Patents

Literature

116results about How to "Avoid sticky situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft start charging circuit and control method thereof

ActiveCN104748288AExtended service lifeAvoid impact damageMechanical apparatusSpace heating and ventilation safety systemsElectrical resistance and conductanceElectricity

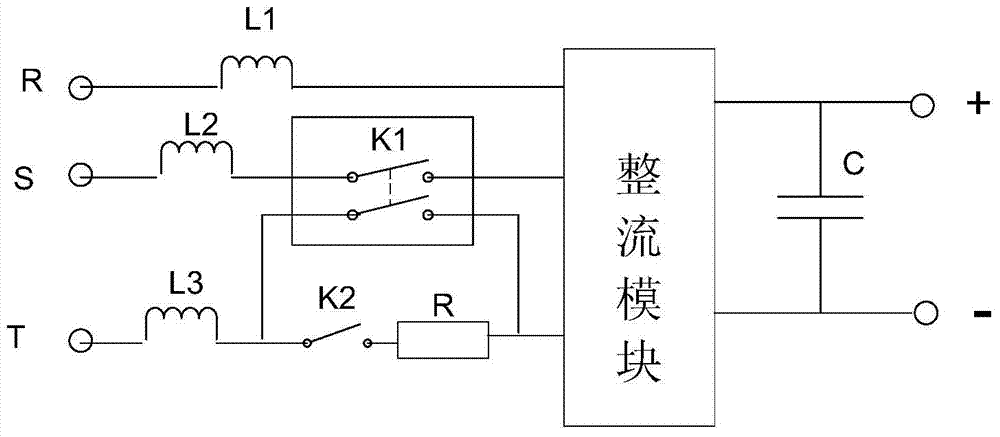

The invention provides a soft start charging circuit, which comprises a controller, a first relay, a second relay and a charging resistor, wherein both the first relay and the second relay are electrically connected with the controller; the first relay comprises two contacts namely the first contact and the second contact; the contact of the second relay is connected in series with the charging resistor and then connected in parallel with the first contact; and the contact of the second relay and the second contact are respectively connected in series with different input ends of a three-phase alternating current power supply. The invention further relates to a control method of the soft start charging circuit. According to the soft start charging circuit and the control method thereof, the two relays are respectively placed between any two phases of the input side of the three-phase alternating current power supply, so that operation is simple and convenient. A primary surge current and a secondary surge current are effectively inhibited, and the impact damage of the surge currents to circuit devices is avoided. Meanwhile, the service lives of the relays are prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

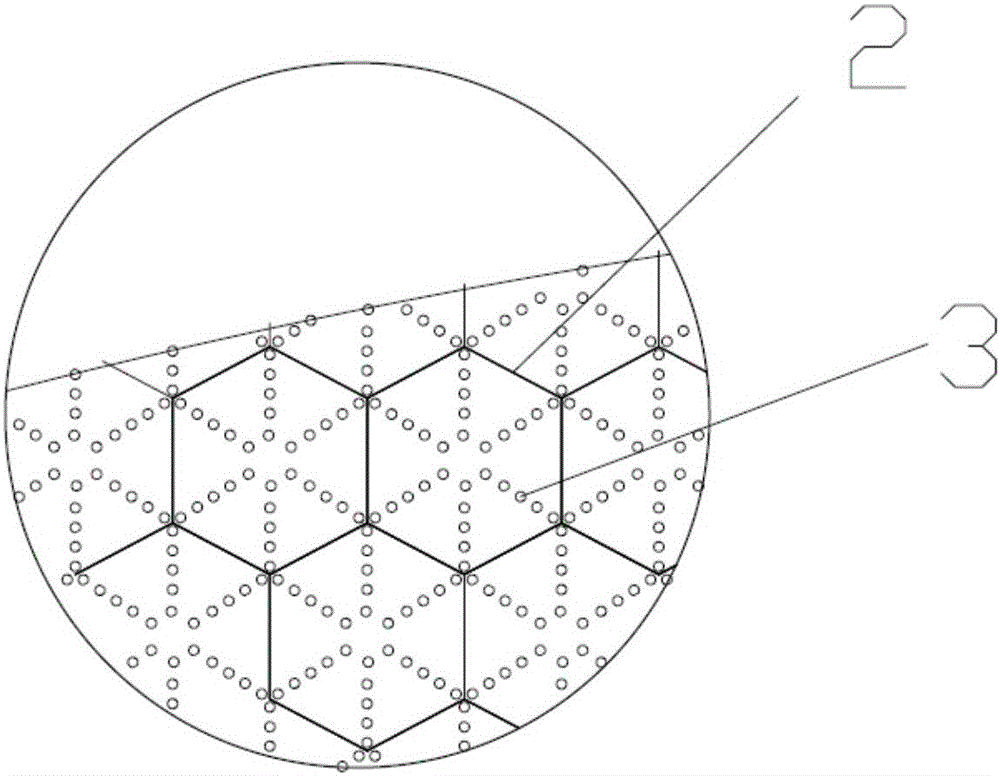

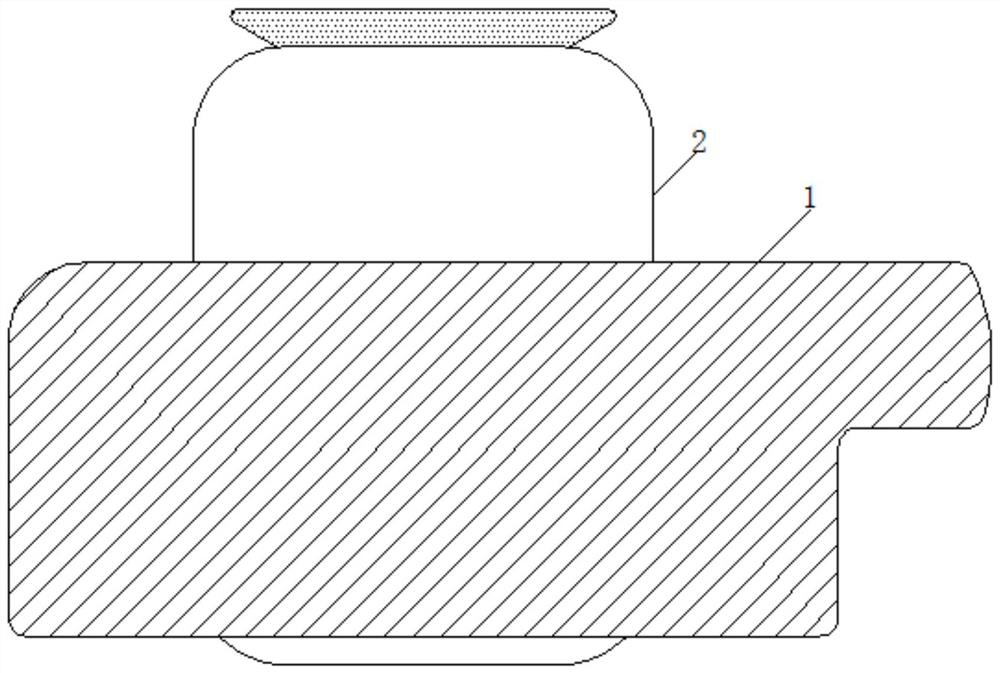

Honeycomb coating non-stick marmite

InactiveCN105768852AEvenly heatedImprove energy efficiencyCooking-vessel materialsCooking vessel constructionsHoneycombHoneycomb Pattern

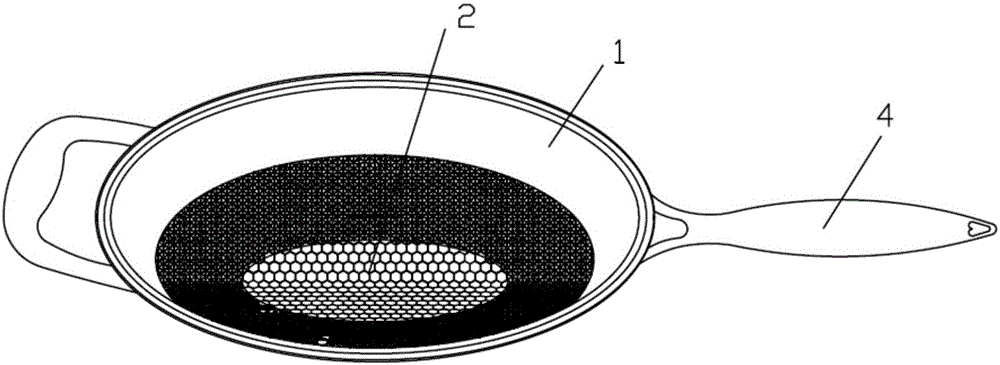

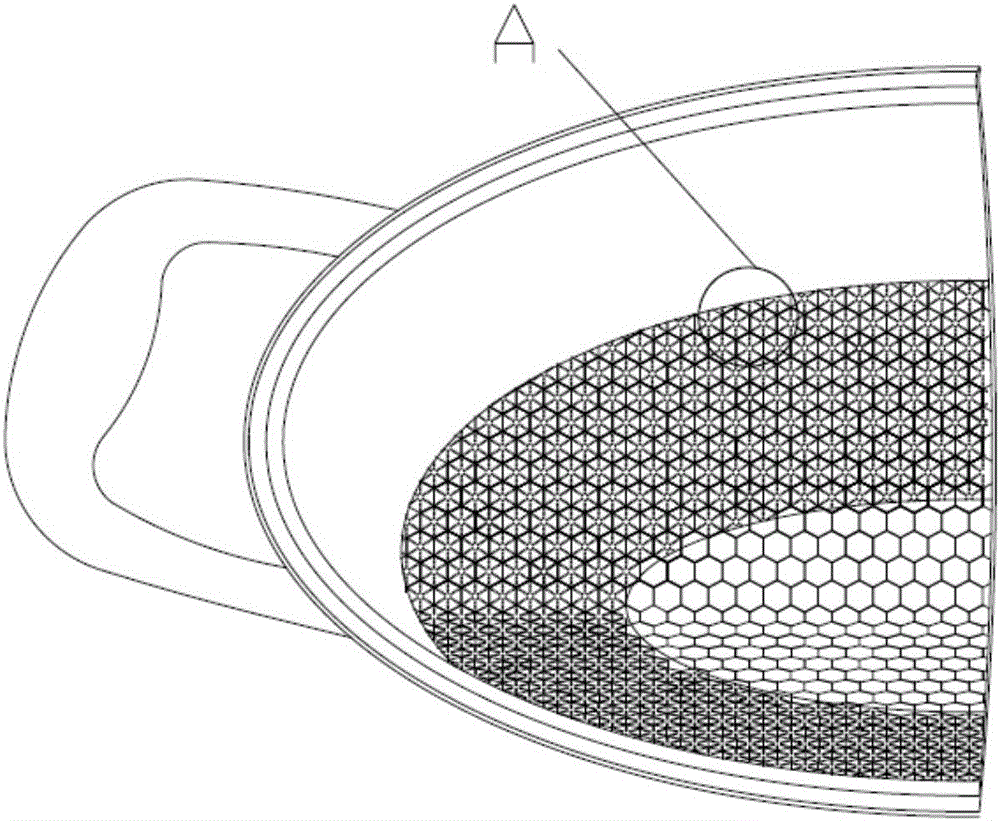

The invention discloses a honeycomb coating non-stick marmite which comprises a marmite body, and a pattern formed on the inner side of the marmite body through an etching process.The pattern at least comprises a honeycomb pattern body at the bottom of the inner side of the marmite body.The inner layer and the outer layer of the marmite body are coated with non-stick coating layers.By arranging the honeycomb pattern body at the bottom in the marmite body and the non-stick coating layers on the inner side and the outer side of the marmite body, the marmite body is evenly heated, energy efficiency is high, energy is saved, it is avoided that when a user uses the marmite, food sticks to the marmite, and the marmite is convenient to clean, not prone to oil splash during cooking and safer.

Owner:SUZHOU JIAYI STAINLESS STEEL PROD

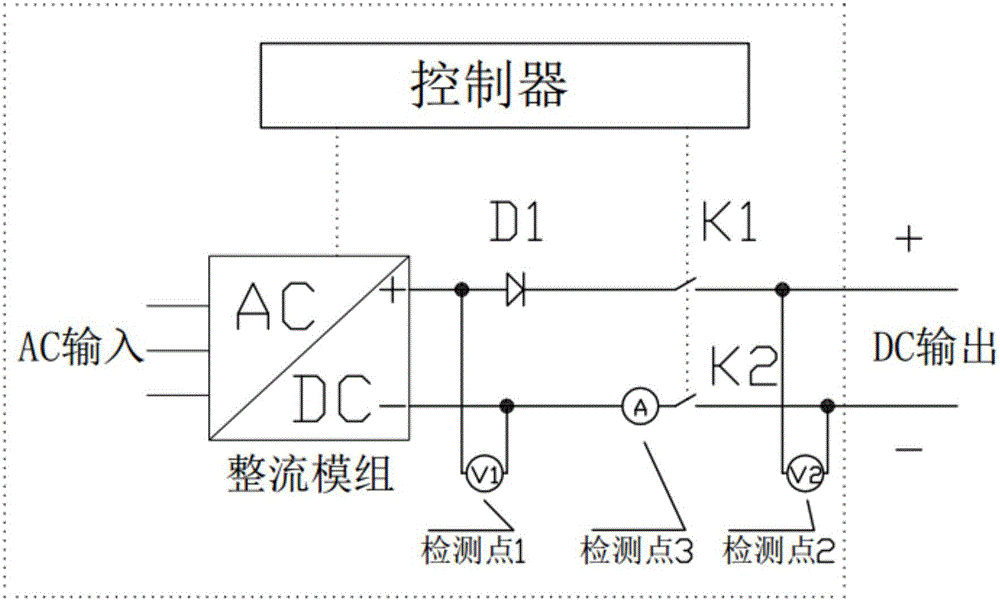

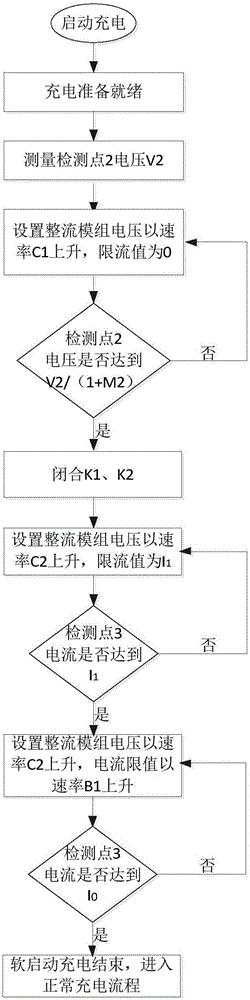

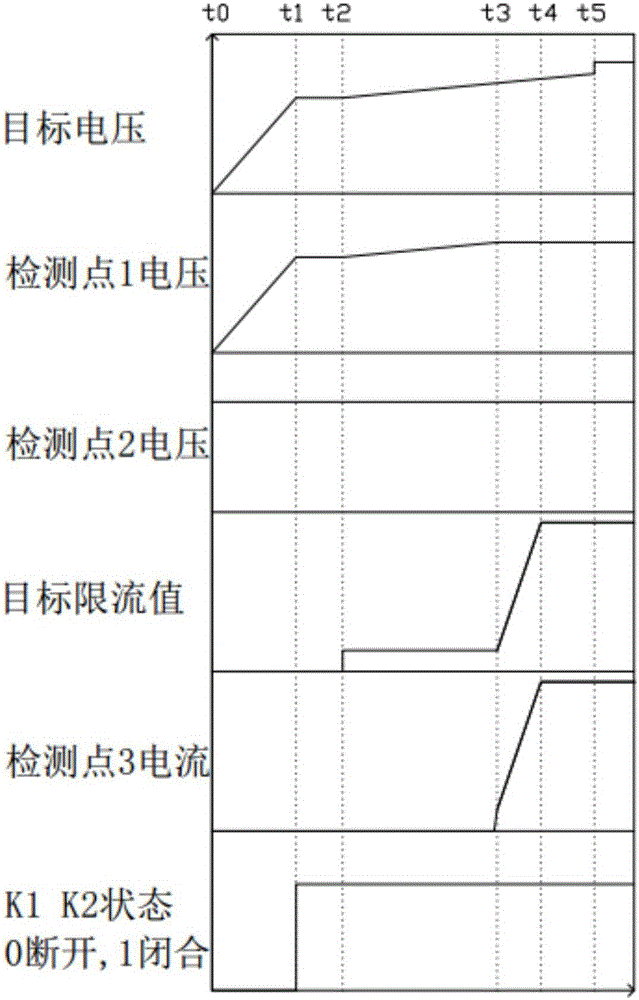

Soft starting circuit, soft starting method and DC charging pile

ActiveCN106505846AAvoid damageAvoid sticky situationsBatteries circuit arrangementsCharging stationsElectrical batteryElectrical devices

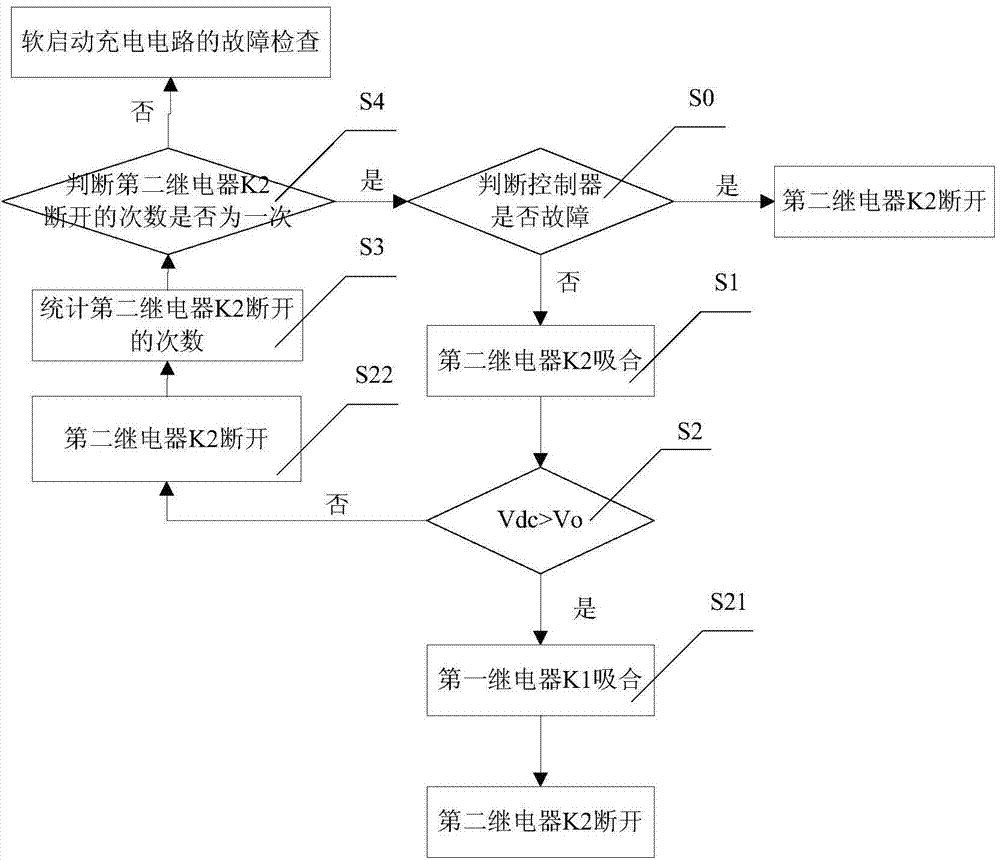

The invention provides a soft starting circuit, a soft starting method and a DC charging pile. The soft starting circuit comprises a controller, a rectifying module, a first switch, a second switch and a backflow prevention diode, wherein the controller acquires measured values of three detection points in real time, and obtains charging voltage and current information of a battery pack from a vehicle battery management system BMS; the first detection point detects voltage between a positive output end and a negative output end of the rectifying module, the second detection point detects voltage between output positive and negative ends of the charging pile, and the third detection point detects output current of the charging pile and the rectifying module; and the controller adjusts the output voltage and current of the rectifying module and controls the on-off time sequence of the first switch and the second switch, so as to avoid the occurrence of surge current in the process of starting the charging. The soft starting circuit, the soft starting method and the DC charging pile effectively suppress the surge current at the time of starting the charging, avoid the damage to electrical devices caused by the impact of the surge current, and avoid the adhesion of contacts of the switching devices through controlling the time sequence of the switching devices.

