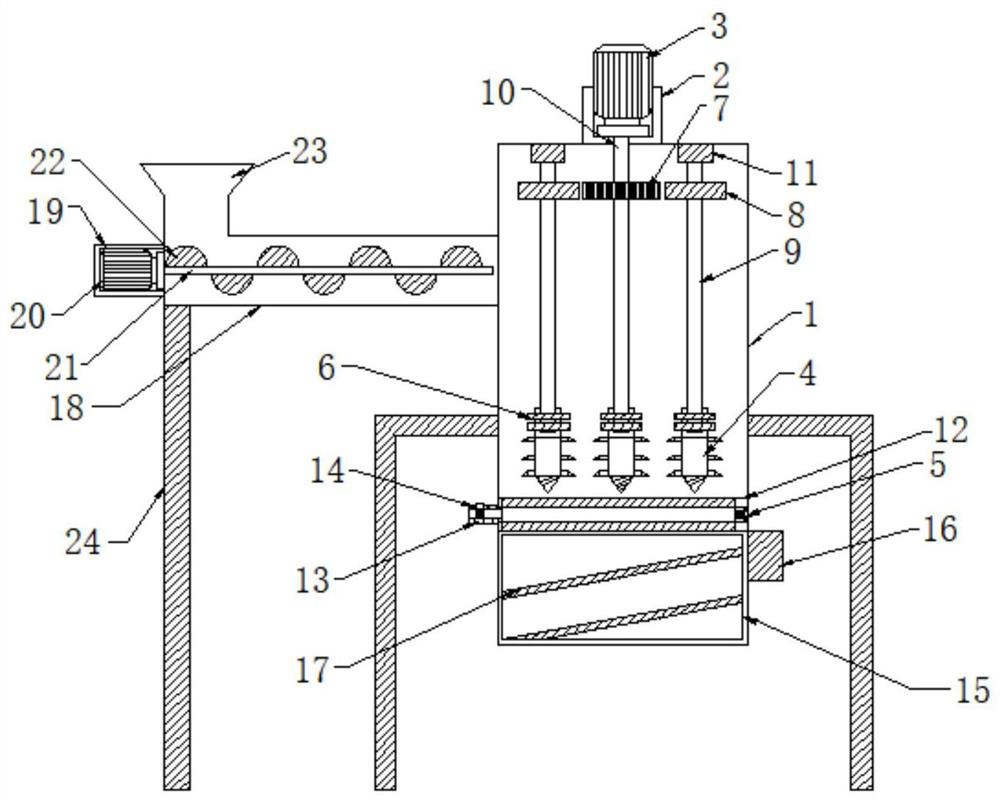

Feed scattering and crushing equipment and method capable of avoiding feed caking

InactiveCN111744605AEfficient breaking and crushingQuick releaseSievingFeeding-stuffReduction driveGear wheel

The invention discloses feed scattering and crushing equipment capable of avoiding feed caking in the technical field of feed processing. The feed scattering and crushing equipment comprises a processing cylinder, a first motor seat is arranged in the center of the top of the processing cylinder, a first speed reducer is arranged in an inner cavity of the first motor seat, a first rotating columnis connected with the bottom of the first speed reducer, and the first rotating column penetrates through the first motor seat and the processing cylinder and extends to an inner cavity of the processing cylinder; the periphery of the first rotating column is sleeved with a main gear, matched driven gears are arranged on the left side and the right side of the main gear correspondingly, and rotating rods are inserted and fixed into inner cavities of the two driven gears correspondingly; bearing seats are arranged at the positions, corresponding to the two rotating rods, of the top of an innercavity of the processing cylinder; and the top ends of the two rotating rods are inserted and fixed into inner cavities of the matched bearing seats, and scattering devices are arranged at the bottomsof the first rotating column and the two rotating rods in a sleeving mode. According to the feed scattering and crushing equipment, high-efficiency scattering and crushing treatment can be realized on the feed, a crushing cutter is convenient to disassemble and maintain, and screening treatment can be directly performed after scattering and crushing.

