Patents

Literature

69results about How to "Easy to change speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

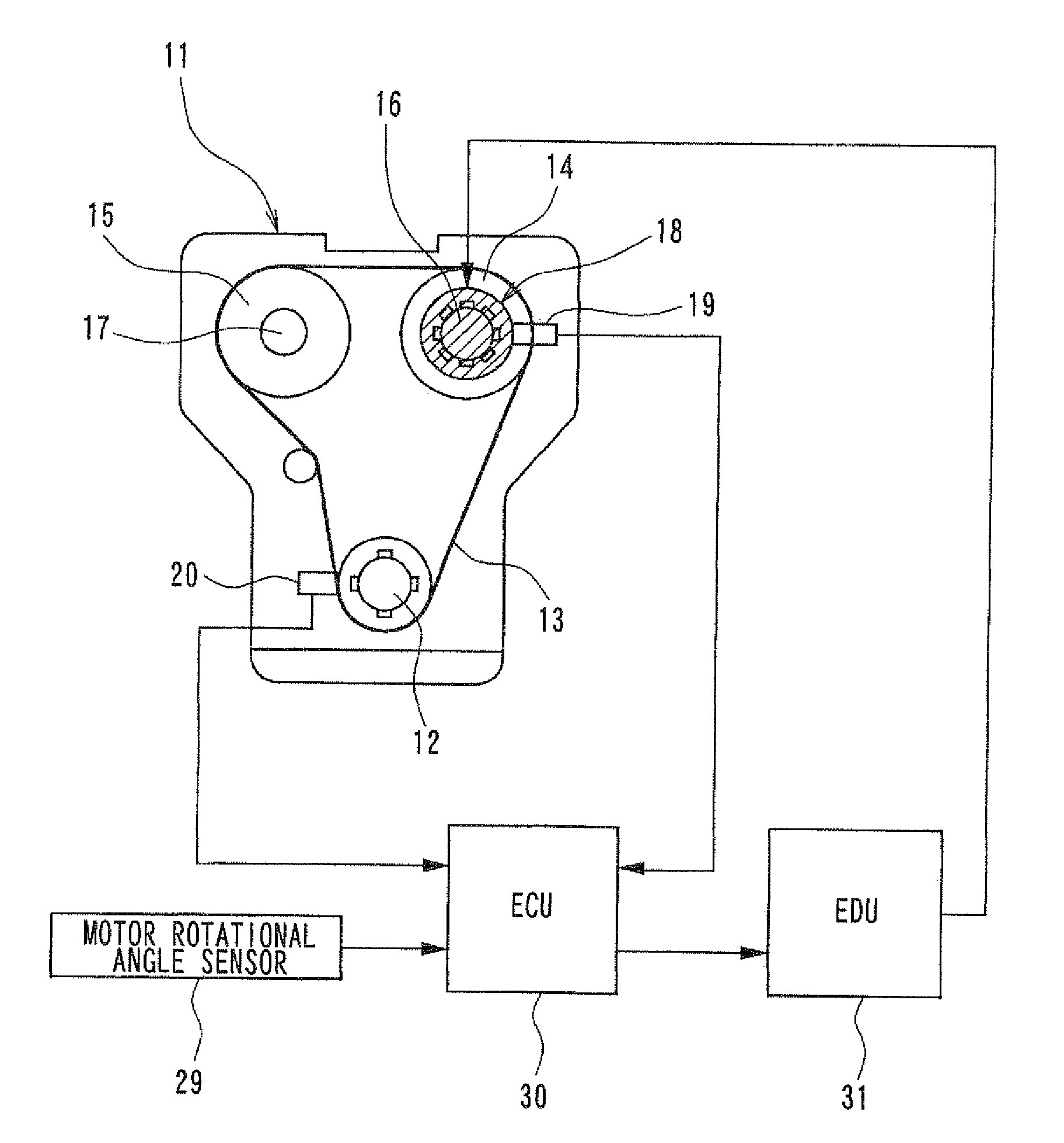

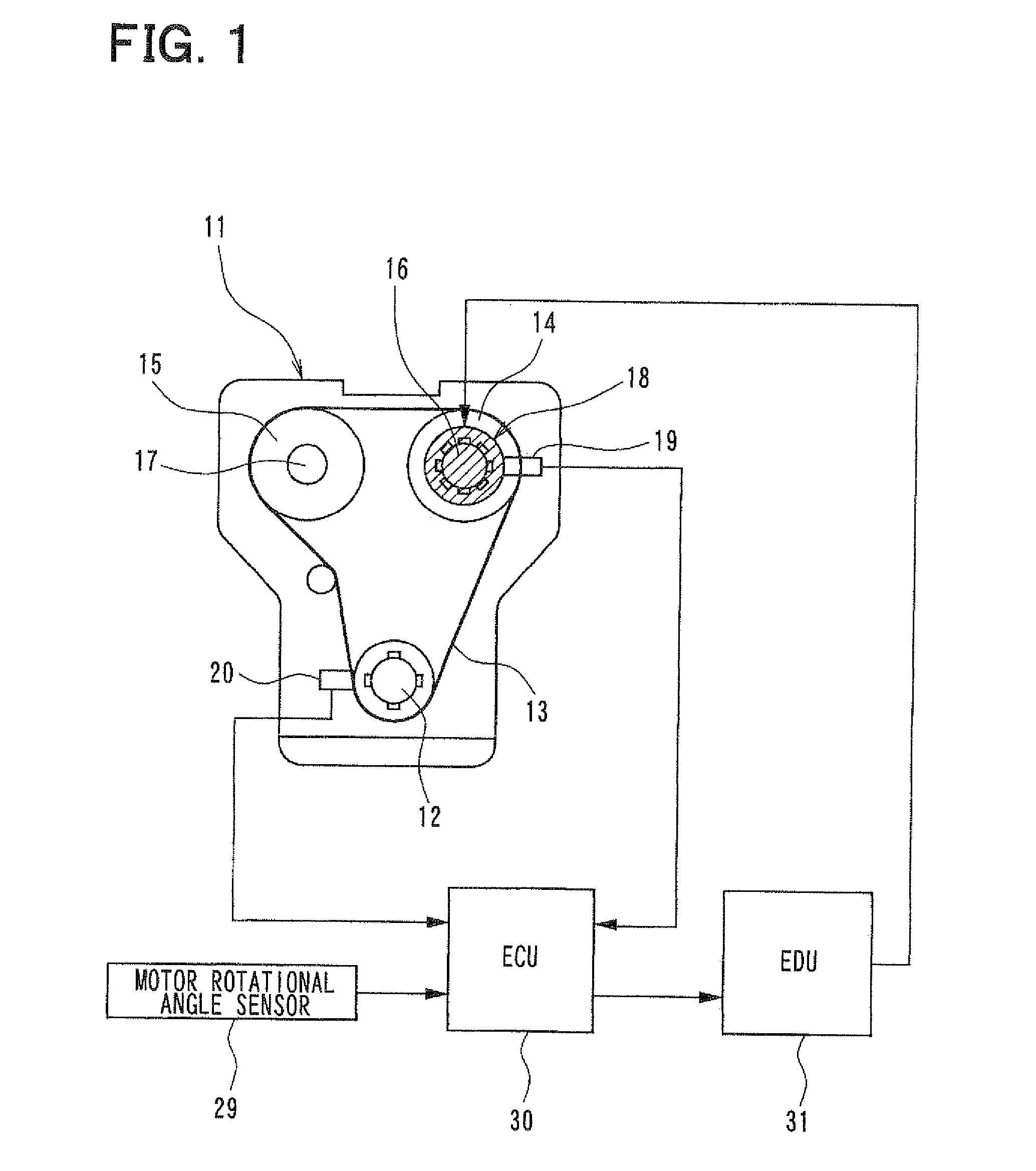

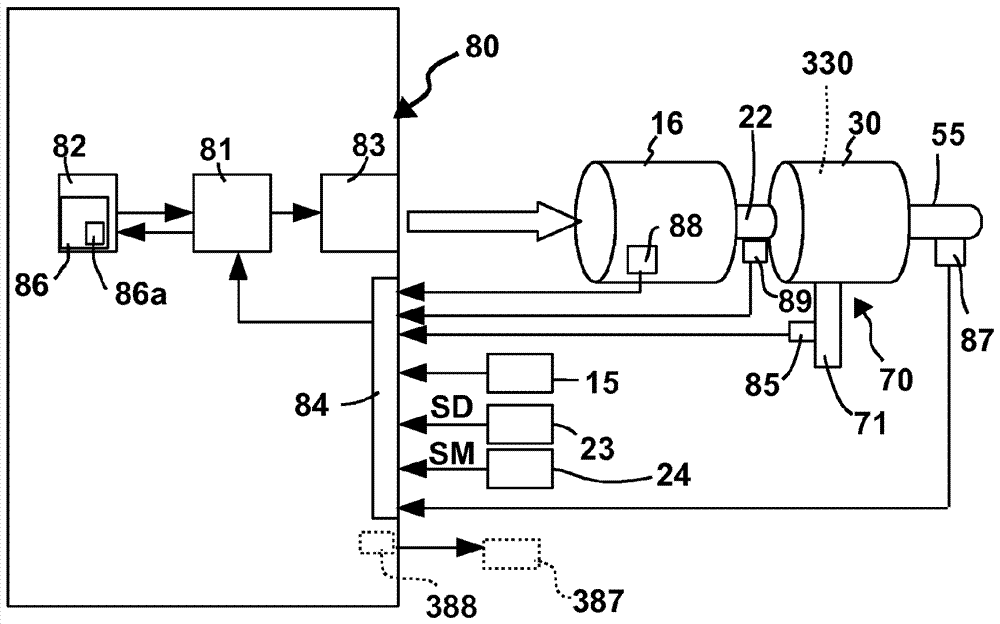

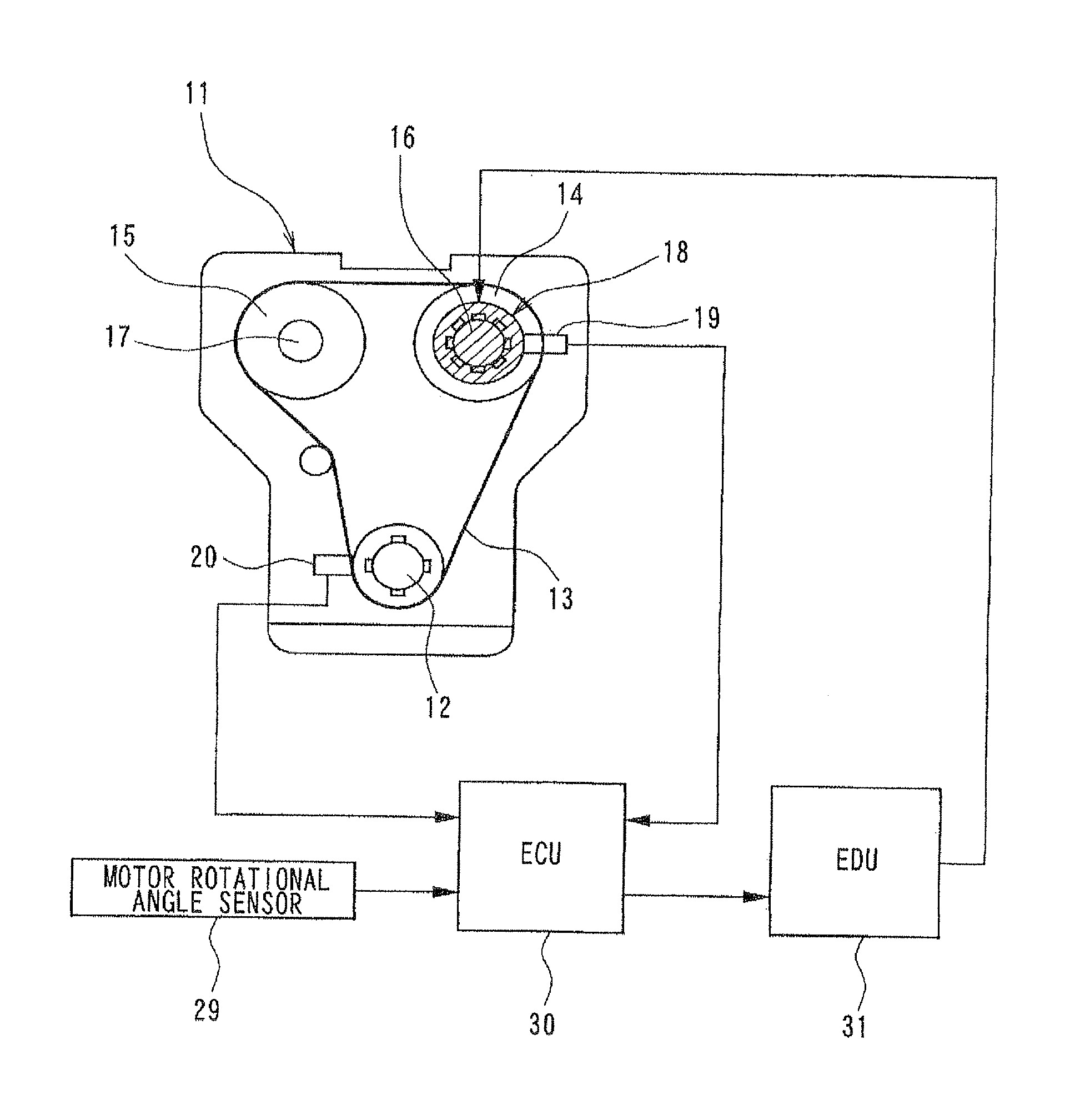

Control system for variable valve timing apparatus

InactiveUS20110100312A1Reduce stepsAccurately reflectValve arrangementsMachines/enginesCamControl system

When a cam shaft phase is changed during engine operation is stopped, a power supply increase control to an electric motor is carried out, according to which a power-supply duty ratio to the electric motor is increased to a predetermined power increase value which is necessary for moving a VVT apparatus during the stop of the engine operation. Then, the power-supply duty ratio is feedback controlled so that an actual changing speed of the cam shaft phase becomes equal to a target changing speed. As a result, the cam shaft phase can be surely changed and operating sound can be reduced by preventing the changing speed of the cam shaft phase from becoming too fast.