Owner:SHANGHAI ENNEAGON ENERGY TECH CO LTD

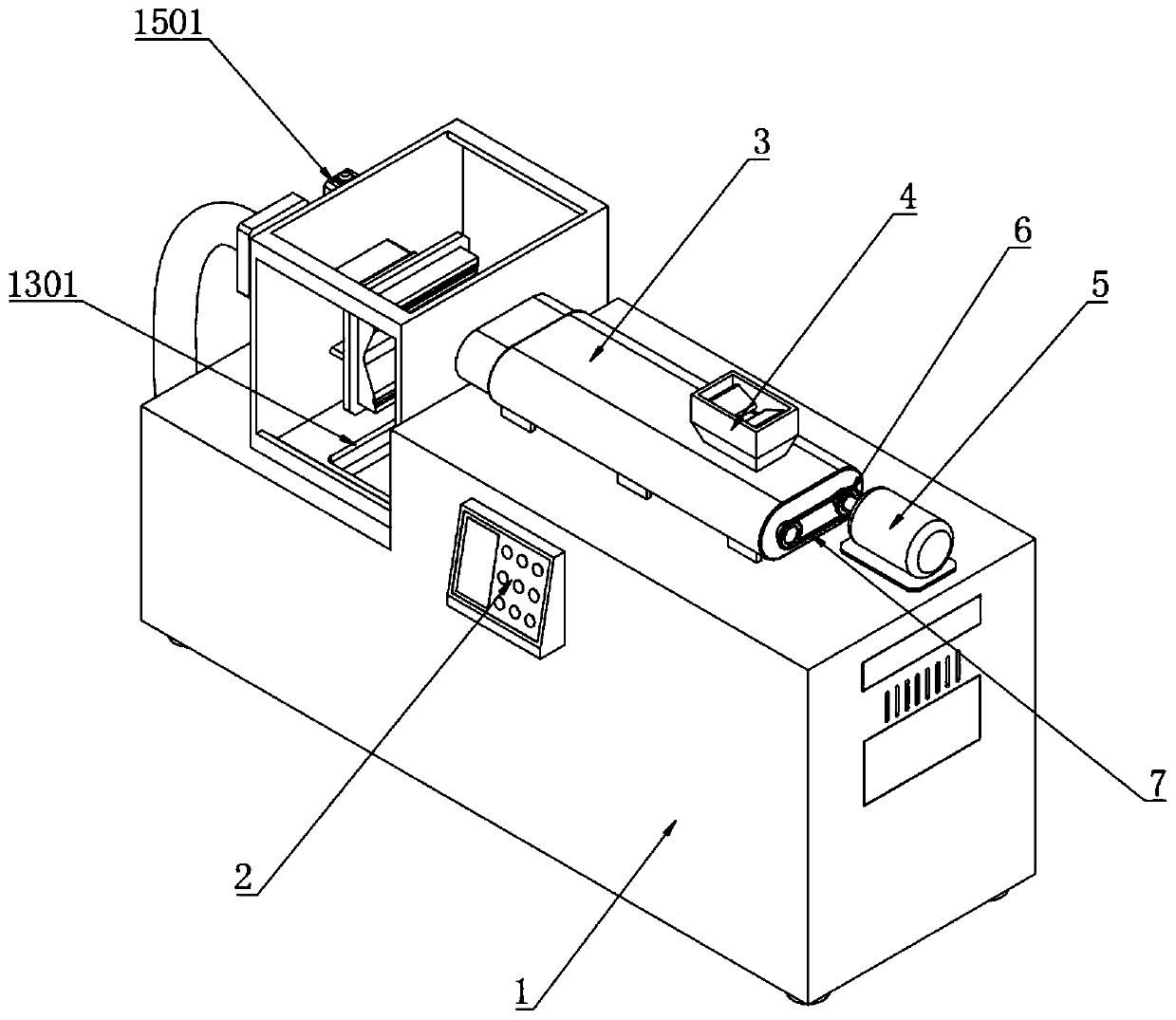

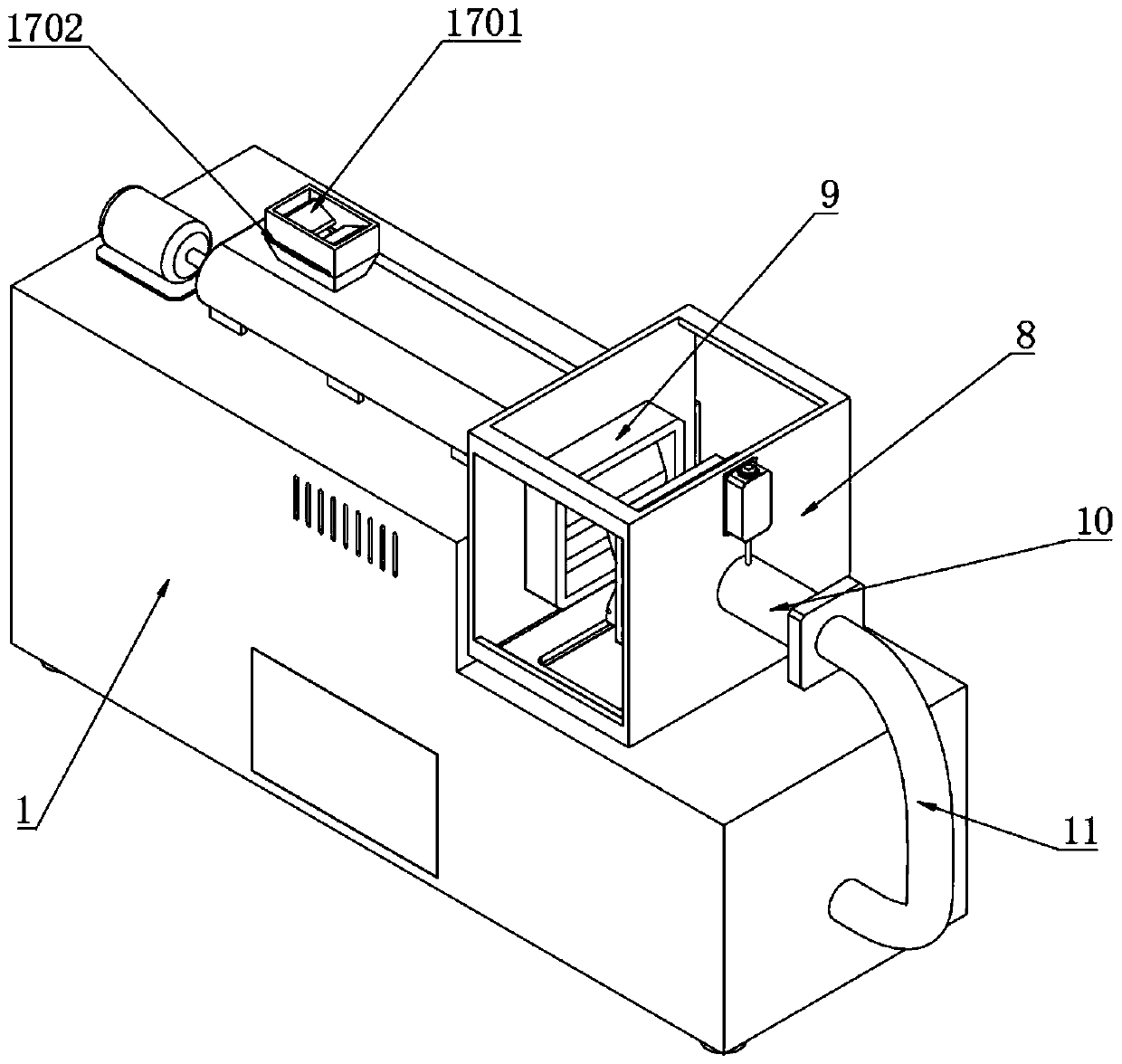

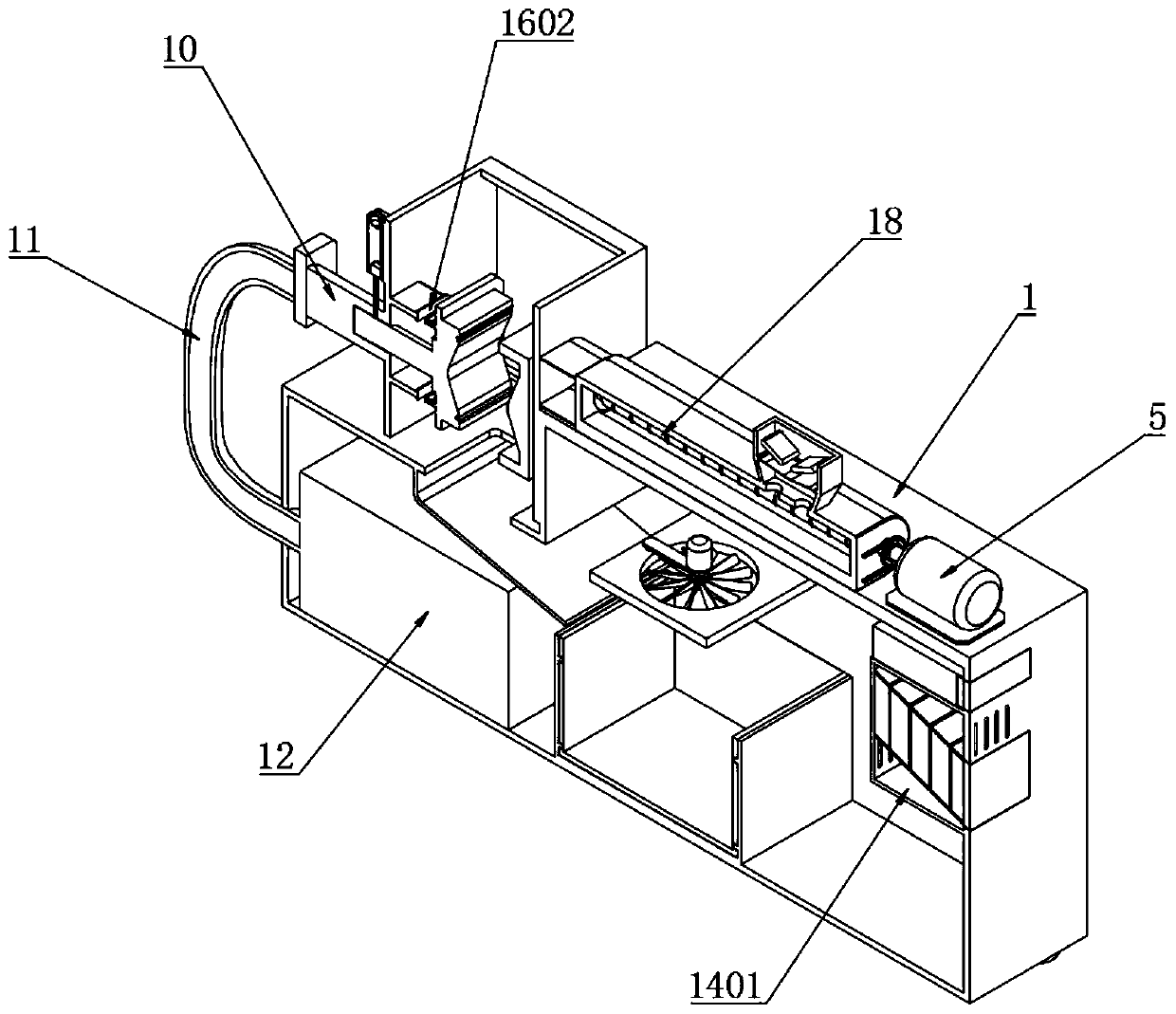

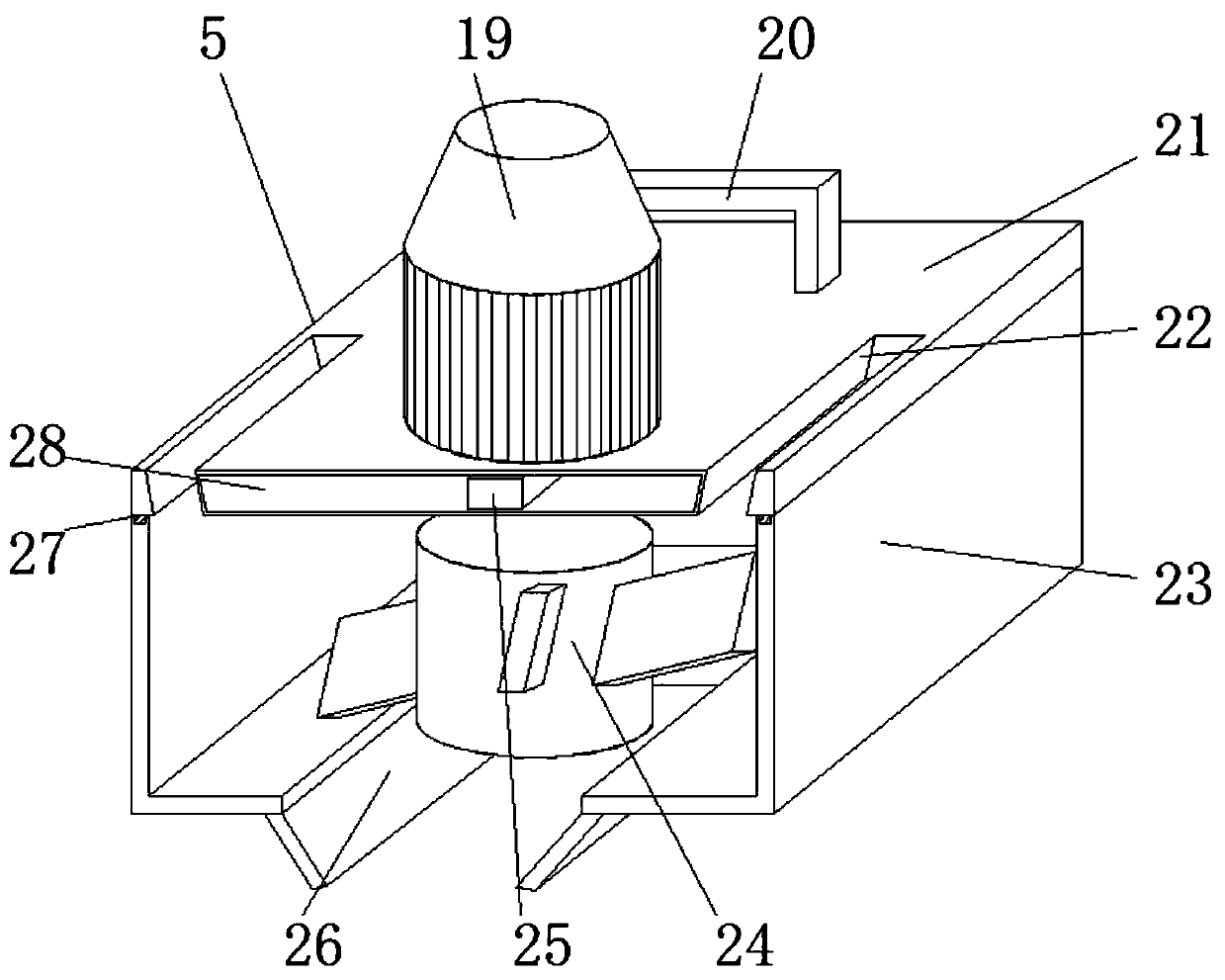

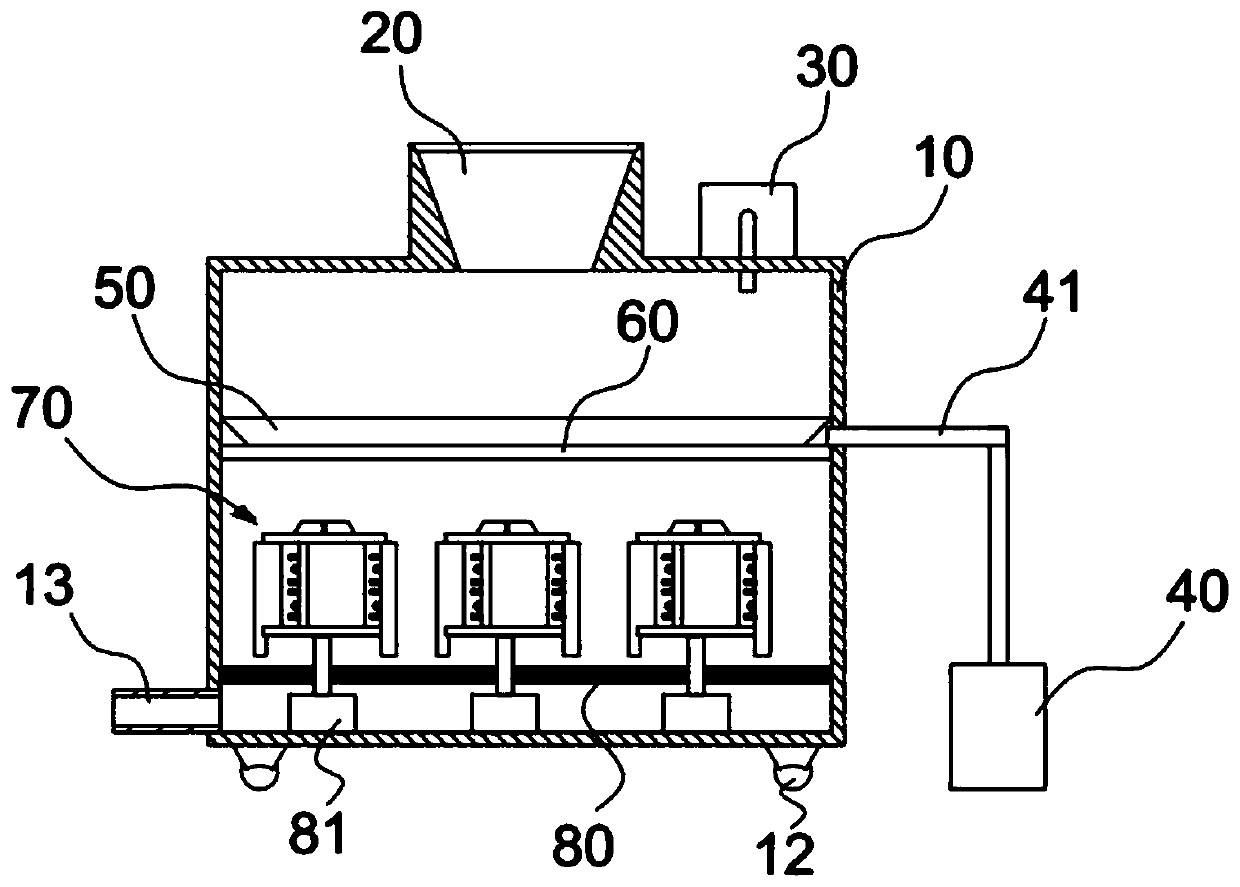

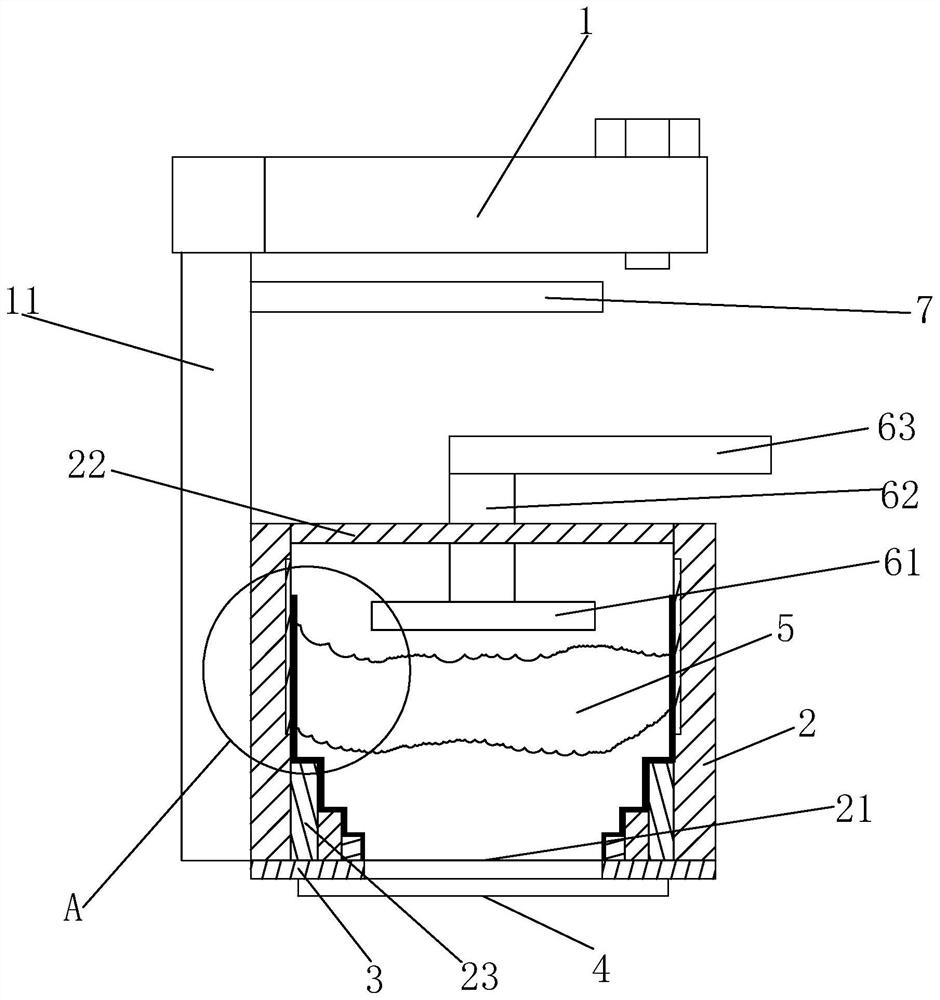

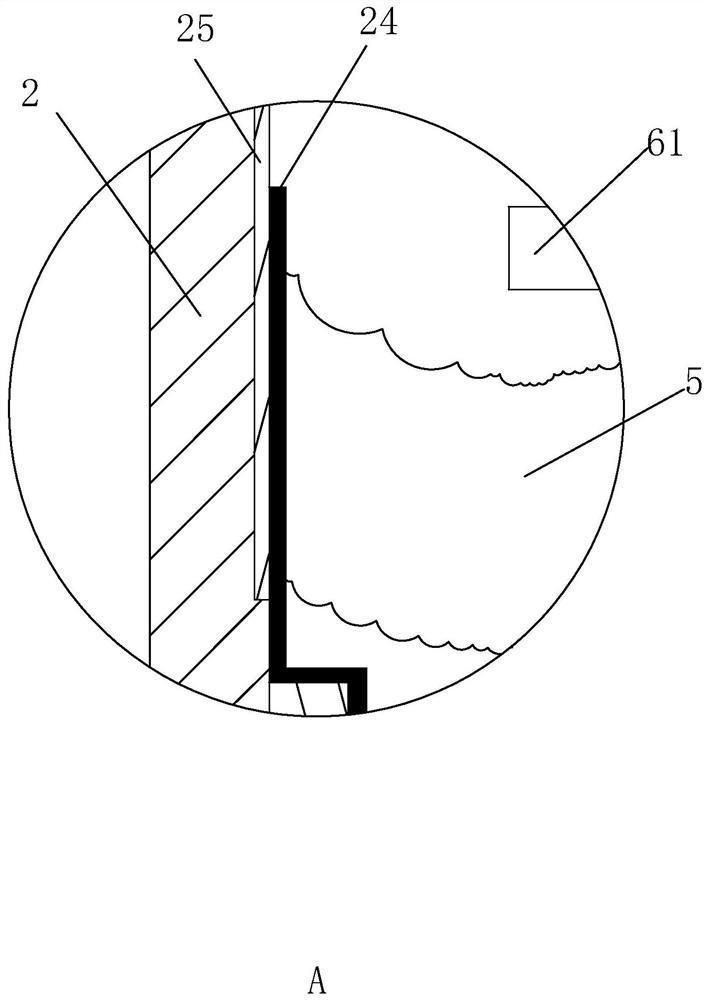

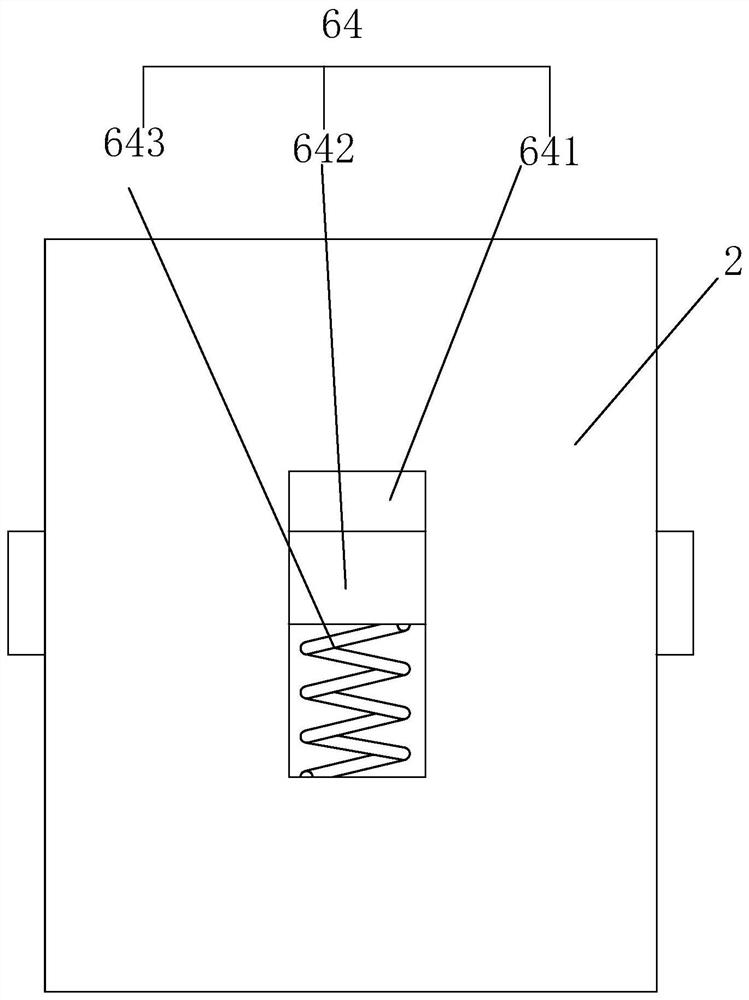

High-efficiency energy-saving type double-screw automatic injection molding machine

InactiveCN111196019AScientific and reasonable structureEasy to useActivated carbonActivated charcoal powder

The invention discloses a high-efficiency energy-saving type double-screw automatic injection molding machine. The high-efficiency energy-saving type double-screw automatic injection molding machine comprises an injection molding box body, one end of the injection molding box body is fixedly provided with a control switch, and the top end of the injection molding box body is connected with an injection molding bin; and the top end of the injection molding bin is connected with a feeding bin. The high-efficiency energy-saving type double-screw automatic injection molding machine is scientific and reasonable in structure, and safe and convenient to use, by arranging a leakage hole, a guide plate, a storage hopper, a cooling fan and a detachable cover, the situation that workpieces adhere toone another because of being overheated can be avoided, the stored workpieces can be quickly taken out, and cooling storage and quick taking out of the workpieces subjected to injection molding are facilitated; by arranging an air exchange fan, air extract holes, an air exchange bin, activated carbon powder bags and an air exhaust hole, air in the injection molding box body can be extracted into the air exchange bin, peculiar smell in the air is absorbed through the activated carbon powder bags, the peculiar smell generated during injection molding can be conveniently absorbed, and the situation that the peculiar smell during injection molding is strong, and the physical health of a user is influenced is avoided.

Owner:山东嘉励智能科技有限公司

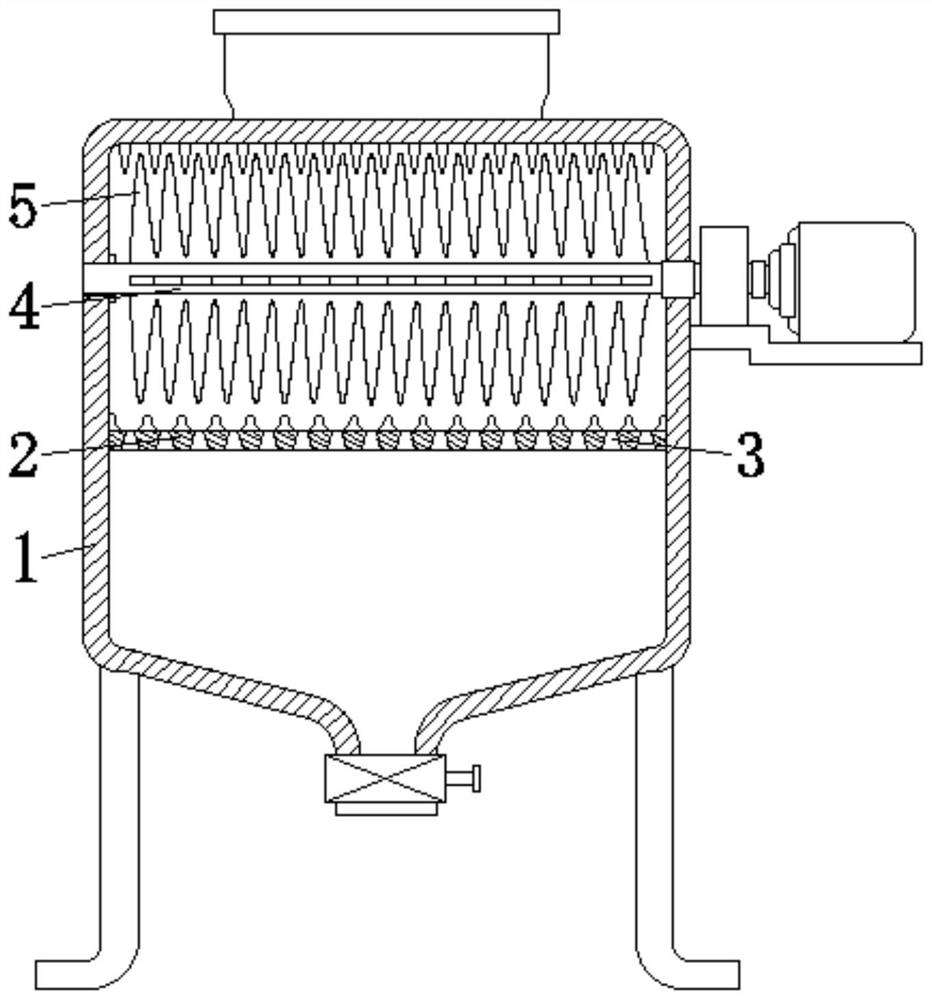

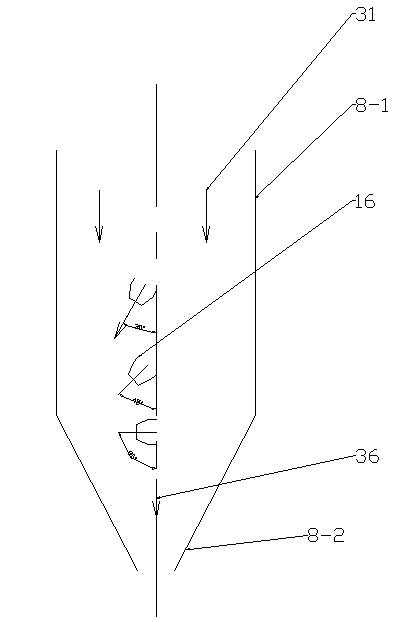

Smashing device for rubber processing with duplex cooling effect

InactiveCN111791386AReduce the temperatureAvoid affecting the crushing operationDielectric plateCooling effect

The invention relates to the technical field of rubber, and discloses a smashing device for rubber processing with a duplex cooling effect. The smashing device comprises an outer shell. A smashing chamber is fixedly connected into the outer shell. According to a principle of a vortex tube, the temperature of a cutter is lowered when rubber is smashed by the cutter, and therefore it is avoided thatdue to long-time friction between the cutter and the rubber, the temperature of the cutter is raised, the cutter adheres to the rubber and the smashing operation is affected; and under the common action of a main disc, a blade, the vortex tube, a hot air pipeline, a cylinder, a dielectric plate and a pole plate group, with the aid of hot air flow generated by the vortex tube, the dielectric constant is changed, a power source is provided for the cooling operation of the rubber, the linkage between structures is increased, the rubber is automatically cooled, and it is avoided that a rubber section is molten due to an excessively high temperature of the cutter and cut rubber granules adhere to one another to form oversized rubber granules and reduce the rubber smashing quality.

