Cutting device and method for cylindrical paper core for filter part

A technology for cylindrical and filter parts, which is applied in the field of cylindrical paper core cutting devices for filter parts, can solve the problems of inability to meet large-scale continuous industrial production, the inability to completely cut the cylindrical cutting surface, and the inability to completely cut off the hot melt adhesive strip. , to achieve the effect of compact structure, uniform force and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

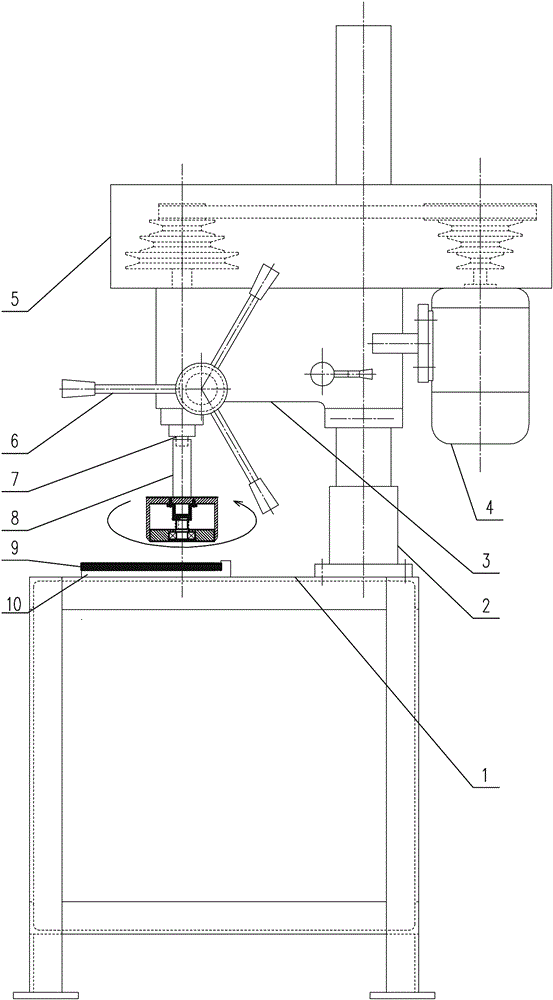

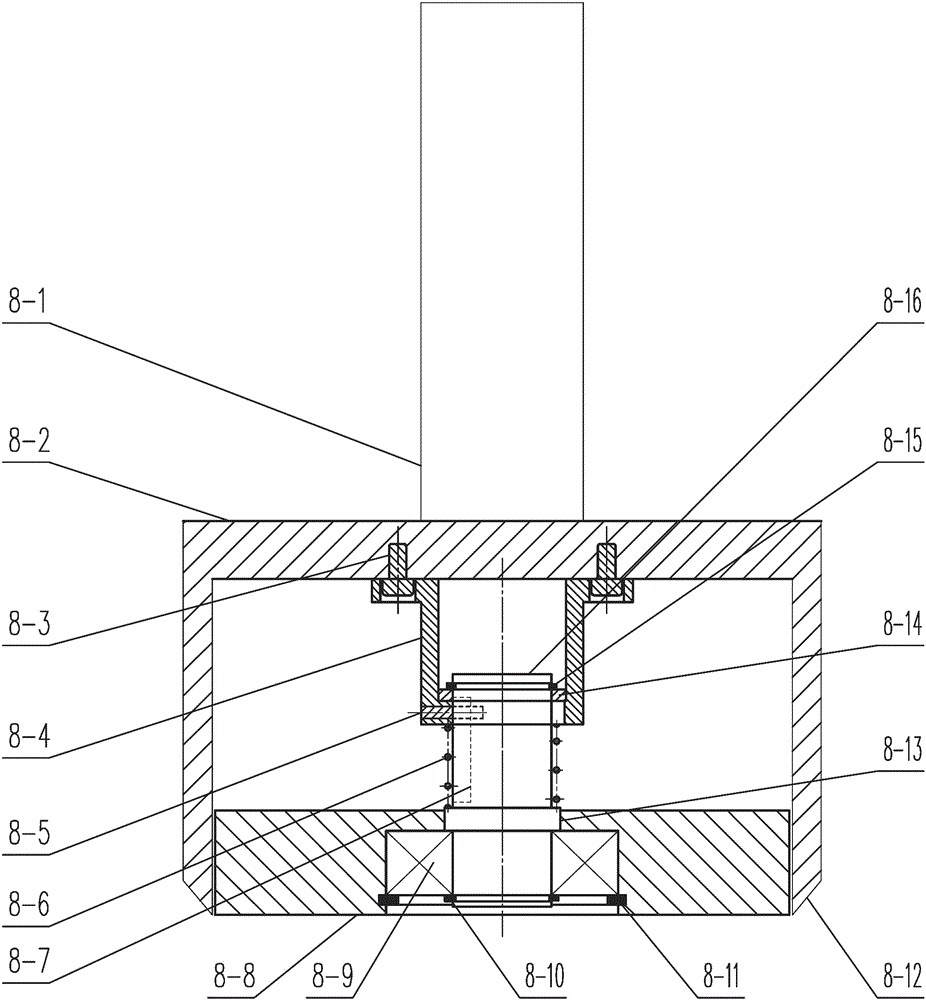

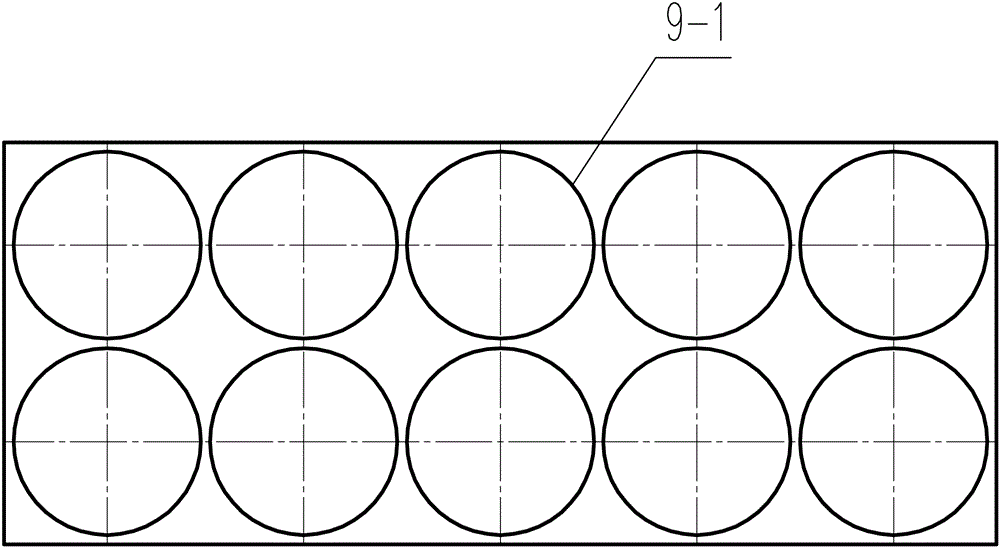

[0031] Such as Figure 1-4 As shown, a cylindrical paper core cutting device for filter elements, it includes a workbench 1, a support 2 is installed on the workbench 1, a mechanical arm 3 is installed on the support 2, and the mechanical arm 3 A rotating motor 4 is installed on it, the rotating motor 4 is connected with a gearbox 5, the output shaft of the gearbox 5 is connected with a rotating shaft 7 and transmits torque, a circular cutter 8 is installed on the rotating shaft 7, and the mechanical arm 3 is equipped with a handwheel 6, and a mounting table 10 is provided directly below the circular cutter 8. During the working process, the gearbox 5 is driven by the rotating motor 4, the rotating shaft 7 is driven by the gearbox 5, the circular cutter 8 is driven by the rotary shaft 7, and then the circular cutter 8 is driven to cut the W-shaped folded filter paper 9. By turning the hand wheel 6 can make the rotating shaft 7 telescopically move up and down.

[0032] Furthe...

Embodiment 2

[0036] Adopt any cutting device to carry out the paper core cutting method, it comprises the following steps:

[0037] The first step: pre-fix the W-shaped folded filter paper 9 on the mounting table 10 on the workbench 1, turn on the switch of the rotating motor 4, the rotating motor 4 drives the rotating shaft 7 to rotate, and the circular cutter 8 rotates together with the rotating shaft 7. Adjust the speed change knob, and the gearbox 5 can make the circular cutter 8 reach a suitable speed through the transformation combination of different transmission wheels;

[0038] In the second step, press the hand wheel 6 downward, the rotating shaft 7 drives the circular cutter 8 to move downward, and the hollow circular pressure plate 8-8 contacts with the W-shaped folded filter paper 9. Under the elastic force of the spring 8-6, the hollow circular Shaped platen 8-8 presses W-shaped folded filter paper 9 so that it does not rotate, while knife edge 8-12 feeds the knife vertically d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com