Owner:DENSO CORP

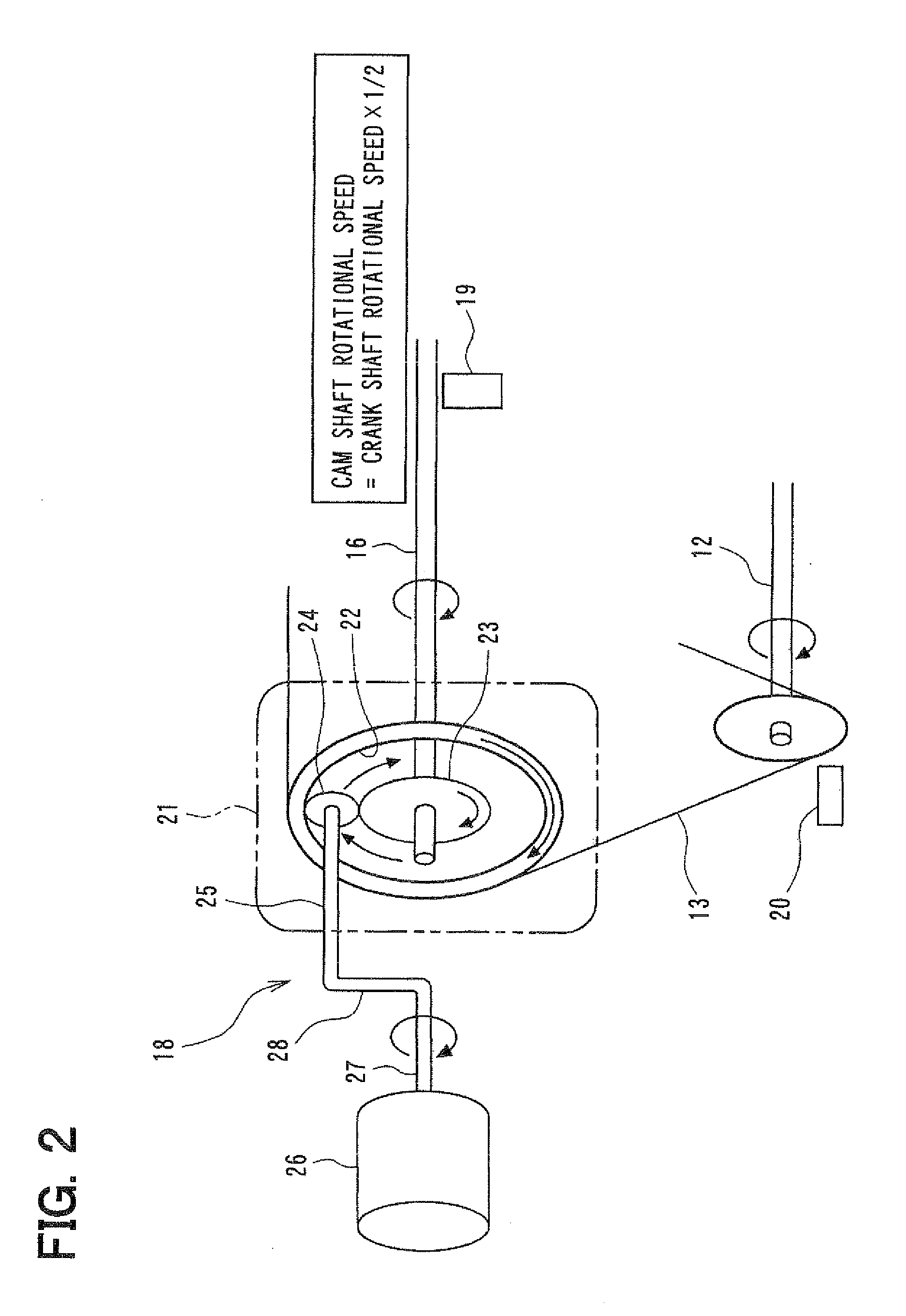

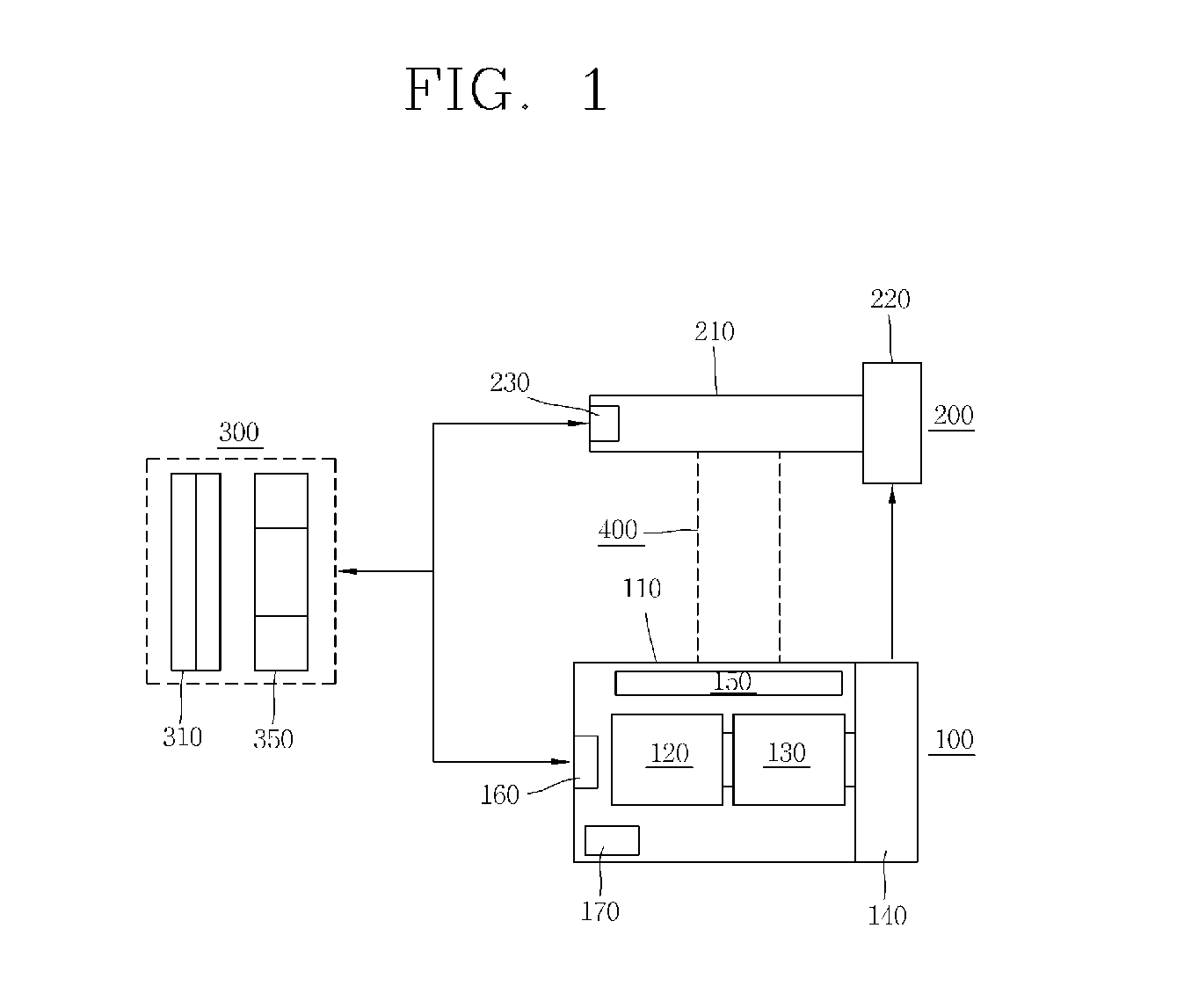

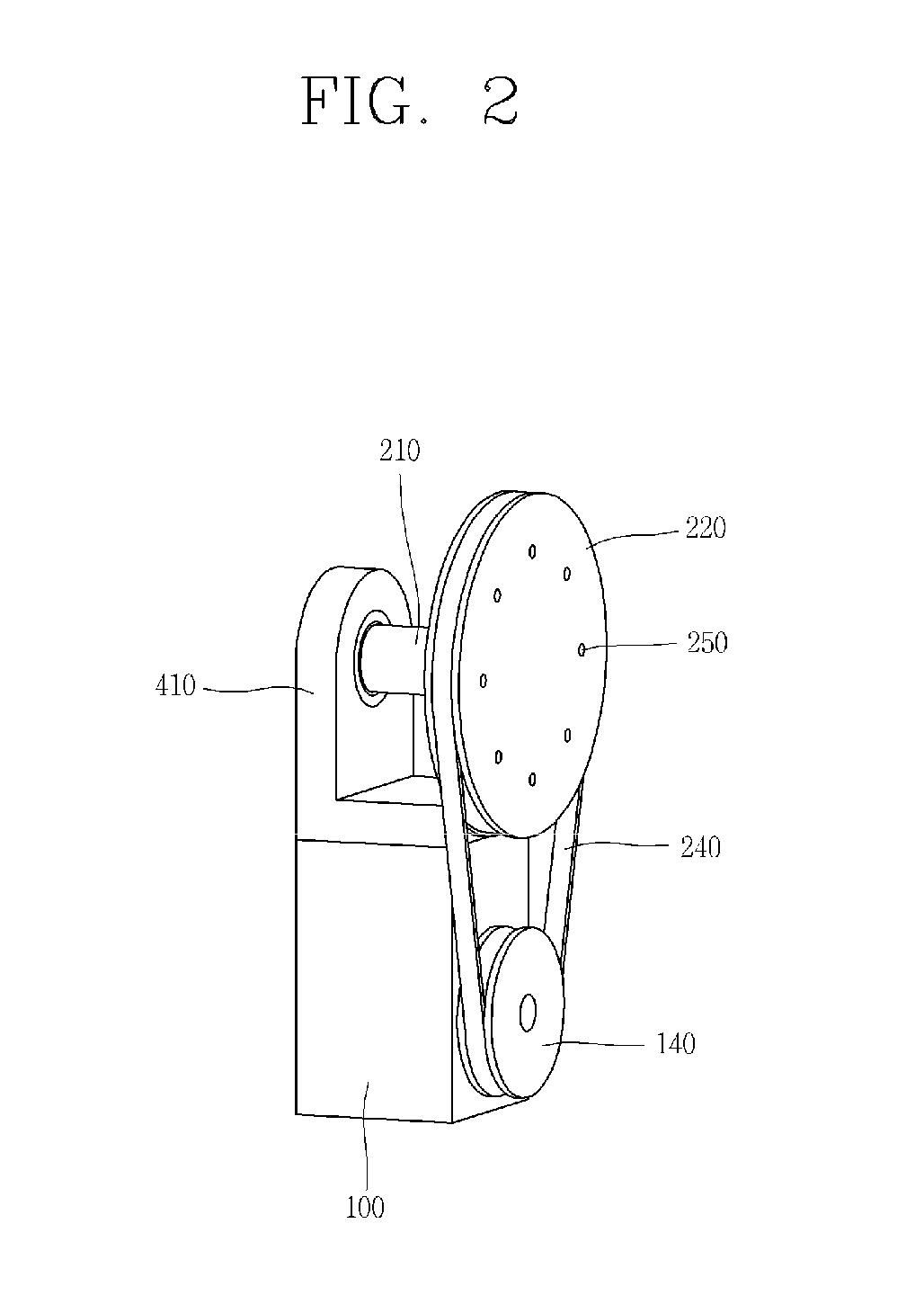

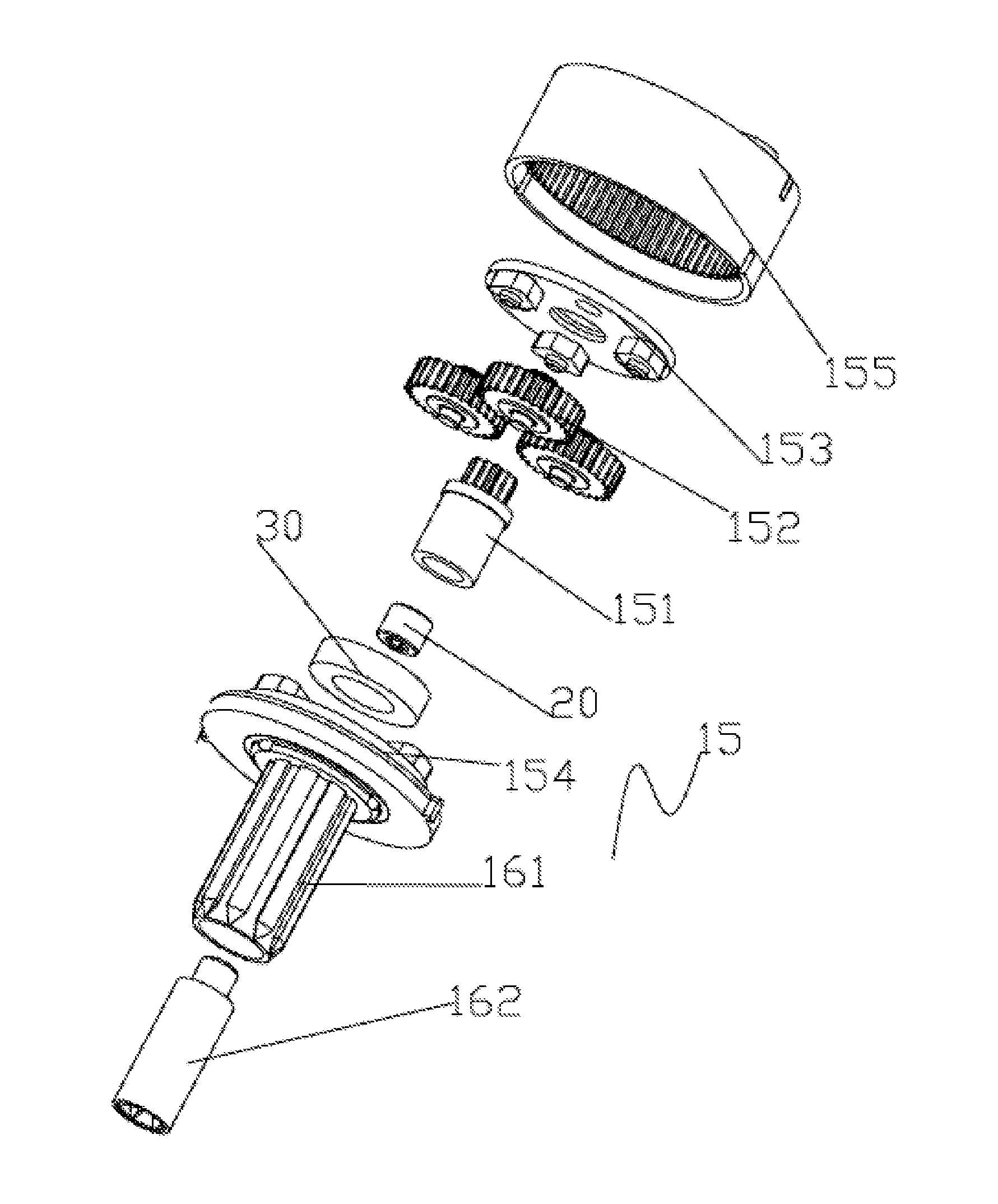

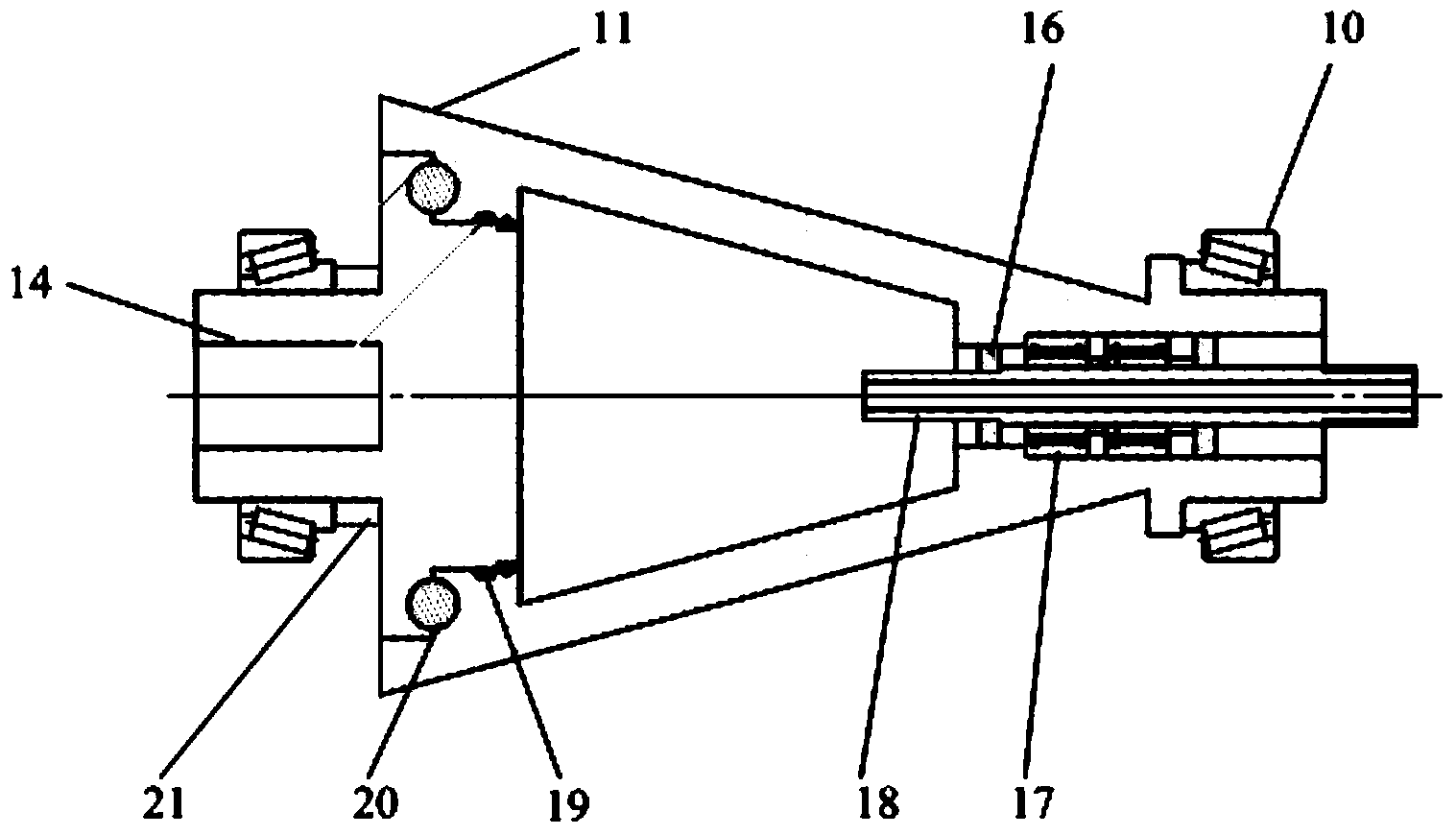

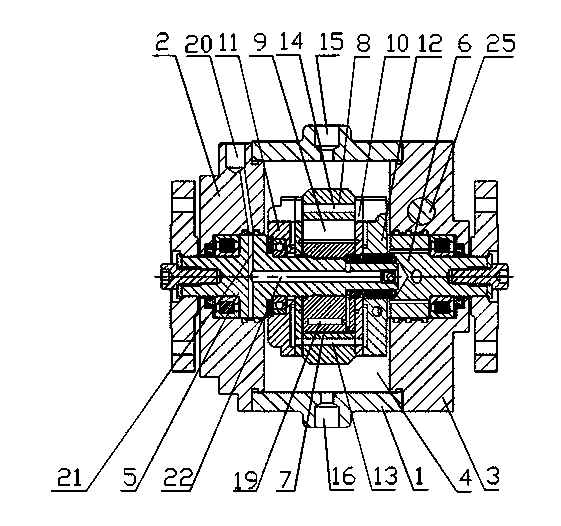

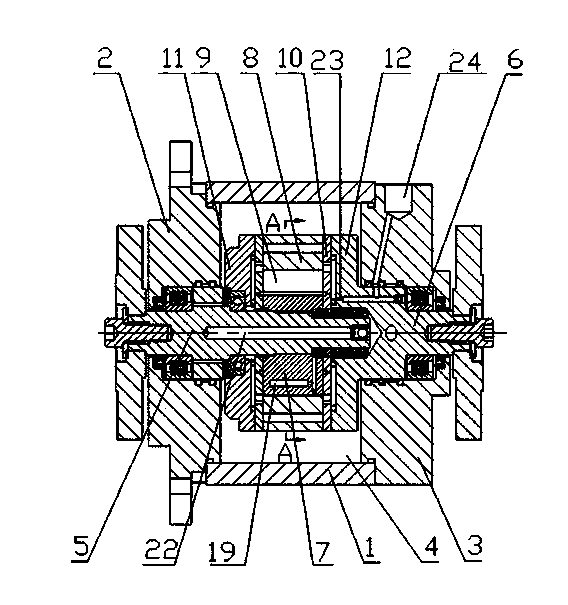

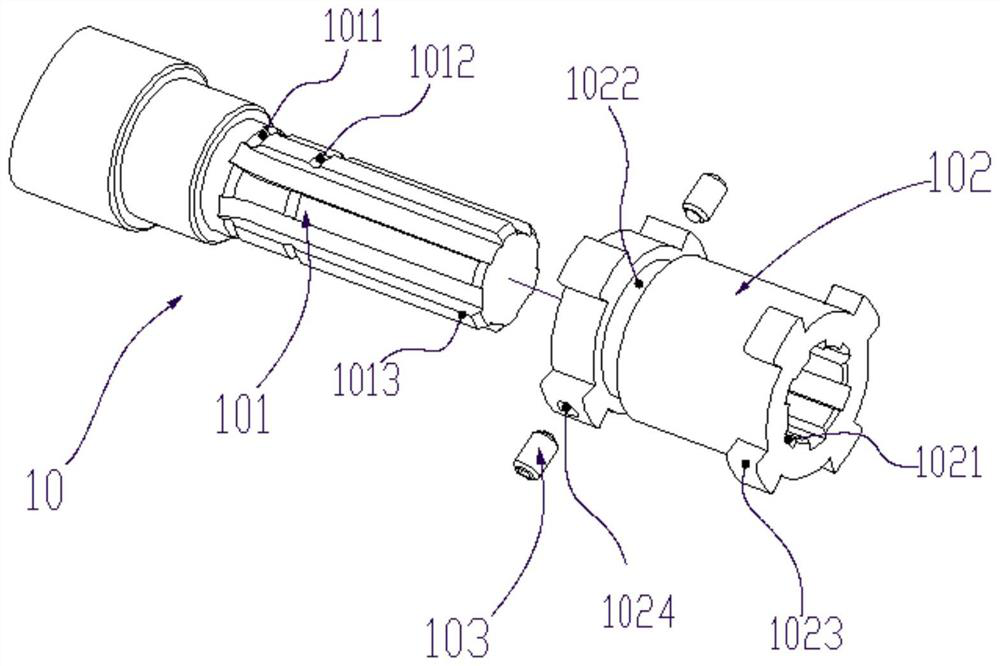

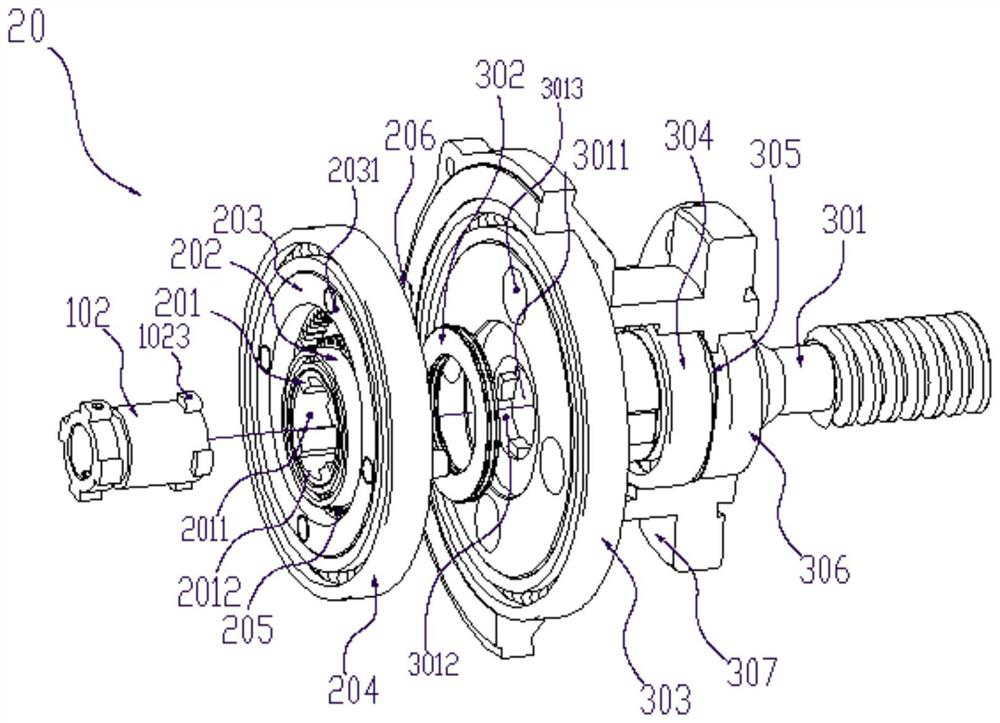

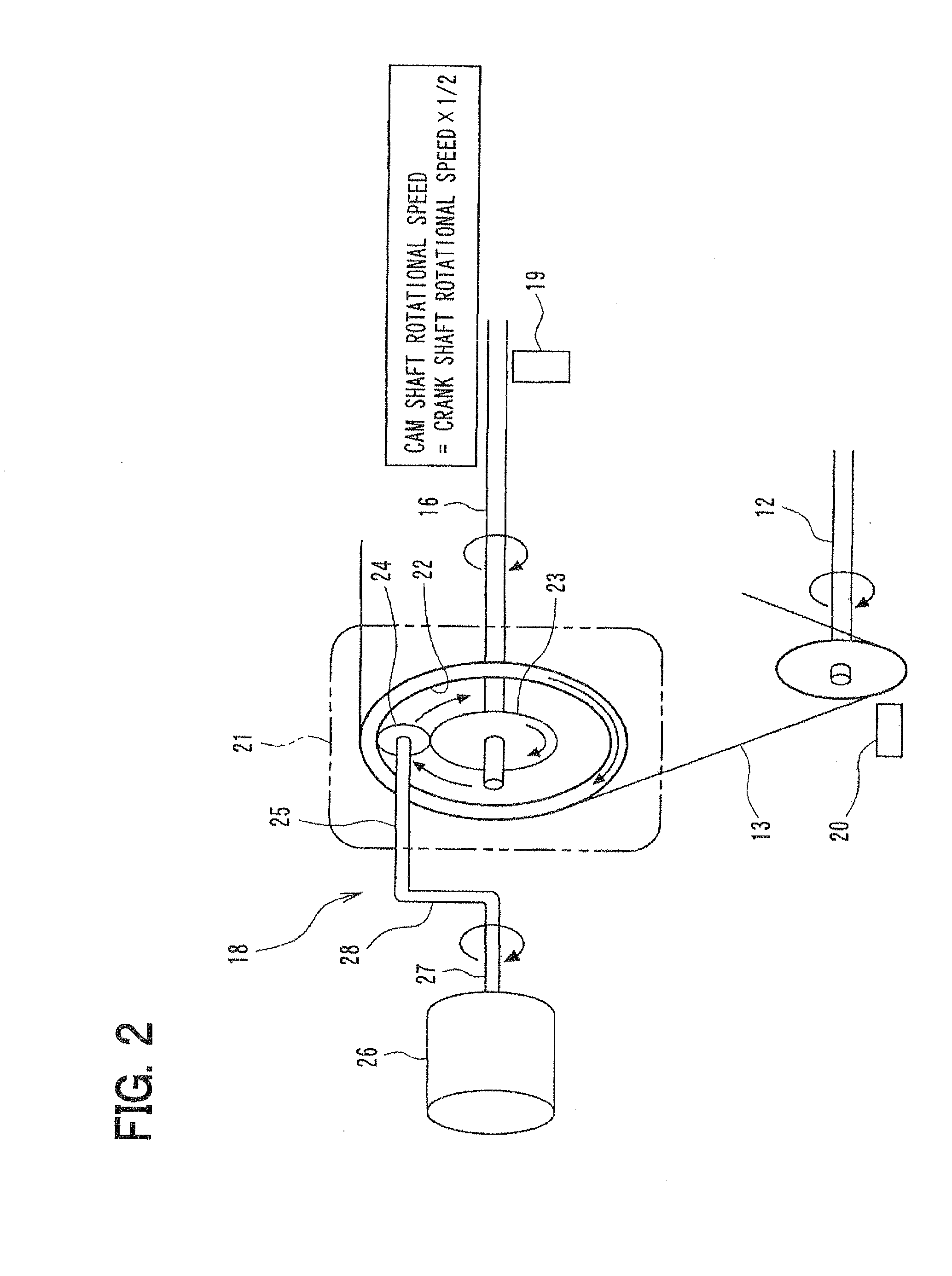

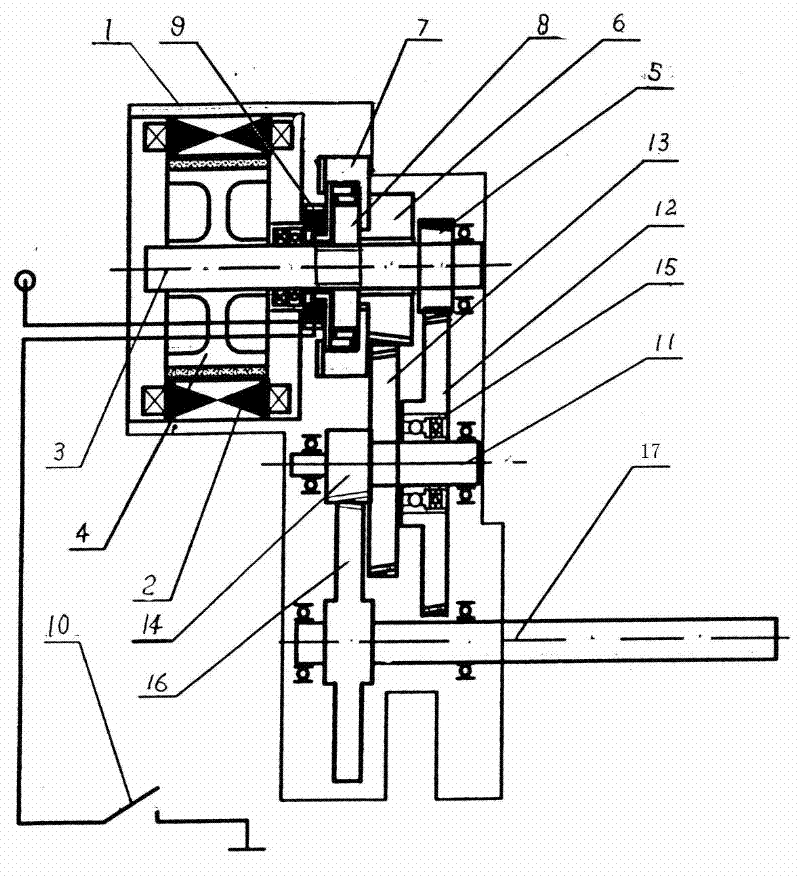

Actuator module applicable to various forms of joint

InactiveUS20110298309A1Maintain balanceIncreased durabilityProgramme-controlled manipulatorJointsElectronic systemsReduction drive

The present invention is about actuator modules that can be applied to various forms of joints and about joint structure using such modules, and the actuator modules includes actuator body comprising of electronics system and drive system and a separately connected decelerator, and the speed and torque obtained from the first deceleration of the actuator module body can be easily changed through the second decelerator, and since the decelerator separately connects with the actuator body it can be applied to various forms of decelerator and the actuator body can be placed varyingly making it applicable to various joint forms, and said actuator modules can be used form various joint structure.

Owner:ROBOTIS

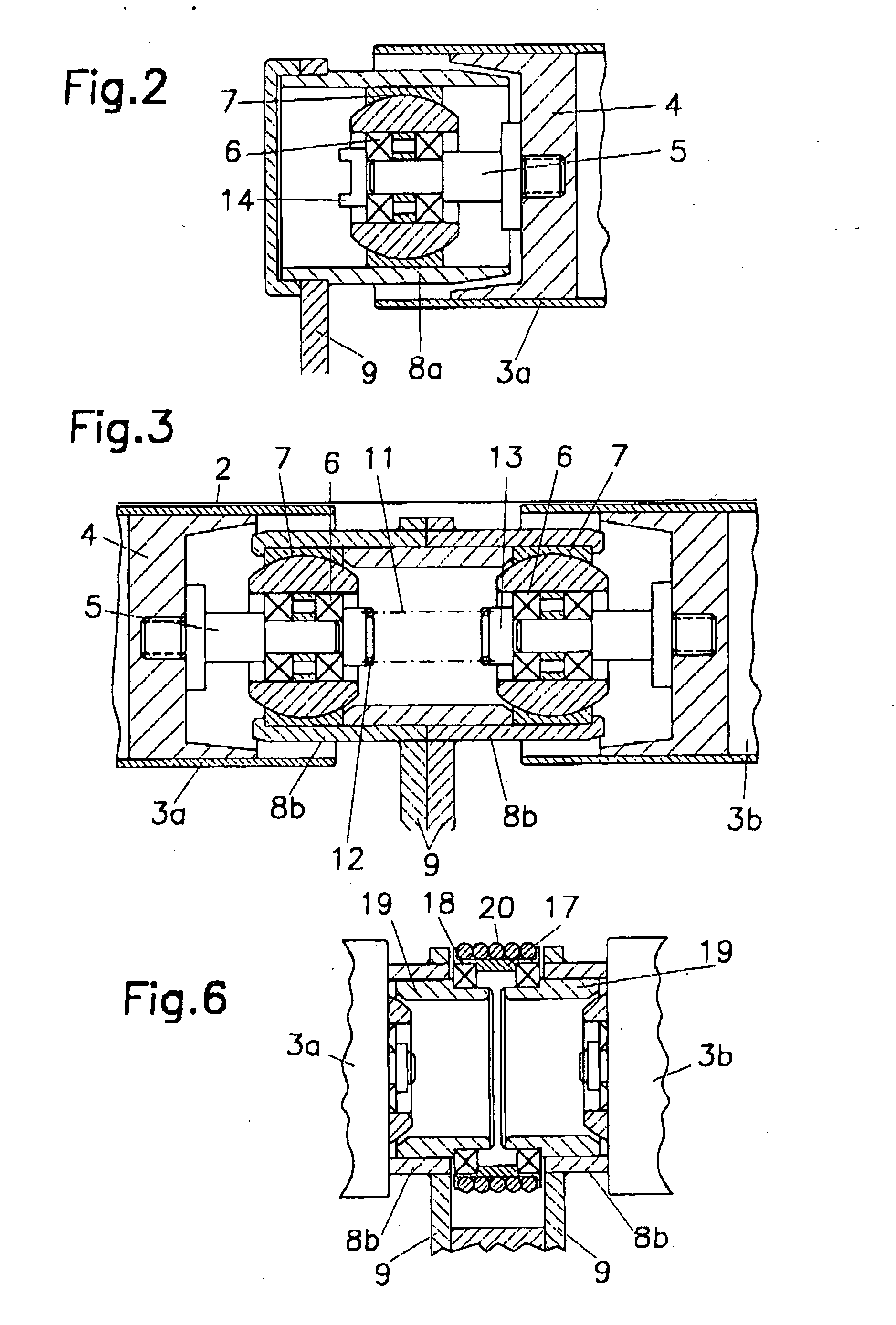

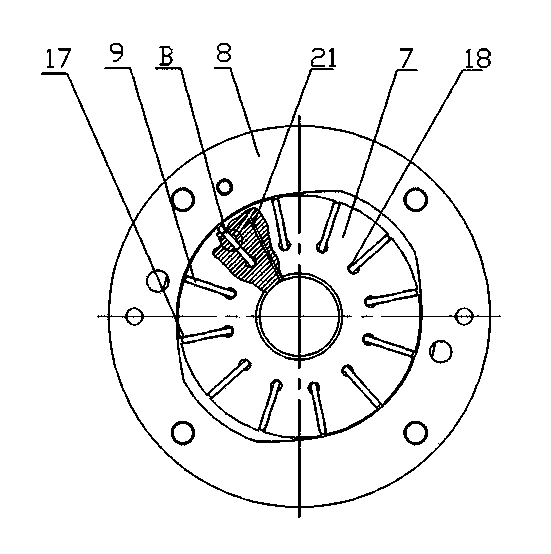

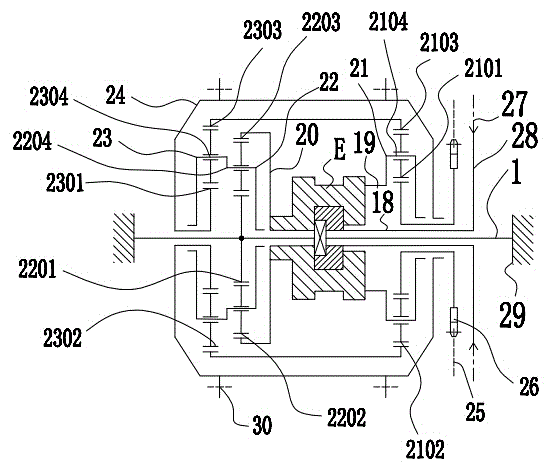

Automatic power speed changer

ActiveCN103104661AImprove self-sufficiencyRealize industrializationToothed gearingsGearing controlLow speedMechanical power transmission

The invention relates to an automatic power speed changer and belongs to the field of mechanical power transmission. According to the automatic power speed changer, on two shafts, achieving speed changing, of the speed changer, at least one high-speed gear and at least one low-speed gear which are provided with different diameters and different numbers of teeth are fixed on one shaft at intervals, at least two remodeled non-inner-ring wedged-block type isolators are axially and detachably sleeved on a spline of the other speed changing shaft in parallel, an inner ring of each isolator is an overall slide sleeve which is provided with a protrusion in the middle and can horizontally slide along the spline, and at least one high-low speed gear and at least one low-speed gear which have different diameters and different numbers of teeth are arranged on an outer ring of each detachable isolator. The automatic power speed changer can reduce self weight and cost and facilitate achieving speed changing.