Owner:赵艳花

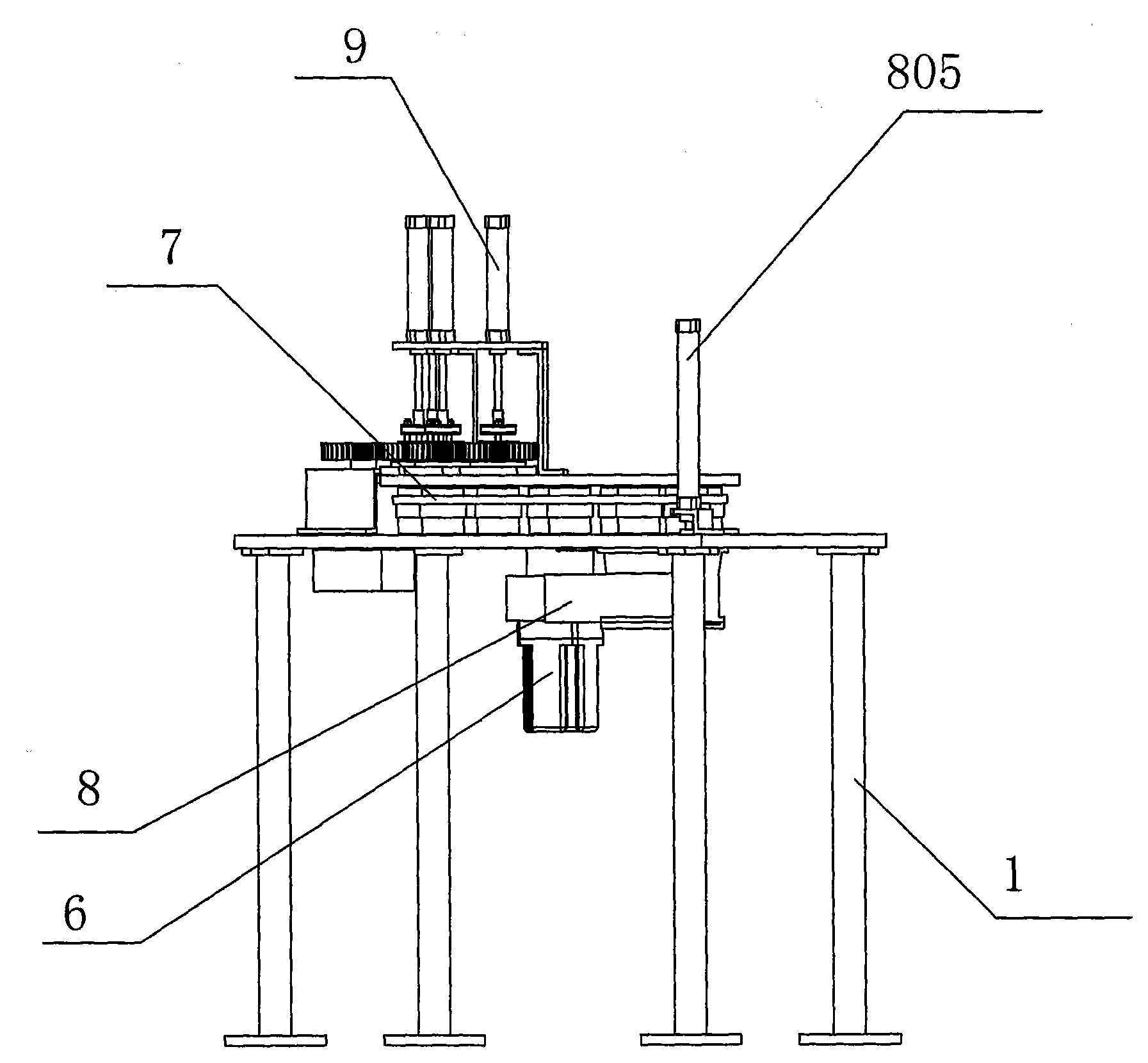

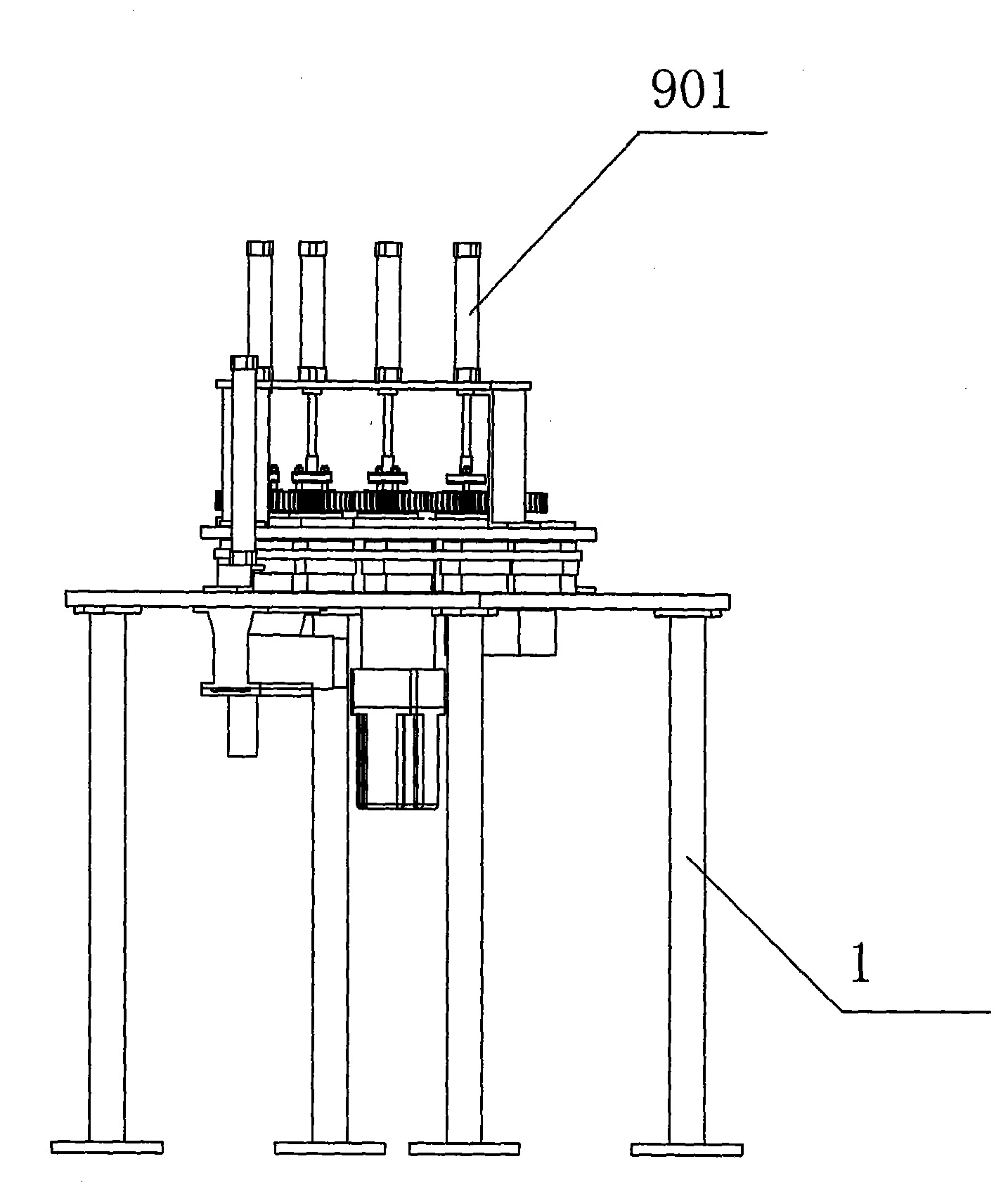

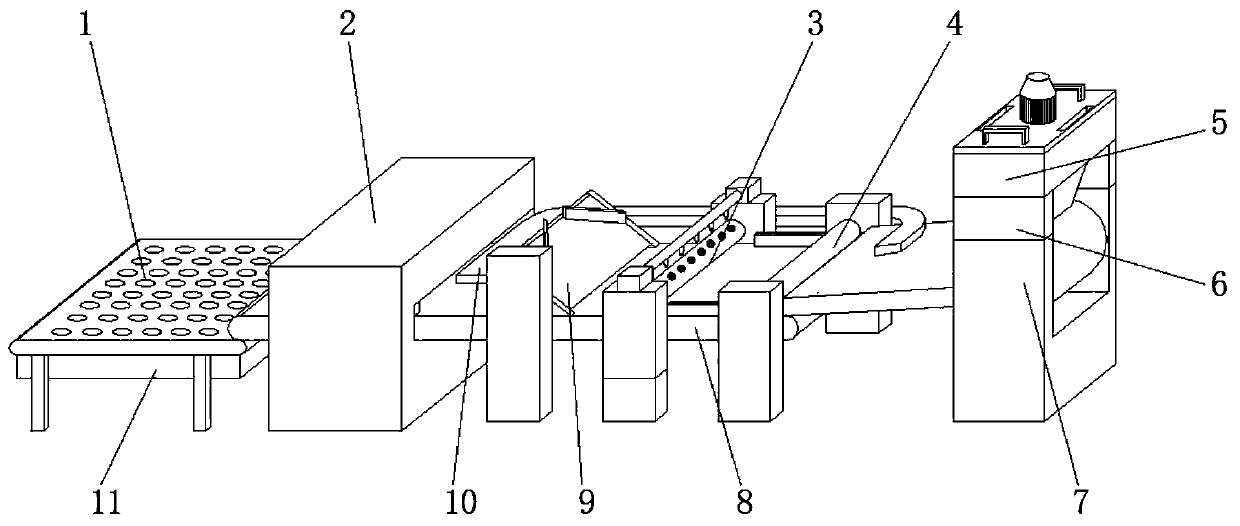

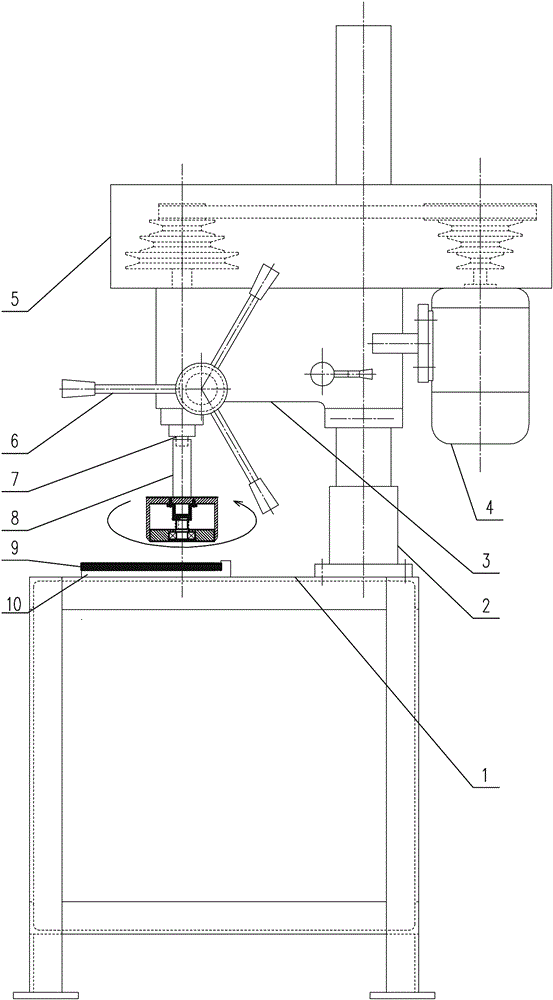

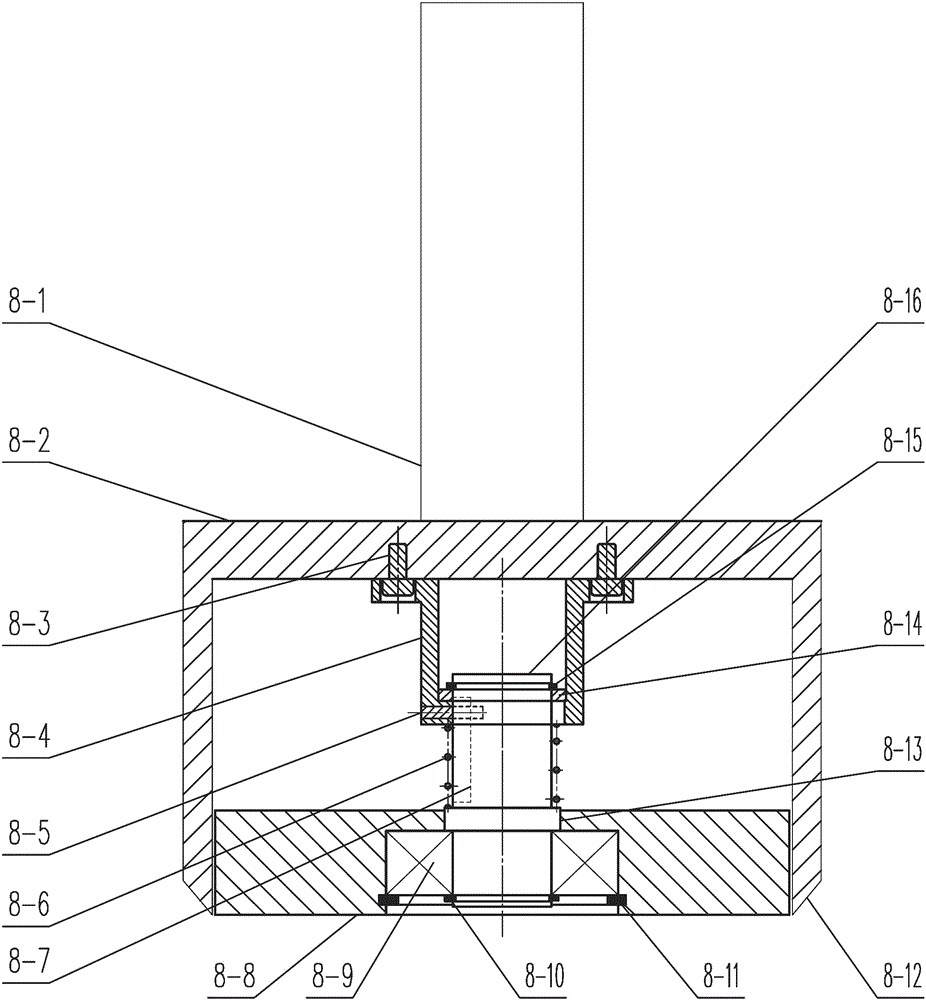

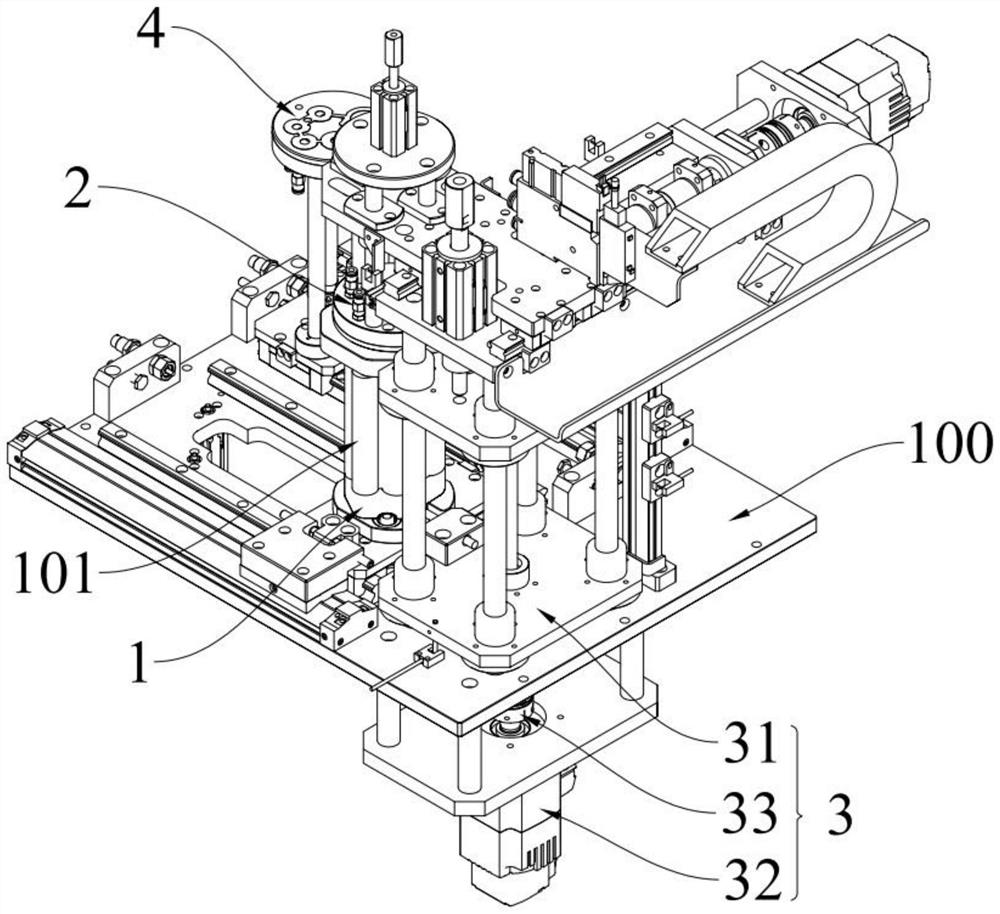

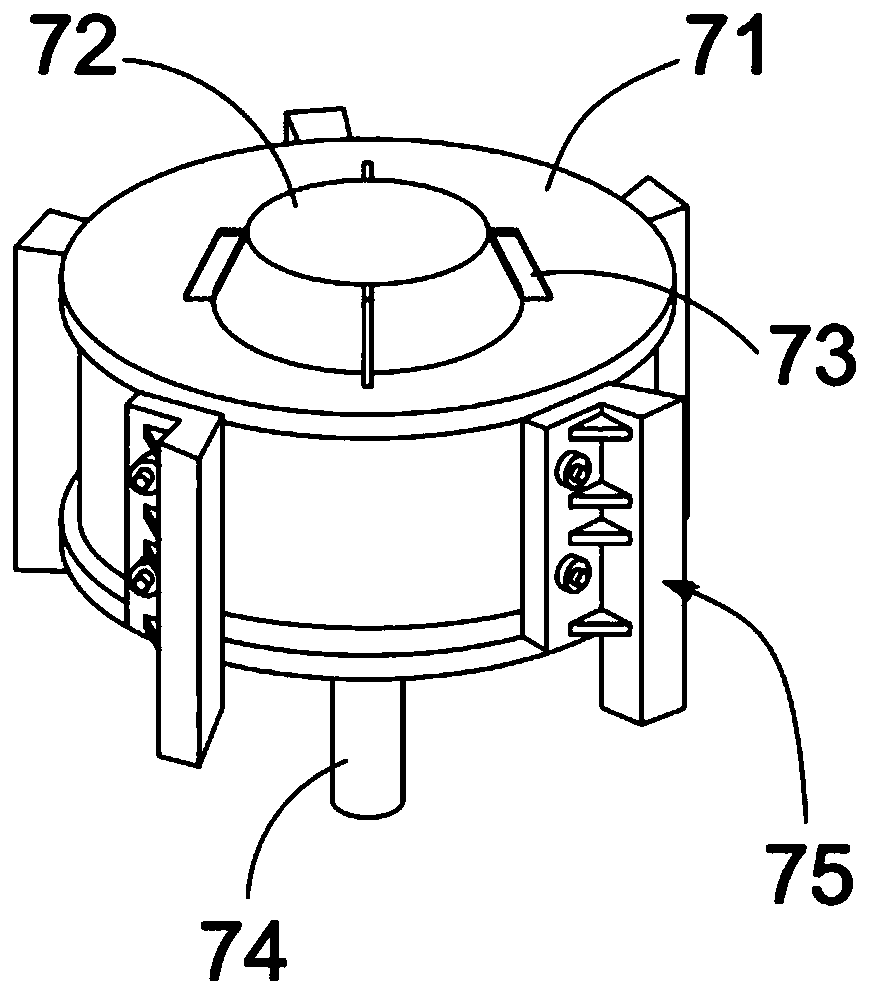

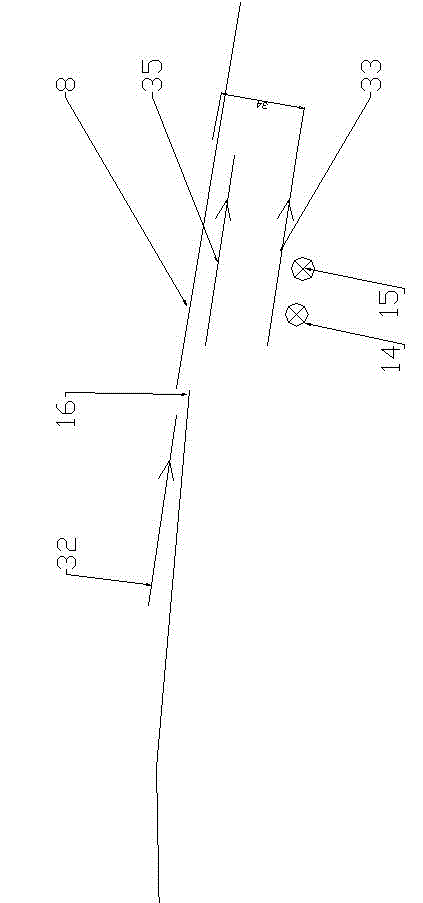

Fish-roe packaging feeding device and method

ActiveCN104369886AAvoid sticky situationsAccurate measurementLiquid materialEngineeringFood packaging

The invention discloses a fish-roe packaging feeding device and method, and belongs to the technical field of food packaging measuring and feeding. The fish-roe packaging feeding device comprises a material stirring system, an installation table top, a lifting air cylinder fixing frame, a rotating disc motor, a rotating disc, a measuring cup set and a material discharging shaping system. The material stirring system comprises two to six material stirring structures, and each material stirring structure comprises a lifting air cylinder, a driven gear and a pair of stirring paddles; a material feeding opening, an oil feeding opening and a reserved hole are sequentially formed in the edge of the installation table top; the upper portions of the lifting air cylinders are installed on the lifting air cylinder fixing frame; the rotating disc is connected between the installation table top and a table top; the measuring cup set comprises six to eighteen measuring cups which are fixedly installed in the edge of the rotating disc; the material discharging shaping system is arranged on one side of the reserved hole. The invention further discloses the fish-roe packaging feeding method, the fish-roe packaging feeding device is adopted, and the fish-roe packaging feeding method includes the steps of adding materials, then adding oil and auxiliary materials, carrying out layered even stirring, and carrying out discharging and shaping. The fish-roe packaging feeding device and method have the advantages that the materials are not pasted, measuring errors are avoided, packaging and bag entering are easily implemented, and the production efficiency is high.

Owner:RUIAN GUCHUAN PACKAGING MACHINERY CO LTD

Fully automatic biscuit production line and production process thereof

The invention provides a fully automatic biscuit production line and a production process thereof. The fully automatic biscuit production line comprises a twisting device, wherein the twisting devicecomprises a twisting device main body, a stirring box, a position limiting block, a second motor, a conveying belt, blades, a movable baffle plate, a movable push button and a spring; the second motoris fixedly arranged inside the twisting device main body; the stirring box is rotationally connected with the middle part of the twisting device main body; the conveying belt is arranged under the stirring box; the blades are fixedly connected with the inner wall of the stirring box; the movable baffle plate is elastically connected inside the stirring box through the spring; the movable push button is arranged on the edge of the upper surface of the movable baffle plate; the upper end surface of the twisting device is fixedly connected with a connecting plate; and the upper end surface of the connecting plate is fixedly connected with a stirring device. The fully automatic biscuit production line and the production process have the advantages that the biscuit production line flow processis optimized, so that the production line realizes high automation; and meanwhile, the production efficiency and the production quality are improved.

Owner:GUANGDONG XINMENG FOOD

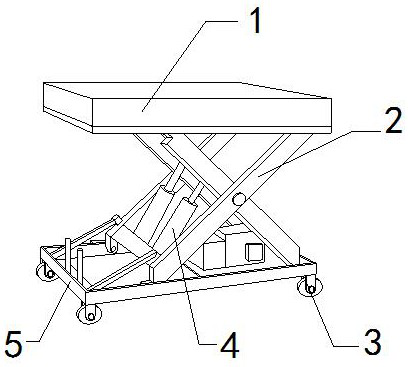

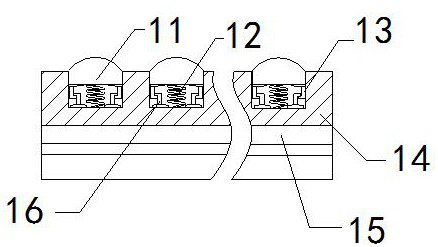

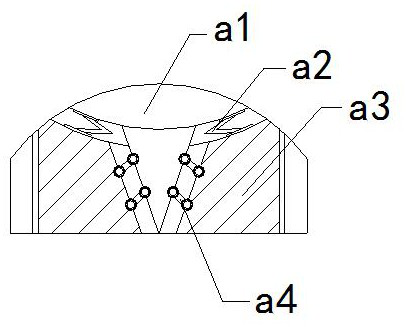

Transportation cargo selection platform

ActiveCN111825013AReduce contact areaAvoid sticky situationsLifting framesHand carts with multiple axesMarine engineeringCarton

The invention discloses a transportation cargo selection platform which structurally comprises a cargo selection table, a telescopic frame, moving wheels, a hydraulic push rod and a base. The telescopic frame and the base are connected through a hinge. The moving wheels and the base are movably clamped. The hydraulic push rod and the telescopic frame are connected. The cargo selection table and the telescopic frame are connected in an embedded manner. Through extrusion generated by a carton placed on the upper surface of the cargo selection table and containing seafood to an elastic strip, theelastic strip slides downwards along the plate face to contract, and therefore the contact area of the bottom of the carton and the upper surface of the cargo selection table can be reduced, and thesituation that the ice face adheres to the bottom of the carton is effectively avoided; and through extrusion generated by the carton containing seafood to a force bearing plate on a bottom plate, theforce bearing plate can descend to contract, and therefore a pressure application block on the force bearing plate can extrude an extrusion block, an outward push block can stretch out along a framework, and the outward push block can push down ice columns formed on the outer surface of the bottom plate.

