Electric assist bicycle

An electric assist and bicycle technology, which is applied to vehicle components, rider driving, transportation and packaging, etc., can solve the problems of reduced torque detection ability, pedal rotation cannot be transmitted, and low detection ability, so as to improve reliability and facilitate And the effect of reliable detection and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

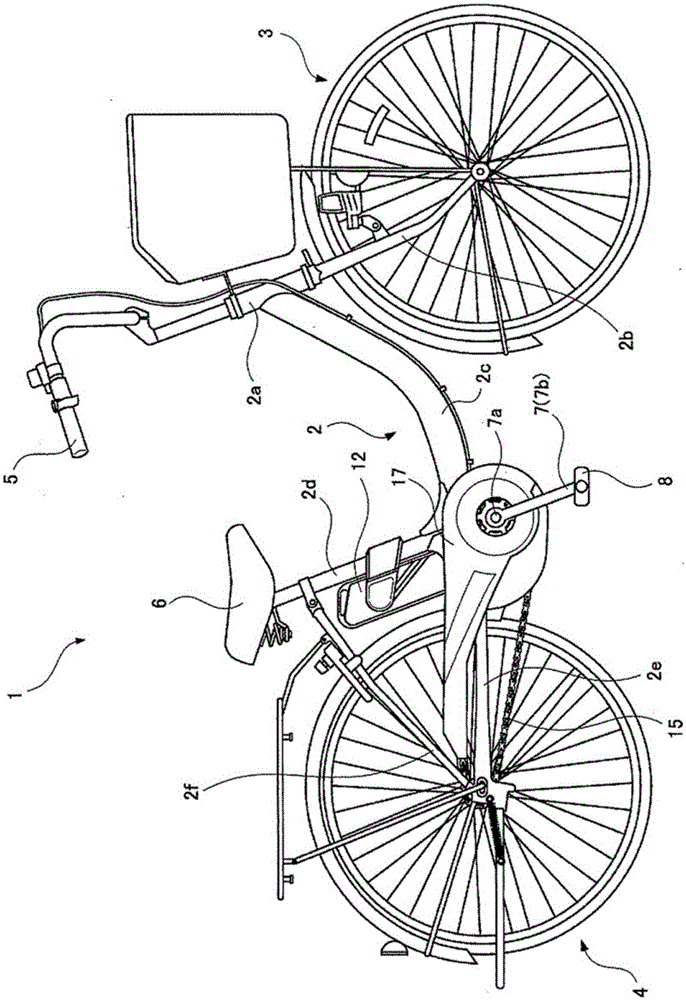

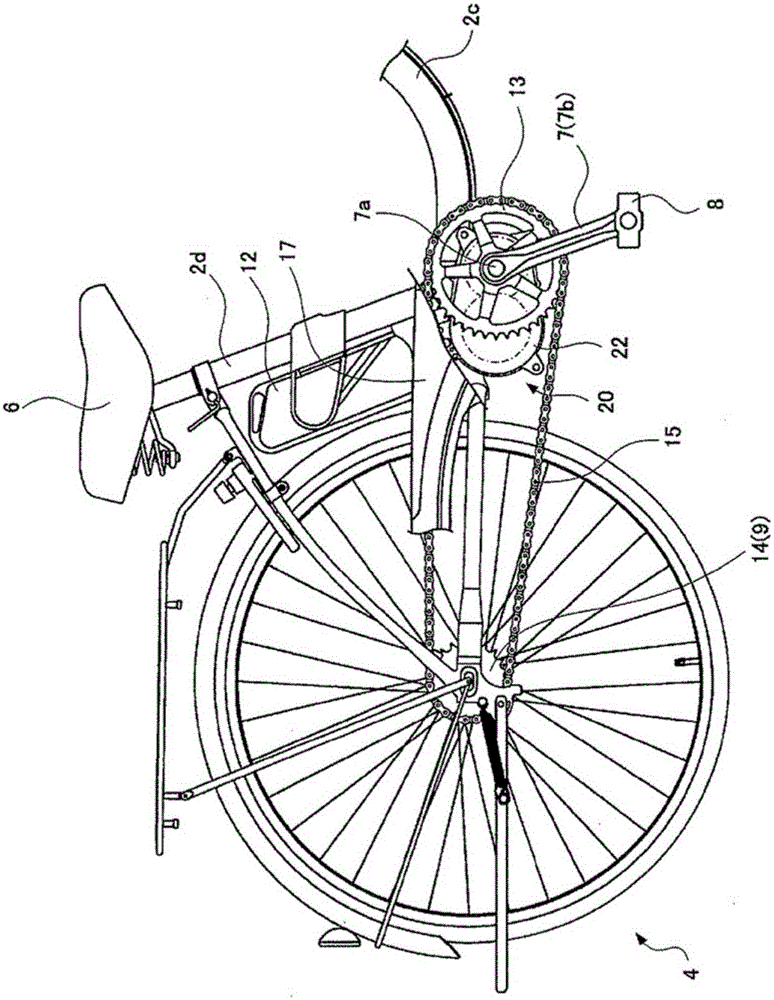

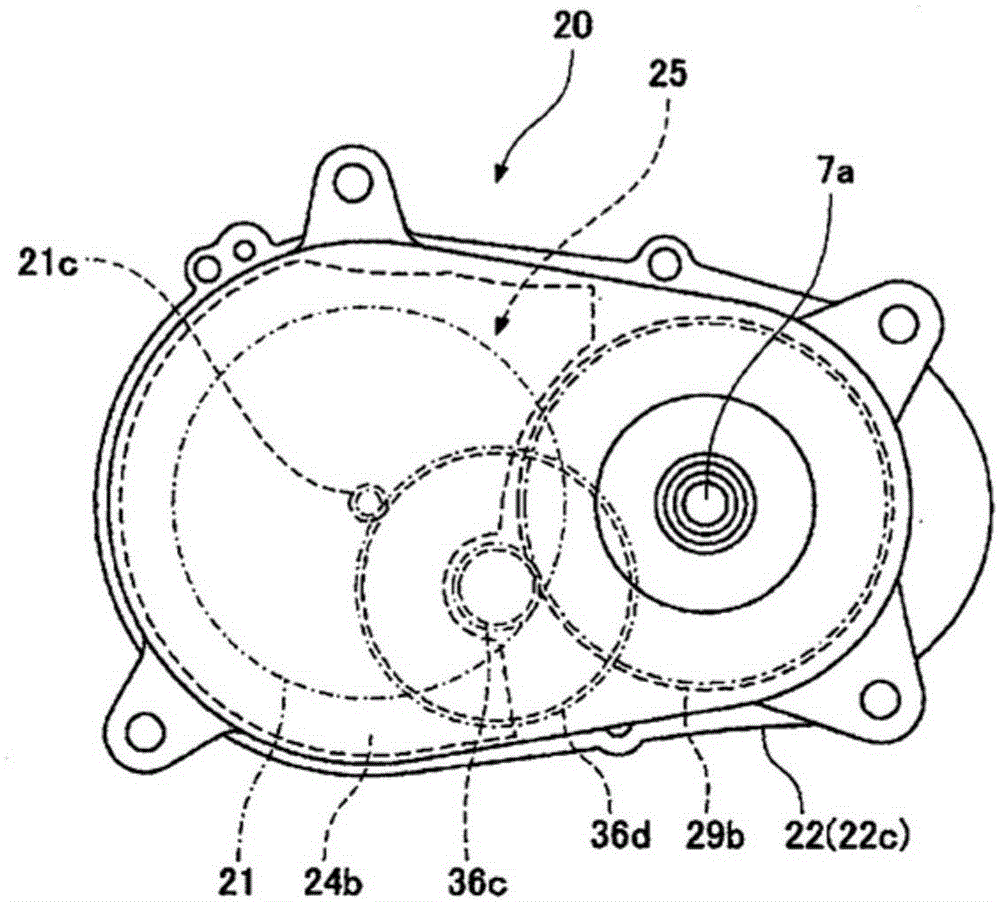

[0068] Hereinafter, a power-assisted bicycle according to an embodiment of the present invention will be described based on the drawings. In addition, the left-right direction and the front-rear direction in the following description refer to the direction in the state of riding on the electric-assisted bicycle 1 toward the traveling direction, but the configuration of the present invention is not limited to the directions described below.

[0069] figure 1 , figure 2 1 is the power-assisted bicycle according to the embodiment of the present invention. like figure 1 , figure 2 As shown, the power-assisted bicycle 1 includes a metal frame 2 including a head pipe 2a, a front fork 2b, a main pipe 2c, a seat pipe 2d, a chain bracket 2e, a seat bracket 2f, and the like; The front wheel 3 at the lower end; the rear wheel 4 rotatably attached to the rear end of the chain bracket 2e; the handlebar 5 for changing the direction of the front wheel; the seat 6; An electric motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com