Owner:苏州宇明鑫电力科技发展有限公司

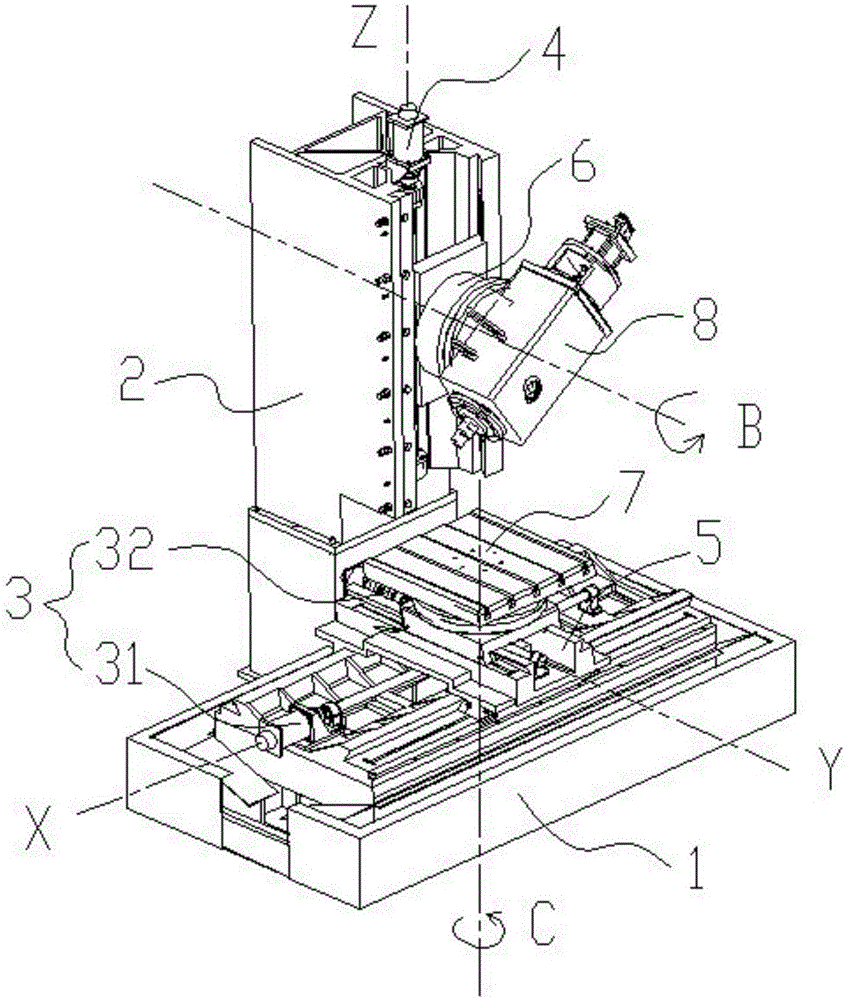

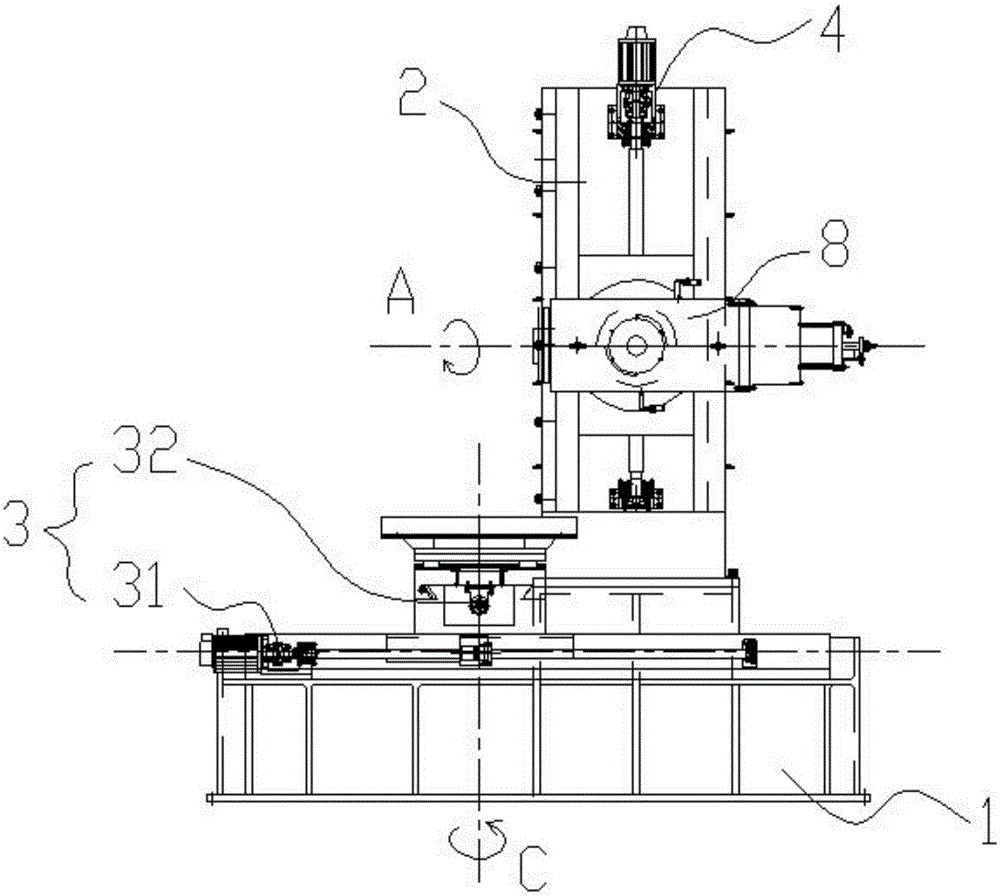

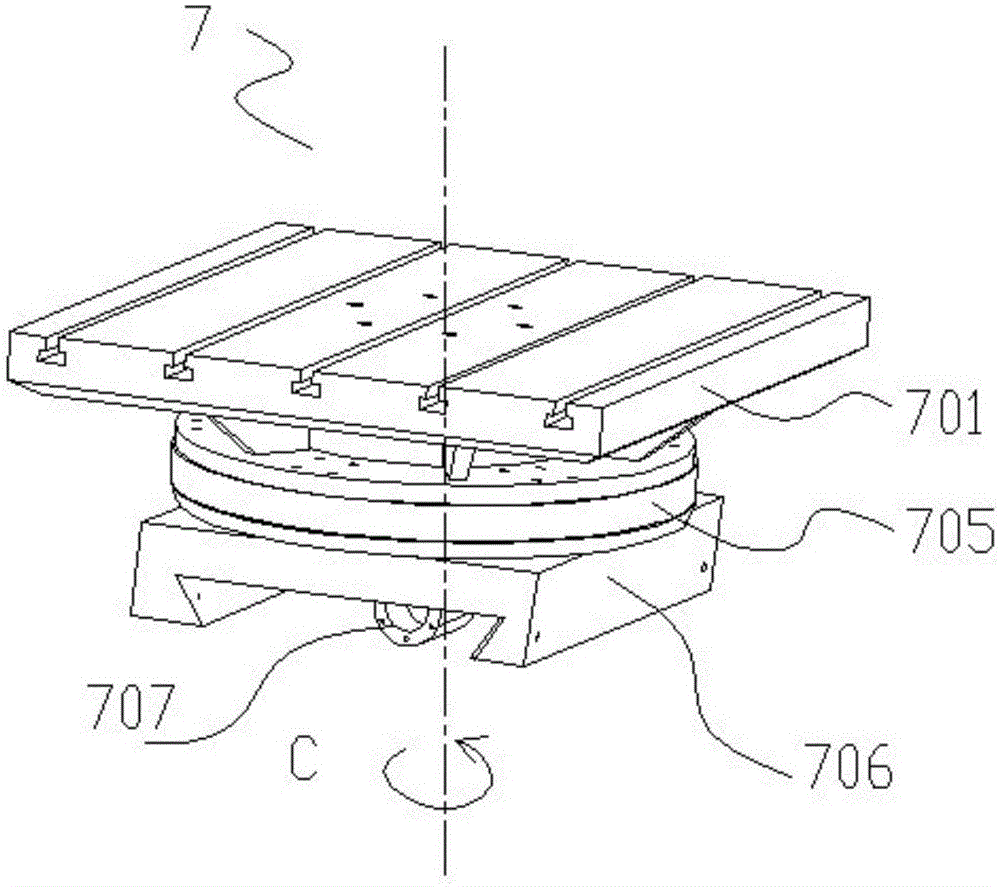

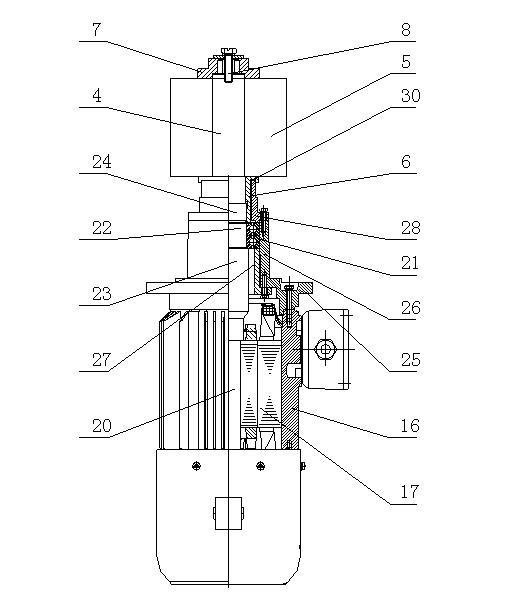

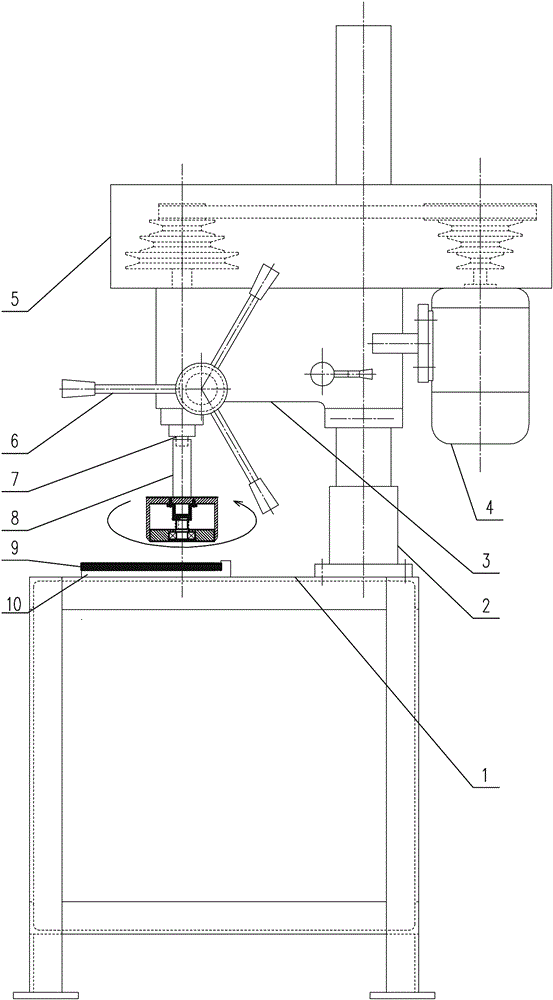

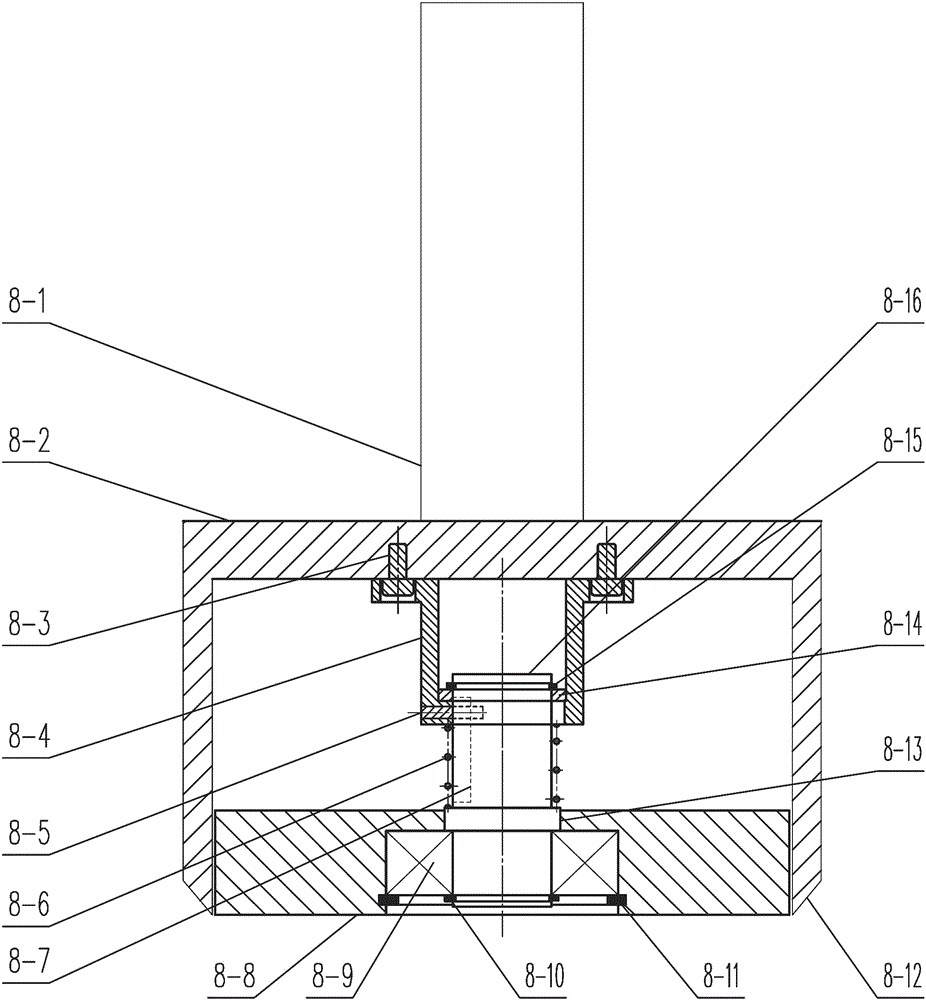

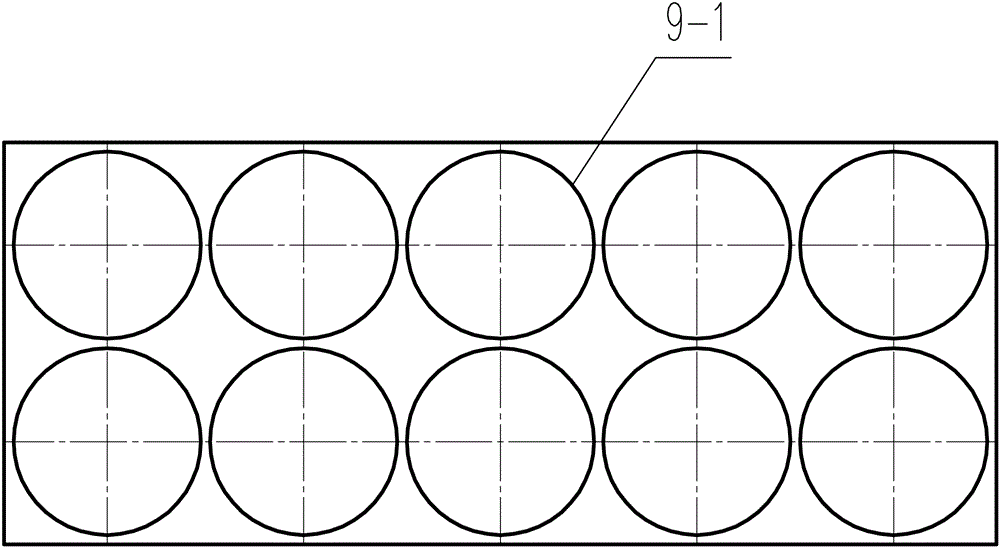

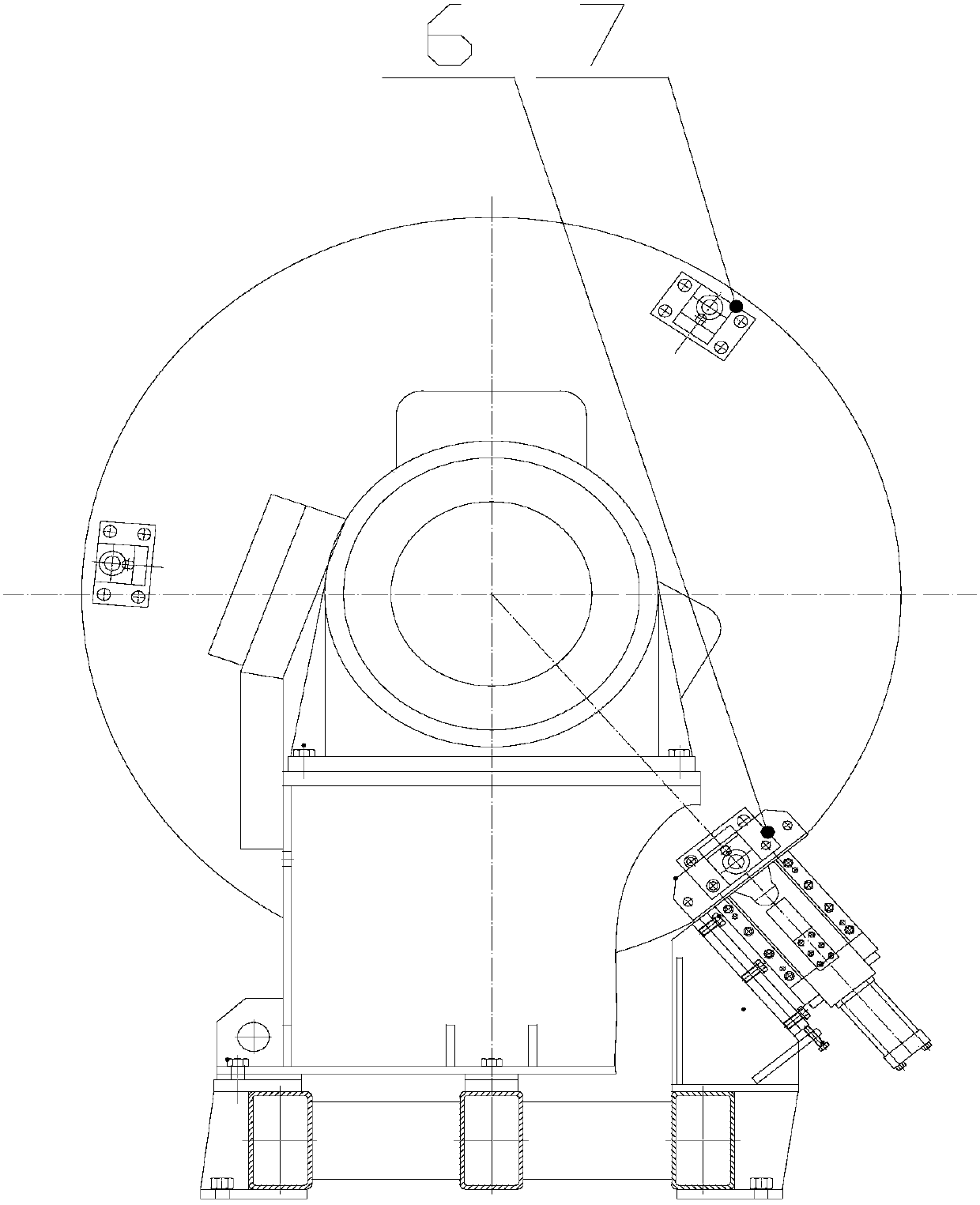

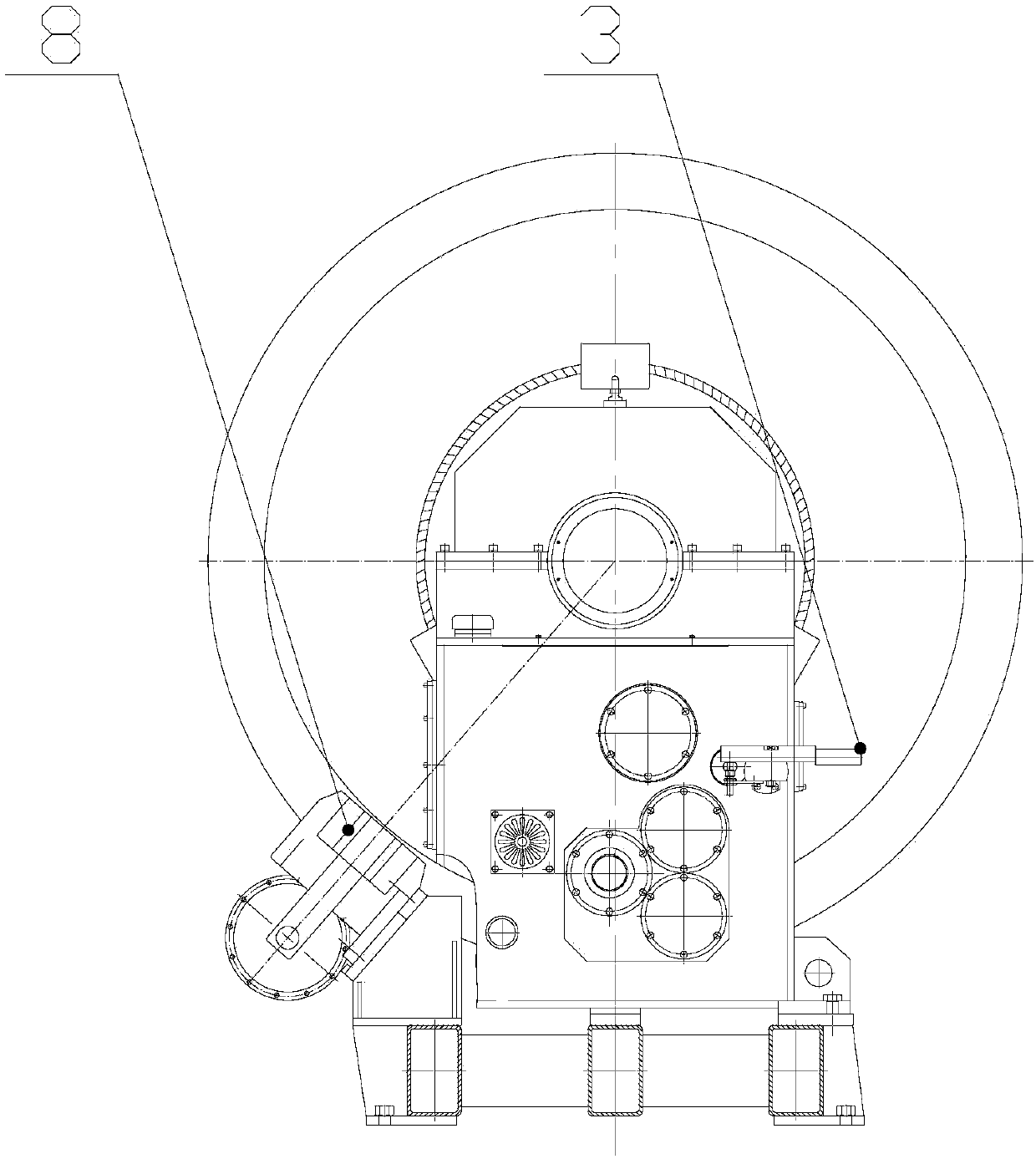

Novel single-spindle pentahedron machining CNC milling machine

ActiveCN105108214AReduce manufacturing costReduce processing costsPrecision positioning equipmentMilling machinesEngineeringPentahedron

The invention discloses a novel single-spindle pentahedron machining CNC milling machine, belongs to the field of numerically-controlled machine tools and relates to pentahedron machining tools. The novel single-spindle pentahedron machining CNC milling machine comprises a lathe bed, a stand column, a horizontal feeding system and a vertical feeding system. The vertical feeding system is connected with a spindle in a 360-degree rotating mode through a spindle indexing device. The horizontal feeding system is connected with a workbench indexing device in a 360-degree rotating mode. According to the novel single-spindle pentahedron machining CNC milling machine, a single-spindle pentahedron can be machined; meanwhile, machining transmission precision and indexing accuracy are improved, the machining range is widened, machining efficiency is improved and the machining cost is lowered.

Owner:邓力凡

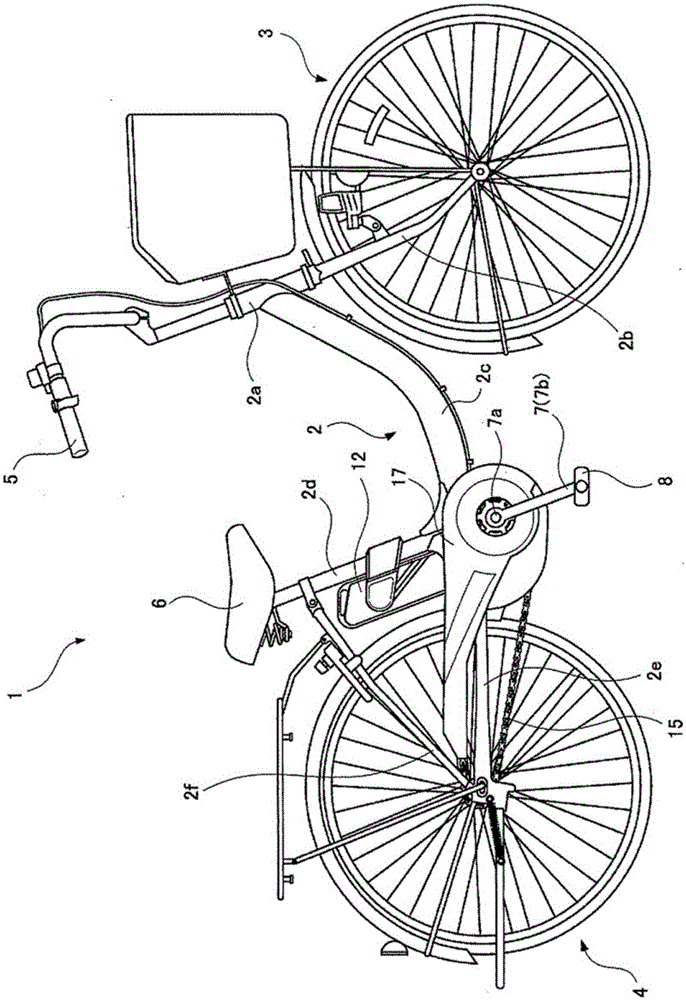

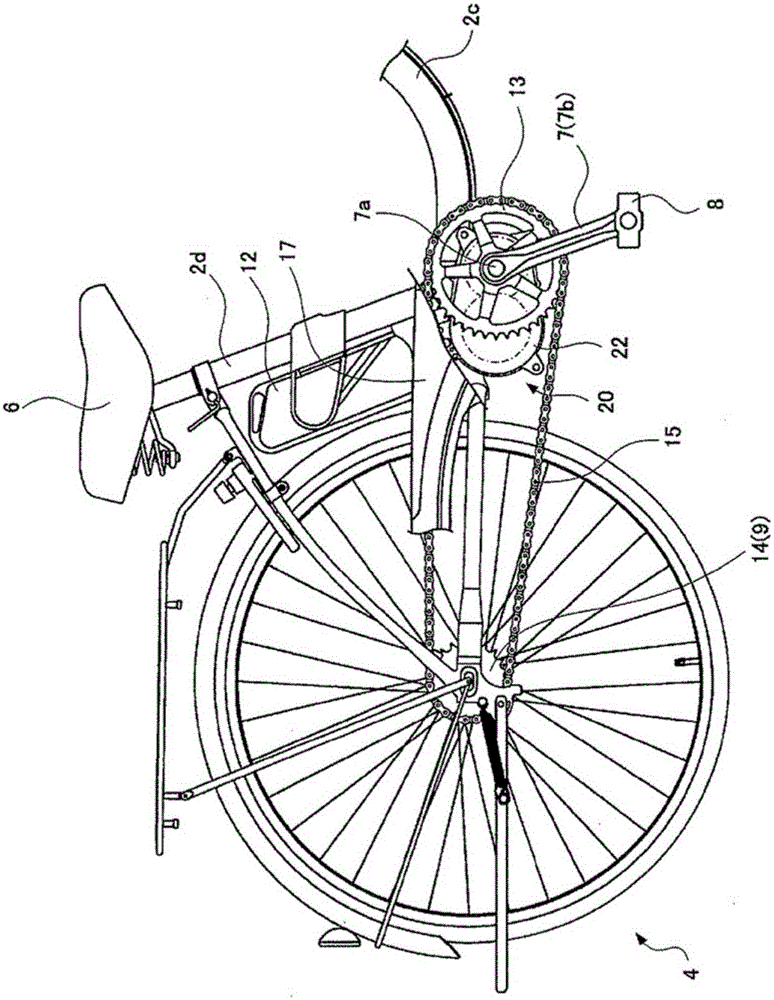

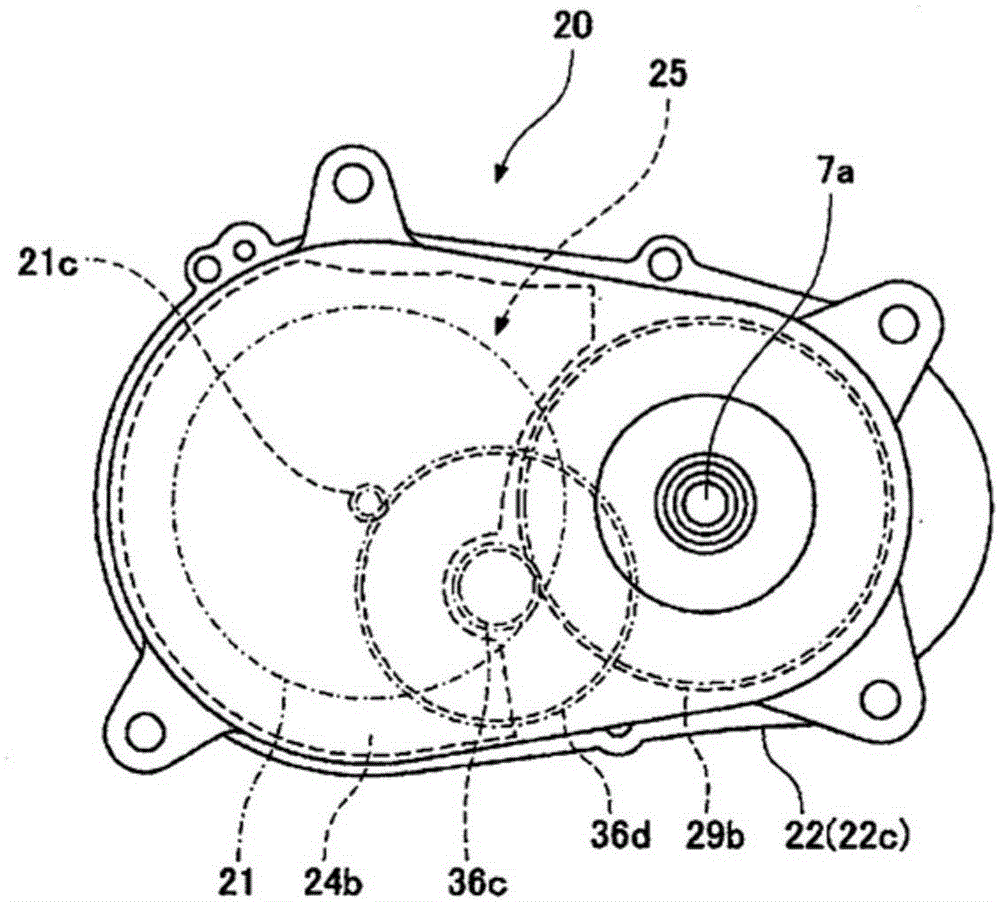

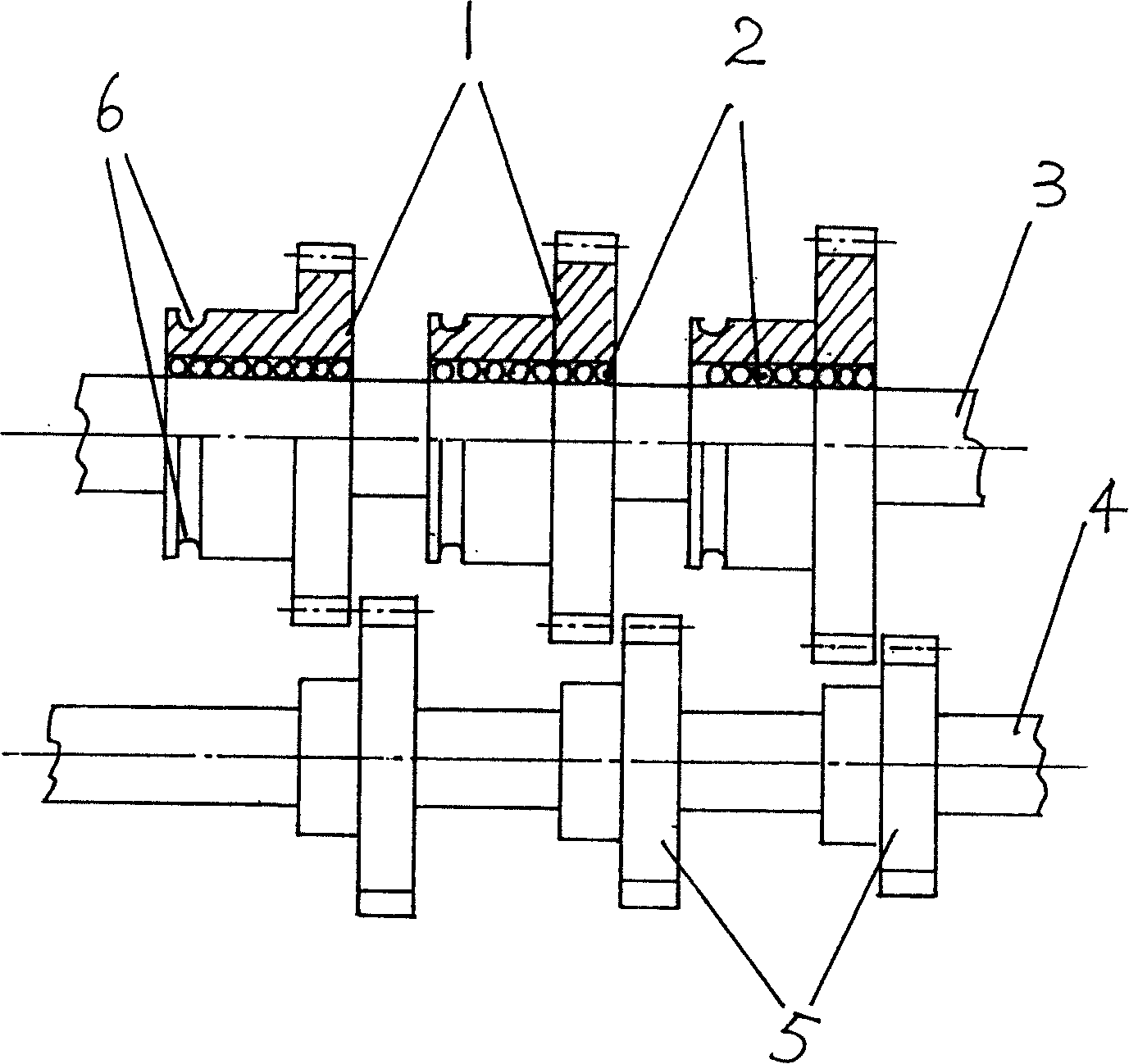

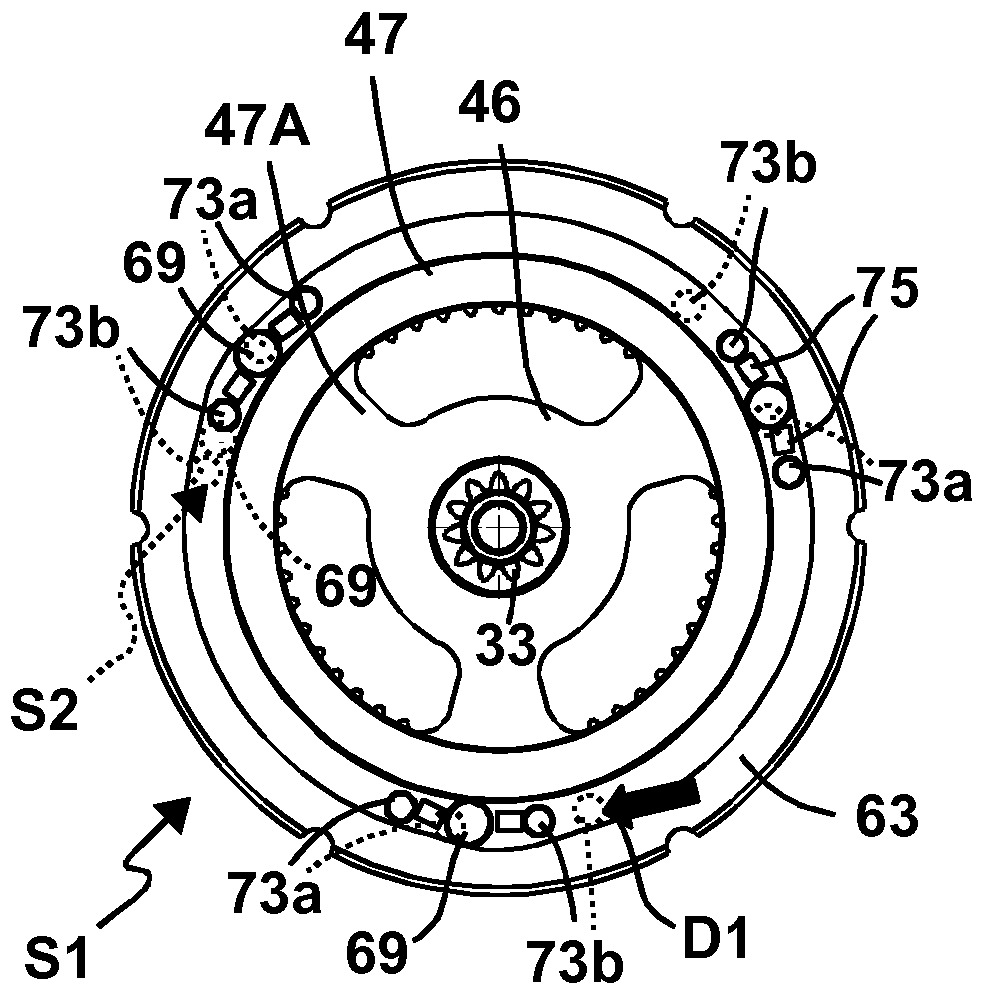

Electric assist bicycle

Provided is an electric assist bicycle provided with a so-called single-axle motor drive unit capable of maintaining high torque detection performance. On an outer periphery of a crank shaft (7a), there are disposed a cylindrical human power transmission member (28) formed with a torque sensor (31) for detecting human power drive force, and a combined-force member (29) that combines the human power drive force and auxiliary drive force from a motor (21). No one-way clutch is disposed in a drive force transmission route spanning the crank shaft (7a), the human power transmission member (28), and the combined-force member (28), so that the human power transmission member (28) and the combined-force member (29) are rotated at all times as the crank shaft (7a) rotates. A rotation detector (10) is also fitted to detect the rotation of the combined-force member (29).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