Owner:河南联农科技有限公司

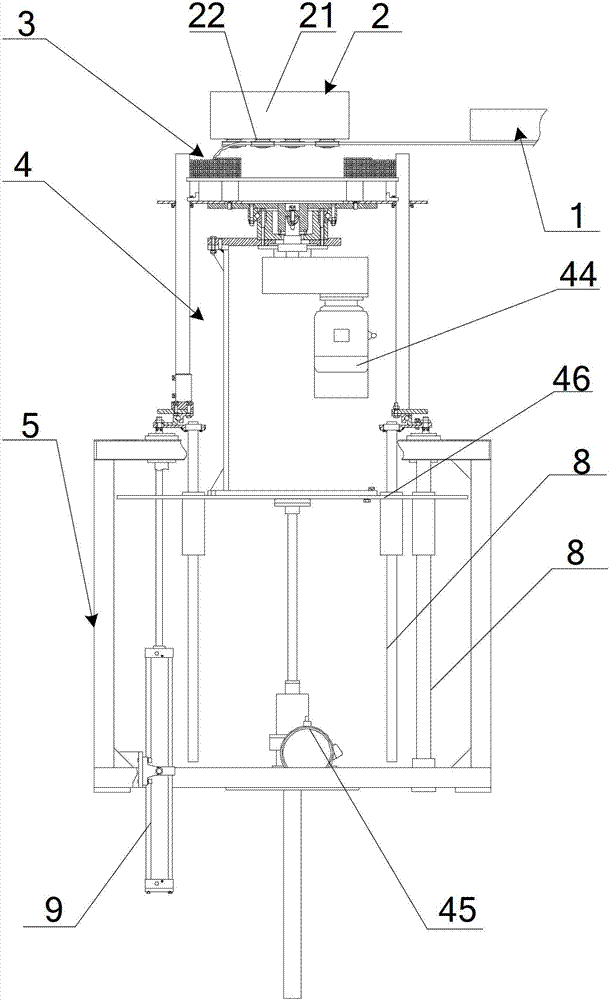

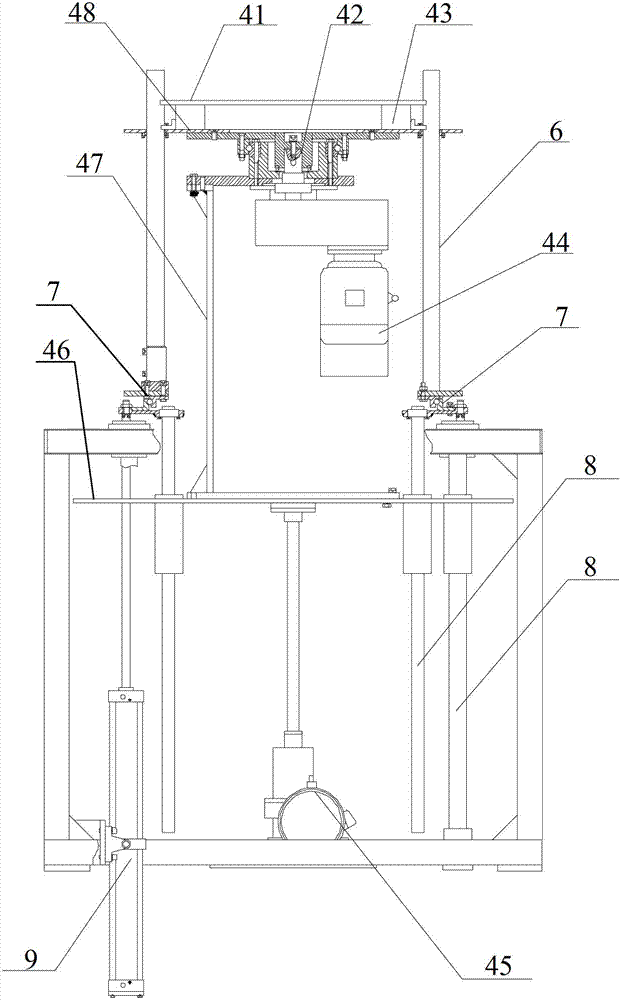

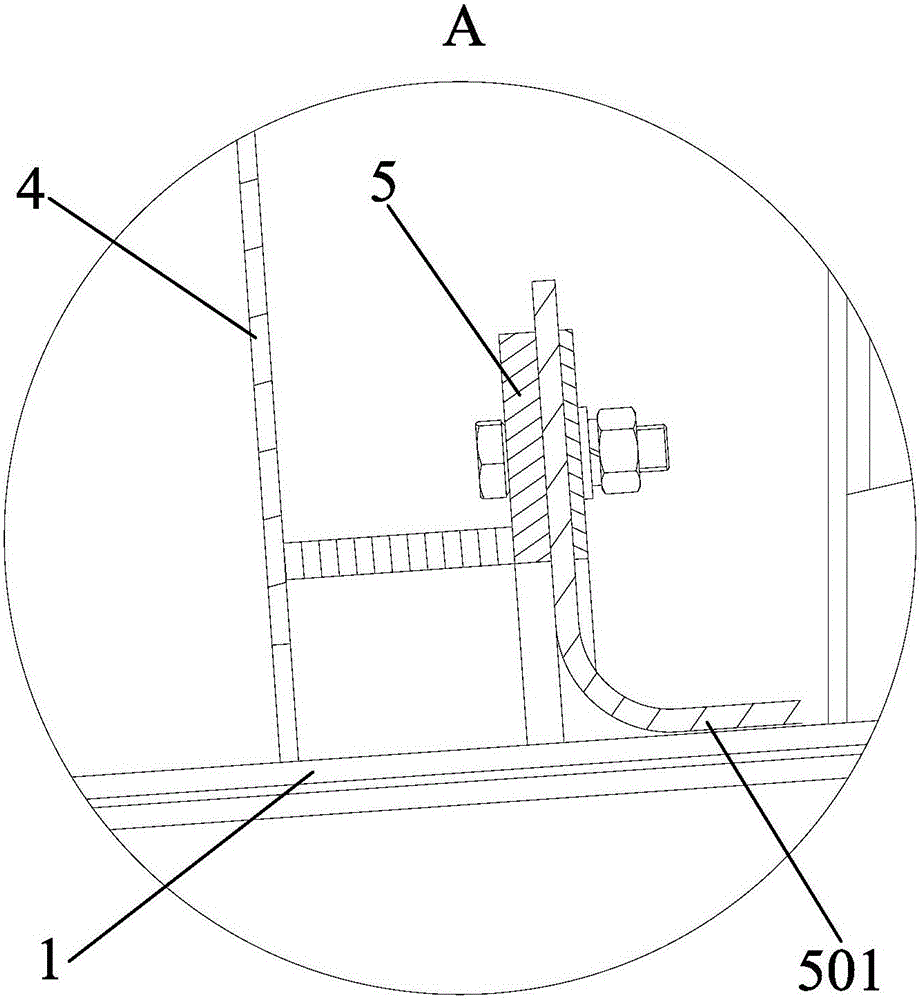

Rolling device

The invention discloses a rolling device which comprises a conveying mechanism (1), a take-up mechanism (4) and a base (5), wherein the conveying mechanism (1) is used for conveying metal tubes (3); the take-up mechanism (4) comprises a coil pipe (41), a rotary support (42) arranged under the coil pipe (41), a first driving device (44) used for driving the coil pipe (41) to rotate, a lifting support seat (46) fixedly connected with the rotary support (42) by an intermediate part, and a second driving device (45) used for driving the lifting support seat (46) to rise and drop; and the base (5) is used for supporting the take-up mechanism (4). Before the rolling device is used, annealing treatment is carried out on the hard metal tubes, so that problem that the metal tubes which are contacted with one another are easily adhered with one another in the annealing treatment process of the hard metal tubes arranged on a whole tray can be effectively solved.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

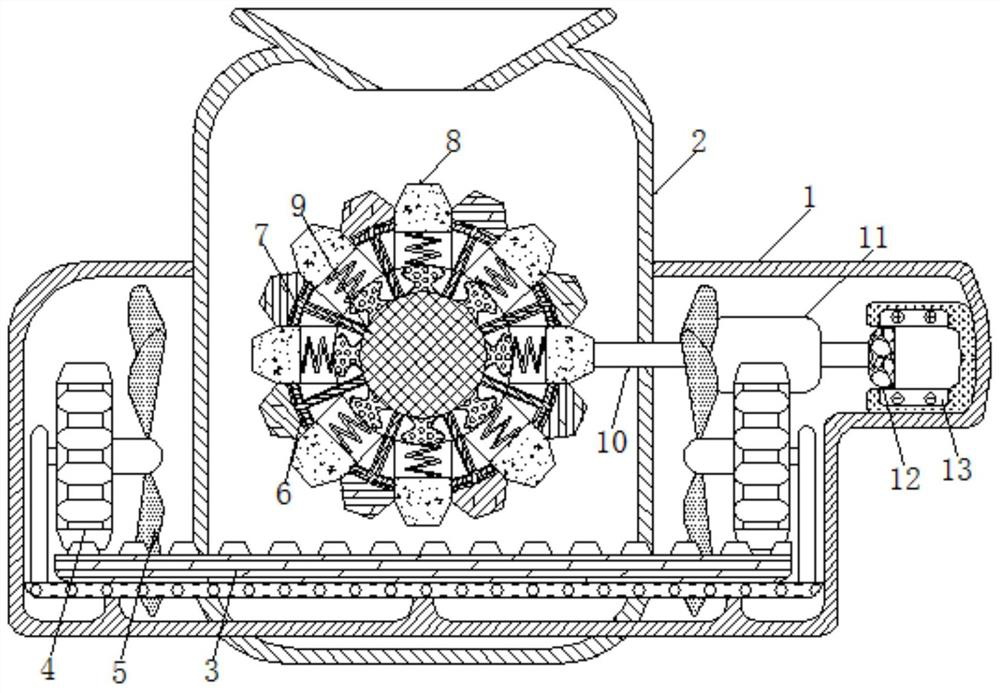

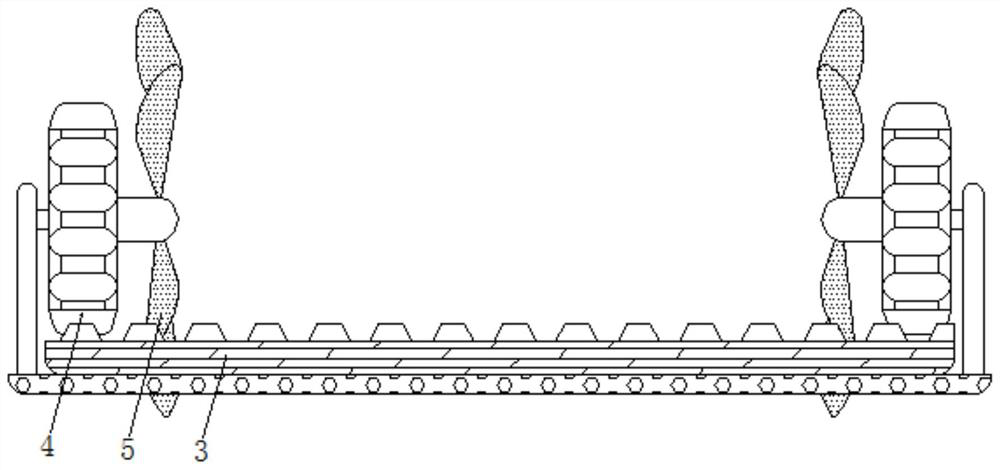

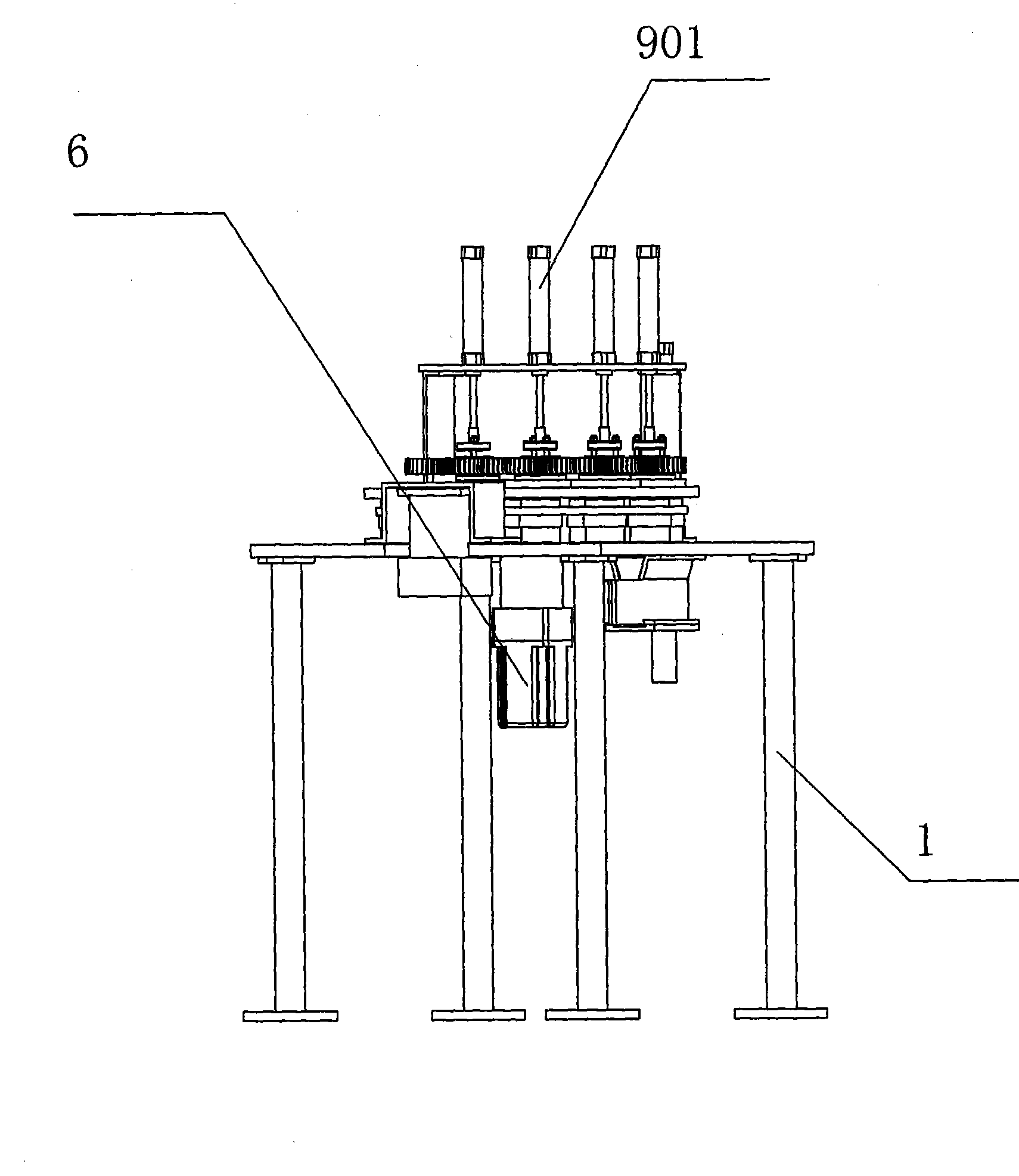

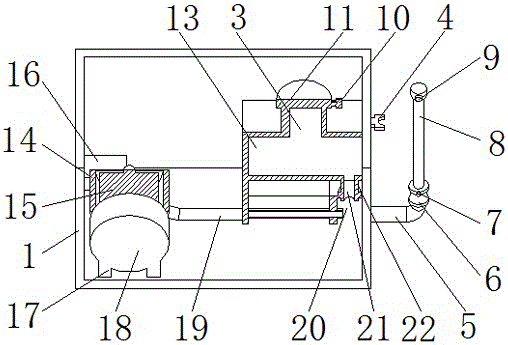

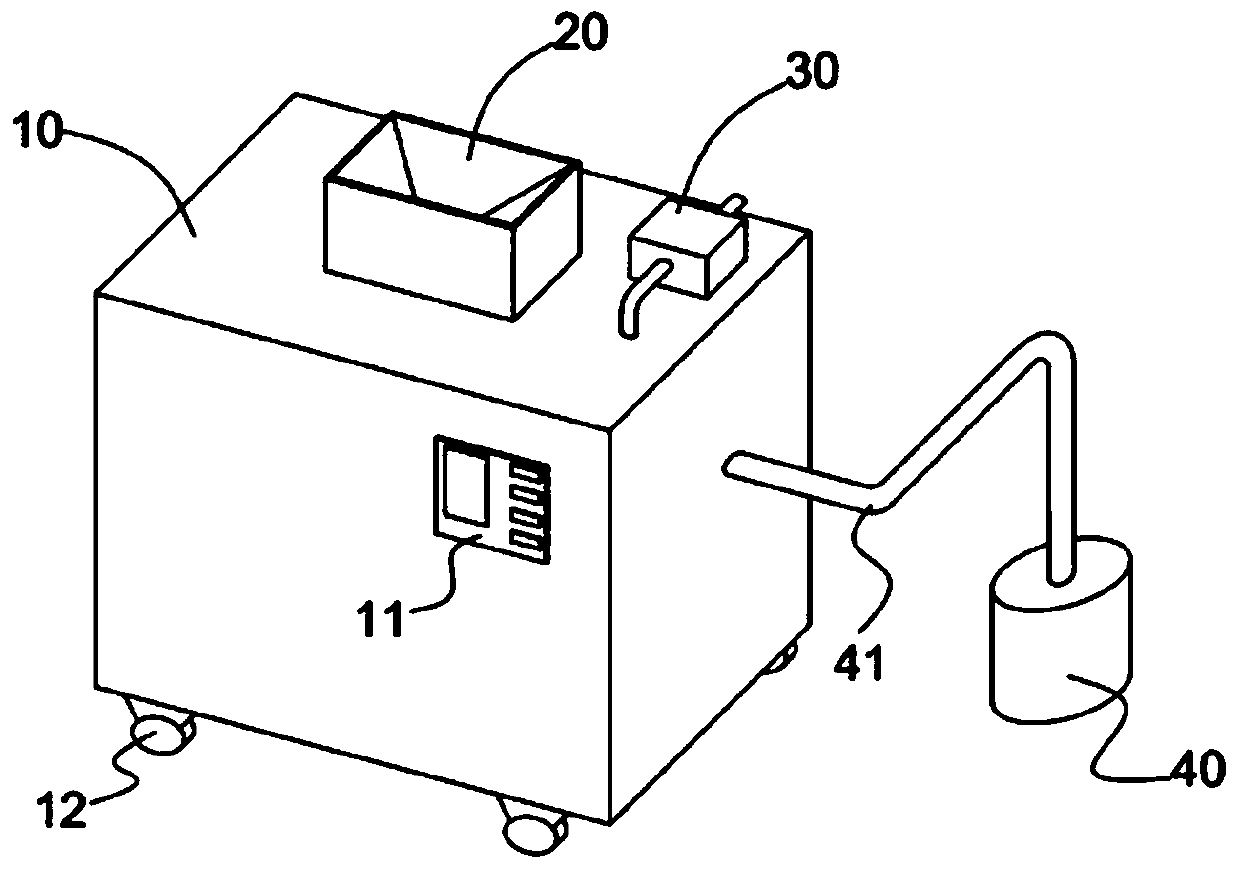

Artificial plant pollination device

InactiveCN105850724AReasonable designEasy to operateAgriculturePlant genotype modificationPollenPollination

The invention discloses an artificial plant pollination device. The artificial plant pollination device comprises a box body, wherein a power supply, a bracket and a pollen spreading chamber are arranged at the bottom part of the box body respectively; a motor and a blast blower are arranged on the bracket respectively; a fan blade is arranged in the blast blower and is connected to an output shaft of the motor in a sleeving manner; one side of the blast blower is communicated with a blast pipe; the blast pipe is communicated with the pollen spreading chamber; a pollen storage chamber is arranged at the top part of the pollen spreading chamber; and the top part of the pollen storage chamber is communicated with a feeding pipe. The device is provided with the blast blower and the pollen spreading chamber; the pollen spreading chamber is provided with pressure by the blast blower through the blast pipe, so that the pollen in the pollen spreading chamber is extruded outside, and the bonding condition is avoided. An extension tube is arranged on the device; the length of the pipe can be freely adjusted; and artificial pollination can also be carried out on relatively high plants without a ladder assembly, so that manpower is greatly saved; meanwhile, the pollination area is also expanded; and the success rate of plant pollination is improved.

Owner:付耀非

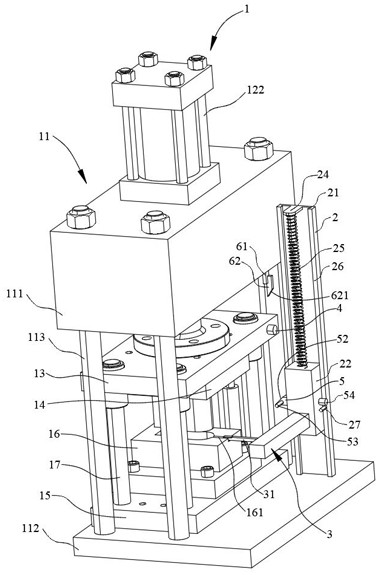

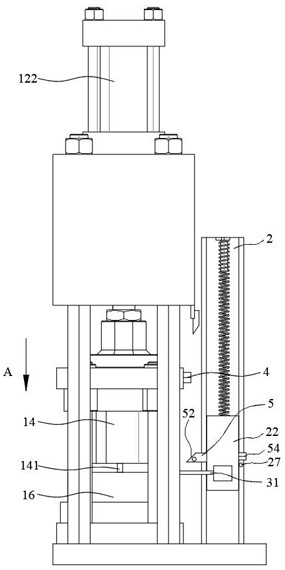

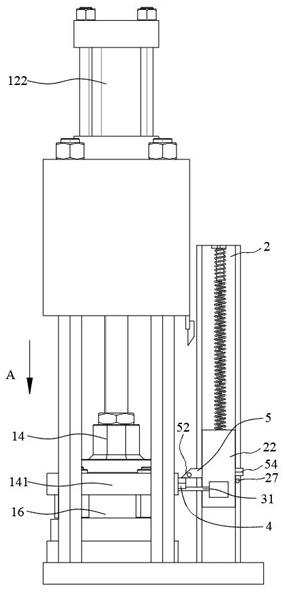

Automobile lampshade stamping die and stamping demolding method thereof

ActiveCN113102636AAvoid Sticky SituationsReduce security risksShaping toolsMetal-working feeding devicesStructural engineeringWaste material

The invention relates to the technical field of automobile accessories, in particular to an automobile lampshade stamping die and a stamping and demolding method thereof. The automobile lampshade stamping die comprises a die body and a clamping mechanism; a push rod is fixedly connected to the movable part of the die body; when an upper die plate and a lower die plate are split, the push rod can be linked with the clamping mechanism to drive a workpiece to lift, so that the workpiece and the lower die plate are demolded; after the workpiece is lifted to a certain height, the push rod can loosen the clamping mechanism, a sliding block slides downwards along a longitudinal guide rail under the action of gravity so that the workpiece and the upper die plate can be demolded, then the workpiece can be demolded automatically, the situation that materials adhere to the workpiece after stamping is completed is avoided, and potential safety hazards caused by manual demolding are reduced; and after the workpiece is demoulded, the workpiece slides downwards and impacts the lower die plate to shake off waste materials on the workpiece, the lower die plate further plays a role in removing the waste materials on the workpiece, use is convenient and fast, the waste materials do not need to be removed manually, the stamping procedure is simplified, and manpower input is reduced.