Owner:陈旭城

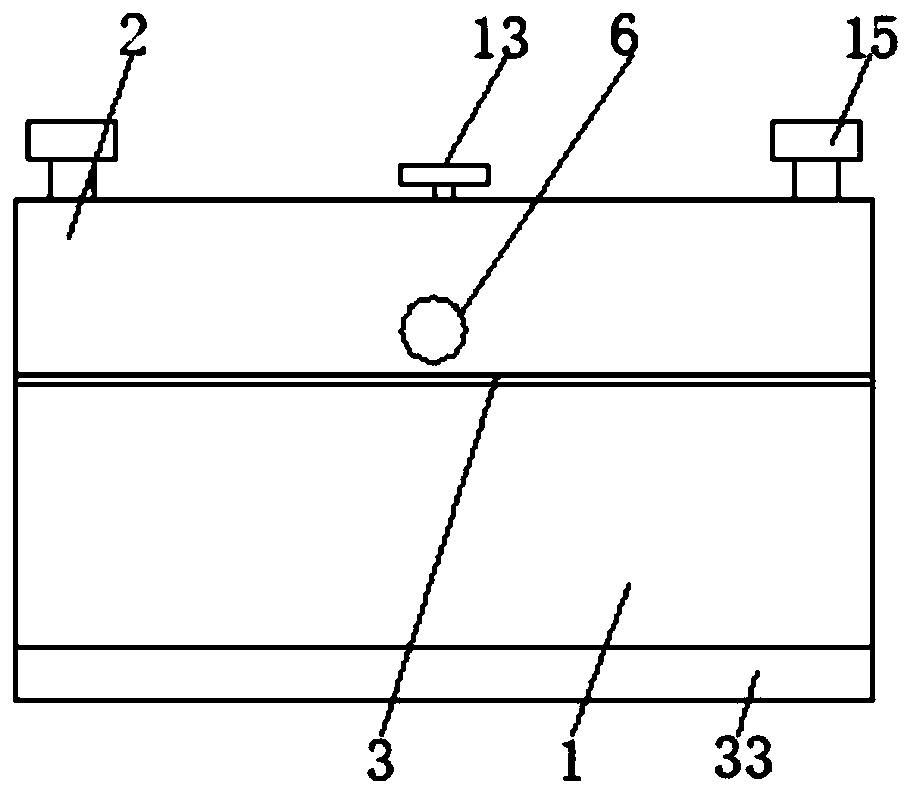

Battery drying device

ActiveCN113280600AHigh degree of automationReduce labor intensityDrying chambers/containersDrying solid materialsElectrical batteryStructural engineering

The invention discloses a battery drying device, and relates to the technical field of batteries.. The battery drying device aims at providing the battery drying device which is high in automation degree and stable and reliable in operation, the battery drying device comprises a tool frame, the tool frame is provided with a plurality of battery placing structures and drying mechanisms matching with a plurality of battery placing structures, the each battery placing structure comprises a driving mechanism and two roller bodies, the two roller bodies are connected to the tool frame in a sliding mode, a first containing gap is formed between the two roller bodies, the driving mechanism is connected to the two roller bodies, the driving mechanism outputs and drives the first containing gap between the two roller bodies to be enlarged, the driving mechanism resets and drives the first containing gap between the two roller bodies to be reduced so as to place a battery, and a second containing gap for placing the battery is formed between the opposite roller bodies of the adjacent battery containing structures. The invention relates to the technical field of batteries.

Owner:ZHEJIANG WANLI UNIV +1

Product molding anti-displacement device for product design and using method thereof

The invention discloses a product molding anti-displacement device for product design and a using method thereof. The product molding anti-displacement device for product design comprises a workbench, a fixing mechanism and an ejection mechanism. The top of the workbench is fixedly connected with a base, the top of the base is fixedly connected with a supporting column, a second push rod is connected in the workbench in a sliding manner, one end of the second push rod penetrates through the workbench and the base and extends into the supporting column to be fixedly connected with a second ejector plate, and the fixing mechanism is arranged at the position, in the supporting column, of the outer side of the second push rod. The product molding anti-displacement device has the beneficial effects that by adding the fixing mechanism, a product can be conveniently positioned and is prevented from deviating in the molding process; by adding the ejection mechanism, the product can be conveniently ejected out rapidly, and the ejection efficiency is improved; by adding limiting blocks and limiting grooves, first sliding blocks can be conveniently limited and prevented from falling off; and by adding second sliding rods, second connecting blocks can be conveniently limited and prevented from moving along with the second push rod.

