Clamping device for slitting of computer display card cooling fins

A technology of clamping device and heat sink, which is applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems that the clamping stability cannot be guaranteed, the clamping device is not equipped with an ejector device, and the work efficiency is affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

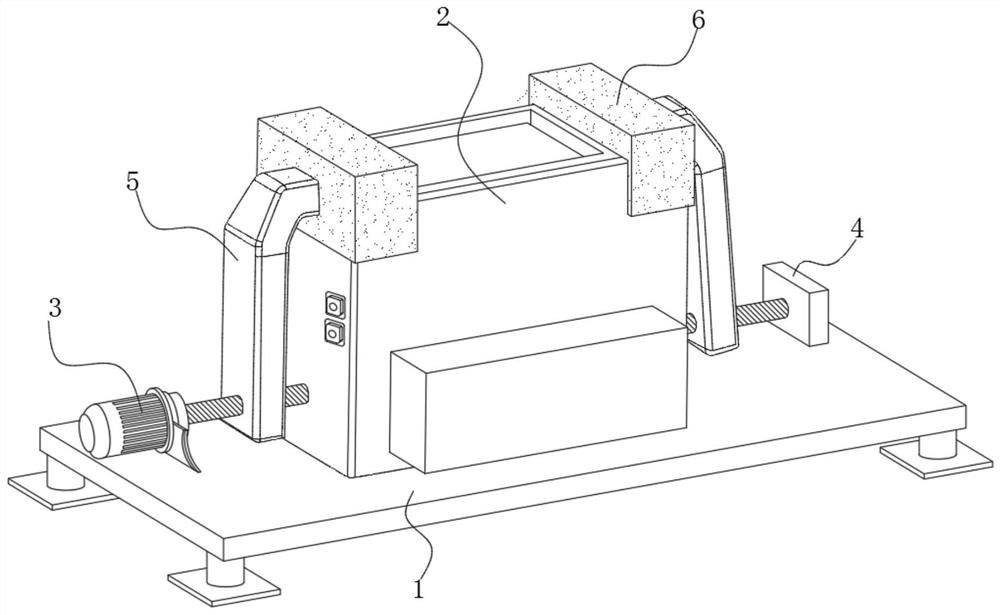

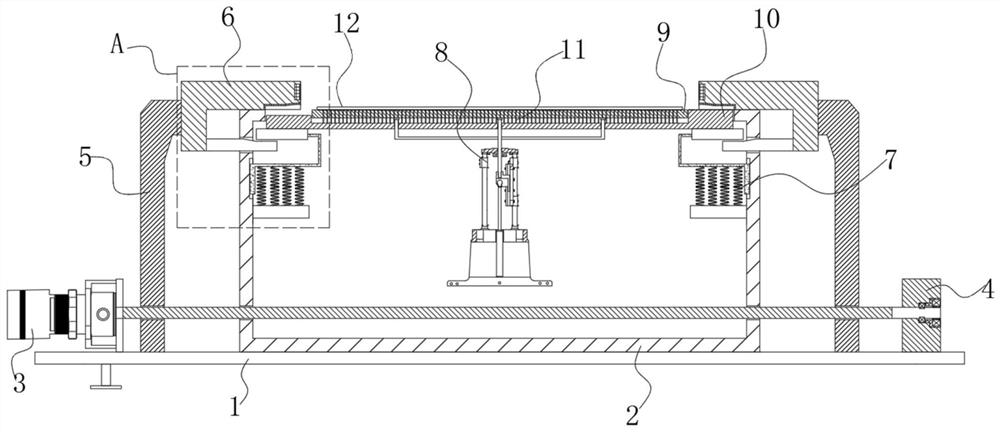

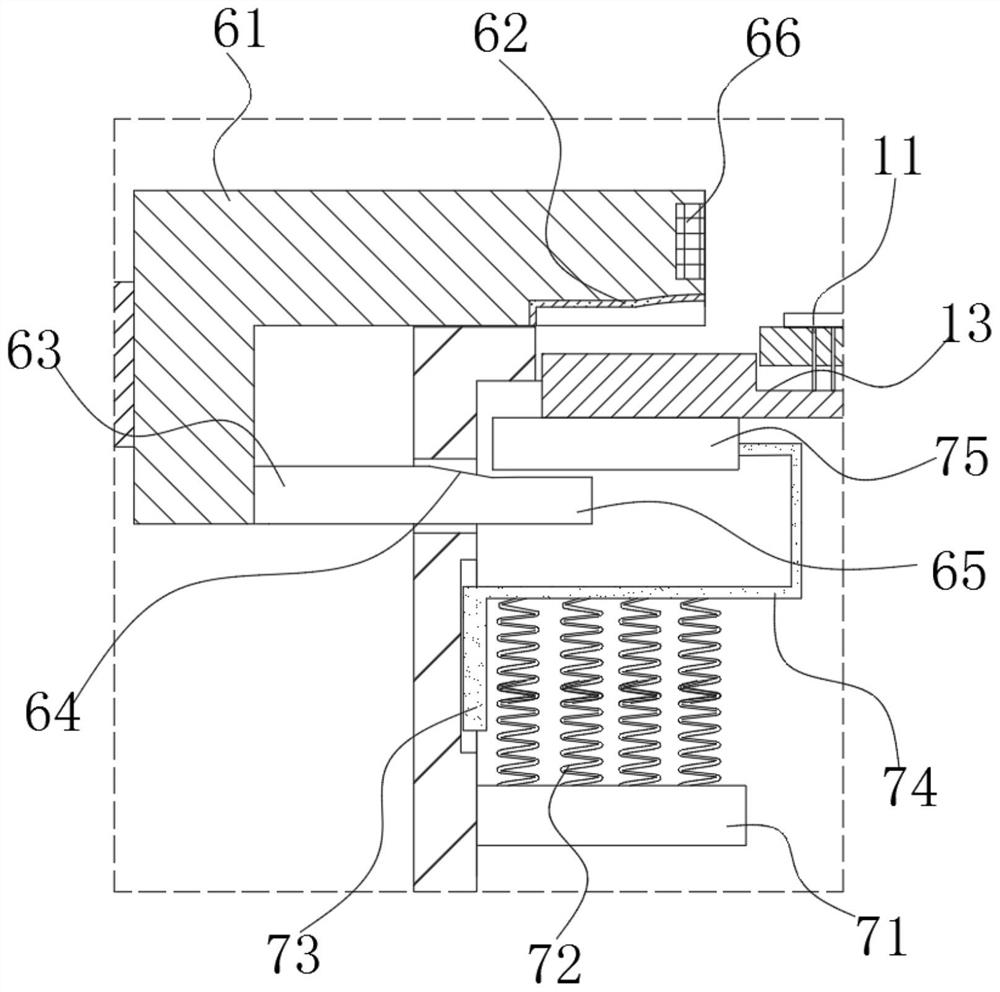

[0032] see Figure 1~4 , in an embodiment of the present invention, a clamping device for cutting heat sinks of computer graphics cards, which includes a base 1, a mounting seat 2, a moving arm 5, a locking assembly 6, a supporting assembly 7 and a processing table 10, wherein the The mounting seat 2 is fixed on the base 1, and the mounting seat 2 is a cavity structure, and an opening is provided on the top thereof for the processing table 10 to move up and down along the opening;

[0033] Wherein, the middle part of the processing table 10 is provided with an accommodating groove 13, and the bottom of the accommodating groove 13 is uniformly arranged with a vertically placed pit-shaped needle 11, and the top of the pit-shaped needle 11 is spherical, And it is used to place the heat sink 12 to be cut;

[0034] Both sides of the mounting base 2 are symmetrically provided with moving arms 5 capable of horizontal displacement, and each of the moving arms 5 is provided with a loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com