Owner:苏州唯准金属制品有限公司

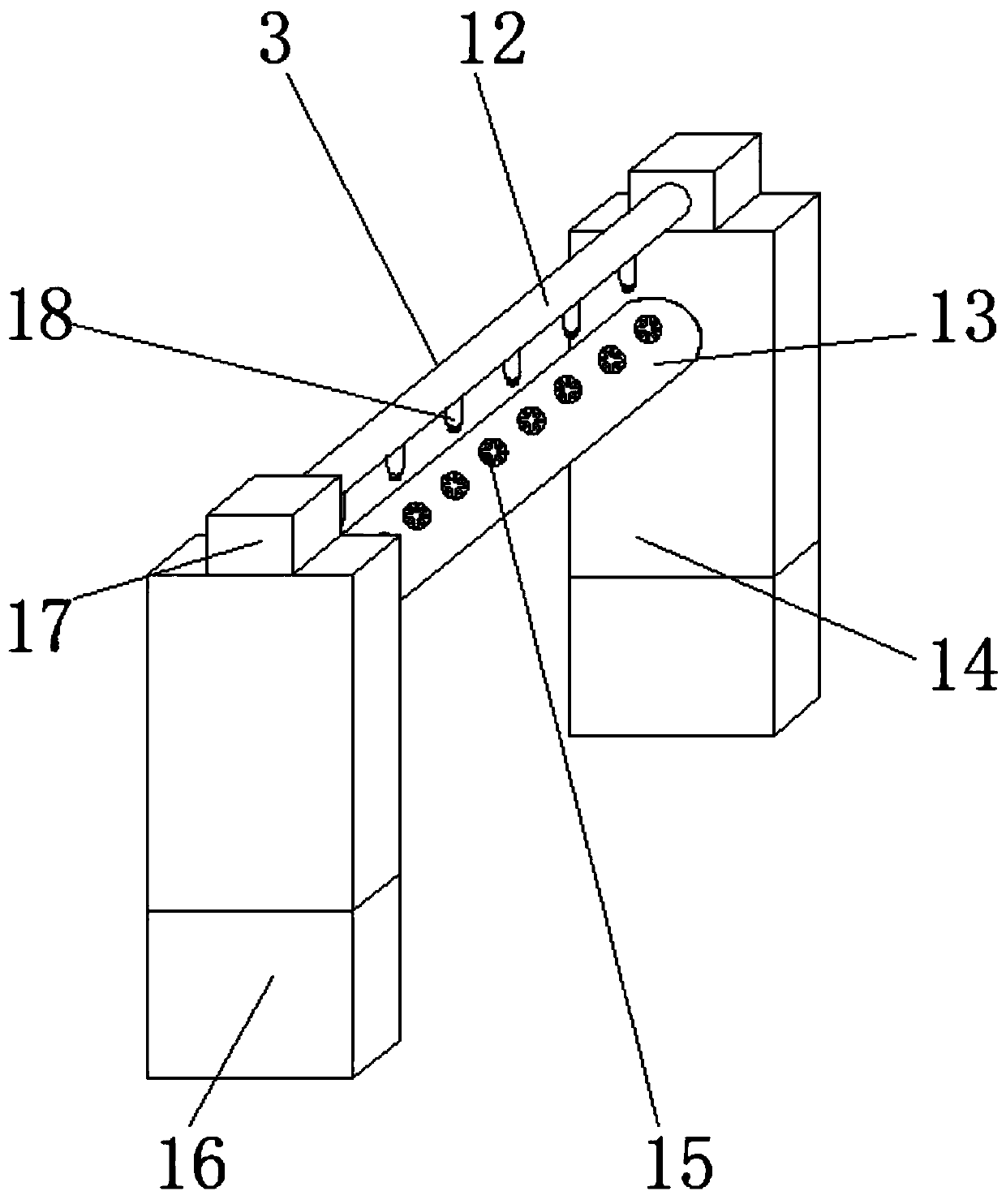

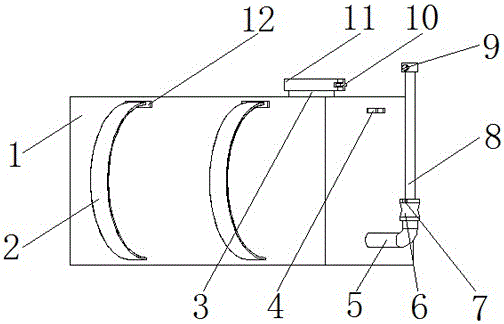

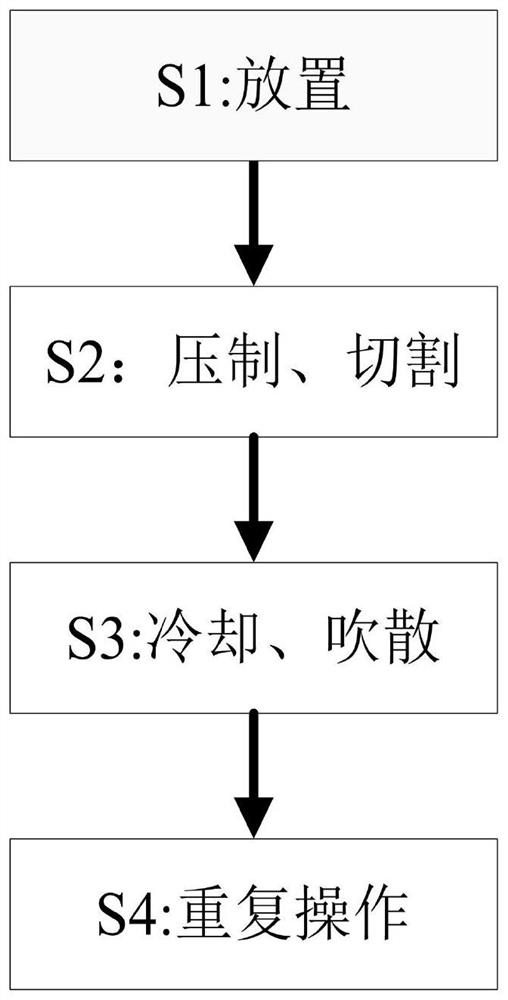

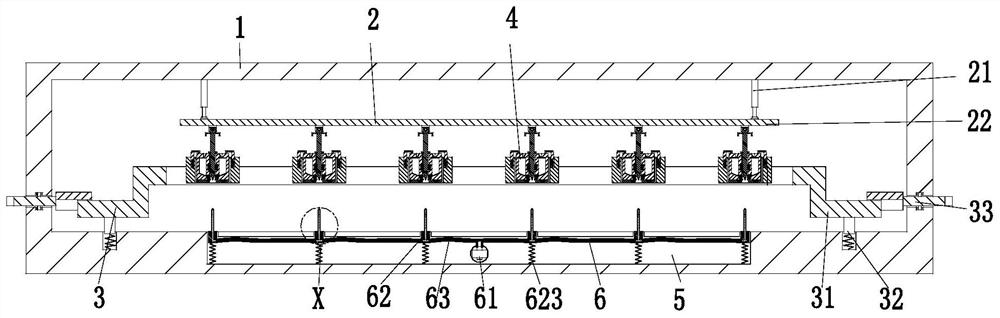

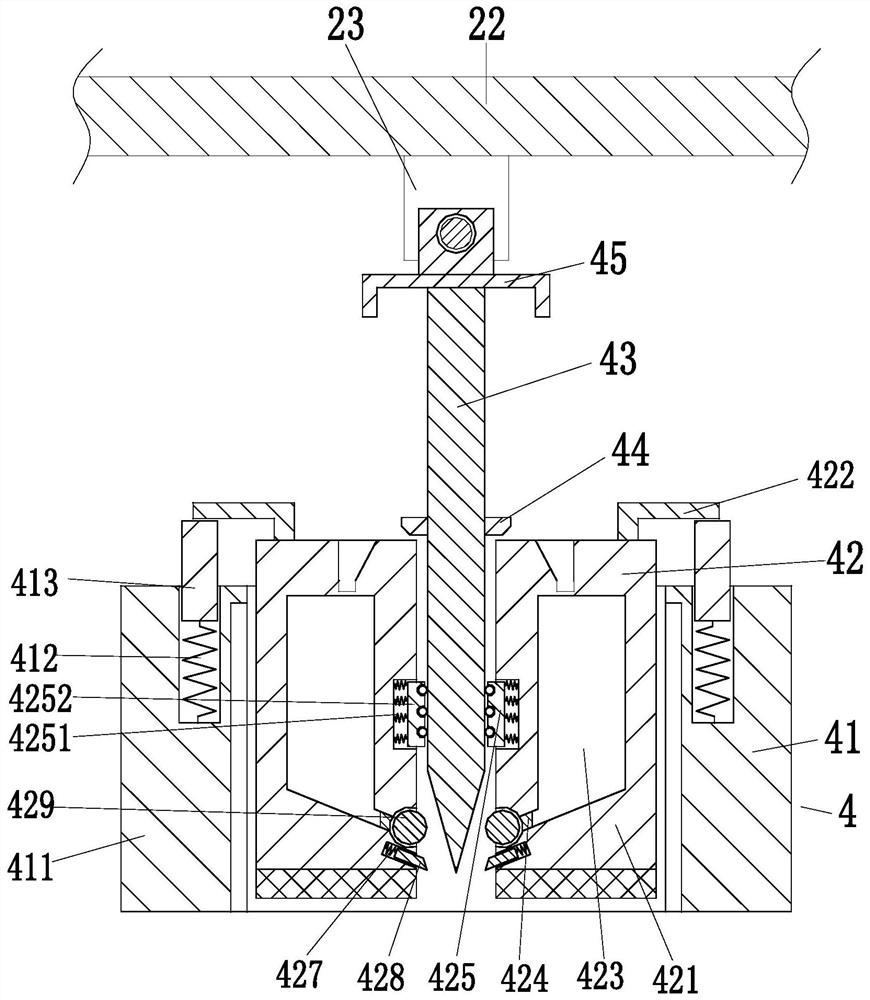

Cutting device and method for cylindrical paper core for filter part

The invention discloses a cutting device and method for a cylindrical paper core of a filter part. The cutting device comprises a workbench, wherein a supporting seat is mounted on the workbench; a mechanical arm is mounted on the supporting seat; a rotary motor is mounted on the mechanical arm; the rotary motor is connected with a gearbox; the output shaft of the gearbox is connected with the rotary shaft for transmitting torque; a circular cutter is mounted on the rotary shaft; a hand wheel is mounted on the mechanical arm; and a mounting table is arranged below the circular cutter. The cutting device can be used for conveniently producing the cylindrical paper core, which is perfect and attractive in appearance, for the filter part on a large scale.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

Cutting processing process for synthetic rubber strip-shaped blocks

InactiveCN111716412APrevent deviationAvoid deformationMetal working apparatusRubber sheetSynthetic rubber

The invention provides a cutting processing process for synthetic rubber strip-shaped blocks. The process is completed by cooperation of a frame, a driving device, a pressing device, a cutting device,a working cavity and a separating device. With the process, the problem that due to the fact that a rubber plate has certain toughness, when a traditional cutting knife cuts off the rubber plate, therubber plate which is very prone to deforming is easily displaced by a small distance after being extruded in the cutting process, consequently, a cut is uneven, moreover, the surface of the cut hasa certain temperature, and rubber is prone to deforming and adhesion after being heated can be solved.

Owner:荣文龙

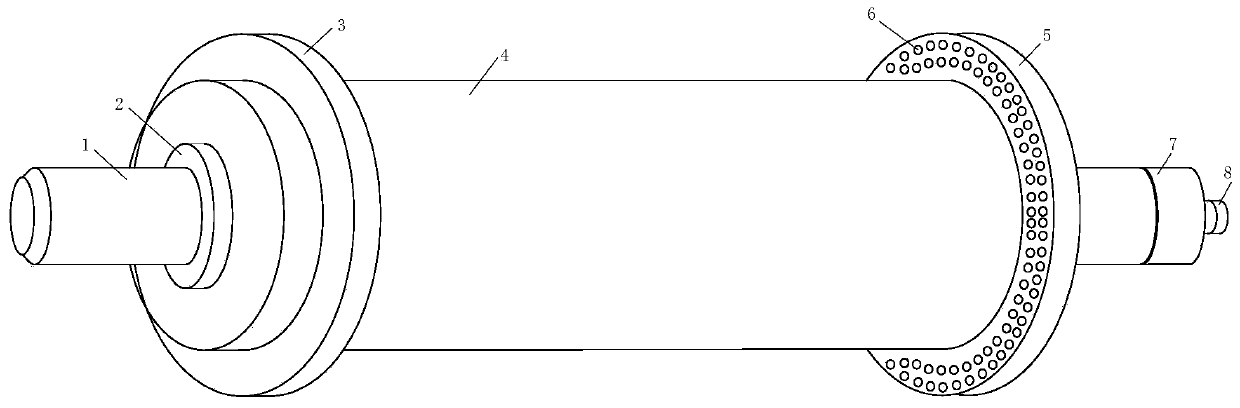

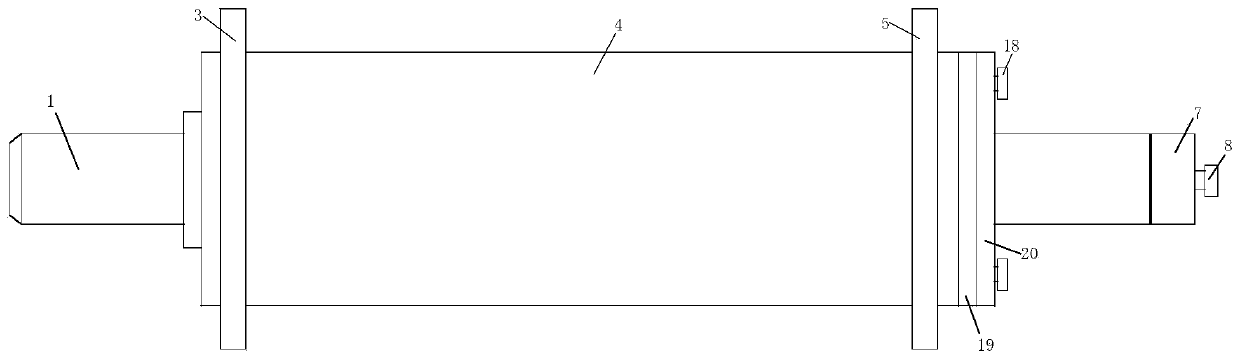

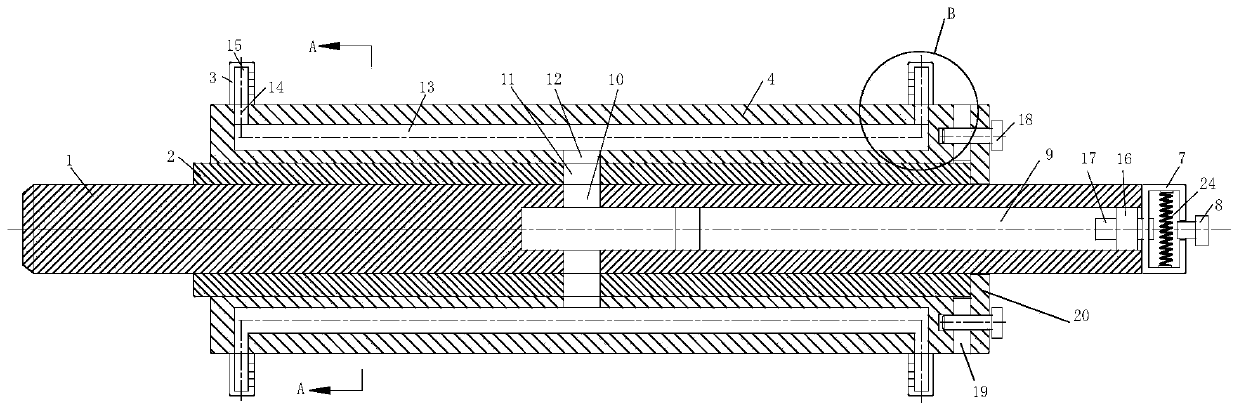

Roller shell

ActiveCN110313496AEasy to replaceReduce replacement costsDough-sheeters/rolling-machines/rolling-pinsDrying gas arrangementsPulp and paper industryFlange

The invention relates to the field of roller shells, in particular to a roller shell. The roller shell comprises a roller, a lining, a first lantern ring, a roller shell body, a second lantern ring, an air hole, a cylindrical shell, an air inlet joint, a first cavity, a first through hole, a second through hole, a third through hole, a second cavity, an air outlet hole, a third cavity, a bearing,a cylinder, a bolt, a sealing gasket, a sealing flange, a threaded hole, a clamping groove, a clamping block and a heating wire. The clamping block at the inner wall of the roller shell is clamped into the clamping groove in the lining, the roller shell can be easily taken down from the lining and replaced, the roller shell can be conveniently replaced, the roller shell replacement cost is lowered, the device comprises an end air inlet mechanism, the air inlet joint of the end air inlet mechanism is externally connected with an air pump, when the device is in use, gas generated by the air pumpis blown out through the air holes in the first lantern ring and the second lantern ring finally, meanwhile, due to rotation of the roller, the phenomena that gas flow guiding of the roller appears and the internal gas circulation effect is poor can be avoided, and the later noodle airing time is shortened.

Owner:苏州琦谷佳科技有限公司

Building smashing device

InactiveCN112844631AReduce diffuseReduce inhalationDispersed particle separationGrain treatmentsDrive shaftArchitectural engineering

The invention discloses a building smashing device. The building smashing device comprises a smashing chamber, a sieve plate device, sieve holes, a driving shaft and a smashing device body; the sieve plate device is fixed to the inner wall of the smashing chamber and located in the center; the smashing device body is fixed to the surface of the driving shaft; pressing blocks are slidably connected to the tops of sieve plate bodies; and arc-shaped ejector rods are rotationally connected into the sieve plate bodies, the top ends of the arc-shaped ejector rods are hinged to the bottom ends of the pressing blocks, and flapping devices are arranged in the sieve plate bodies and located at the positions of the sieve holes. According to the building smashing device, the purposes of preventing blockage and removing dust are achieved, wet dust adhesion is reduced, the blockage condition is avoided, the smashing efficiency is high, meanwhile, dust can be collected, dust diffusion is reduced, the dust suction amount of workers is reduced, human health is facilitated, air pollution is reduced, and the use performance is improved.

Owner:六安十方信息科技有限公司

Recycled asphalt heating device

ActiveCN105951561AImprove formation qualityImprove heating efficiencyRoads maintainenceProduct gasAsphalt

The invention provides a recycled asphalt heating device which comprises a rotary drum, a heater and an air guide and reflux device, wherein the rotary drum is provided with a material feeding end and a material discharging end; the heater is connected with the material feeding end and is used for injecting high-temperature gas into the rotary drum; the air guide and reflux device is arranged at the material discharging end of the rotary drum and is used for heating the outer wall of the material discharging end through the gas flowing out of the material discharging end. According to the recycled asphalt heating device provided by the invention, the air guide and reflux device is arranged at the material discharging end of the rotary drum, so that the air guide and reflux device can be used for guiding the gas discharged from the material discharging end to the outer side wall of the material discharging end of the rotary drum, to enable the gas discharged from the material discharging end to heat a material in the rotary drum again, and temperature reduction of the material discharging end of the rotary drum can be slowed down. Therefore, the phenomenon that the material is attached to the inner wall of the material discharging end of the rotary drum and a material raising device due to extremely low temperature is avoided, the forming quality of a material curtain is effectively enhanced, the heating efficiency of a product is improved, the cleaning period of the rotary drum is correspondingly prolonged, and continuous production of the product is guaranteed.

Owner:HUNAN SANY ROAD MACHINERY

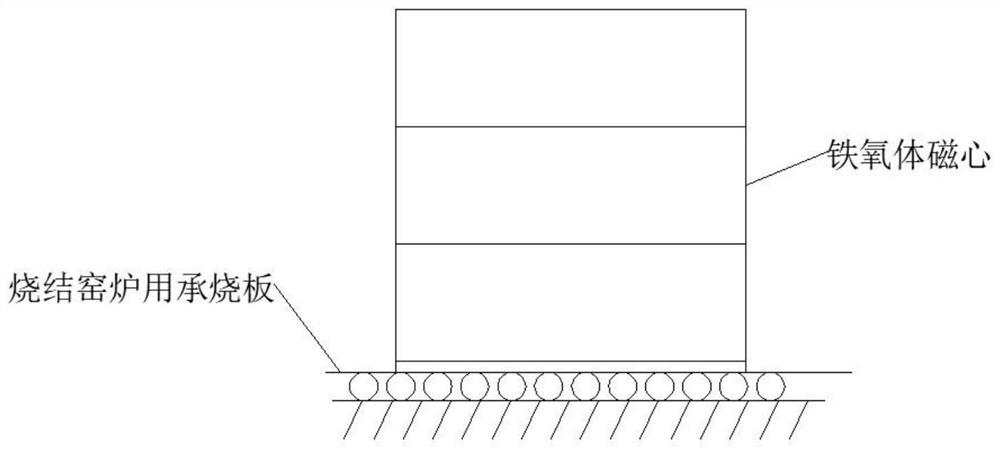

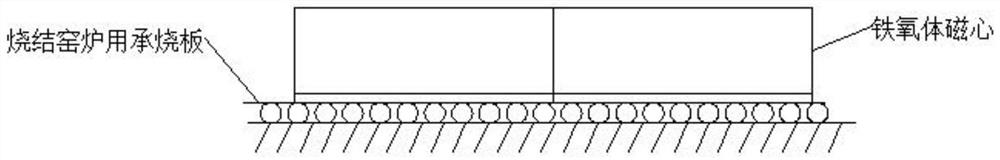

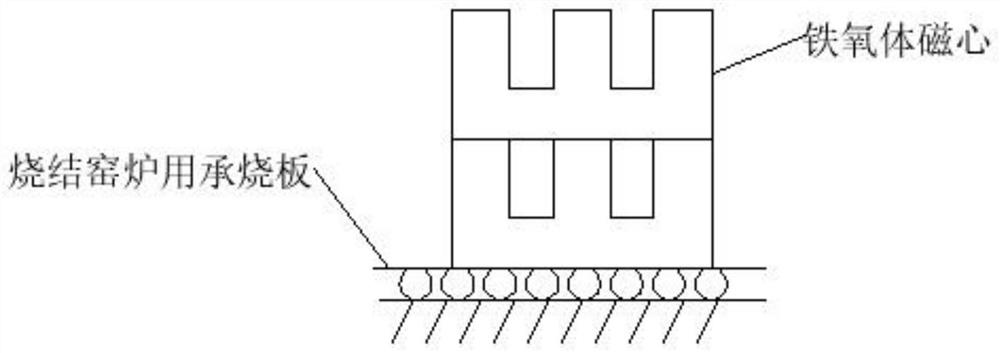

Ferrite blank sintering process

The invention discloses a ferrite blank sintering process which comprises the following steps: according to preset placement positions of a plurality of ferrite blanks, coating contact surfaces of adjacent ferrite blanks with an anti-adhesion coating; the anti-adhesion coating is prepared by mixing and stirring water and emery according to the mass ratio of (2-3): 1; and after a plurality of ferrite blanks are coated and stacked in place, sintering is carried out. The invention further discloses an anti-adhesion coating and application of the anti-adhesion coating in ferrite blank sintering pretreatment. The anti-adhesion coating is prepared by mixing and stirring water and emery according to the mass ratio of (2-3): 1. According to the ferrite blank sintering process disclosed by the invention, the adhesion problem occurring when the ferrite blanks are placed side by side or stacked together for high-temperature sintering can be solved; the ferrite magnetic core blank is large in size specification, different in upper end face and lower end face and not sealed after being sintered.

Owner:北京七星飞行电子有限公司

Printing control method and device, printer and computer readable storage medium

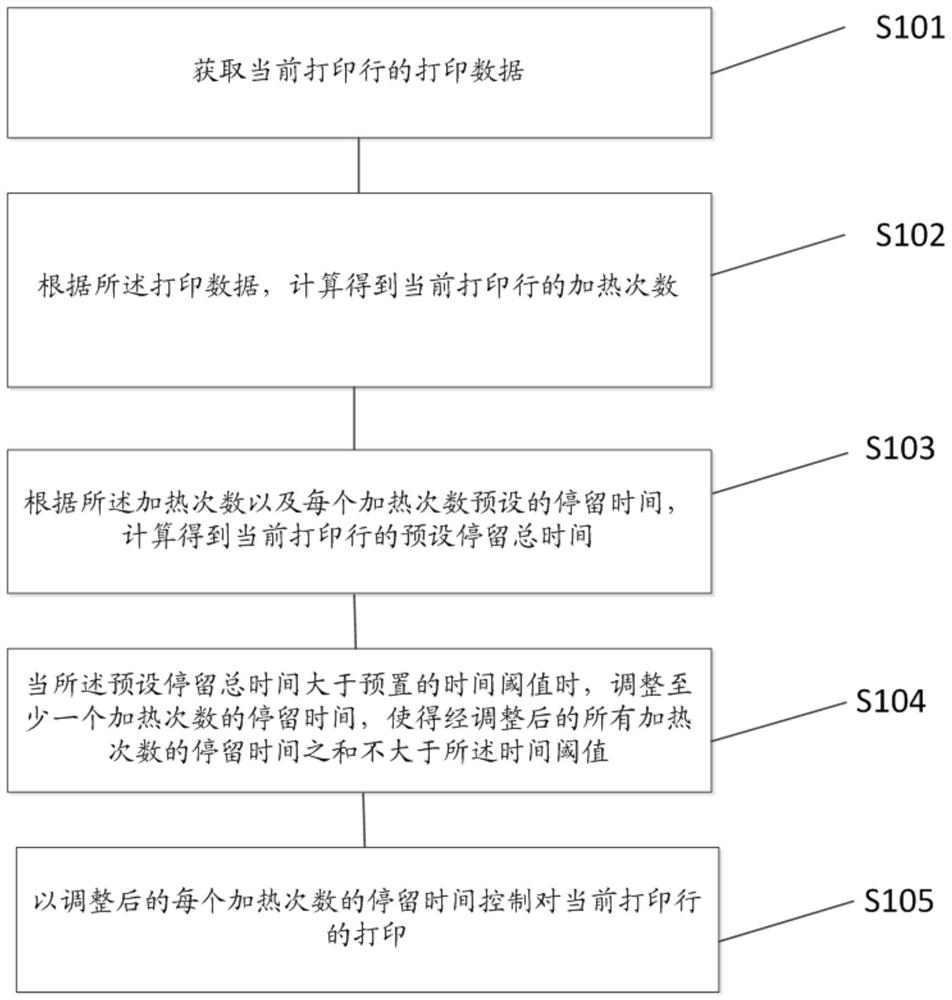

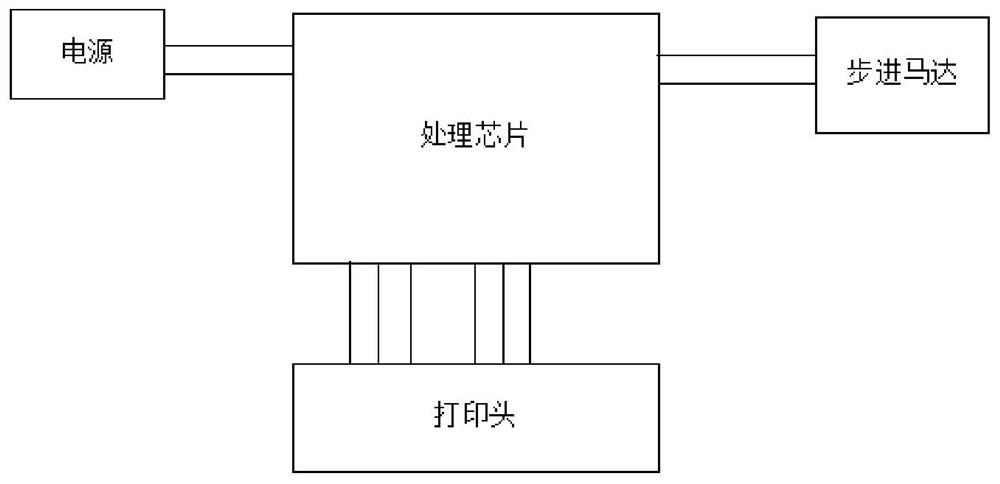

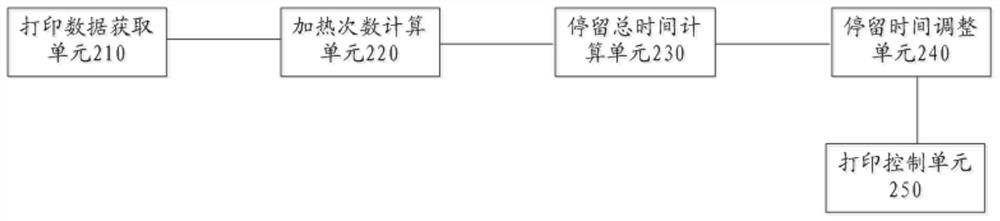

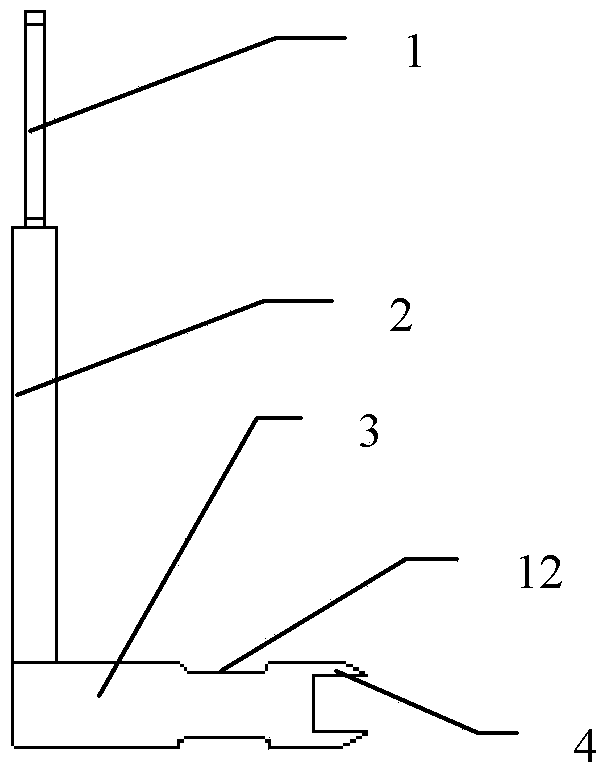

ActiveCN112214183AAvoid sticky situationsTotal dwell time shortenedDigital output to print unitsHeating timeComputer printing

The invention discloses a printing control method and device, a printer and a computer readable storage medium. The method comprises the steps of obtaining printing data of a current printing line; according to the printing data, calculating to obtain the heating times of the current printing line; according to the heating times and the preset residence time of each heating time, calculating to obtain the preset total residence time of the current printing line; when the preset total residence time is greater than a preset time threshold, adjusting the residence time of at least one heating frequency, so that the sum of the residence time of all the adjusted heating frequencies is not greater than the time threshold; and controlling the printing of the current printing line according to the adjusted residence time of each heating frequency. When it is detected that the total retention time of the printing line is too long, the retention time of the heating times is properly shortened,so that the total retention time of the printing line in the current line is shortened, and the situation that a printing point and a thermal transfer ribbon adhere to each other due to the too long total retention time is avoided.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

Disassembly and migration tool for Winchester hard disc magnetic head and use method thereof

ActiveCN103406870AIncrease success rateSimple structureMetal-working hand toolsEngineeringData recovery

The invention discloses a disassembly and migration tool for a Winchester hard disc magnetic head and a use method of the disassembly and migration tool, which relates to the technical field of disassembly and migration of the Winchester hard disc magnetic head in hard disk data recovery. The situation that a magnetic head bracket scratches to deform or a magnetic head adheres because a proper device and equipment for temporarily containing a magnetic head assembly are not provided in the existing disassembly and migration tool for the hard disc magnetic head assembly is avoided, and additionally, the problem of low work efficiency caused by the complicated and difficult usage of the existing tool is solved. The disassembly and migration tool comprises a magnetic head separating bracket, a positioning clamp, a connecting rod and a tool containing box, wherein two clamping grooves are formed in the connecting rod and respectively used for fixing the magnetic head separating bracket and the positioning clamp, the magnetic head separating bracket, the positioning clamp and the connecting rod are placed in the tool containing box, and the head assembly is disassembled from a hard disk through the magnetic head separating bracket and placed on the positioning clamp. The disassembly and migration tool is suitable for disassembling and migrating the Winchester hard disc magnetic head.