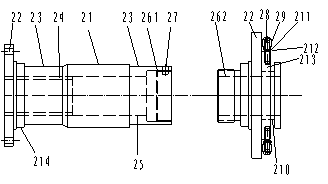

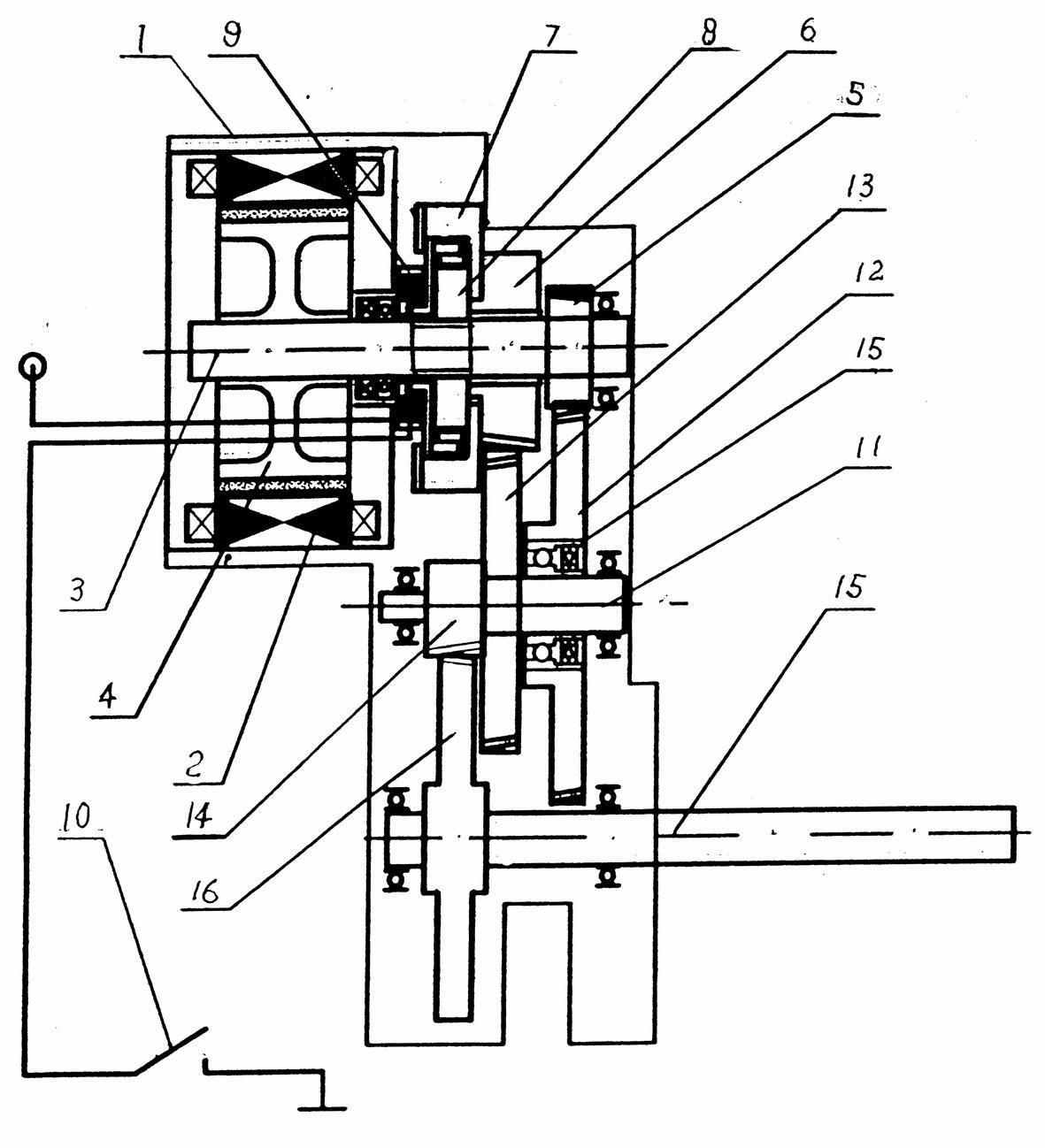

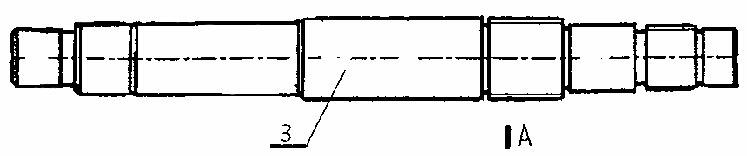

Two-gear electrical control variable speed motor for electric motorcycle

InactiveCN102097892ASimple structureCompact structureMechanical energy handlingCycle actuatorsDrive shaftGear wheel

The invention discloses a two-gear electrical control variable speed motor for an electric motorcycle. The motor comprises a motor stator, a motor shaft and a rotor which are arranged in a shell. A drive I-gear gear, a drive II-gear gear and an overrunning clutch are sequentially from right to left on the right part of the motor shaft. A central cam of the overrunning clutch is in fit connection with the motor shaft, and corresponds to an electromagnet arranged on the shell. A driven I-gear gear, a driven II-gear gear and a drive pinion are sequentially arranged from the right to the left on a central gear shaft. The driven I-gear gear is in fit connection with the central gear shaft by a one-way bearing, and is meshed with the drive I-gear gear arranged on the motor shaft. The driven II-gear gear is meshed with the drive II-gear gear idly sleeved on the motor shaft. The drive pinion is integrated with the central gear shaft, and is in fit connection with a drive bull wheel in fit connection with a drive shaft. The motor is organically combined with a gear shifting mechanism, the motor has a simple and compact structure, good radiation effects and long service life, and simply, conveniently and reliably realizes gear shifting operations.

Owner:秦廷修

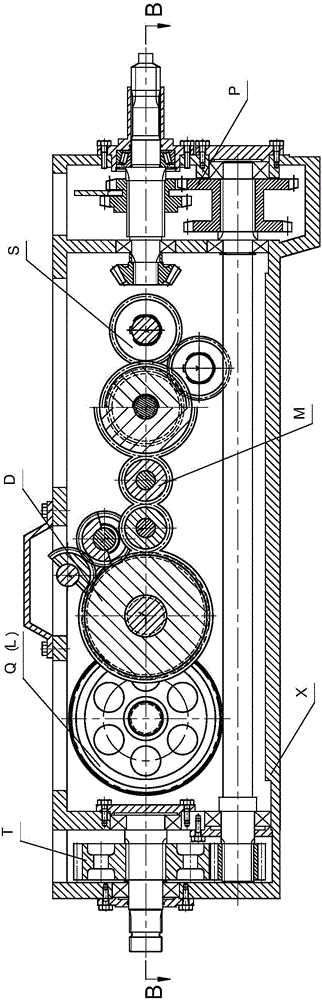

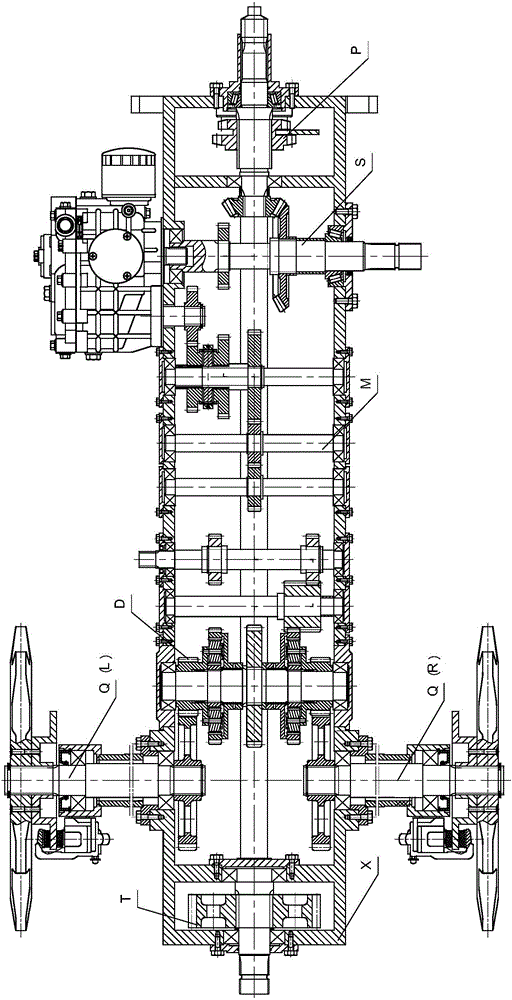

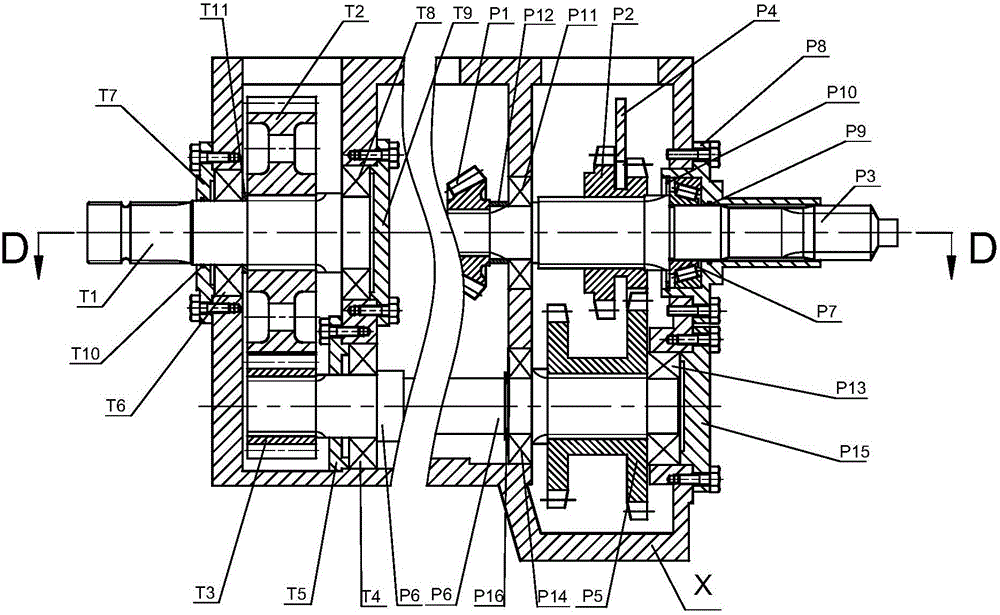

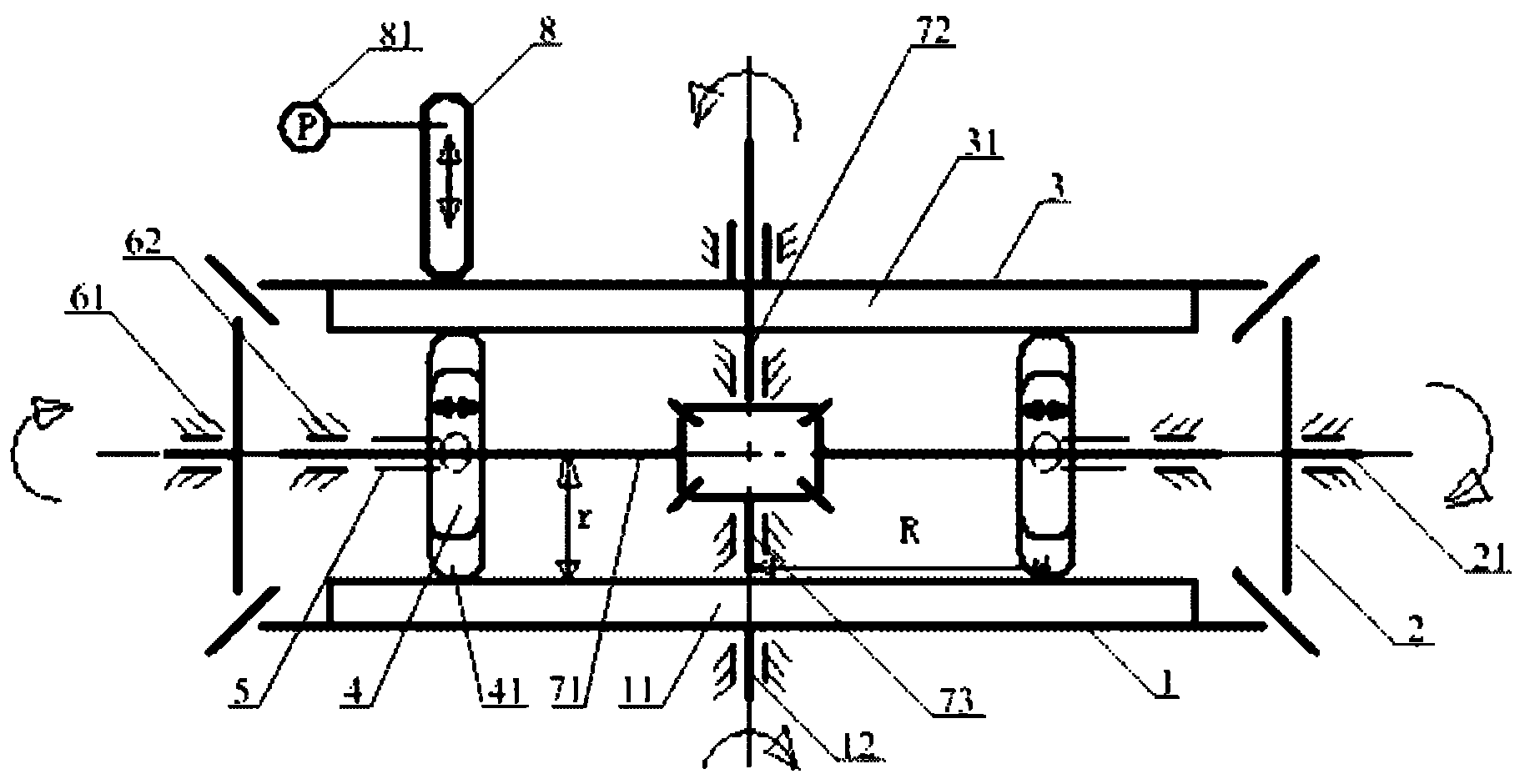

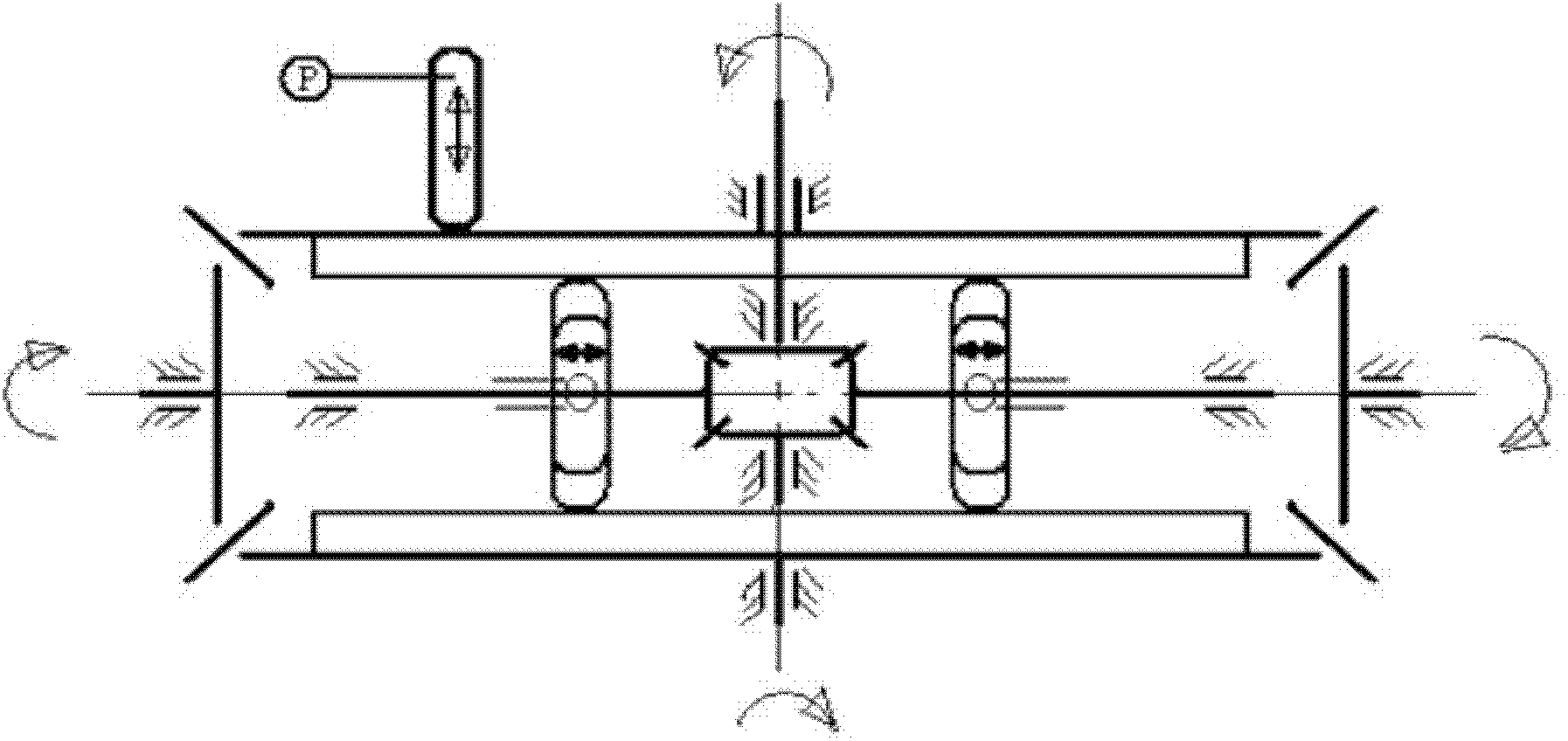

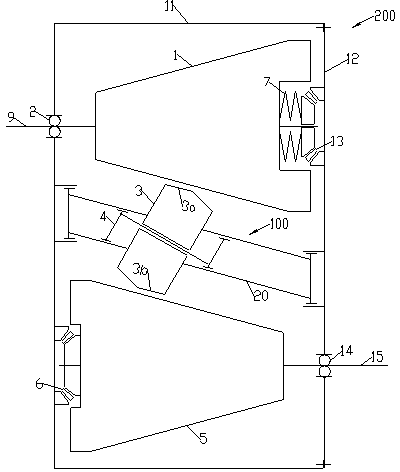

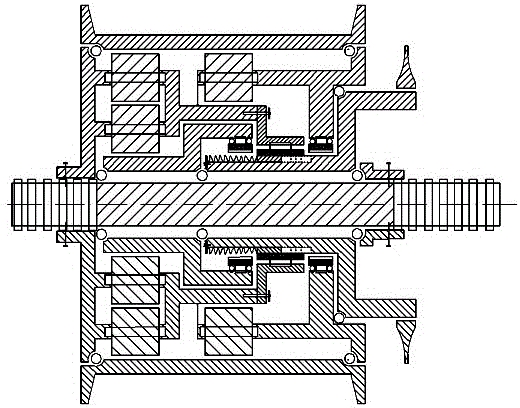

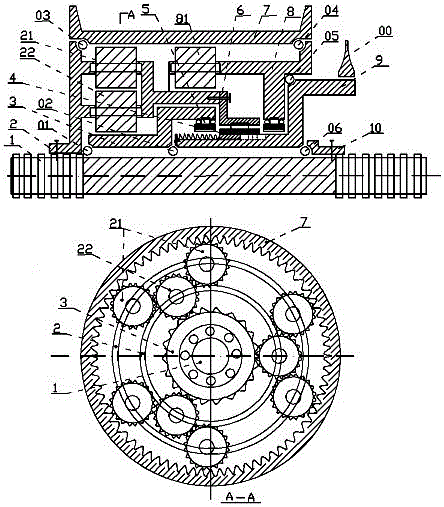

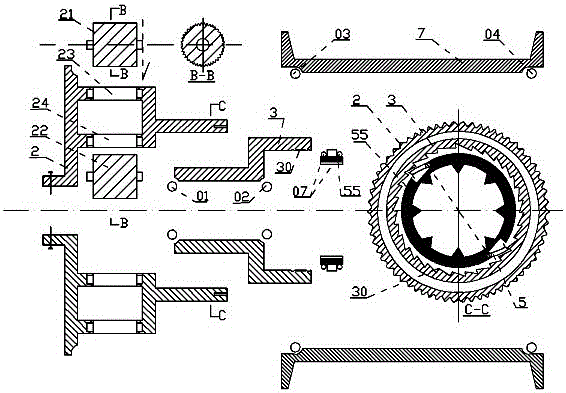

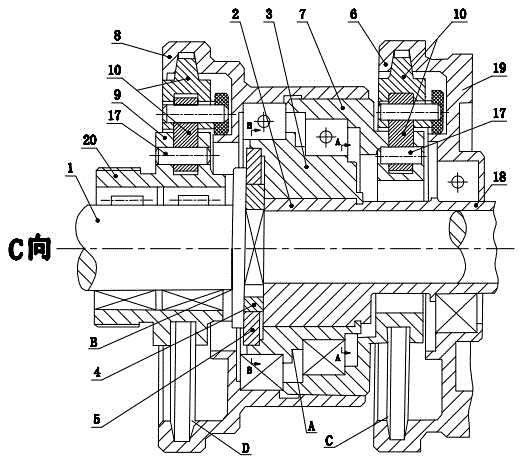

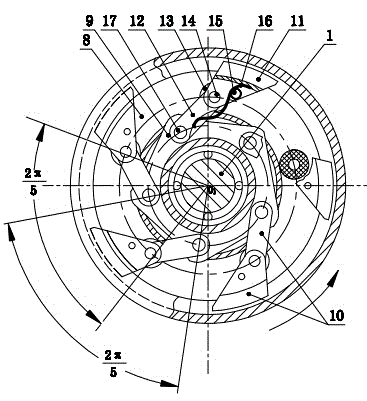

Double-power input type transmission for caterpillar

InactiveCN105151120AImprove handlingImprove transmission efficiencyNon-deflectable wheel steeringControl devicesDrive wheelHydraulic pressure

The invention relates to a double-power input type transmission for a caterpillar. The double-power input type transmission comprises a box body. The box body is provided with a power input mechanism, a double-power input mechanism, a middle transmission mechanism, a differential speed type drive mechanism, a left caterpillar band drive mechanism, a right caterpillar band drive mechanism and a power output mechanism. The power input mechanism is connected with the double-power input mechanism and the power output mechanism. The double-power input mechanism is connected with the differential speed type drive mechanism through the middle transmission mechanism. The differential speed type drive mechanism is connected with the left caterpillar band drive mechanism and the right caterpillar band drive mechanism. According to the double-power input type transmission, a mechanical and hydraulic parallel type double-power input device and a differential speed type steering mechanism capable of controlling gear rings of planetary gear mechanisms on the two sides of a drive wheel through external power to rotate forwards and reversely, the drive efficiency and control convenience of the caterpillar can be improved effectively, steering accuracy is improved, and the defects that an existing caterpillar is low in transmission efficiency and large in traveling side deflection resistance and cannot be controlled easily, and the sludge blocking problem is serious when the caterpillar conducts steering at the edge of a field are overcome.

Owner:HUNAN AGRICULTURAL UNIV

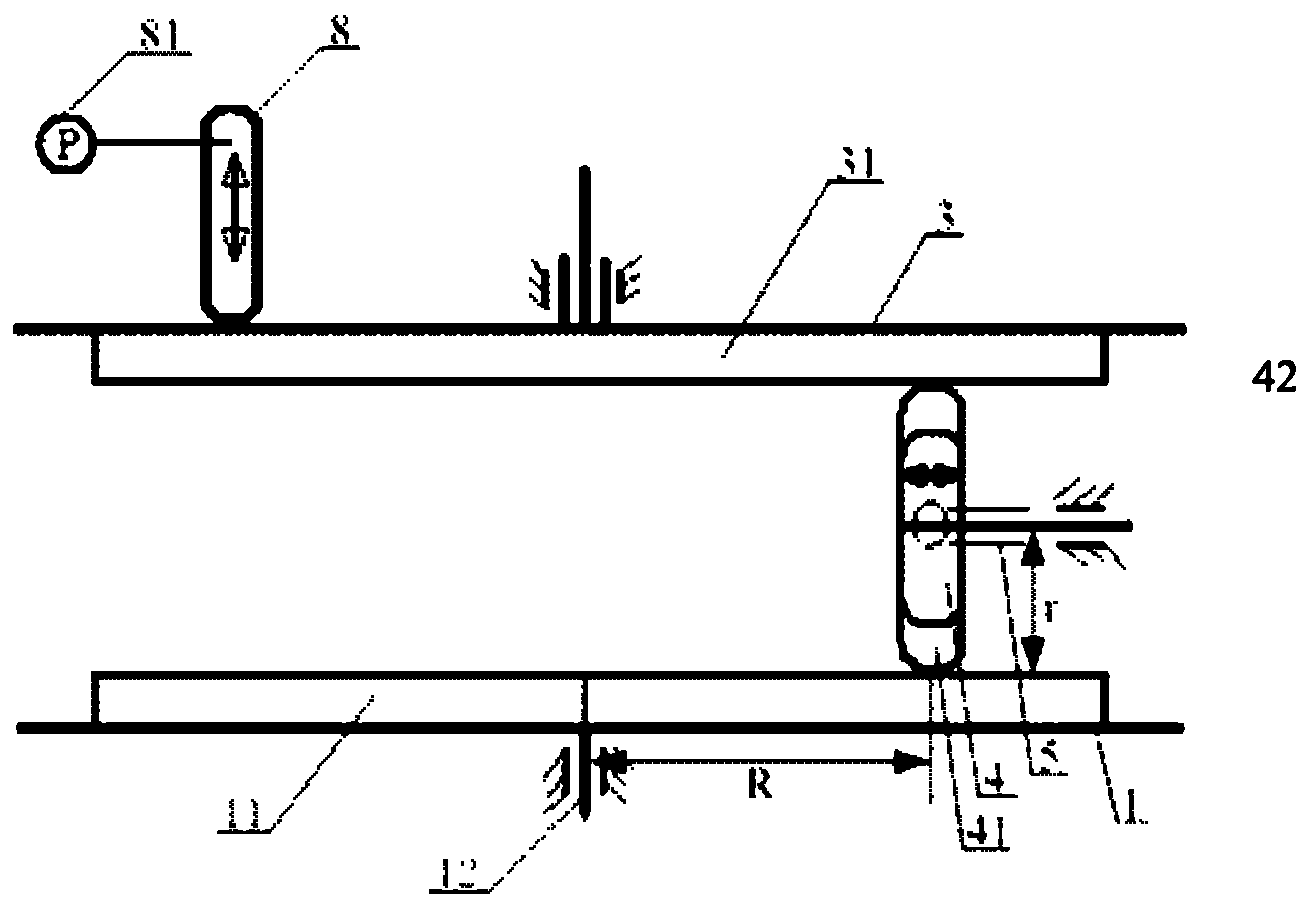

Transmission for a bicycle pedal

InactiveUS7017444B2Easy to adjustEasy to change speedControlled membersVehicle cranksMechanical engineeringVariator

A transmission for a bicycle pedal has a fixed axle with an end operatively connected to a wheel of the bicycle and a guide axle connected to the fixed axle to form a crank. A bicycle pedal is rotatably mounted on a slider which is movably mounted on a guide portion of the guide rod for translation therealong. The ration of gyration of the pedal can be varied by sliding the pedal along the guide axle and / or telescoping the guide axle relative to the fixed axle. The slider and mounted pedal can be rotated toward the bicycle frame for compact storage.