Owner:田景雯

Plastic injection mold and injection molding method

PendingCN114536691AImprove stabilityImprove molding qualityCoatingsEngineeringInjection molding process

The invention discloses a plastic injection mold and an injection molding method, and belongs to the technical field of injection molds. A plastic injection mold comprises a lower mold base and an upper mold base matched with the lower mold base, the lower mold base and the upper mold base are each provided with a mold cavity, the two mold cavities form a forming cavity used for the injection mold, the upper mold base is provided with a first clamping groove and a second clamping groove, and the upper mold base is further provided with an injection molding opening. A first clamping column and a second clamping column which are matched with the first clamping groove and the second clamping groove correspondingly are arranged on the lower die base, and an anti-loosening mechanism is arranged on the first clamping column and comprises an expanding and supporting assembly and an anti-loosening assembly. According to the injection mold, the stability between the upper mold base and the lower mold base is improved, it is guaranteed that the upper mold base and the lower mold base cannot loosen in the injection molding process, then normal operation of the injection molding process is guaranteed, the forming quality of injection molding products is improved, in the demolding process, the injection molding products can be rapidly ejected out through the ejector rod, and the production efficiency of the injection molding products is improved.

Owner:徐海华

Step-by-step demolding mold

Owner:盐城市金德模具制造有限公司

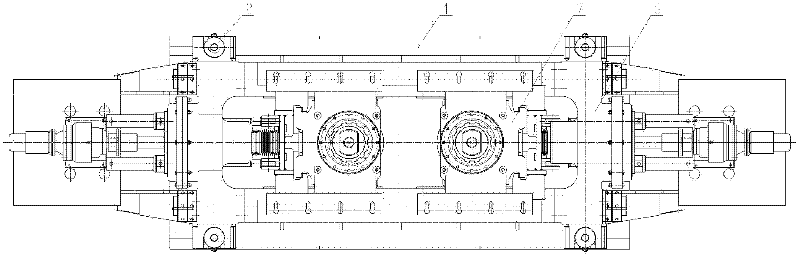

Upsetting forging press and operating method

The invention discloses an upsetting forging press and an operating method. Material ejection servo motors are adopted for driving a material ejection mechanism of the upsetting forging press, and the material ejection mechanism is installed in an integral main die assembly. The integral main die assembly comprises a main die base. A material shearing die installation hole and an upsetting female die installation hole are formed in the main die base. The operating method comprises the steps that feeding is conducted, and displacement all-round material shearing is achieved through horizontal movement of the integral main die assembly; and then upsetting is conducted, and blanks or formed members are ejected out through the material ejection mechanism. According to the operating method, an independent material shearing mechanism is omitted and meanwhile parts in the integral main die assembly can be replaced and adjusted outside a machine body, so that the upsetting efficiency is improved, and the stroke and position of the material ejection mechanism can be adjusted conveniently and flexibly.

Owner:西大(常熟)研究院有限公司

Preparation device and preparation method of nano photocatalytic self-foaming resin cement-based material

The invention relates to a preparation device and a preparation method of a nano photocatalytic self-foaming resin cement-based material. The device comprises a stirring kettle, a material guide pipeis fixedly installed at the bottom end of the stirring kettle, a material storage box is connected to one side of the material guide pipe in an embedded mode, a submersible pump is installed on one side of the interior of the material storage box, a hose is fixedly connected to the top end of the submersible pump, the hose is in embedded connection with the other side of the material storage box,a base is connected to one side of the storage box, a supporting column is fixedly connected to the top end of the base, a bearing plate is welded to the top end of the supporting column, a lower dieis fixedly connected to the top end of the bearing plate, and an upper die is movably connected to the upper end of the lower die. According to the technology that the prepared buoyant raft is used for removing organic compound pollution in a natural water area, a foaming resin material is used for loading a nanometer photocatalyst to form a porous light material, and the material has the advantages of being light in mass, large in specific surface area, low in cost, easy to prepare, capable of being rapidly formed and suitable for various application occasions.

Owner:JIANGXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com