Owner:STATE GRID CORP OF CHINA +1

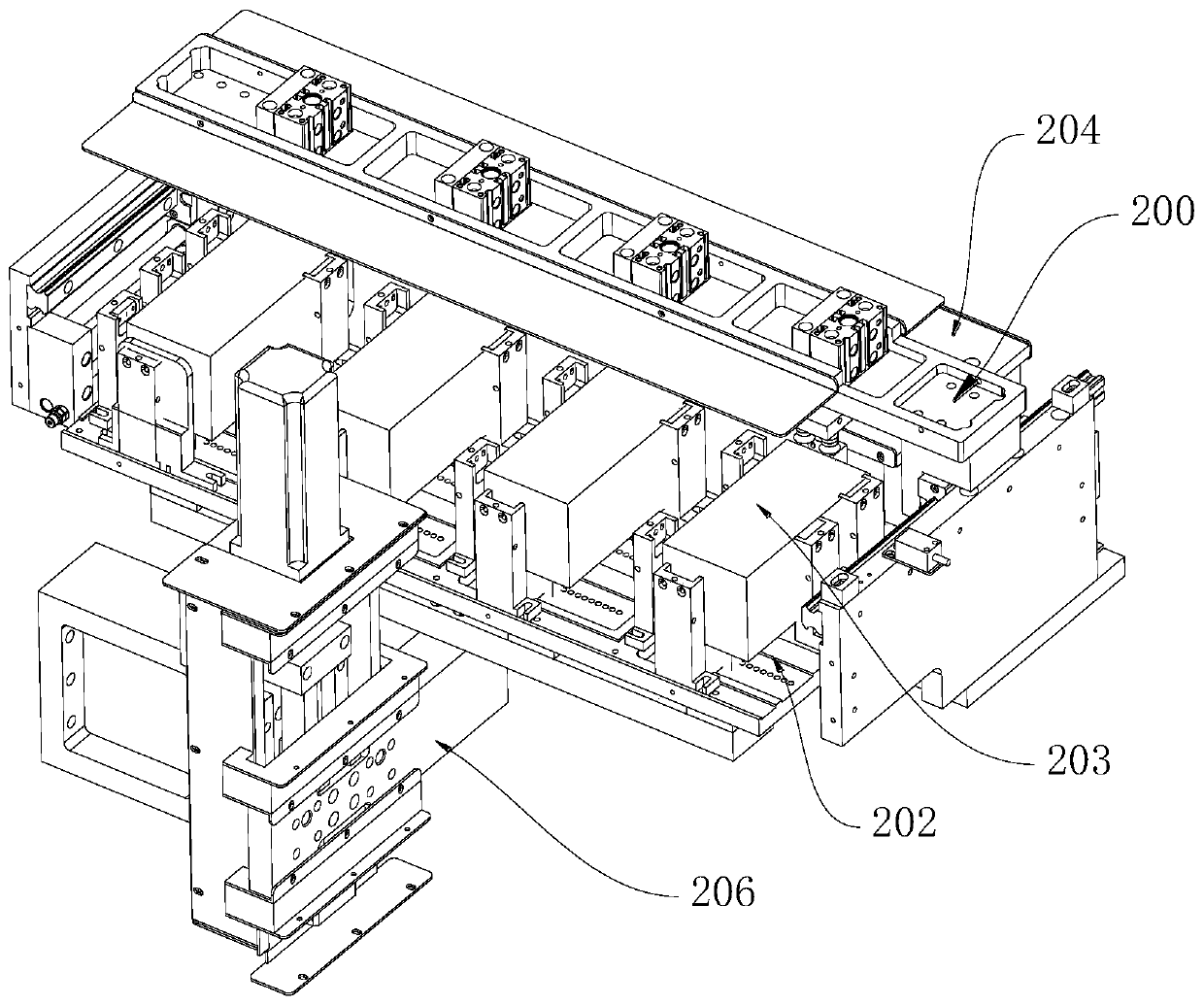

Laminated glass sheet separating and taking-out mechanism and method and glass sheet conveying equipment

InactiveCN110697410ASent accuratelyAvoid sticky situationsConveyor partsMechanical engineeringGlass sheet

The invention discloses a laminated glass sheet separating and taking-out mechanism. The mechanism comprises a platform, a material taking plate is arranged on the platform and can slide back and forth relative to the platform, a raw material box for loading multiple layers of glass sheets is fixedly arranged on the platform, the raw material box is located above the material taking plate, the multiple layers of glass sheets are supported at the top of the material taking plate, the raw material box comprises an outlet clamping plate located on the front side, a gap capable of allowing one piece of glass sheet to penetrate out is formed between between the outlet clamping plate and the material taking plate, a bearing part and an adsorption part capable of forming negative air pressure areformed at the top of the material taking plate, the adsorption part is located at the front end of the bearing part, the glass sheets are adsorbed on the adsorption part through the negative air pressure generated by the adsorption part, and one single glass sheet is sent out of the raw material box by driving the material taking plate to slide forwards. The mechanism has the advantages that onesingle glass sheet can be accurately sent out, non-stop feeding can be realized, and the production efficiency can be improved.

Owner:深圳市环球同创机械有限公司

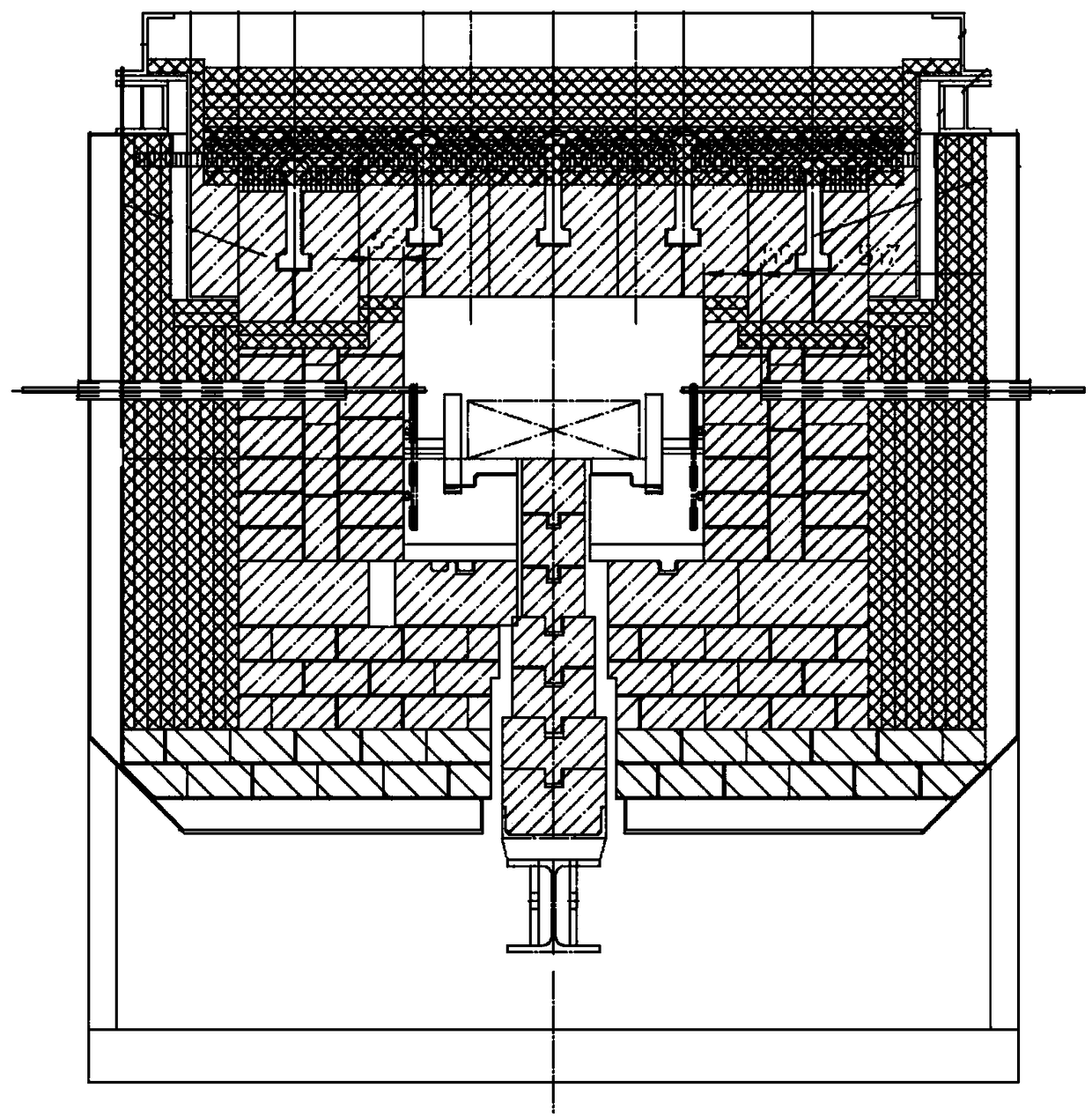

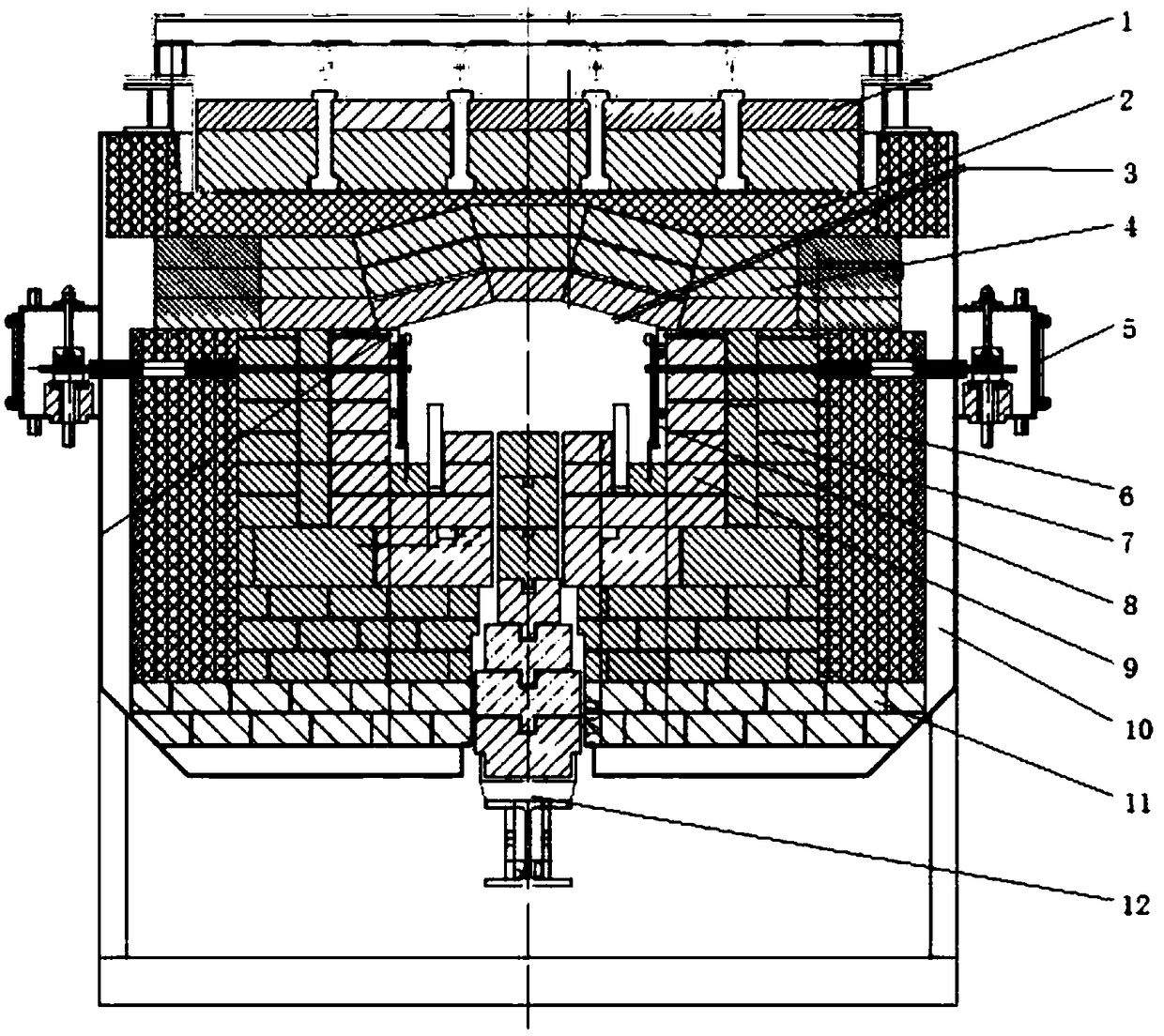

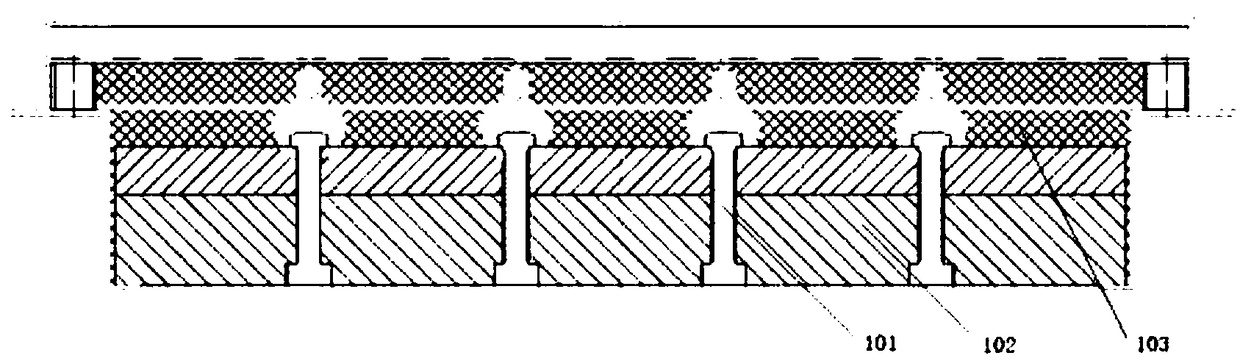

Stepping beam type sintering furnace

ActiveCN108253792AReduce heat conduction lossAvoiding Falling Furnace ProblemsFurnace componentsFurnace typesBrickHearth

The invention relates to the technical field of uranium dioxide core block sintering, in particular to a stepping beam type sintering furnace. The sintering furnace comprises a thermocouple, an electrode box, a heat insulation chopping board structure, a heat insulation brick structure, a heating body, a refractory brick structure, a metal furnace shell, a heat preservation brick structure, a stepping beam structure, a top cover, heat preservation cotton and a dome structure; a design scheme combining arching and hoisting is adopted, the hot bricks in the high-temperature area are built in anarch-raising mode, and the heat insulation material and the heat preservation material are of a hoisting structure, so that the risk of a hearth collapse clamping boat is reduced; the top cover structure is optimized, the number of heat preservation materials and heat insulation materials of the top cover is reduced, the load bearing of the aluminum oxide " I " shaped bricks is reduced, and the heat preservation effect of the hearth of the high temperature area is improved; the temperature of the surface of the top cover of the high-temperature zone is reduced, the operation period of the sintering furnace is prolonged, and the temperature of the working environment of the site is improved; and a mortise and tenon arch structure is adopted in the dome structure, the operation stability isimproved, and the collapse of the hearth is avoided.

Owner:CNNC JIANZHONG NUCLEAR FUEL

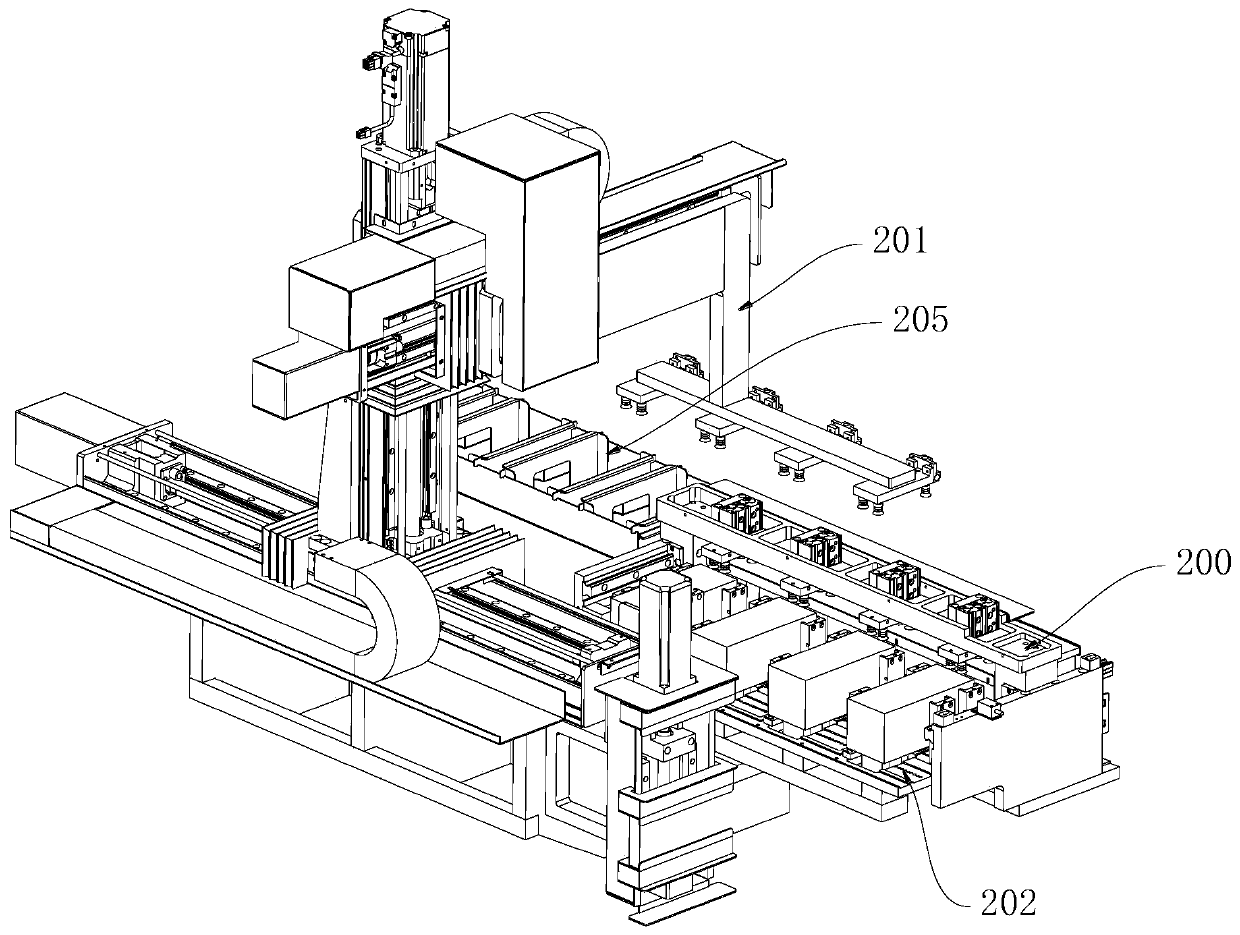

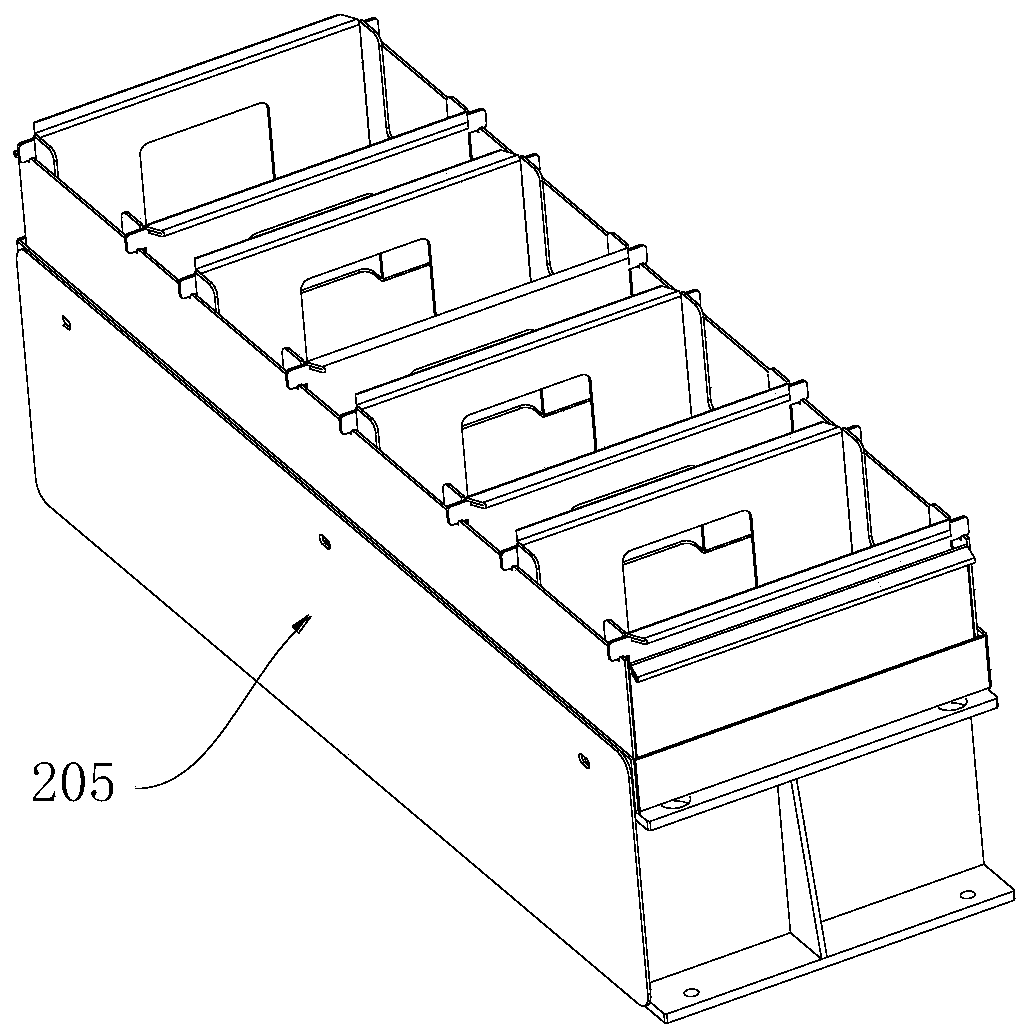

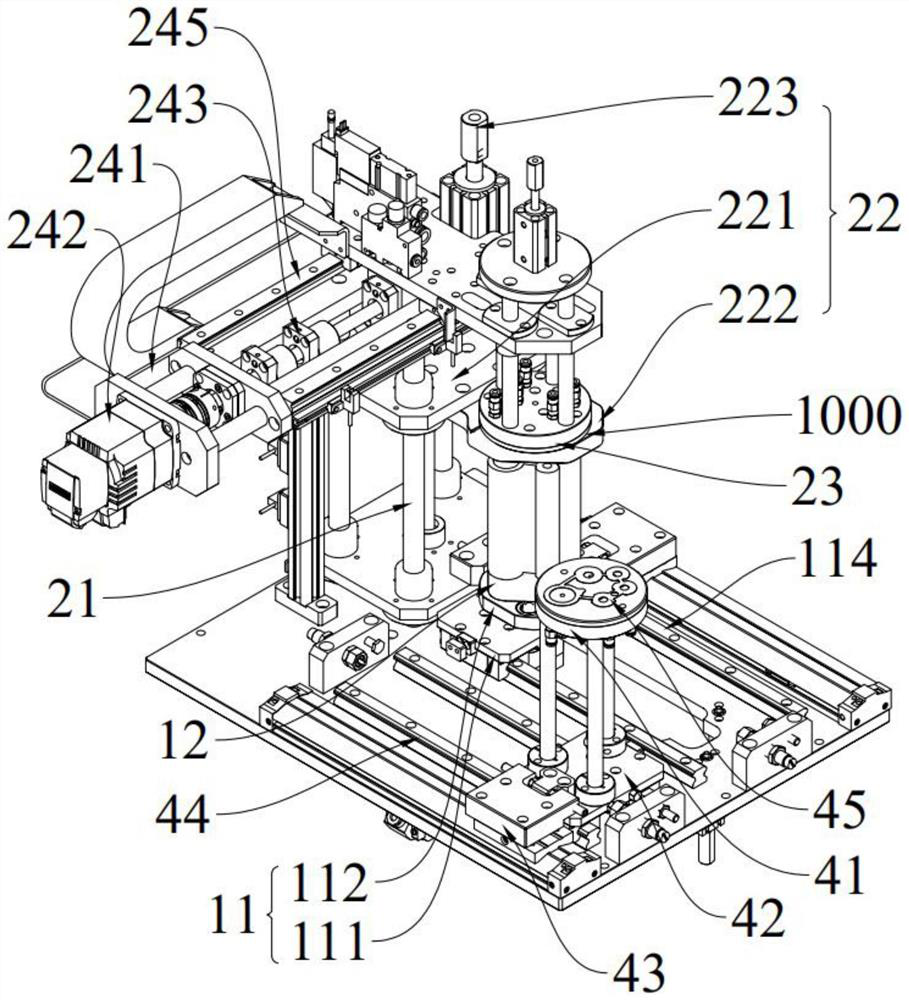

Soldering lug distributing mechanism and distributing method

PendingCN113716370AAchieve separationAccurate separationArticle separationStructural engineeringMaterial distribution

The invention relates to a soldering lug distributing mechanism and a distributing method. The soldering lug distributing mechanism comprises a base, a material frame, a distributing device and a lifting device. The distributing device comprises a mounting column, a downward pressing assembly, a material cutting assembly and a moving horizontally assembly, and the mounting column is vertically arranged on the base. The downward pressing assembly and the moving horizontally assembly are both arranged on the mounting column, and the downward pressing assembly can be partially stacked on the material frame. The material cutting assembly comprises a material cutting installation frame and a material cutting groove, the material cutting installation frame is arranged on the moving horizontally assembly in a sliding mode, and the material cutting groove is formed in the material cutting installation frame in a sliding mode, and the material cutting groove can be partially stacked on the downward pressing assembly. The lifting device comprises a lifting plate, the lifting plate is arranged on the mounting column in a sliding mode, and the lifting plate is detachably connected with the material frame. Manual participation is not needed in the sorting process of soldering lugs, and the sorting efficiency is high. The material cutting groove can only contain the soldering lug located at the topmost end on the material frame every time, the soldering lug at the topmost end is stripped when the material cutting groove moves horizontally every time, the situation that multiple pieces adhere to one another is avoided, and therefore the material distribution precision is effectively improved.