Owner:KIM JUN SUCK

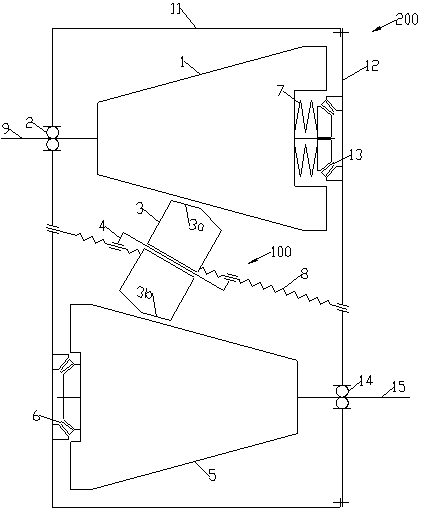

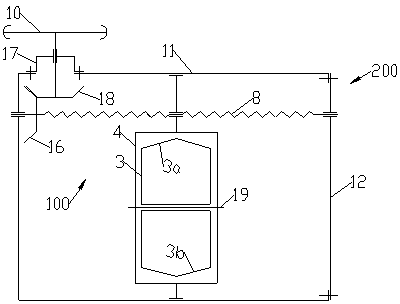

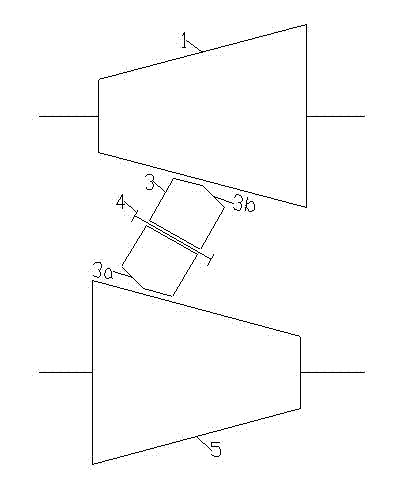

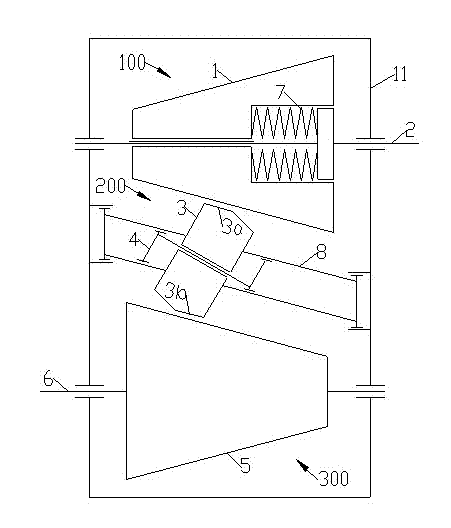

Stepless speed change mechanism and automobile

ActiveCN102927225AEasy to change speedIncrease frictionFluid gearingsFriction gearingsDrive wheelEngineering

The invention discloses a stepless speed change mechanism and an automobile. The stepless speed change mechanism comprises a driving wheel disc and a pressure adjusting wheel disc which are parallel to each other; at least one speed change roller is arranged between the driving wheel disc and the pressure adjusting wheel disc; the axis of the speed change roller is parallel to the driving wheel disc and points to the axis of the driving wheel disc; contact surfaces of the driving wheel disc, the pressure adjusting wheel disc and the speed change roller are provided with friction layers; the speed change roller is provided with a position adjusting device which can adjust a distance from the center of the speed change roller to the center of the driving wheel disc; and the pressure adjusting wheel disc is provided with a pressure adjusting device to adjust the pressure applied to the speed change roller by the pressure adjusting wheel disc. The stepless speed change mechanism can realize stepless speed change and improve the torque transmitting capacity.

Owner:BEIQI FOTON MOTOR CO LTD

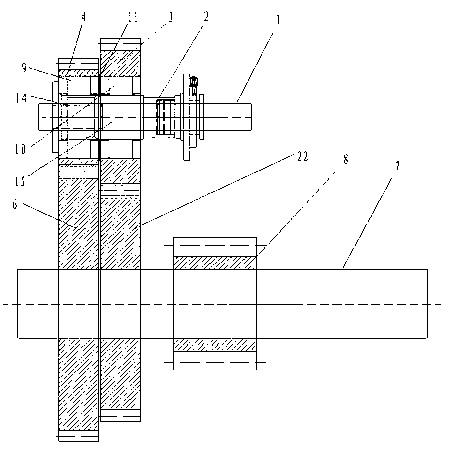

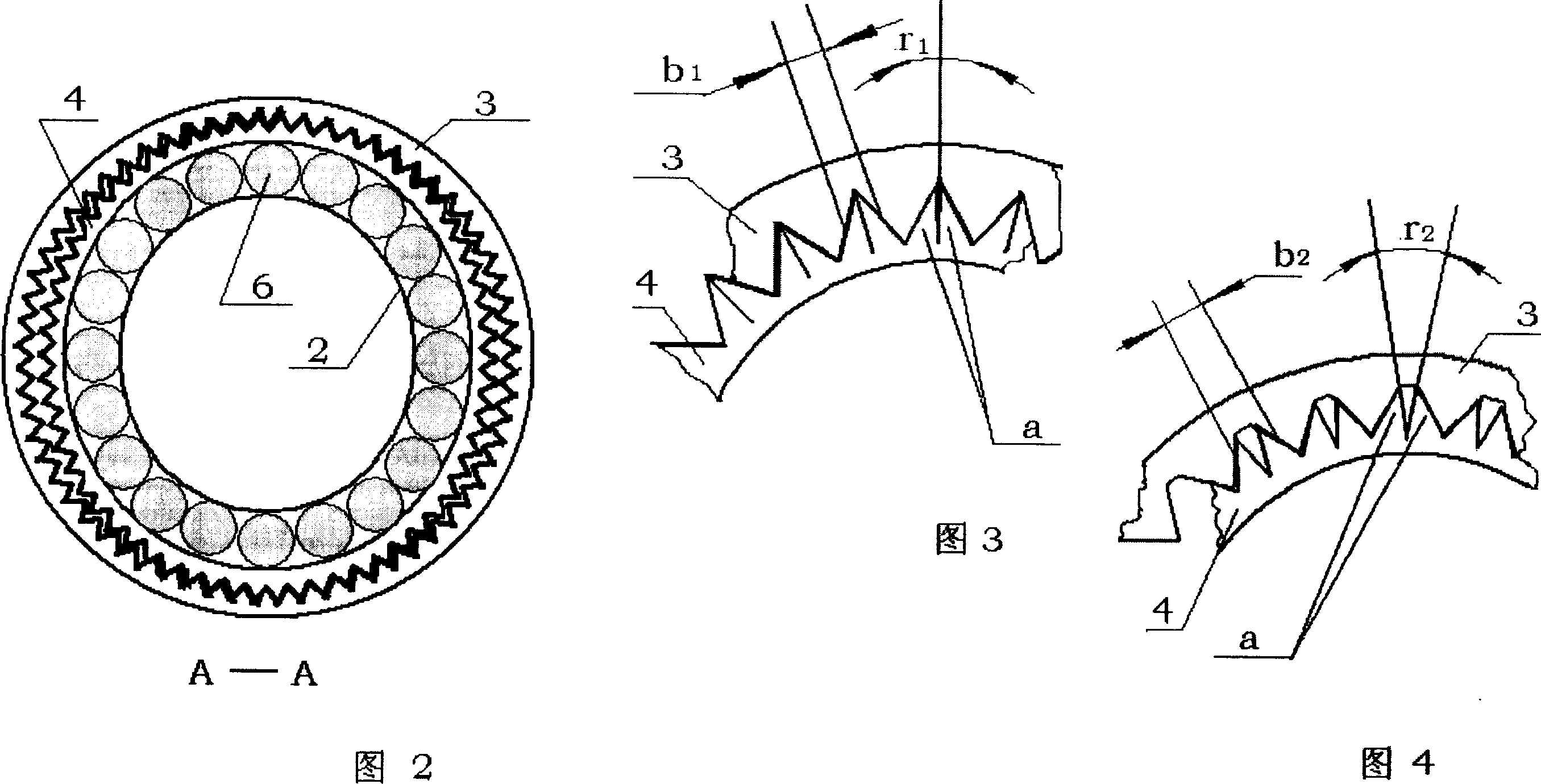

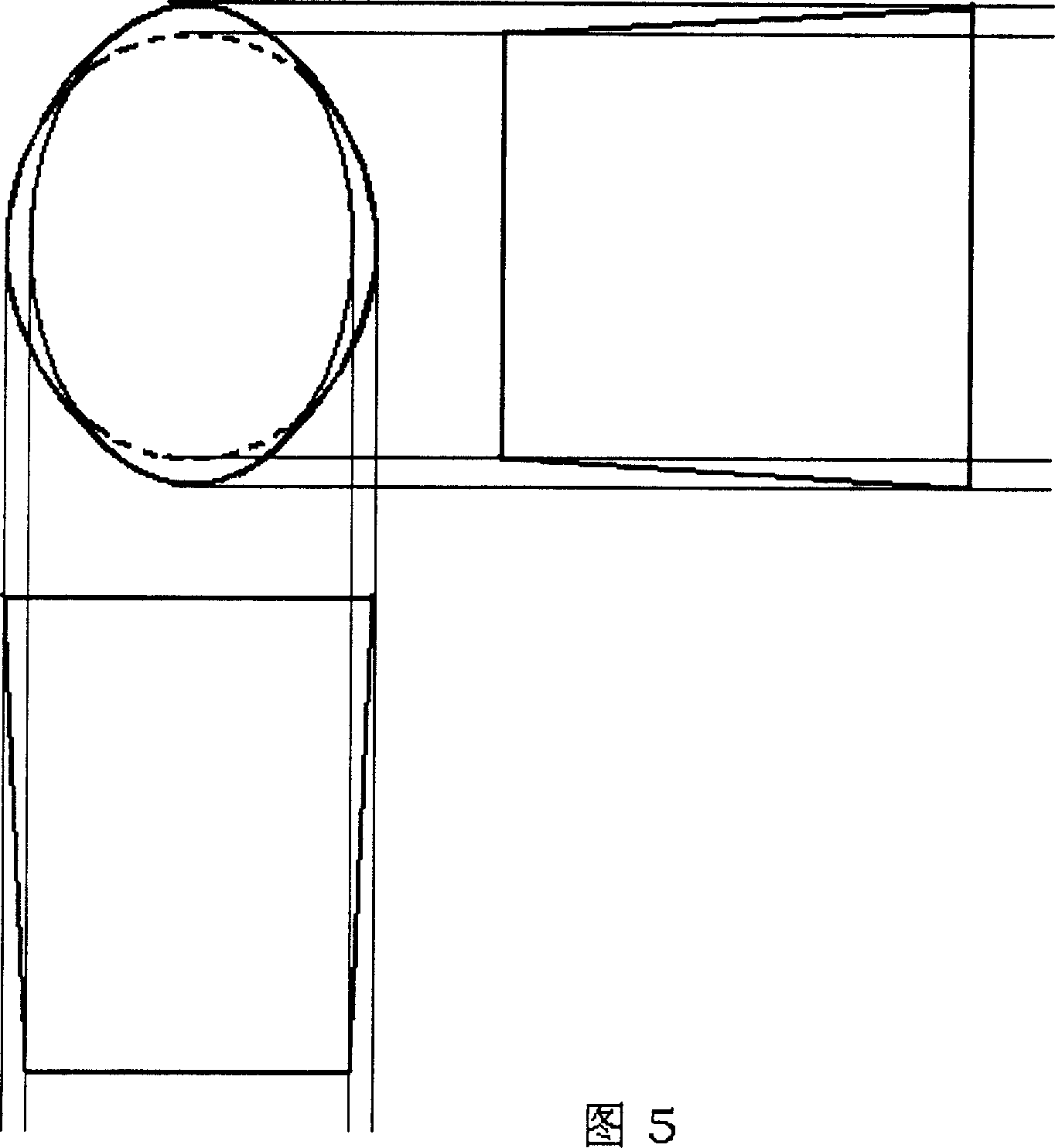

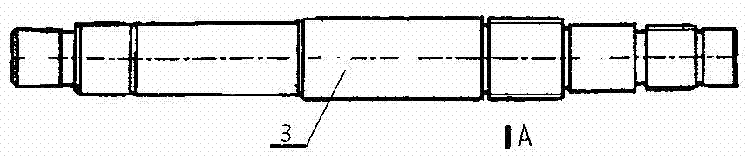

Long cone and rolling cone type CVT (continuously variable transmission)

InactiveCN103016660ASmall geometric slip rateReduced geometric slip rateToothed gearingsFriction gearingsThrust bearingPulp and paper industry

The invention discloses a long cone and rolling cone type CVT (continuously variable transmission), which comprises a box body, a first long cone roller wheel, a second long cone roller wheel, at least one pressure device, a first thrust bearing, a second thrust bearing and a middle rolling cone wheel set, wherein the middle rolling cone wheel set comprises a middle rolling cone wheel, a connecting device and an adjusting device; a first conical surface and a second conical surface are arranged on the middle rolling cone wheel; and the first long cone roller wheel and the second long cone roller wheel are connected with the box body through the first thrust bearing and the second thrust bearing respectively. The axial pressing action of the first long cone roller wheel is performed through the pressure device; the contact positions of the middle rolling cone wheel on the two long cone roller wheels are adjusted; and the working radiuses of the two long cone roller wheels can be continuously changed to achieve the effect of CVT. According to the CVT, the geometrical slippage value in the optimal transmission state is 0, the geometrical slippage phenomenon in the cone wheel type long cone and rolling cone type CVT is effectively reduced, the transmission efficiency is improved and the transmission power is increased. The CVT can be used for the fields of various vehicles, ships, mechanical transmission and the like.

Owner:郭克亚

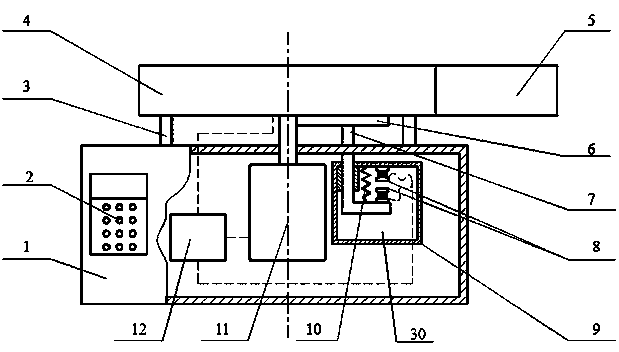

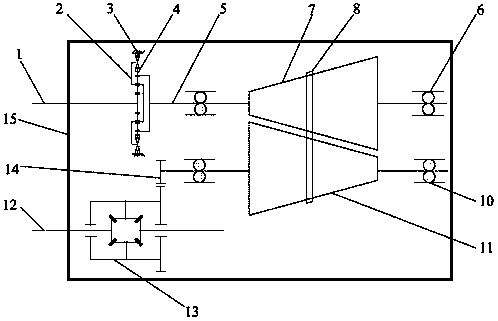

High-speed ejection device for steel ball

The invention relates to a high-speed ejection device for a steel ball. The device comprises an operation keyboard and display, a rotating track, a sliding baffle, a pull rod, a pull rod controller, a motor, a master controller, an electromagnet sleeve, the steel ball and a rotating handle. When a speed required to be reached by the steel ball is set by the keyboard, the master controller controls the motor to rotate, and the steel ball speed is calculated; at the same time, the electromagnet sleeve is powered on, and the steel ball is absorbed so as to be prevented from falling; when the steel ball reaches a required speed, firstly, the master controller controls the pull rod controller to pull down the sliding baffle, the rotating track and an outlet are communicated, the electromagnet sleeve is powered off, and finally, the rotating speed of the motor is decreased, so that the steel ball and the electromagnet sleeve are separated, and the steel ball is ejected from the outlet along the rotating track under the action of the centrifugal force. The rotating speed of the motor is adjusted, so that the ejection speed of the steel ball can be changed very conveniently, and the adjustment range is very wide. The high-speed ejection device for the steel ball is compact in whole structure and convenient to operate, the steel ball speed can be controlled accurately, and the device has the advantages of high reliability and simple adjustment.

Owner:SHANGHAI UNIV

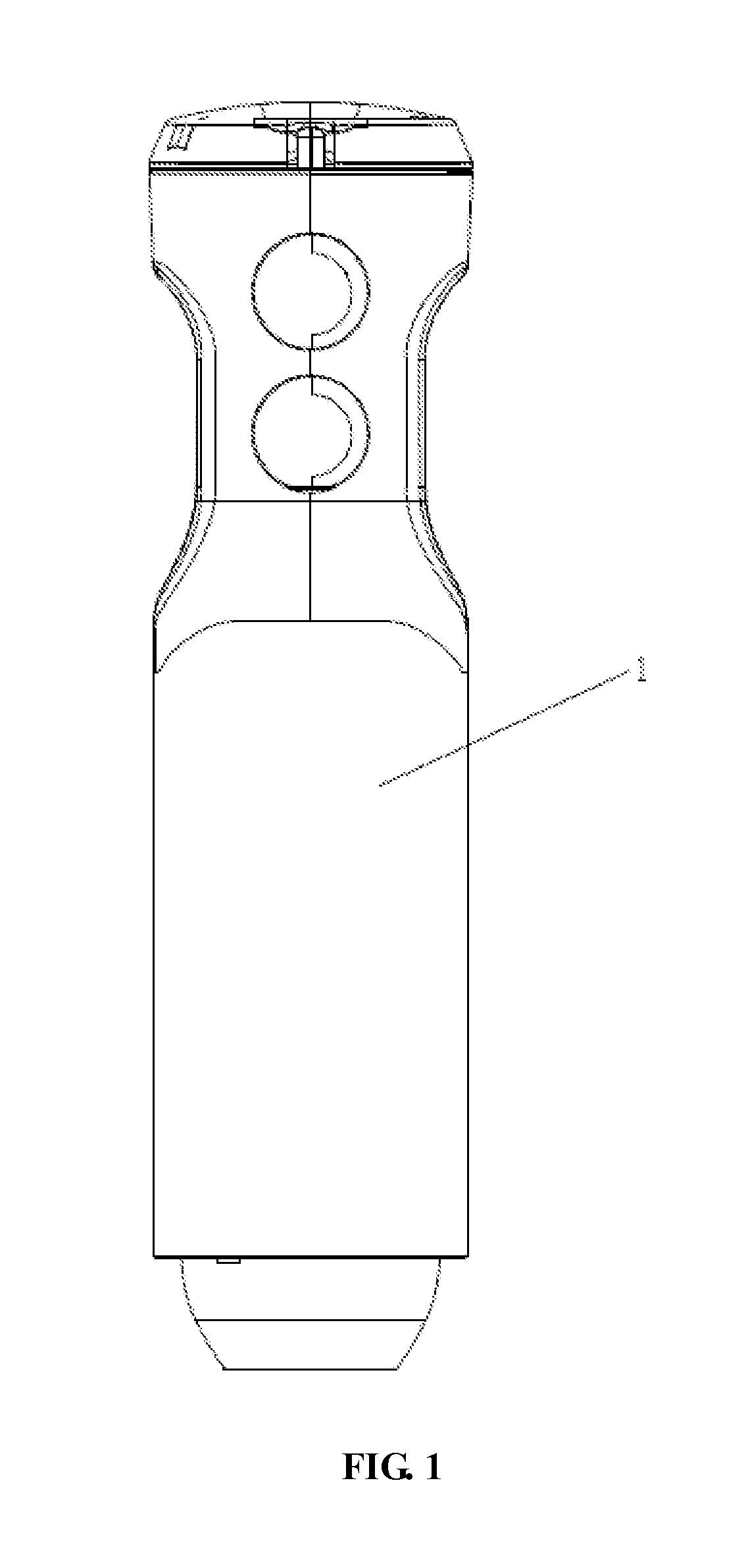

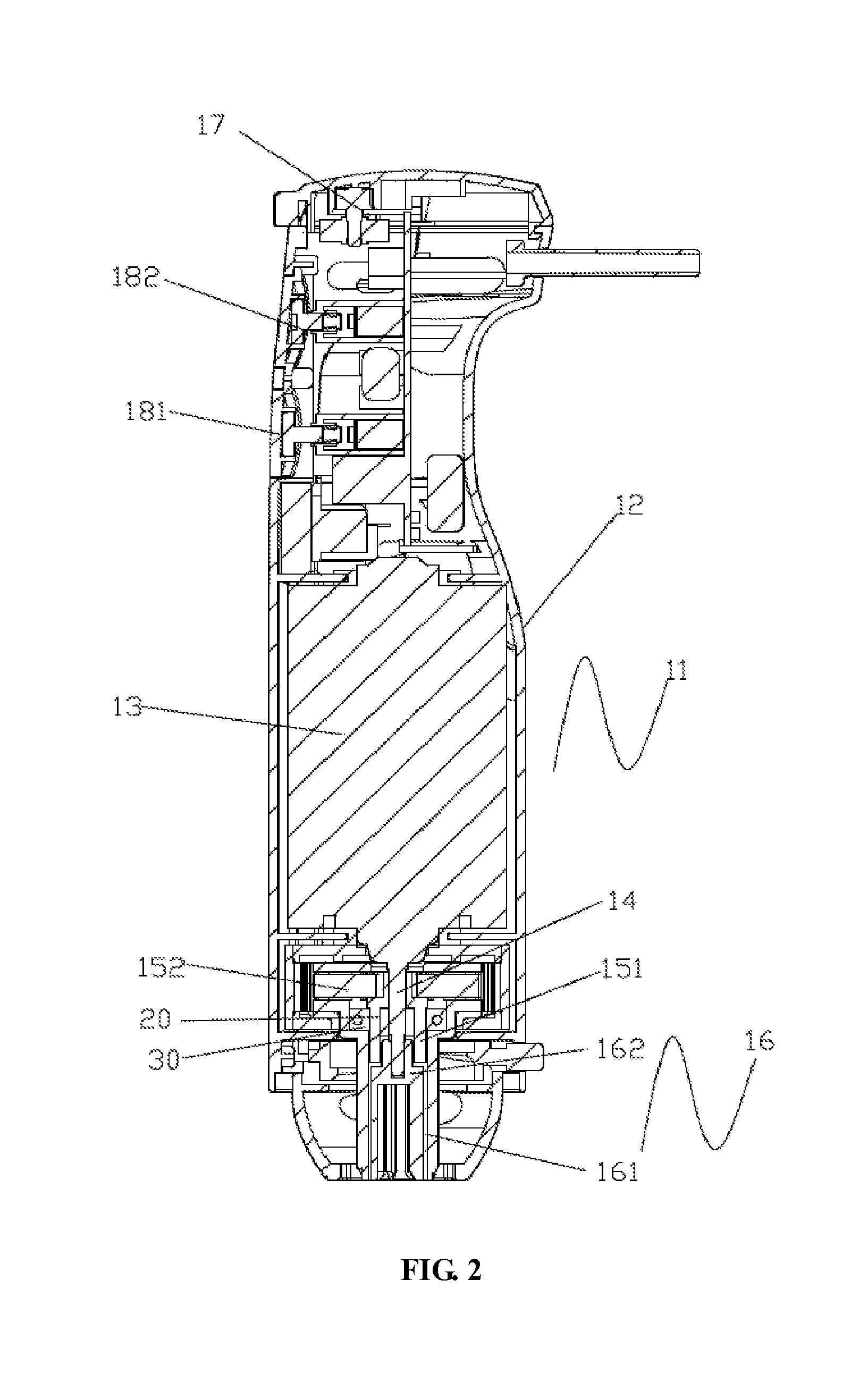

Hand-held blender

ActiveUS20160100716A1Solve the real problemEasy to change speedMixer accessoriesKitchen equipmentHand heldEngineering

The invention discloses a hand blender with a body which can be connected with different stirring tools. The body includes a motor with an output shaft, a deceleration component and a plurality of output connectors. The speed control knob and the safety switch, starting switch which control the moving of the motor are set up of the body. The control circuit includes a half speed control lever and a reverse control lever which can be moved by the corresponding stirring tools. The hand blender can connected with different stirring tools and output different kinds of speeds. It is more convenient and safe.

Owner:HUIYANG ALLAN PLASTIC & ELECTRIC INDS

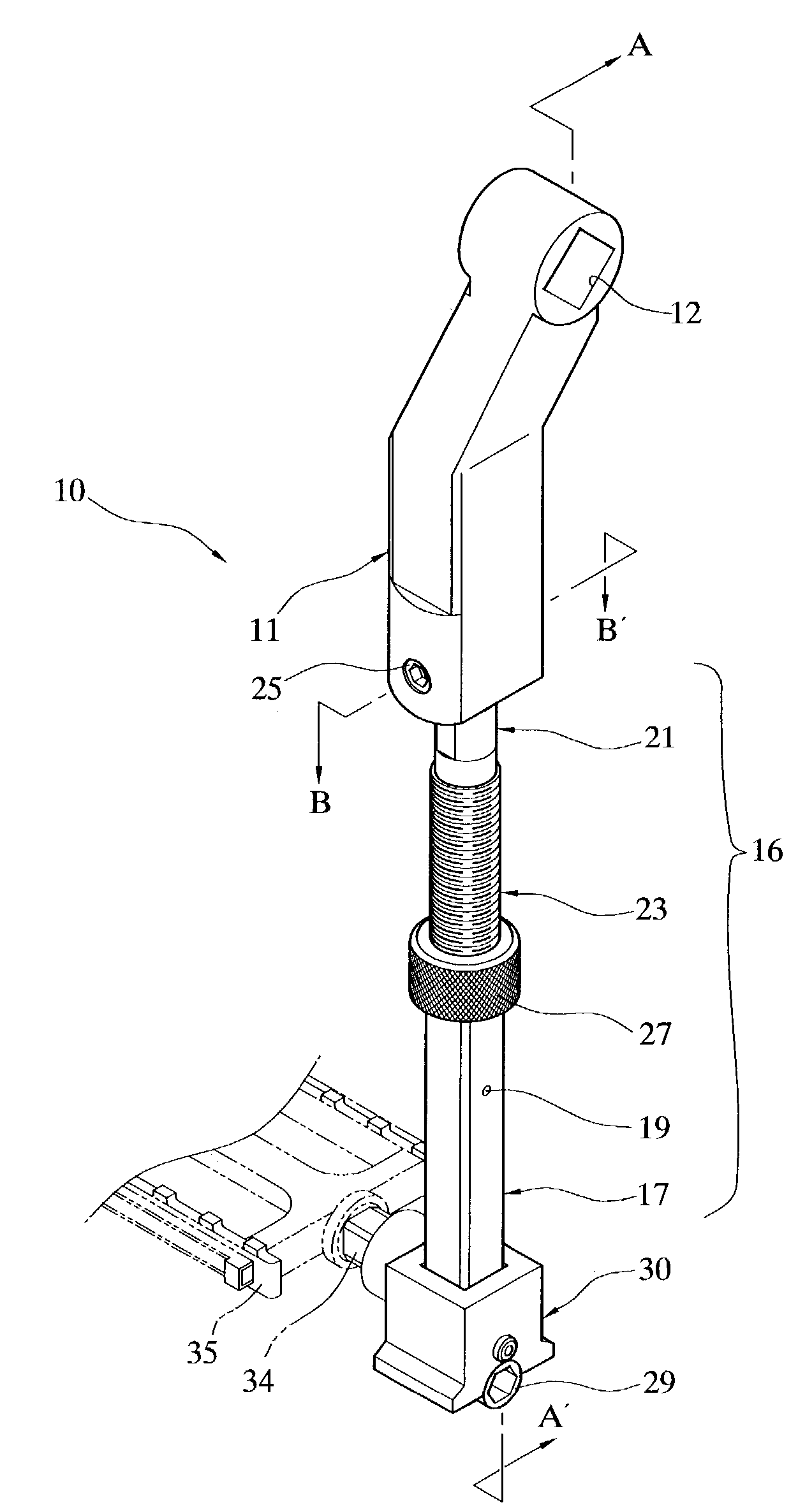

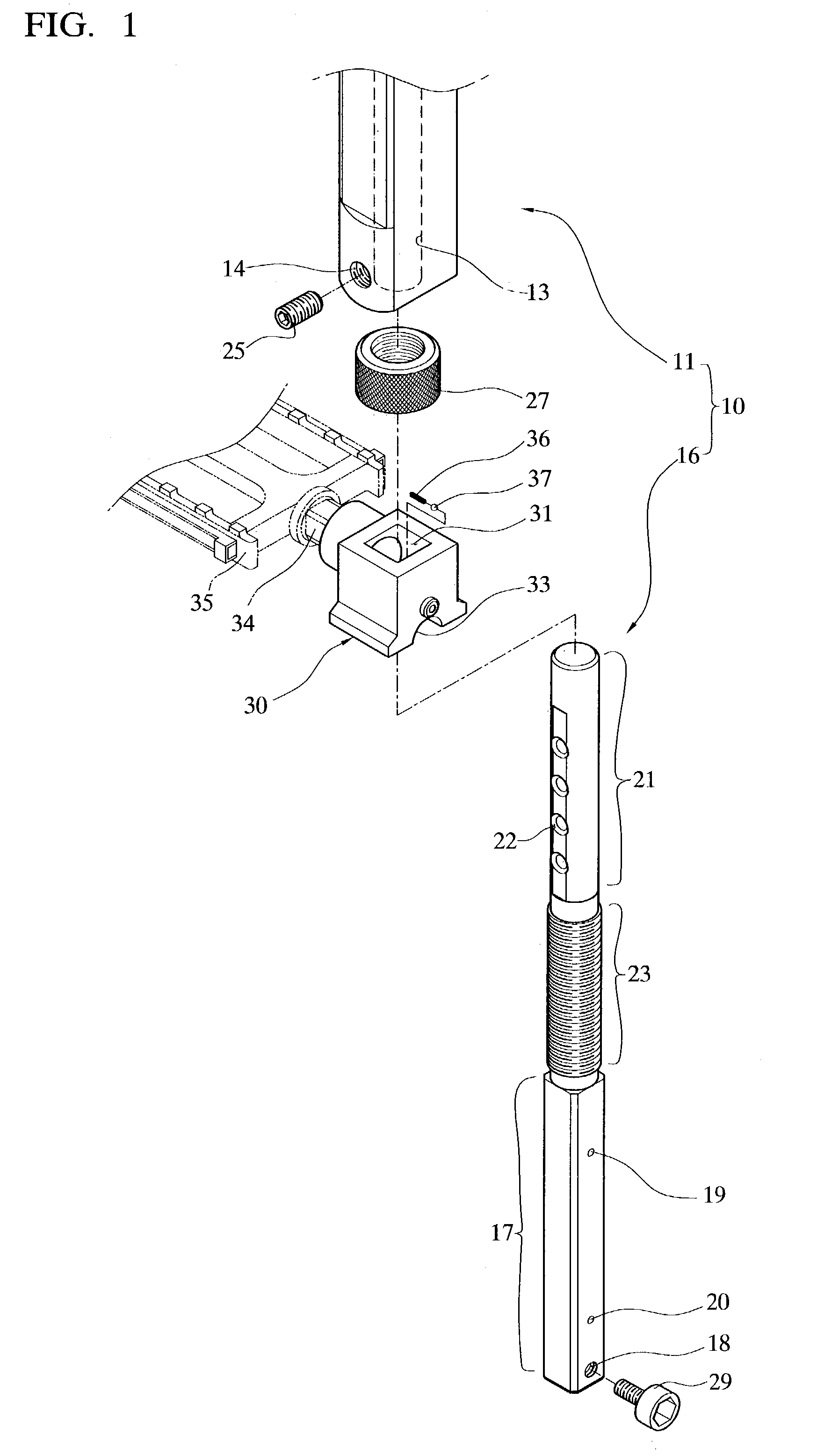

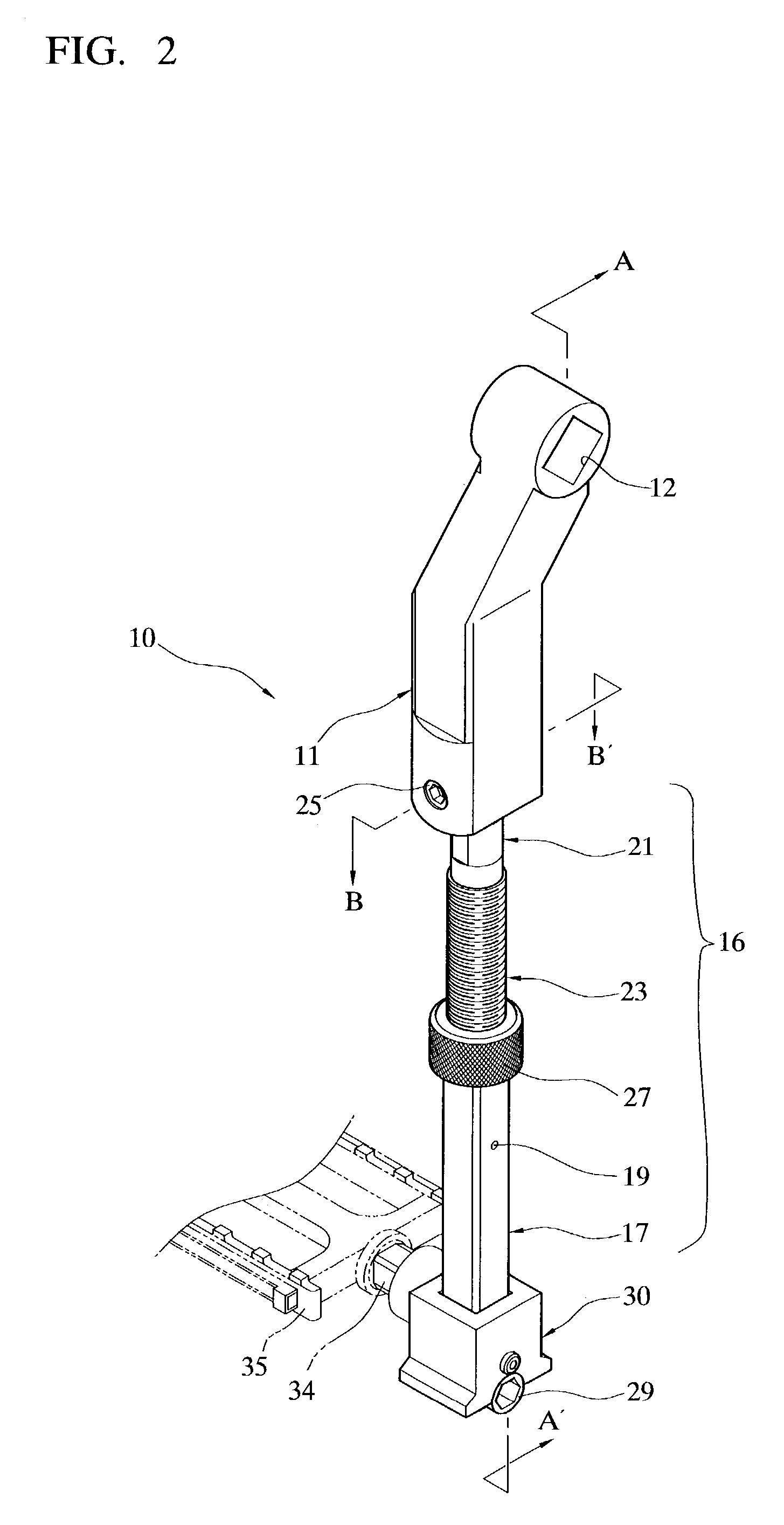

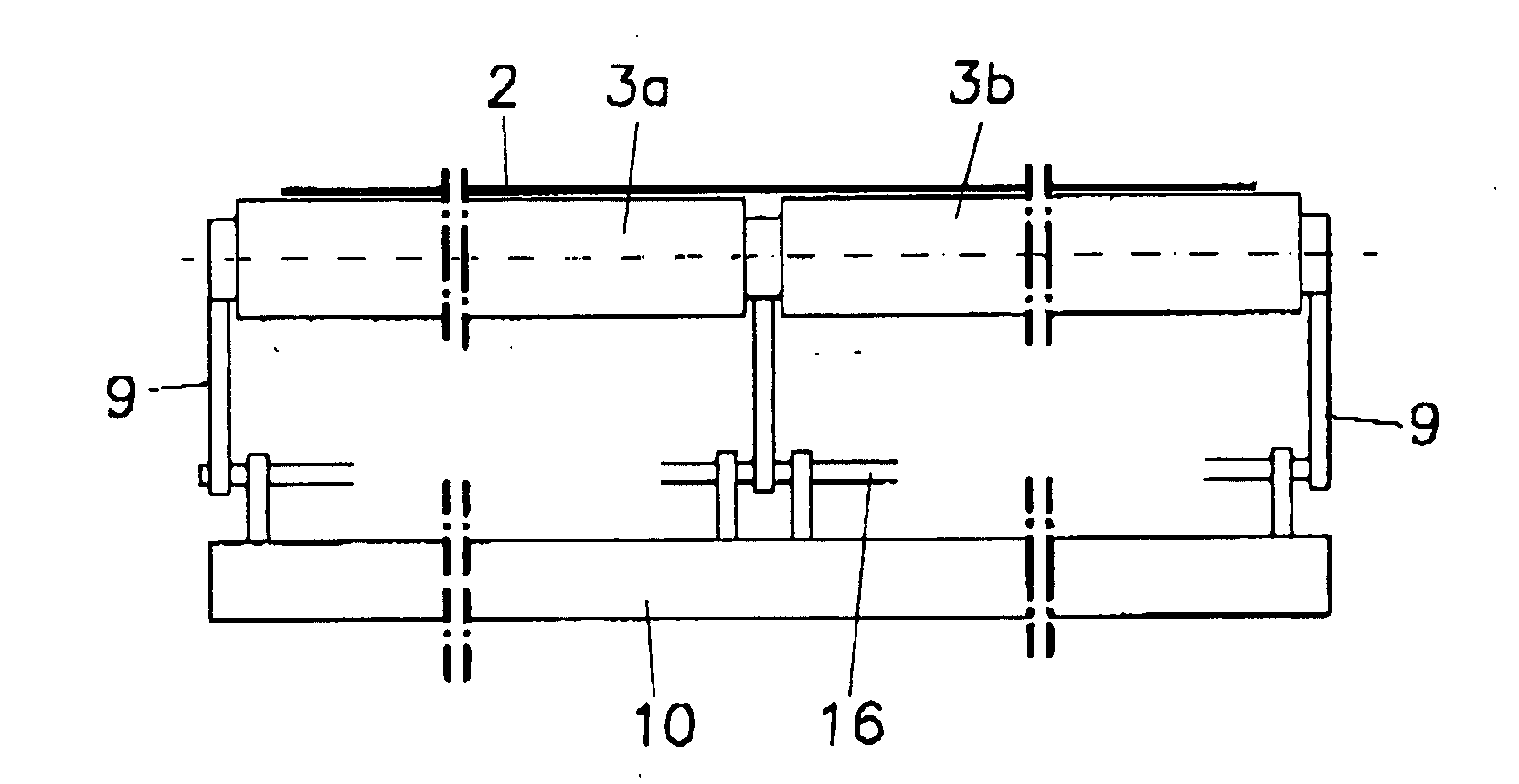

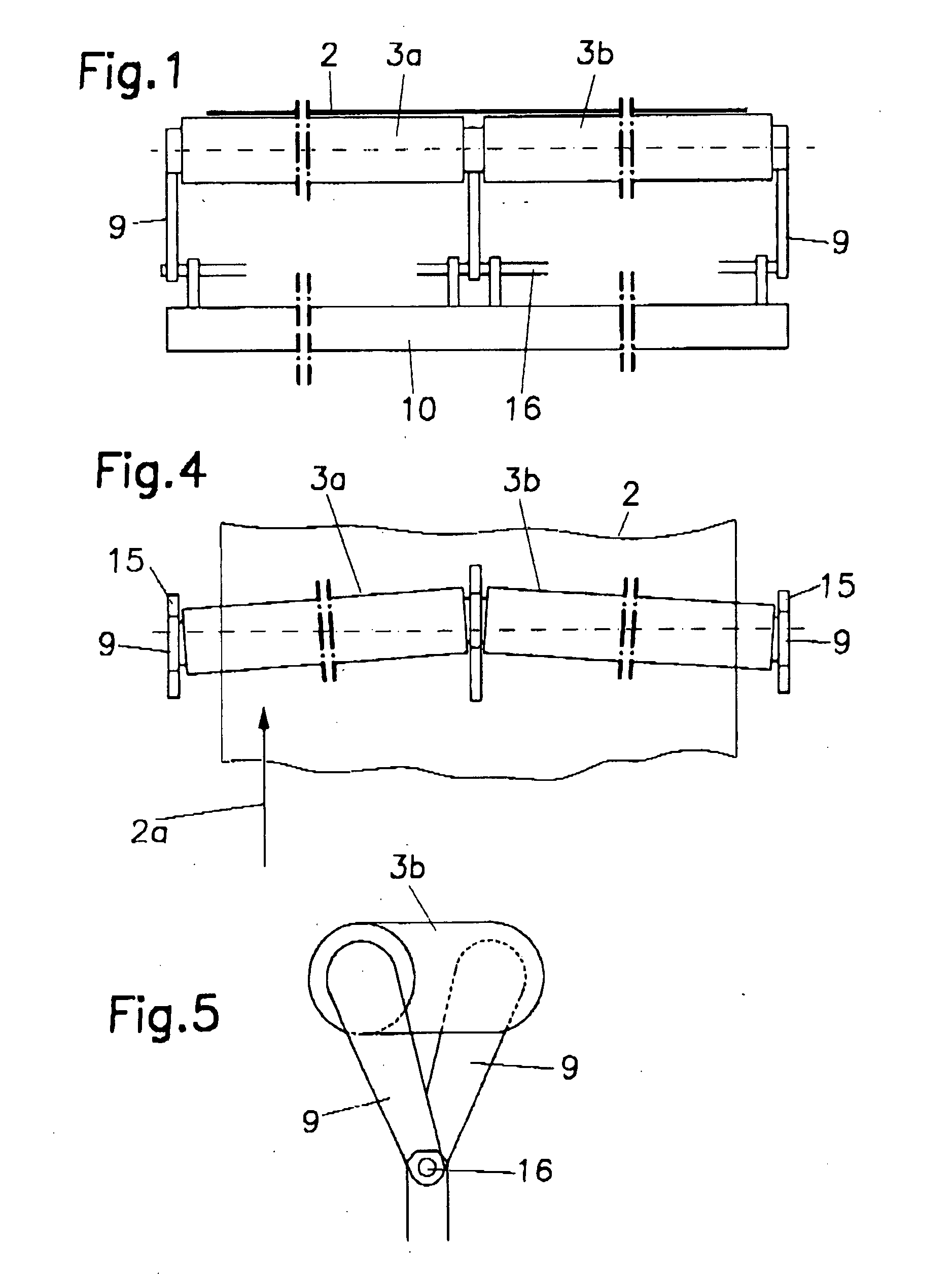

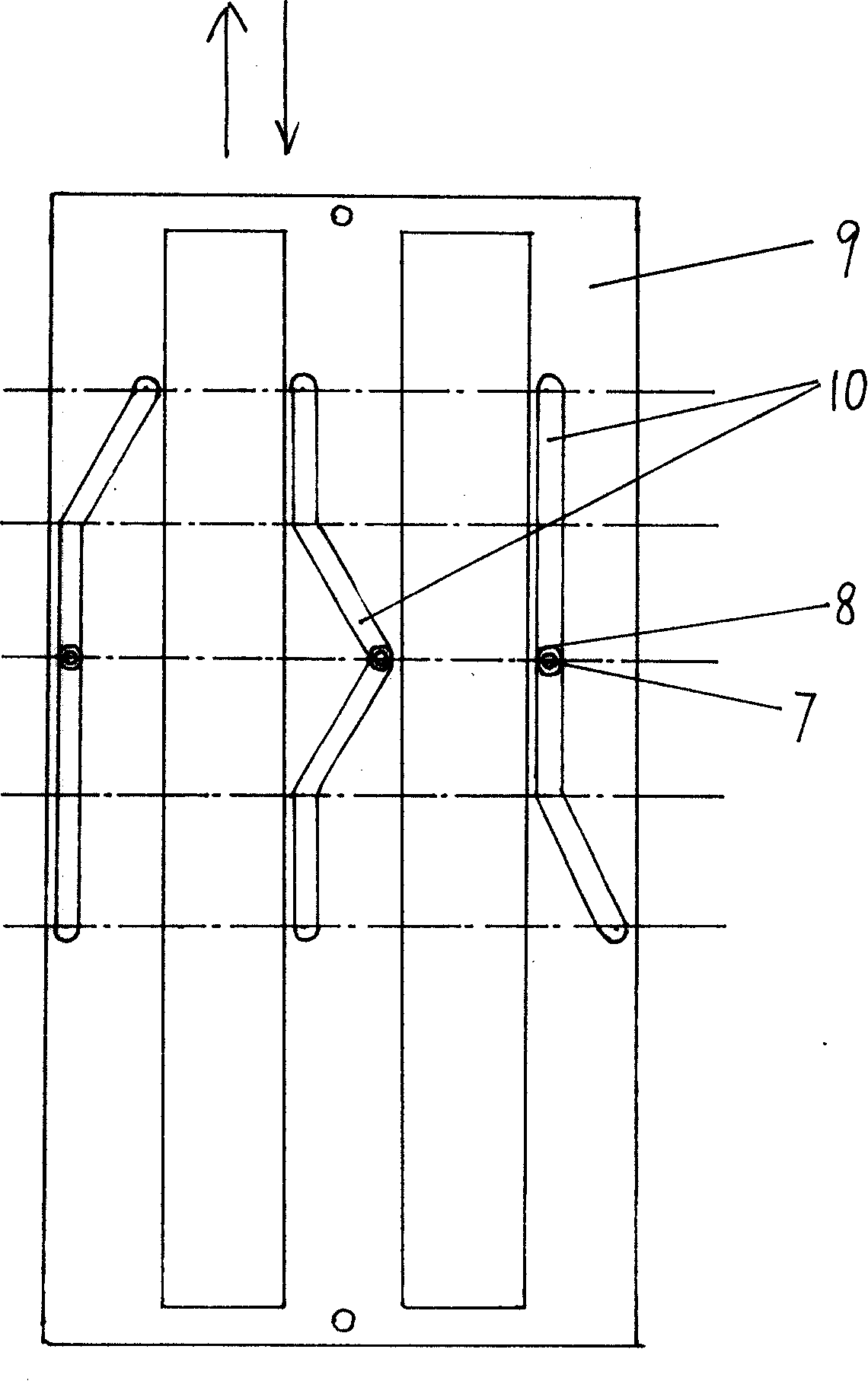

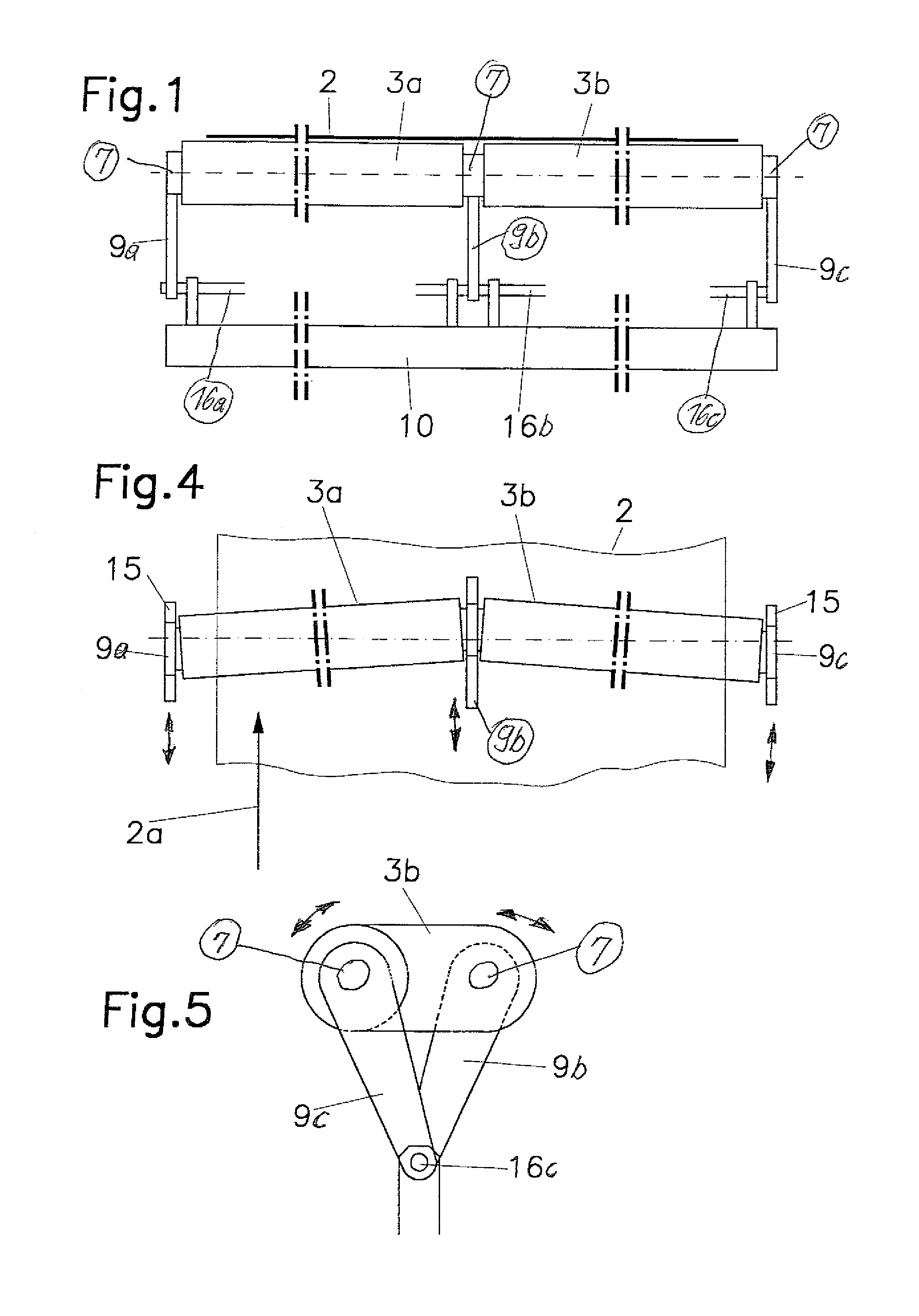

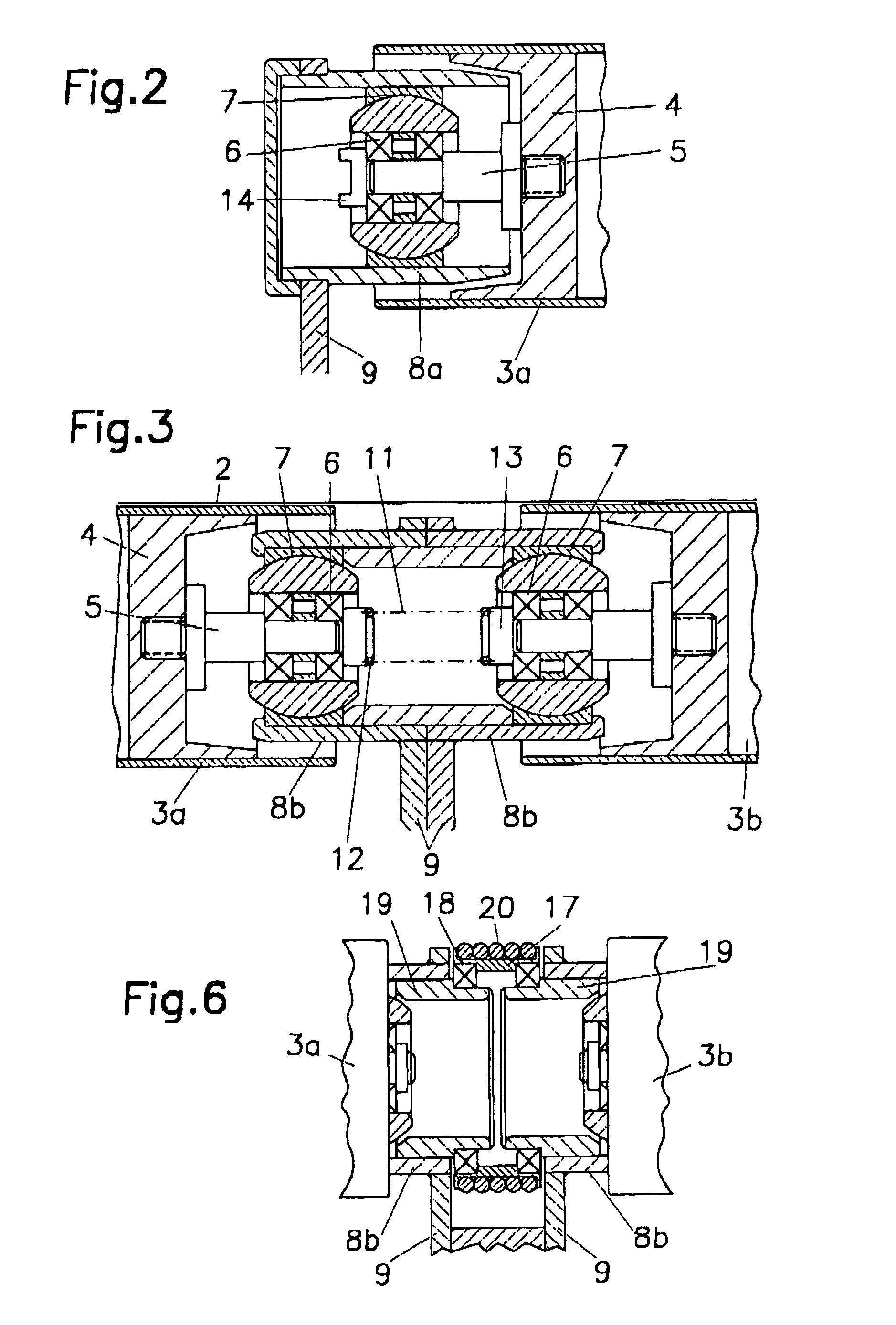

Device for stretching webs of material transversely to their travel direction

InactiveUS20080047115A1Avoid interferenceEasy to adjustStretchingWebs handlingEngineeringBall and socket joint

Owner:KNABEL HOLMER +1

Gear speed variator and folding bicycle

InactiveCN101164827AReduce volumeImprove gripWheel based transmissionFoldable cyclesDrive wheelGear wheel

The present invention relates to a gear speed changer and a folding bicycle. It is characterized by that it has several gears which can be axially moved, said gears can be fit with several fixed gears, one component is moved, a mobile gear can be extended and can be meshed with a fixed gear, said component can be further moved, the meshed gear can be drawn back, and said component is continuously moved, another gear can be meshed with another fixed gear so as to change speed, the reciprocating movement of said component an implement repeated speed increment and decrement, its speed change gear and speed change ratio can be freely selected. Said speed changer can be mounted on the bicycle, and can be connected with ratchet wheel and drive wheel by means of multiple acceleration, the diameter of wheel is less than 10cm, and its speed can exceed that of existent bicycle, said bicycle handlebar can be folded by pressing a spring and sweeping a flab spring, and said bicycle body also can be completely folded by using a mobile slide barrel, so that its volume is small and weight is light. Said speed changer can be used in electric bicycle, motorcycle, power generation equipment and other machine.

Owner:张明亮

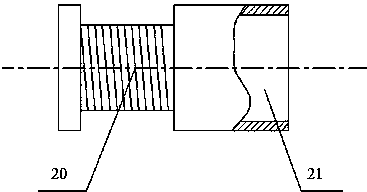

Harmonic teeth-driving stage-less speed variator

InactiveCN101126436ASave the hassle of shifting gearsEasy to change speedFriction gearingsGear driveDrive shaft

The invention belongs to the field of mechanical stepless transmission and includes a harmonic gear-driving stepless transmission, which is composed of a driving shaft, a driven shaft, a rigid gear, a flexible gear, a wave generator and a roller; the flexible gear can make axial movement relative to the rigid gear, the teeth of the flexible gear are composite teeth, which are composed of two branch teeth. When the flexible gear makes axial movement relative to the rigid gear, the angle between the two branch teeth of the composite teeth and the tooth thickness are variable, when the rigid gear keeps stationary and the driving shaft actuates the wave generator to rotate, the wave generator forces the flexible gear to generate continuous elastic deformation by the roller, and the tooth thickness of the composite teeth of the flexible gear also changes with the deformation of the flexible gear; because the tooth thickness or the width between the teeth keeps variable when the teeth number of the rigid gear is fixed, although the teeth number ratio of the flexible gear and the rigid gear keeps unchanged, the arc length passing the nodal circle is variable, and the stepless transmission can be realized so long as the flexible gear makes axial movement relative to the rigid gear.