Owner:HANGZHOU TAISHANG INTELLIGENT EQUIP CO LTD

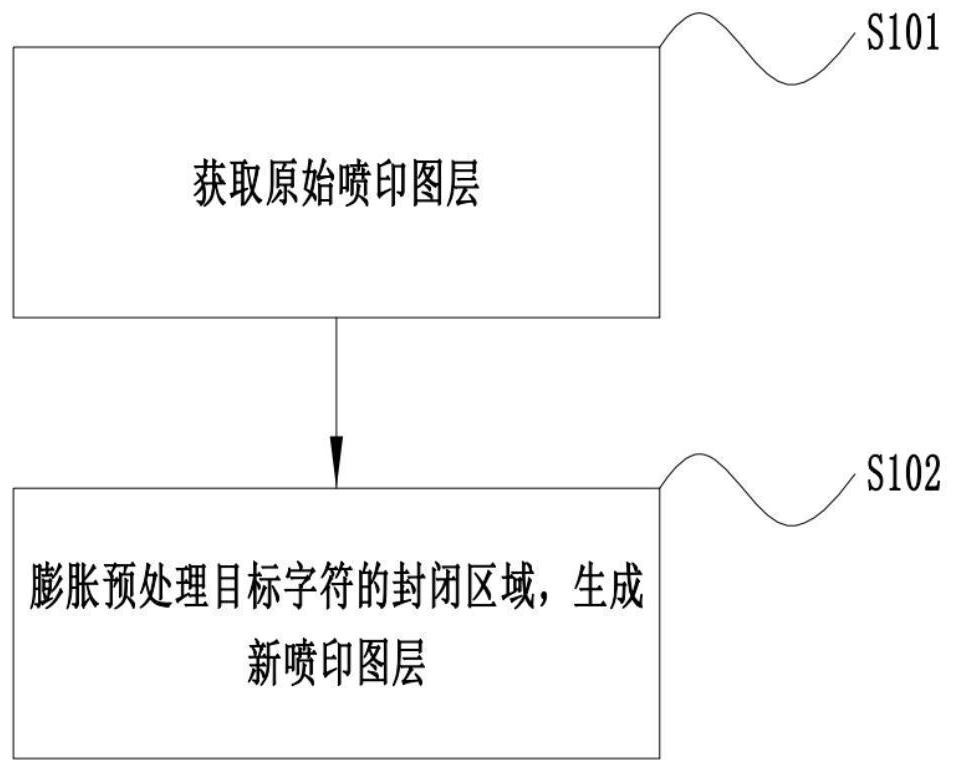

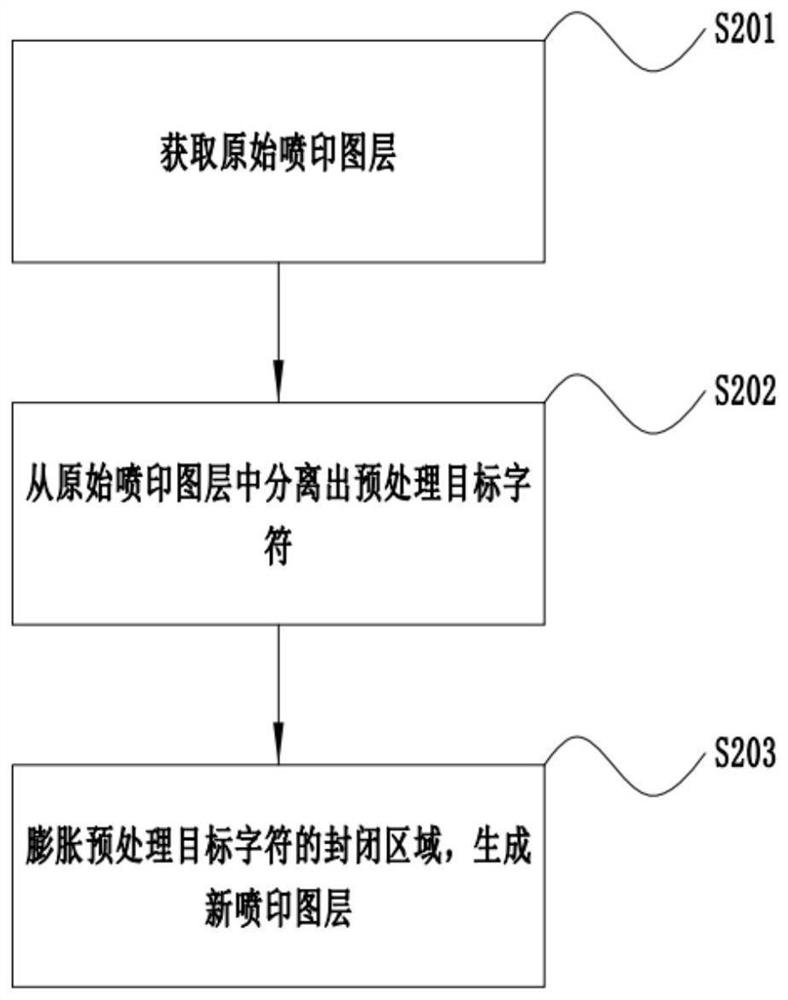

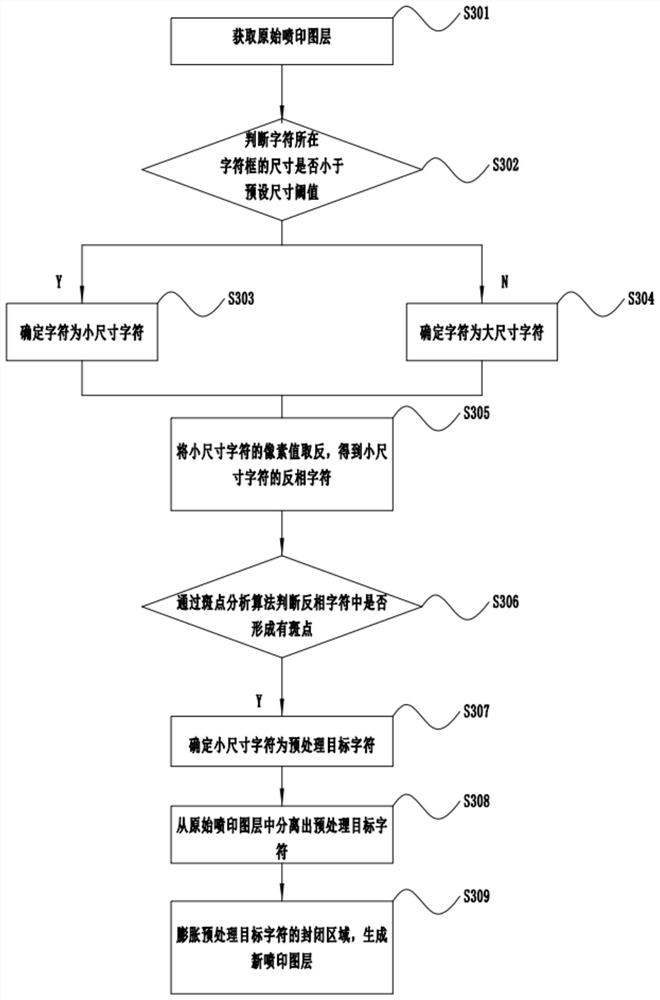

Character processing method and jet printing equipment

PendingCN112150397AAvoid Ink StickingImprove printing effectImage enhancementImage analysisProcess engineeringMechanical engineering

The invention discloses a character processing method and jet printing equipment, and relates to the technical field of circuit board printing. The method comprises the following steps: acquiring an original jet printing layer, wherein the original jet printing layer comprises a plurality of characters and the plurality of characters comprise a plurality of pre-processing target characters with closed areas; and expanding the closed area of the preprocessed target character to generate a new jet printing layer. The jet printing equipment comprises a character processing system; the character processing system comprises an input module and a character optimization module. According to the method, the closed area of the preprocessed target character in the original jet printing layer is expanded to obtain the new jet printing layer, so the complex input layer is optimized, the situation of ink adhesion during character jet printing is avoided, and the jet printing effect of jet printingequipment on complex graphs is particularly improved.

Owner:江西威力固智能设备有限公司

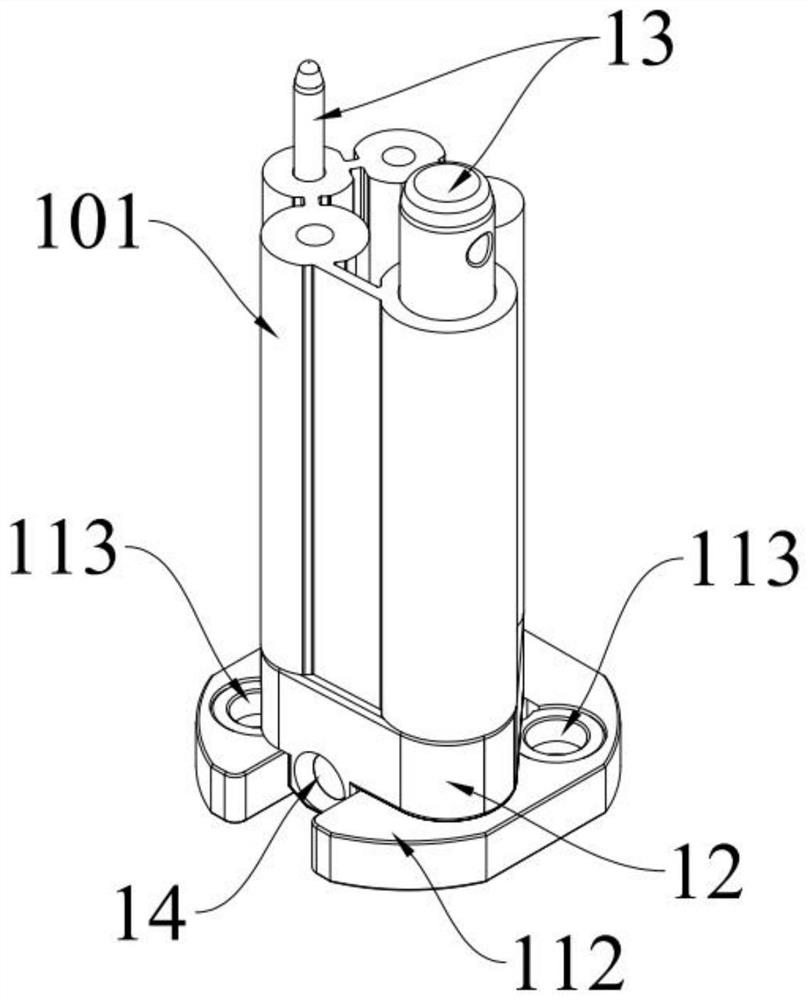

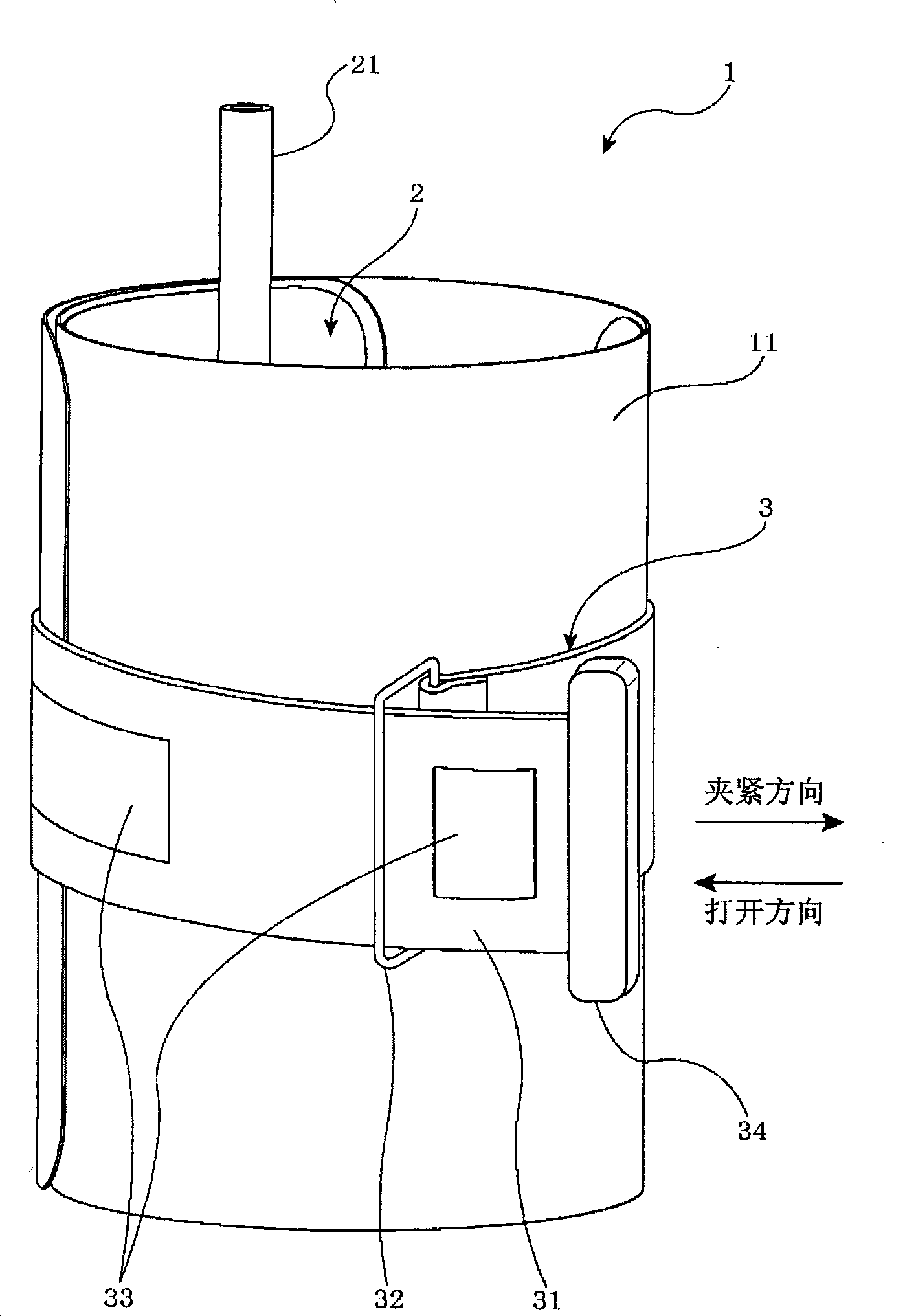

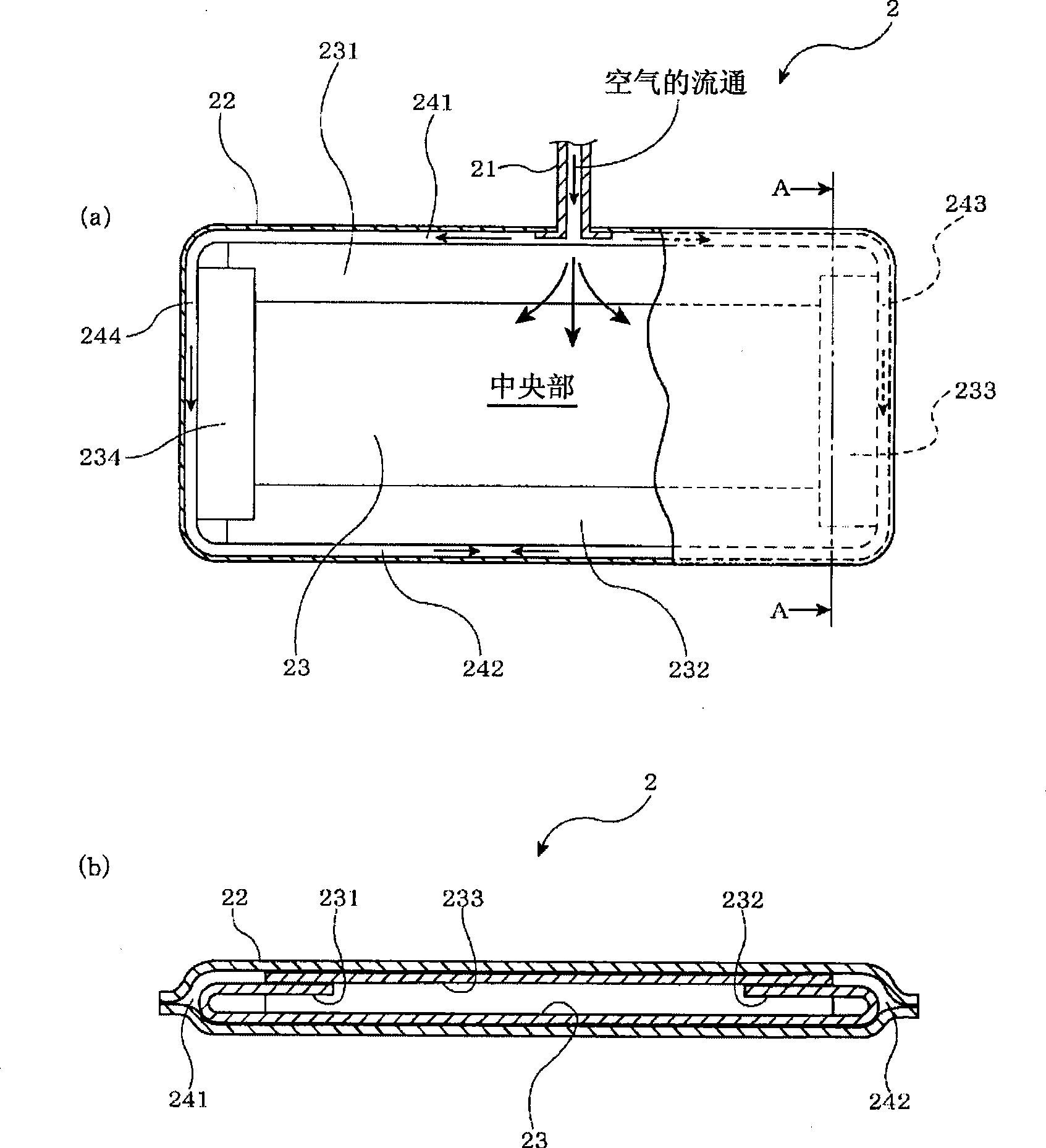

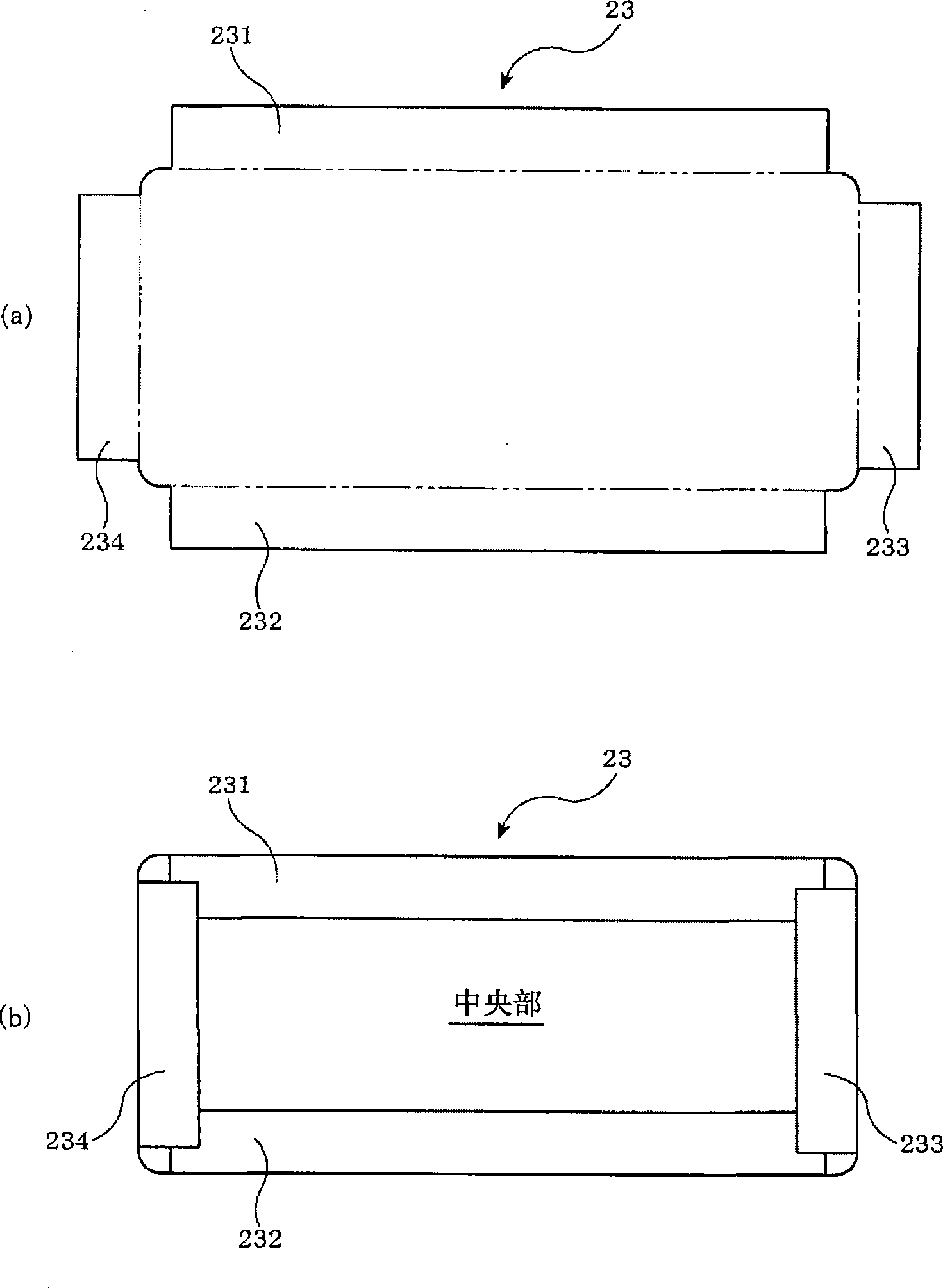

Air bag for pressing living body

ActiveCN101472521AHigh measurement accuracyAvoid uniformityEvaluation of blood vesselsAngiographyEngineeringLiving body

An air bag for pressing a living body, in which a problem that an arm of the user is non-uniformly pressed to give uncomfortable feeling to the user is prevented and in which measurement accuracy is increased. These are achieved by supplying air in a generally uniform way to the entire part of the air bag to totally and uniformly press the arm. The air bag (2) has a substantially rectangular air bag (22), a pipe (21) connected to the air bag (22), and a net-like sheet (23) contained in the air bag (22). The net-like sheet (23) has an upper folded part (231), a lower folded part (232), a right folded part (233), and a left folded part (234).