Owner:李维农

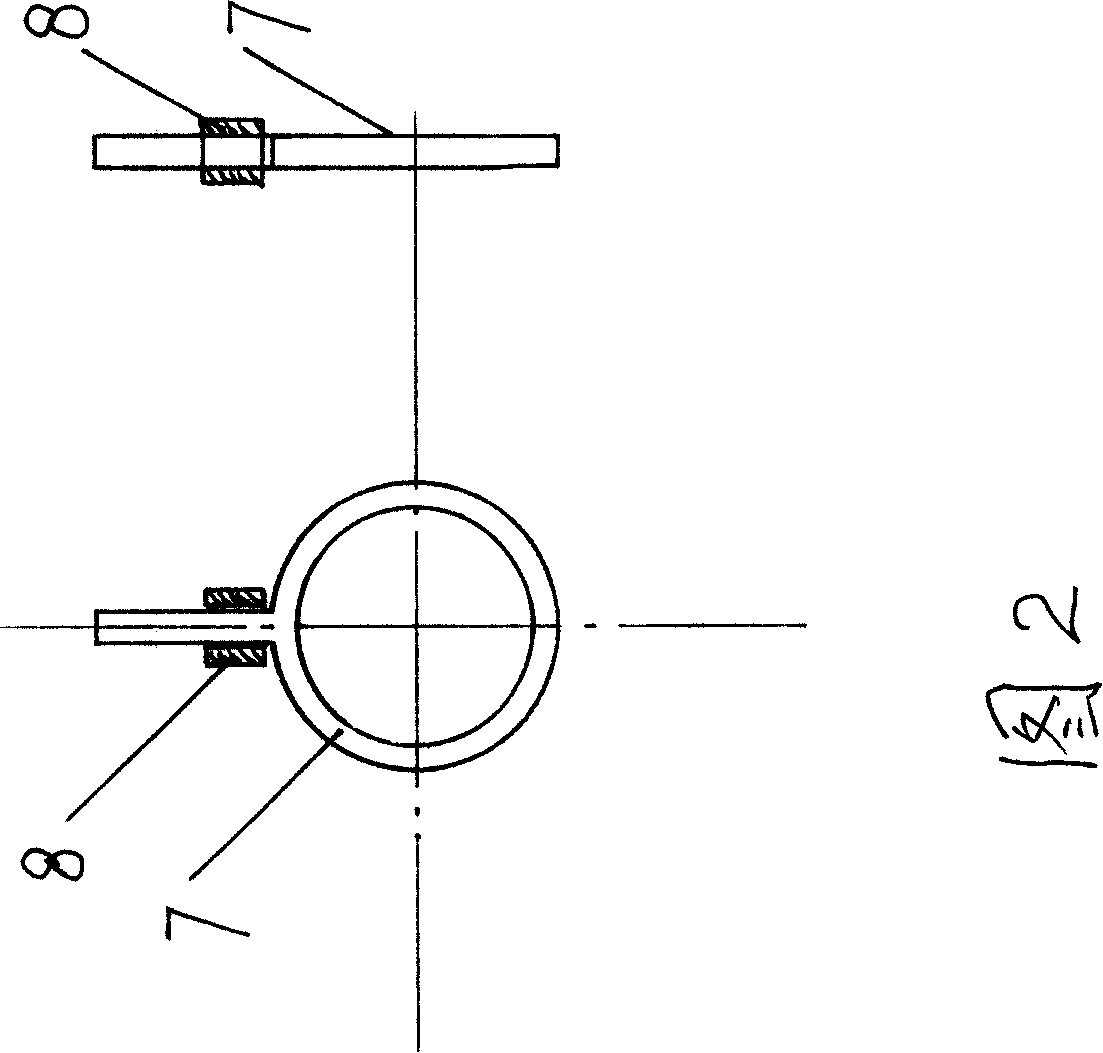

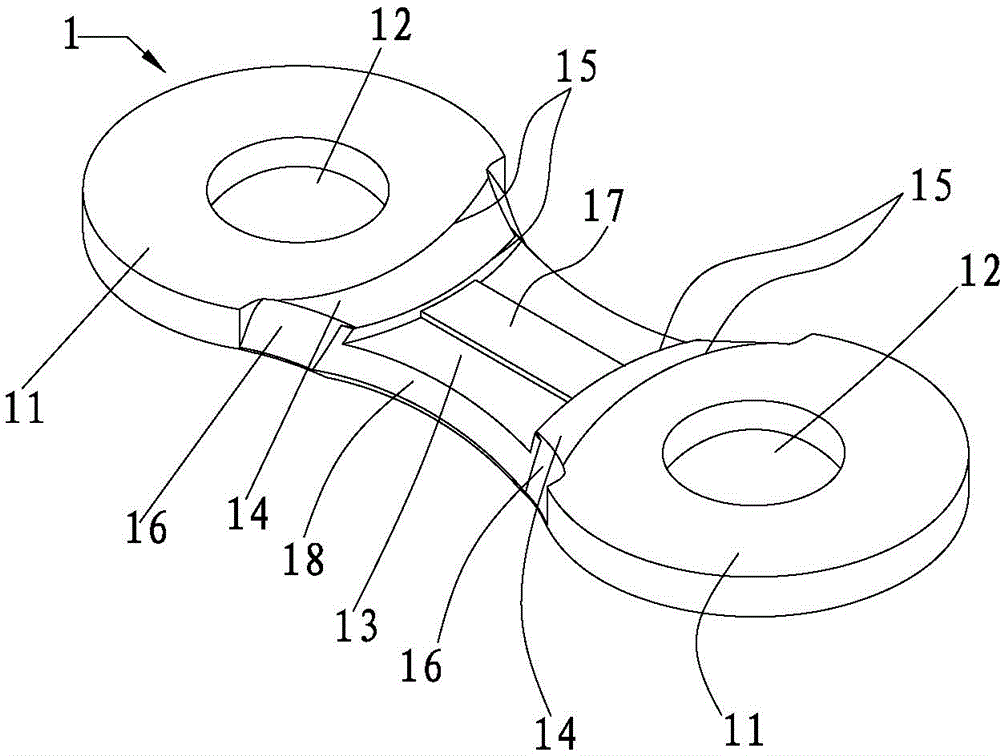

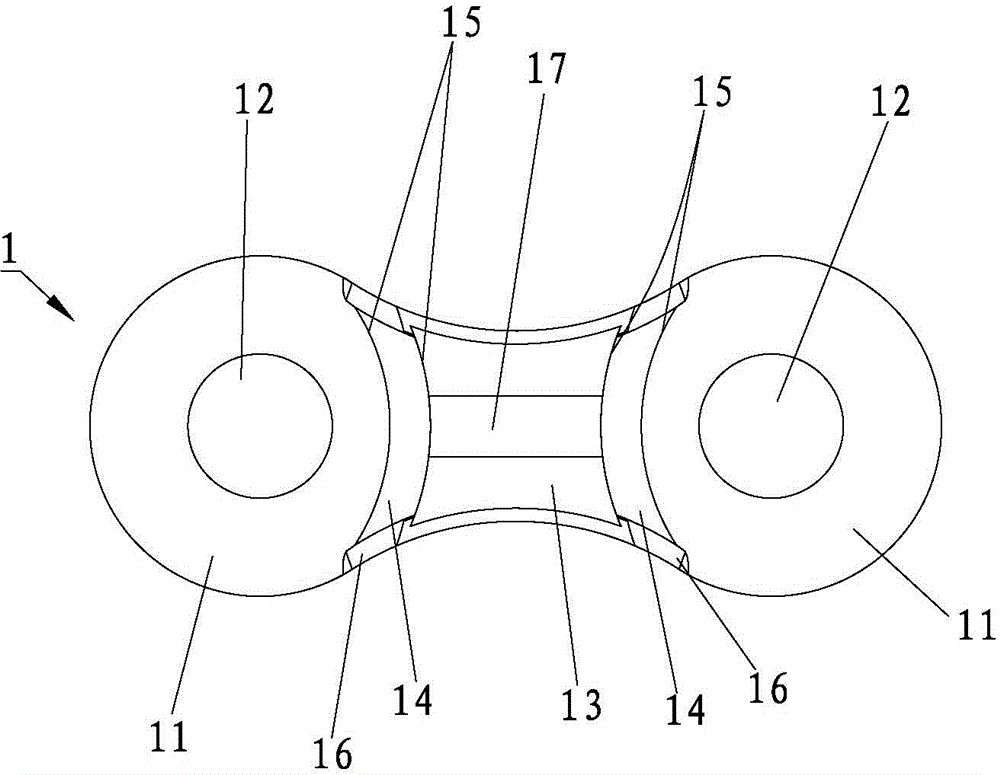

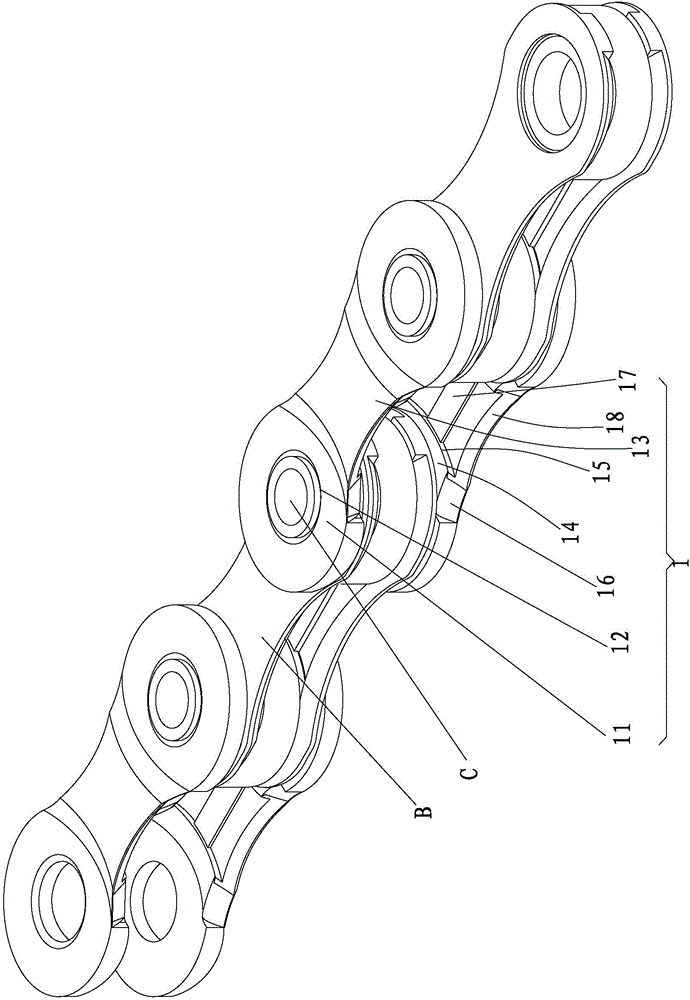

Chain sheet structure

The invention discloses a chain sheet structure. Combining portions are arranged at the two ends of the chain sheet structure. Each combining portion is provided with an axial hole. The inner side face between the two combining portions is provided with a waist portion which relatively swells towards the outer side face and is thinned in a concaved mode. A circular arc connecting face is arranged at the connection position between the waist portion and each combining portion. The inner edge and the outer edge of each connecting face are provided with two circular arc lines, wherein the two circular arc lines are in the state that two circular arcs are arranged in a spaced mode. Each connecting face forms an outward-expanding guide-in face along the two edges of a chain sheet. One or more protruding blocks are arranged between the two connecting faces. The two sides of the waist portion are provided with opening portions which are relatively inclined. The openings are located between the two guide-in faces. By means of the two protruding blocks, meshing speed changing of chain teeth of a tooth disc can be rapidly guided, and chain transmission is stabilized.

Owner:YABAN CHAIN INDAL

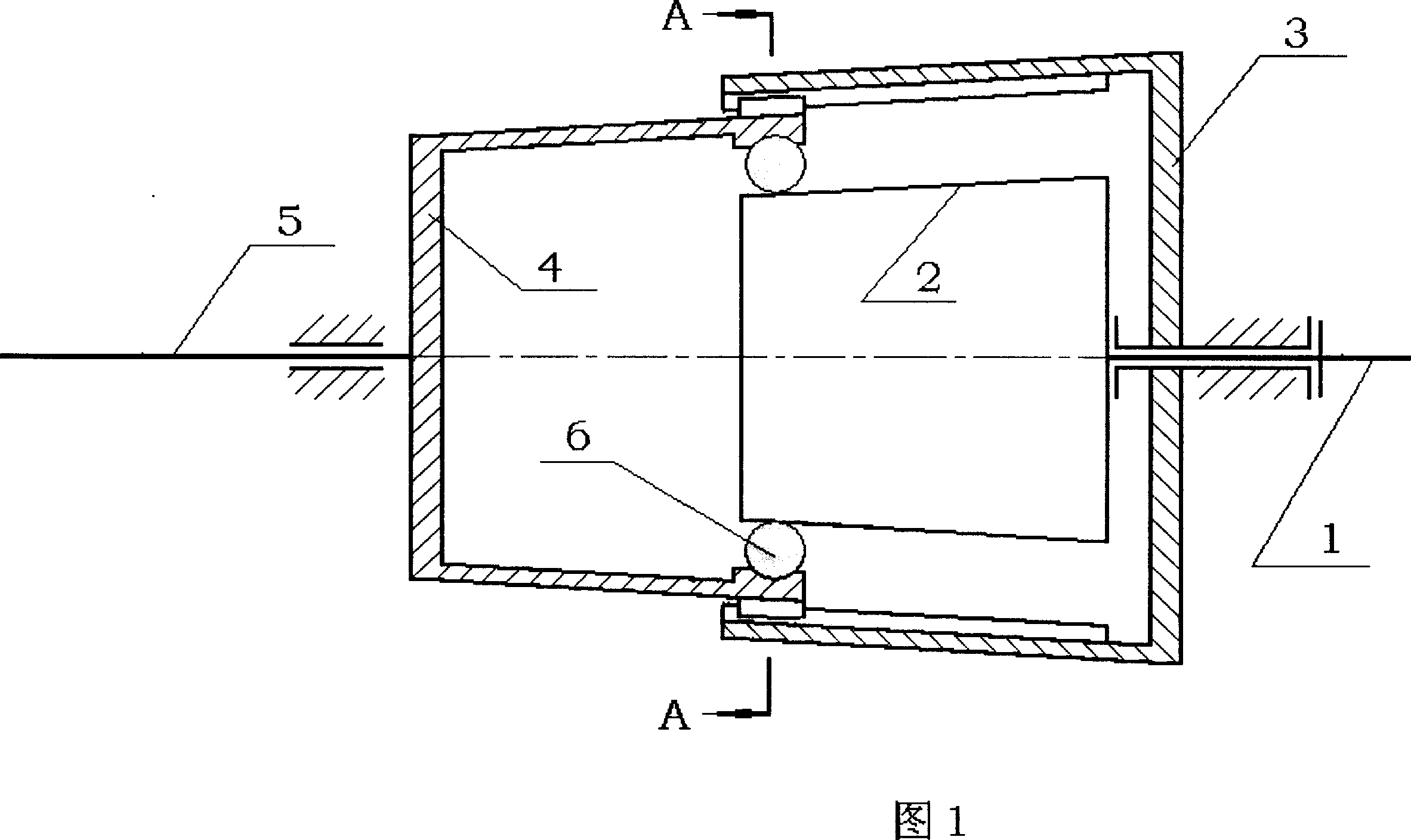

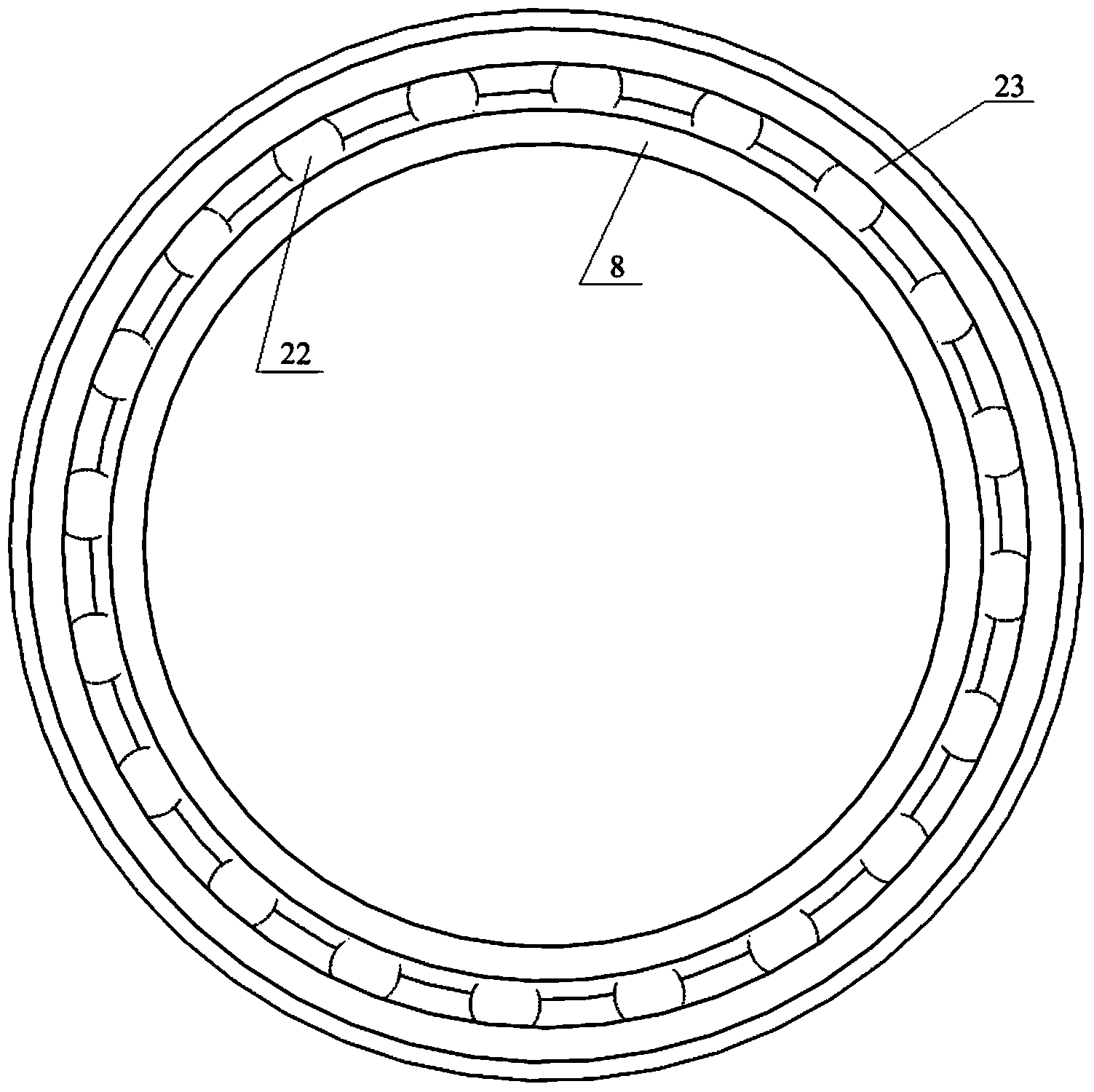

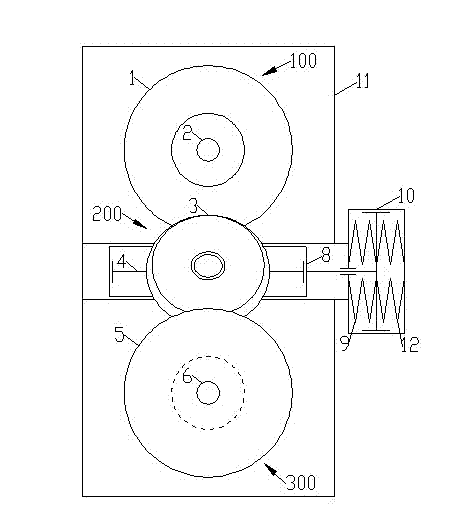

Internal contact conical ring type continuously-variable transmission

ActiveCN103807394AReduce stressExtended service lifeGearing controlGearing detailsGear wheelEngineering

The invention discloses an internal contact conical ring type continuously-variable transmission. Two conical wheels are in internal contact with two conical rings respectively, the stress of a contact area is small, and the service life can be improved. Meanwhile, the reliability is high and the power transmission efficiency is high. The continuously-variable transmission comprises a shell, an input shaft, a planetary line, the input conical wheel, the conical rings, the output conical wheel, an output shaft, a differential mechanism, an output gear, a loading mechanism and a speed changing mechanism, wherein the input shaft, the planetary line, the input conical wheel, the conical rings, the output conical wheel, the output shaft, the differential mechanism, the output gear, the loading mechanism and the speed changing mechanism are located in the shell. Power is transmitted between the output conical wheel and the input conical wheel through the conical rings which are arranged outside the two conical wheels in a sleeved mode. The loading mechanism is a hydraulic-mechanical loading mechanism formed by coupling a hydraulic part and a mechanical part. The speed changing mechanism is of a structure similar to a bearing, and speed changing is realized by pushing an outer ring to drive the conical rings.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

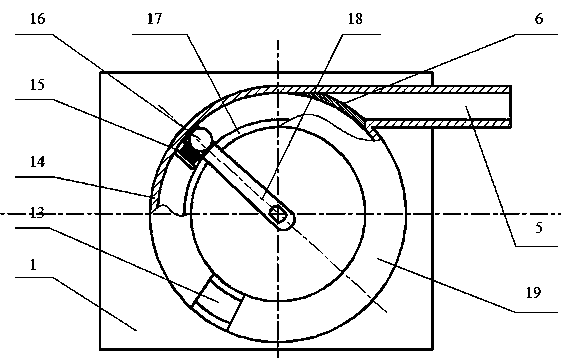

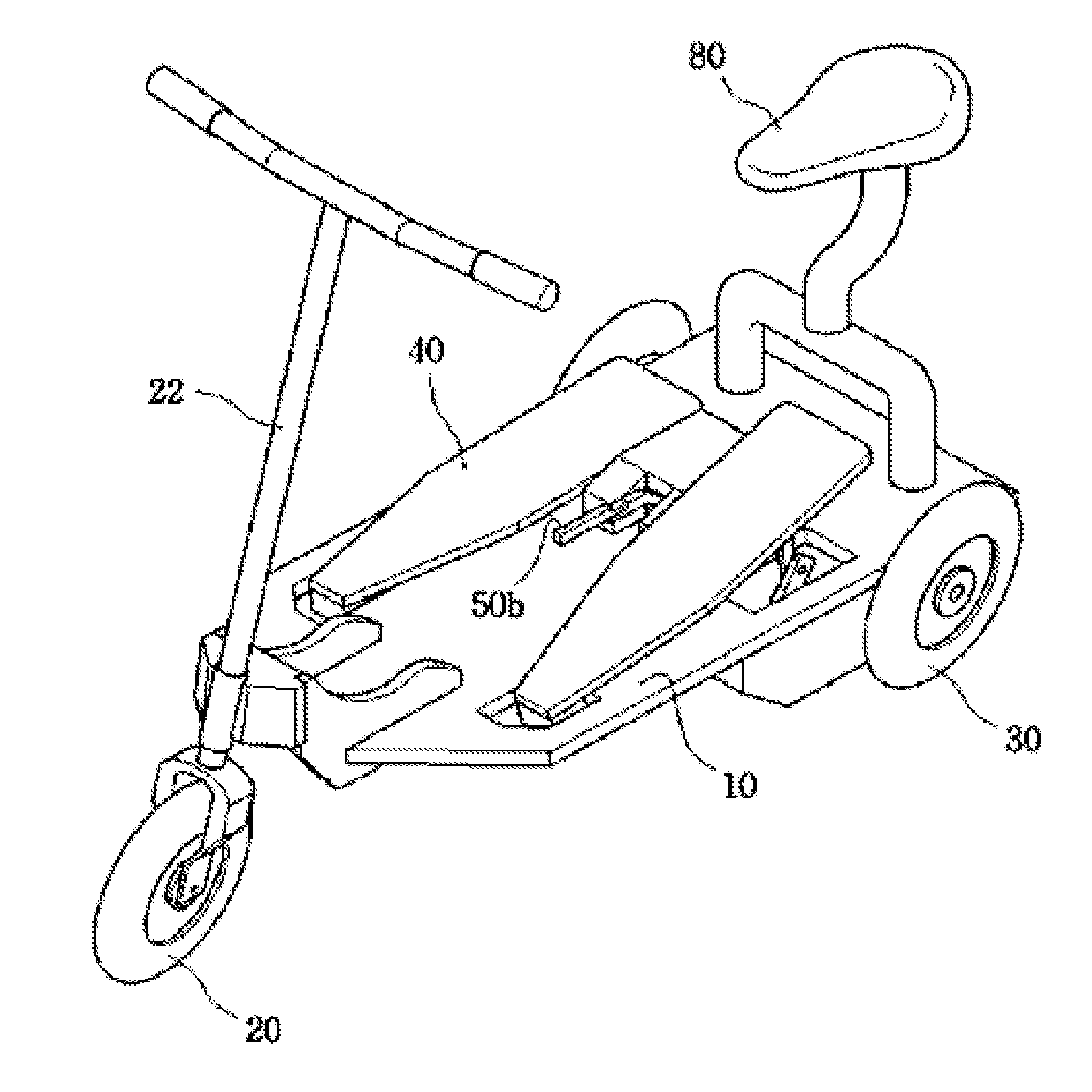

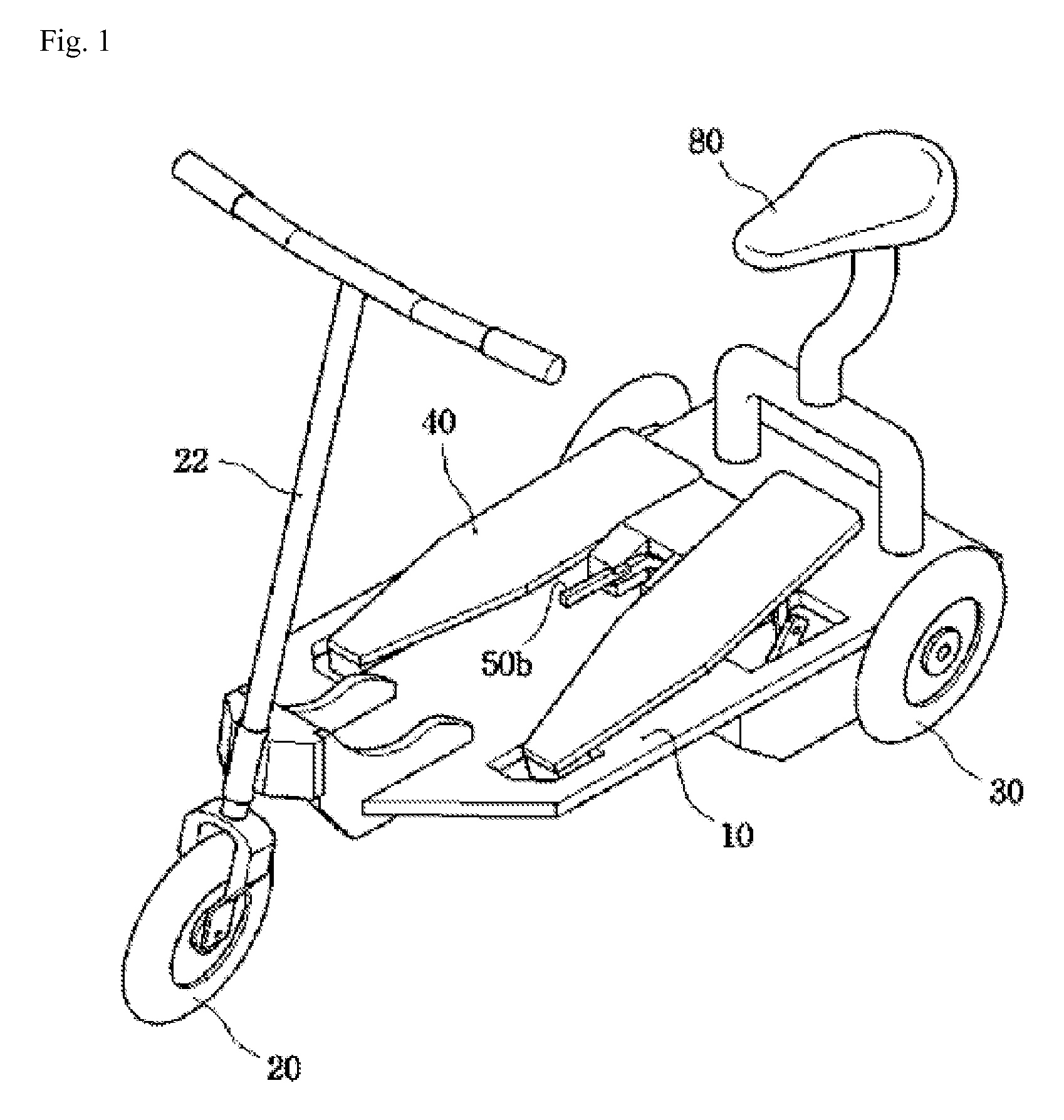

Pedal-driven roller board

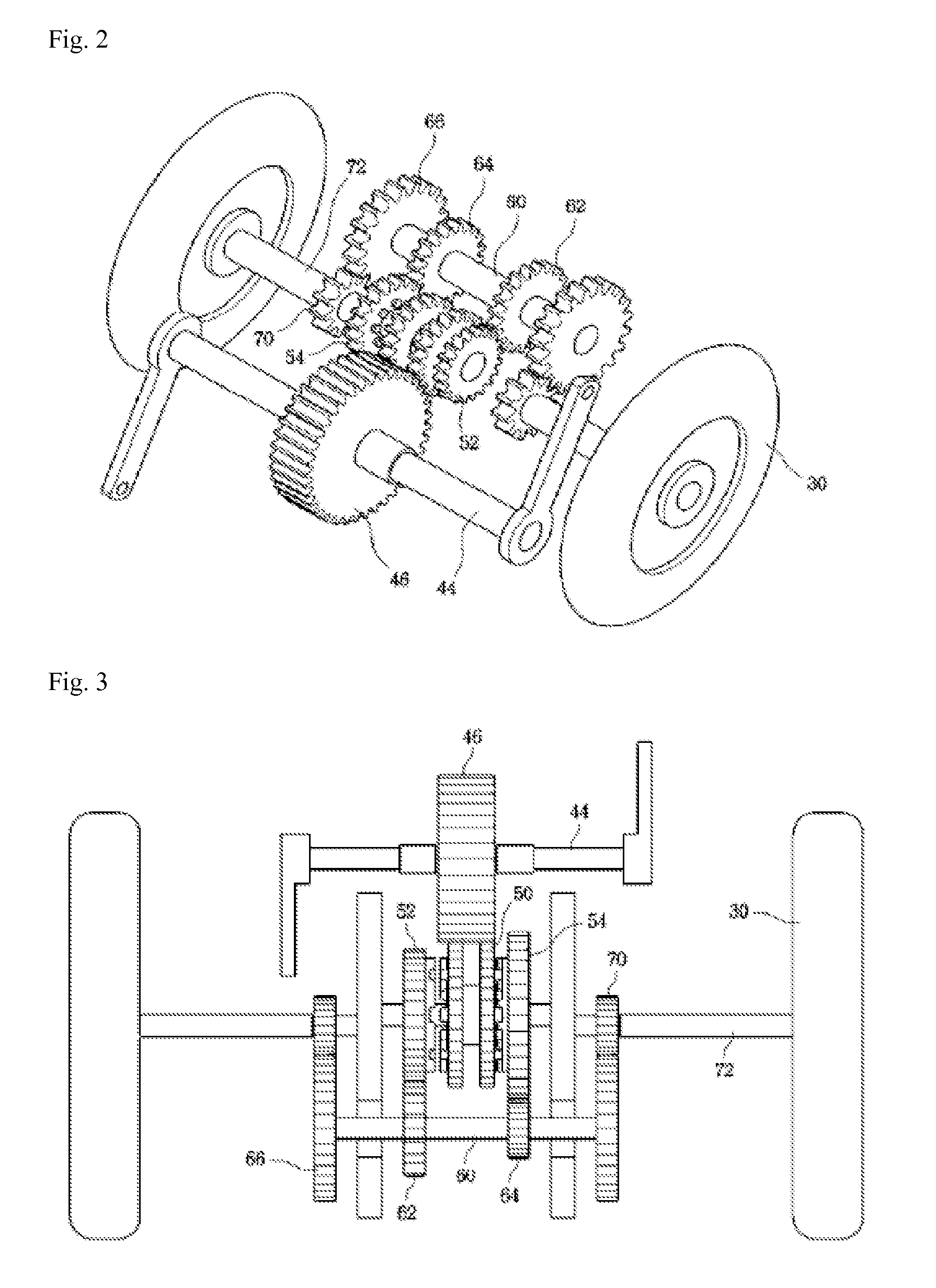

InactiveUS8899605B2Easy to change speedFoot-driven leversBicyclesRotational axisReciprocating motion

The present invention relates to a roller board, and more particularly, to a pedal-driven roller board that converts a reciprocating motion of pedals formed on the board into a rotational motion to drive a gear, so that a user can drive the board without kicking the ground. Furthermore, the pedal-driven roller board includes a derailleur, so that a user can conveniently control the speed of the pedal-driven roller board. Moreover, a user can develop and strengthen his / her muscles by pedaling the pedal-driven roller board. To this end, a pedal-driven roller board according to the present invention includes: a handle disposed at the front side of a board to steer a front wheel; a rear wheel at the rear side of the board; and two pedals formed on the top surface of the board to drive the rear wheel. Further, the pedal-driven roller board includes: a link having an end hinged to the bottom surface of a pedal; a driving gear formed on an end of a crankshaft connected through a shaft to the other end of the link to convert a reciprocating motion of the pedal into a rotational motion; a clutch gear engaged with the driving gear to rotate, and selectively connected to one of either a first speed gear or a second speed gear to rotate same; a first connecting gear and a second connecting gear, which rotatably engage with the first speed gear and the second speed gear, respectively, and are installed on an end of a connecting shaft; a transmission gear installed on both ends of the connecting shaft and rotated by torque transmitted through the connecting shaft from the first and second connecting gears; and a rotation gear engaging with the transmission gear to rotate, and connected to the rear wheel through a rotation shaft to transmit the torque from the transmission gear to the rear wheel.

Owner:KIM JI HOON

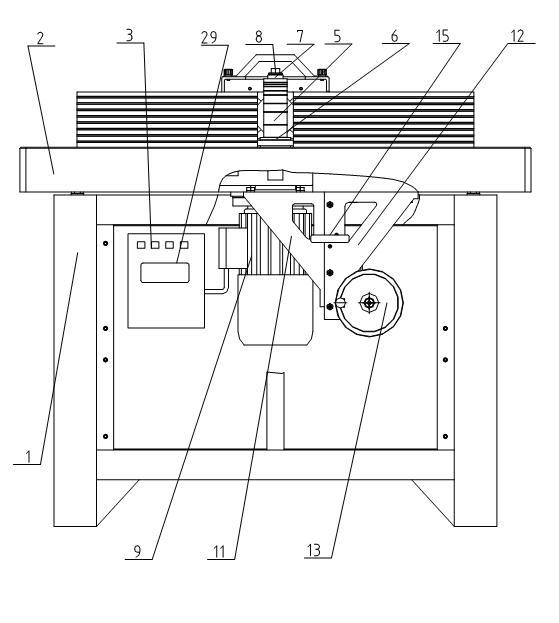

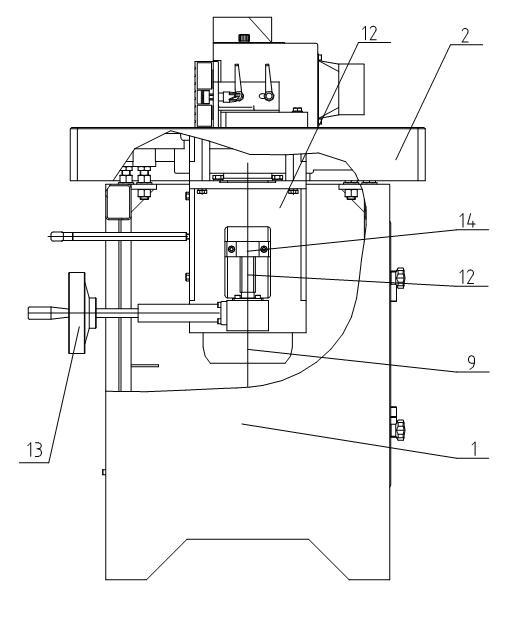

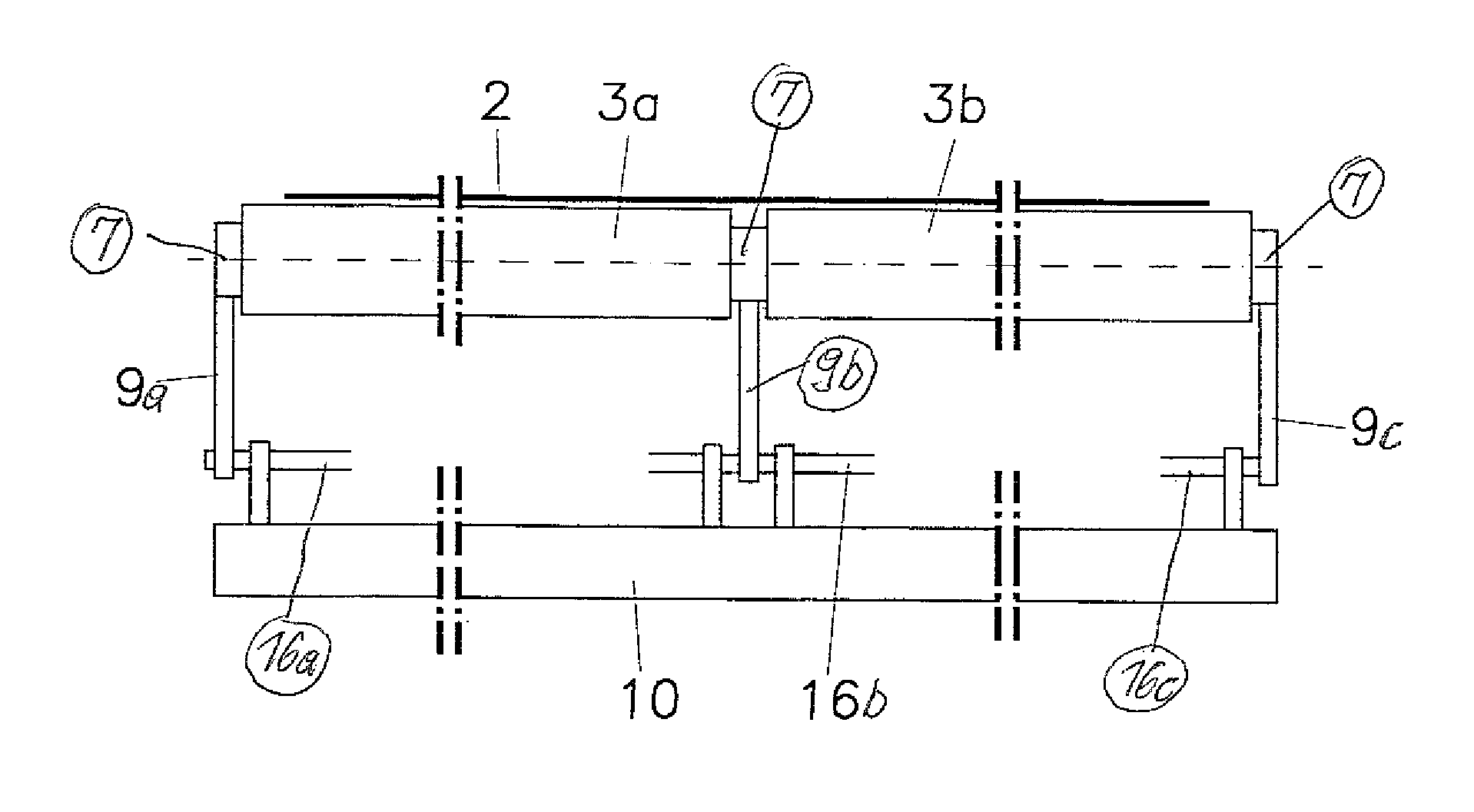

Single-spindle woodworking milling machine with high-speed spindle

InactiveCN102310436AAvoid cloggingTo achieve the effect of dustProfiling/shaping machinesMilling cutterEngineering

The invention relates to the technical field of woodworking machinery, in particular to a single-spindle woodworking milling machine with a high-speed spindle. The milling machine comprises a machine frame, a workbench, a milling cutter device, a milling cutter lifting device and a motor, wherein the workbench and the machine frame are fixedly connected; a control device is arranged on the machine frame; the milling cutter device comprises a spindle, a milling cutter, a cutter assembling nut, a flat hole sleeve and a cutter pressing screw; and the milling cutter lifting device is composed of a lifting screw, a sliding plate, a sliding plate base, a lifting hand wheel, a lifting nut, a locking device, a worm gear, a worm, a bearing and a bearing base. The milling machine is characterized in that the shaft of the motor extends and is connected with the spindle into a whole; the lower end of the cutter assembling nut is fixedly connected with an upper end cover of the motor; the motor and the sliding plate are fixedly connected; the milling cutter is directly driven by the motor; and parts, such as a motor plate, a transmission belt, a motor wheel, a spindle wheel and the like, are saved, thus the manufacturing cost of a machine tool is effectively lowered, the integral performance of the machine tool is steady, the power consumption of the motor is reduced, and the milling machine is steady to operate.

Owner:山东工友集团股份有限公司

Cutting device and method for cylindrical paper core for filter part

The invention discloses a cutting device and method for a cylindrical paper core of a filter part. The cutting device comprises a workbench, wherein a supporting seat is mounted on the workbench; a mechanical arm is mounted on the supporting seat; a rotary motor is mounted on the mechanical arm; the rotary motor is connected with a gearbox; the output shaft of the gearbox is connected with the rotary shaft for transmitting torque; a circular cutter is mounted on the rotary shaft; a hand wheel is mounted on the mechanical arm; and a mounting table is arranged below the circular cutter. The cutting device can be used for conveniently producing the cylindrical paper core, which is perfect and attractive in appearance, for the filter part on a large scale.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

Device for stretching webs of material transversely to their travel direction

InactiveUS7802348B2Avoid interferenceEasy to adjustStretchingWebs handlingEngineeringBall and socket joint

Owner:KNABEL HOLMER +1

Hydraulic transmission device

The invention discloses a hydraulic transmission device which comprises a housing, a front cover and a rear cover which are matched with the housing, and a transmission mechanism arranged in a cavity, wherein the cavity is arranged on the housing; the transmission mechanism comprises an input shaft, an output shaft, a rotor and a rotating ring; the rotor is arranged on the input shaft, and rotates with the input shaft; the rotating ring is arranged outside the rotor, and connected with the output shaft; the rotating ring and the output shaft rotate together; a plurality of sliding blades are arranged on the rotor; and at least one gradual extending section and at least one gradual shrinking section are arranged on the inner surface of the rotating ring in a rotating direction. The transmission device can control the magnitude of output torque and rotating speed by controlling fluid parameters, can achieve torque-free output idling, and is less in energy consumption, stable to start, high in efficiency, simple in structure, safe and convenient to operate, long in service life, high in power density and wide in application.

Owner:胡阳

Long-conical and rolling-conical type stepless variable drive mechanism

InactiveCN102927227ASmall geometric slip rateReduced geometric slip rateToothed gearingsFriction gearingsMechanical driveContact position

The invention discloses a long-conical and rolling-conical type stepless variable drive mechanism which comprises a first long-conical roller, a second long-conical roller and an intermediate rolling-conical wheel; a first conical surface and a second conical surface are arranged on the intermediate rolling-conical wheel; the first conical surface is in contact drive with the first long-conical roller; the second conical surface is in contact drive with the second long-conical roller; the contact positions of the intermediate rolling-conical wheel on two long-conical rollers can be adjusted, therefore, the working radiuses of the two long-conical rollers can be continuously changed, and as a result, the stepless variable drive can be achieved. According to the long-conical and rolling-conical type stepless variable drive mechanism, the geometrical slippage is zero under the optimal drive, so that the geometrical slippage of the conical wheel type long-conical and rolling-conical type stepless variable drive mechanism can be effectively reduced, and the drive efficiency and power can be increased. The long-conical and rolling-conical type stepless variable drive mechanism is applicable to various fields such as the vehicle field, the ship field and the mechanical drive field.

Owner:郭克亚

Bicycle inner transmission and manufacture method thereof

The invention relates to a bicycle inner transmission and a manufacture method thereof. The transmission mainly comprises a fixed star frame, front star wheels, back star wheels, a sun wheel, a pawl ring, a shell cylinder, a moving star frame, an active cylinder, a double gear ring, an eight gear ring, and a gear shifting cylinder. a slow gear, a neutral gear and a fast gear are arranged. the front star wheels and the back star wheels are integrated wheel shaft members; the fixed star frame is a fixed part and is also used as a stationary sun wheel, and there are six front star wheels which are engaged with three back star wheels inside the frame; the sun wheel is engaged with the back star wheels and is provided with the pawl ring; the moving star frame is provided with four front star wheels and a pawl ring; the pawl ring is provided with a pawl milled with clutch teeth; the double gear ring is dynamically engaged with the eight gear ring for contrarotation gear shift and forward rotation transmission; the double gear ring is sleeved by the gear shifting cylinder to form an integrated part; the eight gear ring is sleeved by the active cylinder to form an integrated part and then is provided with a common chain wheel; power is transferred from the active cylinder and the eight gear ring to drive the double gear ring to the pawl ring through the gear shifting cylinder, and if the gear shifting cylinder is engaged with the sun wheel pawl ring, it is the slow gear; if the gear shifting cylinder is engaged with the moving star frame pawl ring, it is the fast gear; non engagement is the neutral gear.

Owner:李建伟

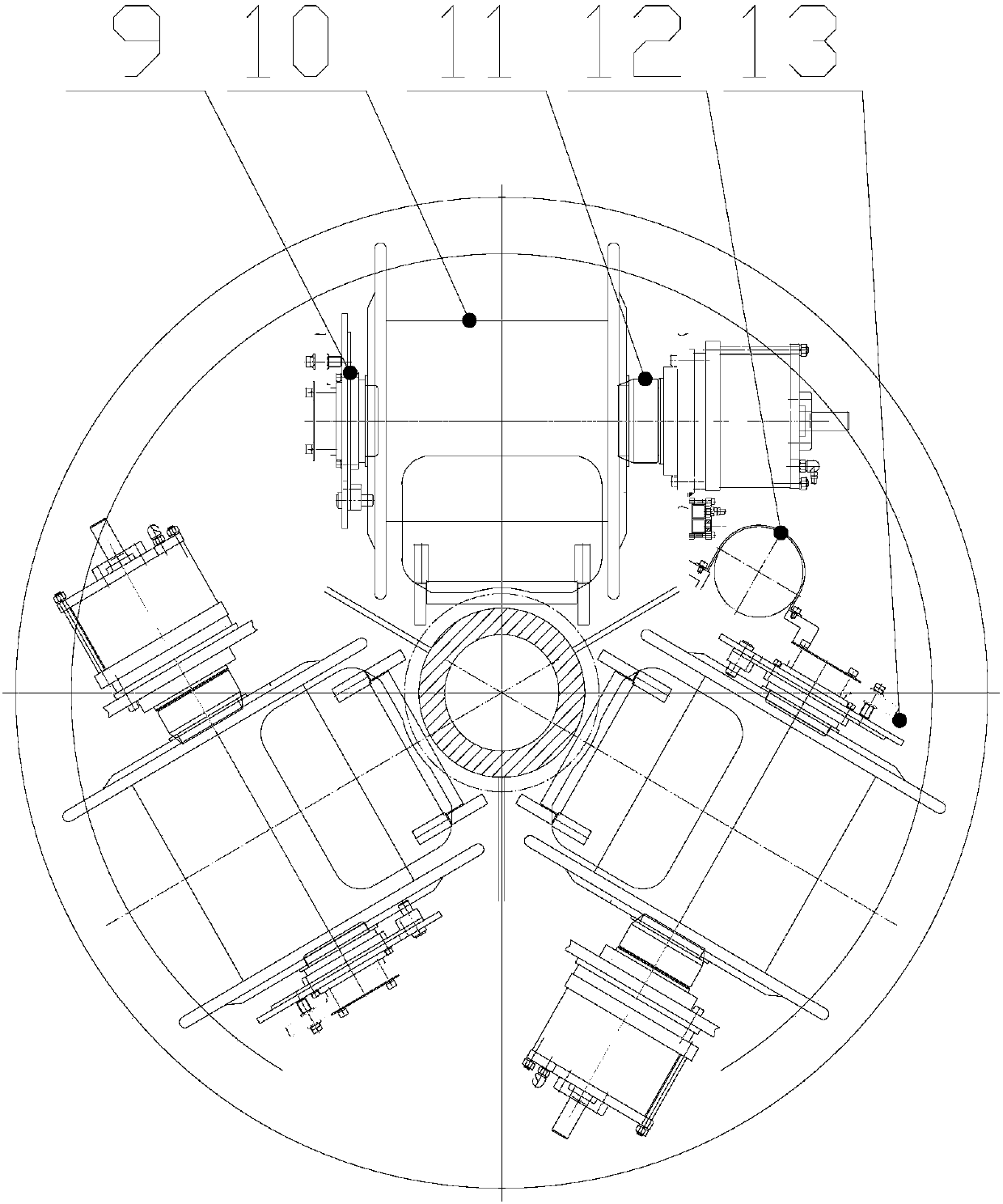

High-speed frame stranding machine

InactiveCN109671538AEasy to change speedLow costToothed gearingsCable/conductor manufactureLow speedEngineering

The invention relates to a high-speed frame stranding machine. A stranding cage gearbox is internally provided with a rotational output shaft, a switching shaft, a transition shaft and an input shaft,the output shaft is provided with a third large gear and a fourth small gear; the switching shaft is provided with a first engaging gear, a second large gear and a clutch wheel; the switching shaft is provided with the third small gear; the transition wheel is provided with a second small gear and a first large gear; the input shaft is provided with a second engaging wheel, and the second engaging wheel is engaged with the first engaging wheel all along; the input shaft is provided with a first small gear; the first small gear and the first large gear, the second small gear and the second large gear and the third small gear and the third large gear are respectively engaged; the fourth small gear is engaged with the fourth large gear at the outer wall of the central main shaft are engagedfor output outwards. The clutch wheel is switched, when the clutch wheel is in a normal operation gear, second-level speed reduction is performed for stranding rotation, or else, when the clutch wheelis in a low-speed operation gear, fourth-level speed reduction is performed to meet the large torque requirement when a single side is heavier after hanging is intensively performed.

Owner:SHANGHAI HOSN MACHINERY TECH

Transmission structure

PendingCN112081881AAchieve variable speed outputAccurate Speed RequirementsControlled membersGearboxesGear wheelControl theory

Owner:FOSHAN V PLUS MACHINERY CO LTD

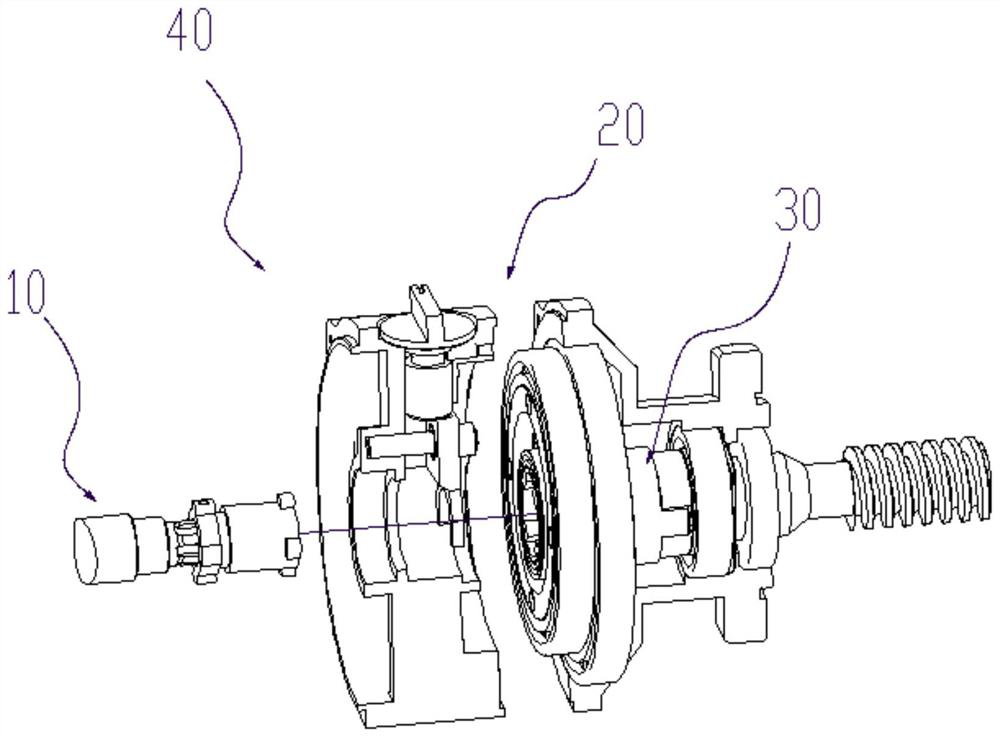

Portable power tool

ActiveCN107980019ACompact structureEasy to change speedPortable power-driven toolsPower driven toolsRatchetControl engineering

The invention relates to a portable power tool (10), in particular a screwing device and / or drilling device, having a drive motor (16) for driving a transmission drive (25) of a transmission (30) which has a transmission output (26) for driving a tool receptacle (18) of the portable power tool (10) and a first gear stage (41) and a second gear stage (42), wherein the transmission has a first blocking device (61) for blocking a gearing element, forming a ratchet gearing element (43), of the first gear stage (41) and a second blocking device (62) for blocking a gearing element, forming a ratchetgearing element, of the second gear stage (42), wherein the gear stage having the respectively blocked ratchet gearing element transmits a torque from the transmission drive (25) to the transmissionoutput (26), wherein a direction of rotation of the drive motor (16) is changeable and, depending on the direction of rotation of the drive motor (16), the first gear stage (41) or the second gear stage (42) transmits a torque from the transmission drive (25) to the transmission output (26). Provision is made for one of the two gear stages to effect a reversal in the direction of rotation betweenthe transmission drive (25) and the transmission output (26).

Owner:FESTOOL GMBH

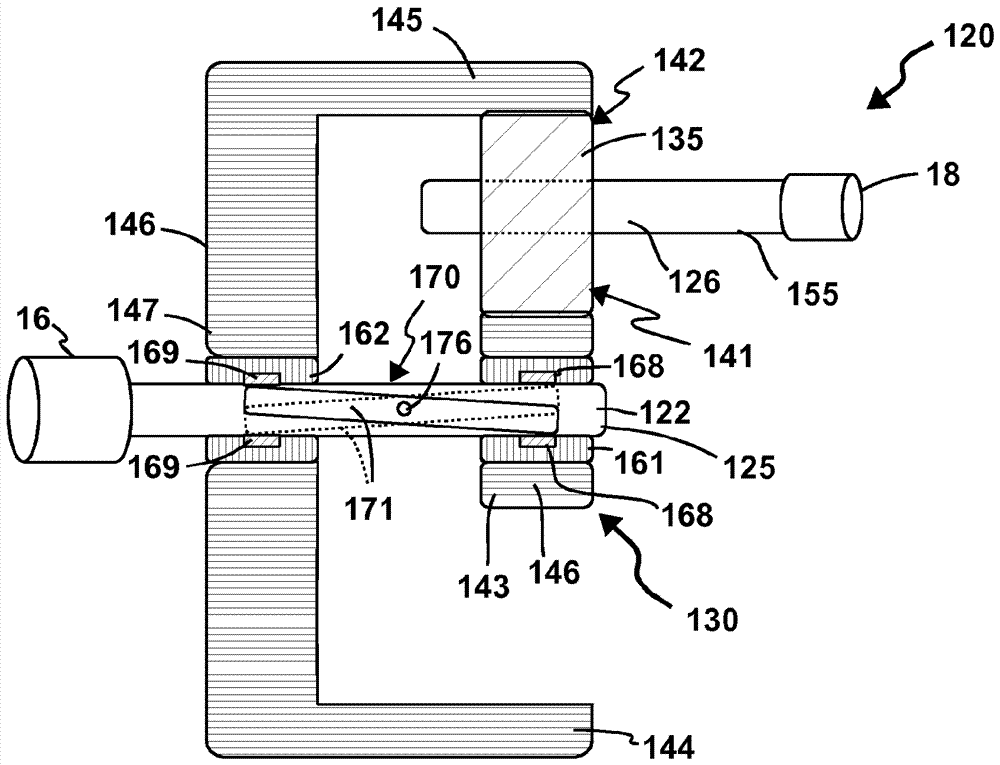

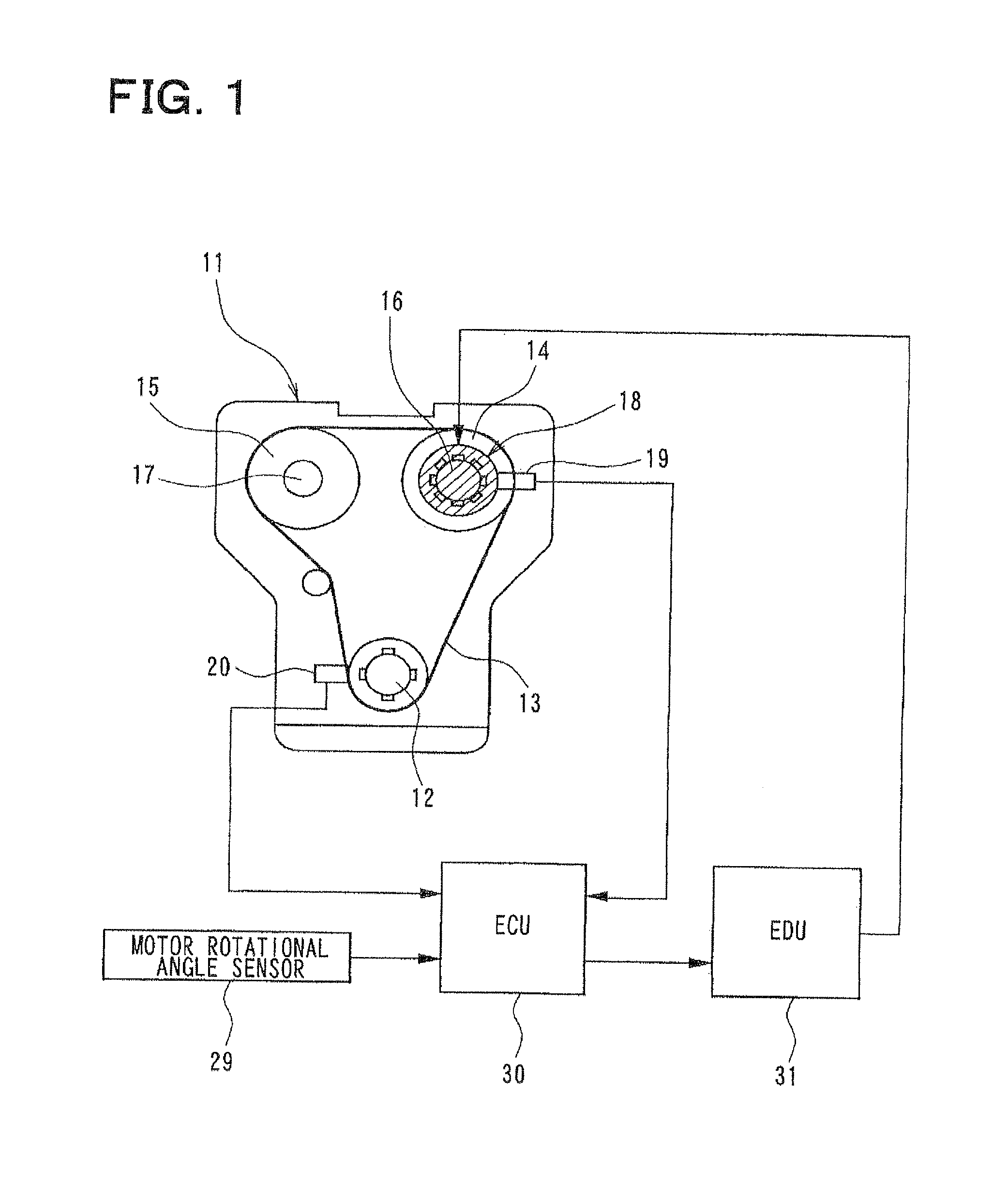

Control system for variable valve timing apparatus

ActiveUS20140069362A1Increase supplyIncrease output torqueValve arrangementsMachines/enginesVariable valve timingControl system

Owner:DENSO CORP

Stepless variable speed rear drive shaft for bicycles

InactiveCN104554609AHigh torqueImprove acceleration performanceWheel based transmissionDrive shaftSprocket

The invention relates to a variable speed rear drive shaft for bicycles, in particular to a stepless variable speed rear drive shaft for bicycles. The shaft comprises a fixed central shaft body, a rear shaft small chain wheel and a rear shaft hub which are arranged on the fixed central shaft body. The rear shaft hub is located on one side of the rear shaft small chain wheel. A first planetary movable shaft wheel train, a wedge claw type stepless speed changing mechanism, a second planetary movable shaft wheel train and a third planetary movable shaft wheel train are arranged on one side of the rear shaft small chain wheel sequentially and are located in the inner cavity of the rear shaft hub. Thus, the stepless variable speed rear drive shaft for bicycles has the advantages of high controllability allowing the variable speed to be in place instantaneously through simple actions, fine acceleration performance allowing continuous gradient-type shifting in various states, highly professional adaptability allowing high torque, low rotation speed and high transmission efficiency, high practicality allowing large adaptive coverage in the large speed ratio range, small size, lightness, noise avoidance and complete-tightness lubrication and the like.

Owner:孙晓雁 +2

Two-gear electrical control variable speed motor for electric motorcycle

InactiveCN102097892BSimple structureCompact structureMechanical energy handlingCycle actuatorsDrive shaftGear wheel

The invention discloses a two-gear electrical control variable speed motor for an electric motorcycle. The motor comprises a motor stator, a motor shaft and a rotor which are arranged in a shell. A drive I-gear gear, a drive II-gear gear and an overrunning clutch are sequentially from right to left on the right part of the motor shaft. A central cam of the overrunning clutch is in fit connection with the motor shaft, and corresponds to an electromagnet arranged on the shell. A driven I-gear gear, a driven II-gear gear and a drive pinion are sequentially arranged from the right to the left on a central gear shaft. The driven I-gear gear is in fit connection with the central gear shaft by a one-way bearing, and is meshed with the drive I-gear gear arranged on the motor shaft. The driven II-gear gear is meshed with the drive II-gear gear idly sleeved on the motor shaft. The drive pinion is integrated with the central gear shaft, and is in fit connection with a drive bull wheel in fit connection with a drive shaft. The motor is organically combined with a gear shifting mechanism, the motor has a simple and compact structure, good radiation effects and long service life, and simply, conveniently and reliably realizes gear shifting operations.

Owner:秦廷修

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com