Owner:CITIZEN WATCH CO LTD

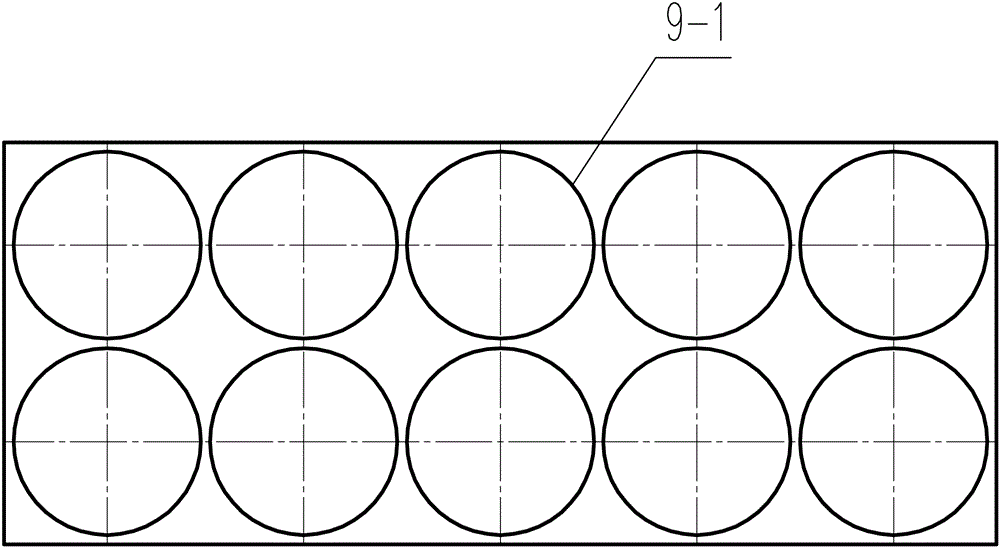

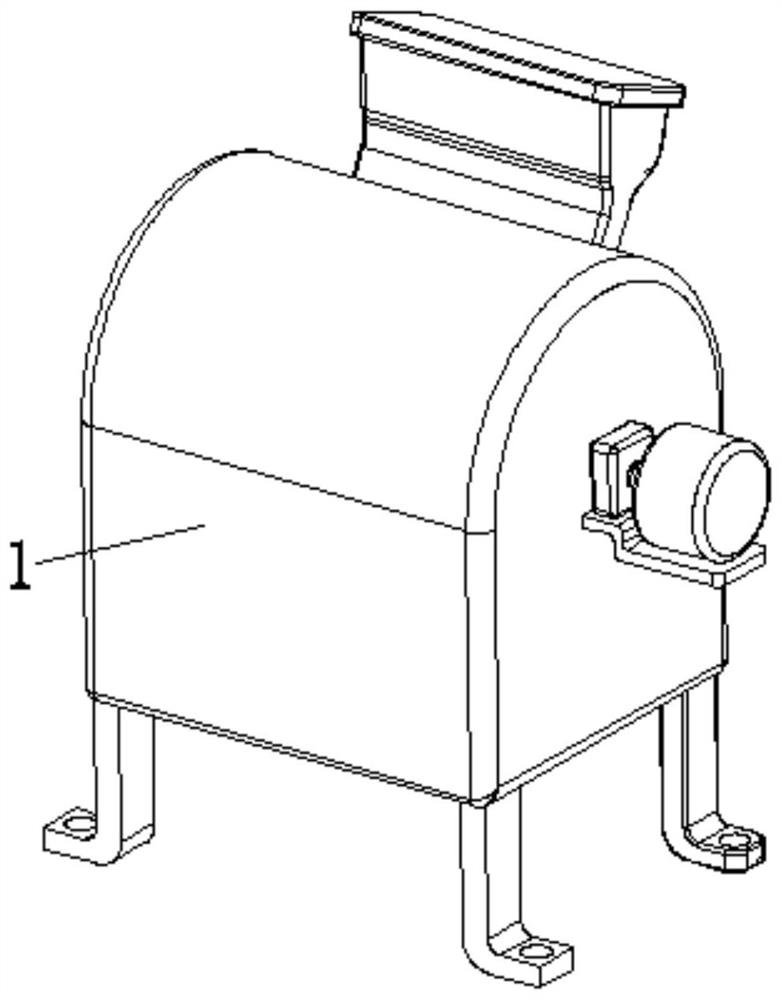

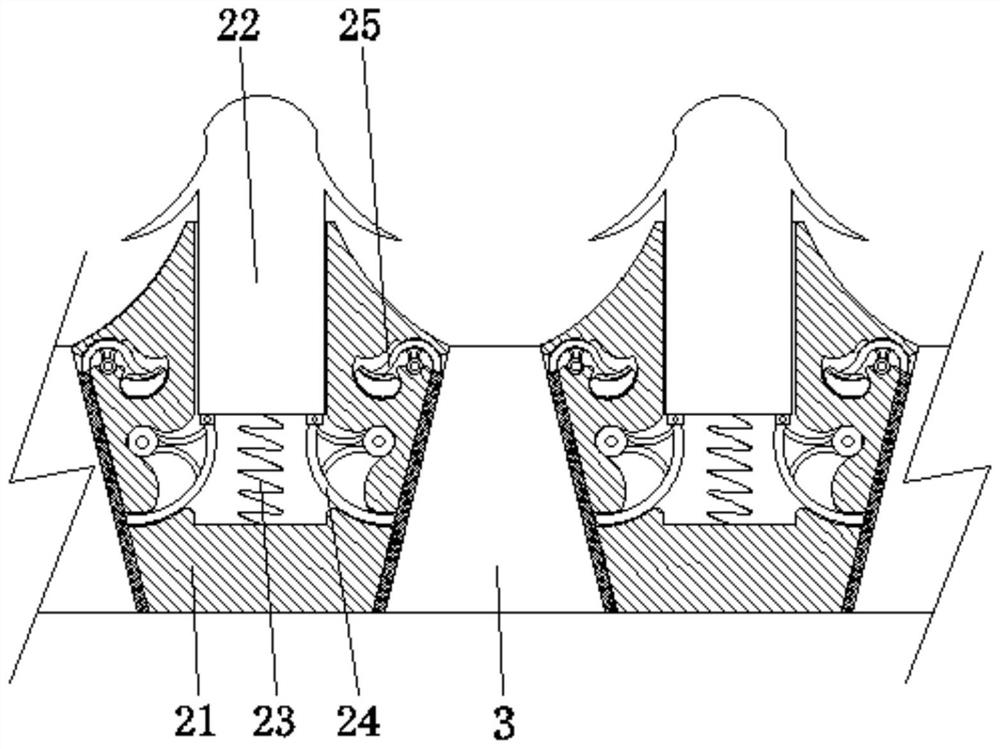

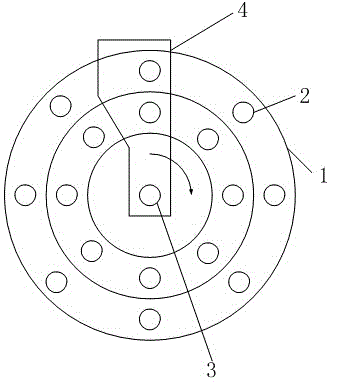

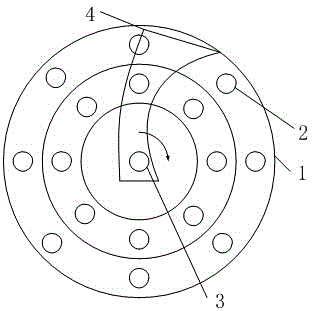

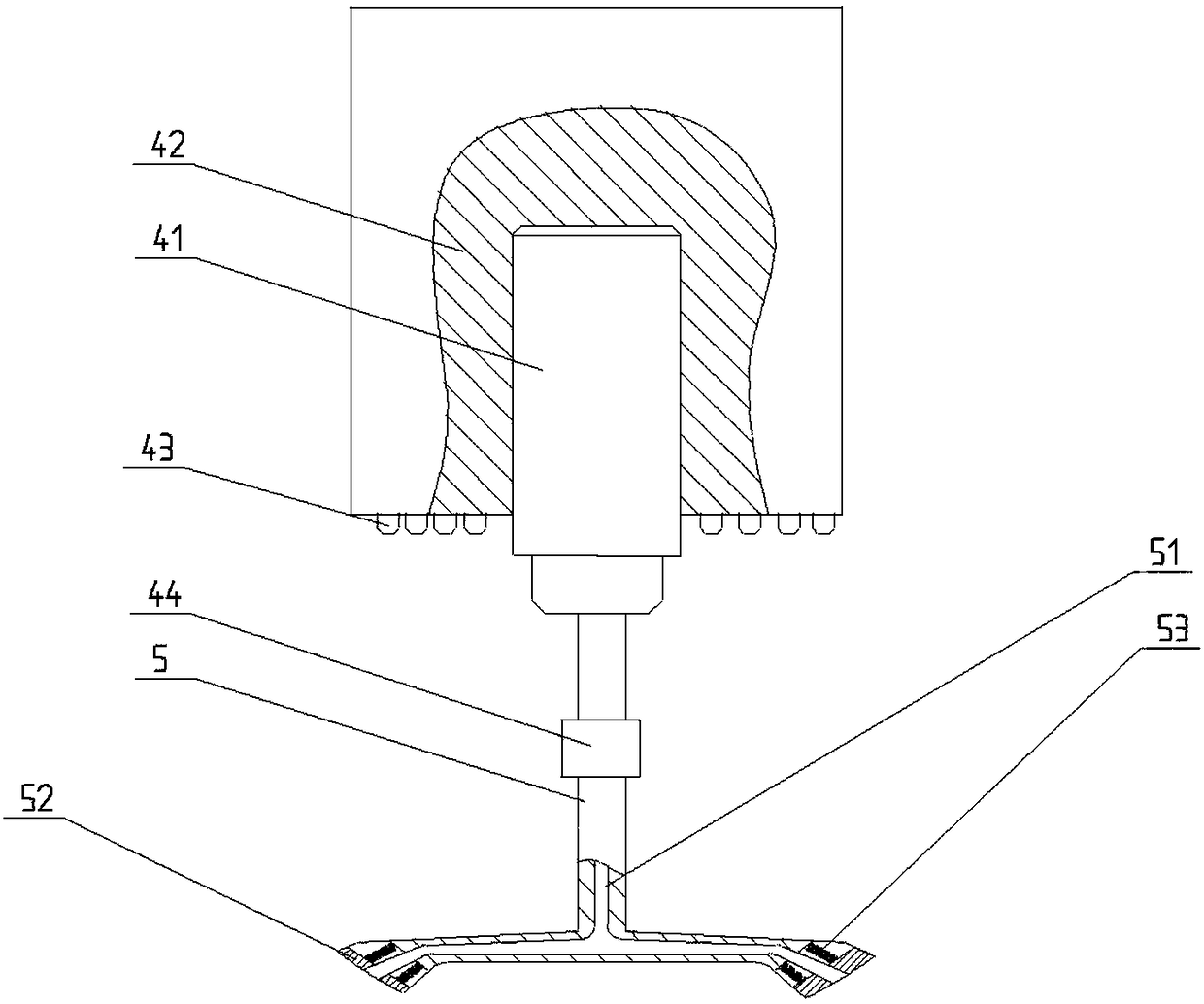

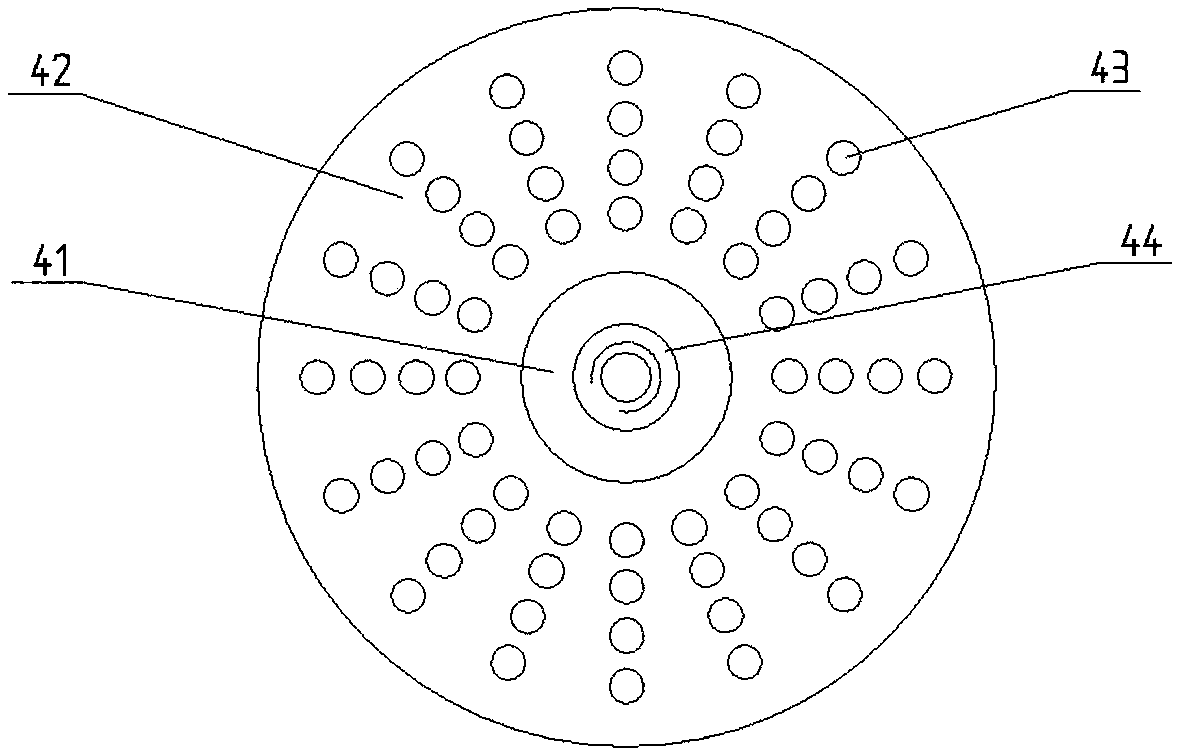

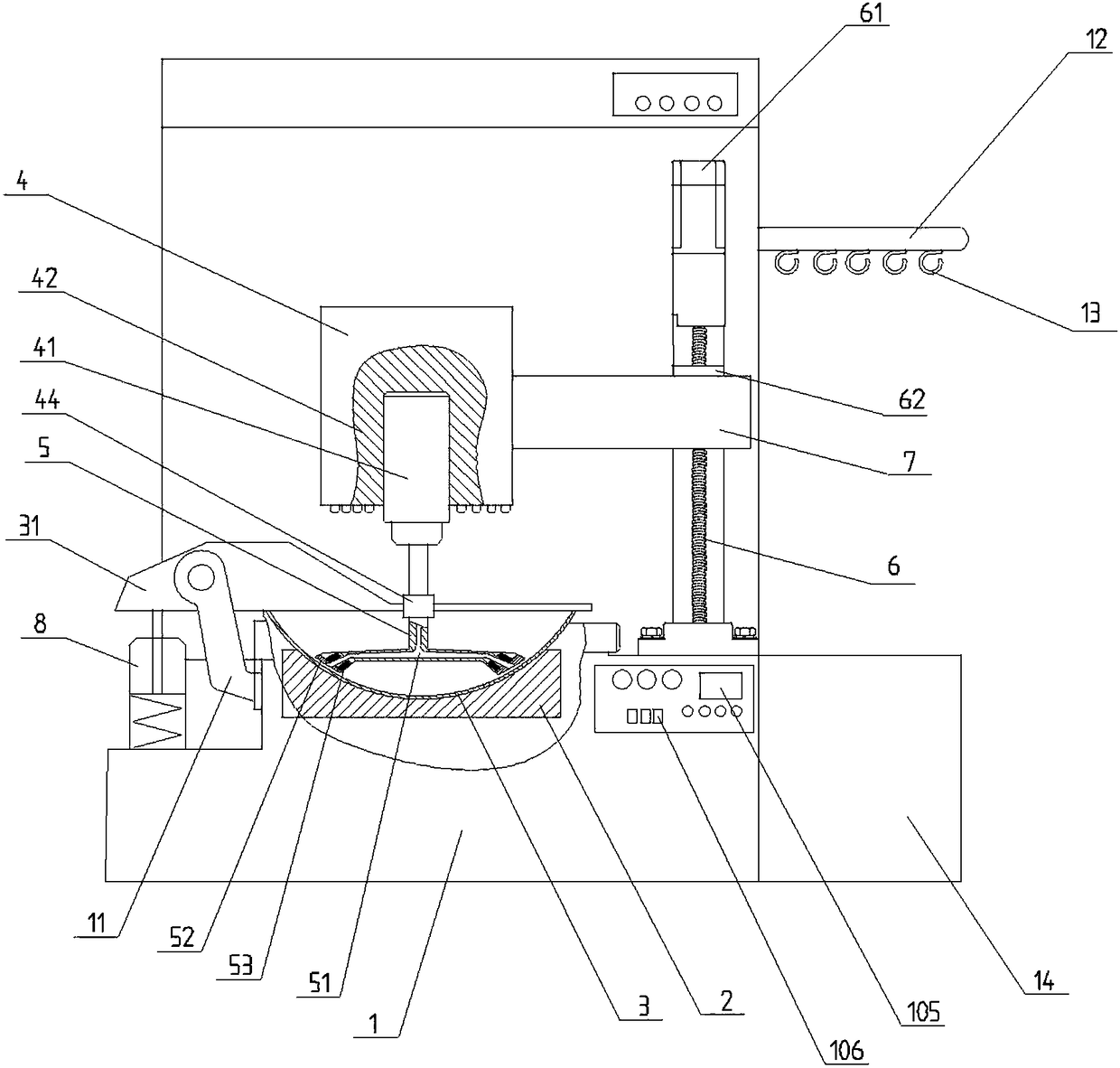

Anti-sticking grain dicing machine for color masterbatch

The invention discloses an anti-sticking grain dicing machine for color masterbatch. The anti-sticking grain dicing machine comprises an extruder head, wherein a blade for grain dicing is connected onto the central part of the extruder head through a rotating shaft; the extruder head comprises an inner ring discharge head and an outer ring discharge head; the inner ring discharge head and the outer ring discharge head discharge the material simultaneously; and the edge of the blade is of an arc-shaped structure. The anti-sticking grain dicing machine has the prominent effects that during a grain dicing production process, grain discharge is more smooth than before; and the situation in a device in the prior art that grains are stuck together when the extruded color masterbatch is diced at the same time is effectively avoided.

Owner:苏州清丰兴业塑胶有限公司

Foaming mold processing method with high cleaning efficiency

InactiveCN111716619AImprove processing efficiencyQuick take outCoatingsPtru catalystToluene diisocyanate

The invention discloses a foaming mold processing method with high cleaning efficiency. The foaming mold processing method with high cleaning efficiency comprises the following steps of firstly, preparing raw materials, wherein the foaming raw materials are prepared from the following components in parts by mass: 40 to 45 parts of resin, 20 to 30 parts of rubber, 8 to 12 parts of toluene diisocyanate, 2 to 4 parts of silica aerogel, 2 to 3 parts of blowing agents, 0.5 to 2 parts of catalysts, 1 to 1.5 parts of surfactants, 2 to 4 parts of foam stabilizers and 3 to 5 parts of graphene. According to the foaming mold processing method with high cleaning efficiency, through the steps of preparing the raw materials, foaming and stirring, brushing an oil layer and placing a membrane, performinginjection molding, performing curing and the like, the processing efficiency of a foaming mold is increased; and meanwhile, an oil brushing layer is arranged and the membrane is placed, so that the foaming mold can quickly clean the residual inside the mold during a machining process, the oil brushing layer can effectively avoid the adhesion of a product and the mold, and the membrane is added toenable the mold to be quickly taken out without adhesion after machining and shaping.

Owner:NANTONG ZHONGHUI MOLD CO LTD

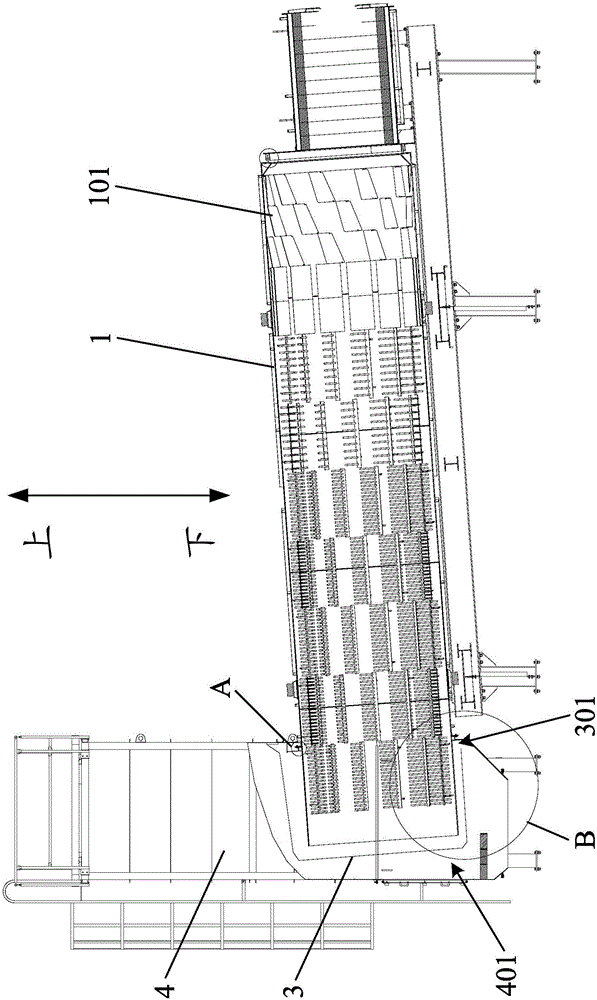

Soil crushing device with screening function

InactiveCN110586270AReduced volatile liquid contentReduce moisture contentContaminated soil reclamationGrain treatmentsEngineeringEnvironmental remediation

The invention discloses a soil crushing device with a screening function and belongs to the technical field of environment repair. The soil crushing device comprises a box body, a partitioning assembly and a crushing assembly, wherein a feeding hopper is arranged on the top; the partitioning assembly is arranged in the box body to partition the inner side of the box body into upper and lower cavities, a gas guide part is arranged around the inner wall of the upper cavity of the box body and is connected to a steam generator arranged on the outer side of the box body through an air conveying pipe, and a gas sucking pump for sucking gas in the upper cavity of the box body is arranged in the box body; and the crushing assembly is arranged in the lower cavity of the box body and is driven by amotor to rotate to crush an object, and a screen plate is arranged below the crushing assembly for screening particles of crushed objects. The soil crushing device screens and crushes bulky cohesivesoil simultaneously. In order to improve the crushing efficiency, the crushing efficiency is improved by reducing the content of volatile liquids in soil by way of steam extraction, and the soil is repaired. The processed soil particles can be in full contact with a chemical repairing agent.

Owner:ZHEJIANG OCEAN UNIV

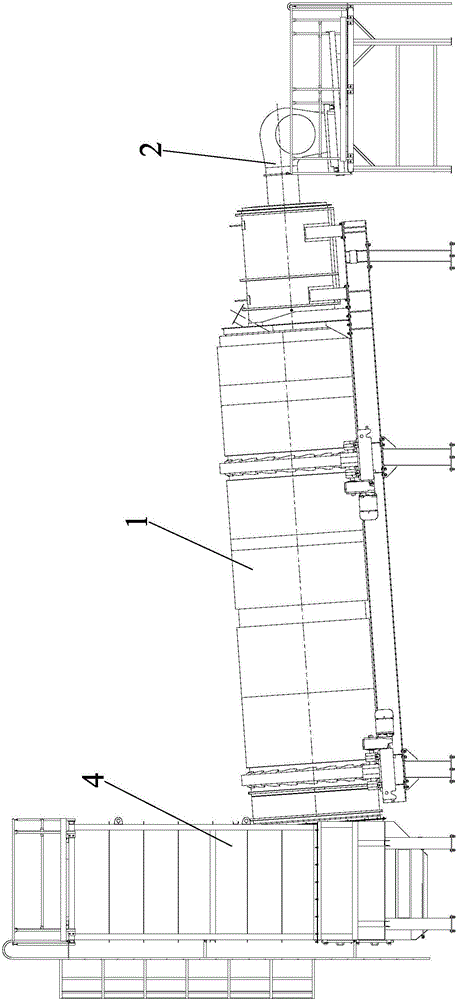

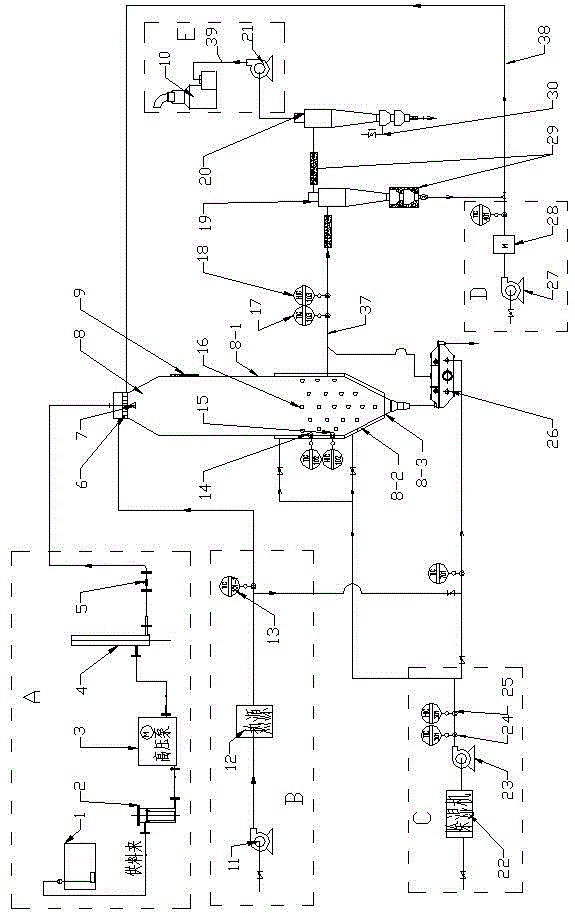

A spray drying system for easy-to-stick materials

ActiveCN103920299BAvoid stickingSolve the sticky situationEvaporation by sprayingAir volumeEngineering

The invention relates to a spray drying system for wall-attaching materials, and relates to the technical field of material drying. According to the invention, a layer of air wall wind with adjustable temperature, humidity and air volume is directly formed at the power-attaching part in a tower, the temperature and the humidity of the air wall wind are lower than the thermal boning temperature and the moisture absorption humidity of powder and particle materials, the air wall wind and the wind in the tower are finally mixed to form mixed wind, the temperature and humidity of the mixed wind are lower than the thermal boning temperature and the moisture absorption humidity of the powder and particle materials, and the temperature of the particle materials under the action of air wall wind before contacting the tower wall is lower than the thermal boning temperature. With the adoption of the system provided by the invention, three wall-attaching conditions of materials can be solved or reduced, and the effects of improving the production efficiency, improving the per unit yield, reducing energy consumption, prolonging the continuous production time, improving the production safety and the improving the quality of a product are achieved through high air inlet temperature.

Owner:陈林书

Air-blowing detachable slice for intelligent frying machine

InactiveCN108056681ASpeed up cookingEasy to manufactureCooking vessel constructionsEngineeringAir blower

The invention relates to an air-blowing detachable slice for an intelligent frying machine. The air-blowing detachable slice comprises a stirring spatula and a rotating motor capable of controlling the stirring spatula to rotate, the rotating motor is sleeved with an air blower capable of blowing air to the surface of a wok, the air blower is in a circular-ring shape, and the air blower and the rotating motor are coaxially arranged; two or above air outlets are formed in the bottom face of the air blower, and are distributed in a circumference array mode; a water through hole capable of spraying to the surface of the wok is formed in the stirring spatula; the stirring spatula is in a reverse-T shape; spatula blocks are arranged at the two ends of the bottom of the stirring spatula and connected with the stirring spatula through springs, and the water through hole is in a reverse-T shape and penetrates through the spatula blocks; the stirring spatula is detachably connected with the rotating motor through a connecting piece. According to the air-blowing detachable slice for the intelligent frying machine, the rotating motor is detachably connected with the stirring spatula through the connecting piece, the air blower is additionally arranged, and the wok can be rapidly dried.

Owner:杭州知意达科技有限公司

A foot pad device for outdoor dining table and chairs

The invention discloses a foot pad device for outdoor dining tables and chairs. The foot pad device includes a hoop used for being connected with the outdoor dining tables and chairs; a connection rodis vertically and fixedly arranged on the hoop, the connection rod is fixedly provided with a storage barrel, the bottom of the storage barrel is provided with a through hole communicated with the outside, the bottom surface of the storage barrel is fixedly provided with an annular electromagnet, the bottom surface of the annular electromagnet is fixedly provided with a plastic film used for blocking the through hole, magnetic mud is stored in the storage barrel, and the storage barrel is internally provided with a pressurization device acting on the magnetic mud; the portion, located betweenthe hoop and the storage barrel, of the connection rod is fixedly provided with a planar disk used for placing the dining tables and chairs, the pressurization device includes a pressurization platearranged in the storage barrel in a sliding mode, the upper surface of the pressurization plate is rotatably connected with a work rod, the top of the storage barrel is fixedly provided with a cover body, and the work rod penetrates through the cover body in a threaded mode and is communicated with the outside. According to the foot pad device, softness of the magnetic mud is made use of, the magnetic mud can be well used for filling gaps between various objects on the ground, the environment in which the tables and the chairs are placed is improved, and the stability of placement of the tables and the chairs in any environment is ensured.

Owner:永康市简零贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com